Oven door with inspection window

PATENT CLAIMS 1st Baekofentüre with and perpendicularly to the direction mentioned standing windowpanes connected in series from a number in looking through direction in the distance (12,1, 14-17; 12.1, 26-28) existing Sehauglaseinheit (4), by it characterized that the sediment bowl unit a dish-shaped I-Iüllkörper (12) from heatproof glass, with which body the ground (12.1) is transparent at least, and with the ground a einstückig connected and this surrounding bowl wall (12.2) contains, within which from each other dissociated transparent disks (14-16; 27, 28) from glass is arranged, and that on the edge of the bowl wall a presented (41) or into this edge inserted thrust washer (17; 26; 37) the inside of the Hüllkörpers gas-tight verschliesst.

2. Backofentüre according to requirement I, by the fact characterized that the thrust washer inserted into the edge of the bowl wall (12.2) (17, 26) is connected with the bowl wall by means of heat resistant Dichtungsund adhesive (18) (Fig. 3, 4).

3. Backofentüre according to requirement 1, by the fact characterized that the thrust washer (37) with the bowl wall, inserted into the edge of the bowl wall (34.1), is welded (Fig. 5).

4. Baekofentüre according to requirement 1, by the fact characterized that the bowl wall (39.1) of the garbage body (39) is put on on the edge flange provided with a auswärtsgeñchteten circulating edge flange (40) and the Abschlussseheibe (41) closing (Fig. 6).

Backofentüre according to requirement 4, by the fact characterized that the thrust washer (41) by feather/spring means (42) on the edge flange (40) pressed ist.

It is well-known with baking-oven doors to build for the observation of the baking procedure without opening the Türe, a sediment bowl into these. Regarding the relatively high temperature differences between the Backraurn and the admission side it is inappropriate despite the bad heat conductivity of glass to build the sediment bowl from only one glass body because during a longer period of operation of the baking-oven the whole glass body is so strongly heated that also at its exterior one does not prevail any longer harmless Berührangs temperature. Can be remedied to this disadvantage by a sight construction, with which in place of only one glass body a number in a framework disks held and from each other reserved are isolation-moderately switched into Sede. The framework consists thereby appropriately of metal, and the arrangement of the individual disks is so met that also at different temperatures at the layer structure no harmful thermal stresses can occur. This causes a relatively loose mounting plate of the disks in the framework, so that it is possible for arising steam or strongly feuchtigkeitshaltiger air with the baking procedure in the furnace, by the Dilatationsspalte in the Sichffensteraufbau outward za arrives. Since with a well heat insulating structure of sight at least at the outermost disk one prevails to the ambient temperature strongly angenãherte temperature, a from the outside not wipe awayable condensation surface can occur on the inside of the window, which prevents the examination into the furnace. The experience necessarily shows that by Wasserund fat steam entrance gradually on all surfaces on the inside of in such a way arranged disks deposits arise, the one periodic cleaning of the structure of sight machen.

Task of the invention is to suggest a Backofentüre with sediment bowl with these disadvantages by an s a compactly shapable dampfdiehte arrangement of the structure of seeing window avoidable sind.

The solution according to invention of this task is by the characteristics of the patent claim 1 gekennzeichnet.

