NOTE DISPENSING DEVICE.

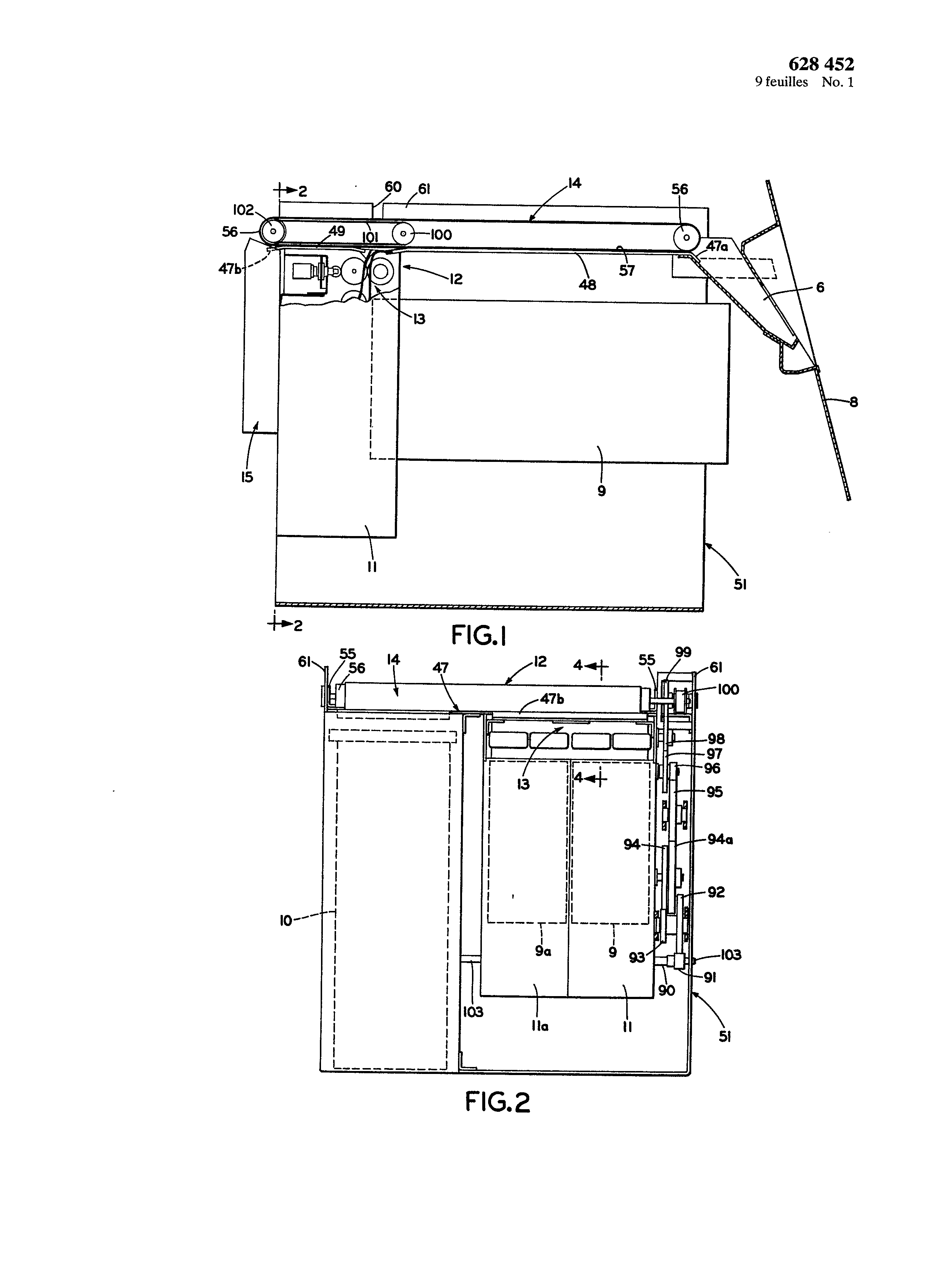

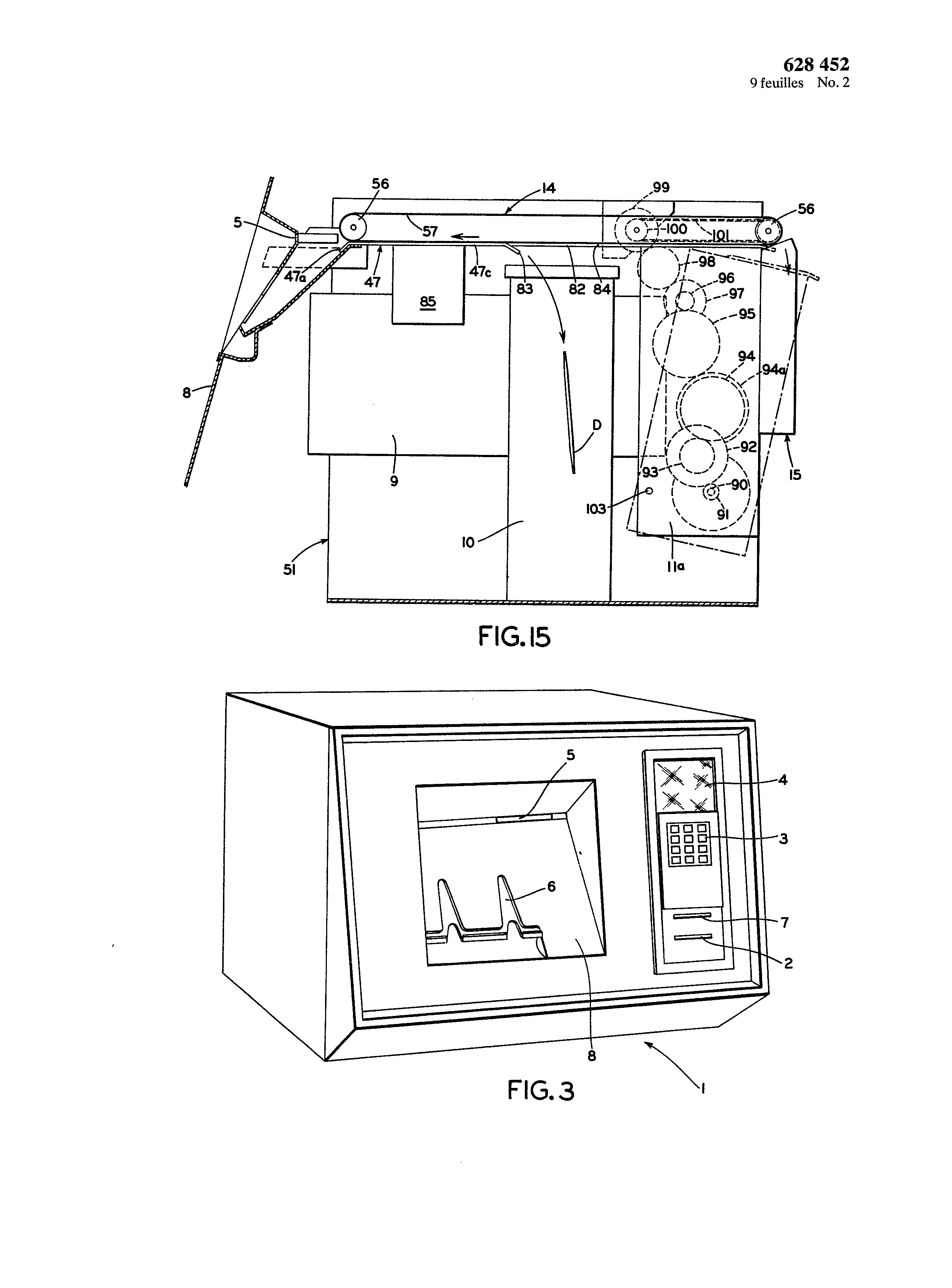

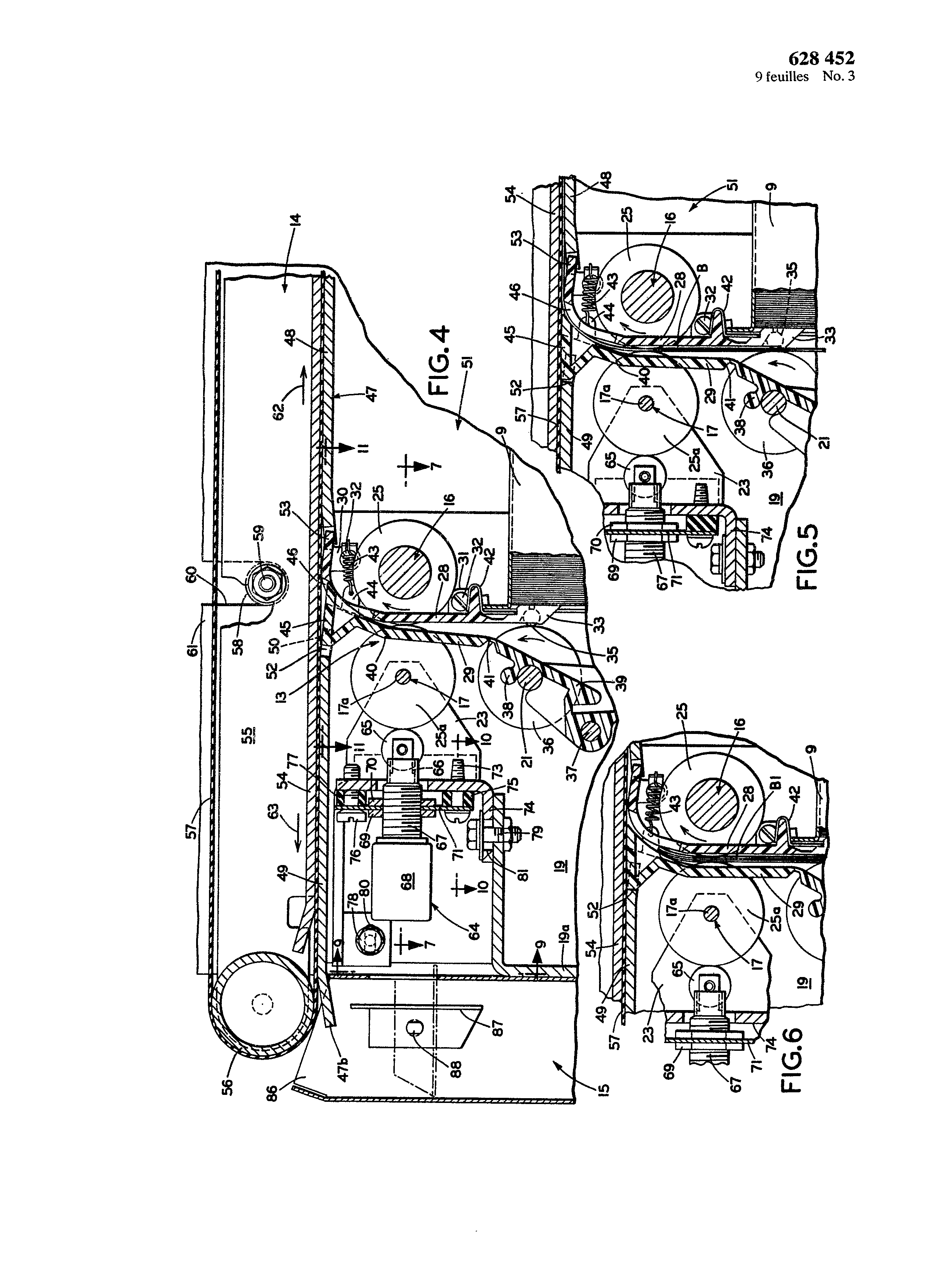

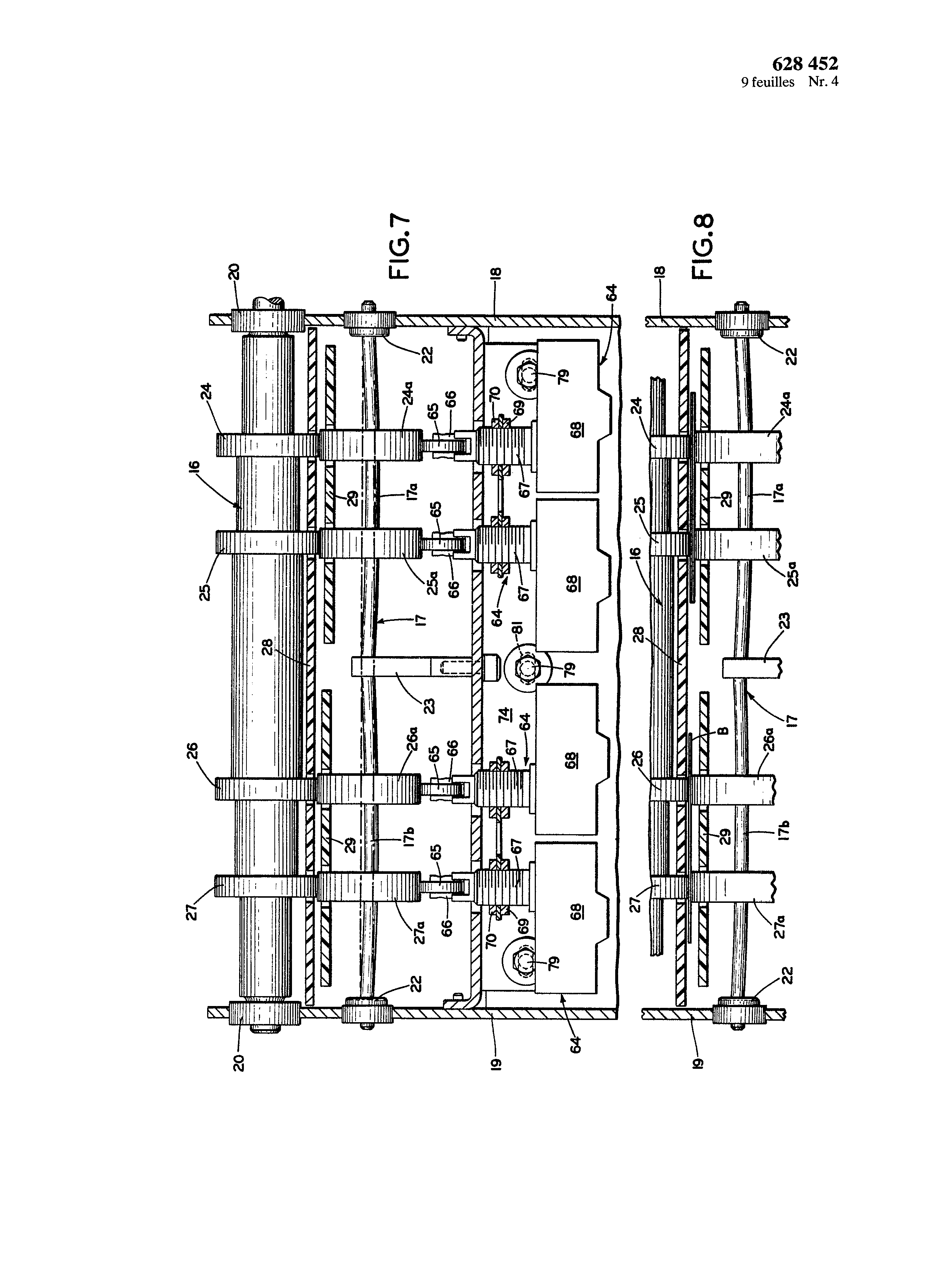

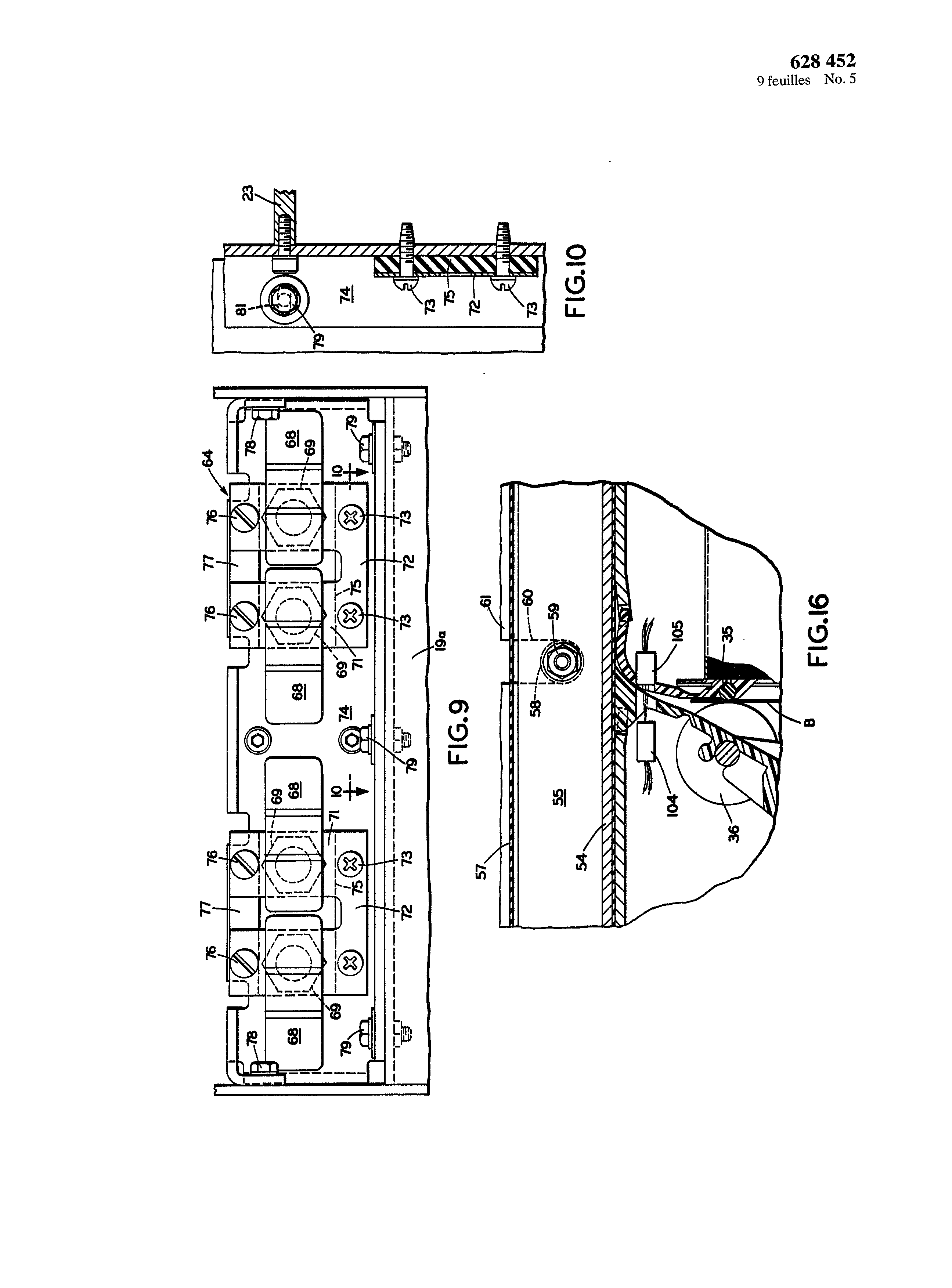

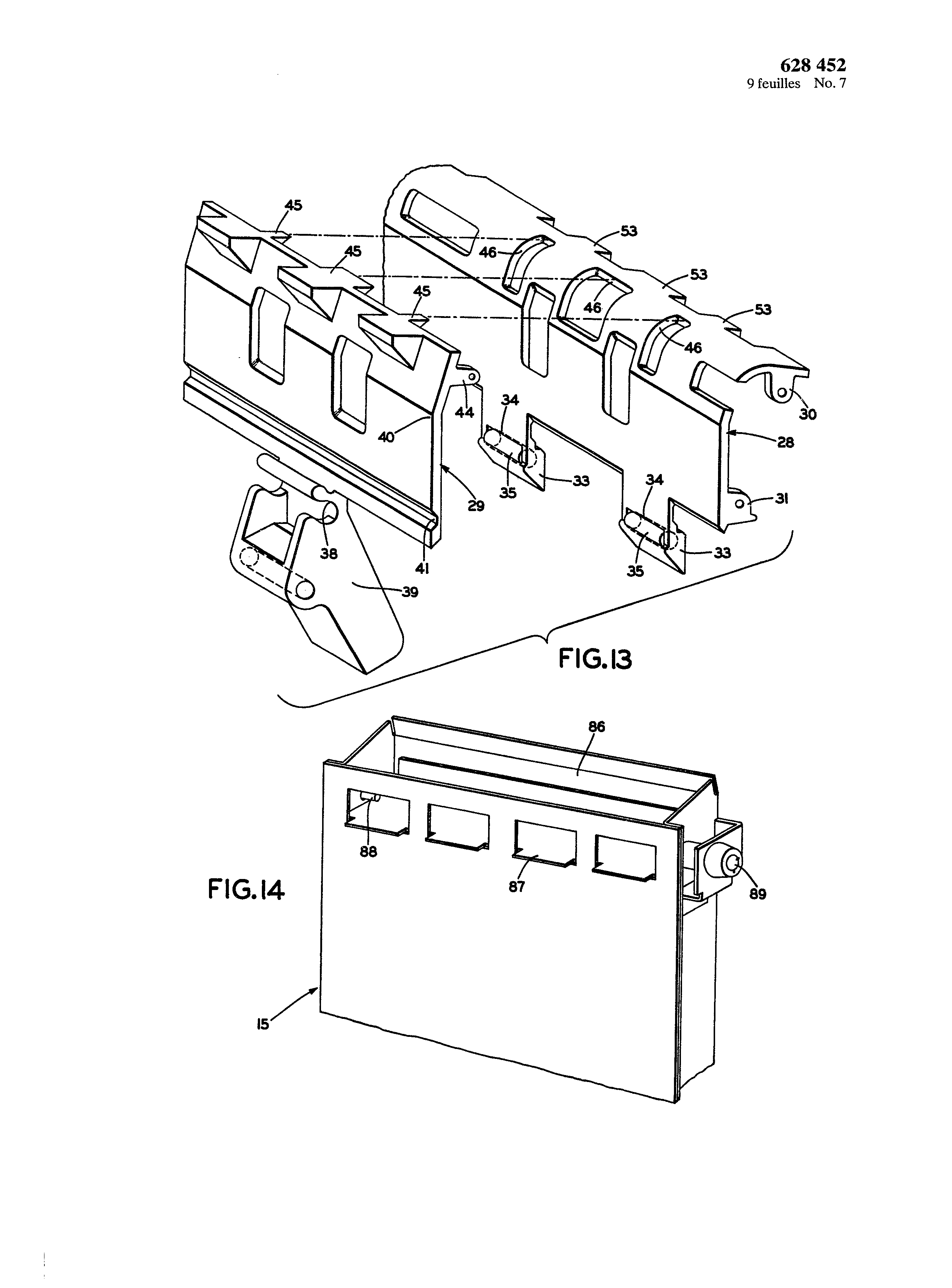

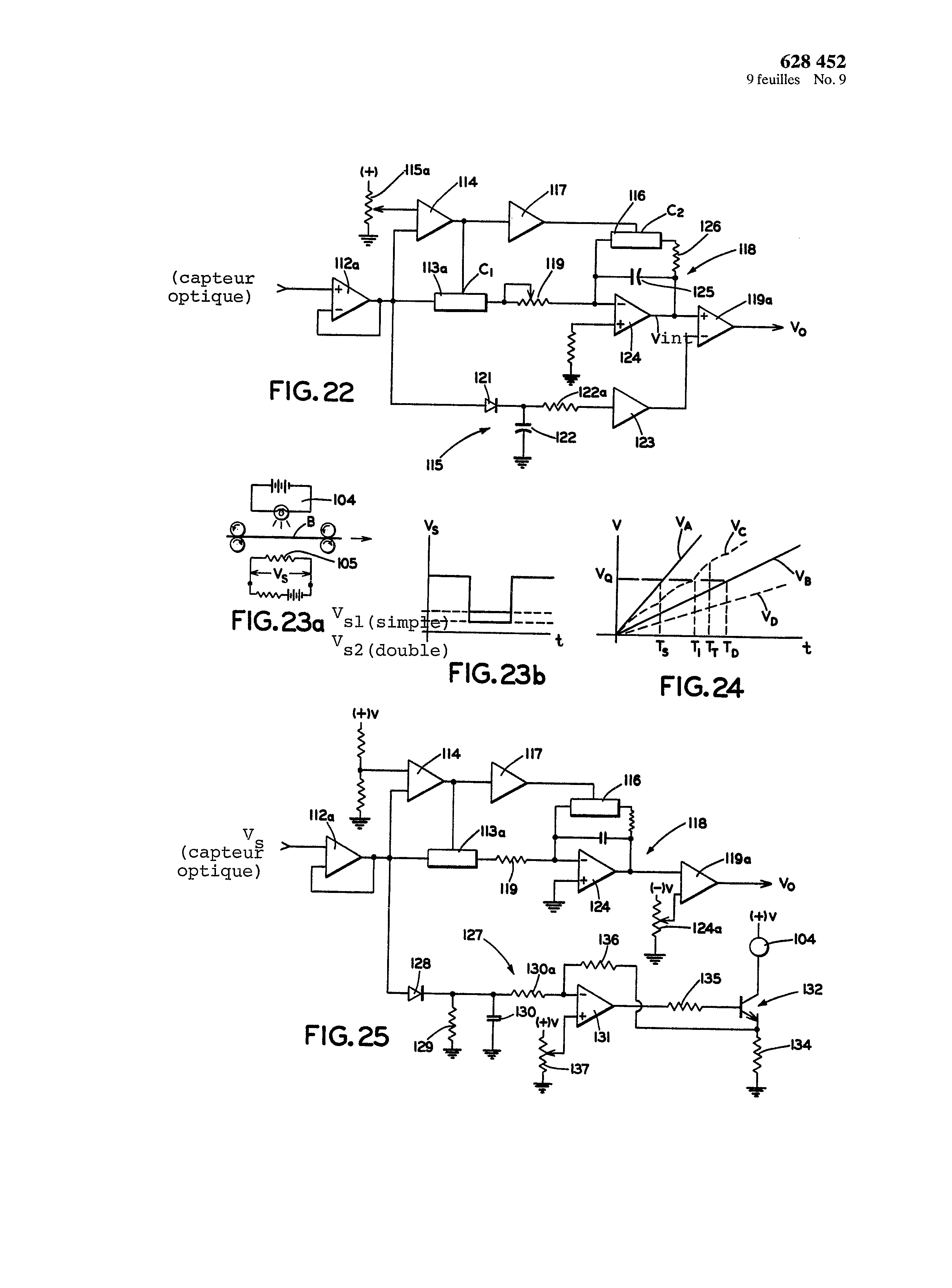

a ticket dual is detected, in that the drive means of the belt conveyor (14) to reversible rollers have a controller (64) inverter, in that the signal "dual detected" actuates said control device for reversing the drive means and the movements of the rollers and the conveyor belt, so that a dual belt conveyor is delivered at the station (6) as ticket délivrement rejected.18. apparatus as in claim 17, characterized in that a container (10) rejected bills is mounted near the end of the lo and belt conveyor remote from the delivery station (6), so that the double rejected is delivered into the container (10) rejected bill mouvment inverted by said belt.19. The dispenser of claim 17, characterized in that the container (10) rejected bill is removable, in that it has locking means to close and lock the closed container, and in that for removing the container from its mount, the locking means are to be closed.A cash dispenser for automatic banking, having a Tf does reserve cash delivery station and a bill to the customer.It has, in the past, used various means for sensing characteristics of bank notes or other documents being transported from one location to another on a path and introduced in series, one by one, along the path to the effect that the banknotes or documents are counted, that contingent recoveries documents detected, and that the presence of double is perceived what that soitl ' location of the pager.Elastically urged levers, switches to rollers, photosensors and other similar devices have been used for such purposes. There are examples of counters or ticket machines in the United States patents bearing the numbers 3,077 983, 3,168 644, 3,578 315, 3,760 158, 3,767 080, 3,997 453, 3,675 816et3 731,916. These prior devices provide substantially instantaneously a signal indicating that the desirable condition is fulfilled. In the case of a series of banknotes being introduced signaling anticipated double is triggered immediately as soon as the light beam of the photo sensor is attenuated to a greater degree than Qu represents the thickness of a single ticket.Such a signal can be triggered by the presence of dirt, a spot of ink or other dark region on the note, s0 or one region folded or a small region too thick anywhere along the region of the note perceived by the sensor, this in that there is actually of double. In fact, when the distribution door on banknotes, it can be said that these previous detectors are too sensitive.Since the color, shade and variations in the thickness of the bills can trigger photoelectric detectors of the prior art so that they produce a signal indiDes similar difficulties are also for handling a mixture of new tickets and used in equipment for banking, because certain features of old notes may differ from that of worn, the sensor thereby emitting different signals for the old notes, when compared to the new notes, for the same adjustment of the sensor.In other words, the detection of double previously practiced in dispensers coins was from examining the ticket at a point: if appeared thicker, it was denied as a duplicate.Hence there is a request for a cash dispenser allowing use of new and used notes and is mixed in the preserve of tickets which are taken 5 notes to be dispensed, and which is not affected by the color of the bill or by changes in the color or intensity thereof, or by the presence of hillocks on a small portion of the surface of the bill.The purpose enumerated above is reached by the note dispensing device of the invention which is defined in claim 1. independent at operational aspects of special or advantageous features are the subject of the dependent claims.In preferred embodiments of the invention are exposed, as an example, in the description hereinafter.Figure 1 is a schematic view representing some components of a dispensing coins equipped with detector double; Figure 2 is a schematic view of certain portions of Figure 1, the observer looking in the direction of the arrows 2 - 2 of Figure 1; Figure 3 is a perspective somewhat schematized water dispensing coins equipped with the doubles detector; Figure 4 is a partial view in cross-section, considerably enlarged scale, along the line, ! 4 fig. 2; it shows the device up the rollers to the thickness of the bills and the switch doubles detector, no banknotes passing between rollers of the gaging device galtes ; Figure 5 is a view similar to fig. 4 showing the device up the rollers to the thickness of the bills as actuated by the passage of a single note between the gauging rollers; the fig.. 6 is a view similar to Figures 4 and 5 and shows a large number of superposed notes accidentally ducts toward the rollers jaugeurs ; the fig.. 7 is a cross-section partial piane set forth line of fig. 4 and 7 - 7 shows the rollers jaugeurs awaiting bills which will pass between them; the fig.. 8 is a partial view similar to Figure. 7, it shows a single ticket through a set of rollers jaugeurs notes forming "dual" through another set of rollers jaugeurs ; Figure 9 is a partial cut in lift along the line 9 - 9 of the fig.. 4; Figure 10 is a cross-section along the line 10 - 10 of Figure 4 and Figure. 9; the fig.. 11 is a partial cut according to the line 11 - 11 of the terms of the double without at all actually, apparaîfig was seen. 4 and shows the guide members in a closed position in TREs difficulties, these previous devices, detectors dou60 the entrance slit of the platinum; bdenoting, not being satisfactory for simply, without delay, efficiently or properly control and manipulation in the automatic equipment for banking in the case of currency issued by some countries where issues to one denomination notes a widely varied colors, or when it is necessary to manipulate notes vañable opacity due to differences in!' color strength or thickness.Fig. 12 is a view similar to Figure. 11, but it shows the guide members in the open position, a bill passing between them; the fig.. 13 is a perspective view exploded both guide members of Figures 11 and 12; the fig.. 14 is a view in partial perspective view of the container. rejected bills; the fig.. 15 is a view similar to Figure 1; the fig. 628,452 4. 16 is a view, similar to fig.. 4, a modified form of construction; the Figure. 