Kraftfahrzeuginnenausstattungsteil mit einer gassackeinrichtung

The available invention concerns a interior equipment part with a gas bag mechanism to the installation into a motor vehicle and in particular a part of an instrument panel with a gas bag module.

A interior equipment part with a gas bag mechanism to the installation into a motor vehicle reveals the block letters DE 43 11 241 c1. In the execution form represented therein is intended to secure the gas bag module taking off Öffnungsebschnitt or cover by a Fangband against the carrying structure. Here however the Fangband aula on the gas bag module is along led. Therefore the gas bag module cannot be fastened so easily directly to the carrying structure of the interior equipment part. Aul rdem arises as a result of the selected arrangement of the Fangbands in the case of the Aufstoßen of the Öffnu ngsabschnitts its separation from the being certain remaining sections of the interior equipment part. Thus that is separated opening section only over that relatively yields Fangband connected, which can result in unforeseeable dynamics of the loose part.

Another typical interior equipment part with a gas bag mechanism to the installation into a motor vehicle shows the official publication DE 297 11 679 U1. There is also intended to secure the cover or opening section in the carrier by a Fangband. Also this execution form plans a separating of the opening section from the carrier.

Femer reveals the block letters DE 297 08 446 U1 different possibilities for the attachment of a Fangbands at the Öffnungsebschnitt of the carrier of a gas bag cover which can be secured. In particular possibilities are there descriptive of connecting the Fangband with the Öffnungsebschnitt of the carrier by Umspritzen or Umschäumen sufficiently durable.

An alternative to loose Fangbändern reveals the block letters DE 44 37 773 c1. In is suggested securing the Öffnungsebschnitt with a superficially fastened reinforcing ply against a Abreillen. However a firing channel can be stuck together or not welded or otherwise the development area of the gas bag limiting element with the lower surface of the carrier because of the reinforcing ply. Besides [NACHGEREICHTI oo oo 70442gAT 05.03.2007 needs the safe mounting of the reinforcing ply an expanded boundary region beside the opening section.

Regarding that managing indicated well-known designs and Ausführungswelsen places itself the available invention the task to suggest a structure for a interior equipment part with a gas bag mechanism with which the attachment of a Fangbands can take place in particularly simple way when the assembling of the Gessackmoduls.

The available invention solves this task by a interior equipment part with the Merkmalskombinatlon indicated in the following principal claim.

In a favourable further training of the available invention it can be intended that the mounting of the Fangbands sets as accurately as possible to the Scharniedinie of the opening section and the Fangband runs approximately tautly from there out by the firing channel up to the other tying up place. This results in an only slightly flexible support of the opening section to the intended Scharniedinie. This cannot bulge then under Kraft of the expanding gas bag into a curved shape with the consequence of the break or the Einreil ens. An unwanted Abreil EN of the opening section at the hinge line with unfolding the gas bag could result otherwise in undefined dynamics of the separated part and justify an unforeseeable danger of injury.

Still further favourable arrangements of the available invention are indicated in the Unteransprüchen.

A preferential execution form of the available invention is described in the following example for the sake of, whereby to the attaching designs is referred.

In it show:

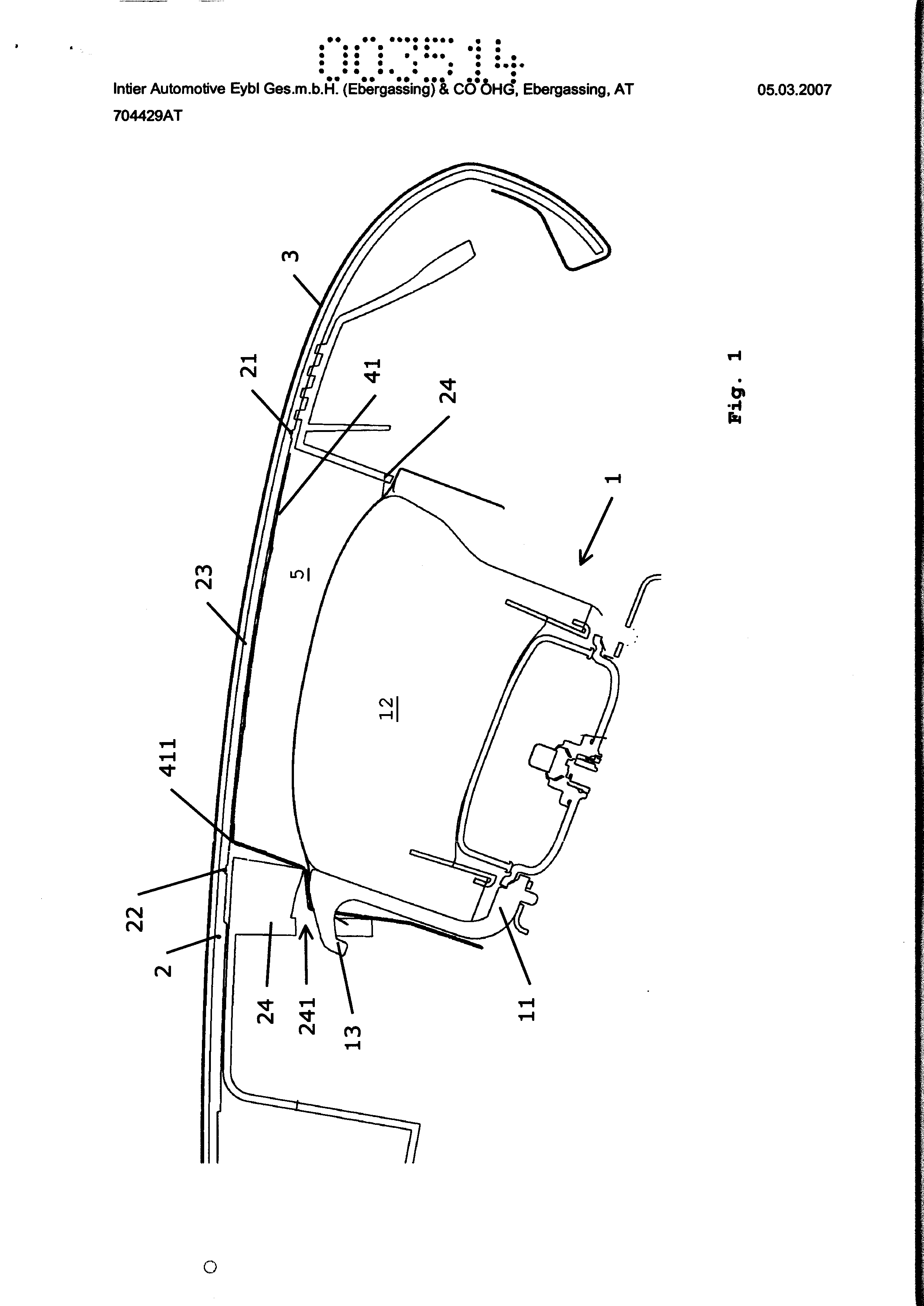

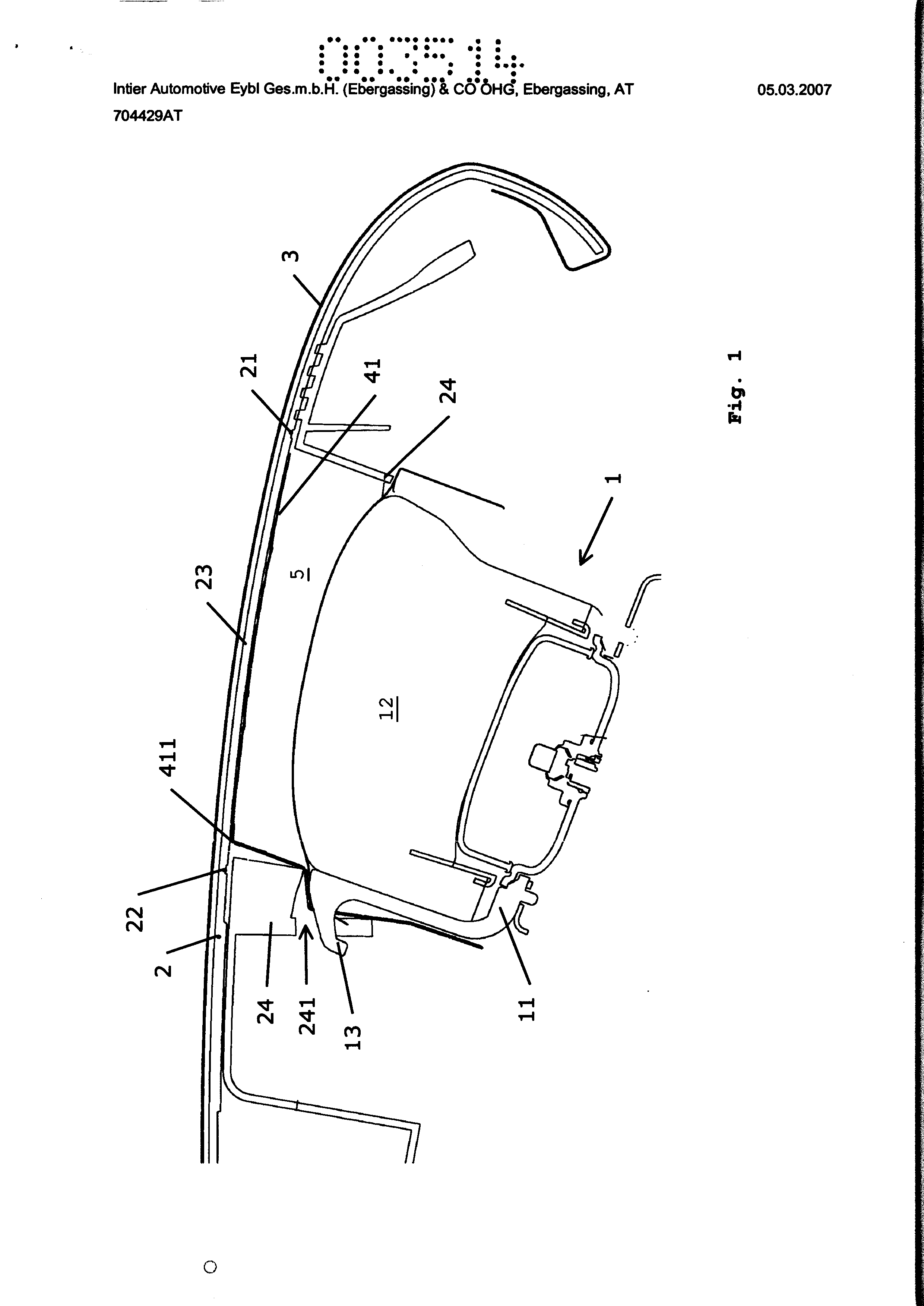

Fig. 1 a schematic vertical cutaway view by a interior equipment part with a gas bag mechanism; and Fig. 2 a perspective partial section opinion by the parts the interior equipment part in accordance with Fig, lying below the carrier. 1.

O {SUPPLIED LATER ee ee eeee eeee • • inter Automo, VE Eyb, G: . i11; i: ; ; in0; jÖH6 704429AT 05.03.2007 in accordance with the Fig. 1 and 2 a interior equipment part with a gas bag mechanism covers a rigid carrier 2. the available almost even top side of the carrier 2 points after the installation interior equipment part to the passenger compartment and is intended to be a decorative layer 3 as vague ones or otherwise decoratively trained. Below the carrier 2 a gas bag module 1 of a passenger protection device is arranged in actually well-known way. The gas bag module 1 covers a more topfoder becherförmiges housing 11, in which a folded gas bag 12 is taken up. Typically also a gas producer is intended for unfolding the gas bag 12 within the housing 11 of the gas bag module 1. For the protection of the gas bag 12 the opening of the housing 11 with a protective plastic film or such a thing is locked.

