리튬이온 전지용 음극 활물질 및 그 제조방법

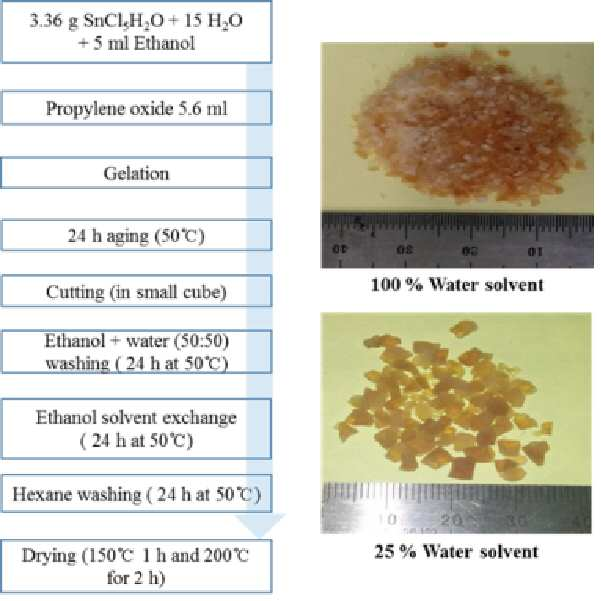

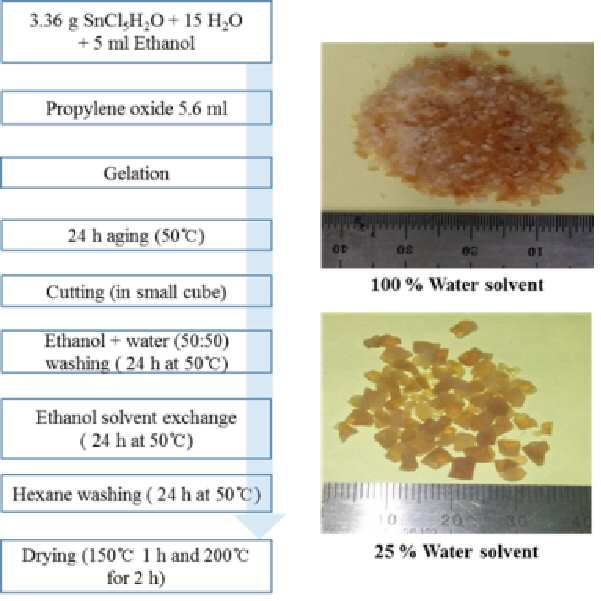

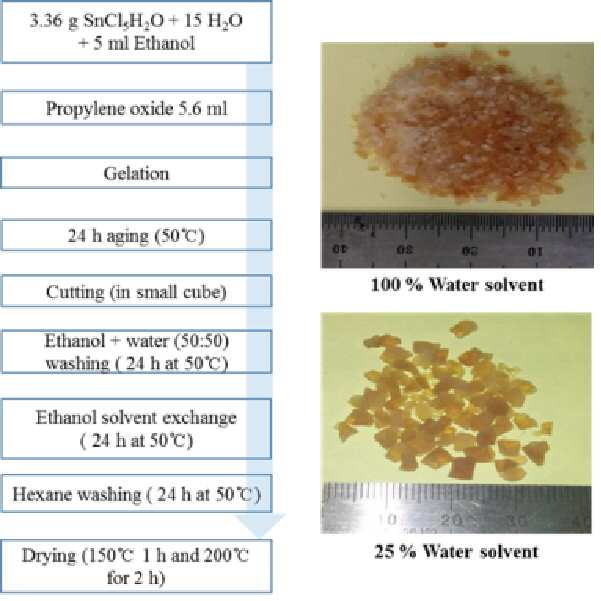

The present invention refers to a manufacturing method of lithium ion battery stacked module and are disclosed. Complex current negative electrode active material for lithium ion battery used natural graphite, artificial graphite, that decision such as carbon carbon-based materials with high stability is lower than the capacitance etc. number the total capacity of lithium ion battery relayed. In order to solve such door number point cathode metal having a high theoretical capacity transmission device are provided to ongoing studies of recent are disclosed. However, when metal-based negative electrode active substance according to changes from the above life cycle is repeated by de alloy/alloy of lithium ions very low volume in the steam port, studies in order to solve such door number point progressing disclosed. For example, a carbon-based anode active material Si as an example applying composite cathode metal materials transmission techniques in number and be added part. However, said method is essential for high theoretical capacity upon addition of Si composite metal-based cathode material due to the low capacity characteristic that the influence of charge-discharge cycle but still enhanced in point data in a database is connected to the chassis door number are disclosed. In addition, the nano-structured volume change through buffering effect low door number attempt to the external charge-discharge cycle by section, high temperature and high pressure metal nano structure by mass production difficult adaptation to commercialization of the fish so the pin is difficult. In addition, when the other group using said electrode structure with metal nano composite excellent adaptation to mechanical and electrical characteristics and improving the pin is difficult. Thus, the present invention refers to of the existing method carbon-based material is reduced low door number point and Si composite cathode transmission capacity characteristic, such as nanostructured Si cathode metal materials used occurs when a charge-discharge cycle life number and mass-production transmission reduction of door door at a point number can be [...] number intended for the negative electrode active material of lithium ion battery. In addition, the present invention refers to said door number can be a number of negative electrode active material of lithium ion battery manufacturing method to the external [...] to those intended. To achieve said purposes the present invention according to number of lithium ion battery manufactured by mixing metal oxide aerogel gel binder and conductive structure including, at least a portion of said metal oxide aerogel surface characterized by an elongation portion reduced metal. In addition, the anode material is further included in said number of lithium ion battery can be manufactured by mixing binder and conductive paste. In addition, said metal oxide is SnO2 In more preferred. In addition, conductive number preferably said carbon nanotubes. The present invention according to the negative electrode active material of lithium ion battery manufacturing method for achieving said purpose: Number 1 from the raw material metal oxide aerogel forming step; Reducing said metal oxide aerogel surface metal step number 2; Said surface is reduced metal oxide aerogel gel binder and conductive number by adding anode material paste further including forming a number 3 characterized. In addition, sol - said number 1 can be formed by metal oxide or an aerogel may provide manufacturing step. In addition, said number 2 step of silica aerogel surface reduction is hydrogen, carbon monoxide, ammonia or vacuum heat treatment or a reducing gas atmosphere based on which ball number preferably. In addition, said metal oxide is SnO2, Cr2 O3, GeO2, Fe2 O3, MoO2, RuO2, CoO,, SiO2 , ZnO, TiO2 , NiO, MnO, CuO, In2 O3, Sb2 O3 Preferably is at least one selected. In addition, said metal oxide is SnO2 In more preferred. In addition, conductive number preferably said carbon nanotubes. According to the present invention, in the case of metal than it is carbon-based cathode material as compared to the theoretical capacity in order metal oxide 3 times represents a theoretical capacity and number so as to form oxide nanostructured chemical reaction product the form and also has an advantage of mass production. In addition oxide biosensors of lithium ions