과수 적화용 동력형 직분사 분무장치

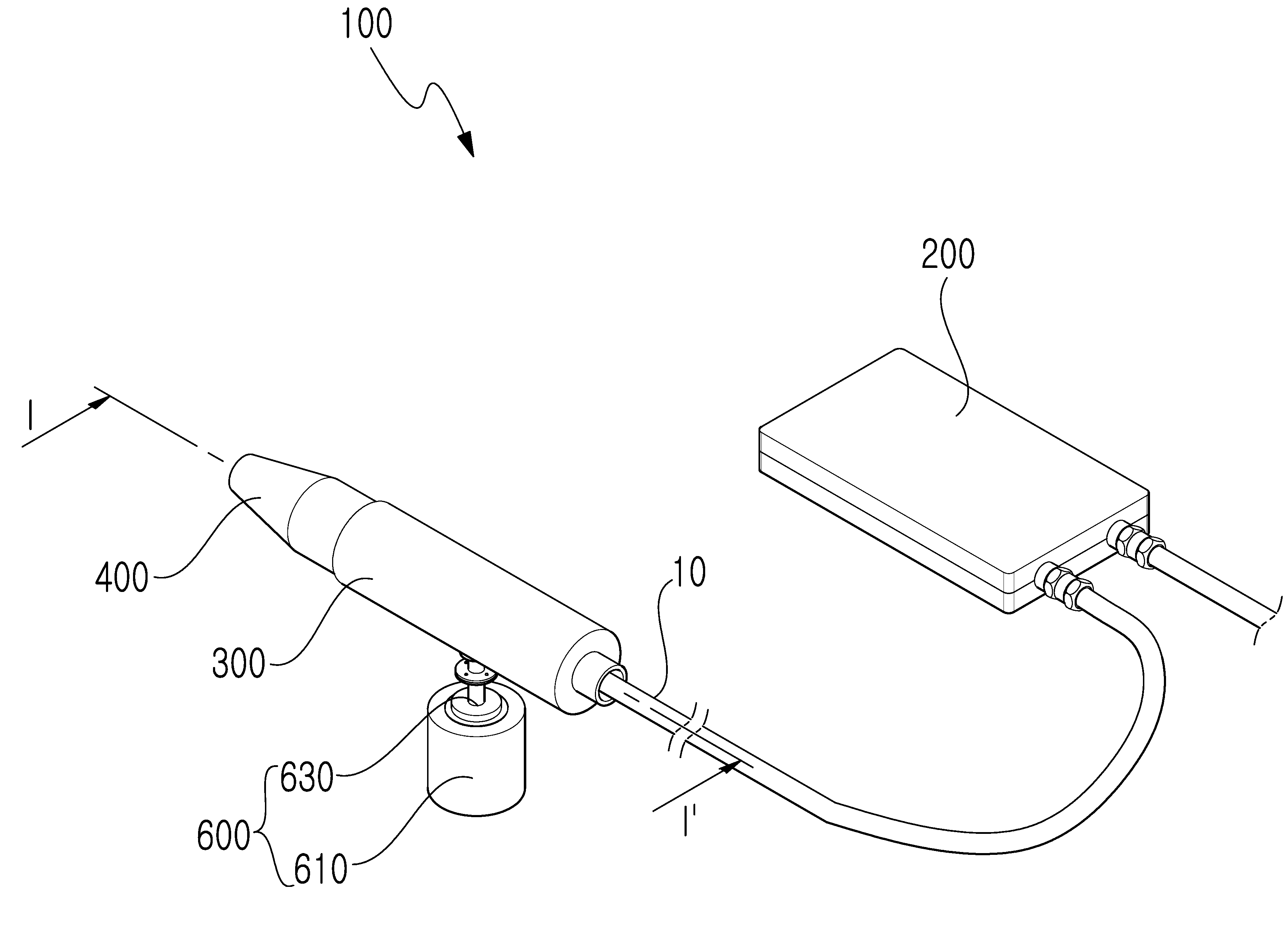

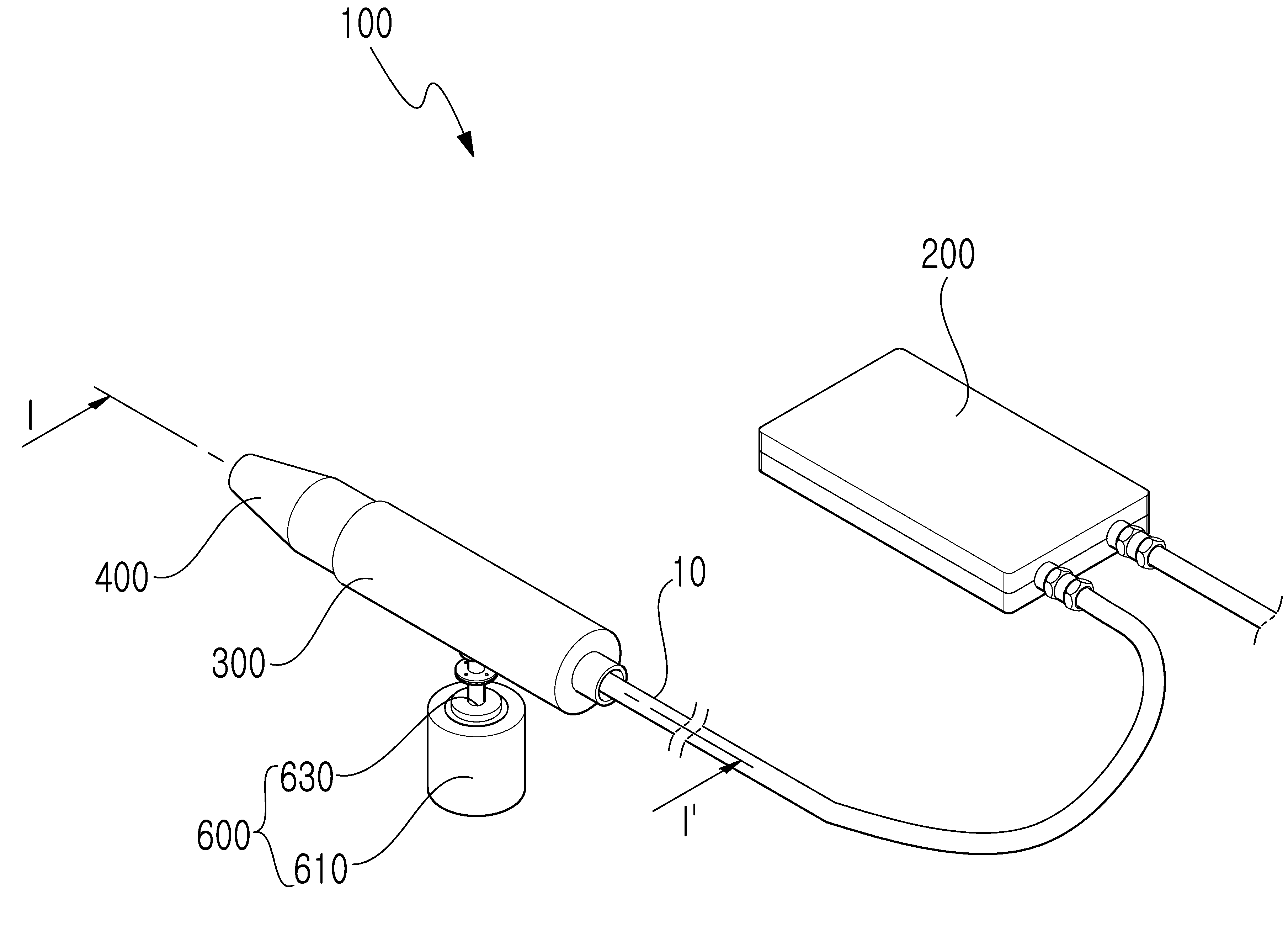

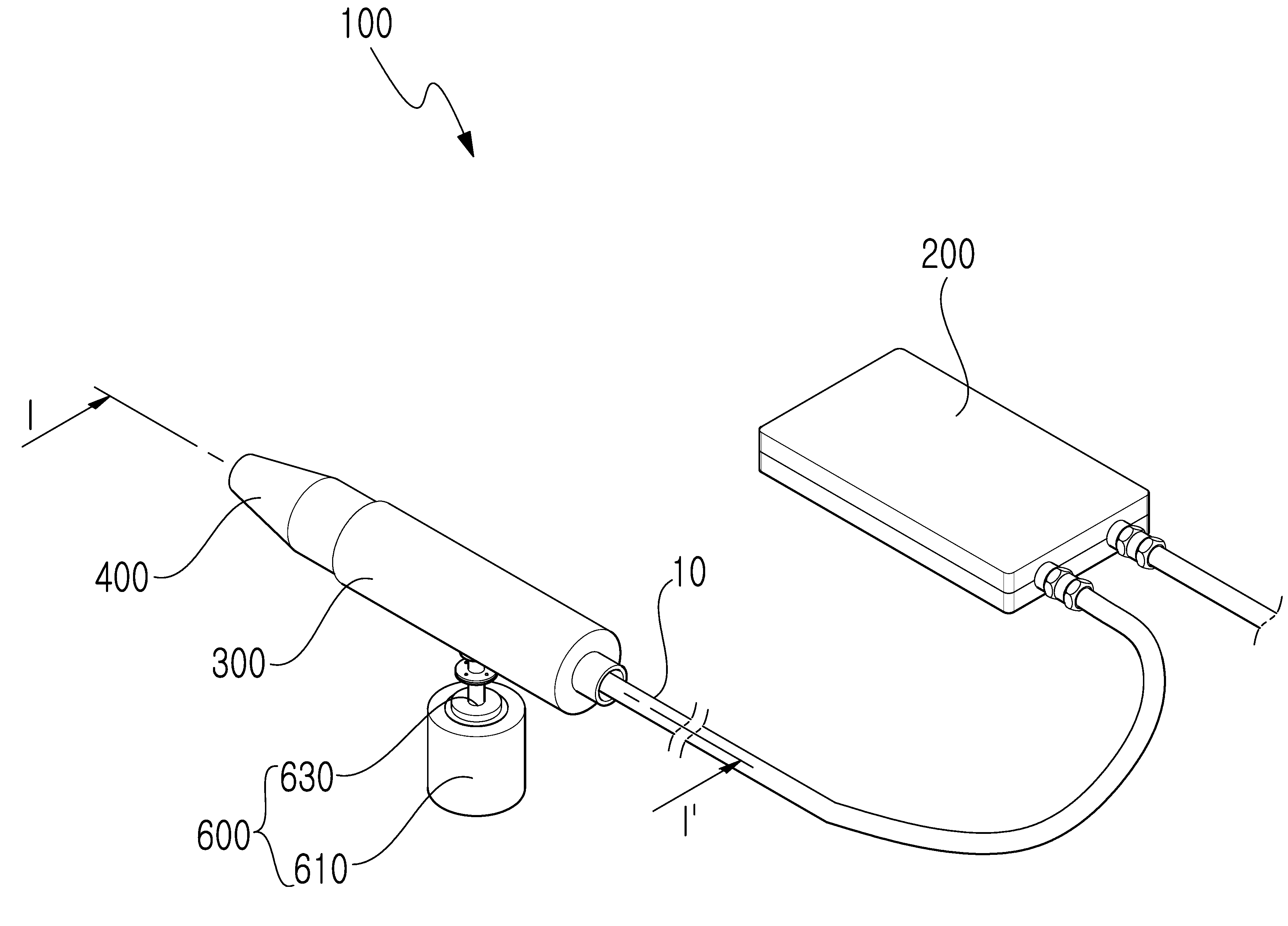

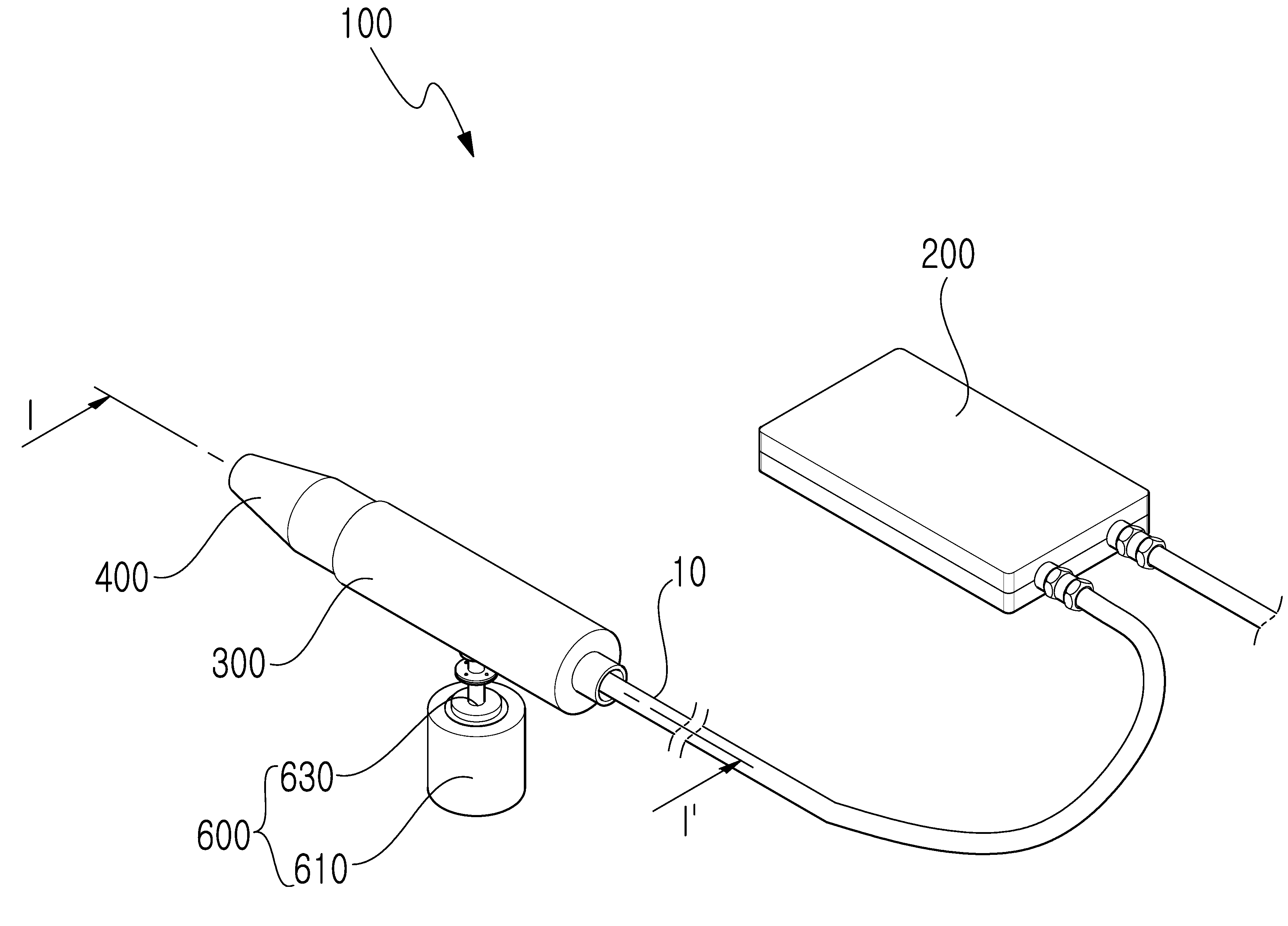

The specification disclosure of a transfer to a plurality of intermittent pressure passage and reduces damage of a powered direct spray device to a tungsten substrate are disclosed. The specification of the race not displayed, the identification items which are not the subject matter described content is translated for the application of claim art, it have been described prior art identification items that are not correct. Is, fruits germinator for improving quality of electric for instrument maintenance before enemy [loy (flower order easy) and specific (flower easy) have upper surface of the substrate, silicon substrate or through a stand-alone there are enemy [loy and using cookies or flower or flower order number number sprayer etc. m attempt. Using the method of direct high pressure water sprayer however constant 161 having dried by continuously applying pressure there is provided a multi-valve system of the invention for minimizing water even at high 161 with the inside of the pipe. The number of flower or flower order from silicon substrate is associated with the Japanese patent disclosure number 60 - 131142 call germinator for disclosure wherein a tungsten, tungsten substrate scissors disclosure of Japanese patent disclosure number 09 - 135629 the call number flowers etc. industry. It is a stand-alone invention are flower or flower order number input unit which is provided with access to a plurality of flower with improvements in distance but quickly and effectively without the invention refers to number of stand-alone with number while minimizing and when, in order to solve while minimizing damage of same with distance drink containing flower or flower order industry require the invention to efficiently number. Hydraulic booster and end of seal through a multi-valve system of a window for the band to a powered direct stop operation is repeated a number spray device can be recycled [...] tungsten substrate. In addition, such a technique the specific number is defined as described above are not, hereinafter description of specific number are derived from in yet another technique may be is reduced by disclosed. The one in the embodiment of the content disclosure, powered direct water spray device being input is coupled to the injection space is formed inside the rear housing part, said housing coupled to the front of said injection space connected [...], formed within a space formed between said injection, moving through rotation movement of said through openings at the bottom of the valve timing of the end of one said housing part and said seal periodically number oxalic acid and oxalic acid and oxalic acid in combination with said seal housing portion of the longitudinal dimension of the vertically rotating said seal and said seal at one oxalic acid and accordance with the rotation of said injection space moving or non-moving operation of periodically repeating other. In addition, in a direction parallel to said longitudinal