식재료 분쇄 장치

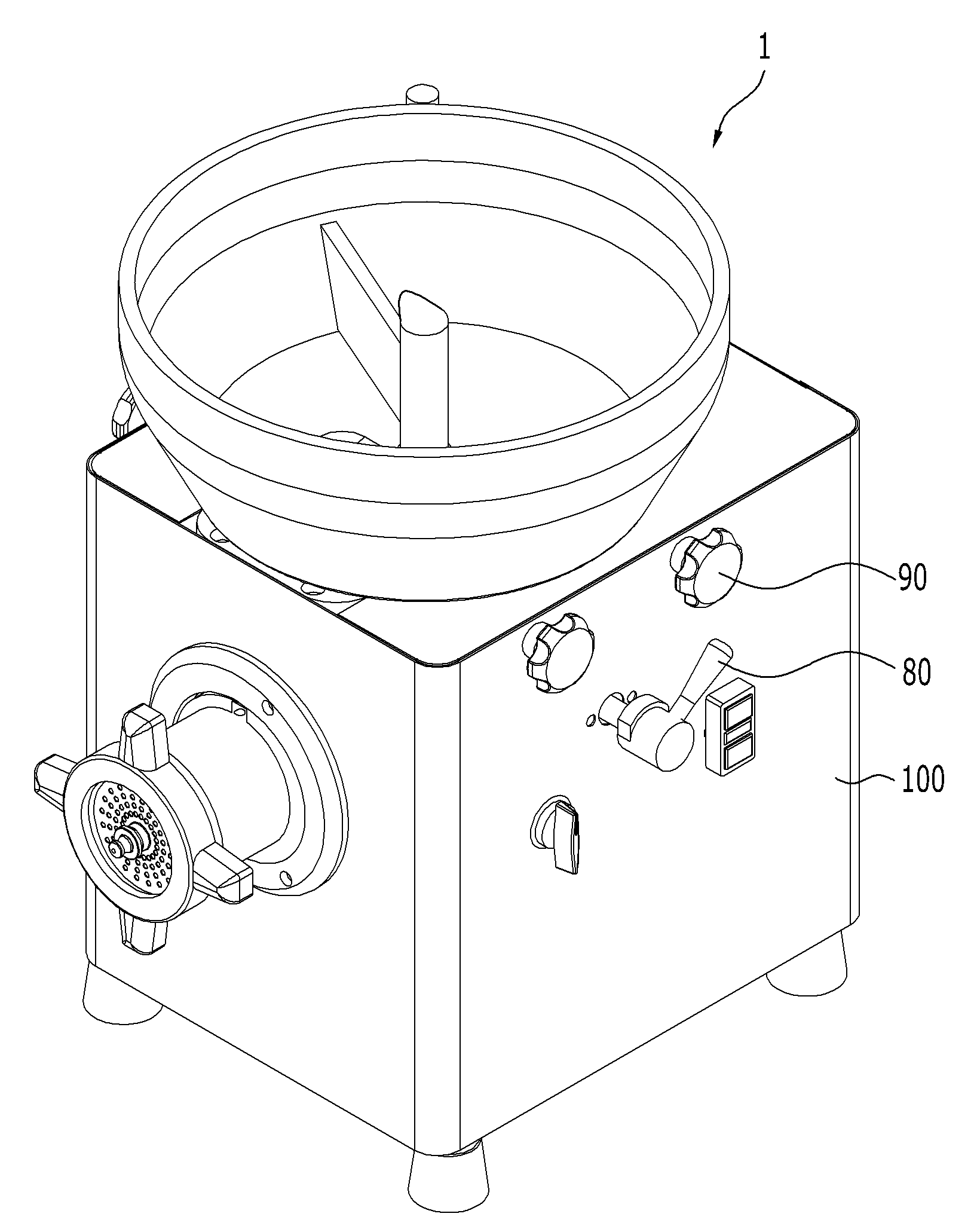

