Absorbing solution, and method and apparatus for the removal of CO2 or H2S or both

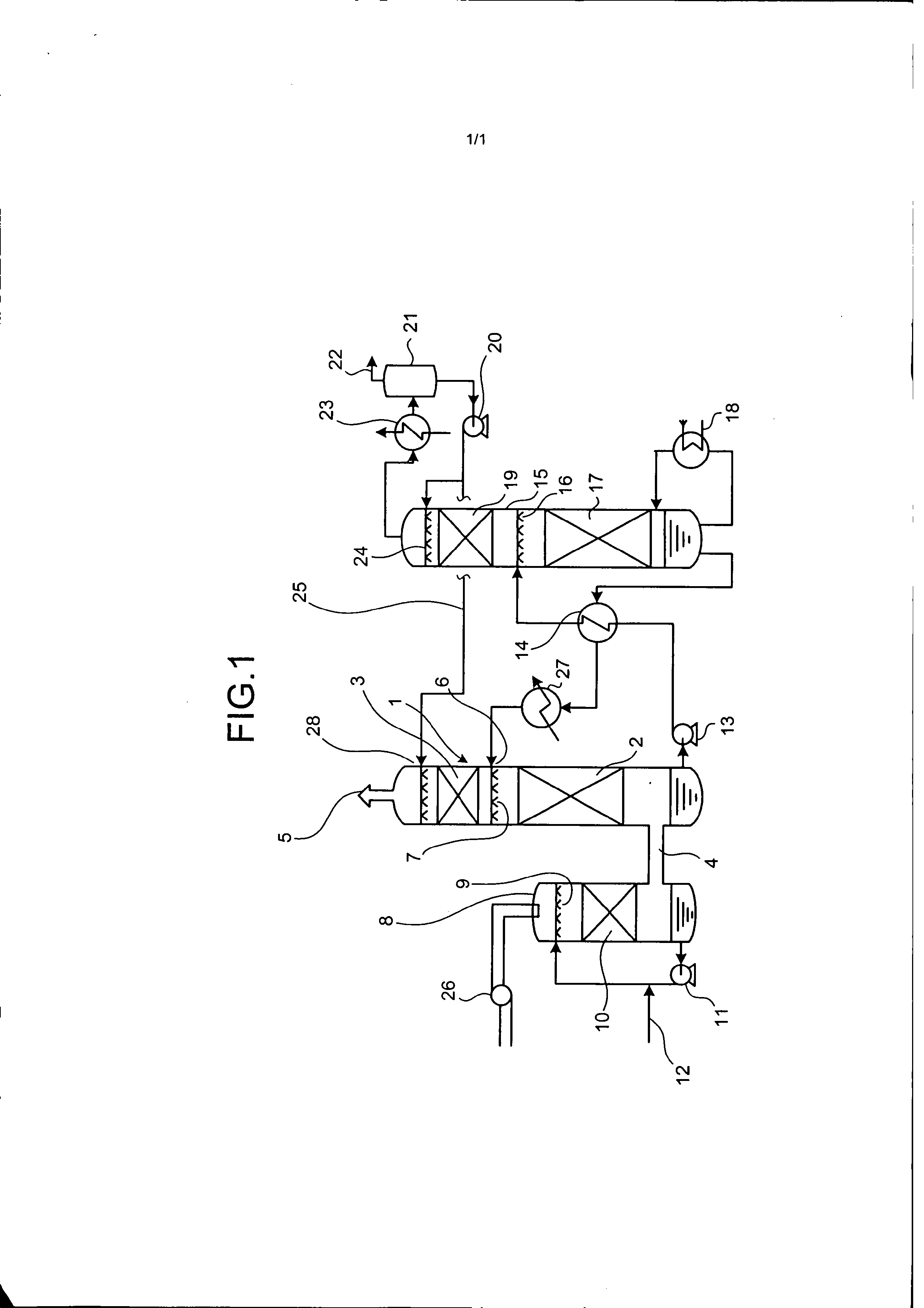

[0002] Various methods have been proposed for collecting and removing acidic gases such as CO 2 that are often contained in gases (treatment object gases), for example in industrial gases manufactured in chemical plants, such as a natural gas and synthetic gas and flue gases. In the case of flue gases, a method of bringing a flue gas comprising CO 2 into contact with an alkanolamine solution or the like to remove and collect CO 2 , and a method of storing CO 2 without emitting CO 2 to the atmosphere have been actively studied. As the alkanolamine, it is possible to use monoethanolamine (MEA), 2-methylaminoethanol, 2ethylaminoethanol, 2-propylaminoethanol, nbutylaminoethanol, 2-(isopropylamino)ethanol, and 3ethylaminoethanol. For example, an absorbing-solution formed of a mixture of secondary amine or a mixture of secondary amine and tertiary amine is disclosed in a United States Patent specification. It is proposed that this mixed absorbingsolution is an advantageous absorbing-solution because an absorbing ability and regeneration energy are substantially improved in the mixed absorbing solution compared with an MEA single absorbing solution (Patent Document i). When a monoethanolamine (MEA) absorbing solution is used, there is a problem in that degradation in the absorbing-solution severely progresses because of oxygen or the like in gas. A method has therefore also been proposed for stabilizing an absorbing-solution by adding, for example, trialkanolamine or methyldiethanolamine (MDEA) to the absorbing-solution (Patent Document 2 and Patent Document 3). Patent Document i: United States Patent No. 5,618,506 specification Patent Document 2: United States Patent No. 3,535,260 specification Patent Document 3: United States Patent No. 4,840,777 specification However, these patent documents are primarily concerned with the absorbing ability and the like of the absorbing-solution formed from the mixture of secondary amine. In particular, the documents do not disclose a method of preventing degradation in the absorbing-solution due to oxygen or the like present in the gas. Furthermore, control of degradation in the absorbing-solution still remains a problem to solve. Taking the problem into consideration, the present invention seeks to provide an absorbing-solution which can minimize or prevent self-degradation due to oxygen or the like that is present in gas, and a method and an apparatus for removing any one of CO 2 and H 2 S or both. SUMMARY OF THE INVENTION The present invention provides an absorbingsolution that absorbs at least one of CO 2 and H 2 S or both that are present in a gas, the absorbing-solution comprising: secondary-amine composite absorbent; and tertiary monoamine that is added to the secondary-amine composite absorbent; wherein the secondary-amine composite absorbent is a mixture of secondary monoamine and secondary diamine, and wherein 1 to 20 weight percent of the tertiary monoamine is added to the secondary-amine composite absorbent. In one embodiment, the secondary monoamine is a compound that is selected from at least one kind of 2- methylaminoethanol, 2-ethylaminoethanol, 2-npropylaminoethanol, 2-n-butylaminoethanol, 2-npentylaminoethanol, 2-isopropylaminoethanol, 2-secbutylaminoethanol, and 2-isobutylaminoethanol, and the secondary diamine is a compound that is selected from at least one kind of piperazine, 2-methylpiperazine, 2,3dimethylpiperazine, 2,5-dimethylpiperazine, N,N'- dimethylethanediamine, N,N'-dimethylpropanediamine, N,N'- diethylethylenediamine, N,N'-diethylpropanediamine, N,N'- diisopropylethylenediamine, and