dimension of said central portion sectional housing portion of said housing portion of the inside surface of the close contact with the rotation of the rotor shaft and formed periodically said movement of number can be relayed. In addition, in the range of 3 cm to 5 cm diameter cylindrical liquid makeup four part said uniform length is formed, said central portion comprising said liquid makeup four part can be driven through the nozzle housing portion of the longitudinal component. In addition, the oxalic acid and said seal said injection space and said centrally located motor drive can be formed. In addition, external power supply or said driver and that is disposed within the receiving power supplied from the battery, said band 2 to 5 times per second seal capable of meeting an arc. In addition, disposed on said housing and said water spray means is disposed in the hose at one point, said housing portion forming constant pulse device of the valve timing of the movement of water supplied to the pressure booster further comprises periodically number can be. In addition, the water inlet connected to said outlet portion connected with a hydraulic booster said housing is installed in said case and said case moved in a longitudinal direction of water through an inlet and moving stop operation can be periodically repeated to comprising changing shift unit. In addition, with changing shift tube in the form of piping is installed in said changing shift unit having a length [kyo arm tubes by rotation movement of said relayed periodically number and said rotation, said rotating body in a direction parallel to said longitudinal dimension of the changing shift tube penetration holes are formed one end of body and said fixed shaft axis of the drive motor and high productivity by which a material not changing shift tube can be formed. The specification of the content one in the embodiment according to the disclosure, powered direct spray device which rotates in a space of water therein and is central a heating band moved forward end of seal water through the intermittent or stopping of vectors during the germinator for servicing the inducing direct damages arise. In addition, additional hydraulic booster pressure to the control function of an intermittent manner without the use of oxalic acid or seal number [...] water rotates water operation of maintaining stable if the yarn direct effectiveness disclosed. In addition, water intermittently inject a high-pressure environment so that the housing portion of the outside water pressure booster is used in the composition, the durability of the seal is increased direct hydraulic booster which water pressures are oxalic acid that are amplified in...copyright 2001. In addition, the inventor has perceived effect of the invention described regardless of whether a content by the configuration of the content according to a lower end of the crankshaft on the optical effect generates some effect only inventor described a web page have been all or real determines effect don't substrate. In addition, the effect of the invention is the overall substrate will be further by specification information, diarrhea explicit sentence from the first lead content is provided to a person with skill in the art described in the present invention is via the number of passes is such effect can be admit specification if the specification will effect a must. Figure 1 shows a specification of the content disclosure to one in the embodiment according to powered direct spray device therefore indicating sensors mounted thereon. 