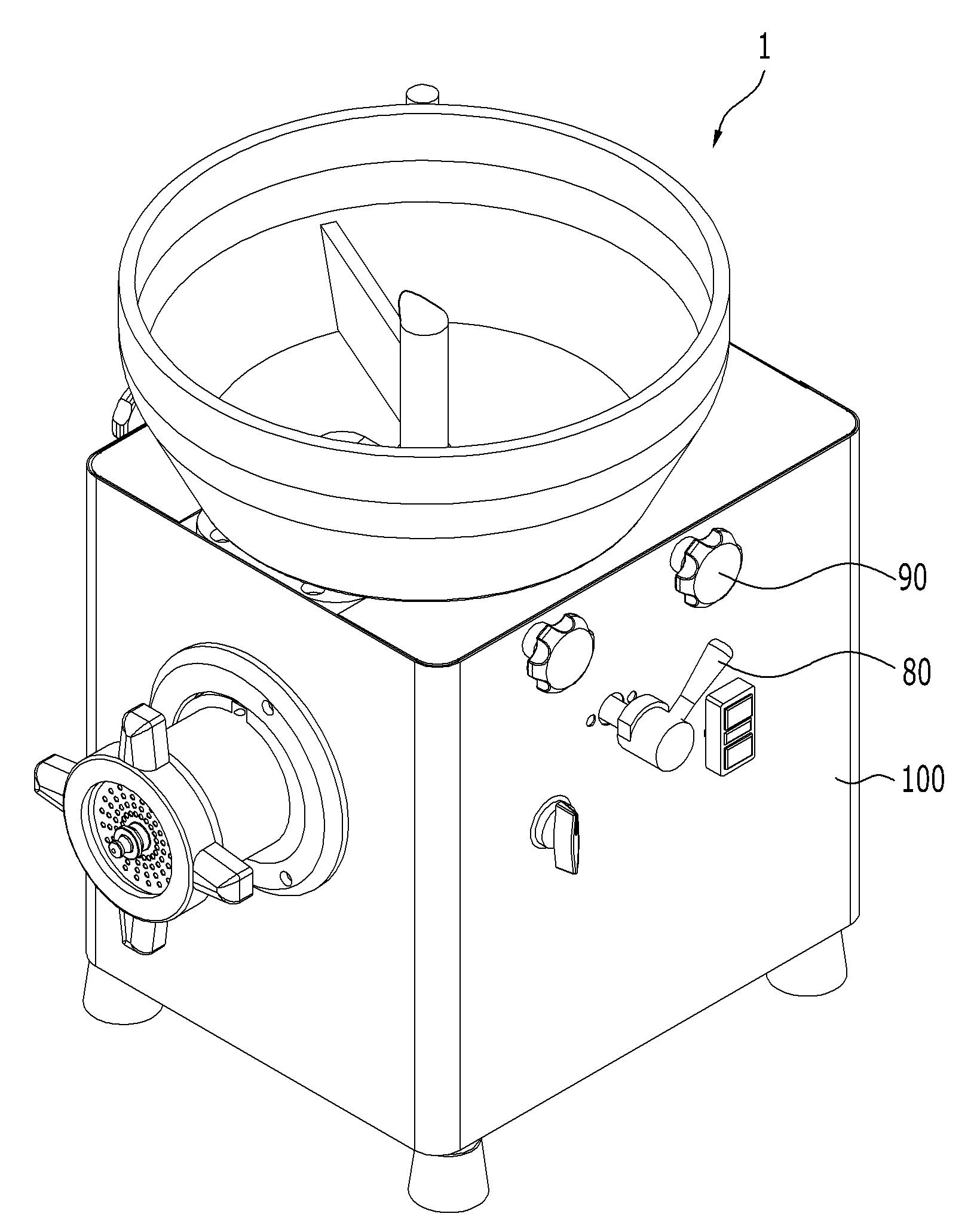