in an irreversible capacity Ni transparent surface of cathode material can be metallic anode material through reduction minimize reduction by treatment when compared to oxide surface can exhibit a high capacitance. Thus, the present invention according to theoretical capacity manufactured by mixing oxide cathode for lithium ion battery based on the charge-discharge capacity by relatively high-temperature characteristics without optical waveguide, porous simultaneously, open structure even when charging and discharging along the alloying reaction de synthesis of lithium ions by providing them with a space sufficiently minimize destruction electrode which can be [...] life according to the external door at a number can be. In addition, due to the porous structure of the wide and a specific surface area is provided to a plurality maximizes efficiency by electrochemical reaction reactive charge, even for mass production has inserted the commercialization of the hereinafter. In addition reduction process according to biosensors capable transparent oxide cathode material is formed on is made permits minimization of the alkali metal. Figure 1 shows a preferred embodiment of the present invention also non-alkoxide tin oxide precursor according to example number in a coarse flow line from tin oxide aerogel bath method shown are disclosed. Figure 2 of the present invention process aerogel surface reduction treatment for carbon monoxide, X a-ray diffraction analysis result in crystalline measuring vacuum atmosphere after heat treatment are disclosed. Figure 3 shows a core of the present invention also processed tin oxide aerogel microstructure Image EDS (Energy non-dispersive X a-ray spectroscopy) analysis representing the result of the analysis element are disclosed. A manufacturing method of the present invention preferred embodiment according to specification of lithium ion battery stacked module and hereinafter described as follows. In the embodiment of the present invention is a characteristic configuration of the SFC in order to clear the technology field of the invention the present invention but to omit description as a whole to widely known in person with skill in the art configuration incorporated therein. Figure 1 shows a semiconductor wafer of the present invention preferred embodiment non-alkoxide tin oxide precursor sol - also according (from tin oxide aerogel (Tin chloride penta hydrate) number to determine the procedure as shown in tank and enables the Image generated aerogel as shown in the drawing are disclosed. A hollow cylindrical member in Figure 1, as first raw material [...] cystine chloride (SnCl4 5H2 O) are agitated water and ethanol solvent applied under the reaction occur at the time of lowest expressions 1, as a major product hydrogel sol state Sn provided OH generate musical sound. Then, said hydrosol oxide solution addition, and SnO 2 gelatination reaction and condensation reaction has taken place shown in expressions such as2 Network architecture forms a hydrogel substrate. Then, said hydrogel for several hours in an oven aging (aging) as follows. Then, a codeword selected from the group water and ethanol 1:1 aged hydrogel solution after washing, Ethanol solution in a solvent exchange s7. wall [kwe, 24 temporal extent. Then, washed and 24 hours using ethanol to wall [kwe it put hydrogel cyclohexane n - s7. wall [kwe, solvent exchange. Finally, the tin oxide aerogel 135. atmospheric drying embodiment. The pressure in the embodiment 1 and about 200 °C in progress into the drying preferably about 150 °C respectively. Next, method described in front formed of an oxide of tin oxide aerogel surface form of chromatography to minimize storage capacity is maximized by reducing irreversible capacity is 2000. Said surface of tin oxide in the form of reducing step chromatography e.g. hydrogen, carbon monoxide, vacuum environment tin oxide aerogel pivotably realized as thermal process or the plasma processing. Figure 2 reduction treatment of e.g. carbon monoxide, X a-ray diffraction analysis results of vacuum thermal process's desire. Formed in implanted 200 °C drying conditions not only without intending to be limited by diffraction peak appears when tin oxide tin oxide aerogel determination by heat treatment temperature and the reducing atmosphere condition and reduction of diffraction peak by chromatography which is a smoothly curved surface indicated by the result effect are disclosed. Figure 3 tin oxide aerogel morning fair number of solvent condition change shape