실리콘 재질의 도금 마스크 및 그 제조방법

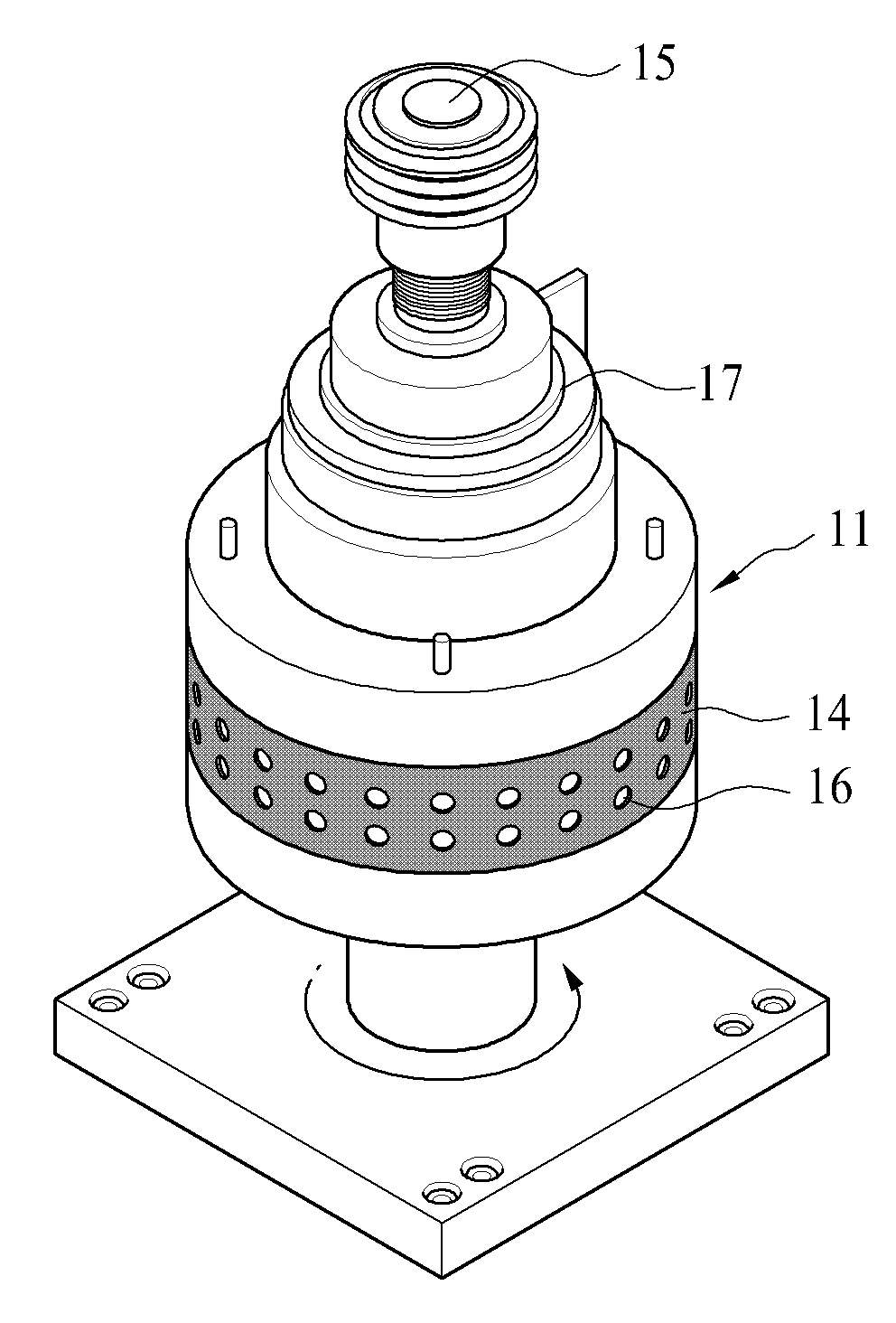

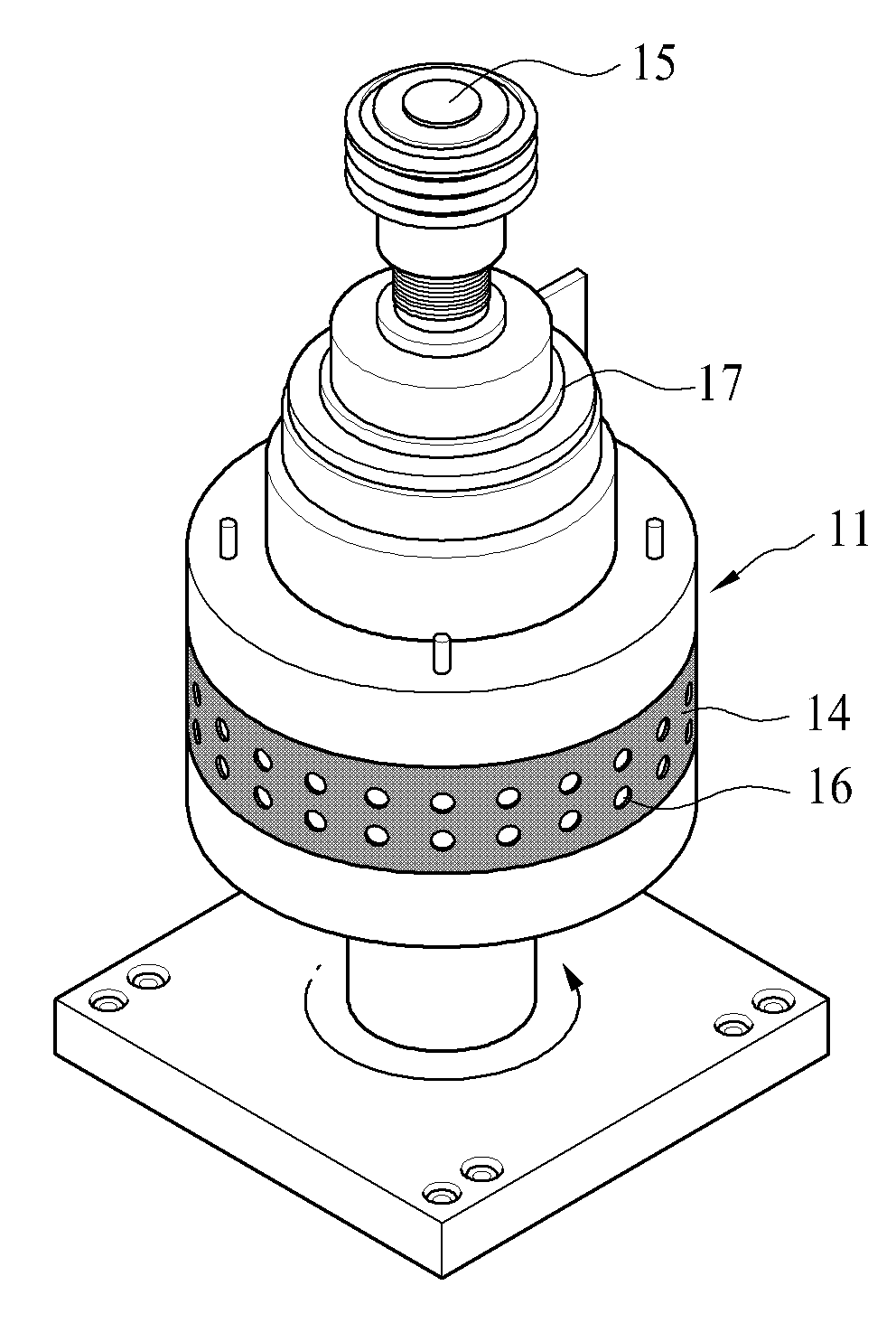

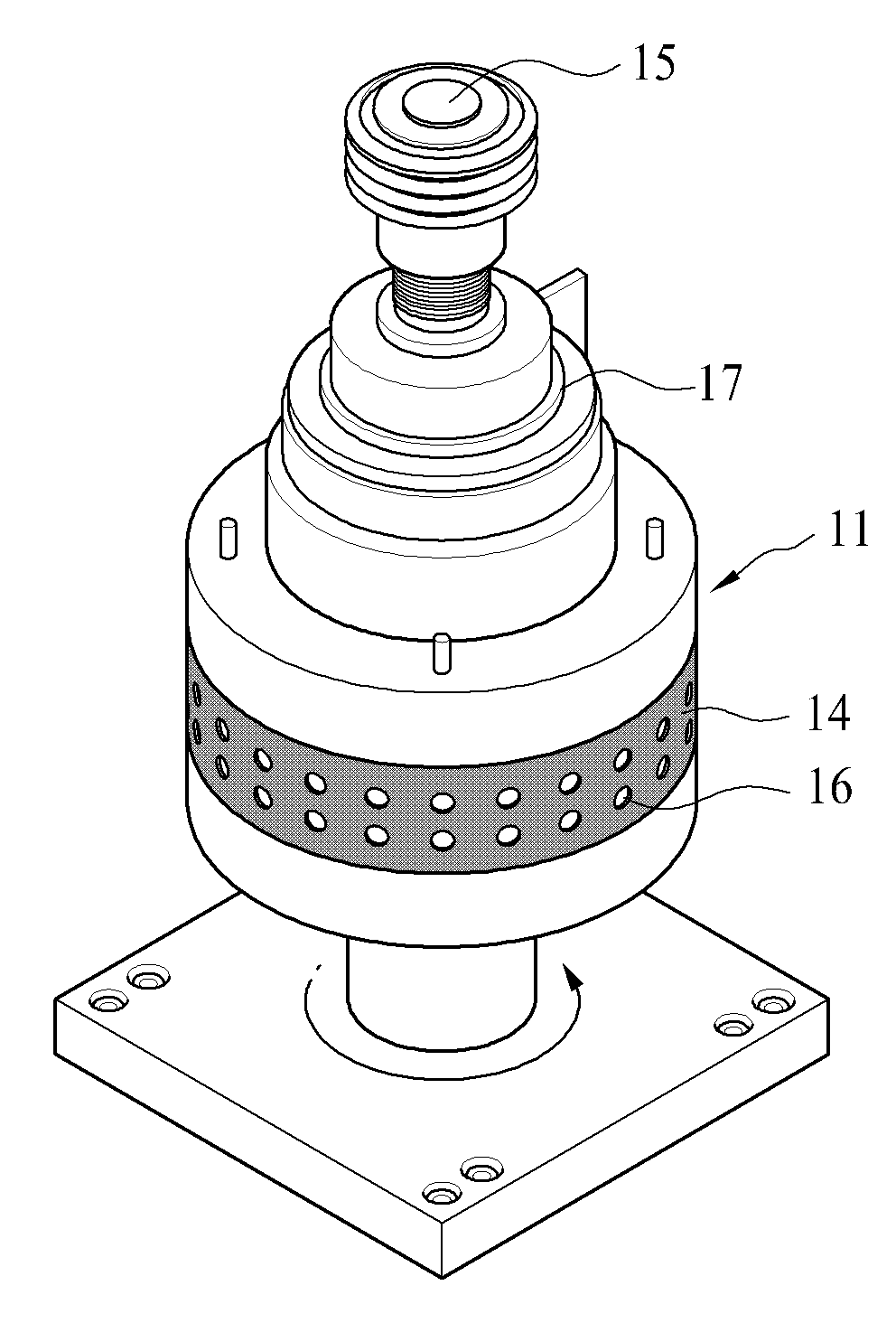

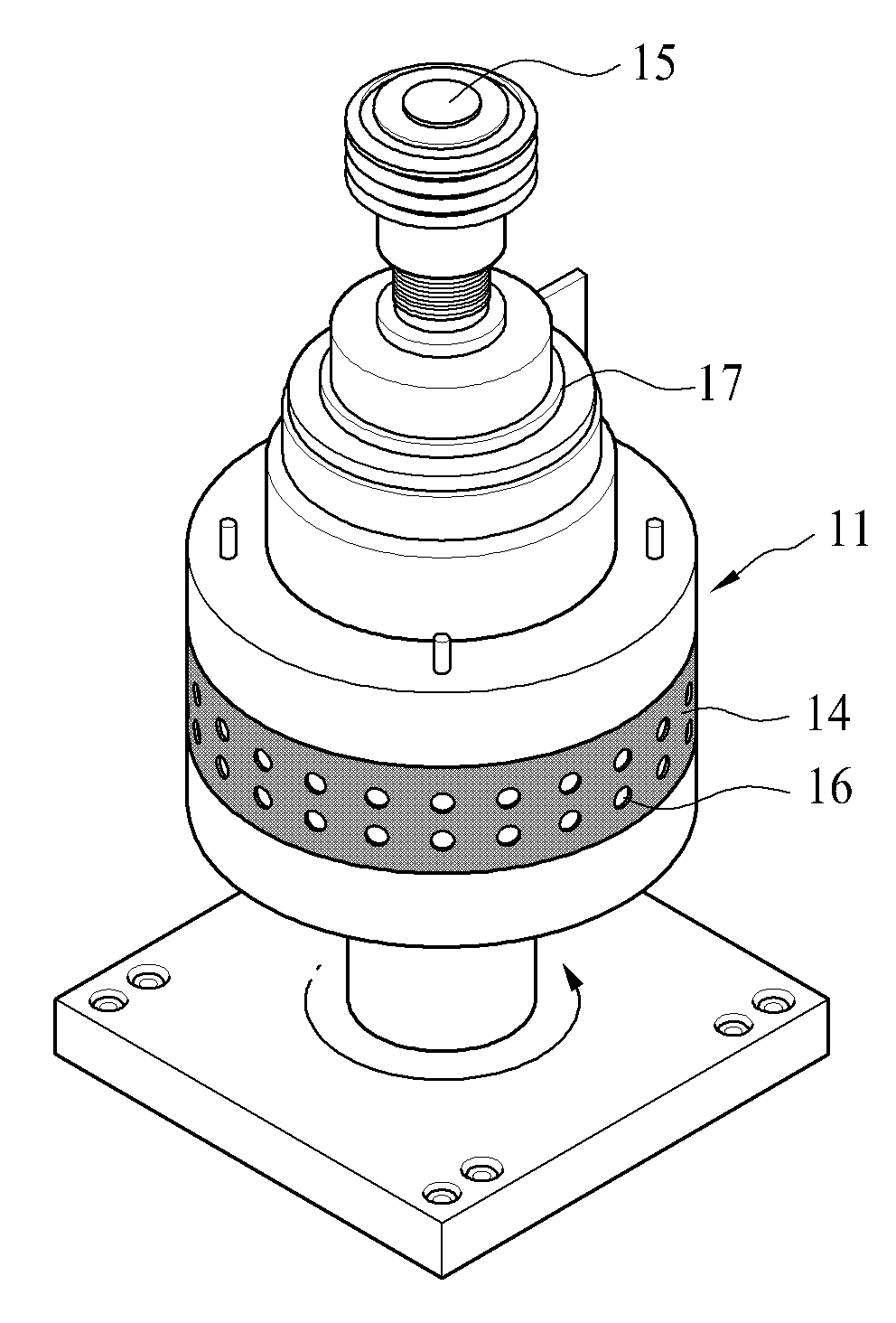

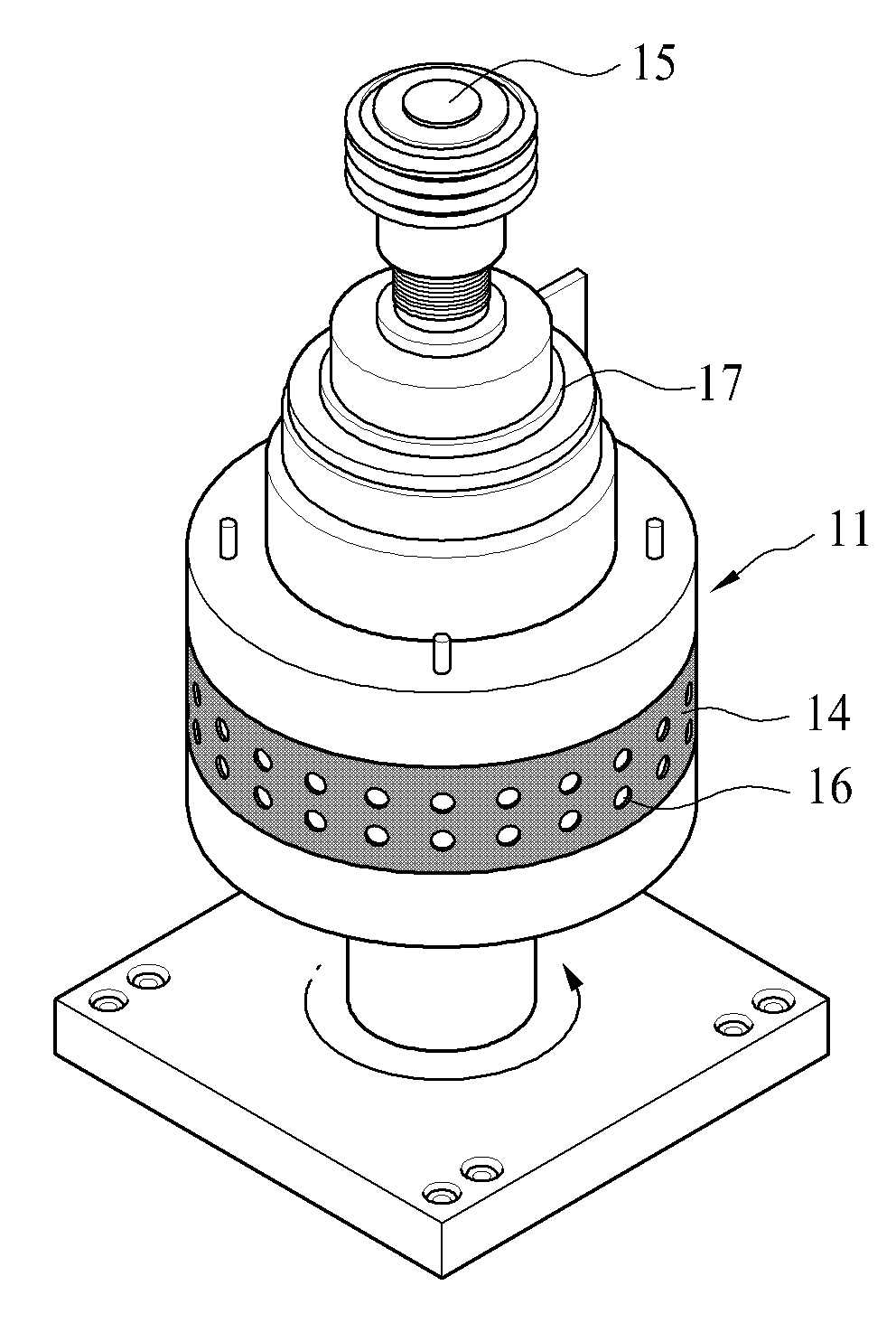

The present invention refers to a plating mask and manufacturing method relates to search silicon, more particularly plate-like band-like injection ends after combination by using high pressure liquid coolant picked number number larger than the size and cost savings to the convenience of silicon to a plating mask and manufacturing method are disclosed. Metal plating is generally prevent the corrosion of the object, as carried out improve the decorative appearance, etc. electroplating or electroless plating. Wherein, electroplating is possible in a thin layer in the surface of the object using the principle of method and other metal covering, external electroless plating metal salt aqueous solution supplied electrical energy from the magnetic force of the metal ions reduction number without catalytic reduction method the metal treated solids are disclosed. Metal plating is mainly used for the decoration of the existing method in color only one side of a stage, not simply decoration as well is received rocket industrial, engine and information communication, electronic machinery parts like industrial moving nodes etc. used. In particular metal plating in the gold plating has superior corrosion resistance and electrical resistance and reduced contact resistance soldering characteristics on because electronic component in an integral element are disclosed. By its very nature printed circuit board, connector, switch, such as a method for converting electrical method and apparatus for surface treatment is gold plating which it is highly important disclosed. In particular those components Cu and Cu alloy elements most material configured by aluminum and surface oxidation when exposed to air and pollution environment occur, repeated contact, electrical, discharge etc. discoloration, the gold plating to prevent corrosion deterioration etc. are used. The and gold plating is a method electroplating, electroless plating, substituted discharging fermented soybeans are used among the most used method continuously connecting the anode and convenience by the axial are disclosed. In addition recent performance of article number required field as the number corresponding to the height and complex plating metal increases the amount of metal has been. The increase number article to print out and use of expensive metal parts to avoid unnecessary parts prevails for selectively