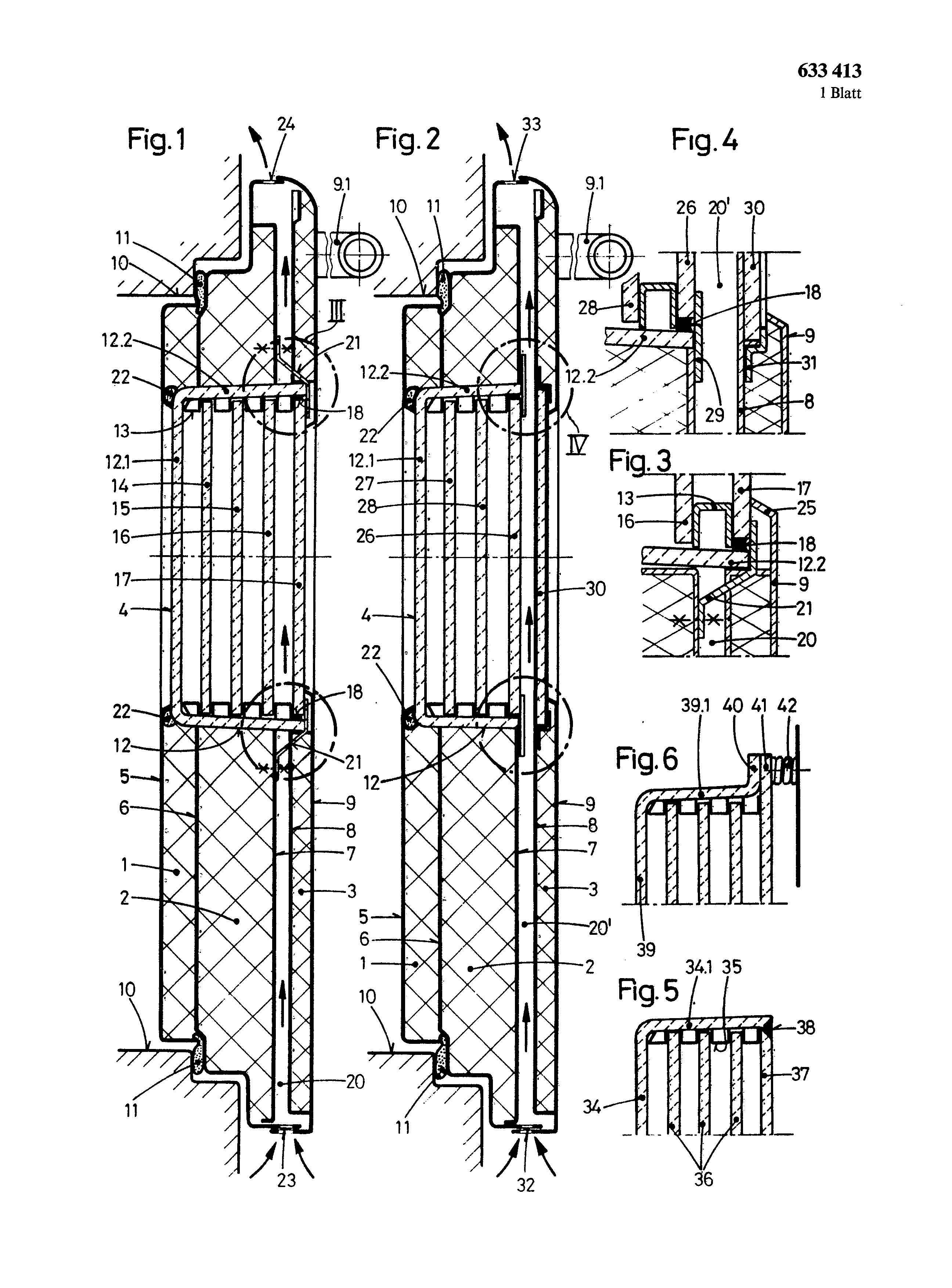

Ausführtmgsbeispiele of the Erfmdungsgegenstandes are below described RST on the basis the design. Dañn shows and/or shows:

Fig. 1 and 2 vertical cuts by first and a second execution form of the Backofentüre according to invention, is Fig. 3 and 4 in larger yardstick the mounting plates of the sediment bowl units in the circles III and IV in Fig. 1 and 2, Fig. 5 a Partialschnittdarstellung of a sediment bowl unit and Fig locked by welding the cover disk into the Hüllkörper. 6 a PartialschnittdarsteUung of a sediment bowl unit, with that the Deckseheibe by spring pressure gas-tight against a seals flange at the Hüllkörper pressed ist.

Into the Fig. 1 the inside, 2 the middle and 3 the äuiseren Isolierschiehtaufbau of a Baek2s ofentüre designates 1 and 2, into which one altogether with 4 designated sediment bowl unit is built. The layer structures are contained of arranged laminar construction units, which are locked outward by sheet metal covers 5-9 with one (not-designated) recess each for the Sehauglaseinheit 4, in way not described more near inside an insulating material, which is accordingly selected that temperature range which can be bridged in each case, and in conventional kind are firmly or solvable with one another connected. Between insulating layer superstructures 2 and 3 and/or the Btechabdeckungen 7 and 3s 8 is an air circulation channel 20, whose task is descriptive later, and to the outermost structure of insulating layer 3 covering Bleehabdeckung 9 is fastened a door handle 9,1. The sealing of the Türe in relation to the Ofenöffnung 10 takes place via a poetry I 1 from a loose glass fiber fabric, the Schtiessspalt between a renaming shoulder to the Ofenöffnang and a circulating Diehtungsfläehe at the Bleehabdeekung 6 überbrüekt.