17 to 25 schemes are more circuits comamnde of duplicate detection.Figure 3 represents in 1 an automatic station for banking, modeled, for providing coins in response to the presentation by a customer of a coded card. These stations can be supplied with power when a customer presents a coded card to the entry slot 2 or the introduced there. The key card is verified, to confirm that lo or not an authorized card and that its user is the authorized user, by a card reader and other known devices enclosed within the station 1 or électñquement connected at that station.After verification of the card and the customer, the customer may proceed in 3 inputting data using a forceps in accordance with the instructions presented to him on the panel 4. data infused may indicate inter alia the sum cash that the dient desires to remove, or indicate that the client desires to make a deposit.Deposition may be by introducing, into the slot dépõt 5, an envelope containing the deposition object. If species to be distributed they may be authenticated by the mechanism contained in the station 1 to the receptacle 6, accessible to the customer, where the bills are delivered. A record or receipt Z's with respect to the transaction may in some cases be delivered to the customer by the slot 7. received the entry slot cards 2, 3 the forceps, the panel of instructions that may be a television screen 4, the deposit slot 5, the delivery receptacle notes 6 and the slot to received 7 are preferably formed by the recessed panel 8 forming a facade, or borne by the panel.Components of the dispenser of coins and receptor deposits are shown schematically in their entirety in Figures 1 and 2 and 9 can comprise a container accommodating a reserve of bills that may be for new and old notes randomly mixed and form a stack maintained in the container 9 which protects it. The storage container 9 can be bill type "scellée TamperIndicating money valuations Dispensing containers for path inserts systems that banking industry" ( Conteneurdistributeur of coins, sealed and indicating the break-in attempts, for automated systems for banking) represented and described in Patent Revenue on behalf of Graefe and ai, No. of 761,288 series, or consist of any other desired embodiment of a receptacle for holding a supply of tickets arranged in a stack.It often is desired, automatic in the stations for banking, distñbuer notes two different values. Fig. 2 thus represents two containers of banknotes 9 and 9a. The containers 9 and 9a are preferably disposed side by side ã . It is however contemplated that any number of containers note one to three or four containers, is provided in an automatic station for banking, said containers being placed side cõte as Figure 2 indicates the general for the containers 9 and 9a.Often it is desired to predict, in a station for automatic banking, a component for making deposits to. The location of the component is, so généraie , indicated by 10, the slot to deposits of fig. 3 in communication with the component. The side by side disposition containers cash 9 and 9a to deposits and component 10 has particular advantages.Each storage container bill 9 or 9a has its own note picker mechanism 11 or 11 has, associated therewith (Figures 1 and 2). Here also there may be used the type of préle6s exchange ideas and notes desired, to to pick up one at a time notes from a stock pile and introducing them, note by note, in other components of the apparatus.The mechanism for detection of dual functions to automatically reject the double; rejected bills to a container for receiving the dual ejected is indicated in general 15 on Figure 1, but is absent from fig. 2 for clarity.In a first embodiment the mechanism 12 for the detection of double comprises means gauging 13 bills and the thickness of a belt conveyor, reversible and driven 14.The gauging of the thickness of the bills 13 has a pair of rollers and switching members for gauging the thickness continuously bill passing between the rollers as seen in Figures 4, 5 and 6.The roller devices jaugeurs , as seen in Figures, have shafts 16, 17 mounted on the walls 18 and 19 of latéraies housings of the pickers mechanism 11 and 1.Shown in the Figure. 7 that the shaft 16 journaled at its ends in bearings 20 to rotate in synchronism with!' shaft 21 rollers transporters picker mechanism, also journaled in the housing of the picker and located above the shafts 16 and 17 jaugeurs rollers.The shaft 16 nozzle is a large cross-section to have a ñgidité preventing it flex, while the shaft 17 flume has a small section so as to have a flexibility permitting it to flex. The shaft 17 is mounted, but not rotate, in end supports 12 mounted on the walls 18 and 19 of the préleveut , it is also supported intermediate its ends by a support member 23 décñtes purposes (Figure 8) farther.The shaft 16 carries a pair of rollers 24 and 25, adjacent the side wall 18 to the catcher, and another pair of rollers 26 and 27, adjacent the side wall 19 to the catcher. A pair of rollers 24a and 25a 17a is mounted on the portion of the shaft 17 which is located between the wall 18 and the centerline support 23. Another pair of rollers 26a and 27a 17b is mounted on the portion of the shaft 17.The rollers 24a, 25a, 26a and 27a preferably comprise circular outer contour antifñction bearings, mounted rotatably on the portions 17a and!7b of the shaft. The rollers bearing 24a and 25a are normally in rolling contact with the rollers 24 and 25, respectively, and serve the reserve note picker 9 11. Similarly the rollers to bearings 26a and 27a are normally in rolling contact with the rollers 26 and 27, respectively, and serve the reserve tickets 9a picker ALL.The pairs of spaced rollers 24, 25 and 24a, 25a, so engaged, form two mating rolls gauging between which can be transported a banknote from the resist 9, as seen in b in Figures 5 and 8. similarly the pairs 26, 26a and 27, 27a serve reserve tickets 9a.The fixed brackets 22 and 23 corresponding to portion 17a the slender shaft 17 are placed, with respect to the axis of the shaft 16, of teile so that when the members are assembled, the rollers jaugeurs to bearings 24a and 25a being in rolling contact, respectively, with the rollers 24 and 25 carried by the shaft 16, the shaft 17 takes a slight arrow as shown by the dashed lines in fig. 7. of the fig.. 7, representing the portion of the shaft 17a théoñque represent the contour of the portion 17a of the shaft if the disagreement was straight and not subject to the yielding pressure resulting from the mounting mode represented and described.A movement path extending from the notes picker mechanism 11 to pass through the mechanism doubles detector 12 is defined as a whole by guide means containing guides 28 and 29 detachable preferably formed by a plastic material giving flexibility to the guides. The guide 28 is provided at its ends 30 and 31 lugs, fixed by screws 32 to the side walls 18 and 19 to the catcher, which hold this member in relatively fixed position.628,452 rectangular lugs 33 project downwardly from the lower region of the stationary guide 28 (Figure 13) and rounded pockets 34 are formed therein. Rollers-needles 35 are mounted rotatably in the pockets 34 of the guide, they are in contact with rollers rubber drive 36, carried by the drive shaft 21. The drive shaft 21 acts as a conveyor shaft for powering the sensor mechanism of double by passing bills b of the picker mechanism 11 members a gauging 13 by driving the bills b by the rubber rollers drive 36 which lo and press the rouleanx -needles 35 as shown, for example, the fig..The other guide 29 guide means is mounted on a shaft 37 carried by the housing of the picker and comprises a portion 38, having a cross section in the form of an escutcheon, which folds over the shaft 21 so as to fixedly position the lower portion 39 of the guide 29. The upper portion 40 of the guide 29 can move relative to the lower portion 39 by flexing in the region 41 which acts as a pivot point for moving the upper portion 40 of the guide.There are for each line bill insertion a pair of rollers 36 eaoutchoutésservmlt training or ã feeding, each roller being opposed to a rouleauaiguille 36 35, the rollers-needles 35 being urged against the rollers-needles 36 by the flat springs 42 whose ends z5 lower recall the rollers 35 to the rollers 36.As II has been said, the shafts 16 and 21 are driven synchronously and rotate in the directions indicated by the arrows of Figure 4 and 5 so that a note of teile b is carried on their route between the rollers 35 and 36 on the one hand and the rollers 24 and 25 or detectors 24a and 25a on the other hand upon the belt conveyor 14 by passing between the guides 28 and 29.While the b-ticket (Figure 5) is driven by the conveying members and mounted between the guides, it spreads the guide 28 the upper portion 40 of the guide 29, as shown in Figure.The flexibility of the guide 29 and the pivoting of the upper portion 40 around the region 41 enables this separation that is opposed however the very slight action of a tension spring 43 connected to the housing and to the catcher to a lug 44 carried by the upper end of the upper portion 40 of the guide 29.The upper end of the upper portion 40 of the guide 29 has a series of projections or teeth spaced relative to each other, forming a kind of comb, which project toward openings 46 formed in the top of the guide 28 and penetrate it as seen in Figures 4 and 11 to 13.While the ticket b is introduced between the guides 28 and 29 it passes between the teeth 45 and the curved region of the guide 28 in which plug the openings 46, and the portion of a note describing supépassage its travel, as shown in the Figure.The conveyor belt 14 itself also comprises a bearing plate 54 is generally rectangular in shape having side flanges 55 arranged in the direction of the length of the platen 47. 