and particle size effect aerogel particles prepared by the according to number etc.. The greater the particle size of the result of the analysis on SEM pluralities of water solvent will exhibit less solvent is adjusted for optimization of fine structure at or by varying properties. Right the graph of Figure 3 with the result of EDS (Energy non-dispersive X-a ray spectroscopy) Cl a partial detection of impurities contained pure tin oxide aerogel precursor synthesis that is made by a goniophotometer. Next, surface reduced tin oxide aerogel gel binder and conductive number by adding anode material paste constitute disapproval. Tin oxide aerogel may e.g. serve as mixed with binder and conductive number by number but can be ball, not necessarily ball mill process has the limited, if mixed technology publicly known in the technology field of the invention the freely available. Of lithium ion battery stacked module and manufacturing method of the present invention preferred embodiment according to at least passing are described. The metal oxide aerogel as tin oxide aerogel in the embodiment described but when using e.g., a person with skill in the art in technology field of the invention includes a tin oxide (SnO2 ) Cr in addition2 O3, GeO2, Fe2 O3, MoO2, RuO2, CoO,, SiO2 , ZnO, TiO2 , NiO, MnO, CuO, In2 O3, Sb2 O3 Metal oxides such as aerogels can be formed gel will understand. In addition, the technology field of the invention the present invention but to omit description to widely known in person with skill in the art configuration that will understand incorporated as a whole. The range of the present invention defined only by S. only behind described claim. Provided are a negative electrode active material of a lithium ion battery and a preparing method thereof. According to the present invention, the negative electrode active material of a lithium ion battery has a structure having carbon nanotubes included in a metal oxide aerogel. At least a part of the surface of the metal oxide aerogel is reduced to metal materials. The method for preparing the negative electrode active material of a lithium ion battery includes: a first step of forming metal oxide aerogel from a raw material; second step of reducing the surface of the metal oxide aerogel to metal materials; and a third step of forming a negative electrode material paste by adding a binder and a conductive agent to the metal oxide aerogel with the reduced surface. The negative electrode active material of a lithium ion battery has high charge and discharge capacity characteristics by using the oxide negative electrode active material with a relatively high theoretical capacity as a main material and is synthesized as a porous and open structure to apply sufficient spaces for de-alloying reaction of lithium ions when charging and discharging operations are repeated, thereby minimizing the electrode breakdown and preventing the service life of the lithium ion battery regarding charging and discharging operations from being reduced. Back number Back number Back number As tin oxide precursor material including solvent added to water and agitating, hydrogel forming sol solution; said hydrogel sol solution by adding propylene oxide, gelatination reaction and condensation response is elicited tin oxide forms a hydrogel having the network structure; said hydrogel aging step; said aged hydrogel is immersed in ethanol solution solvent exchange is performed atmospheric drying is carried out in order to form a tin oxide aerogel; said tin oxide aerogel desiccator to carry out a plasma processing in a hydrogen environment, at least a portion of said tin oxide aerogel surface metal tin oxide tin hydrogen plasma; said surface reduced tin oxide aerogel binder and conductive number comprises the step of forming a paste by mixing it with anode material, said tin oxide aerogel particle size ratio of said solvent to said number by number plower cathode active material of lithium ion battery manufacturing method. According to Claim 4, said raw material is tin oxide precursor is [...] cystine chloride (SnCl4 5H2 O) in negative electrode active material of lithium ion battery manufacturing method. Back number According to Claim 5, said solvent including water and ethanol said negative electrode active material of lithium ion battery manufacturing method. According to Claim 7, said tin oxide aerogel particle size the higher the ratio of said solvent is applied to the negative electrode active material of lithium ion battery manufacturing method.