N,N'-ditertiary- butylethanediamine. In a further embodiment, 2.5 to i00 weight percent of the secondary diamine is added to the secondary monoamine. The present invention also provides a removing apparatus that removes at least one of CO 2 and H 2 S or both that are present in a gas, the removing apparatus comprising: an absorber that receives the gas, causes the gas to come in contact with an absorbing-solution whereby at least one of CO 2 and H 2 S or both is absorbed by the absorbingsolution; and a regenerator that regenerates the absorbing-solution that absorbed at least one of CO 2 and H 2 S or both by removing at least one of CO 2 and H 2 S or both from the absorbingsolution, and supplies the absorbing-solution that is removed of at least one of C0 2 and H 2 S or both to the absorber, wherein the absorbing-solution includes secondaryamine composite absorbent, and tertiary monoamine that is added to the secondary-amine composite absorbent; wherein the secondary-amine composite absorbent is a mixture of secondary monoamine and secondary diamine, and wherein 1 to 20 weight percent of the tertiary monoamine is added to the secondary-amine composite absorbent. The present invention further provides a method for a removing apparatus to remove at least one of CO 2 and H 2 S or both that are present in a gas, the method comprising: causing the gas to come in contact with an absorbingsolution whereby at least one of CO 2 and H 2 S or both is absorbed by the absorbing-solution; and regenerating the absorbing-solution that absorbed at least one of CO 2 and H 2 S or both by removing any one of CO 2 and H 2 S or both from the absorbing-solution, wherein the causing includes causing the gas to come in contact with an absorbing-solution that is regenerated at the regenerating step, wherein the absorbing-solution includes secondaryamine composite absorbent, and tertiary monoamine that is added to the secondary-amine composite absorbent; wherein the secondary-amine composite absorbent is a mixture of secondary monoamine and secondary diamine, and wherein 1 to 20 weight percent of the tertiary monoamine is added to the secondary-amine composite absorbent. According to an embodiment of the present invention, it is possible to reduce a loss of an absorbingsolution due to degradation in amine used as the absorbingsolution, to minimize or prevent deterioration of performance, and to reduce a cost. BRIEF DESCRIPTION OF DRAWINGS The present invention is also illustrated by way of example only with reference to the accompanying drawing in which Fig. 1 is a diagram for explaining an example of a process that can be adopted in the present invention. EXPLANATIONS OF LETTERS OR NUMERALS In Figure I: 1 Decarbonator Absorbing-solution/regenerator DETAILED DESCRIPTION OF THE INVENTION Exemplary embodiment of the present invention is explained in detail below with reference to the drawings. The present invention is not limited by the embodiment and an example. Components in the embodiment and the example include components that those skilled in the art can easily anticipate, or include components that are substantially identical with the components that those skilled in the art can easily anticipate. An absorbing solution according to an embodiment of the present invention is an absorbing solution that absorbs at least one of CO 2 and H 2 S or both of CO 2 and H 2 S in gas. The absorbing solution is formed by adding tertiary monoamine to a secondary-amine composite absorbent. Consequently, it is possible to control degradation in amine in the absorbing solution due to oxygen or the like in gas. The secondary-amine composite absorbent is a mixture