Set of parts, which can be assembled like a kit, to produce a clamping connection between a hose or a pressure-medium line and a connecting stub

The invention concerns a sentence yon component system-like build upable parts for the production of a compression joint between a hose or an argument line and a Ansehlussstutzen, e.g. a Geniuses, or zwisehen Schlfiuehen or argument lines among themselves, to Web ehem purpose a slit Klemmhiilse for the admission of the end of the Sehlauches or the argument line and on these adjustable Klemrnring to the Festklernmen or - stretch the put in Leitungsoder of hose end zusammenwirken.

There is well-known different kinds of Verbindungsstiicken fiir DruckmittelIeitungen, which for connecting in particular flexible argument lines with Geniusen yon to Verbrauehern such as actuators, with valve-go iusen or to connecting yon Druekmittelleitungen among themselves to serve. This Verbindungsstiicke already is starting from factory fiir a certain employment intended, e.g. as Verbindungsstiicke between a Schlauehleitung and a threaded connection of a Gehtiuses, when 90°-Kriimmer for connecting two argument lines, when T-Sttick seems to etc. in practice it when assembling from Druekmittelleitungssystemen that the mechanic at the assembly place has still Verbindungsstiicke a kind, but no more VerbindungsstiJcke of the other kind vorr tig. This can do on it zuriickzufiihren to be that he provided himself in the workshop not sufficiently with appropriate Verbindungsstticken of this kind, abet also on it that only at the assembly place a gtinstigere kind animal shifting of the argument lines showed up, which the use of other types yon Verbindungssttieken makes necessary. The procurement of the necessary Verbindungsstficke from the assembly place is usually connected with high zus itzlichen costs. If one gives turned around a very grossziigig measured supply of Verbindungsstiicken of jegIicher kind to each mechanic, then the storekeeping is substantially more complicated and teurer.

The invention placed itself more demgegeniiber the task to be created a sentence yon component system-well-behaved-build upable parts be manufactured with its assistance compression joints practically fiir all conditions of practice k6nnen and when very einfaeher food confining in tigers production the parts a conceivably simple and time-saving assembly gew ihrleistet.

For the above-mentioned purpose it is in accordance with eats the invention during the new arrangement intended that he ilt the following parts enth: a MehrzahI yon different Str6mungswege of the Druekmittels giving GrundkiSrpern, niimlich an axial Verbindungsstfick, bend-tick and a T-stack, which Grundk6rper exhibits a first rest means in each case at least at an end of the Strfmungswege, and at least the Klemmhtille and the locking ring containing Klemmk6rper, which exhibits with the first rest means co-operating second rest means and into the end one containing the first RastmitteI the zugeh6rigen Grundk6rper is removable einsteekbar in each case that bases are made nnd Klemmk6rper of plastic material dureh syringes and that the Grundk6rper at the junction points to the Klemmk6rpern in the light press fit in them in-sitting sealing rings aufweisen.

By the available invention is created from there a component system for production yon Verbindungsstficken untersehiedlicher kind, which predominantly standardised parts enthral, which become in all types yon Verbindungsstticken ben6tigt, and in addition only some few type-specific parts aufweist.

From these latter parts the mechanic the most diverse also in gr6sserer number can rnitnehmen, and the mechanic can plug then at the place of work those together ben6tigten types in each case yon Verbindungsstiicken raseh. The structure is simple, the HerstelIung is kostengiinstig, one can itself here all requirements of practice anpassen.

Favourable further educations of the invention are in abhiingigen Anspriiehen angegeben.