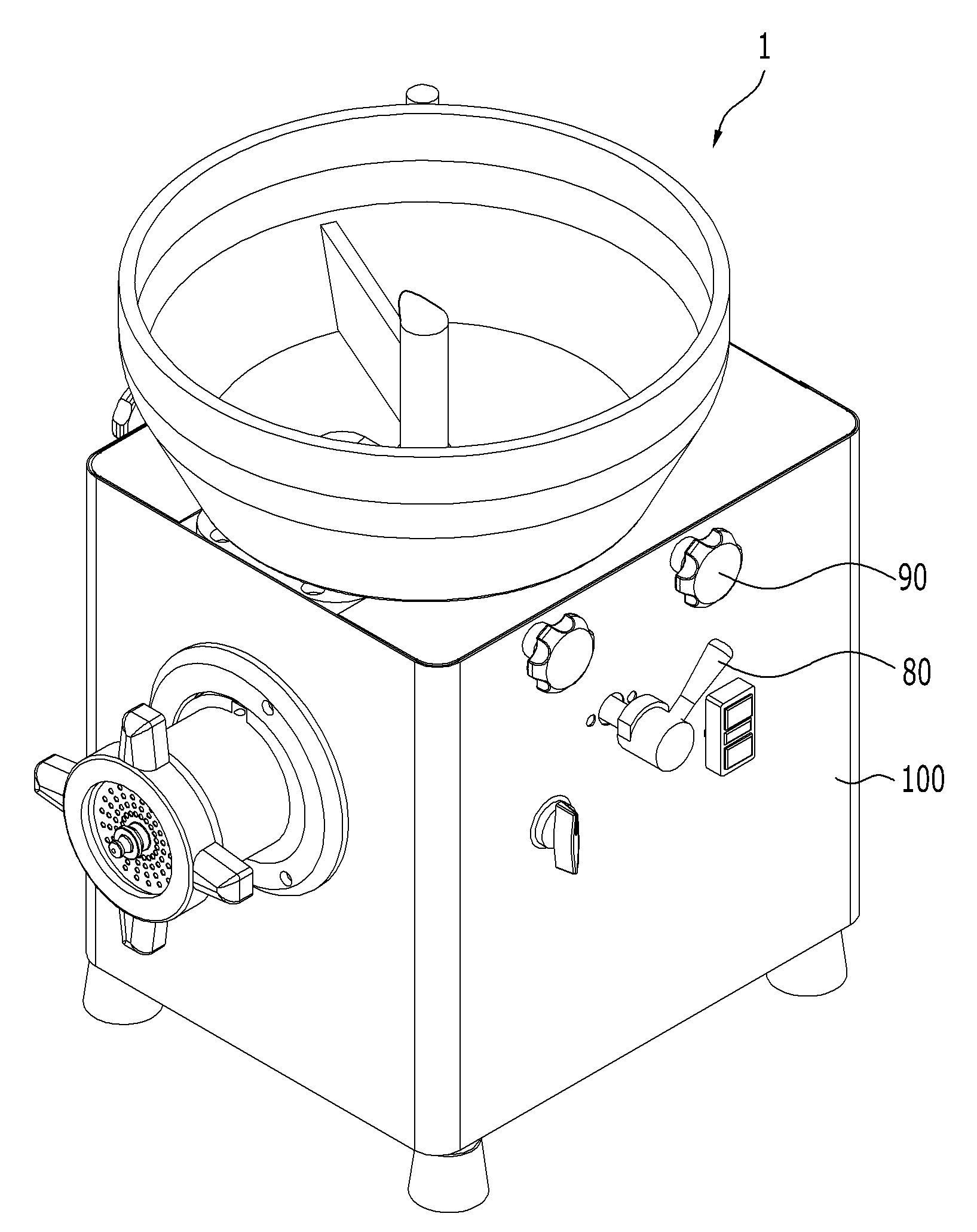