plating a metal for removing oxides from the voice portion plating technique keeps a 0.15 mm, unlike metal plating is adversely even if functional surface that is formed inside the surface need not be electrolessly plated plated surfaces separated in part by plating has been applied. It deposited (or partial soaking,) type method for producing partially plating portion, masking scheme, brush type, number [thu[thu] participle various method such as been used. Figure 1 shows a completed application number 10 - 2010 - 0135819 according to conventional injection device indicating the scene using the plating bath are disclosed. As shown in fig. 1, according to the prior art injection device has a rotating spraying unit partially plating (11) on, cylindrical drum (11) and plating contacts for (17) comprises. Said cylindrical drum (11) side and on the plating solution can be inserting port (15) contact with each other. Wherein, said drum (11) the upper drum, mask drum and lower drum can be composed. Said upper drum is cylindrically formed they are respectively the positively charged anode. In addition, the outer peripheral surface of one side of the upper drum is formed to engage with the drum consists of a plurality of combining or mask. To a front upper drum of said mask drum, such as cylindrically formed upper drum. It can be interlocked with the upper drum and output from the mask thus drum is preferably formed at the same diameter. On the other hand, said cylindrical drum (11) a plurality of outer holes (16) with a body section (14) with a plating mask silicon (10:1 also, reference 2 also) a semiconductor device is provided. Said silicon plating mask (10) is made gold body and separating the silicon coated to execute the concave cross and, plating mask hole formed in the silicon (16) mask plates simultaneously a plurality of hierarchies. The ends, as shown in also 1 and 2 also, according to the prior art silicon plating mask (10) has a circular tank where they form a number of, the high pressure liquid coolant picked number order silicon plating mask (10) consists of a circular drum-shaped mold for numerical control machine in addition number number of mold and mold itself becoming a dielectric layer increases in addition been increasing in number point at the Jim and feeding door. In particular, producing large mold at the time of each differs in size from the plating mask silicon then necessary number saves the cost of the circular EPDM door been measured number. The present invention refers to the above-described number point and number of the existing method for door is provided