Control device for industrial machine

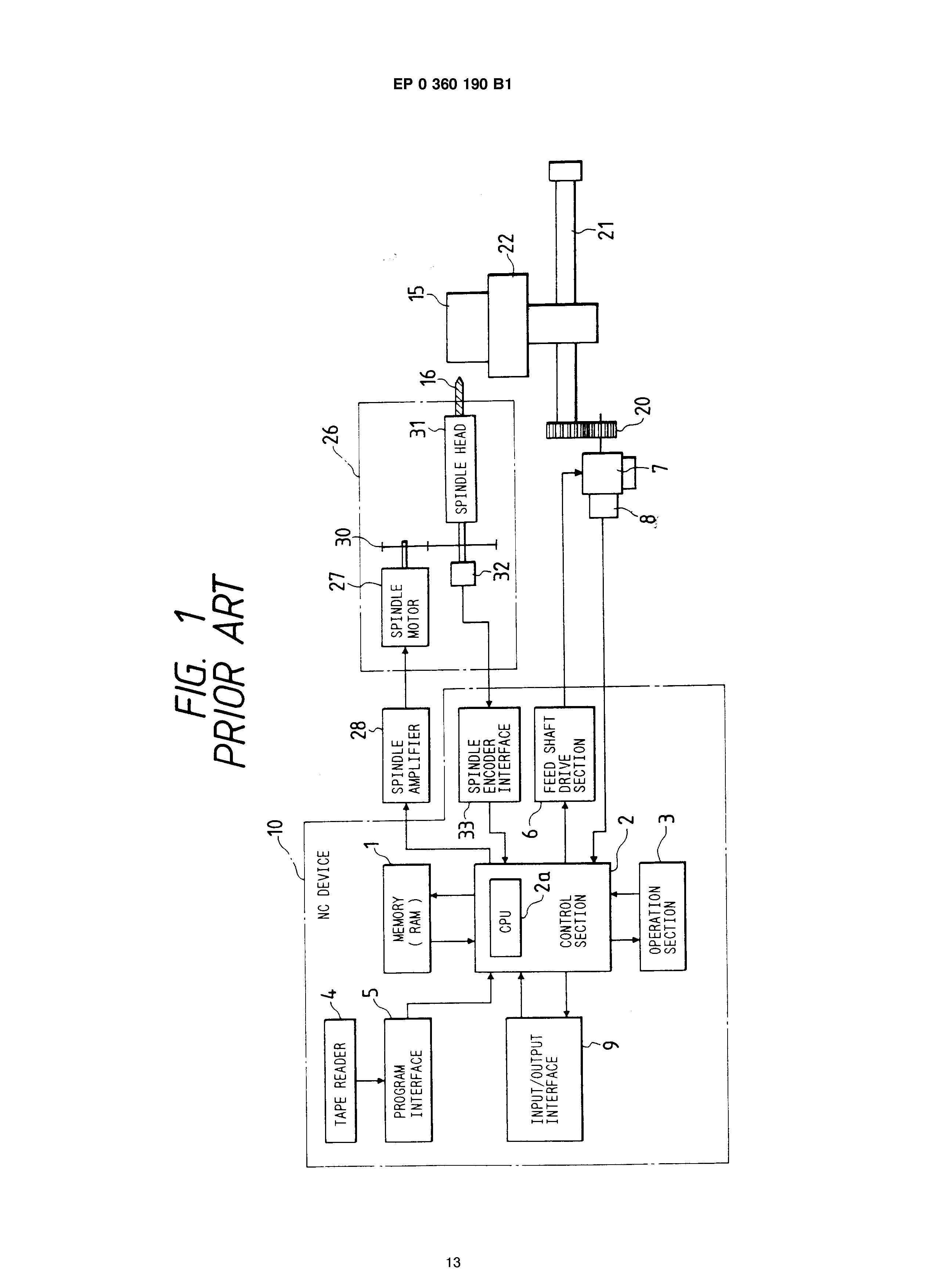

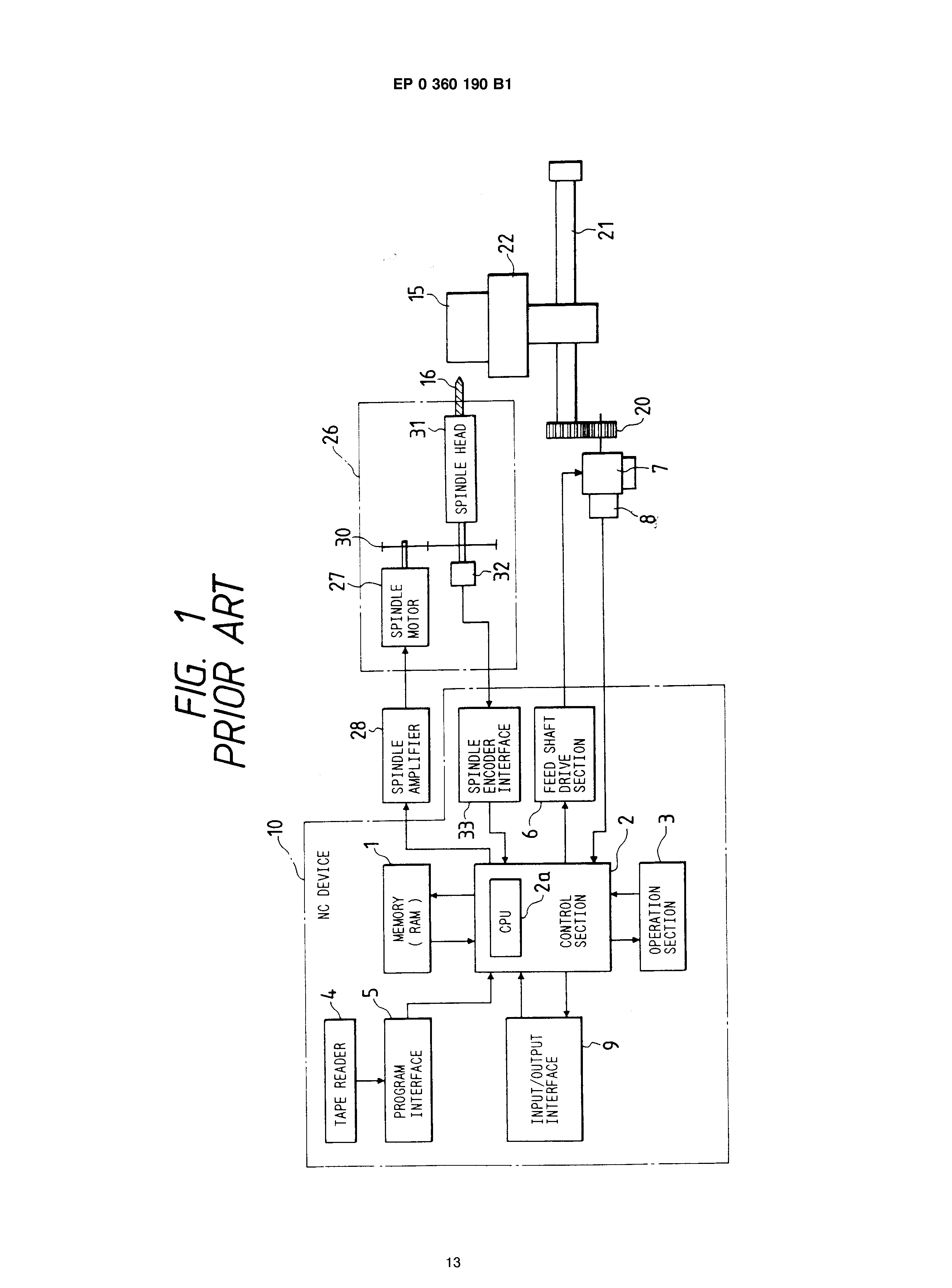

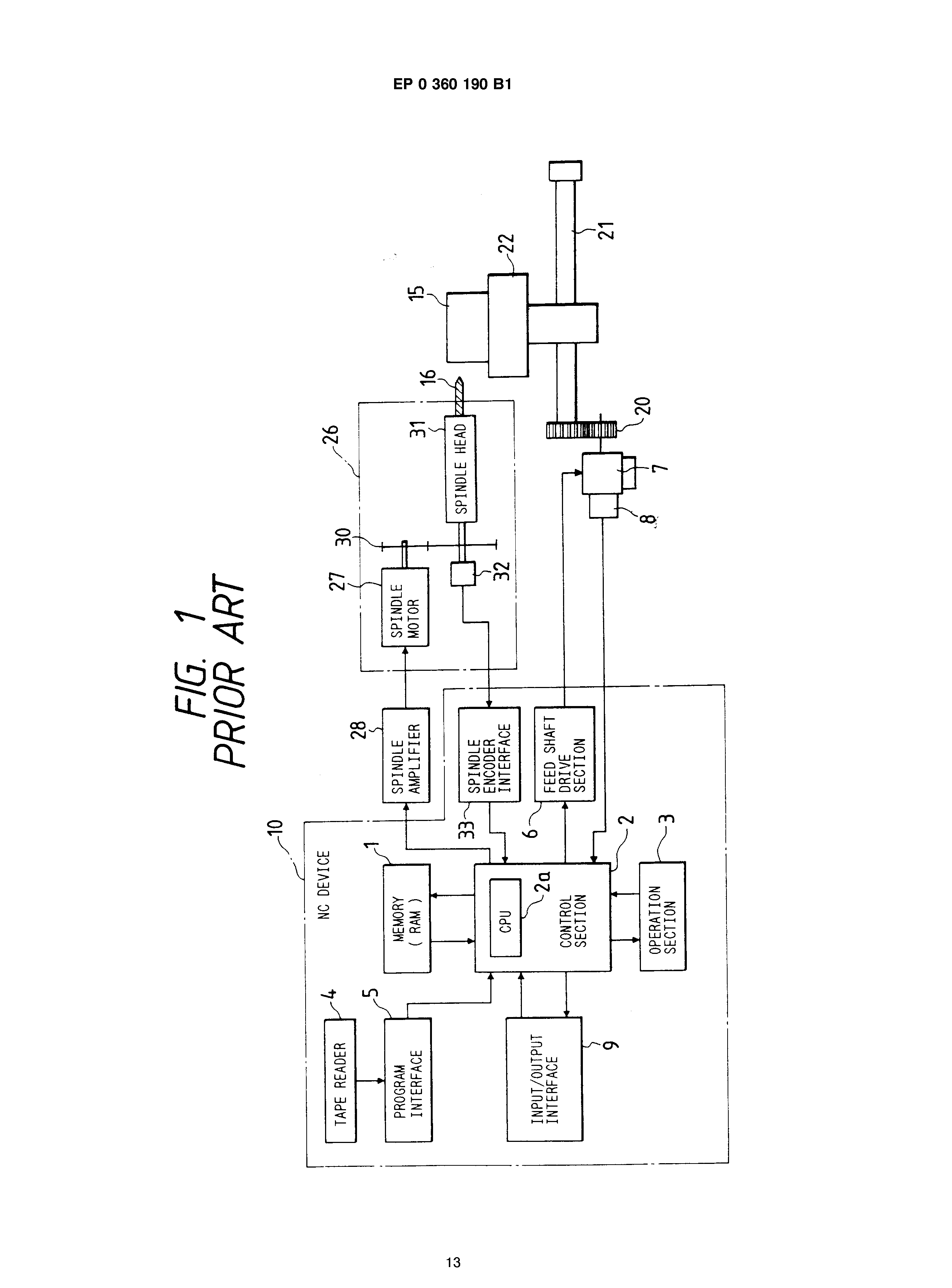

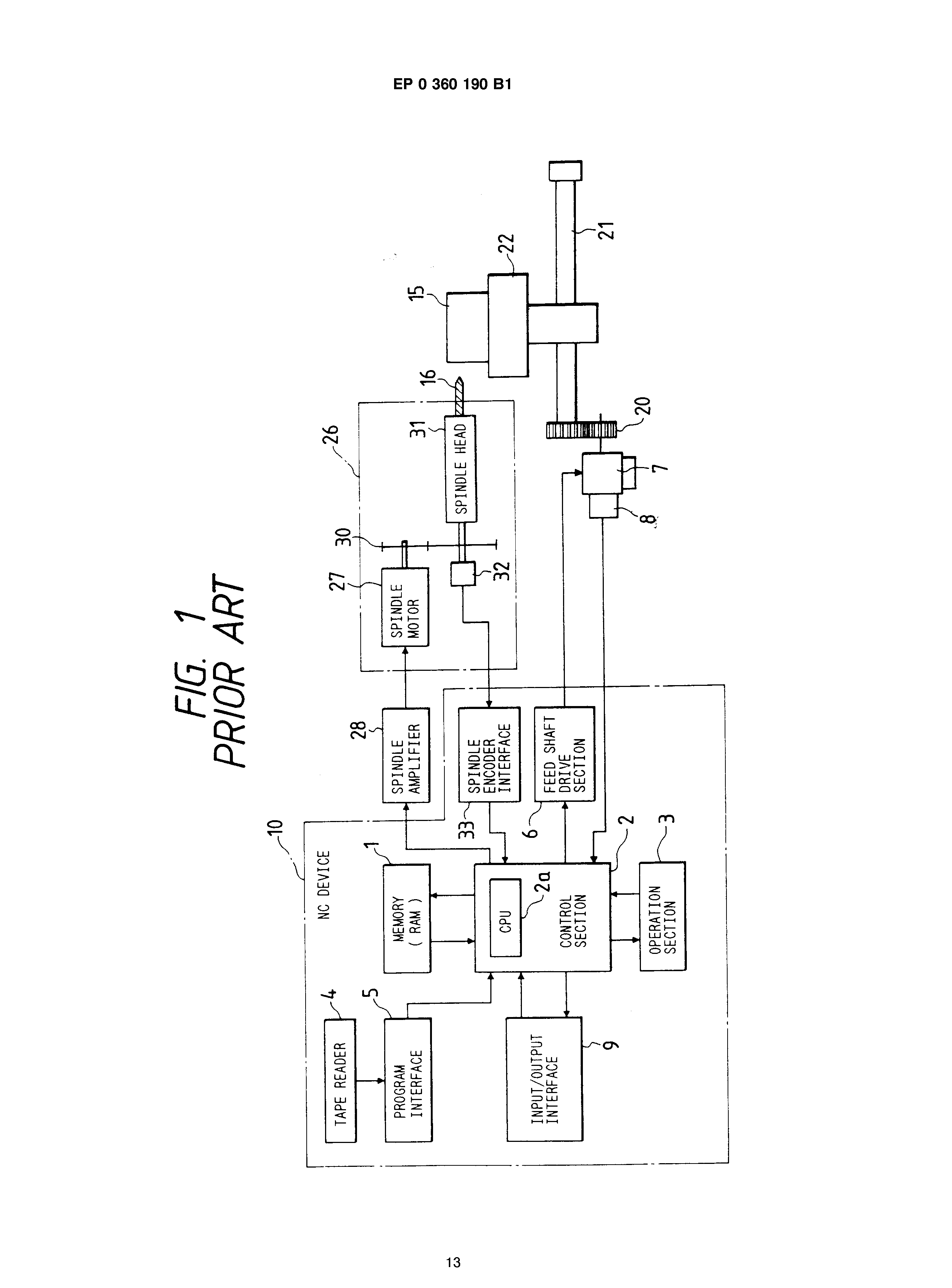

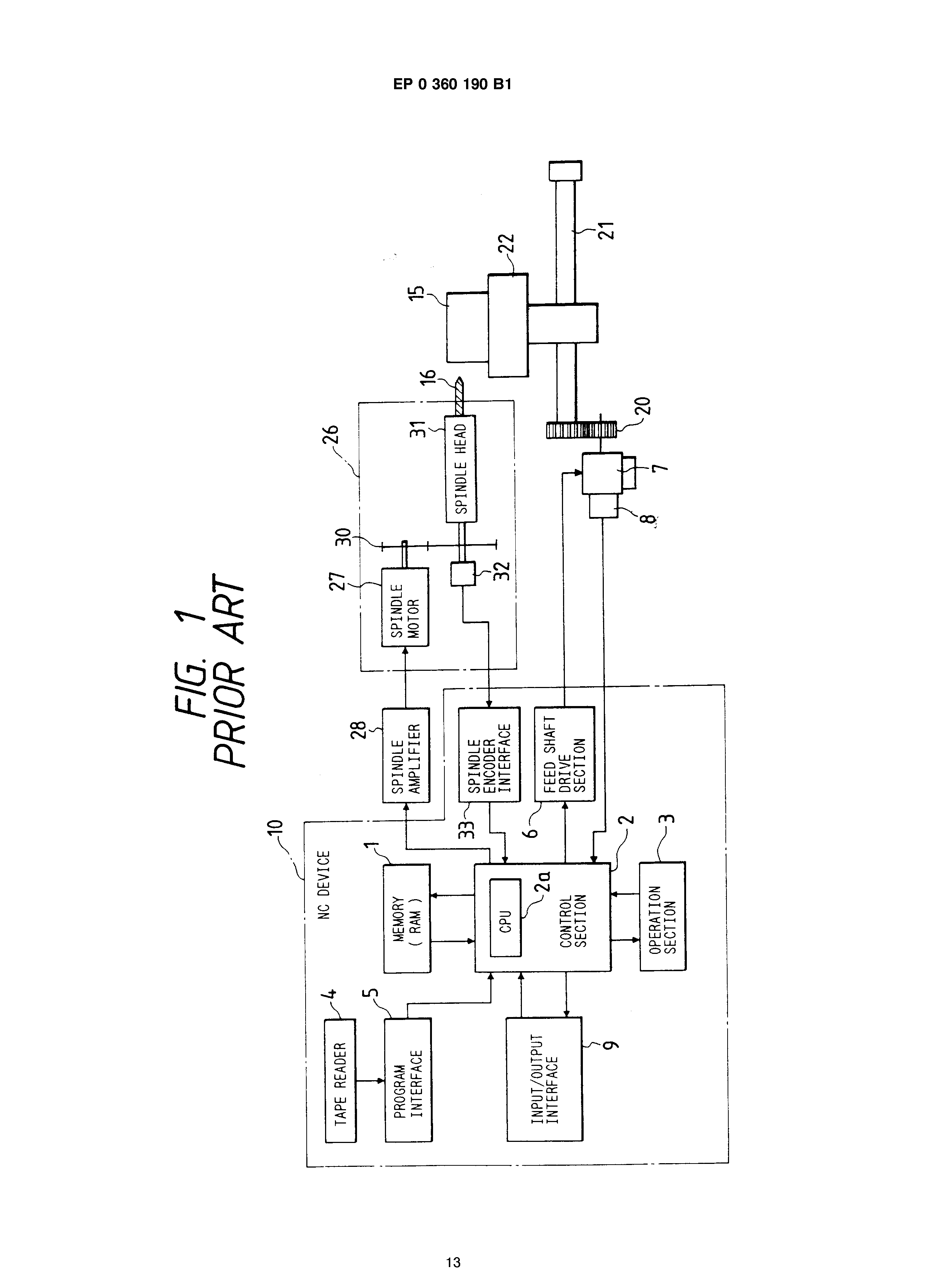