56 supporting the belt rollers are journaled between the ends of the flanges 55 of the support plate 54. An endless flexible belt 57, rubber preferably, rotates around supporting rollers 56 and has a working section which passes under the supporting plate 54 and 47 on the platen.The bearing plate 54 with the rollers 56 and the belt 57 to which it is associated is a collection box which rests on the plate 47 but is movable upwardly and downwardly relative thereto for exposed farther.The position of the assembly, during said movements, is defined by idler rollers 58 mounted by bolts 59 on the side edges of the support plate 55, the rollers outwardly-projecting flanges. The guide rollers 58 housed in the slots 60 open at the top and vertical walls 61 formed in the main housing 51 (Figures 1 and 4).The belt 57 has a reversible drive arrangement described below and its working strand is normally supported on the stage 47 by the bearing plate 54 of the belt conveyor.Thus notes b is introduced between the guides 28 and 29 and through the entry slot 52 are supported by the plate 47 and are, in the normal case, conveyed or transported by the belt 57 in the direction indicated by arrow 62 of fig. 4. the arrow 62 indicates the normal direction of movement notes b on their pathway that leads them guides 18 and 29 at delivery receptacle 6 notes.When the direction of movement of the belt is reversed, as indicated by arrow 63 (Figure 4), any ticket which is located on the stage 47 is transported by the belt 57 in the direction of arrow 63, this operation having the duplicate detection by the sensor mechanism of double described below. But note that the belt 57 conveys in the direction of arrow 63 is sent by the conveyor belt in a container removably supported 15 rejected bills on a wall of the housing 19a to the catcher.As a result, any ticket out of guide members with the entrance slit 52, moves to lie under the active side of the belt and to describe a normal forward path which carries it "delivery" to the end of the platen 47a, in the direction of arrow 62, when the belt is moving its drive movement normal forward. When the direction of movement of the belt is reversed due to the duplicate detection, any ticket B which is arranged between the active side of the belt and the plate 47, to the right of the entrance slit 52, will be transported in a direction opposite to the normal one forward, 40 ment and the guide 29 separates from the waveguide 28 as shown in 50 it will pass on the entrance slit 52 being closed to arrive at fig..The belt conveyor 14 comprises a plate 47 which is constituted by two plates 48 and 49 which separate into (Figure 4). The plate 49 is carried by the housing to the catcher while the plate 48 is mounted to the top of the housing 51, which contains the components on the Figure 1 and rcprésentés 2.The plate 47 has, between its ends, an inlet slot 52, in the region that overcomes the reed organs gauging 13. The slot 52 is preferably at the location of the seal 15 rejected bill or receptacle located in the vicinity of the end of the "rejection" 47b 47 platinum.The slight initial arrow portions 17a and 17b the slender shaft 17, for holding the rollers jaugeurs to bearings 24a to verbs 27a contacting the rollers 24 to 27 of the large axis 16 has already described depending on the fig. 7. the left side portion of the fig.. 8 shown by an arrow 17b normal portion of the shaft when a single note b. passes between the pairs of rollers 26 - 27 and 26a27ajangeurs , while the right side portion of the Figure shows the region of the separation between the plates 48 and 49. The slot 52 has 60 17a the slender shaft which has assumed an arrow higher because a contour in the form of saw teeth or teeth spaced to receive various teeth 45 carried by the guide 29 as well as teeth 53, located at the top of the guide 28 (see fig. 11).The teeth 45 and 53 which engage the slots 46 and 52 is openings, the plate 47 have a continuous top face when the guide members are closed as in Figure. 4, but not when the guides 28 and 29 are separated by the two notes (a "dual") pass between the pairs of rollers 24 - 25 and jaugeurs 24a and 25a.The doubles detector mechanism 12 comprises, in addition to rollers jaugeurs , switching members 64. Any switch 64 is associated with a pair of opposed rollers 24 and 24a, 25 and 25a, which actuates it. Each of the switch members can be a pin, button or roller. A roller switch is preferable as shown in Figure.628,452 each switch 64 has a roller 65 mounted on a pin 66 which is axially movable in a sleeve 67 to actuate contacts contained within the housing of the switch 68. The sleeve 67 is blocked by nuts on a thinned region 69 and 71 and flexible supporting plate 72 U-shaped (Figure 9). The support plate 72 is mounted by screws 73 on a bracket support 74 carried by the housing of the prélevcur . A rubber damper 75 is interposed between the piaque 72 and corner piece 74. The ends supéñeures regions 71 are clamped by set screws 76 onto the angular support, lo and a rubber damper 77 exerting pressure antagonist.This functions by acting on the screw 76 to precisely position the switch 64 corresponding thereto relative to its roller bearing 24a flume.The angle iron support 74 provides mounting of the four switches 64. The angle iron support 74 can, with respect to said rollers jaugeurs be, as a whole, moved towards or away from members 13 (Figure 4) gauging by adjusting the bolts 78 and 79 80 and 81 in slots formed in the bracket 74.The average thickness normal banknote b of U.S. currency is 0.0889 mm. The actual degree of precision gauging multiple tickets by mechanical switch is related to the sensitivity of the switch which gauge the excess thickness affect in the normal thickness. The switch can have a differential range movement corresponding to a 0.00508 to 0.0127 mm between when the it operates and the moment of its recycling which enables it, be operated again after leaving its normal position. This differential range of stroke allows gauge variations of the thickness of the bill reaching at least '/ 7 of the thickness of the bill when the switch has a differential range of 0.0127 mm stroke, and 1/7 when the differential is of 0.0508 mm.The idea of applying a mechanical gauge thickness notes thus allows very sensitive for the detection of double. Further, when the switch is, at the beginning, very sinsible (differential 0.0508 mm), if the differential passes, in use, to 0.0127 mm, the switch still detect a variation in thickness of the corresponding ticket t/7 at the normal thickness of a bill.In addition the switches 64, especially those of sprag type represented can allow a large overshoot and cope with e.g. exceeded rintroduction resulting from accidentally into the mechanism doubles detector of a large number of tickets packet, ten or more, who could get hooked to each other as shown in the Figure. 