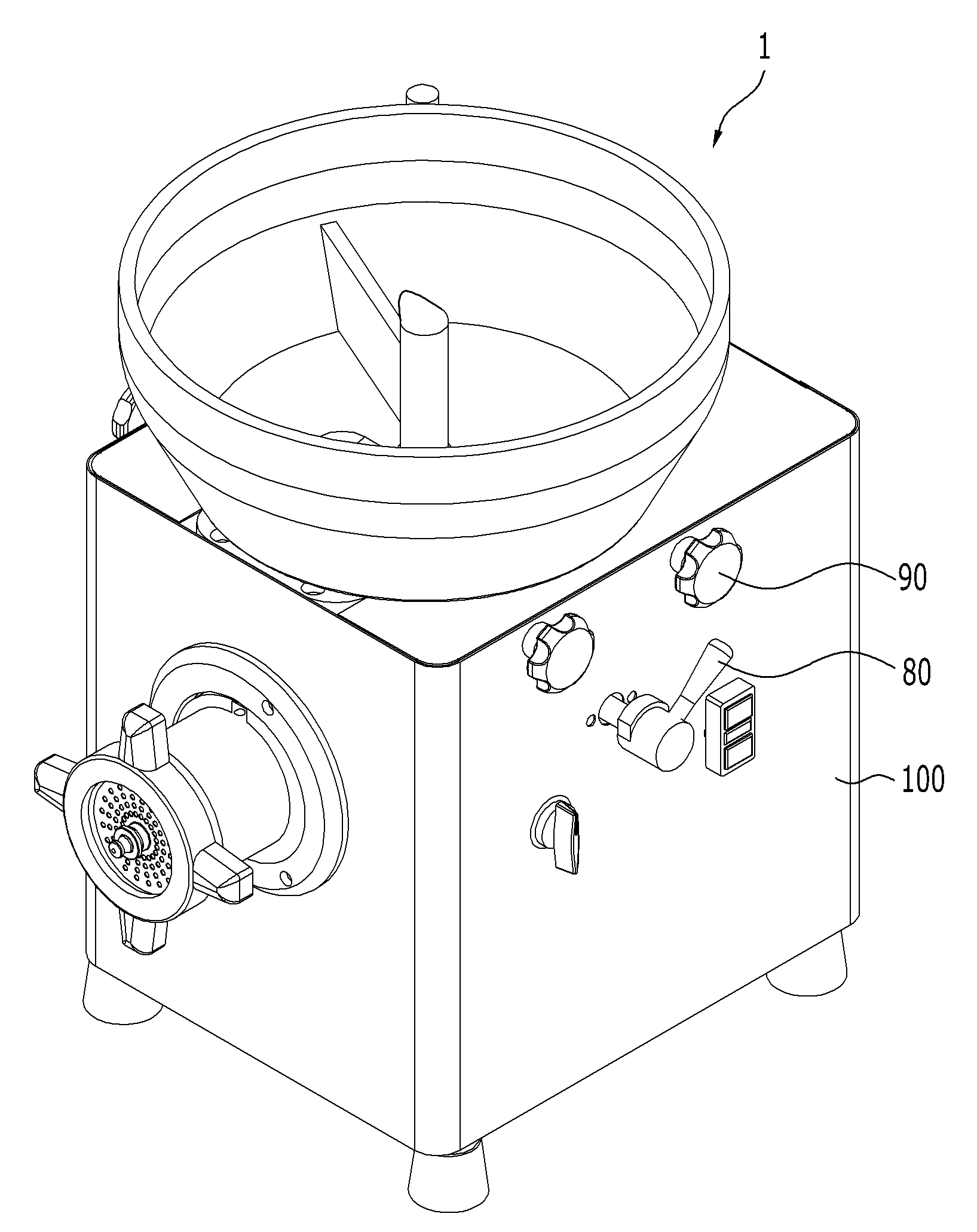