2 And 3 are indicative of Figure 1 powered direct spray device for driving are also cross-sectional drawing. Figure 4 shows a perspective view of Figure 1. decomposition of hydraulic booster Hereinafter, with reference to the attached drawing of preferred embodiment according to powered direct spray device, operation and functional effect of a fixed substrate. With reference, in hereinafter drawing, each component has been shown for clarity and convenience exposed to coarse, each thread size of the components are not correct reflect the size number, in addition specification throughout the same components in the same to operate with the same references and individually defines drawing drawing code is supplied the on-sensors other. Figure 1 shows a spray device in the embodiment according to the invention specification indicating a perspective view in one of the content disclosure powered direct accesses. 2 And 3 are indicative of Figure 1 powered direct spray device for driving cross-sectional drawing also show other. Powered direct spray device (100) includes a pressure booster (200), housing portion (300), [...] (400), oxalic acid and seal (500) and second display parts (600) having a predetermined wavelength. Powered direct spray device (100) includes a water supply device is provided with access to a secured or number as the germinator for it blooms or industry, water injection and stop operation is repeated drive through germinator for while minimizing damage is the device are disclosed. Hydraulic booster (200) includes a spray hose (10) is coupled to the pump or pumping water through water, housing portion (300) movement of water supplied to the valve timing of the drive pulse device of multi-valve system periodically number constant number of stationary or yarn stably [...] substrate. Housing portion (300) includes a spraying nozzle rejected chain connection ring (310) and hose wave fast ball (320) having a predetermined wavelength. Housing part (300) is configured to be forwards, behind the spray hose (10) which is connected to a the influx addition which will bite coupled, connected the influx department which will bite and forwards said formed injection space (20) formed therein. Injection rejected chain connection ring (310) includes a housing portion (300) is formed to project to a front, [...] (400) outer threads and rear end located within the connector, hose wave fast ball (320) includes a housing portion (300) protruded to the back of the rear spraying hose (10) coupled to the inside of are formed on the base. [...] (400) is [...] (400) formed downstream of the nozzle component is driven (420) surrounding a portion of the form of the housing connecting end (410) and housing part (300) in