6 bi. The possibility, for switches for a wide overshoot, accommodate this situation prevents the mechanism doubles detector lie blocked or damaged when, through accident, it is in the situation of the fig.. 6, notes b1 passing then to the conveyor belt and being rejected as double.A switch 64 is actuated by a given given torque rollers 24 a-a-a-24a jaugeurs , and so on as seen, there is a pair of switches 64 for each distribution line assigned to bills of a denomination. One of the switches 64, corresponding to the pair of rollers 24 and 24a jaugeurs , can fill a role of counting and counting the number of NC billcts during jaugeagc . The other switch of the pair corresponding to the same laundry distribution, e.g. the switch 64 assigned to the torque rollers 25 and 25a, is the switch doubles detector for said line distñbution bill. 6 as mentioned, each of the switches 64 is provided with adjusting means very sensitive and when a bill, or more, jaugeurs projects between rollers, the deflection in the slender shaft portion 17a (or portion 17b) increases depending on the thickness of the notes in game. The switch 64 detects continuously the magnitude of its own motion, thereby measuring the thickness of the bills thus continuously through heterozygous the detector.In the case where the station for banking 1 is designed to provide notes Amterdam different denominations, for example, tapped on the reserves note these denominations, it should be possible to provide for each distribution line a mechanism separate detector or individual. The Figure. 7 and 8 show two of these lines and, in similar cases, can be used common shafts and other common components for both lines, as seen in Figures, allocates to the mechanisms of dual detectors assigned to each line distñbutrice bill.The pñncipe shaft flexed for gauging continuous mechanical roller by the thickness of the bills requires the slender shaft 17 comprises, for each line, a distinct portion, result that cytopathy obtains for the two lines using a single shaft 17 which supports centrally by the centerline support 23.The station has a compartment for banking 10 (Figure 2 and 15) for making deposits to, and the belt conveyor 57, cooperating with the plate 47, acts as a means for receiving and carrying the deposited pieces, introduced into the assembly by the slot (Figure 3) 5 deposits which is aligned with the end of the "delivery" 47a platinum 47 of the belt conveyor (fig.. 15).The plate 47 (Figure 2) extends laterally above the mechanism of dual detectors assigned to the two distribution lines and also above the top of the compartment 10, for receiving deposits. The deposited pieces extend from the end of the stage "delivery" 47a and the portion of the plate that overcomes the compartment 10 deposits to deposit them by a wide slot 82 whose edges are indicated at 83 and 84 in the compartment or trunk 10 deposits, where they fall as provided in d.A mechanism impñmant 85 is mounted to the compartment rintéñeure deposits 10 and below the region of the platen 47c identify pieces deposited being received.The deposited pieces d are carried in the device by the belt whose movement counter to the direction - usual - is triggered for the deposition operation of a dient which, on instructions, actuates the members to turn the compartment to deposits.This arrangement substantially simplifies the structure and the manufacturing cost of stations to banking combining the distribution of species and deposit taking because the conveying members assigned to the issuance of cash - the belt 57 as well as the platinum and other components therein rattachentservent also for transporting to the compartment to deposits.As it is intended that the belt conveyor can move up and down (as guided by the guide rollers 58 and the open slots 60), the conveyor belt 57 can rise and accept envelopes to deposits, D., relatively thick.The rejection of double, when detected, has been décñt : it is performed by a reversal of the direction of travel of the conveyor which transports the dual repelled to the container to double 15 represented in Figure. 14. The container may, as mentioned, being detachably joined to the housing of the picker near the end of the "rejection" 47b 47 platinum. The container is a box-shaped building with five surfaces 86 open at its top for receiving rejected bills which falls from the belt conveyor. The container 15 is removably mounted on the housing to the catcher as seen generally on figures I, 4 and 15. It is preferably provided with a closing member 87 628,452 pivotably mounted lock operated 88 and 89 whose key is maintained by the picker mechanism and which must be latched before that we can disengage the container 15 of the drawing.A teile arrangement by retention of key, is applied to the protection of the container 15 to reject bills, may be similar to that described Patent Revenue NO 761,288 aforementioned, and which can be used on the occasion of bringing piace and removing the containers sealed 9 and 9a, containing reserves of coins, provided in the station 1 to banking.The conveyor belt and the mechanism doubles detector may have a common device for drive them, this device being allocated to the pickers mechanism associated with each laundry cash dispensing. This drive is shown diagrammatically in Figure. 15 and may have a motor main drive, not shown, having a drive shaft 90 which operates various elements of the mechanism to the catcher by a gear train comprising the gears 91, 92, 93, 94, 94a, 95, 96, 97, 98 and 99. The gears 96 and 97 are mounted on the shaft 21 driving rubber rollers 36. The sprocket 98 is mounted on the large shaft gauging 16. The wheel 99 is assigned to the conveyor belt assembly and mounted on a short shaft which also carries a pulley belt drive 100 connected by a driving belt to a pulley 101 102 mounted on the spool 56 supporting the belt at the end "rejection" 47b of the belt conveyor.The wheels 97, 98 and 99 have the same number of teeth are shortened and that the banknotes b are introduced directly, starting at 35 and rollers 36, between the guides 28 and 29 upon the conveyor belt 14.A photosensor is provided between the inlet slot 52 and the rollers 35 and 36, it comprises a source lumnineuse 104 105 and a photocell. The sensor 104 - 105 acts as a gauge thickness that operates continuously to provide signals thickness and thickness modification to the photodetector output 105. These signals are substantially the same as those generated by switches 64 of the first embodiment.In other words the signals produced mechanically by deflecting or signals produced by attenuation of a light beam act as signals by measuring the thickness of the security and are processed by the electronic systems described below, similarly, to provide an average with respect to time of the thickness of the security and to generate decision signals are indicative of the presence or absence of double.By referring to Figures 17 to 25 there are several drivers that are used for detection of double and which to von be described.The fig.. 17 gives a bank pattern of the basic circuit of the doubles detector. The signal VS1 can be generated by a gauge or a mechanical sensor such that the gauging members 13 (Figures 1 to 15) or by an optical system such as 104 - - 105 (Figure 16) and is delivered to an averaging circuit or integrator 106. The integrator 106 is one of the circuits which will be described below in detail, it integrates the thickness measurements made by the gauging members 13 or the photoelectric system 104 - - 105 so that the shafts on which they are mounted are sync 30 function of time. The term integrating means here integrate nisés in rotation; therefore the forward movement communifonction time on substantially all of the length of the ticket réqué all arrive at the feed rollers 36 and contacting the rollers 35 is uniform throughout the range of notes to their destination last.To facilitate the operation of uvre and improved for banking 1, 9 and 9a seellés containers containing the reserves of species are preferably of the type shown in Patent Revenue 761,288 NO. To be able to install it on the peer-to-banking 1, or removed from, it is necessary to move the pickers mechanisms 11 and 11 has, that can be obtained by post to pivot, on a pivot 103, the entire mechanism picker. The pivoting movement of the housing to the catcher, indicated in fig. provides mixed. 