Pneumatic Fender and Mouth Piece Metal for Pneumatic Fender

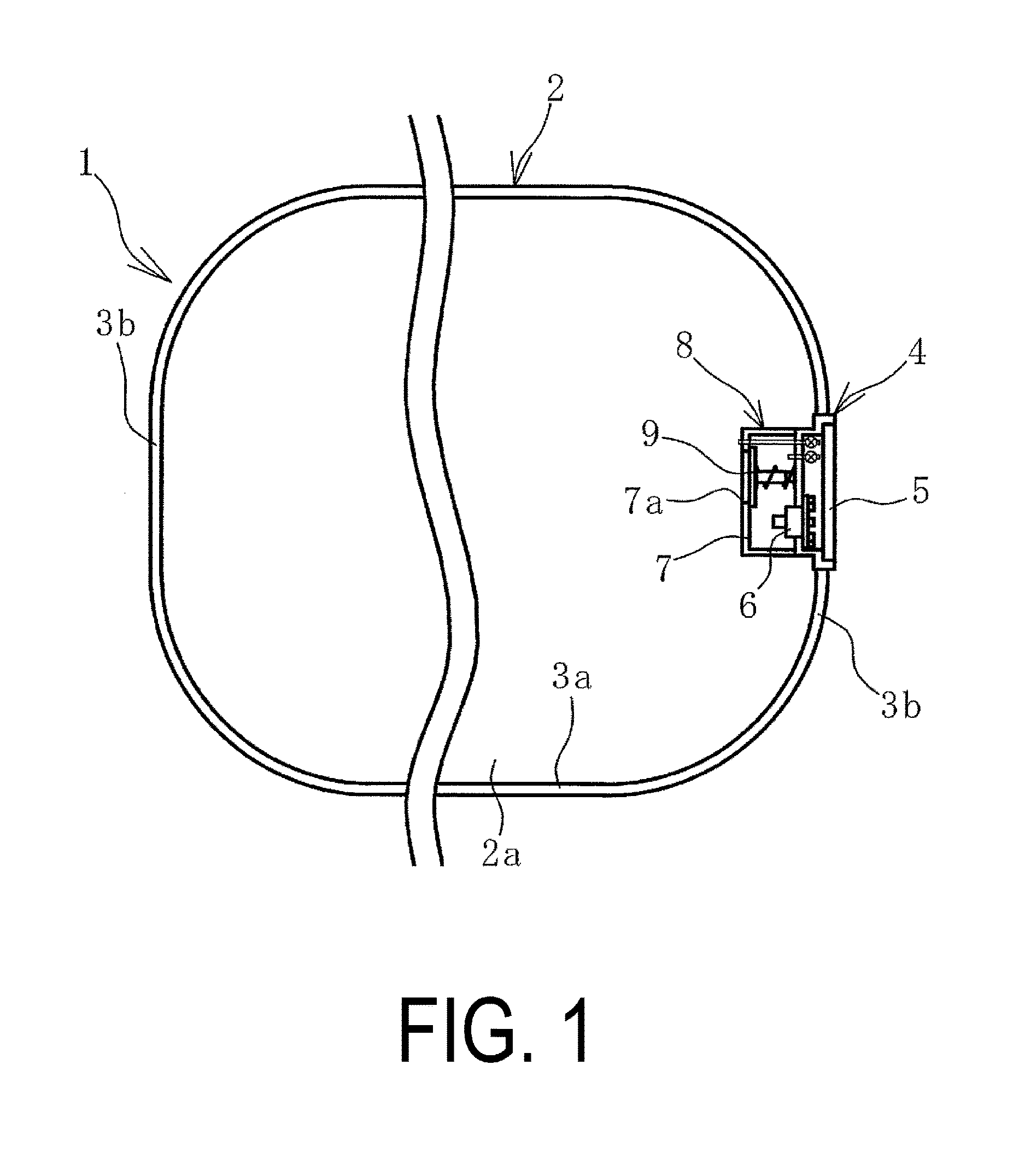

The present technology relates to a pneumatic fender and a mouth piece metal for a pneumatic fender, and further relates to a pneumatic fender and a mouth piece metal for a pneumatic fender with significantly enhanced maintainability wherein a safety valve can be detached and attached and a confirmation test of the valve opening pressure of the safety valve can be performed on the pneumatic fender while in use, and the labor and time required for these operations are greatly reduced. Pneumatic fenders are designed to have air sealed in the cavity of a fender bladder so as to be provided with predetermined performance such as shock absorbing performance. If the fender bladder remains sealed when the fender is excessively compressed, the internal pressure in the cavity may increase beyond a preset pressure threshold and cause failure of the fender bladder. To combat this, a safety valve that connects the cavity to the outside air may be provided on a mouth piece metal provided on the fender bladder for such cases when the internal pressure of the cavity of the fender bladder exceeds the pressure threshold (see, for example, Japanese Unexamined Patent Application Publication No. 2003-129446A). Such a safety valve is routinely (for example, every 1 to 3 years) detached from the mouth piece metal for confirmation testing of the valve opening pressure, cleaning, and other such maintenance. However, the cavity of the fender bladder of such a pneumatic fender when in use is inflated to a predetermined internal pressure, and so detaching the safety valve from the mouth piece metal of the fender bladder when the pneumatic fender is in use would result in air being violently ejected from the cavity. Thus, such detachment of the safety valve is not possible. Accordingly, the detachment of the safety valve is performed after sufficiently discharging the air from the cavity of the fender bladder. Specifically, to detach the safety valve from the mouth piece metal, the in-use pneumatic fender is brought onto land or a marine vessel before the air is discharged. Upon completion of the confirmation testing of the valve opening pressure, cleaning, and the like of the detached safety valve, the safety valve must be reattached to the mouth piece metal, the cavity of the fender bladder must be inflated with air, and the pneumatic fender must be installed in a predetermined position. Accordingly, the maintenance of detaching and attaching the safety valve to the mouth piece metal requires a great deal of man-hours and time. The present technology provides a pneumatic fender and a mouth piece metal for a pneumatic fender with significantly enhanced maintainability wherein a safety valve can be attached and detached and a confirmation test of the valve opening pressure of the safety valve can be performed on the pneumatic fender while in use, and the labor and time required for these operations are greatly reduced. A pneumatic fender comprises: a fender bladder including a cylindrical portion and bowl-like hemispherical portions connected to each end of the cylindrical portion; a mouth piece metal disposed on at least one of the hemispherical portions, the mouth piece metal including: a safety valve that, upon an internal pressure of a cavity of the fender bladder reaching a pressure threshold, opens to connect the cavity of the fender bladder to outside air and reduce the internal pressure, and a communication passage that connects the cavity of the fender bladder and outside air; and an bladder open/close valve that opens and closes the communication passage; wherein the mouth piece metal further includes: a receiving chamber that isolates the safety valve from the cavity of the fender bladder, a through hole that connects a cavity of the receiving chamber and the cavity of the fender bladder, the through hole being formed on a dividing wall constituting the receiving chamber, an open/close valve that opens and closes the through hole, a resilient