which involved, the present invention refers to a plating mask for silicon to silicon mirror production facility can be a plating mask and manufacturing method to the pin is a number under public affairs. In addition, the present invention refers to a plating mask formed of silicon along a horizontal direction to a convenient number trillion processes silicon under public affairs number pin is a plating mask and manufacturing method. Number number into one or more of the present invention and number are pipeline and not, another and number are not mentioned below may be clearly understand one skilled from the substrate are disclosed. In order to achieve said purposes, the present invention according to the plate-like body having a plating mask silicon shape in said body portion and a plurality rows and columns of a plurality of applying ceramic, said body including a ring-shaped unit is formed has a characterized ends. In addition, combining a plurality of said plate-like shape and are ceramic body a plurality through holes in a plurality of rows and columns, each of said plurality of body portion with one end coupled to the other side of the body part at the other in the form of a ring shape including characterized to the ends. In addition, the connection to said case both ends said body portion additionally includes a facing each other, with a portion of said engagement protrusions is one joint, said joint portion of said other connector arm coupling groove portions is characterized. In addition, the plating mask manufacturing method of forming a plating mask silicon silicon mold prepared by the number using a silicon compacts with a hot air drawn from said mold body number bath and a body section and said hot air-dried drying and hot air-dried process and a body portion joining the two end portions including a ring formed in combination characterized adhesive step. In addition, said hot air-dried step drying time 30 - 60 minutes, the greater drying temperature between 50 provided 150 °C characterized. Said manufacturing method of the present invention is a plating mask and the one in the embodiment according to such as silicon, high pressure liquid coolant in the form of number after a predetermined length of a plating mask silicon pitches, a plating mask of silicon body by coating applied to ring coupled ends injection device to be coated. Accordingly, generally not large mold drum on silicon mold number bath and plating mask production capacity to equal to or higher than cost is capable. In addition, injection mold even when various width number according to a plating mask