METHOD FOR THREE-DIMENSIONAL PRINTING

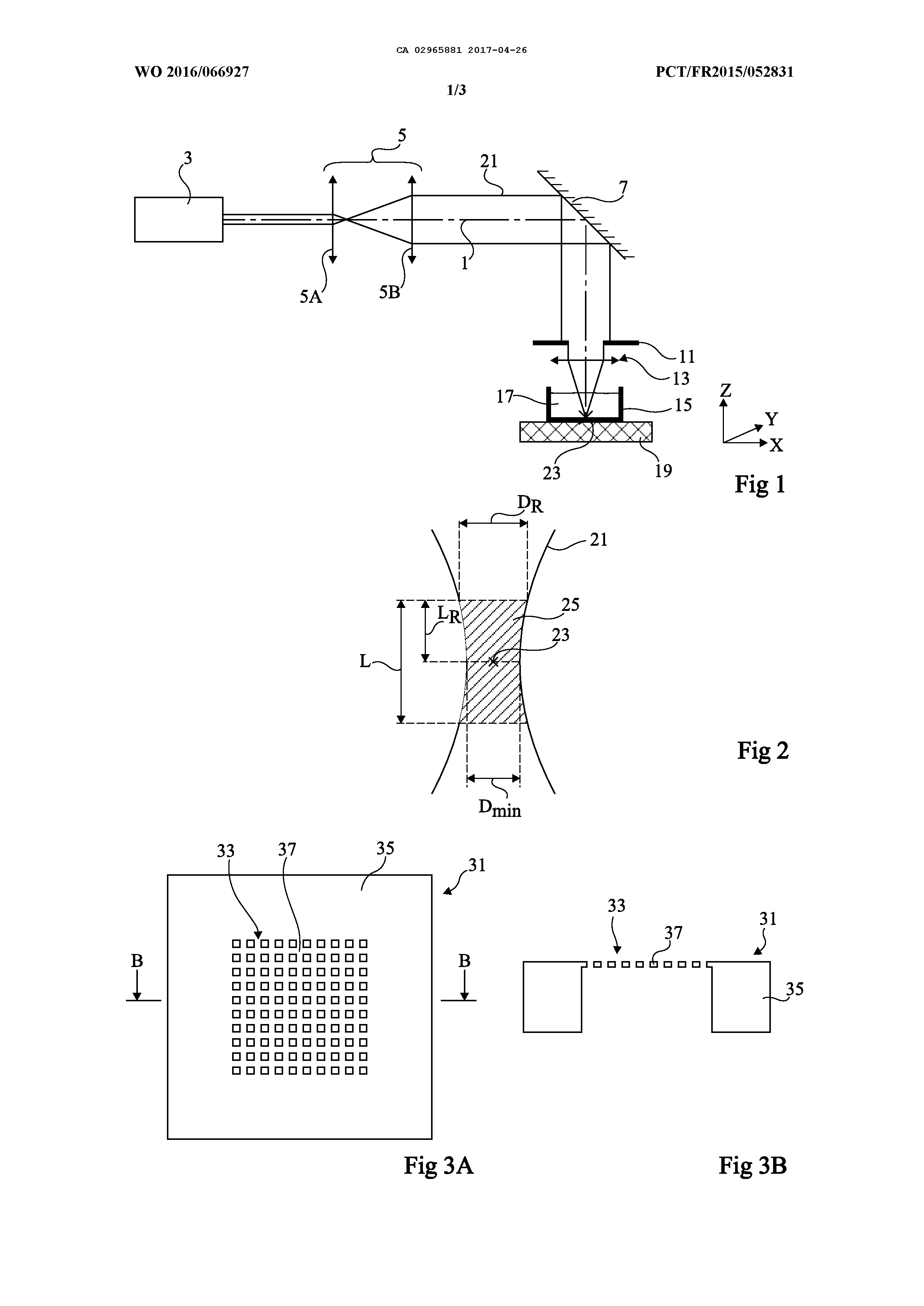

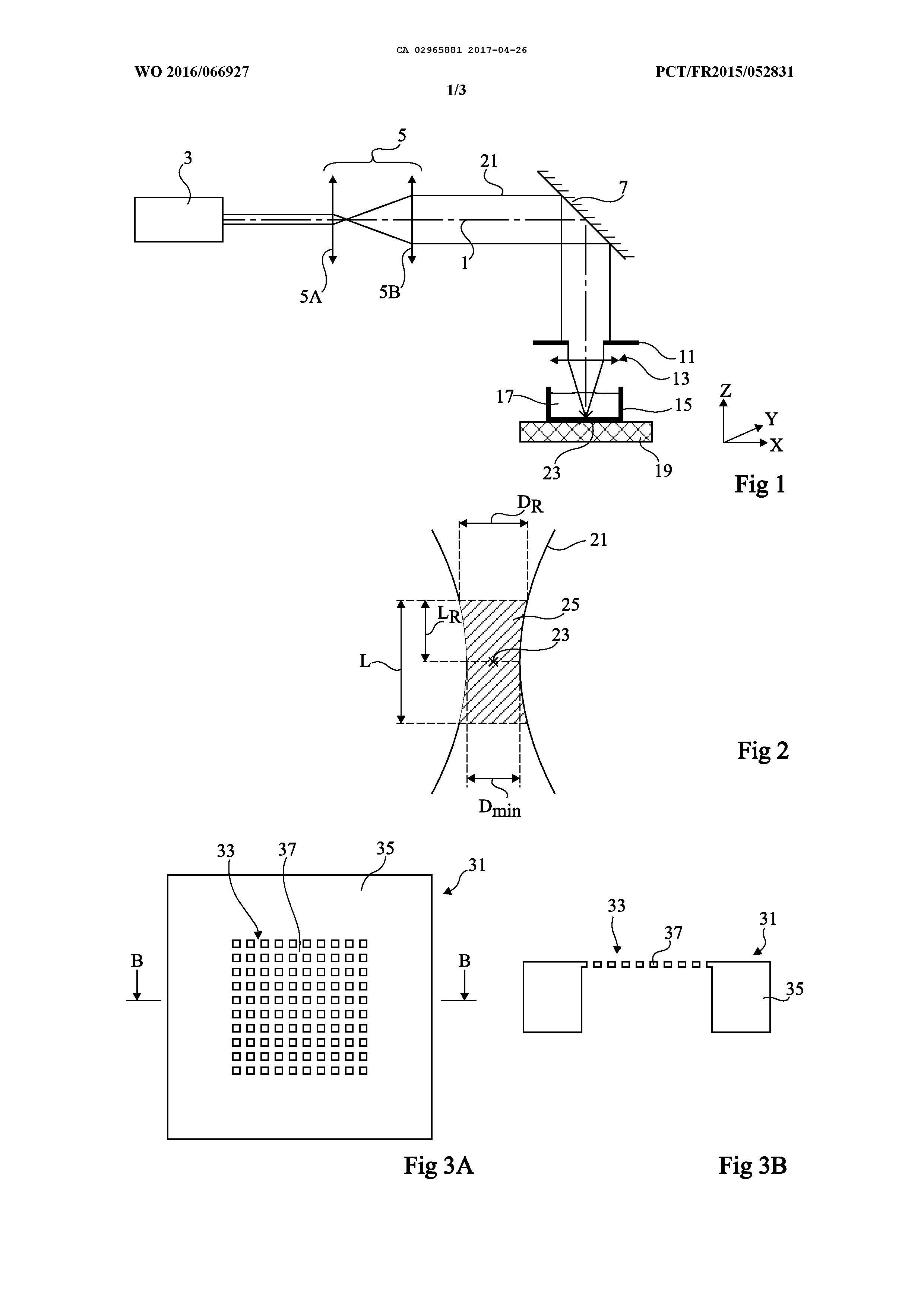

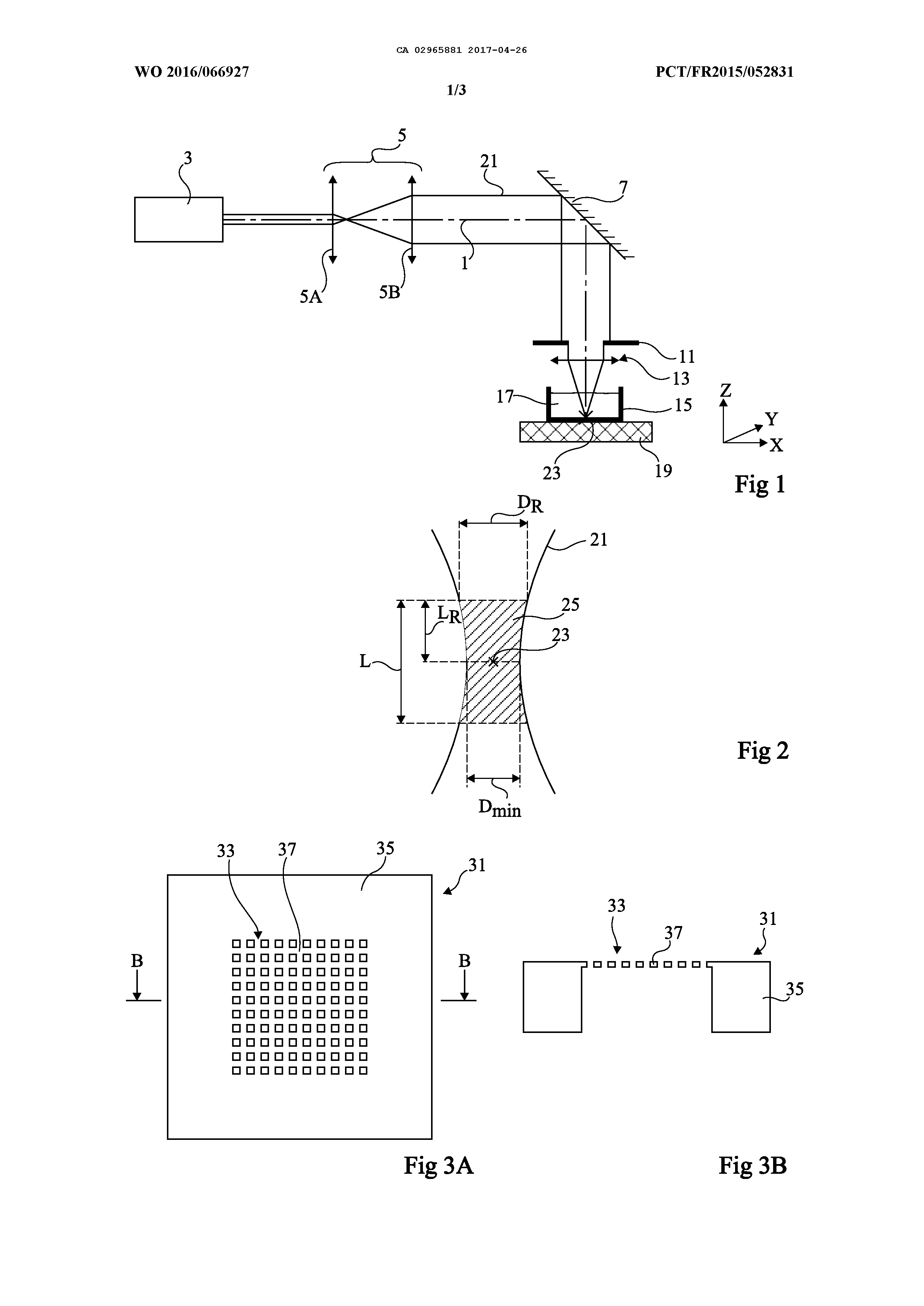

The present application claims the benefit of French Patent er14/60282 which will be considered as part of the present disclosure. The present application relates to a method of three-dimensional printing (3d), most commonly called 3d printing, which consists in transforming the voxels of successively, or voxels, a material by irradiation. A known method based on 3d printing successive transformations of elementary volumes of a material by irradiation using a photochemical reaction induced by multiphoton absorption to at least two photons. A printer using such a method is commonly called 3d printer to two-photon absorption. Figure 1 schematically shows an example of 3d printer to two-photon absorption. The printer 3d successively comprises, on an optical axis 1, a laser source 3, a beam expander 5, a plane mirror 7, a diaphragm 11, and a focusing lens for 13. In the example illustrated, the beam expander 5 comprises two lenses 5a and 5b. A tank filled with a photosensitive material 15 17 19 the XYZ on a table movable along orthogonal directions (X-Y) and (Z-) parallel to the propagation direction of a laser beam 21 generated by the source 3, and can selectively rotate about axes of rotation X, Y and Z. the photosensitive material 17 may comprise a solidifying resin by polymerizing or photo-cross-linking, a resin whose solubility properties change by photochemistry, proteins solidifying photocrosslinking, solidifying metal salts or photocrosslinking. It is considered hereafter as an example the case where the material is a resin solidifies by photo-cross-linking. In operation, the laser beam is focused by the lens 21 13 at a point 23 located in the material 17. The focusing point 23, when the laser power is sufficient, a volume element of the material 17 is transformed and solidifies. In Figure 1, the point 23 is shown as bottom of tank 15. The XYZ table 19 is controlled so that the focal point 23 of the beam 21 is moved in the material 17 to form other voxels until the entire volume of the object to be printed has been solidified, the excess unreacted material for example being dissolved by a suitable solvent. Figure 2 is a sectional view schematically illustrating the course of the focal region of the laser beam 21. At its focal point 23, the laser beam 21 has a maximum convergence zone for which the beam has a minimum diameter (waists) the beam diameter increases in the direction away from the maximum convergence zone. In particular, a distance LR1 (Rayleigh length) maximum convergence zone, the energy per unit area of the laser beam is equal to half the energy per unit area at the maximum convergence zone. 25 focal volume called the volume portion of the laser beam 21 centered on the maximum convergence zone and of length L equal to twice the Rayleigh length of Ir. As an example, it is considered in the following focal volume 25 corresponds to the volume portion of the laser beam 