of secondary monoamine and secondary diamine. The secondary monoamine may be an amine compound represented by Formula (i) below. RICHR2NHCH 2 CH 2 OH (i) In the formula, R I represents a lower alkyl group with a hydrogen or carbon number 1 to 4 and R 2 represents a hydrogen or methyl group. Specifically, examples of the secondary monoamine include a compound selected from at least one kind of 2- methylaminoethanol, 2-ethylaminoethanol, 2-npropylaminoethanol, 2-n-butylaminoethanol, 2-npentylaminoethanol, 2-isopropylaminoethanol, 2-secbutylaminoethanol, and 2-isobutylaminoethanol. However, the present invention is not limited to this. Examples of the secondary diamine include a compound selected from at least one kind of piperazine, 2methylpiperazine, 2,3-dimethylpipera ine, 2,5dimethylpiperazine, N,N'-dimethylethanediamine, N,N'- dimethylpropanediamine, N,N'-diethylethylenediamine, N,N'- diethylpropanediamine, N,N'-diisopropylethylenediamine, and N,N'-ditertiary-butylethanediamine. However, the present invention is not limited to this. The tertiary monoamine may be an amine compound indicated by Formula (2) below. R3R4NRSOH (2) R3 is a lower alkyl group with a carbon number 1 to 4, R4 is a lower alkyl group or hydroxyethyl group with a carbon number 1 to 4, and R5 is a lower alkyl group with a carbon number 2 to 4. As the tertiary monoamine indicated by Formula (2), it is desirable to use, for example, N-methyldiethanolamine (MDEA), N-ethyldiethanolamine, N-butyldiethanolamine, 2dimethylaminoethanol, 2-diethylaminoethanol, 2-di-n- butylaminoethanol, N-ethyl-N-methylethanolamine, 3dimethylanimo-l-propanol, 2-dimethylamino-2-methyl-lpropanol, or 4-dimethylamino-l-butanol. However, the present invention is not limited to this. The percentage of addition of tertiary monoamine to the secondary-amine composite absorbent is 1 to 20 weight percent. This is because, as indicated by Table 1 below, when the percentage exceeds 20 weight percent, a fall in an absorption capacity undesirably increases. On the other hand, when the percentage is lower than 1 weight percent, undesirably, it is impossible to eliminate an influence of contaminant. Table 1 Table 1 (50°C, I0 mol% dry CO 2 condition) Tertiary amine concentration with respect Absorption to a mixture of secondary monoamine and capacity ratio secondary diamine (weight %) 0 1 (reference) I0 0.99 0.96 0.93 A percentage of addition of secondary diamine to secondary monoamine is not specifically limited. However, it is desirable to add 2.5 to i00 weight % of secondary diamine. A process that can be adopted in the method of removing CO 2 or H 2 S in a flue gas or both of CO 2 and H 2 S according to the present invention is not specifically limited. An example of the process is explained with reference to Fig. i. In Fig. I, only main equipment is shown and additional equipment is not shown. In Fig. i, reference numeral 1 denotes a decarbonator; 2, a lower filling unit; 3, an upper filling unit or a tray; 4, a decarbonator flue-gas supply port; 5, a decarbonator flue-gas exhaust port; 6, an absorbing-solution supply port; 7, nozzles; 8, a flue gas cooler provided when needed; 9, nozzles; i0, a filling unit; ii, a humidifying-coolant circulation pump; 12, a makeup-water supply line; 13, an absorbing-solution discharge pump for an absorbing-solution in which CO 2 is absorbed; 14, a heat exchanger; 15, an absorbing-solution regenerator; 16, nozzles; 17, a lower filling unit; 18, a reboiler; 19, an upper filling unit; 20, a reflux water pump; 21, a CO 2 separator; 22, a collected CO 2 exhaust line; 23, a regenerator reflex cooler; 24, nozzles; 25, a regenerator reflux-water supply line; 26, a flue-gas supply