In Fig. 1 and portion! l in Fig. 3 sediment bowl unit shown 4 contains a dish-shaped HüUkörper 12 from heatproof glass, whose ground is arranged 12,1 as the internal disk of a disk package arrangement. It understands itself that of this garbage body only the ground needs to be clearly transparent 12,1, while the bowl wall can consist 12,1 s0 also of opakem glass. A number is inserted into the area limited by the bowl wall 12,2 by measuring rod 13 reserved middle, likewise hitzbeständige windowpanes 14-16 and a Glasanssenscheibe 17. The latter is gas-tight closing inserted into the edge of bowl by means of Dichtungsund/or ss adhesive 18. The spacers are preferably from U-Prolìlen arranged closed metal frames, which are inserted with the structure of the disk package arrangement with disks alternating into the HüUkörper 12. The beschñebene disk package arrangement is thus a gas density Sehauglaseinheit, those vorfabñzierbar ready to be installed ist.

The Scbauglaseinheit 4 is by means of to the Blechabdeekung 7 of the middle structure of insulating layer 2 fastened abgewinkeltert, springy clamping latches 21 so into the Türe built, 6s that the exterior of the ground 12,1 of the HüUkörpers 12 against a poetry 22 on the neighbouring side of the internal Blechabdeekung 5 lies close. The poetry 22 soli prevent the fact that in the baking-oven developing steam or smoke in substantial extent arrives by one between the exterior surface of the Sehalenwand 12,2 and the Isoliersehichtaufbauten 1 and 2 (niehtgezeigten) Dilatationsspalt which can be planned at the front of the Türe. It understands itself that the sediment bowl unit on that can be zentñert the oven turned side naturally also with additional latches or handles (not-shown), around the poetry 22 with a Zentñeraufgabe does not load too müssen.

The Laftzirkulationskanal 20 between the Isolierschiehtautìaauten, already mentioned, 2 and 3 extends preferably over practically the whole door width, at least however over a width range, which hinausreieht on both sides the sediment bowl unit 4,2-3 cm over their side edges. It serves particularly for sucking off if necessary by the Dilatationsspalt approximately uro the sediment bowl unit 4 from the furnace withdrawing steam and smoke, in addition, to the additional cooling of the front-lateral and/or outermost structure of insulating layer 3 and the Frontabsehnitt of the Sehauglaseinheit 4. the Luftzutritt to the channel 20 over the Lnftaustritt takes place over to waiters edge of door existing louvers 24. at untern the edge of door left blank louvers 23,

In Fig. I does not project the Sehauglaseinheit with their front section in the outside Isolierschichtautìaau 3, however by this any more is not supported. The seeing surface of the sediment bowl unit 4 approved by the recess in the Frontbleeh 9 corresponds about on the one hand by the parts of the spacers turned inward and on the other hand by the edge to 25 of the recess in the front sheet metal 9 released light Durohblickbereiehes.

In Fig. 2 Backofentüre shown yields to that extent of in Fig. that the Luftzirkulationskana120' likewise runs between the middle Sehichtaufbau 2 and the outside layer structure 3, in addition, more äber the front-lateral windowpane 26 of the sediment bowl unit 4 it extends 1 shown off. The sealing of the Türe in relation to the Ofenöffnung 10 can, as shown, with the same means as in Fig. 2 takes place. It is noticed that the unit 4 in Fig. 2 only me two middle windowpanes 27, 28 in place of their three (14-16) in Fig. 1 is shown an actually arbitrary number of such disks, in practice however as to exhibit there can. In all other respects the Sehauglaseinheit 4 in Fig.<br can/>

2 exactly equal as in Fig. 1 developed its, is thus fastened however appropriately with relatively flat springy, to the Blechabdeekung 7 of the middle structure of insulating layer 2 lying close clamping latches 29 that the exterior is practically concise the disk package arrangement covering windowpane 26 with the surface of the sheet metal cover. See in this connection also the Fig. 4. Thus dust deposits at more einoder out-jumping surface transitions leave themselves vermeiden.

The poetry 22 fulfills the same task as the poetry 22 mentioned already in former times after Fig. 1.