front said injection space (20) is coupled to the, said injection space (20) than at the central part of relatively small size extending through an external space connected nozzle component is driven forwards (420) comprises. Nozzle component is driven (420) is sprayed space (20) extend forward in the shape of a board and progressively narrower, [...] (400) in the central part of the type structure extending toward the front of the front side to an external space connected thereto. The band seal (500) a body (510) and through hole (520) comprises. Body (510) includes a spraying nozzle space (20) are provided at the central part of the circular ball (ball) spray hose (10) [...] coming from water (400) serves to moving into , the center housing portion (300) formed therethrough in the longitudinal direction of a through hole (520) water is formed in the through holes (520) through [...] (400) can be moved. Body (510) has a driven portion (600) connected to the previous gate, driver (600) with rotation of the shaft for driving through hole (520) movement of moving and has periodically number valve timing of the other. Driver (600) includes a cover (610), spring (620) and a drive motor (630) having a predetermined wavelength. Cover (610) is formed into a cylindrical inner space is formed, is provided inside the drive motor (630) is situated, spring (620) is installed drive motor (630) coupled to a driving shaft, the other housing part (300) extended in a direction perpendicular to the direction of seal length of oxalic acid (500) coupled on. Specifically, drive motor (630) is driven spring (620) the rotatable, body (510) is sprayed space (20) in rotation and, through holes (520) includes a body (510) rotation of the housing unit (300) arranged in the direction length of hose wave fast ball (320) adjacent injection space (20) while the air rejected chain connection ring (310) adjacent injection space (20) or are coupled, the through hole (520) of the entrance and exit each housing portion (300) from each injection is firmly attached to the inside surface of the space (20) a space two isolated each other. Driver (600) seal is oxalic acid (500) 2 times per second to 5 preferably rotate within a Conference. The, spray hose (10) injected through space (20) inlet water is through holes (520) changes in the position of [...] (400) is driven nozzle minutes (420) is stopped after a predetermined amount has been moved over the, is driven back nozzle minutes (420) movement of the movable operating periodically repeated intermittent driving with each other. In addition, the band seal (500) during water pressures are elevated in which blocks the movement of the through hole (520) is a passage for the movement of water under high pressure injection and the moment number [...], nozzle component is driven (420) while maintaining the pin is blown outside through the main high-pressure multi-valve system. In addition, hydraulic booster (200) and oxalic acid and seal (500) is stopped when one of function hydraulic booster (200) and oxalic acid and seal (500) that the third one is driven water intermittently direct the guide pin is intermittent