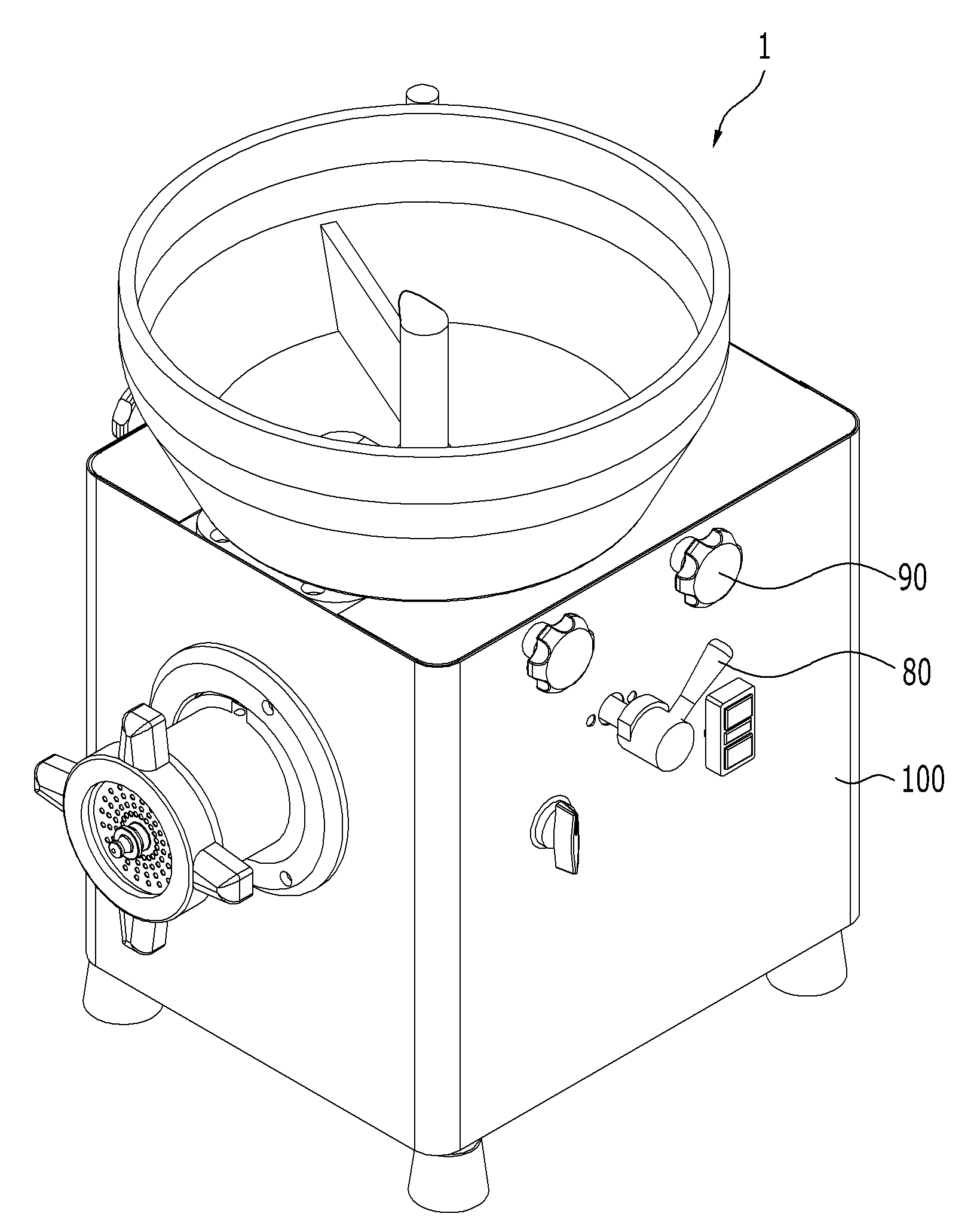

