Apparatus for the destalking and swathing of pumpkins

The invention concerns a device to the Entranken and cloud of Kürbisfrächtea on the field, which is articulated connected with a machine and raised by means of a preferably hydraulic Hebeeimächtung into transport position and/or lowered into working position.

Gathering Kürbisfrüchten of the field presupposes that - before these are supplied in a collector or a direct Entkernangsvorgang - the fruits from climbing are separated and to a Schwad united, whereby the Kürbisfrüchte freely of adhering Acke, rerde and Rankenstengein into the following admission to arrive to be supposed.

A well-known Sammelveffahren, by means of to front hydraulics of a tractor of coupled earth levelling scoops has the disadvantage of large fault liability due to getting stuck climbing or adhering field earth, which leads schliel31ich to Verschoppangen and thus to Arbeitsanterbrechangen.

The available invention placed itself it to the task to eliminate these disturbing influences as far as possible. This in favourable way by the fact it was drawn that at a front pylon framework of the Hebeeimichtung or several with more closed, preferably smooth surface equipped rollers propelled frictionconclusively over ground drive are arranged, whereby the angle lies ct between roller axle and Fahrlriehtung in a range between 40° and 80°.

The Kürbisranken presses the rollers unreeling when driving on the field into the ground, whereby the Kürbisfrüchte is torn off at the same time and shifted by the schräggesteUten rollers laterally, until they form a Sehwad after leaving the hinleren roller end.

A further advantage of these Anordnang is the high self cleaning ability of the inclined/slanted rollers of continuous field earth by the Reibkrafte developing during the combined roll/slip motion.

The moving invention will show it on the basis two possible Ausf'ührangsbeispiele dargestellL:

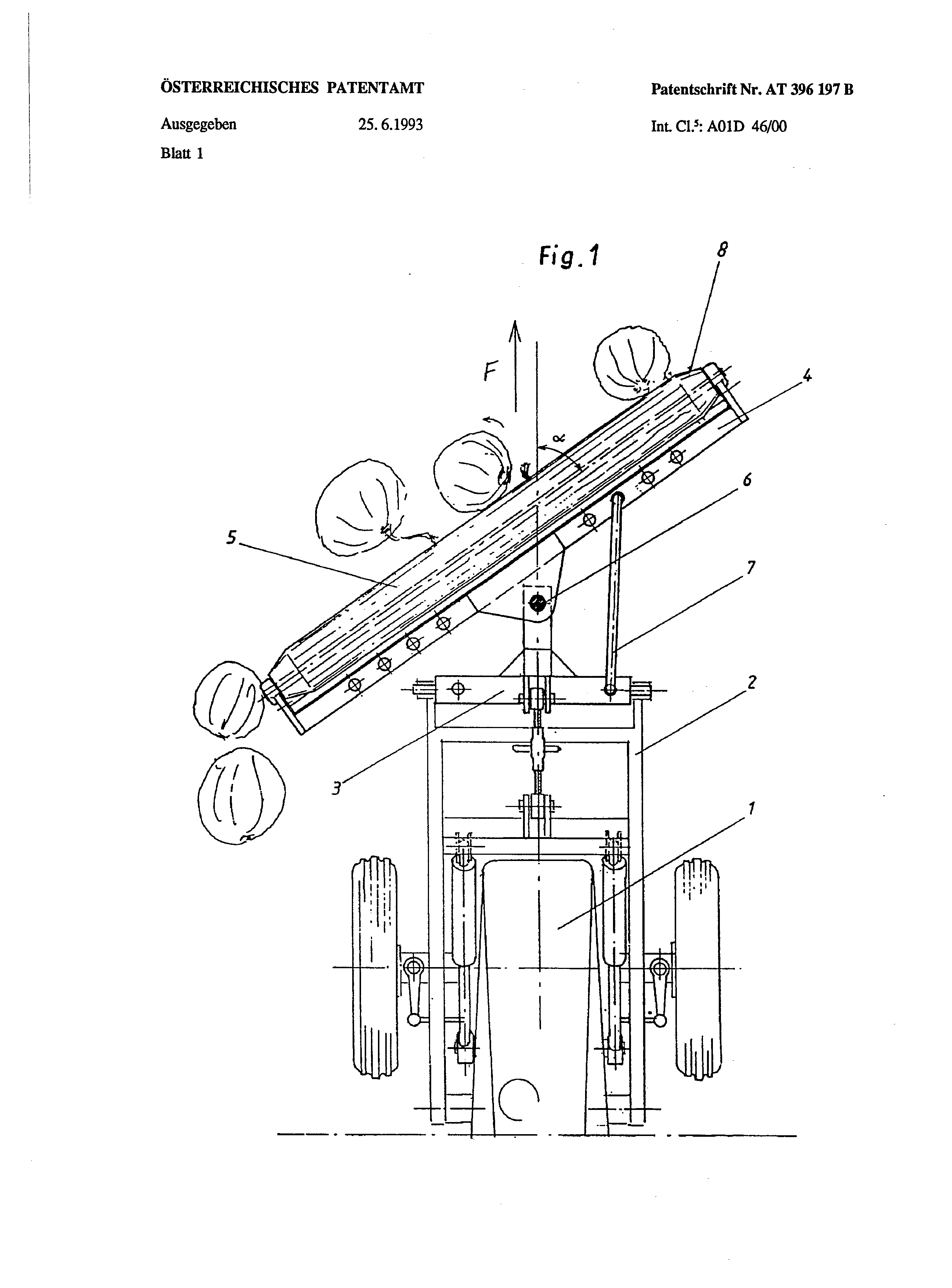

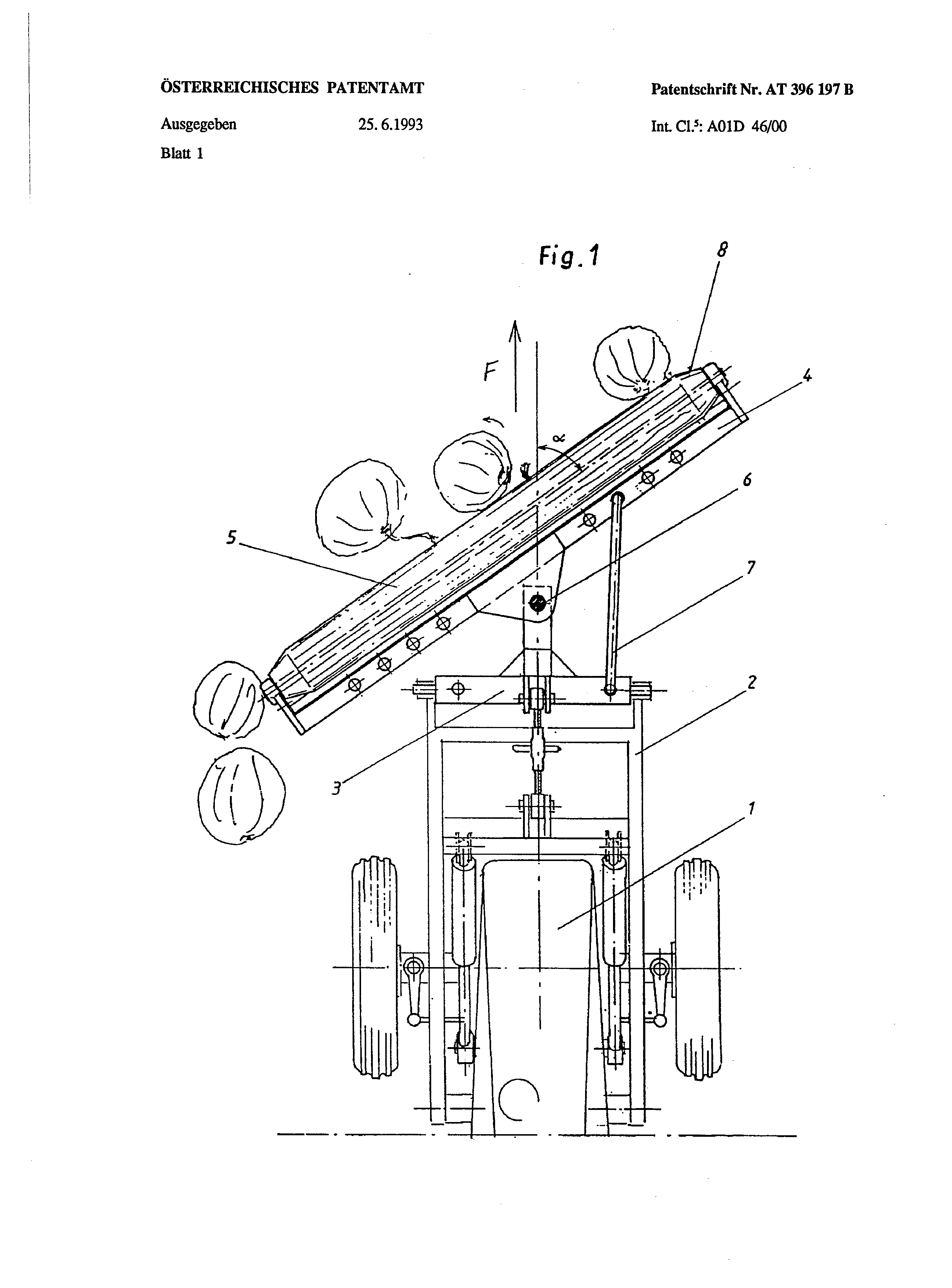

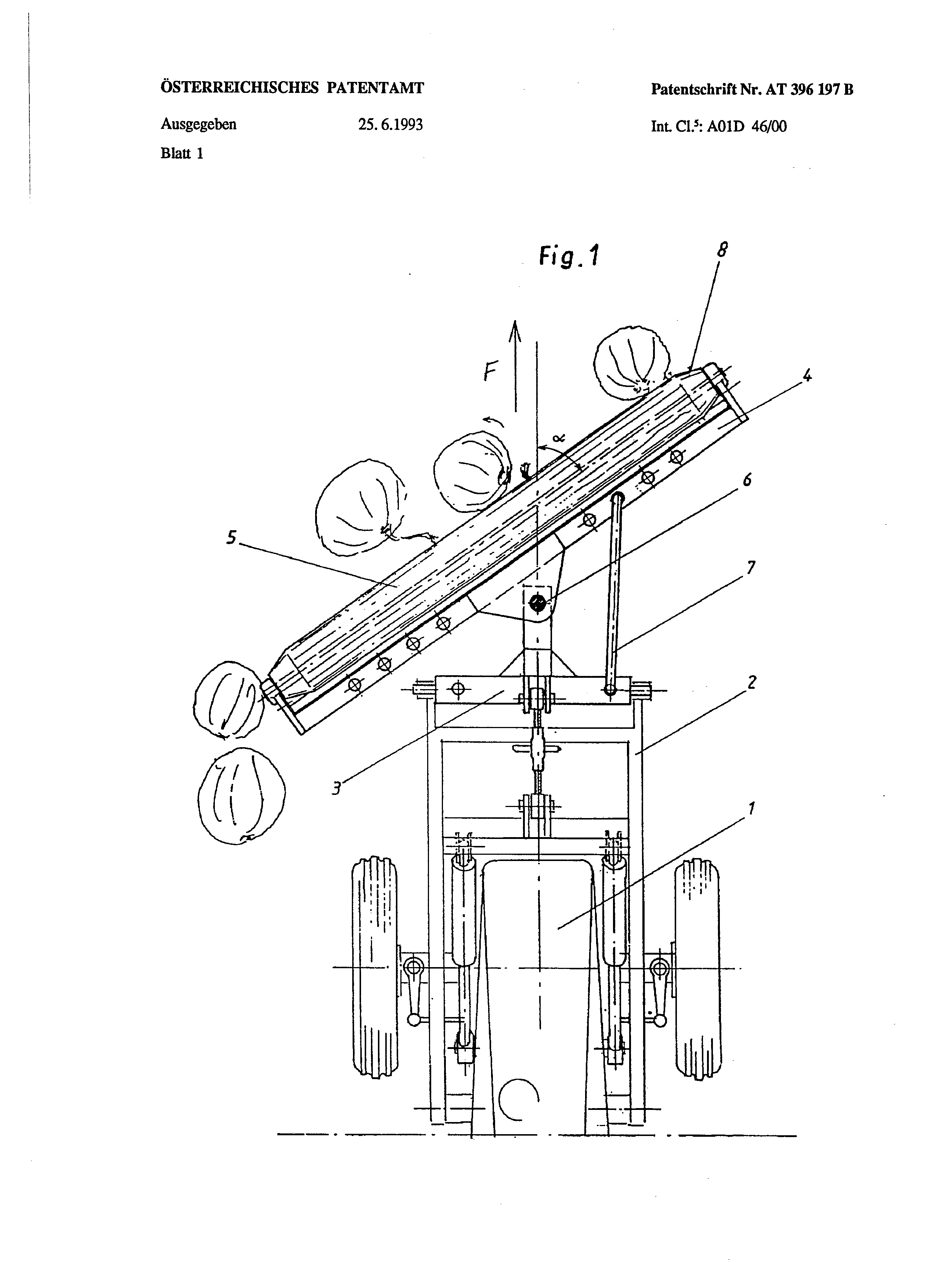

Fig. 1 a plan view on a device according to invention, Fig. 2 a side view on a effindungsgemäße device, Fig. 3 a schematic representation of the Wirktmgsweise of a device according to invention in side view and Fig. 4 a Drauf view on a remark example of the erf'mdungsgemäßen device with two rollers.

In Fig. I becomes the front of an agricultural tractor (1) shown, at whose front hydraulics a harvest device is coupled in working position, • this consists of a rear frame part (3) for the cultivation to the hydraulic linkage (2) and a front pylon framework (4) for a reciprocally stored roller (5).

Both frame parts (3, 4) are connected with a perpendicularly stored pin (6) and can within a Sehwenkbereiches by a locking bar (7) in their inclination to be fixed. An optimal attitude