member that constantly biases the open/close valve toward a closing direction of the through hole, a receiving chamber communication passage that connects the cavity of the receiving chamber and outside air, and a receiving chamber open/close valve that opens and closes the receiving chamber communication passage; and upon the internal pressure of the cavity of the fender bladder being less than the pressure threshold and greater than a standard pressure, which is a sum of a predetermined initial internal pressure and an allowable pressure, the open/close valve opens, opening the closed through hole. A mouth piece metal for a pneumatic fender comprises: a safety valve that, upon an internal pressure of a cavity of a fender bladder reaching a pressure threshold, opens to connect the cavity of the fender bladder to outside air and reduce the internal pressure; a communication passage that connects the cavity of the fender bladder and outside air; and a bladder open/close valve that opens and closes the communication passage; the mouth piece metal being attached to a bowl-like hemispherical portion constituting the fender bladder; wherein the mouth piece metal further includes: a receiving chamber that isolates the safety valve from the cavity of the fender bladder, a through hole that connects a cavity of the receiving chamber and the cavity of the fender bladder, the through hole being formed on a dividing wall constituting the receiving chamber, an open/close valve that opens and closes the through hole, a resilient member that constantly biases the open/close valve toward a closing direction of the through hole, a receiving chamber communication passage that connects the cavity of the receiving chamber and outside air, and a receiving chamber open/close valve that opens and closes the receiving chamber communication passage; and upon the internal pressure of the cavity of the fender bladder being less than the pressure threshold and greater than a standard pressure, which is a sum of a predetermined initial internal pressure and an allowable pressure, the open/close valve opens, opening the closed through hole. According to the present technology, the mouth piece metal includes a receiving chamber that isolates the safety valve from the cavity of the fender bladder, a through hole that connects a cavity of the receiving chamber and the cavity of the fender bladder, the through hole being formed on a dividing wall constituting the receiving chamber, an open/close valve that opens and closes the through hole, and a resilient member that constantly biases the open/close valve toward a closing direction of the through hole, wherein upon the internal pressure of the cavity of the fender bladder being less than the pressure threshold and greater than a standard pressure, which is a sum of a predetermined initial internal pressure and an allowable pressure, the open/close valve opens, opening the closed through hole. Thus, when the internal pressure of the cavity of the fender bladder reaches or exceeds the pressure threshold, the open/close valve opens, and the cavity of the fender bladder and the cavity of the receiving chamber are connected via the through hole and the safety valve opens. Accordingly, the safety valve functions as per convention and prevents damage by reducing the internal pressure of the cavity of the fender bladder when excessively compressed. When the internal pressure of the cavity of the fender bladder is equal to or less than the standard pressure, which is the sum of the predetermined initial internal pressure and the allowable pressure, the open/close valve closes and the through hole is closed. Accordingly, in the typical in-use state of the fender bladder, the through hole is closed and the safety valve is isolated from the cavity of the fender bladder by the receiving chamber. Accordingly, the safety valve can be safely detached from the mouth piece metal and safely attached to the mouth piece metal. Thus, the safety valve can be detached and attached from an in-use pneumatic fender while in