Below the invention is more niiher erliiutert on the basis yon Ausfiihrungsbeispielen with reference to the enclosed design. In this show:

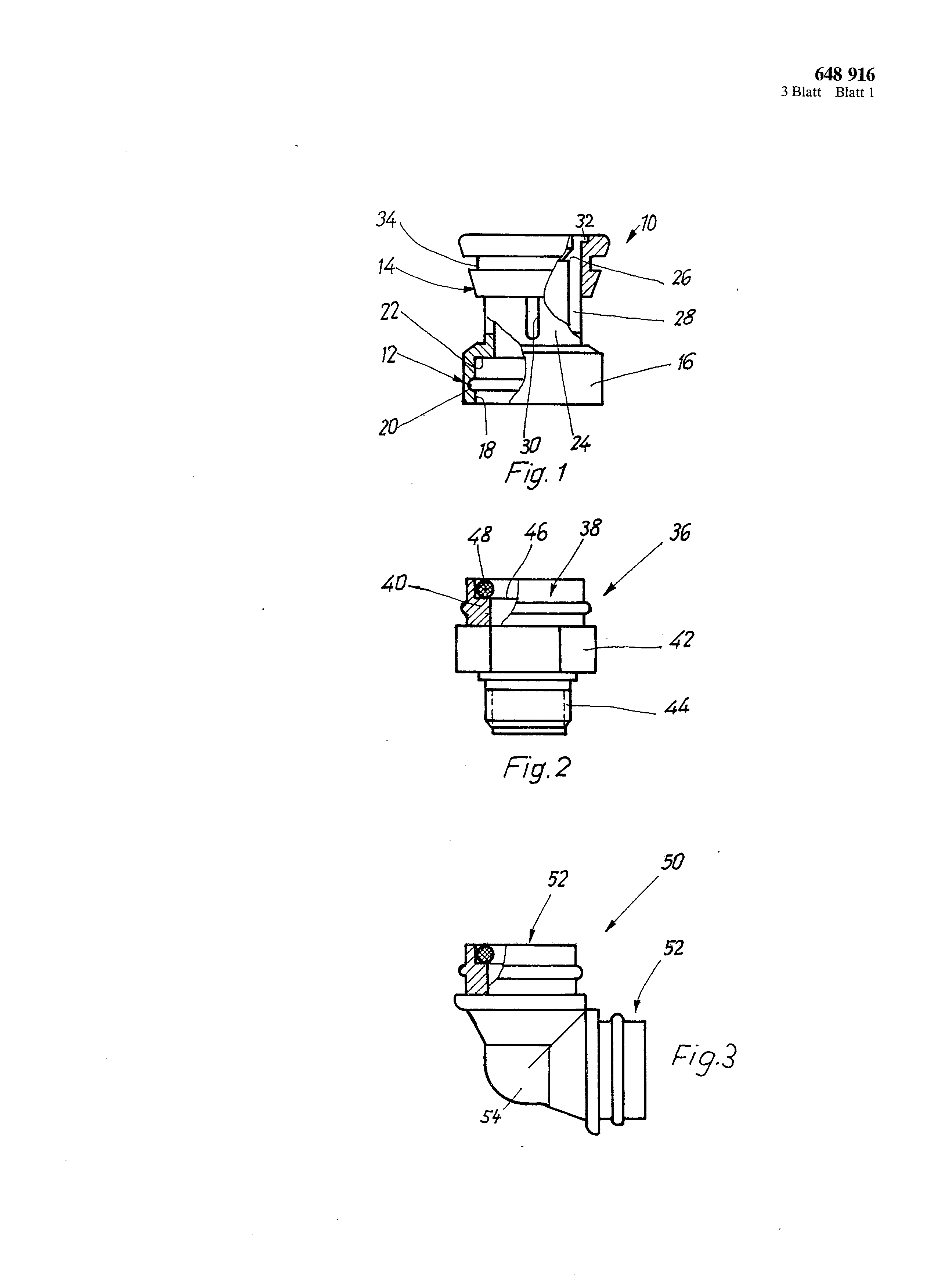

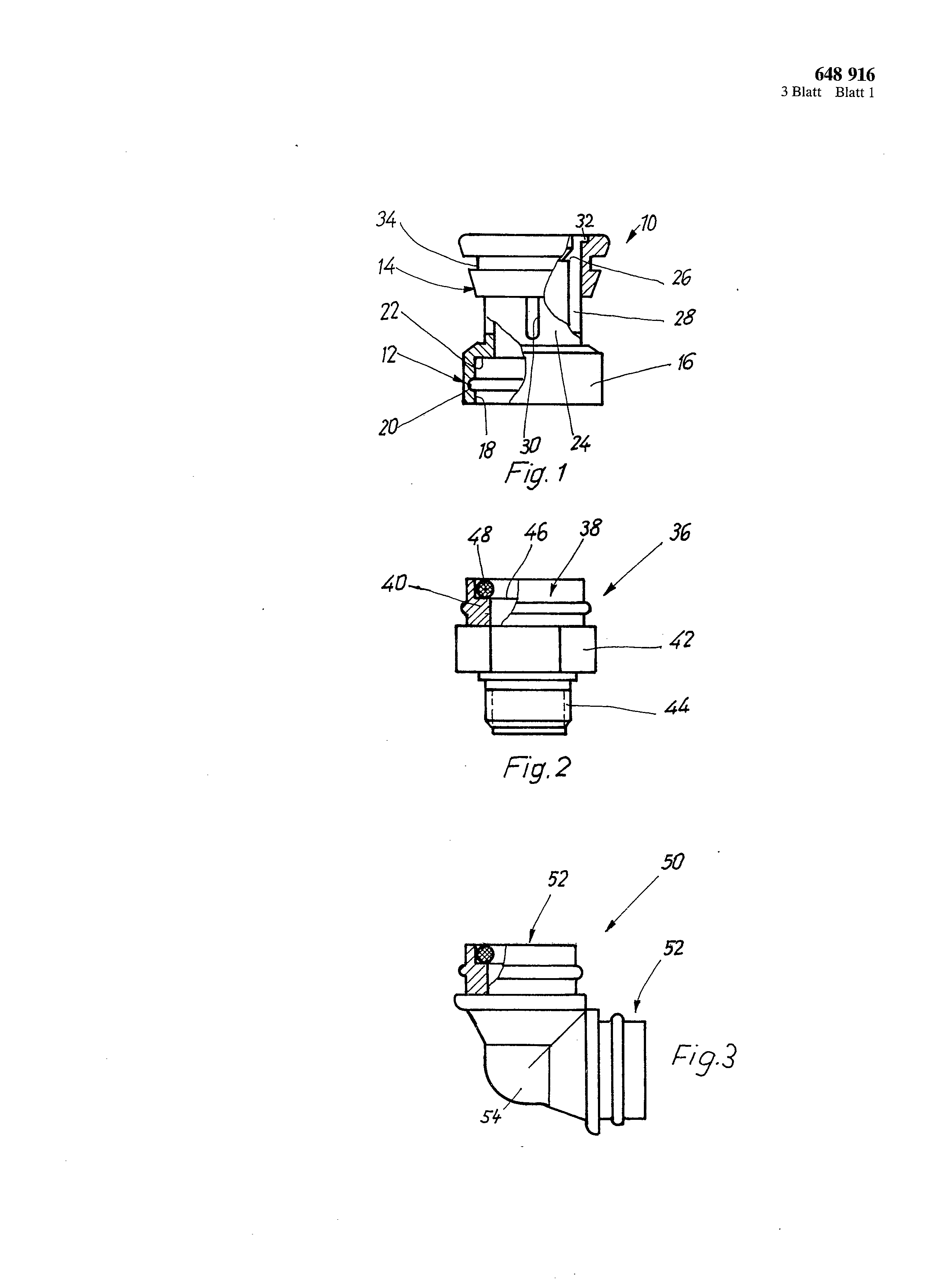

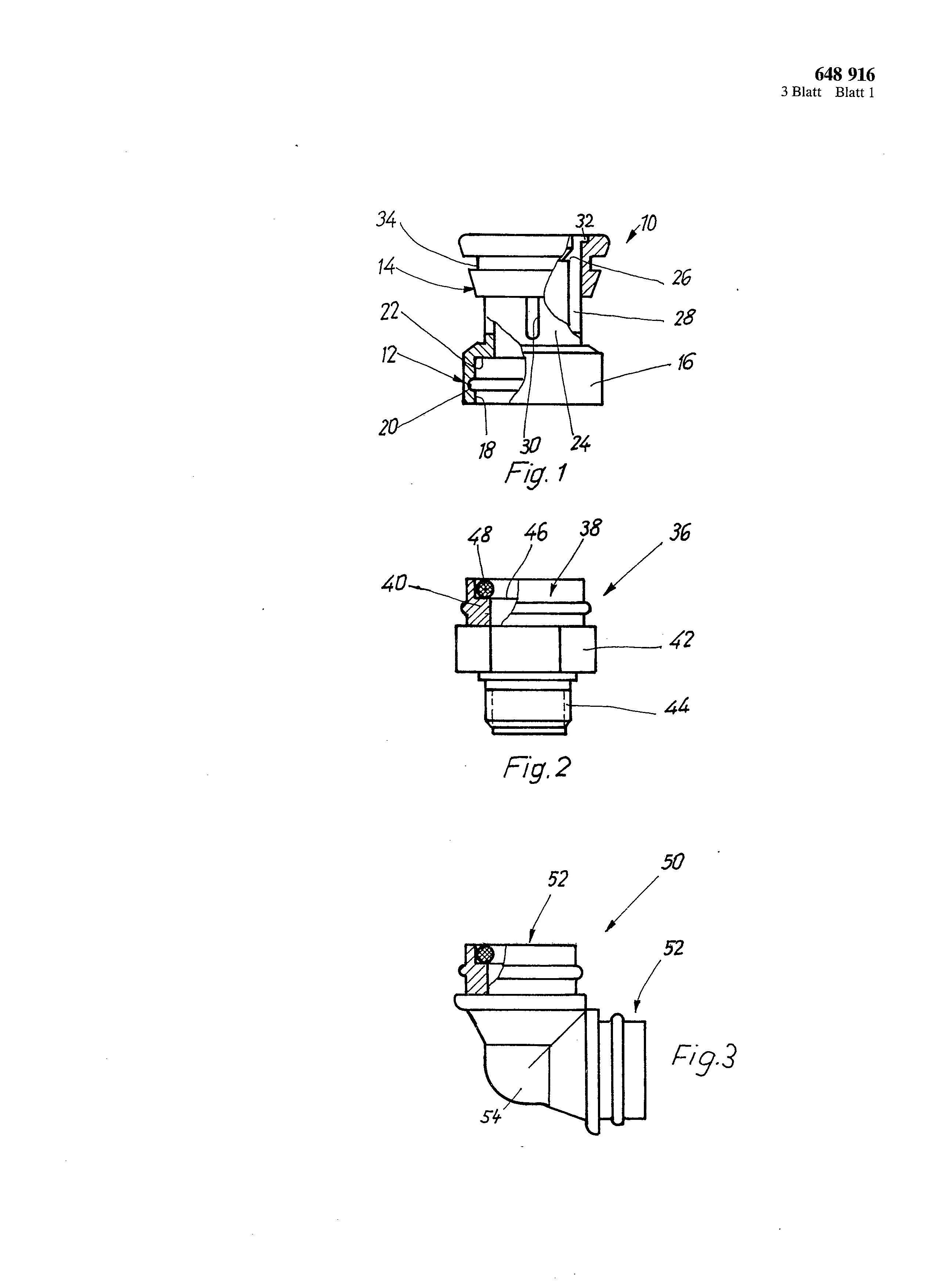

Fig. I a lateral opinion of a Standardklemmk6rpers of a component system to the HersteIlung of versehiedener types yon Verbindungsstiicken f/Jr argument lines, partly on average; Fig. 2 a lateral opinion of a Grundk6rpers, partly on average, which rnit together a KIemmk6rper after Fig. 1 a Obergangsstiick yon an argument hose on a threaded connection erNbt; Fig. 3 one would since-borrow opinion of a further Grundk6rpers, partly on average, more weleher together with two Klemmk6rpern after Fig. I a 90°-Krfimmer for the connection of two Druckmittelschliiuehe results in; Fig. 4 a lateral opinion of a further Grundk6rpers, teiIweise on average, for production yon T-Verbindungsstiicken; 3,648,916 Fig. 5 a T-Verbindungsstfick, which from a Grundk6rper after Fig. 4 and 3 Klemmk6rper after Fig. 1 is manufactured; Fig. 6 an axial cut by a modified Standardklemmk6rper.