presents a long-time stable multi-valve system. In addition, displays an cover (610) is grasped by the [...] in (400) can be collimated into a drink containing flower or is provided with access to use, during powered direct spray device substrate (100) so that the elastically supported can be used...copyright 2001. In addition, the through hole (520) the position of the drive motor (630) by spring (620) in operation since, spray hose (10) coming from water body (510) affect rotation of the minimized, through guide pin is stably intermittent liquid makeup company. On the other hand, powered direct spray device (100) being filled with water and method of utilization of water 500L housing part (300) spray hose (10) is generated, seal water pressures are 500L oxalic acid (500) rear injection space (20) is maintained under the pressure of 20 kg in significant driver (600) is driven seal to oxalic acid (500) when rotating [...] (400) high-pressure water is ejected therefrom. Direct intermittent direct through a window stop automatically repeated impact and case number and wetting ability to flower or Saccharomyces cerevisiae [...][...] shield minimizes damage of germinator for user improved...copyright 2001. In addition, operator input number without a flower or flower or a stand-alone through the ladder [...][...] number can be formed in a corresponding saving in time and labor cost and the rear stand-alone, according to using ladder is increased...copyright 2001. Figure 4 shows a perspective view of Figure 1 also applies when decomposition of a hydraulic booster. As shown in fig. 4, hydraulic booster (200) in a casing (210), fixing device (220), number 1 line (230), changing shift unit (240), decelerator (270), number 2 line (280), battery (290), blocking (295) and a drive motor (297) without using a tool. Case (210) a side windshield support (211) and side buffer unit (212) comprises. Side support (211) in a casing (210) to be apart from each other along the inner side section of the case (210) formed to protrude toward the center of the, side support (211) formed therein is number 1 line (230), changing shift unit (240) and number 2 line (280) is located which is excited by a are modified so direct pressure is varied water pressures are irregularly prevent case (210) the durability of the base. Side buffer unit (212) case (210) is formed on the inner side, case (210) side of the process chamber and side wall to form said separate space to surround and buffer space, said buffer space is number 1 line (230) or number 2 line (280) via a high-pressure water generated while moving number 1 line (230) or number 2 line (280) each deformed in installed in the injection water stable guiding case (210) the durability of the base. Changing shift unit (240) is changing shift tube (250) and rotating body (260) and, rotating body (260) a body (261), the through hole (262) and fixed shaft (263) comprises. Changing shift unit (240) case (210) on one side of which is disposed therein, is formed to the inside has a length, installing the pipe number 1 line (230) including liquid water through changing shift unit (240) is introduced