blower; 27, a cooler, and 28, a regenerator reflux-water supply port. In Fig. I, a flue gas is squeezed into the flue gas cooler 8 by the flue-gas supply blower [translator's comment: reference numeral 26 should be affixed]. The flue gas comes into contact with a humidifying coolant from the nozzles 9 in the filling unit i0 and is humidified and cooled and led to the decarbonator 1 through the decarbonator flue-gas supply port 4. The humidifying coolant coming into contact with the flue gas accumulates in a lower part of the flue gas cooler 8 and is circulated to the nozzles 9 by the pump II and used. Since the humidifying coolant is gradually lost by humidifying and cooling the flue gas, the humidifying coolant is filled by the makeup-water supply line 12. The flue gas squeezed into the decarbonator 1 is brought into counter-contact with an absorbing-solution of a fixed concentration supplied from the nozzles 7 in the lower filling unit 2. CO 2 in the decarbonated flue gas is absorbed and removed by the absorbing-solution and the decarbonated flue gas flows to the upper filling unit 3. The absorbing- solution supplied to the decarbonator 1 absorbs CO 2 . Temperature of the absorbing-solution usually rises to be higher than temperature in the absorbing-solution supply port 6 because of reaction heat due to the absorption. The absorbing-solution is sent to the heat exchanger 14 by the absorbing-solution discharge pump 13 for the absorbingsolution in which CO 2 is absorbed. The absorbing-solution heated and led to the absorbing-solution regenerator 5. It is possible to perform temperature adjustment for the absorbing-solution regenerated using the heat exchanger 14 or the cooler 27 provided between the heat exchanger 14 and the absorbing-solution supply port 6 as required. In the absorbing-solution regenerator 15, the absorbing-solution is regenerated in the lower filling unit 17 according to heating by the reboiler 18, cooled by the heat exchanger 14, and returned to the decarbonator I. In an upper part of the absorbing-solution regenerator 15, CO 2 separated from the absorbing-solution comes into contact with a reflux water supplied from the nozzles 24 in the upper filling unit 19 and cooled by the regenerator reflux cooler 23. Water vapor accompanying CO 2 is separated from the condensed reflux water by the CO 2 separator 21 and led a CO 2 collection process from the collected CO 2 exhaust line 22. The reflux water is partially refluxed to the regenerator by the reflux water pump 20 and partially supplied to the regenerator reflux-water supply port 28 of the decarbonator 1 through the regenerator reflux-water supply line 25. Since a small quantity of absorbingsolution is contained in this regenerated reflux water, the absorbing-solution comes into contact with exhaust gas in the upper filling unit 3 of the decarbonator 1 and contributes to removal of a small quantity of CO 2 contained in the exhaust gas. Example A non-limiting example according to the present invention is explained. In the example, temperature was set to 60°C and oxygen concentration in gas was set to 20 mol%. As a compounding ratio, concentration of tertiary amine with respect to a mixture of secondary monoamine and a secondary diamine was set to 2 weight percent. In this example, secondary monoamine was used and a piperazine compound was used as secondary diamine to form a secondary-amine composite absorbent. 