Fig. 1 shows one altogether with 10 designated Klemmk6rper, consisting of a Klemmhfilse 12 squirted from plastic and on this adjustable, likewise locking ring 14.<br squirted from plastic/>

The Klemmhfilse 12 has a connecting section 16 with a recess 18. The extent wall of the latters is provided with I0 of a stop notch 20. The ground of the recess 18 forms a sealing shoulder 22. The connecting section a clamping section 24 follows 16, which with sfigezahnf6rmigen clamping ribs of 26 provided springy clamping arms 28 aufweist.

Between the latters lie axial slots 30, which often to from the connecting section 16 abliegende end of the clamping section 24 lain are. A radial BuM 32 interrupted with this end more lying, likewise by the slots 30 in circumferential direction forms an attack fiir the locking ring 14 in axial Auswfirtsrichtung.

The locking ring 14 is provided with a groove 34 running in circumferential direction, which attacking and verse blows erleichtert.

To the establishment of an argument hose in the Klemmk6rper the locking ring 14 is induced to the end of the Sehlitze 30, and the hose is pushed under expansion of the clamping arms 28 into the clamping section 24, so world that it lies with its free Stirnflfiche in one level, which essentially zusammenffillt with the Stirnflfiche of the connecting section 16. In this way a sealing a0 of the Aussenfl iche of the argument hose is obtained then at the same time by an O-ring poetry, how is described further down still more exactly. Now the locking ring becomes 14 again in Fig. 1 SteUung shown zuriickbewegt, whereby he drfickt the clamping arms 28 again radially inward, so that the clamping ribs 26 read against the exterior of the argument hose rest and these unverfiickbar in the Klemmk6rper 10 festlegen.

The recess 18 serves k6rper 36 for the connection of the Klemmk6rpers with different Verbindungsstfick-Grundk6rpern, like it limited argument channel outward abgedichtet.

Now into the Klemmk6rper 10 if an argument hose is slid in such a way, as was already described further above this, then the Aussenflfiche of the argument hose comes at the same time into plant to the inside of the O-ring 48 and becomes in such a way abgedichtet.

Fig. 3 shows a 90°-Krtimmer representing, likewise Grundk6rper squirted from plastic 50, which exhibits two connecting sections 52, the two just as trained are as in detail above the descriptive connecting section 38 of the Grundk6rpers 36. Between the two connecting sections 52 a Krfimmerabschnitt 54 lies. On the two connecting sections 52 k6nnen two Klemmk6rper after Fig. 1 to be pressed on, in which Dmckmittelschlfiuche in the way str6mungsmitteldicht descriptive already above are then specified to k6nnen. The Druckmittelsehlfiuche is then right-angled with one another verbunden.

Fig. 4 points a further Grundk6rper 56 to manufacturing a T-Verbindungsstficks. This likewise from plastic squirted Grundk6rper 56 has three connecting sections 58, which are just as trained as the connecting section 38 of the Grundk6rpers 36 described above, and this basic T-section 60. The latter is zusfitzlich provided with two angeformten Traghfilsen 62, which in each case a through-hole 64 for the admission of a Befesfigungsmittels begrenzen.