silicon device appears to be working in an establishment and convenience softness results...copyright 2001. In addition, silicon with a plating mask on both ends of the joint, coupling protrusion and an engaging groove is desired and applied forces enriched forms i.e. increasing durability can be small number of plating mask silicon pattern is formed substrate. The effect of the invention mentioned above are not one number to effects, they can be referred to another effects not unambiguously to one skilled in the range of from the substrate may be understanding are disclosed. Figure 1 shows a plating mask is provided according to the conventional techniques the plating injection device indicating one form of silicon. Figure 2 shows a plating mask indicating silicon sensors mounted thereon according to the conventional technique. In the embodiment of the present invention also Figure 3 shows a plating mask indicating the one silicon material. In the embodiment of the present invention Figure 4 shows a schematic represents a number of plating bath the decoded signal to one silicon also mask order. Figure 5 shows a plating mask indicating one in the embodiment according to of the present invention also form a silicon coupled sensors mounted thereon. In the embodiment according to Figure 6 shows a plating mask plating device of the present invention also provided indicating valve for modifying the one silicon sensors mounted thereon. In the embodiment of the present invention also Figure 7 shows a plating mask indicating the other silicon material. The purpose of the invention of the present invention preferred embodiment hereinafter with reference to the attached drawing specifically can be realized through a browser substrate. The in in the embodiment described, the same code is used according to the same configuration are identical in name and description which additional dispensed the on-sensors other. First, products on the attached drawing to explain and functional configuration of the present invention preferred embodiment according to less than 1000. The attached drawing, in the embodiment of the present invention also Figure 3 shows a plating mask indicating the one made of silicon are disclosed. As shown in fig. 3, in the embodiment according to one of the present invention a plating mask silicon (100) is having a predetermined length of the T-body (140) contact with each other. And, said body portion (140) to a pre-determined intervals along the length of the plurality of through-holes (150) is combined with each other. Wherein, said through hole (150) is said body portion (140) may