An opening section 23 at the carrier 2 makes the withdrawal of the gas bag for 12 possible with its development into the range of the passenger compartment. The opening section 23 is available into actually well-known way through together hanging Aufreis 21 and hinge lines 22 defined. As breaking line 21 available approximately linienförmig in special way an out-arranged range is taken in the material of the carrier 2 in purchase, at which a foreseeable Aufreil EN of the material under the effect of a pre-determined Kraft is possible. In the simplest case a line perforation is brought in into the material of the carrier 2 as breaking line 21. With the hinge line 22 it concerns also an approximately linienförmig particularly out-arranged range of the substrate, which makes possible or facilitates a bending or for hinges. Available the Scharniedinie 22 is designed as straight-line groove.

Below the opening section 23 a firing channel 24 is arranged at the carrier 2.

The Schusskana124 limited on the one hand the development area 5 of the gas bag 12 after the sides and aligns thereby the effect of the unfolding gas bag 12 to the opening section 23. Further the firing channel serves 24 as Ransch or delta for the mounting of the gas bag module 1 at the carrier 2. the firing channel 24 can with the carrier 2 be einstückig manufactured or of it manufacture separately and in the following permanently to the carrier 2 fasten. The descriptive execution form plans a separately manufactured firing channel 24, which is able one been suitable selected material mating with the carrier 2 is permanently welded.