Fig. 5 shows T-Verbindungsstfick 66, which of a component system, which was made enthiilt Klemmk6rper 10 and Grundk6rper 36, 50 and 56, by the fact that one pressed 56 three clamping bodies 10 on a Grundk6rper. Furthermore one recognizes a thread Verbindungsstfick 67, which from the same component system using a Grundk6rpers 36 and a Klemmk6rpers 10 is plugged together. From these few examples it is already evident that one using a component system, which Klemmk6rper 10 and Grundk6rper can manufacture 36, 50 and 56 as well as iihnliche ausgebUdete further Grundk6rper fiir other Anwendungsffille enthral, in very simple way a multiplicity of different Verbindungsstficke still at the place of work on the basis of the few types of different standard construction units, which without fiberh6hte now below with reference to the Fig. 2 to 4 beschrie4o costs contained in sufficient Zahlim component system its ben werden.

In Fig. 2 shown, altogether with 36 characteristic and from plastic-squirted Grundkfrper serves for manufacturing such Verbindungsstfickes, with an argument hose to a threaded Anschluss6ffnung to be attached kann.

The Grundk6rper 36 has a connecting section 38 with a rest rib 40, which fits exactly into the recess 18 of the Klemrnk6rpers 10, a hexagonal section 42 for setting a Sehraubenschlfissels and a thread section 44, s0 of which into the threaded Anschlussfffnung passt.

The connecting section 38 has a Gegenbohrung 46, in which an O-ring 48 in-sits in more easily tight fit, so that it also in the condition of the Grundk6rpers 36 captive in this, not installed yet, held ist.

If one puts the connecting section on 16 of the Klemmk6rpers under Kraffanwendung on the connecting section 38 of the Grundk6rpers 36, then the rest rib 40 rests reads in into the stop notch 20, and the O-ring 48 rests against the sealing shoulder 22. In this way is at the same time with the production of the mechanical connections also by Klemmk6rper the 10 and Grundk6nnen.

Fig. a modified Klemmk6rper 10 ', its connecting section 16 shows 6 is just as trained as above-mentioned with reference to Fig. lffir the Klemmk6rper already one described. The connecting section now a Gewindeabsehnitt 68 the Klemmhiilse 12 follows 16 ', and to him the Klemrnarme 28 angeformt with the clamping ribs 26 is. The Aussenfl iche of the clamping arms 28 is now however trained as the ffeien end of the Klemrnhfilse 12 ' in the diameter removing easily k gelf6rmig, as with 70 gezeigt.

A modified locking ring 14 ' has a thread section 72 running on the thread section 68 and with the Aussenfliiche 70 of the clamping arms 28 co-operating conical clamping section 74.

In Fig. 6 Klemmk6rper shown 10 ' works completely fihnlich like the Klemmk6rper 10 after Fig. 1, only effolgt axial shifting of the locking ring 14 ' by bolting on the thread section 68 the Klemmhfilse 12 ', w it-ends this axial movement with the KIemmk6rper 10 directly by shifting the locking ring to be durchgeffihrt kann.

M 3 sheet designs 648,916 3 sheet sheet 1 22 16 ':

32 /0 28 58 57 IIIll A plurality of basic bodies (36, 50, 56) are provided in this kit, namely an axial connecting piece (36), an angle piece (50) and a correspondingly constructed T-piece, which basic bodies (36, 50, 56) prescribe different flow paths for the pressure medium and each have a first latching means (40) at at least one end of the flow paths. The kit furthermore has a clamping sleeve (12) and a clamping body (10) which contains a clamping ring (14) and has second latching means (20), which interact with the first latching means (40) and into which that end of in each case one of the associated basic bodies which contains the first latching means can be removably inserted. The basic bodies and clamping bodies are produced from plastic material by injection moulding. At the junction points to the clamping bodies (10), the basic bodies (36, 50, 56) have sealing rings (48) which are seated in them with a slight push fit. <IMAGE> ILS identically and to each other are complementary trained scblussverbindung to be manufactured are. The task of the invention is it to remedy these disadvantages and a Anschlussverbindungseinhcit/a u