use without bringing the pneumatic fender onto land or a marine vessel. The mouth piece metal further includes the receiving chamber communication passage that connects the cavity of the receiving chamber and outside air and the receiving chamber open/close valve that opens and closes the receiving chamber communication passage. This configuration allows the safety valve to be isolated from the cavity of the fender bladder, thus allowing the receiving chamber open/close valve to be opened and the internal pressure of the cavity of the receiving chamber to be raised to the pressure threshold via the receiving chamber communication passage. In other words, a confirmation test of the valve opening pressure of the safety valve can be performed on the pneumatic fender while in use. In such a manner, according to the present technology, the safety valve can be detached and attached and a confirmation test of the valve opening pressure can be performed on the pneumatic fender while in use. As such, the labor and time required for these operations can be greatly reduced, and maintainability can be significantly enhanced. Hereinafter, a pneumatic fender and a mouth piece metal for a pneumatic fender of the present technology will be described with reference to embodiments illustrated in the drawings. A pneumatic fender 1 (hereinafter, also fender 1) of the present technology illustrated in A mouth piece metal 4 of the present technology is provided on one of the hemispherical portions 3 The mouth piece metal 4 includes a safety valve 6, a communication passage 11 that connects a cavity 2 The receiving chamber 8 is formed extending toward the cavity 2 The through hole 7 So that the fender bladder 2 is not damaged when excessively compressed, the safety valve 6 opens when the pressure reaches a set pressure threshold Pm. The open/close valve 9, which is constantly biased toward the closing direction of the through hole 7 When the pneumatic fender 1 is used, the cavity 2 When the fender bladder 2 is compressed and the internal pressure P of the cavity 2 When the fender bladder 2 is further compressed and the internal pressure P of the cavity 2 When the internal pressure P of the cavity 2 Additionally, with the pneumatic fender 1 in typical in-use state with the open/close valve 9 thus keeping the through hole 7 The allowable pressure Pt is set to, for example, from 5 to 20%, both inclusive, of the predetermined initial internal pressure Pi and more preferably from 5 to 10%, both inclusive. The allowable pressure Pt being less than 5% of the predetermined initial internal pressure Pi would result in a state in which the open/close valve 9 frequently opens the through hole 7 The area of the opening of the through hole 7 The resilient member 10 preferably includes a coil spring as in the present embodiment. Various kinds of coil springs are available. As such, a coil spring with the desired biasing force and durability can be easily found. Alternatively, an elastic member made of rubber or the like, a leaf spring, and the like may be used as the resilient member 10. In another embodiment of the mouth piece metal 4 illustrated in A pneumatic fender and a mouth piece metal with an open/close valve is biased by a resilient member toward a closing direction of a through hole formed on a dividing wall constituting a receiving chamber. A safety valve is isolated from a cavity of a fender bladder by a receiving chamber, thus allowing the safety valve to be able to be detached and attached while the pneumatic fender is in use. A confirmation test of a valve opening pressure of the safety valve is performed by opening a receiving chamber open/close valve and raising an internal pressure of a cavity of the receiving chamber to a pressure threshold (Pm) via a receiving chamber communication passage. Upon an internal pressure (P) of the cavity being less than the pressure threshold (Pm) and greater than a standard pressure (Pc), the open/close valve opens the through hole, thus allowing the safety valve to function. 1. A pneumatic fender comprising:

a fender bladder including a cylindrical portion and bowl-like hemispherical portions connected to each end of the cylindrical portion; a mouth piece metal disposed on at least one of the hemispherical portions, the mouth piece metal including: a safety valve that, upon an internal pressure of a cavity of the fender bladder reaching a pressure threshold, opens to connect the cavity of the fender bladder to outside air and reduce the internal pressure, and a communication passage that connects the cavity of the fender bladder and outside air; and a bladder open/close valve that opens and closes the communication passage; wherein the mouth piece metal further includes: a receiving chamber that isolates the safety valve from the cavity of the fender bladder, a through hole that connects a cavity of the receiving chamber and the cavity of the fender bladder, the through hole being formed on a dividing wall constituting the receiving chamber, an open/close valve that opens and closes the through hole, a resilient member that constantly biases the open/close valve toward a closing direction of the through hole, a receiving chamber communication passage that connects the cavity of the receiving chamber and outside air, and a receiving chamber open/close valve that opens and closes the receiving chamber communication passage; and upon the internal pressure of the cavity of the fender bladder being less than the pressure threshold and greater than a standard pressure, which is a sum of a predetermined initial internal pressure and an allowable pressure, the open/close valve opens, opening the closed through hole. 2. The pneumatic fender according to 3. The pneumatic fender according to 4. The pneumatic fender according to 5. A mouth piece metal for a pneumatic fender comprising:

a safety valve that, upon an internal pressure of a cavity of a fender bladder reaching a pressure threshold, opens to connect the cavity of the fender bladder to outside air and reduce the internal pressure; a communication passage that connects the cavity of the fender bladder and outside air; and a bladder open/close valve that opens and closes the communication passage; the mouth piece metal being attached to a bowl-like hemispherical portion constituting the fender bladder; wherein the mouth piece metal further includes: a receiving chamber that isolates the safety valve from the cavity of the fender bladder, a through hole that connects a cavity of the receiving chamber and the cavity of the fender bladder, the through hole being formed on a dividing wall constituting the receiving chamber, an open/close valve that opens and closes the through hole, a resilient member that constantly biases the open/close valve toward a closing direction of the through hole, a receiving chamber communication passage that connects the cavity of the receiving chamber and outside air, and a receiving chamber open/close valve that opens and closes the receiving chamber communication passage; and upon the internal pressure of the cavity of the fender bladder being less than the pressure threshold and greater than a standard pressure, which is a sum of a predetermined initial internal pressure and an allowable pressure, the open/close valve opens, opening the closed through hole. 6. The mouth piece metal for a pneumatic fender according to 7. The mouth piece metal for a pneumatic fender according to 8. The mouth piece metal for a pneumatic fender according to 9. The mouth piece metal for a pneumatic fender according to 10. The mouth piece metal for a pneumatic fender according to 11. The pneumatic fender according to 12. The pneumatic fender according to TECHNICAL FIELD

BACKGROUND ART

SUMMARY

BRIEF DESCRIPTION OF DRAWINGS

DETAILED DESCRIPTION