15, carries with it the gear train 91 to 98, the wheel 98 99 4s disengaging the wheel from the belt conveyor. The portion 49 of the plate, which closes the top of the casing to the catcher, also moves with said housing, thereby separating the platen is at the slot 52 and the dividing point the mechanism and the system improved, dual detectors, have an important advantage: lines providing a plurality of currency bills of different denominations and/or a receiver deposits, or both, may form a whole, by common drive devices, and other, with the new mechanism and the doubles detector.The thickness of a bill, or doulbes , may be gauged in a variety of ways. So far the description has mainly carried on a Typical mechanical. Meanwhile, to gauge the thickness of a bill, use some of its physical characteristics suchre uests that opacity or ability to weaken the transmission of light. The second embodiment described below, a modified form of the doubles detector, which involves the use of a gauging of thickness by photosensitive devices.The description of the equipment, illustrated by the Figures 1 to 15, applies to the alternative embodiment of the fig.. 16 except that the members 13 constituted by gauging the rollers 24, 25 and the switches and other 64 are eliminated, that the guides 18 and 29 expe gauged ticket b. the term "integrated as a function of time" also covers variants according to the invention in which the integration is accomplished in accordance with another independent variable teile that length or position.The signal from the integrator 106 Cint is the average thickness of the note of b, measured on substantially all of the length of the portion of the note gauged and it is fed to a comparator which compares the signal 107 twenty (function of Vr and the thickness of the note) to a reference signal Vr generated by a reference circuit 108. The signal from the comparator 107 VOs depends on the result of the comparison and indicates whether the ticket B should, or not, be classified among the double.Shown in the Figure. 18 that the integrator i06 109a comprises a resistor in series with a diode 109 connected to one of the inputs of the comparator 107, a predetermined reference signal being supplied to the other input of 107 by the potentiometer 110. The resistor and the capacitor 110a 110b are connected between the cathode of the diode 109 and ground. The anode of the diode 109 is connected to the output of the thickness sensor, preferably a flume 13.11 thickness must be understood that the circuits shown in the Figure. 18 may be associated with any thickness sensor capable of generating a digital signal corresponding to the thickness of the bill, for example a signal 1 (in Boolean logic) having a double and a signal 0 (in Boolean logic) in response to the absence of double.The signal Vs of the detector or sensor is supplied to the capacitor by the diode 109 110b, the exponential value of the signal is stored in the capacitor.The capacitor discharge 110b can only be accomplished by neither the diode 109, which blocks it, nor by the high-impedance input of the comparator 107, it is implemented by the resistor ll0a , at a pace determined. The signal from the comparator 107 VOs responds to the comparison result of the voltage across the storage capacitor to the voltage supplied by the potentiometer reference 110. The value of the voltage across the storage capacitor 110b is a function of the average measured thickness gauged on the portion of the note: when there is a dual 628452, gauging the members 13 provide a logic signal 1, which causes the capacitor to charge the ob 11 to approximate the voltage level corresponding to the logic signal 1, five volts for example. When the members gauging 13 is not detecting double, gauging the members provide a logic signal 0, zero volts for example, allowing the capacitor to discharge to a 110b course determined by the resistor 110a. Thus, the voltage across the storage capacitor 110b depends on all the time duration during which the gauging members 13 detects a dual, duration which is compared with a total time of detecting angstroms.The operation of the circuit shown in Figure. 18 is described in more detail on the Figure. 19a to 19c. The fig.. 19a represents as a function of time, for two tickets successively passed through the gauging means, sensing signauxtypes of V-generated by said sensing members 13. See that the outgoing signal detection means is at logic 0 when no duplicate is not detected and a logical 1 when a double is detected. The signals ærtant gauging means 13 for the first ticket show that the thickness of the note is only two regions relatively short of the note large enough to cause the gauging members 13 to signal a double. These regions relatively short where the ticket is thick, characterize local thickening of which may be caused by dirt or folds of a single ticket.The first pulse charges the capacitor at a relatively low voltage because this first pulse a is relatively narrow. The second pulse of b, wider, adds to the voltage across the capacitor 110b, but the total voltage across the capacitor 110b is lower than a threshold voltage generated by the potentiometer of the fig. 110. 17.The first ticket is therefore recognized as a single note though there is locally thick regions reported by the pulses a and b. this different from prior systems, in which the presence of localized regions where certain quantities take supéñeures values to a determined value would tend to falsely identify the bill as being double. The fig.. 19c shows that the output signal VO is at logic 0, thereby indicating that it has not been detected double.On the other hand, assuming that the gauging members 13 now generate pulses of c, d and e having relative widths shown in Figure. 19a, the capacitor is charged 110b succession through the voltage level indicated, which exceeds the level of the voltage threshold indicated dashed. This is an indication that the second ticket t'a mean thickness is sufficient to be classified as dual, a logic signal I is thus generated by the comparator 107, as shown in the Figure. 19c.It is clear that the successive increases in voltage generated by the organs jaugeurs 13 during the gauging of each ticket accumulate to reach a maximum magnitude to be examined by the comparator 107. The time constant of the system 110a - 110b is large enough to prevent the capacitor 1 i0b discharge between pulses signal, at 1, issued for the same ticket, but suffisamss centeredly small to enable the condenser 11 ob is almost totally discharging between notes as shown in the Figure. 19b.Shown in the Figure. 