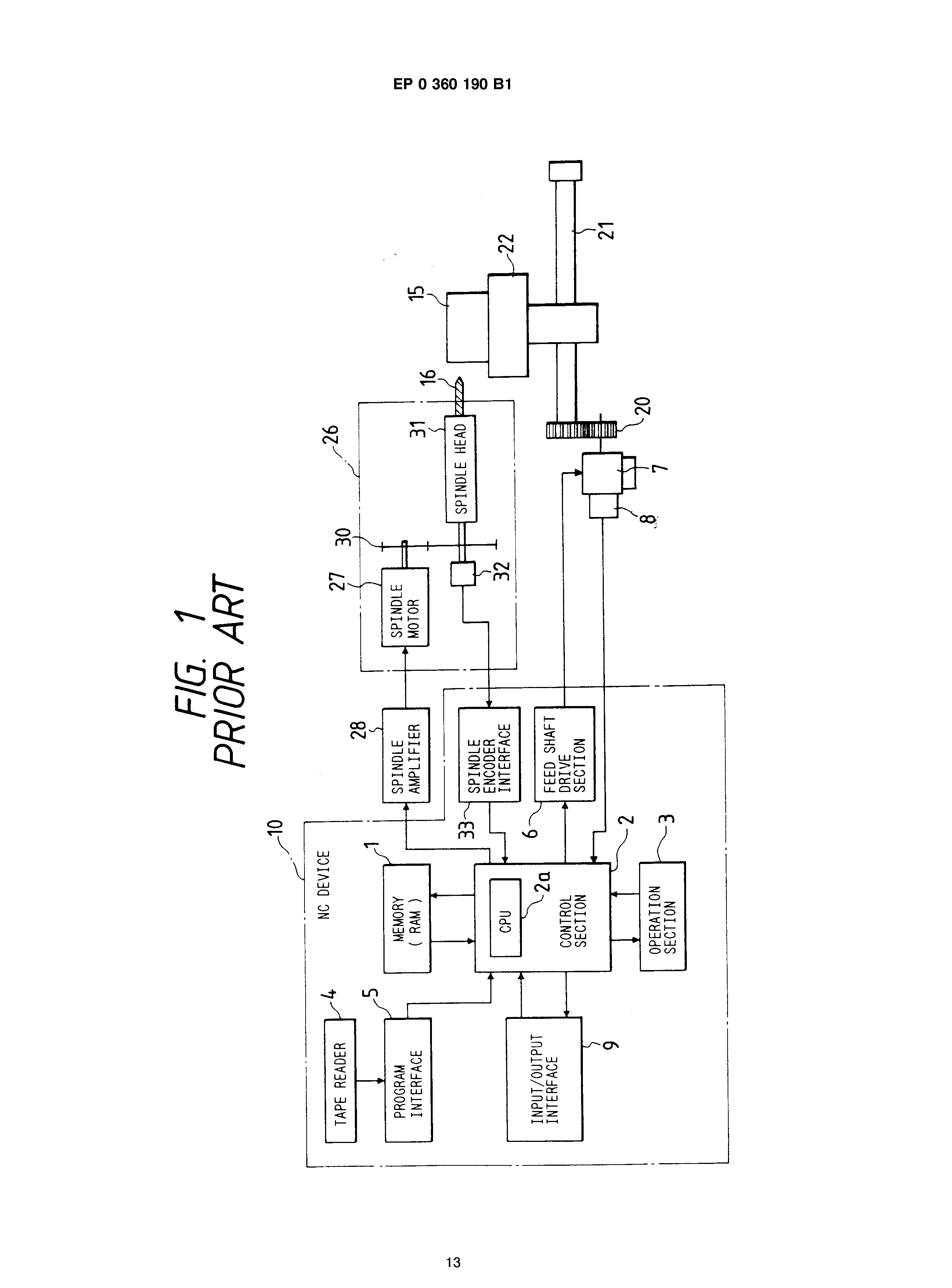

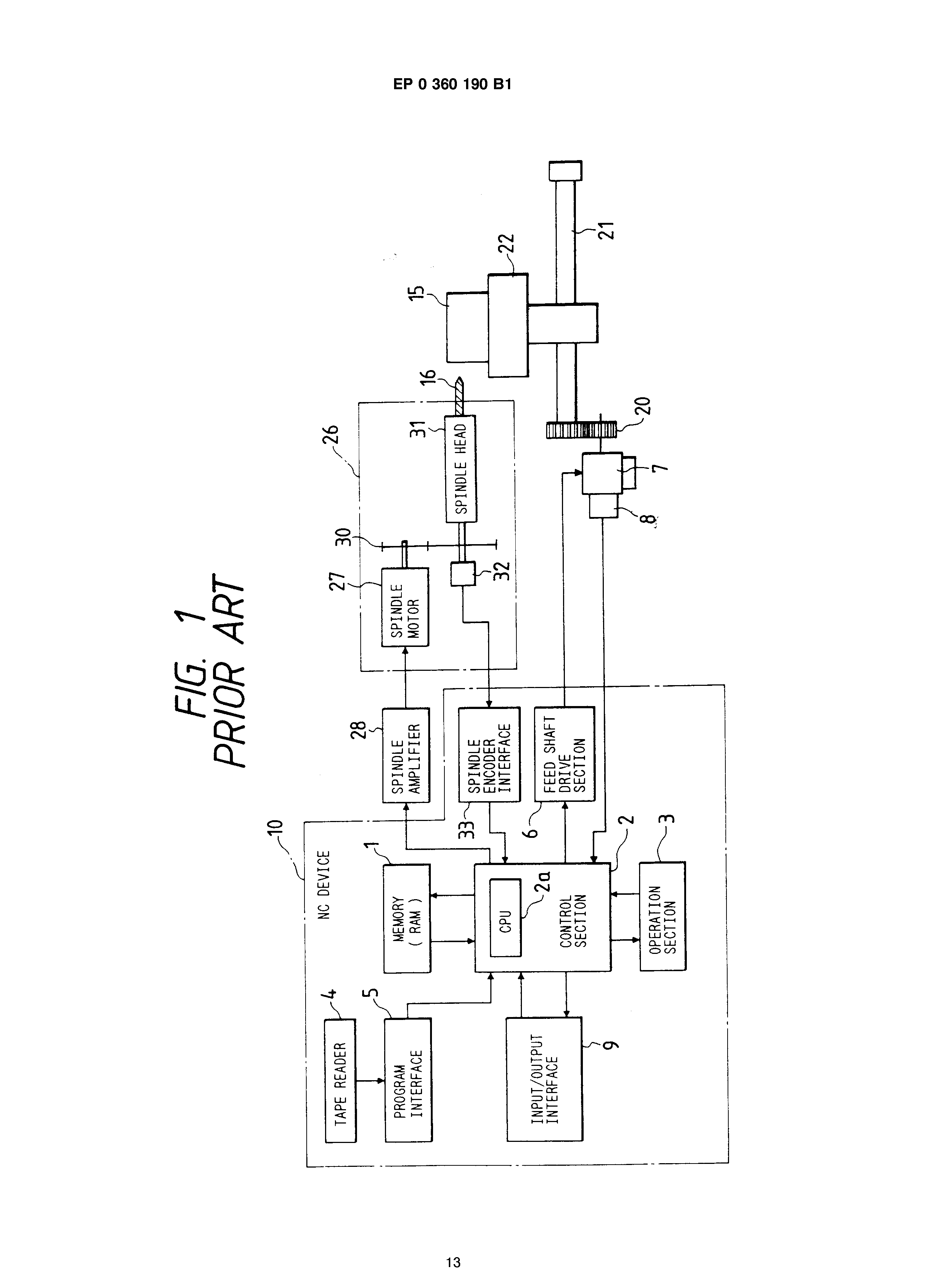

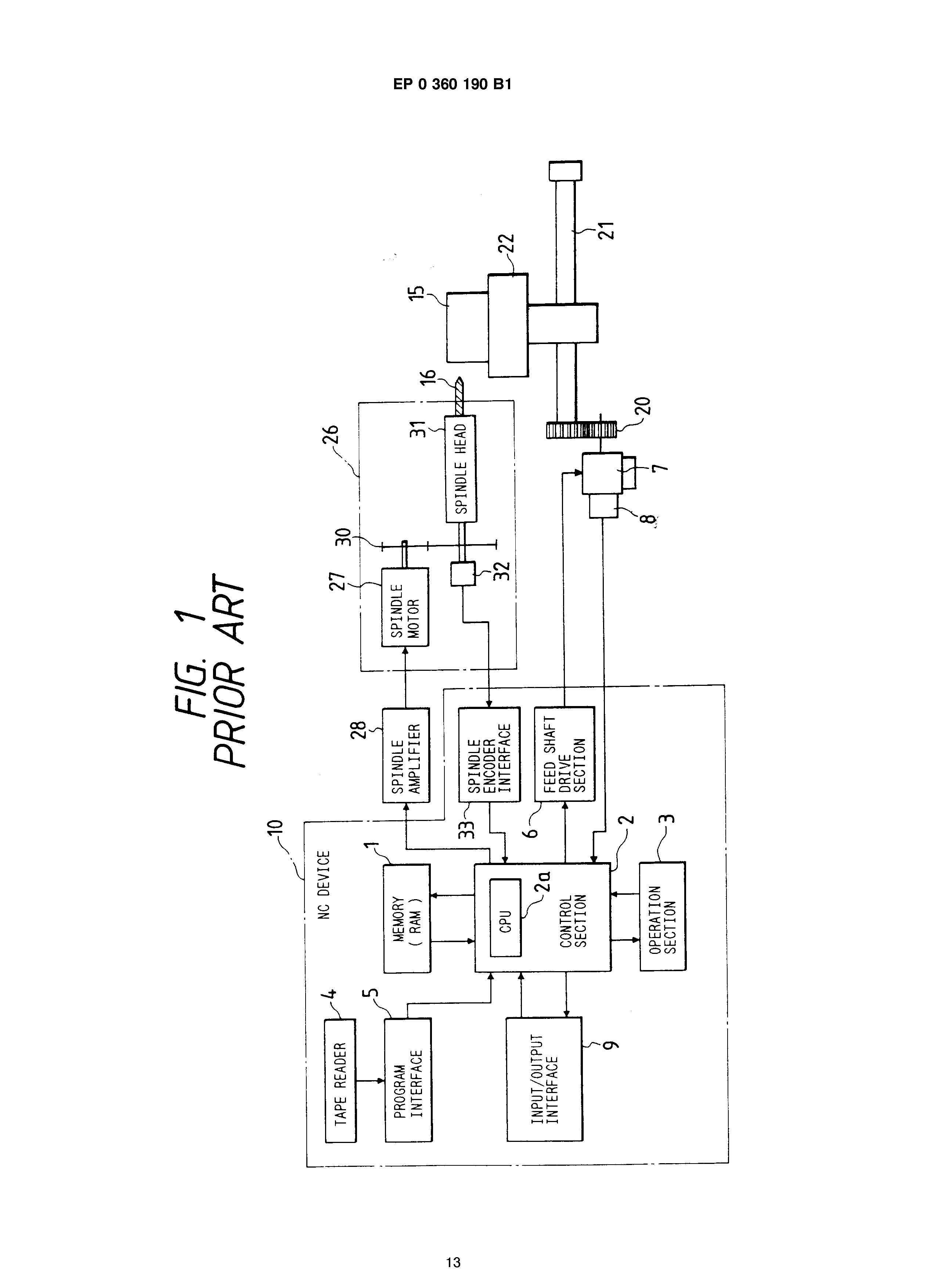

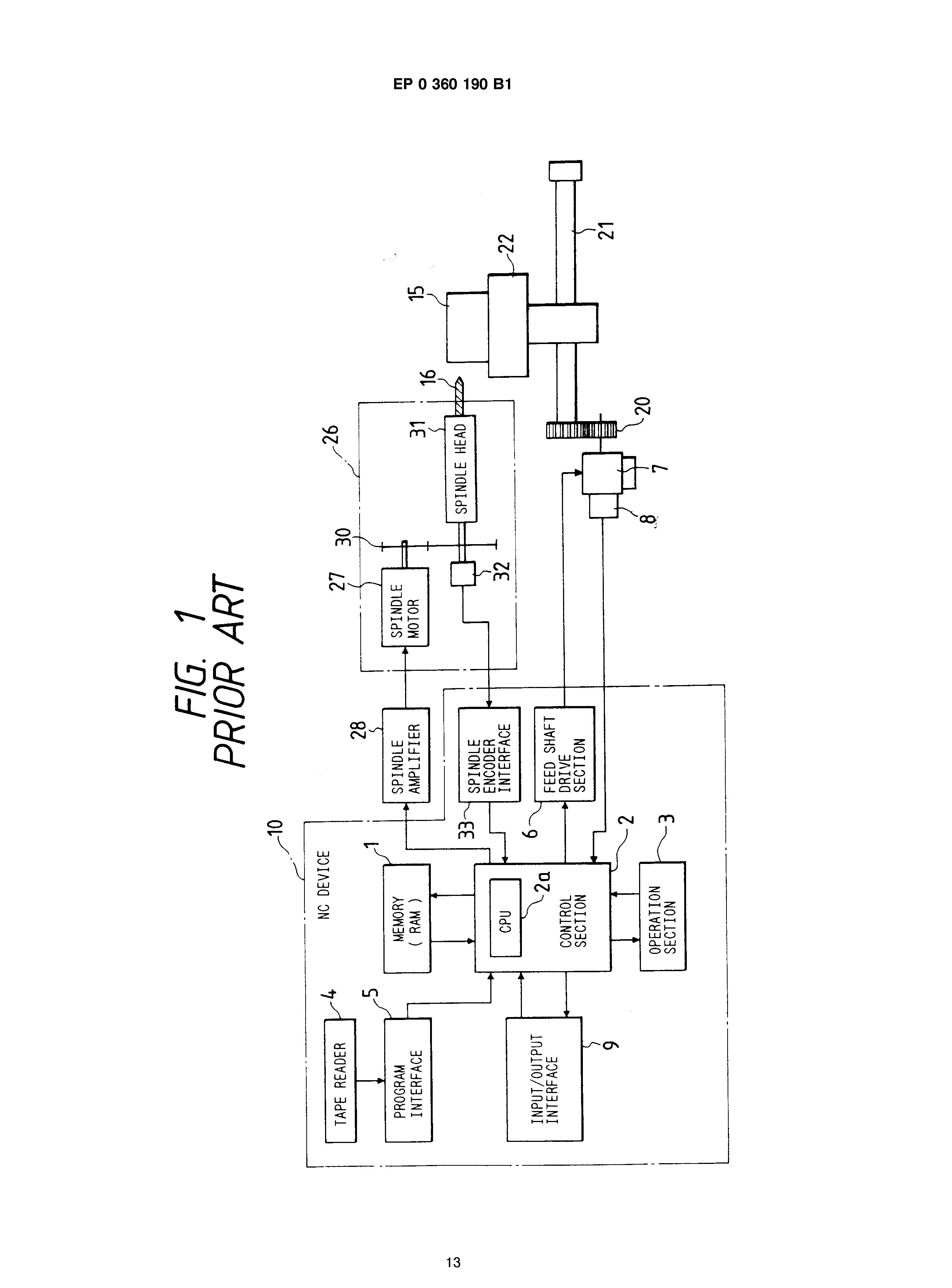

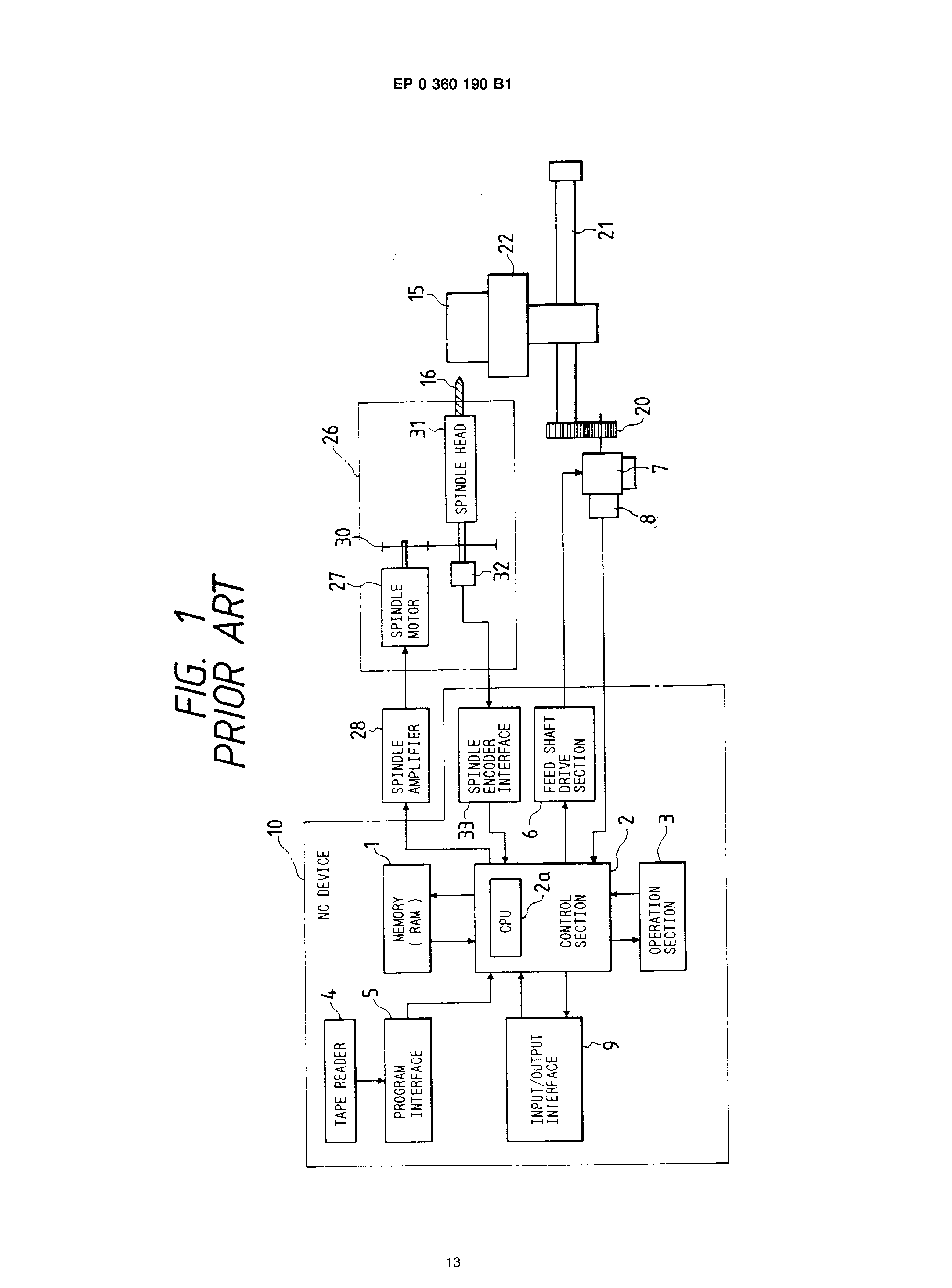