21 in which the energy per unit area of the beam 21 is sufficient to induce photochemical reaction by two-photon absorption resulting in a voxel of same dimensions and L that the focal volume 25, L denoting then the height of a voxel. In practice, according to the intensity of the incident laser beam and the exposure time of the photosensitive material to the beam, a voxel of solid material having a different volume than the focal volume can be obtained. For example, a voxel may be substantially in the form of a tubing diameter % TiN and height L it is shown that L is proportional to the square of IIN is % - by way of example, for a MFCthe I the n=(- )' 25 mW, was l=0, 7 MW. Multiplied by the dimension D ^ IIN is 100, the value of L is multiplied by 10000, it is to say that there is more voxels extremely stretched (Β ^ ΐ 1 η=25 PM and l=7 mm in this example). The resolution Z is then insufficient for printing a 3d object, even with millimeter resolution. 3d printers to two-photon absorption have therefore essentially been developed for the manufacture of objects requiring high resolution in the micrometer, or even of some hundred nanometers, and are generally used for the manufacture of objects whose dimensions are less than one millimeter. 3a and 3b drawings represent schematically an example of print object in 3d, Figure 3a is a top view of the object, and Figure 3b is a sectional view along a plane BB Figure 3a. The object to be printed is a filter comprising a filtering grid 31 33 integral with a ring 35. The grid, or sieve, 33 has extremely fine patterns which are to be performed with a high resolution while the ring 35 does not require a very high resolution. The gate 33 has an array of bars 37 having small dimensions, for example, a width of 0.1 MW with an interval between rungs of 0.2 MW. The ring 35, square-shaped, has for example a height of 0.6 cm, a thickness of 0.4 cm, and an inner diameter of 0.8 cm. If it is desired to manufacture the filter 31 with the printer 3d of Figure 1 it should be, for printing the gate 33 with a desired accuracy, choose a printer such that the voxels have dimensions less than or equal to one hundred nanometers, resulting in that, for printing the ring 35 having dimensions are disclosed at least 10000 times that voxels, the printing times become very long. There is thus a need for a method of printing successive 3d by irradiation of a material for reducing the printing time of objects comprising parts to be printed with high resolution and portions that can be printed with a lower resolution, for example at least 100 times lower. Thus, one embodiment provides for a method of printing 3d, which consists in transforming the voxels of sequentially, or voxels, a material by irradiation, comprising the steps of: decomposing the volume of a portion of an object to be printed not requiring a maximum resolution in identical blocks; associating, for printing, to each block a brick of the same contour comprising recessed portions; and irradiating for printing the voxels of the bricks. In one embodiment, is carried