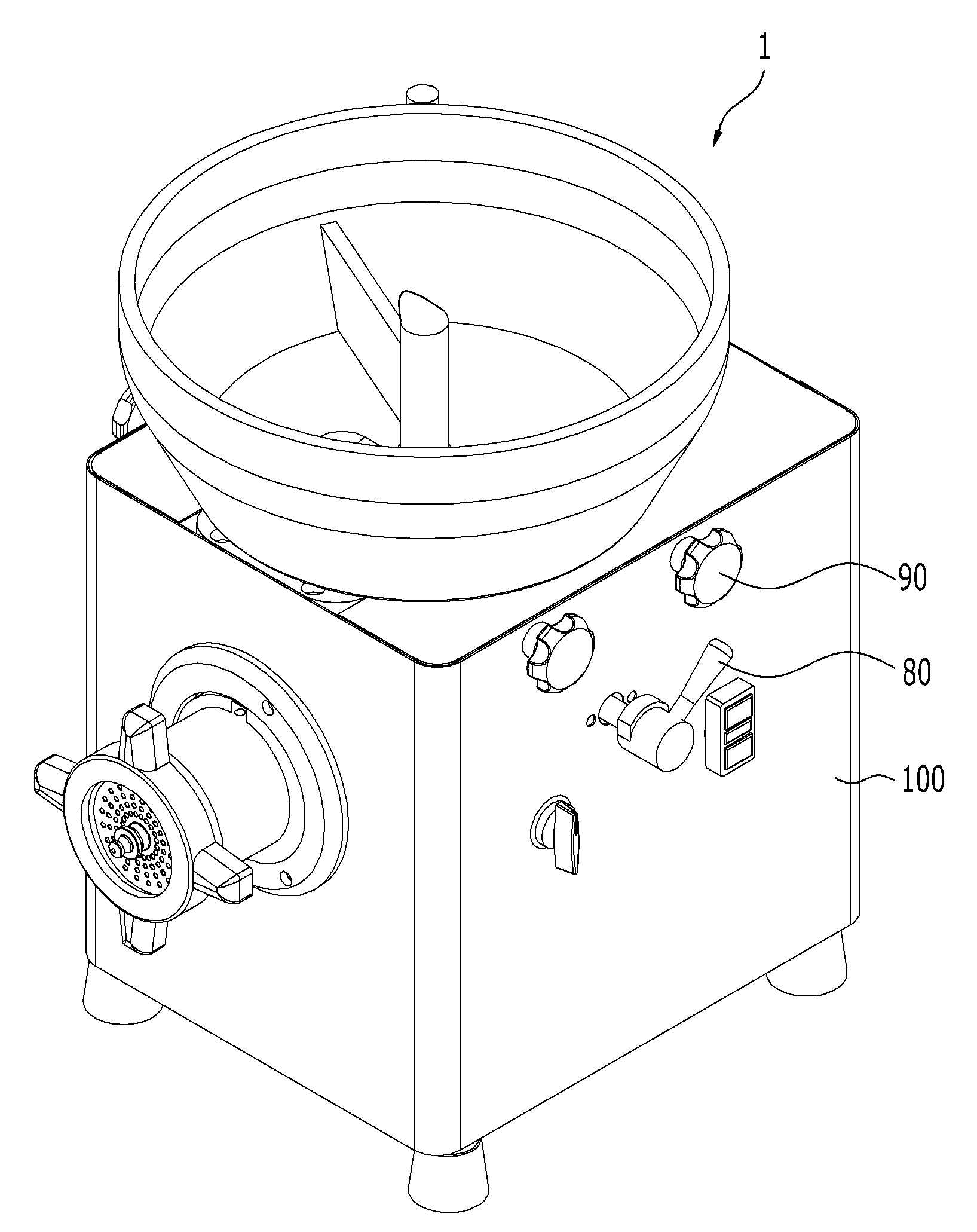