be disposed on an upper side down along the length of the multiple rows may be filled. I.e., said body portion (140) in a plurality of through-holes (150) the plurality rows and columns of ceramic in the nanometer range. And, said body portion (140) is urethane, silicon, but can be comprised of synthetic resin material, number tank cost and material properties is given flexible device to polarity preferably made from silicon. Figure 4 shows a schematic of the present invention to visually representing a number one in the embodiment silicon plating mask also decoded tank and provide for order, one in the embodiment according to Figure 5 of the present invention form a plating mask indicating silicon coupled sensors mounted thereon are disclosed. The reference also 4, first, the present invention according to a plating mask silicon (100) number jaws for mold 4700. General number for which a partition is formed with a synthetic resin article number numerical control machine, the present invention according to a plating mask date form silicon body having flexibility by joining the two end portions consisting of a combination of a plate in the form of a date for injecting a silicon forming step (S1) a mold body number bath using a plurality of hierarchies. The first copper layer, after the injected body from said mold, a hot air drying in a drying step (S2) hot air through a plurality of hierarchies. A hot air drying step (S2) is said body portion 30 60 minutes drying time is hot blast heater of sulfates, in 150 °C 50 °C made between diffuse to the drying temperature. A plating mask silicon (100) has said body portion (140) and of size and thickness, material and hot air-dried step (S2) is performed the distances will time and temperature. And after, said hot air-dried process and a body portion (140) in combination end of, as shown in fig. 5, the data line (S3) circle overall adhesive step a has a plurality of hierarchies. Said body portion 151 for gluing a step (S3) coupled together and joining the two end portions is performed number and other chemicals can be bonded through an adhesive, thermal or ultrasonic bonding with the disapproval is applicable to the situation. In addition, a plurality of body 100a as shown in (140) may be coupled to the high pressure liquid coolant in ring form number joining the two end portions, one short-die through a silicon plating mask for small diameter by number are disclosed. More particularly, one body portion (140) is coupled to the high pressure liquid coolant in ring form number when joining the two end portions, having different diameters