out a succession of irradiation, providing an array of each irradiation exposure beams focused onto an array of points distributed in the material in the same way during two successive irradiation, the array of dots being offset in the material between two successive irradiation. In one embodiment, when some irradiation, some beams are inhibited. In one embodiment, the array of dots is shifted in the material by moving a tray filled with material. In one embodiment, the array of dots is shifted in the material by an amount less than the dimensions of a voxel. In one embodiment, the array of dots corresponds to an array of voxels each of which is located at a given position of a brick distinct. In one embodiment, the array of dots corresponds to an array of voxels each of which is located at a given position of a single brick. In one embodiment, the transformation of a voxel is the result of a photochemical reaction induced by two-photon absorption. In one embodiment, the dimensions of said blocks are at least 100 times higher than those voxels. In one embodiment, the part not requiring the maximum resolution has dimensions at least 100 times larger than the maximum resolution. These features and advantages, as well as other, will be exposed in detail in the following description of particular embodiments made not exclusively in connection with the accompanying drawings of which: figure 1, described above, is a schematic representation of an example of 3d printer to two-photon absorption; figure 2, previously described, schematically shows the profile of a laser beam at its focal point; 3a and 3b drawings, described previously, represent schematically an example of object 3d printing; figure 4 schematically shows a step of an embodiment of an imprint process 3d; figures 5a to verbs 5c represent schematically different embodiments of a 3d printing method; figure 6 is a schematic representation of another example of 3d printer to two-photon absorption; and figures 7a to verbs 7th schematically illustrate steps of an embodiment of a 3d printing process. For clarity, the same elements are designated by the same references to different figures and, furthermore, the various drawings are not drawn to scale. Provided herein is a method wherein the 3d printing sections of an object 3d having dimensions which are much greater than those of a voxel are printed from bricks of voxels having hollow portions. In following the description directional references such as "on", "side", "upper", "lower", "left", "right", and the like, apply to devices oriented as depicted in the sectional views corresponding, it being understood that, in practice, the devices may be oriented differently. In an initial step of analyzing print object, identifying which portions of the object that needs to be printed at high resolution and the parts of the object that can be printed with lower resolution, the latter having dimensions which are much superior to those of parts requiring high resolution, for example 100 to 1000 fold higher, even more than 10000 times. For example, for the