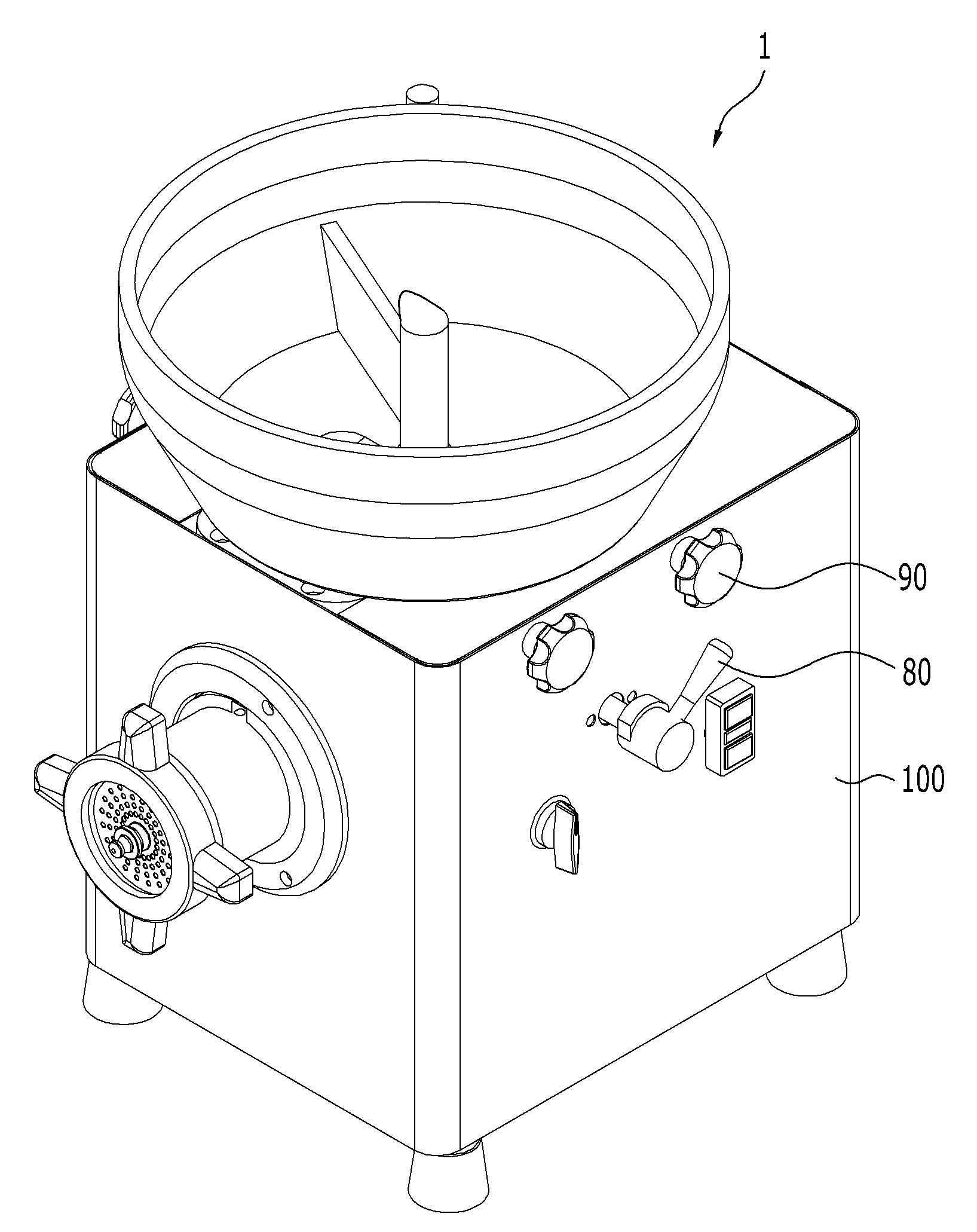