20 another embodiment of the dual detector circuit DC voltage, wherein the signal of a thickness detector as the device 13 gauging mechanical or photoelectric system 104 - 105 is sampled at predetermined intervals and short. The signal from the detector is sampled at times at logic 1 or classified as a double 0 is detected or not at the time of sampling, the total number of logic signals 1 (double) is related to the total number sampled to determine whether the ticket should be classified as dual.The signal VS1 exiting from the detector is fed to a circuit 111 conventional sampler that samples said signal at predetermined intervals, equal and short, as shown in the Figure. 2 lb, these samplings corresponding to points distributed over the region gauged the ticket. Assuming that the signal from the thickness sensor is, in Figure. 21a, identical to that of the fig. represents. 19a, réchantiilonneur signal 111 generates pulses which coîncident , sampling at times, with the signal Vs of the detector 2 lb.the pulses generated by the lo and signal sampler and that represents the fig. 111. 21c, is sent to a pulse counter 112 which counts the number of pulses generated by the sampler on the length of each note gauged. The signal from the pulse counter 112 is monitored continuously by a digital threshold circuit 113 is reduced in a signal CV indicating a double if the number of pulses counted by the pulse counter 112 for load ticket reaches or exceeds a set value, the counter being reset after each ticket. Assume for example that the count threshold from the threshold circuit numéñque either 7:no signal is generated during the gauging of the first ticket since only five pulses are counted, while a signal is generated during the gauging of the second ticket (it coincided with the end of the stream of seven pulses generated by the sampler 111 (see fig. 21d).It is clear that the number of pulses counted by the pulse counter 112 during gauging each ticket is proportional to the thickness of the bill averaged over the region gauged thereof. The circuit of the fig.. 20 réond therefore to the average thickness of the note.In practice a bill remains in contact with the members 13 during gauging miUisecondes 180 about its route, it is sampled 40 times. The number of samples indicating a reflection may be of 20, for example, before the ticket during gauging is classified as dual.The fig.. 22 represents another NNU réafisation doubles detector circuit. The circuit of the fig.. 22 is particularly adapted for use with an optical detector of the type to which thickness referred above, as shown in Figure. 23a, but is not limited to. Said sensor has an output characteristic of the type of the Figure. 23b. B in a note during gauging passes, on its path, between a light source 104 that may for example be an incandescent lamp or a light emitting diode, and a photoeellule 105. Exposing a note B to detector 104 - 105 at yard movement of said ticket is here called "scanning" of the note. The output voltage Vs of the sensor 105 is maximum when there is not a ticket 104 between the lamp and the detector 105. It should however be understood that the operation of the detector 105 could be reversed.In this case, as shown in the Figure. 23b, the voltage Vs of the sensor falls to a first level of c 1 in response to the transmissivity of a single ticket vs2 and at a second level, lower, in response to the transmissivity pleat low a double. But, because of the gain characteristic of a photodetector circuit, the difference between the stresses arising respectively at blocking property of light by a simple and by a double bill is relatively low. Further, the waveforms of the fig.. 23b represent an ideal case where the ticket has a transmissivity constant throughout the region gauged the ticket. In practice, it appears transitions between the voltage detector of the polyvinylidene fluoride locked by a single ticket from the detector and the voltage vs2 blocked by a double.With the circuit of the fig.. 22, as with those of fig.. 18 and 20, the classification between single and double notes is based upon the thickness averaged, or the transmissivity (or opacity) to light along the region of said bills gauged.In principle the circuit of the fig.. 22 continuously monitors the amount of light received by the photodetector to 105 to determine whether any banknote is or enter between the lamp and the detector 104 105 or if it passes at least one ticket therebetween. When a bill at least is passing between the lamp and the photodetector 105 104, the resulting output of the dérecteur 105 is sent to an integrator circuit. As the detector 105 generates, in response to a single ticket, a higher voltage than the session in that it generates in response to a duplicate ticket, and as the response of an integrator at a constant voltage or DC is a ramp whose slope is proportionlo of or to the value of the voltage, it is clear that the slope of the curve representing the voltage generated by rintégrateur is larger for a single ticket.It is clear, furthermore, that transients or disruptions low importance tend to be smoothed by the integrator, the slope of the ramp voltage generated by the integrator is little affected by transient variations of the opacity or transmissivity of the ticket as this transition values are "eliminated" characteristics by the integration.The presence of a single ticket, or a duplicate, which can be accurately determined by monitoring the output signal of the integrator after an integration period set in advance for determining whether the output voltage is less than or greater than a preset value. For example, if the outgoing of the integrator is, at a time determined integration, above a determined value, the ticket being gauging is classified as "single". One may also continuously monitor the signal from the integrator and determining the instant the integration for which this signal reaches a predetermined value.If this value is attained prior registrability a time determined the bill will be classified as "single".Examining now the fig.. 22 in more detail see that the signal from the detector 105 is sent to a buffer circuit 112a which avoids loading the detector. The signal output from the buffer circuit 112a is connected to the input of a first analog switch 113a and also to a comparator 114 and a peak voltage detector carrying a whole the mark 115. The output voltage of the buffer circuit 112a is maximum when there is not a ticket between the lamp and the detector 104 105, as has been said. This situation will be referred to herein as "quiescent". The output voltage of the buffer circuit 112a falls to a lower level when there is at least one biIlet 104 between the lamp and the detector 105 for intercepting light.The comparator 114 compares the voltage generated by the buffer circuit 112a to a reference voltage generated by the potentiometer 115a so as to determine whether a note at least lies between the lamp and the detector 104 105 or not.When there is at least one sheet between the lamp and the detector 104 105, voltage outputted from the buffer circuit 112a will be less than the reference voltage taken in 115a, whereby a control signal is generated by the comparator 114. The control signal generated by the comparator 114 is supplied to the control terminal of the switch 113a c1 and to the control terminal of a second analog switch c2 ll6. The control signal provided to the switch 116 is inverted in an inverter circuit 117 so that the MOC mutatcurs 113a and 116 are always in an opposed state, the first being closed when the second is opened, or vice versa.The signal from the first switch 113a is sent to an integrator circuit 118 which corresponds to the block of the fig. 106.17, by a potentiometer 119. The potentiometer 119 adjusts the gain of the integrator 118; it is organized so that the system is able to be accommodated of bills of different denominations or of different types, as will be set forth in detail farther. The output of the integrator 118 is connected to one of the input terminals of the comparator circuit 119a which corresponds to the block of the fig. 107. 