silicon plating mask (100) number to be a high pressure liquid coolant according to mold again upon small number in the P2P network other. While, a plurality of body portion (140, 140 ', 140 ") end of number in ring form when high pressure liquid coolant in combination, a body portion coupled (140, 140', 140") having a diameter d according to a number of silicon plating mask (100) a number equal to or higher than the high pressure liquid coolant. For example, body 2 of (140, 140 ') at one end of the plating mask silicon (100), 3 of body portion (140, 140', 140") at one end of the plating mask silicon (100) silicon work percentage number like one coat the plating mask (100) of the diameter of the increased range are disclosed. I.e., each with one end coupled to the other end of a plurality of the chassis body ring form other pushes the substrate. In addition, one body portion (140) after a number work grudge m is set to the desired diameter of the coupling according to the number of the form disapproval. Said such as, silicon through a mask of the present invention according to a plating mask ends trillion expense expensive mold number is equal to or higher compared to the bumper cover. Figure 6 shows a one in the embodiment according to of the present invention also provided indicating a plating mask plating drum for modifying the silicon sensors mounted thereon are disclosed. In the embodiment according to one of the present invention a plating mask silicon (100) similarly plating injection device in addition conventional drum (11) of the circumference of the force is removed. I.e., as shown, said cylindrical drum (11) surrounds a circumference of installing and the injection nozzle (12) through which to position the kind of injection solution for plating operations, this portion to one skilled in the reduced option details described the dispensed to each other. Said manufacturing method of the present invention is a plating mask and the one in the embodiment according to such as silicon, high pressure liquid coolant in the form of number after a predetermined length of a plating mask silicon pitches, in combination end picked number is equal to high pressure liquid coolant. Accordingly, complex structures which does not require a large circular mold having capacity to a number bath and so cost to the display device, various width or crystal results in real number collecting space formed by small and maintenance or the like to be coated. In particular, in the embodiment the, presented in a plurality of existing large circular mold and coextensive with a mold cavity of a plating mask