2 weight percent of methyldiethanolamine (MDEA) was added to the secondary-amine composite absorbent as tertiary monoamine. Thereafter, a predetermined quantity of water was added to the secondaryamine composite absorbent to form a C0 2 absorbing-solution. Concentration of a decomposition product (a vapor-like basic compound in the C0 2 absorbing-solution obtained was 8 ppm. On the other hand, concentration of a decomposition product (a vapor-like basic compound) in a CO 2 absorbing-solution formed of a secondary monoamine and a piperazine compound, which was a comparative example in which 2 weight percent of methyldiethanolamine (MDEA) was not added to the secondary-amine composite absorbent as tertiary monoamine, was 15 ppm Thus, it was found that, when tertiary monoamine was added to the secondary-amine composite absorbent, it is possible to control degradation due to oxygen in exhaust gas. As described above, the absorbing-solution according to the present invention is suitably used in a facility that removes CO 2 or H 2 S in a flue gas or both of C0 2 and H 2 S, in which a reduction in a loss of an absorbingsolution due to degradation in absorbing-solution amine, prevention of malfunction, and a reduction in cost can be realized. The reference in this specification to any prior publication (or information derived from it), or to any matter which is known, is not, and should not be taken as an acknowledgment or admission or any form of suggestion that that prior publication (or information derived from it) or known matter forms part of the common general knowledge in the field of endeavour to which this specification relates. Throughout this specification and the claims which follow, unless the context requires otherwise, the word "comprise", and variations such as "comprises" and "comprising", will be understood to imply the inclusion of stated integer or step or group of integers or steps but not the exclusion of any other integer or step or group of integers or steps. (51) m i :---!F : BOlD 53/40 (2006.01) BOlD 53/34 (2006.01) BOlD 53/14 (2006.01) BOlD 53/77 (2006.01) (21) [N , - -: PCT/JP2006/307054 (22) [Nl .q4. R: 2006fg4 3 R(03.04.2006) (25) N 0 = : [ (26) I l E - : I t : 0o) - -- : 4# 2005-107950 2005 fg4 ,El4 [] (04.04.2005) JP (71) . A( < - Iz Lx-C): -- T - (MITSUBISHI HEAVY INDUSTRIES, LTD.)[JWJP]; ¥1088215 A$' --T 1 6 Tokyo (JP). N i$ *± fine KANSA1 ELECTRIC POWER CO., INC.). (72) ; (75) (MIMURA, Tomio). J\ : (YAGI, Yasuyuki). d\ , g =- - (OGURA, Kouki). (IIJIMA, Masaki). n (TAKASHINA, Toru). [] a (TANAKA, Hiroshi). ] t (HIRATA, Takuya). (74) J z : i= 3 (SAKAI, Hiroaki); ¥ 1006019 . 2,' * " /-1 l i¢ l::i/4 jP Tokyo (JP). (81) 1 ( O)tgb\]l ), (D O)I IX [If n--]" ): AE, AG, AL, AM, AT, AU, AZ, BA, BB, BG, BR, BW, BY, BZ, CA, CH, CN, CO, CR, CU, CZ, DE, DK, DM, DZ, EC, EE, EG, ES, FI, GB, GD, GE, GH, GM, HR, HU, ID, IL, IN, IS, JP, KE, KG, KM, KN, KP, KR, KZ, LC, LK, LR, LS, LT, LU, LV, LY, MA, MD, MG, MK, MN, MW, MX, MZ, NA, NG, NI, NO, NZ, OM, PG, PH, PL, PT, RO, RU, SC, SD, SE, SG, SK, SL, SM, SY, TJ, TM, TN, TR, TF, TZ, UA, UG, US, UZ, VC, VN, YU, ZA, ZM, ZW. (84) ( bx 9, CO O r ): ARIPO (BW, GH, GM, KE, LS, MW, MZ, NA, SD, SL, SZ, TZ, UG, ZM, ZW), "1- -> T (AM, AZ, BY, KG, KZ, MD, RU, TJ, TM), N--I::1 ,y, (AT, BE, BG, CH, CY, CZ, DE, DK, EE, ES, FI, FR, GB, GR, HU, IE, IS, IT, LT, LU, LV, MC, NL, PL, PT, RO, SE, SI, SK, TR), (54) Title: ABSORBING SOLUTION, AND METIIOD AND APPARATUS FOR TIIE REMOVAL OF CO OR 11 2 S OR BOTII (54) l Y]0) : CO 2 XI H 2 S. I " 0') J 0')[ .- " .g 23 22 "19 11 13 18 (57) Abstraet: An absorbing solution capable o£ absorbing CO 2 or HzS or both contained in a gas, which is obtah]ed by adding a tertiary monoamine preferably in an amount of 1 to 20 wt% to a seconda O, amine composite absorbent such as a mixture o£ a econdary monoaminc with a secondary diaminc. The tertiary monoamine inhibits the secondary amines contained in the solution from deterioration by oxygen contained in a gas or the like to bring about reduction in absorption loss, less lowering in performance and cost reduction. The absorbing solution is suitably usable in apparatus for the removal of C0 2 or HzS or both. i. An absorbing-solution that absorbs at least one of CO 2 and H 2 S or both that are present in a gas, the absorbing- solution comprising:

secondary-amine composite absorbent; and tertiary monoamine that is added to the secondary-amine composite absorbent; wherein the secondary-amine composite absorbent is a mixture of secondary monoamine and secondary diamine, and wherein 1 to 20 weight percent of the tertiary monoamine is added to the secondary-amine composite absorbent. 2. The absorbing-solution according to claim I, wherein the secondary monoamine is a compound that is selected from at least one of 2-methylaminoethanol, 2ethylaminoethanol, 2-n-propylaminoethanol, 2-nbutylaminoethanol, 2-n-pentylaminoethanol, 2isopropylaminoethanol, 2-sec-butylaminoethanol, and 2- isobutylaminoethanol, and the secondary diamine is a compound that is selected from at least one of piperazine, 2-methylpiperazine, 2,3dimethylpiperazine, 2,5-dimethylpiperazine, N,N'- dimethylethanediamine, N,N'-dimethylpropanediamine, N,N'- diethylethylenediamine, N,N'-diethylpropanediamine, N,N'- diisopropylethylenediamine, and N,N'-ditertiarybutylethanediamine. 3. The absorbing-solution according to claim I or 2, wherein 2.5 to i00 weight percent of the secondary diamine is added to the secondary monoamine. 4. A removing apparatus that removes at least one of CO 2 and H 2 S or both that are present in a gas, the removing apparatus comprising:

an absorber that receives the gas, causes the gas to come in contact with an absorbing-solution whereby at least one of C0 2 and H 2 S or both is absorbed by the absorbing- solution; and a regenerator that regenerates the absorbing-solution that absorbed at least one of CO 2 and H 2 S or both by removing at least one of CO 2 and H 2 S or both from the absorbingsolution, and supplies the absorbing-solution that is removed of at least one of CO 2 and H 2 S or both to the absorber, wherein the absorbing-solution includes secondaryamine composite absorbent, and tertiary monoamine that is added to the secondary-amine composite absorbent; wherein the secondary-amine composite absorbent is a mixture of secondary monoamine and secondary diamine, and wherein 1 to 20 weight percent of the tertiary monoamine is added to the secondary-amine composite absorbent. 5. A method for a removing apparatus to remove at least one of CO 2 and H 2 S or both that are present in a gas, the method comprising:

causing the gas to come in contact with an absorbingsolution whereby at least one of C0 2 and H 2 S or both is absorbed by the absorbing-solution; and regenerating the absorbing-solution that absorbed at least one of CO 2 and H 2 S or both by removing any one of CO 2 and H 2 S or both from the absorbing-solution, wherein the causing includes causing the gas to come in contact with an absorbing-solution that is regenerated at the regenerating step, wherein the absorbing-solution includes secondaryamine composite absorbent, and tertiary monoamine that is added to the secondary-amine composite absorbent; wherein the secondary-amine composite absorbent is a mixture of secondary monoamine and secondary diamine, and wherein 1 to 20 weight percent of the tertiary monoamine is added to the secondary-amine composite absorbent. 6. An absorbing-solution according to claim 1 substantially as hereinbefore described. 7. A removing apparatus according to claim 4 or a method for a removing apparatus according to claim 5 substantially as hereinbefore described.