filter 31, the gate 35 should be printed with a high resolution of the order of some hundred nanometers, and the printer 3d is selected so that the diameter Dmin isI t the height L of the voxels are for example equal to 0.1 to 0.3 MW P and. A lower resolution, for example of the order of mm, will be selected for printing the ring 35, and the dimensions of the focal volume, and thus voxels, will then be increased using a focusing objective of lower resolution to have the diameter and the height L of the voxels are for example equal to 1 MW and 10 MW. Figure 4 is a schematic view in perspective and cross-section of the filter 31 according to the plane BB Figure 3a. The volume of the parts does not require printed at high resolution, here the volume of the ring 35, is decomposed into identical blocks 39. The lateral dimensions of the blocks 39 selected is higher, such as at least 10 times, and preferably at least 100 to 1000 times higher, to those voxels are used for their printing. For the sake of clarity, but it is represented as a few blocks 39 resulting from such decomposition, right in Figure. In this example, the blocks 39 are rectangular parallelepipeds having e.g. sides of approximately 1 mm and a height of 10 MW equal to the height L voxels used to print them. To make portions of an object to be printed not requiring high resolution, is printed for each block 39 a brick of voxels of identical outline and comprising one or more hollow portions. Each brick is achieved by printing, for example successively, each constituting the voxels. In one embodiment, may be it does not print bricks of voxels than at the surface portions need not be printed at high resolution, on a thickness sufficient to provide good mechanical rigidity of these parts. It will further providing form a sealing layer overlapping the outer surfaces of a given volume. Figures 5 Α, 5b and 5c are perspective views illustrating schematically examples of bricks of voxels comprising one or more hollow portions. In these drawings, the voxels 43 are not drawn to scale and, in practice, each brick includes a number of voxels is much larger than that shown in these drawings. In Figure 5a, the brick 41a is defined by a contour of voxels 43 corresponding to its perimeter. In this example, each of the upper and lower sides of the brick comprises a number m of voxels, and each of the right and left sides of the brick comprises a number n of voxels. In Figure 5b, the brick 41b further comprises a spider median. In Figure 5c, the brick 41a 41c includes two bricks piled on one another. As shown in Figure 5a to 5c, each voxel 43 can penetrate partially into its voxel neighboring 43 thereby increasing the mechanical stability of the brick. It will be appreciated that, although represented bricks of voxels comprising lines of voxels 43 constituted by a single row of voxels, in alternative embodiments, the lines of voxels may include multiple rows of voxels. See in Figures 5a to verbs 5c that each of the bricks 41 Α, 41b and 41c in a middle portion thereof comprises one or more hollow portions 