The binding of the gas bag module I at the firing channel 24 can be caused in simple way by projections/leads 13 or hakenförmige rest noses at the housing 11 of the GasO NACHGEREICHT1 EO • • • • • 0 • ' • Q • Q Q 704429AT 05.03.2007 of bag module 1, which in corresponding recesses or break-throughs at the firing channel 24 intervenes. At the transverse edges or on to the rest connection in relation to lying edge the gas bag module 1 is held in conventional way by bolt connections.

For the discharge of the opening section 23 in relation to the pressure of the enffaltenden gas bag 12 a retaining strap 4 is intended. A first section 41 of it is preferably laminar connected with the opening section 23 of the carrier 2. It is particularly favourable to train and to this align this connection if possible close to the Scharniedinie 22. On the basis of the opening section 23 the retaining strap 4 by the firing channel 24 to the junction point to the gas bag module 1. vedäuft is as tautly as possible fastened the retaining strap 4 for the training of a back support there. In the execution form shown the attachment is caused favourably by the fact that in the retaining strap 4 break-throughs or recesses 241 corresponding to the projections/leads 13 at the housing 11 of the gas bag module 1 are put on. Thus the retaining strap 4 can like represented of the rest connection between firing channel 24 and gas bag module 1 reached through to become.

During the release of the passenger protection device the gas bag is blown up by the gas from the gas producer and from the housing 11 into the firing channel 24 becomes extinct. As soon as the gas bag takes the development area 5 completely, the gas pressure affects the tautly led retaining strap 4 the opening section 23 of the carrier 2. evenly supports thereby the opening section within the range of the Scharniedinie 22 against the gas pressure off. As soon as Kraft introduced by the gas bag on the opening section exceeds a pre-determined extent, or breaks the opening section tears to 23 fold-like from the carrier 2 out. The opening section 23 remains however connected by the hinge line 22 surely with the carrier 2 and swivels around the edge edge 411 of the binding to the retaining strap 4 into a geöffTlete position.

If the Scharniedinie 22 is beabstandet to the mentioned Randk.ante 411, this with the Aufschwenken of the opening section pressing the carrier part down bordering on the hinge line 22 causes 23. This effect is however unproblematic and does not lead not to a damage of the opening section 23, the hinge line 22 or the carrier 2, if the distance between edge edge 411 and Schamiedinie is SUPPLIED LATER 22 small limited isL i 1 o • • • • • • o0o m • • 704429AT 05.03.2007 that managing described effect missing, if the edge edge 411 coincides with the Scharniedinie 22 accurately.

[NACHQERE cù'r1 • "" “'“s-s; ö Intier automotive Eybl Ges* n.b. (E n C OHG 704429AT 05.03.2007 Bezuasze hen gas bag module 1 housing 11 gas bag of 12 projections/leads of 13 carriers 2 Aufreil line 21 Scharniedinie 22 opening section 23 firing channel 24 recesses 241 decoration 3 retaining strap 4 first section 41 edge edge 411 breaking through 42 Enffaltungsbereich NACHGEREICHTi oo oo • .o.::. . o: •:: …, .o: öo:.

InUer Automoüve Eybl Ge S. '1 *.b*. i11 §§/ng CO: OHG 7044 3AT 05.03.2007 AnsDrüche 1st interior equipment part with a gas bag mechanism, exhibiting a gas bag module (1) with a topfförmigen housing (11) for the admission of a gas bag (12) and a forntabilen carrier (2) with one by Aufreis (21) and Schamierlinien (22) it defined opening section (23) and which is away a firing channel (24), on one side from it, for adjustment the development of the gas bag (12) on the opening section (23), whereby the gas bag module (1) at the abstebenden end of the firing channel (24) is arranged, by the fact characterized that at the opening section (23) a first section (41) of a retaining strap (4) is attached, within of the Firing channel (24) up to the beginning place of the gas bag module (1) runs and there is fastened.

2. Interior equipment part with a gas bag mechanism according to requirement 1, whereby the mounting of the retaining strap (4) to opening section (23) in the proximity and/or aligned to the hinge line (22) sets, in order to relieve with the development of the gas bag (12) the hinge line (22) in relation to the opening forces.