results in sees from the respective operating conditions; Slope inclinations or aufgeweichte grounds require often geanderte Sclwägstellungen.

The range of adjustment lies between 40° and 80°, which cover the angle A, which between driving direction (F) and roller axle one forms. An enlargement of (ct) furnishes gröl3ere work width, decreases however the Schwadeffekt, while a reduction furnishes a better lateral unreeling with however smaller work width.

The 90°-Stellung, which is: Roller axle transverse to the driving direction (F), is valid for fields, their lateral I-Iangneigung the migration of the Kürbisse along the roller (5) caused to a Schwad.

By tapering or rounding the roller ends (8) off getting stuck earth or Pflanzenfiickständen is avoided.

Fig. the erf'mdungsgemäße device shows 2 in the side view as well as Fig. 3 the representation of the Entrankungsphase by holding the climbing stack and way pushing of the Kürbisfrucht.

Fig. a remark example with two rollers (5) shows 4 in a rigid framework. A front baffle (9) a stop catch within the range between the rollers (5) prevents.

An adjustment of the skew of the rollers (5) is possible also over manipulation of a hydraulic servodyne from the driver's seat. Apparatus for the destalking and swathing of pumpkins in the field, which is connected in an articulated manner to a working machine 1 and which is raised into the transport position and lowered into the working position by means of a preferably hydraulic lifting device, there being arranged on a front supporting-tube frame 4 of the lifting device one or more rollers 5 equipped with a closed, preferably smooth, surface and driven frictionally by ground drive, the angle alpha between the roller axis and the direction of travel F being in a range of between 40 degree and 80 degree. <IMAGE>