45 in which no voxel is not formed. Unlike 3d printing methods previously known in which would give a large number of voxels 43 to fill the whole of each volume corresponding to a block 39, in the method described herein, is printed only voxels in the webs of each brick corresponding to a block 39. Thus, the number of voxels printed is much lower, whereby the printing time of the ring 35 and hence the filter 31 is greatly diminished. As has already been mentioned previously, the voxels Α constituent bricks 41, 41b and 41c can be printed one after the other. The inventors also propose to print more voxels simultaneously. Figure 6 schematically shows another example of 3d printer to two-photon absorption for printing more voxels simultaneously. The printer includes on its optical axis 1 of the same elements as the printer 3d of Figure 1, namely a laser source 3, a beam expander 5, a plane mirror 7, a diaphragm 11 and a focusing lens for 13. The printer further comprises means for generating 51, preferably simultaneously, a number K of laser beams 53 forming an array of exposure beams. The K beams in the array are focused by the lens 13 in an array of K point 23 in a photosensitive material 17 contained in a trough 15 based on the XYZ table 19. Thus, an array of K voxels corresponding to the array of K focus points can be formed at each irradiation of the material 17. The fact that K voxels of a network are formed simultaneously to each irradiation, the result is reduced by a factor K times in regard to a printing method in which a single voxel is formed to each irradiation. By way of example, for simultaneously generating K beams focused laser array in an array of K point, means can be used such as microlens arrays, diffractive phase masks, arrays of liquid crystal phase modulation and/or amplitude, and arrays of micro-mirrors. Various examples of these means are described in the literature, in particular in: - "Than white-light alaising the Talbot array which comprises Illuminator if avec la has a variable density OC the LIGHT spot" of Tajahuerce and Ε. - "Binary Decision surface-relief gratings zu finger array which comprises illumination optics" of A. willwill vasara and - "Multi spot in parallel with the laser micronanofabrication zu technical jargon" of J. Ktr56 and For example, using a phase mask suitable associated with a pulse laser nanoseconds of amplified 1 watt at 130 kilohertz, more than 1000 voxels may be simultaneously formed within milliseconds in a commercial resin. In one embodiment, the K identical bricks are manufactured simultaneously from a given network of K focus points. For this, the K focus points of the network are chosen so that each corresponds to a given position (for example the top left corner) of K distinct bricks. Constructed the K bricks by moving the tray 15 between each irradiation to form all voxels constituent K bricks. Thus, for concurrently making K-bricks, the focusing conditions of the K laser beams 53 of the network is determined only once, and the motions of the tray 15 are determined very simply from