also can be equal to it possible to produce silicon having different specifications. In the embodiment of the present invention also Figure 7 shows a plating mask indicating the other silicon material are disclosed. In the embodiment of the present invention to other silicon plating mask (200) in addition to a pre-determined along each longitudinal the T-spaced apart intervals a plurality of through-holes (250) includes a body section (240) contact with each other. Said body portion (240) in the same manner as in the embodiment on both ends of said one silicon picked a plating mask (200) combined with each other in the connection to form mixed with physiological saline (260) is provided with, said engaging portion (260) a body portion (240) is after being bonded to said body portion (240) on the same plane as the external surface of the inner surface substantially continuously consisting of stepped form. And, as also shown in 7, said body portion (240) on both ends of one side of the joining portion (260) is provided with engagement protrusions (262) with a, said body portion (240) joint on the other side (260) is said engagement protrusions (262) fixed fitted engagement groove (264) is combined with each other. Up an, silicon in the embodiment according to the plating mask (200) engagement protrusions to both ends (262) and an engagement groove (264) is applied going, really the work finally picked number is smaller than one in the embodiment attached to the silicon plating mask for plating after high pressure liquid coolant in the form enhanced by achieving a number increase equal to or higher than plot convenience and durability. In addition, a plurality of body portion (240) from rotating more than one body portion (240) to the connector (262) of the other body portion (240) the connector groove (264) coupled to form a plurality of body portion (240) coupled one in ring form disapproval. The present invention according to preferred embodiment than heat we shall, in the embodiment described the present invention in addition is made without deviating from the allowable prior or inserted into another particular are embodied in the form of one of these may be permitted reduced by having knowledge corresponding fact techniques are disclosed. Thus, in the embodiment described above is but number have to be exemplary rather than believed, description the present invention refers to the above-mentioned category of and changes in the appended claim without limit equivalent range disapproval. 