17.The remaining input of the comparator 119a is connected to the output of the detector circuit 628,452 peak voltage 115 which elaborates, 119a for the comparator, a reference voltage dependent on the peak voltage, or quiescent, generated by the detector 105.The reference voltage for comparator 119a depends on the quiescent voltage, or voltage of the detector "unblocked" so that the reference voltage is automatically compensated for conditions that have to do with the thickness of the note: change sensor parameters, dirt in the optical system, andc.The peak voltage detector 115 which corresponds to the block of the fig. 108. 17 includes a diode 121 connected to the storage capacitor 122 and 123 to the inverter by the resistor 122a.The inverter 123 serves to invert the polarity of the voltage peak, or quiescent, stored in the capacitor 122, to be supplied to the comparator 119a to be compared with the voltage of the integrator 118.The integrator comprises an operational amplifier 118 124 which has a capacitor 125 in its loop which is. The switch 116 is connected across the capacitor 125 by a small resistor 126 to place the integrator or disable specific times.In operation, when a bill is between the light source and detector 104 105, the switch is closed and the switch 113a 116 opened by the signal from the comparator 114. In this situation the integrator is operating and a conductive path for the signal is established between the buffer and the integrator 118 112a. The signal coming from the integrator 118 is therefore a straight line whose slope is proportional to the value of the outputs from the sensor, which is a function of the instantaneous thickness of the ticket.The fig.. 24 shows the operation of the integrator 118, the right will corresponds to the response of the detector 105 to transmitted light of the discipline of a single ticket, and its slope is relatively large, and the right and VB corresponds to the response of the detector 105 to light transmitted through a double, and its slope is relatively lower. The time at which the voltage of the line will cross the reference voltage or quiescent voltage VO is the ts, and the time at which the right and VB intersects the reference voltage VO is Tg. As a result, it is happening more time before the output of the integrator 118 reaches the reference voltage Vo Iorsqu ' there is a dual between the lamp and the detector 104 105 that when there is a single ticket.The dashed line Vc represents a real signal exiting the integrator 118; it has defects linéaritié associated with transient changes in the transmissivity for light, or opacity, along the region of a bill gauged, and it intersects in t1 the reference voltage Vo. The ticket can be classified "single" or "dual" according to the definitions adopted, thickness dependent or opacity averages. It is therefore clear that it can be determined whether the number of bills that lies between the lamp and the detector 104 - 105 - single or double ticket by determining whether the value of the ramp voltage is higher or lower than a predetermined value, at an appointed time as it was shown.For example, in Figure. 24, at the time, Tt of, the value of Vc exceeds the value of the reference voltage VO and the ticket during gauging is classified as a single ticket. On the other hand, at the time Tt of, the value of the voltage of the right to Vo VB is lower, and the bill is classified as dual.The slope of the line generated by the integrator 118 is controlled by the potentiometer 119, so that the operation of the integrator can be adjusted to become operable with notes denominations or of different types, the timing at which it is measuring the value of the ramp voltage being however touiours the same. In other words the potentiometer 119 controls the slope of all straight lines which generates the integrator 118, thereby calibrating the circuit for it 628,452 can operate with notes of a type or any denomination.Fig. 25 shows another embodiment of the detector circuit of double, and is similar to the circuit of the Figure. 22 except that a constant voltage, preselected, réfés is provided as one input of the comparator to Conference 119a, instead of a varying voltage, the constant voltage is supplied by the potentiometer 124a. Changes in ambient conditions, unrelated to the thickness of the note, compensate each other because the current flowing through the lamp 104 is automatically adjusted lo and by a lamp control circuit 127. The engrée 127 of the control circuit is connected to the output of the buffer 112a so as to respond to the output of the detector 105. The control circuit 127 has a peak voltage detector circuit including a diode 128, a resistor 129 and a capacitor 130 and whose output is connected to an amplifier 131 by the resistor 130a. The amplifier 131 controls the base of the transistor 132 of the lamp control circuit, the transistor being connected in series with the lamp 104 and to the supply voltage source V the resistor 135, limiting intensity, is mounted between the amplifier and the transistor 131 132.A feedback resistor 134 is provided between the emitter of the transistor and the input of the amplifier 131 by the resistor 136.In operation the voltage across the capacitor voltage Vo follows the Z's 130, which is the quiescent voltage generated by the sensor 105 in the absence of locking by a ticket. The resistor 129 is a résistanee fall for partially discharging capacitor 130 when the voltage quiescent VQ codevectors decreases. The voltage across the capacitor 130 serves to control the base of the transistor 132, depending on the value of the quiescent voltage VOs, via the amplifier 131. The signal coming from the amplifier 131 is a manually, by means of the potentiometer 137, to pass normal intensity in the lamp 104. Subsequently, the intensity is automatically cable assembly to insure the constancy of VO by feedback resistor 136.The detector for detecting double may be used for detecting and rejecting double in any remote, as described by in the many patents and in particular in the following U.S. patents:3, 876864 NO behalf AL of the Clark and 8 . 4.1975 NO 3,880 320 on behalf deMORELLO and AL of the 29. Patent 4.1975 3,909 595 on behalf of Morello and AL of the 30. Patent 4.1975 3943335 on behalf of KINKER and AL of the NO 3 . 3.1976 3,954 260 on behalf of Morello and AL of the 4 . 4.1976 NO 3,999 681 on behalf of Graefe and Al du28.12.1976 4,016 NO 405 on behalf of McCune and AL of the Patent 4,023 013 5 . 5.1977 aunomdeKINKER of 10 . 