offsets between the voxels of a bricks to be printed. The result is reduced calculations of focus conditions and displacements of the tray 15, and thus a decrease in the printing time. For example, the realization of a surface of one square centimeter of bricks one millimeter from side comprising portions of hollow square of about ten microns in side by printing simultaneously k=2401 voxels each irradiation requires only 10 min while with the methods of the prior print time greater than 2500 hours is necessary to print a same surface of a continuous layer of voxels. Provision may be made for modulating the intensities of the K beam of an array, for example with a liquid crystal array. On the one hand, provision may be made to homogenize the intensity of each beam at the focal point thereof so that all voxels formed simultaneously upon irradiation have identical dimensions. On the other hand, upon irradiation, there may be provided close certain of the K beams in the array. In this case, no voxel is not formed at the focal points corresponding to the sealed beams. This allows for example it does not print only a portion of the voxels of a brick, in particular in the vicinity of the surface of a given volume for that the contours of the brick conform to this surface. Figures 7a to verbs 7th are views of top of the material 17 of Figure 6 illustrating successive steps for such an embodiment of a method of 3d printing. In this example, k=4 and produced four bricks type brick 41a of Figure 5a. In Figure 7a to 7th, was represented by circles the voxels of a network printed concurrently during the last irradiation, by a partial circle the voxels printed previously, and by dotted lines the contours of K bricks, and b, c and d to be printed. In these drawings, the voxels are not drawn to scale and, in practice, each brick includes a number of voxels is much larger than that shown in these drawings. In Figure 7a, the focusing conditions of each beam of an array of K laser beams 53 of a printer 3d-type Figure 6 were chosen to provide a given network of K focus points 23 in the material 17, each focusing point 23 corresponding, in this example, at upper left corner of each of the K bricks, b., c and D. the material irradiation 17 then allows to simultaneously form voxels has]_ b.]_ In Figure 7b, without changing the network given focus points of the K, the tray 15 is moved in the XY plane by an amount corresponding to the deviation between the voxel has]_ 2. and its neighboring voxel of Ag 1 at the upper side of the brick A. the material 17 is then irradiated to form abrasive that voxel. When forming the voxels of the voxel P-a2 b2 1 P-GCI T-D 2, l of bricks of b, c and d are formed simultaneously. The steps of movements and irradiation are then repeated to successively forming each of the m voxel ai ^] _, bj is ^] _, the j ^, 1I To dj ^ In Figure 7c, the steps of movements and irradiation are repeated until each of the n successively form voxel hasthe m/j_, b.LTIj_, C.the mj_ and e ^ ^ In Figure 7d, the steps of movements and irradiation are repeated until