By the arrangement of the air circulation channel 20 ' before the front-lateral windowpane 26 the Sehauglaseinheit 4 the looking through recess in the outside structure of insulating layer 3 in Fig must. 2 provided with a glass Abdeekscheibe 30 its, those, as in larger detail in Fig. to the internal Bleehabdeckung 8 of the layer structure 3 to be fastened the air circulation channel 20 can do 4 represented, with a clamping latch 31 ' extends likewise like the channel 20 in Fig. 1 preferably over practically the whole door width, can do however 633,413 (similar to the restriction of width with the firstdescriptive example on a part of its length (from bottom to top) on the looking through width of the sediment bowl unit 4 if necessary to be limited. Lufteintrittsund withdrawal open us towards 32, 33 can as in Fig. 1 with 23 and 24 bezeichrieten arranged werden.

The advantage of the execution form after Fig. it consists 2 of the fact that with same operation conditions of the furnace the temperature at the outer-surfacenear Glasabdeckung is somewhat lower RST than at the outermost windowpane 17 after Fig. 1. It is unfavorable against the fact that one allf'ålliger dust precipitation on the turned sides of the windowpanes 26 and 30 depart if necessary only after disassembly of the outside Isoliersehichtaufbaus 3 from the bag is kann.

During in both remark examples described above in the bowl wall 12,2 in-cemented outermost and/or front-lateral windowpane 17, 26, shows the Fig is shown sediment bowl units 4 also by Dichtungsund/or an adhesive 18. 5 and 6 two variants for the production of the Scheibenpaket Diehtung. In Fig. a I-Iüllkörper 34 the early beschñebenen kind is shown 5, which contains 35 reserved middle windowpanes 36 by measuring rods, and by one with the free end of the bowl wall ãusserste windowpane 37 welded 34,1 with 38 2s is gasdieht locked. In Fig. an auxiliary body 39 is shown 6, whose bowl wall 39,1 with a renaming flange 40 is provided with piangeschliffener projection surface. On this flange a Deckseheibe 41 with likewise planner bearing surface, if necessary put on under Zwisehenlegen of a sealant, is. So that the thrust force resulting from the structure of glass plate measuring rod package can be caught zuvedässig, the cover disk 4t is appropriate a spring element 42 pushing against the Flanseh. This knows the flange and the edge of cover disk embracing spring clip in place of the coil spring schematically shown also sein.

With all execution forms shown of the sediment bowl units is substantial that those can be put to junction point between the garbage body 12 and the extreme and/or the cover disk into a zone, in which no extremely high thermal load takes place. This is particularly with so-called self-cleaning baking-ovens of importance, where with the 4s cleaning procedure furnace temperatures of approx. 500 arise °C. Although with the materials normally used for sticking together or cementing the garbage body 12 with the extreme and/or the Deekscheibe temperatures of up to 320 are permissible °C, it is favourable, if into the Verbinso dung zone one prevails approx. to 100 °C not exceeding temperature. This can be reached by the structure of disk package shown comfortably. An extreme thermal load at the Scheibenpaket Aufìoau can be moderated thereby being reflected the bowl ground screen end disk on the inside ss, whereby a large Teli of the radiant heat can weden reflected. Air between the disks of the structure of package and the disks form a so good Wärrnedämmung for convection warmth that also with extreme operation conditions at the outermost disk a not substantially higher temperature than to the Tfiraussenfläche besteht.

s 1 sheet designs F'ig. 1 11 24 22 1 Fig.2 11 11 33 32 F, G. 4 26 20 ' 3 39,1 40 41 &2 Rg.6 39 34,1 Rg. /l --37 34 36 633,413 1 sheet The oven door with a door body of a multi-part insulation layer structure (1, 2, 3) contains an inspection window unit (4) which is provided with a plurality of individual parallel glass panes (12.1, 14 - 17) arranged thermally in series in the direction of looking through. The inspection window unit (4) contains a shell-shaped envelope body (12) of glass, in which the said glass panes are contained, and is sealed gas-tight by a cover pane (17) cemented into the edge of the shell wall. The door body has an internal air circulation channel (20), whose air inlet and outlet slots (23, 24) are located in front of the front side of the oven and which is arranged in the door body in such a way that a free cooling air draught is passed into the region of the junction between the envelope body and the said covering pane. The inspection window unit is elastically suspended in the door body. <IMAGE>