3. Interior equipment part with a gas bag mechanism according to requirement 2, whereby the mounting of the retaining strap (4) to opening section (23) a laminar connection is, which sets along a substantial section of the hinge line (22).

4. Interior equipment part with a gas bag mechanism after one of the preceding requirements, whereby the first section (41) of the retaining strap (4) with the opening section of the carrier (2) stuck together.

Interior equipment part with a gas bag mechanism after one of the requirements 1 to 3, whereby the retaining strap (4) in the first section (41) preferably small holes or pores exhibits, which of the material of the carrier (2) for the training of a positive connection is interspersed.

6. Interior equipment part with a gas bag mechanism according to requirement 5, whereby the retaining strap (4) a textile structure exhibits, their fibers into the material of the carrier (2) is embedded.

7. Interior equipment part with a gas bag mechanism according to requirement 6, whereby the carrier (2) from a thermoplastic plastic material and the imbedding of the first exists section (41) of the retaining strap (4) by Umspdtzen, Umschäumen, Hinterspritzen or Hinterpressen is available.

nachgereichtI Inner part comprises an airbag module (1) having a holding band with a first section (41) joined to an opening section (23) and running within a channel (24) up to a projection site of the airbag module. Preferred Features: The holding band is guided through a joint between the airbag module and the channel. The first section of the holding band is adhered to the opening section of a support (2). The holding band has a textile structure with fibers embedded in the material of the support. • .o.::. . o: •:: …, .o: öo:.

InUer Automoüve Eybl Ge S. '1 *.b*. i11 §§/ng CO: OHG 7044 3AT AnsDrüche 1. Interior equipment part with a gas bag mechanism, exhibiting a gas bag module (1) with a topfförmigen housing (11) for the admission of a gas bag (12) and a forntabilen carrier (2) with one by Aufreis (21) and Schamierlinien (22) it defined opening section (23) and which is away a firing channel (24), on one side from it, for adjustment the development of the gas bag (12) on the opening section (23), whereby the gas bag module (1) at the abstebenden end of the firing channel (24) is arranged, by the fact characterized that at the opening section (23) a first section (41) of a retaining strap (4), that is attached within the firing channel (24) up to the beginning place the gas bag module (1) runs and there is fastened. 2. Interior equipment part with a gas bag mechanism according to requirement 1, whereby the mounting of the retaining strap (4) to opening section (23) in the proximity and/or aligned to the hinge line (22) sets, in order to relieve with the development of the gas bag (12) the hinge line (22) in relation to the opening forces. 3. Interior equipment part with a gas bag mechanism according to requirement 2, whereby the mounting of the retaining strap (4) to opening section (23) a laminar connection is, which sets along a substantial section of the hinge line (22). 4. Interior equipment part with a gas bag mechanism after one of the preceding requirements, whereby the first section (41) of the retaining strap (4) with the opening section of the carrier (2) stuck together.

Interior equipment part with a gas bag mechanism after one of the requirements 1 to 3, whereby the retaining strap (4) in the first section (41) preferably small holes or pores exhibits, which of the material of the carrier (2) for the training of a positive connection is interspersed. 6. Interior equipment part with a gas bag mechanism according to requirement 5, whereby the retaining strap (4) a textile structure exhibits, their fibers into the material of the carrier (2) is embedded. 7. Interior equipment part with a gas bag mechanism according to requirement 6, whereby the carrier (2) from a thermoplastic plastic material and the imbedding of the first exists section (41) of the retaining strap (4) by Umspdtzen, Umschäumen, Hinterspritzen or Hinterpressen is available.

nachgereichtI oo oo oaÖù 704429AT 8. Interior equipment part with a Gassackeinrichlung after one of of the preceding requirements, whereby the retaining strap (4) approximately tautly vedäuft by the firing channel (24). 9. Interior equipment part with a gas bag mechanism after one of of the preceding requirements, whereby the retaining strap (4) by a joint between gas bag module (1) and firing channel (24) from the development range (5) of the gas bag led and there out is fastened.

Interior equipment part with a gas bag mechanism according to requirement 9, whereby the retaining strap (4) breaking through (42) positive exhibits connection at projections/leads (13) at the firing channel (24) or on the gas bag module for (1). 11. Interior equipment part with a gas bag mechanism according to requirement 10, whereby the projections/leads (13) further between gas bag module (1) at the firing channel (24) the breaking through (42) in the retaining strap cause (4) thorough Verrastung.

l SUPPLIED LATER