each of the m voxel successively forming ai ^the n , Bj is ^the n , The Cj ^the n the j and d In Figure 7th, the steps of movements and irradiation are repeated until successively forming each of the n-1 voxel has] ^ d, b-j-^, the c] _, J and D] ^ j as stopping at voxel of Ag GB P-P-P-Dc GC I and the end result is all voxels the j-j ^, ^ j-Bj_, the Cj ^ ^ Dj_ j and j-constitutive of bricks, b., c and d. Preferably, in a portion of the object to be printed not requiring a maximum resolution, simultaneously fabricated all bricks constituting a layer of this part. In the case where the number K of beam of an array is not sufficient for forming all bricks forming a picture layer, forming the other bricks from one or more new networks of K focus points 23. For printing a next layer of the object, the tray 15 is displaced in the Z axis for example of less than or equal to the height L of a voxel. We have previously described a printing process 3d of parts of an object that does not require a high resolution printing from hollow bricks of voxels and one embodiment includes fabricating the K bricks simultaneously. Various variations and modifications apparent to those skilled in the art among which may be mentioned the following. - Print object may include more than two zones of different resolutions. In this case the volumes of parts of the object not requiring a high resolution printing are decomposed 39 from blocks of different sizes. - Any type of printing process 3d based on successive irradiations to a photosensitive material can be used, and not just printing processes 3d to two-photon absorption. - The dimensions and shape of the blocks, bricks and voxels can be modified. For example, bricks round or hexagonal (honeycomb) can be printed, the movements of the at least one focus points 23 in the material 17 being tailored to the shapes of these bricks. - Between each irradiation of the material 17, the one or more focus points 23 can be moved in the material by an amount greater than the separation between two neighboring voxels. - The movements of the one or more focus points 23 in the material 17 can be performed by checking the settings of the optical system of the printer 3d rather than shifting the tray 15 containing this material 17 relative to the optical system of the printer 3d. - From the high resolution may be performed layer by layer before or after printing, in each layer, brick corresponding to parts of lower resolution. If the type of photosensitive material so permits, the high resolution can be printed before or after printing of the set of one or more portions having low resolution. In the case of the embodiment include printing simultaneously several bricks, there can be mentioned the variants and the following modifications. - Instead of printing the K voxel K distinct bricks, a given network of K focus points 23 can be chosen so that the K point 23 of this network corresponds to a same one or a small number of bricks. - Instead of simultaneous production of several bricks of the same layer, more bricks may be made simultaneously in different layers by selecting a given network of K focus points distributed in more than one XY planes 23. 