5.1977 a advantageous traits of the improved equipment so exposed and described is that it allows a cooperative arrangement between the components "dispenser coins", and "doubles detector" and "receiver deposits", which are connected to each other by single conveyor belt ã , reversible, which serves both to the distñbution and deposition.C. 9 sheets drawings 628,452 9 sheets NO 1 it.............. .................................................. FIG.I of 47 and 4 - the I - 55, 99 51, 13 the II I when I-I-I-I-I-I-Q-I-I-I-I-I-I-I-I-1 I-I-I-I-I-I-I-I-I-- - I-I-I-I-I-I-I-I-I-I-I-I-I-I-I-I-I-I-I-SHS 1 I/2......... j-I-I-, I-I-I-T-!1 - t-I-I-it GJs - I-I-I-I-- - 9a 9, 93" ALL fig. 51 it and 2. A detector mechanism and system for currency dispensers for automatic banking equipment which senses the presence of multiple or double bills, called "doubles," at any bill location in a series of bills intended to be fed one by one in a path of travel from a supply of bills to a place of delivery to a customer. The bill thickness of each bill is gauged continuously while moving in the path of travel, and the thickness measurements are time averaged over substantially the entire length of the gauged portion of the bill. The averaged and normal bill thicknesses are compared to determine if the averaged thickness is greater than the normal thickness by a predetermined amount. A greater thickness determination generates a signal of the presence of doubles, and the signal actuates means to reject the doubles while moving in the path of travel before delivery of the doubles to a customer. I. note dispensing device for automatic banking, having a supply of notes and a delivery station notes, characterized in that it comprises a detector (12) doubled bills, a picker mechanism (11) for removing the bills to a a note stack in a container (9) note, means for successively transporting bills from the picker mechanism via the mechanism (12) doubles detector to the delivery station (6), the conveying means comprising a lo and belt conveyor (14) having a pair of rollers (56), a flat plate (47) extending between the rollers, a bearing plate (54) for the belt, spaced from the plate and extending between the rollers, an endless rubber belt (57) about the bearings (56) and having a working section extending between the plate (47) and the backing plate (54) and in contact therewith, and drive means connected to at least one of the rollers (56) of the conveyor for rotating and moving the active side of the belt (47) between the plate and the support plate (54), the [...] active of the belt being pressed against the plate by the pressure plate, so that the bills transported from the picker mechanism (11) by the detector (12) of duplicates are delivered to the belt conveyor (14) and are conveyed by the belt (57) along the stage flat (47) to (6) delivery station. 2. apparatus as in claim 1, characterized in that the plate (47) has a slot (52) input, and that!of the means for transporting the bills are arranged to deliver the tickets from the reserve tickets through the entry slot. 3. apparatus as in claim 2, characterized in that the plate (47) comprises two plates (48, 49) with the entry slot therebetween (52). 4. dispenser according to any of claims 2 and 3, characterized in that two members (28, 29) guides entering the gap (52) for input notes guided therein, a guide members which can bend under the action of a ticket when the I! is guided in the inlet slot while the guide means was not flexed. A dispenser according to one of claims 1 to 4, [...] NC that it includes a mechanism to deposit with a panel formed with a keyhole (5) deposition by which the object [...] deposited in the compartment, the conveyor belt (14) being located above the deposition mechanism, the bearing plate for the belt being resiliently supported for admitting the transporting objects of varying thickness deposited, and the active side of the rubber belt being pressed against the plate (47) by the support plate (54) mounted belt elastically, so that the deposit item supplied to the conveyor belt from the entrance slit (5) deposition is conveyed by the belt rubber along the stage flat in the deposition. 6. apparatus as in claim 5, characterized in that the mechanism to deposit and the doubles detector (12) are housed side by side in one compartment and in that the plate (47) is formed with a discharge slit through which the fob} and deposited is discharged from the conveyor belt in the deposition. 7. apparatus as in claim 6, characterized in that it comprises delivery rollers (24 - 27, 24a and 27a) for moving!in ES notes discharged from the picker mechanism successively by the doubles detector, the conveyor belt being disposed for holding notes conveyor rollers, means being provided to actuate the picker mechanism, the conveyor rollers and the conveyor belt. 8. apparatus as in claim 7, characterized in that the store container includes a container (9) protective sealed having an access opening which is closed and locked until the container is in position. 9. dispenser according to one of claims 6 and 7, characterized in that the detector (12) double includes means (25, 25a, 64) [...] thickness for measuring the thickness of each ticket in substantially full length in a gauged aligned in the direction of the bill along its path running in front of the members of gauging [...], and also includes means for averaging the thickness measurements made on the note's gauged length so as to provide an average of the thickness of the note, and means for comparing the average value with a reference value greater than the average thickness of normal money, and a means for generating a signal "dual detected" when the average exceeds the reference value. The dispenser of claim 9, characterized in that the ticket [...] members comprise a pair of rollers [...] (25, 25aß between which move successive bills, two shafts (16, 17) on which are respectively mounted the [...], the first shaft having a strength that prevents the flex, while the second shaft is flexed so as to maintain contact between the rollers, the arrow shaft increases to a degree that depends on the thickness of the bills fed between the rollers, and a switch (64) in contact with the second roller, which is mixing valve assembly for generating a signal 6 "dual detected" when a dual moves between the rollers. 11. 10 [...] claim, characterized in that two pairs of rollers [...] (25, 25a, and so on) are mounted with a gap therebetween respectively on the two shafts (16, 17) in that the switch (64) that senses the degree of flex to either the second roller pairs is arranged to be operated to generate a signal "dual [...]", and that the switch that senses the degree of deflection of the second roller of the other pair is arranged to be actuated to count the number of bill whose thickness is measured. 12. apparatus as in claim 11, characterized in that two sets of two pairs of rollers [...] are respectively mounted on the two shafts (16, 17). 13. Dispenser according to any of claims 10 to 12, characterized in that the first shaft (16) [...] at its ends in the side walls (18, 19) of the gear housing and is rotated in synchronism with the means for moving the notes from the reserve tickets to the issuing station (6), in that the first rollers (24 to 27) [...] are fixed on the first shaft for rotation therewith, in that the second shaft (17) is mounted against rotation in the walls of the housing, and in that each second roller flume (24 to [...]) has an anti-friction bearing of circular outer contour rotatably mounted on the second shaft in rolling contact with its corresponding first roller flume. 14. Dispenser according to any of claims 10 to 13, [...] in that the switch (64) that senses the degree of movement of the second shaft [...] (17) is engaged with the second roller and is adjustably mounted on the transmission housing. The dispenser of claim 14, [...] in that the switch (64) (65) comprises a roller engaged with the second roller flume, the roller being mounted on a stem (66) axially displaceable in a sleeve (67) to actuate contacts housed in a switch housing (68) mounted on the mechanism housing. 16. The dispenser of claim 1, characterized in that the conveyor belt (14) and!in ES driving means coupled to at least one of the conveyor [...], are reversible. 17. The dispenser of claim 16, characterized in that it comprises means (13) for generating a signal when