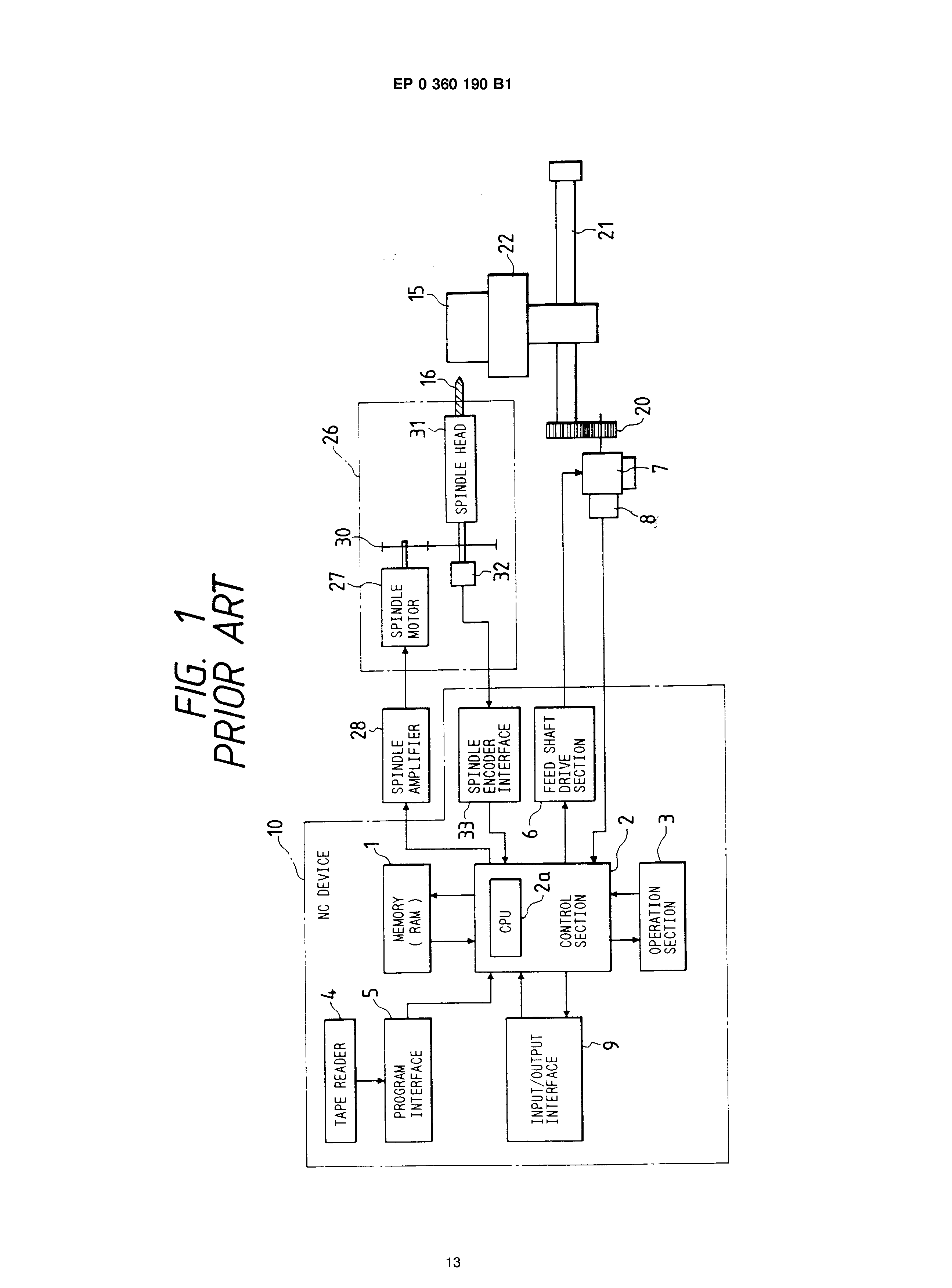

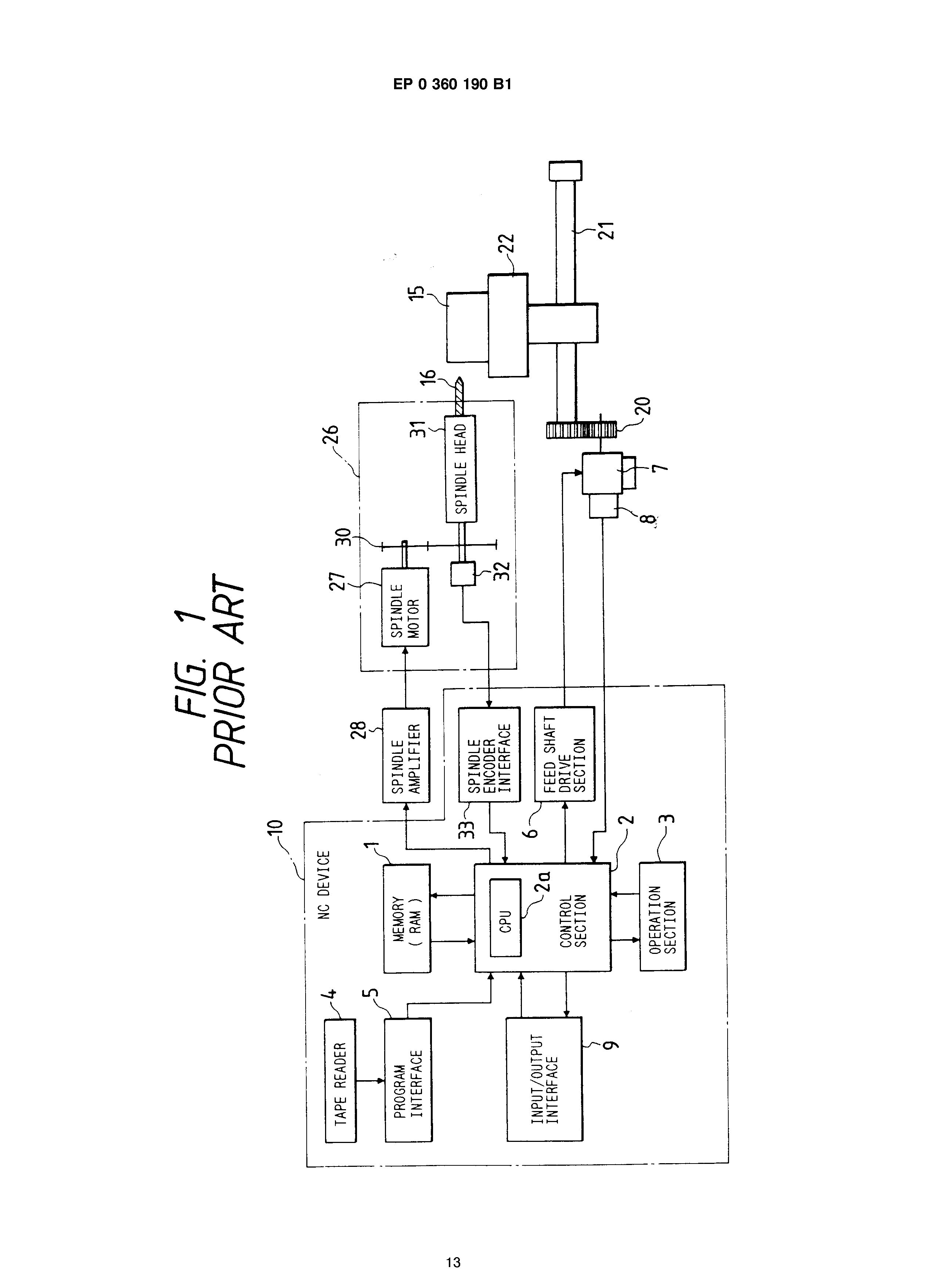

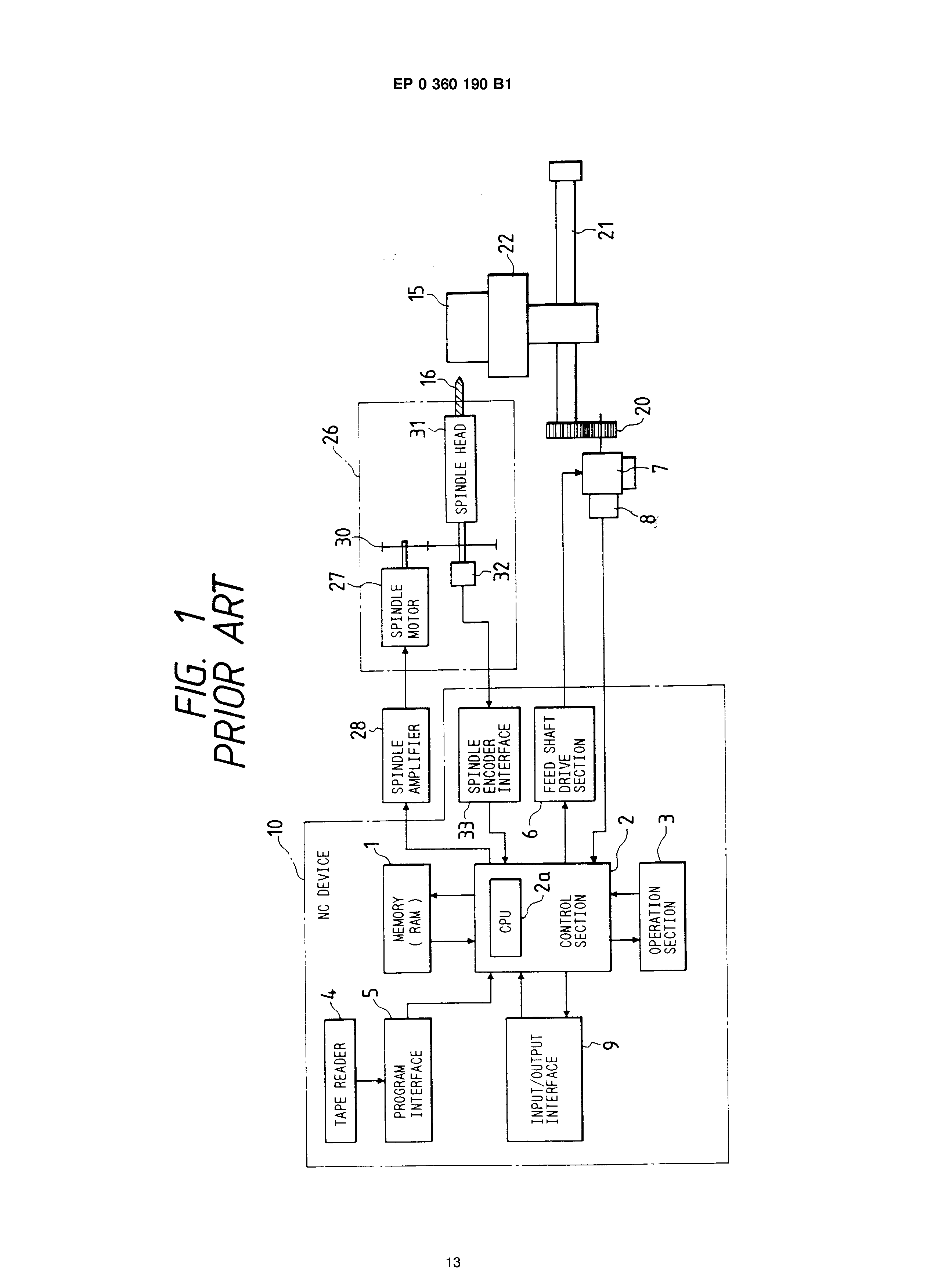

A control device for an industrial machine comprising a numerical control device (10), said numerical control device comprising:

a data processing section (2) comprising a memory (1) and a central processing unit (2a), for analyzing and operating input numerical data, outputs of said data processing section being used for performing numerical control of a machine to be controlled and of rotation of a spindle (31) of said machine;

characterized by further comprising a programmable controller (130);

a gear ratio data memory (12a) for storing gear ratio data of gear means (30) through which a spindle motor (27) is coupled to a spindle head (31) holding a tool (16), said gear ratio data either being applied to said gear ratio data memory through a bus (35) from said programmable controller which is adapted to perform sequence control of said machine, or being stored in said gear ratio data memory for different tools in advance, and being selected according to the tool number specified by a machining program,

and synchronous operation control means for calculating actual speed of rotation of said tool through operation using said gear ratio data and a feedback signal of said spindle motor (27), and performing synchronous operation control of said tool (16) and a feed shaft (7,8).