53 - the K laser beams on a network may be generated and focused by any type of known means rather than the means 51 described in Figure 6. Various embodiments with various embodiments have been described above. It should be noted that the ordinarily skilled artisan will be able to combine various elements of the various embodiments and variations without inventive procedure shows activity. A method for 3D printing, wherein elementary volumes, or voxels, of a material are sequentially transformed by irradiation, including the following steps: breaking down, into identical blocks, the volume of part of an object to be printed that does not require a maximum resolution; for printing, associating with each block a brick having the same contour and comprising hollow portions; and irradiating in order to print the voxels of the bricks. 1. 3d printing method, which consists in transforming the voxels of sequentially, or voxels (43), (17) a material by irradiation, comprising the following steps: decompose the volume of a portion (35) of an object (31) to be printed not requiring a maximum resolution in the same block (39); associating, for printing, to each block a brick (41 Α, 41 Β, 41c) of same contour comprising hollow portions (45); and performing a succession of irradiation for printing the voxels of the bricks, each irradiation providing an array of exposure beams (53) focused onto an array of points (23) distributed in the material (17) similarly during two successive irradiation, the array of dots being offset in the material between two successive irradiation. 2. the method of claim 1, wherein, when certain irradiation, some beams (53) are inhibited. 3. the method of claim 1 or 2, wherein the dot array (23) is offset in the material (17) by moving a tray filled with material (15). 4. method according to any one of claims 1 to 3, wherein the array of dots (23) is offset in the material by an amount smaller than the dimensions of a voxel (Dnrm) (43). 5. method according to any one of claims 1 to 4, wherein the dot array (23) corresponds to an array of voxels (43) each of which is located at a given position of a brick distinct (41 Α, 41 Β, 41c). 6. method according to any one of claims 1 to 5, wherein the dot array (23) corresponds to an array of voxels (43) each of which is located at a given position of a same one (41 Α, 41b, 41c). 7. method according to any one of claims 1 to 6, wherein the transformation of a voxel (43) results from a photochemical reaction induced by two-photon absorption. 8. method according to any one of claims 1 to 7, wherein the dimensions of said blocks (39) are at least 100 times higher than those voxels (43). 9. method according to any one of claims 1 to 8, wherein the portion (35) not requiring the maximum resolution has dimensions at least 100 times larger than the maximum resolution.THREE-DIMENSIONAL PRINTING METHOD

Domain

Exposed prior

Abstract

Brief description of the drawings

Detailed description