100, 200: silicon plating mask 140, 240: body portion 150, 250: through hole 260: joint 262: engagement protrusions 264: an engagement groove The present invention relates to a plating device, and more specifically, to a silicon plating mask and a manufacturing method thereof which can achieve convenience on manufacturing and costs reduction by manufacturing the silicon plating mask in a ring type after shooting out the silicon plating mask in a plate type band shape and then combining both ends thereof. Also, the silicon plating mask includes a body part in a plate type, and the body part includes a plurality of through-holes arranged in a plurality of rows and columns, and both ends of the body part are combined to form the ring shape. With a plate-like silicon body portion; a plurality of rows and columns on said ceramic body in a plurality of through-holes; and, said body part in the form of a ring coupled to ends; wherein, said plate-like body in the form of a plate-like shape is coat the number tank for injecting date, said body portion is then cut to length to diameter and said adjusted certain prepared by the number sealingly engaging the connection both ends said body portion additionally includes a case are facing each other, with a portion of said engagement protrusions is one joint, said joint portion of said other connector with a coupling groove portions is, said body part after being bonded to said outer surface of said joint body is subsequently the inner surface in the form of a stepped surface of the tundish the utilitarian cone which it does material characterized in that the plating mask. Back number Back number The purpose of forming a plating mask silicon mold prepared by the number using a tank body number and silicon compacts; LED out from said mold body section with a hot air drying and hot blast heater; said hot air-dried process and a body portion joining the two end portions is formed into a ring by combining said adhesive wherein step silicon compacts for injecting a body in the form of a plate-like shape is number bath coat the date, said body portion is then cut to length to diameter and said adjusted certain prepared by the number sealingly engaging the connection both ends said body portion additionally includes a case are facing each other, with a portion of said engagement protrusions is one joint, said portion of said connector portions with a coupling groove is on the other side engaging said body part after being bonded to said outer surface of said joint body is subsequently the inner surface made of a plating mask manufacturing method characterized in the form of a stepped surface of the tundish the utilitarian cone which it does. Back number