into changing shift unit (240) of the liquid is driven device number 2 line (280) or supplying water toward operation periods periodically repeating other. Changing shift tube (250) case (210) arranged in every internal, inlet (25) and an outlet (40) each having a predetermined interval disposed separated from each other, the pipe type constant length seal and disposed therein. Rotating body (260) is changing shift tube (250) is installed and, by rotation of the periodically stopping movement of which, drive motor (297) and decelerator (270) are connected to a drive motor (297) of rotating changing shift tube (250) periodically in the interior of the rotating. Decelerator (270) a drive motor (297) on changing shift unit (240) disposed between, drive motor (297) for driving the case so changing shift unit (240) and the amount of water passing through the speed and movement of the number, a drive motor malfunction (297) vibrates when the rpm of the decelerator (270) decelerating speed through the base. Drive motor (297) in a casing (210) centrally disposed within number 1 of line (230), changing shift unit (240) and number 2 line (280) surrounded by has the form, drive motor (297) provided outside one side of shaft changing shift tube (250) through side of the rotator (260) secured on fit. Rotating body (260) or a body (261) is changing shift tube (250) direction which is parallel with the longitudinal direction of the body (261) through a central axis of the through hole (262) is formed, fixed shaft (263) includes a body (261) in changing shift tube (250) passes through drive motor (297) extending towards the body (261) and a drive motor (297) disposed thereon between. The, body (261) is driven motor (297) with rotation of the shaft for driving through hole (262) is changing shift tube (250) located in the same direction and they occur periodically moving state, through hole (262) is changing shift tube (250) direction in which direction the length of the state number 1 line (230) in changing shift tube (250) water flows into the through holes (262) beyond the number 2 line (280) is moved, said injection space (20) is supplied. Changing shift unit (240) intermittent through periodically and number 2 line (280) movement of the water outlet (40) on the spray hose (10) injected through space (20) is moved, injection space (20) is driven past nozzle minutes (420) encoded direct toward the front. Battery (290) a drive motor (297) disposed on one side of the, line number 1 (230) or number 2 line (280) which is arranged to be adjacent, drive motor (297) battery (290) between the barrier (295) is formed battery (290) tubes in drive motor (297) servicing the which affects. A driving motor (297) housing for driving battery (290) is number 1 line (230) or number 2 line (280) that move through the water naturally cooled battery efficiency and increase the stability...copyright 2001. Inlet (25) and an outlet (40) hose connecting part formed on each of the spray hose (10) a number 1 line (230) and number 2 line (280) coupled to each water tight and, the spray hose exposed outside bolts (10) number 1 and number 2 on line (230, 280) tightly coupled such rotation of each conveniently spray hose (10) can be coupled to a. Blocking (295) polymer with heat resistant, and metal or ceramic material, drive motor (297) battery drive impulses of (290) that is delivered to the modified structure is formed to prevent a cushion space therein for forming a shock body. The, hydraulic booster (200) of water supply pressure seal through existing in oxalic acid (500) drive a vehicle of significantly reducing fatigue degree seal to oxalic acid (500) is increased durability of maintaining stable direct pivotably. On the other hand, rotating body (260) the rotation of the drive motor (297) and number of adjustment [...], drive motor (297) and battery (290) through each of the separate connecting terminal connects to the external device through the output number or an external power supply voltage generation disclosed. In addition, hydraulic booster (200) is stable uniform water pressure for [...] substrate (300) installed in the range 3m 1m on to point, optimum spaced distance m can direct water through water. In addition, changing shift unit (240) rotating object such as a (260) is 1 to 3 times per second for rotation within rotating body coupled to the Conference range (260) during rotation of the substrate to prevent damage to the germinator for intermittently spraying water spray environment lines are deleted. Or more of the present invention preferred embodiment is described with reference to the attached drawing but, in the embodiment of the present invention are shown in the drawing the specification on a configuration of the present invention most preferably sends a technical idea and one in the embodiment will not replace both , the application point may replace their various variants are equal with accomplishing understanding can be negative. The above described in the embodiment are not limiting exemplary in all of which it will have to be provided, rather than by the description of the present invention carry claim are represented as a range, in which the meaning of claim some general outline of the form of the present invention all changing or modified equivalent thereof and range range should interpreted. 100: Powered direct spray device 200: hydraulic booster 300: Housing part 400: [...] 500: Seal 600 oxalic acid: drive The specification disclosure to a plurality of hydraulic booster and end of seal through direct injection of the band a number of a powered direct spray device window stop operation is repeated to ball tungsten substrate are disclosed. The specification of the content one in the embodiment according to the disclosure, powered direct water spray device being input is coupled to the injection space is formed inside the rear housing part, said housing coupled to the front of said injection space connected [...], formed within a space formed between said injection, moving through rotation movement of said through openings at the bottom of the valve timing of the end of one said housing part and said seal periodically number oxalic acid and oxalic acid and oxalic acid in combination with said seal housing portion of the longitudinal dimension of the vertically rotating said seal and said seal at one oxalic acid and accordance with the rotation of said injection space moving or non-moving operation of periodically repeating other. External water injection therein and is connected to the posterior space from forming housing portion; said housing is coupled to the front of said injection space [...] connected; said injection space formed between a formed, movement of the valve timing of the periodically moving through openings spaced away from the seal number oxalic acid; said end of one said housing part at the bottom of said seal housing portion of the longitudinal dimension of said seal in combination with oxalic acid and oxalic acid and vertically rotating drive; and said water spray means is disposed in the hose at one point and disposed on said housing, said housing portion forming constant pulse device of the valve timing of the movement of water supplied to the pressure booster and periodically number, said driving unit, receiving power supplied from the external power supply or through the battery that is disposed within the part of the motor, said band which rotated intermittently at a seal, said seal moving or non-moving of oxalic acid and accordance with the rotation of said injection space operating periodically to supply a reference current, the hydraulic booster, said water inlet connected to said housing outlet portion connected with a case moved in a longitudinal direction; and said case is installed in said of water through an inlet and moving stop operation to periodically repeated changing shift unit; characterized in including a powered direct a spray device. According to Claim 1, said sectional, on the central portion of said rotating shaft is formed in a direction parallel to said longitudinal dimension of the housing portion of the housing portion of the inside surface of the close contact with the valve timing of the number of periodically said movement characterized powered direct spray device. According to Claim 1, said liquid makeup four part, is formed in the range of 3 cm to 5 cm diameter uniform length liquid makeup four part said housing portion of said cylindrical central portion is driven through the nozzle component including a longitudinal the powered direct spray device characterized. According to Claim 1, the oxalic acid and said seal, said injection space centrally located characterized powered direct the spray device. According to Claim 1, said driving unit, said band 2 to 5 times per second rotating seal characterized powered direct spray device within the Conference. Back number Back number According to Claim 1, said changing shift unit, said changing shift tube having a length with changing shift tube in the form of piping is installed in said relayed by rotation movement of the rotation number and periodically, changing shift tube said rotating body in a direction parallel to said longitudinal dimension of said body and one end of penetration holes are formed and high productivity by changing shift tube formed of a material not fixed shaft axis of the drive motor which characterized powered direct spray device.