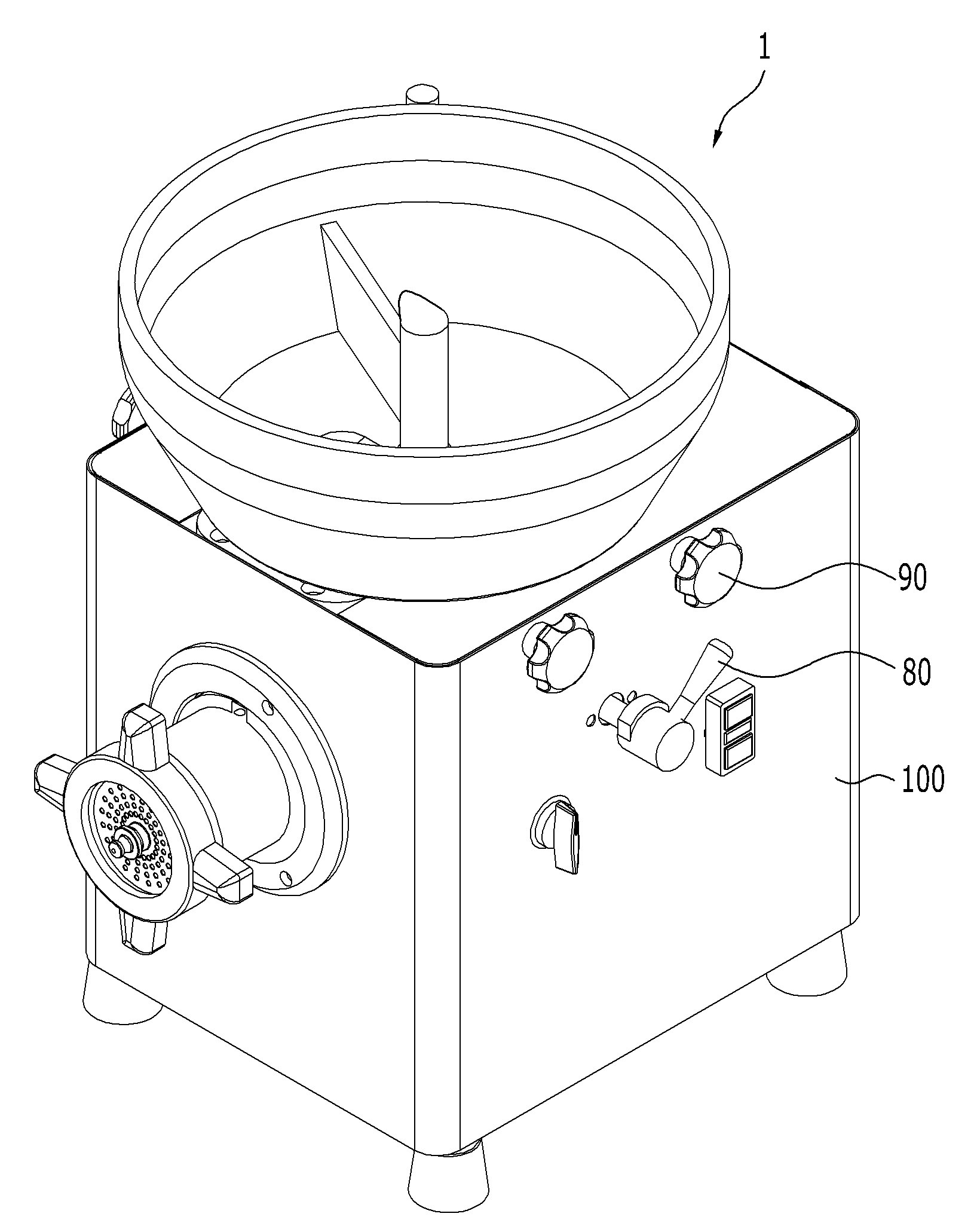

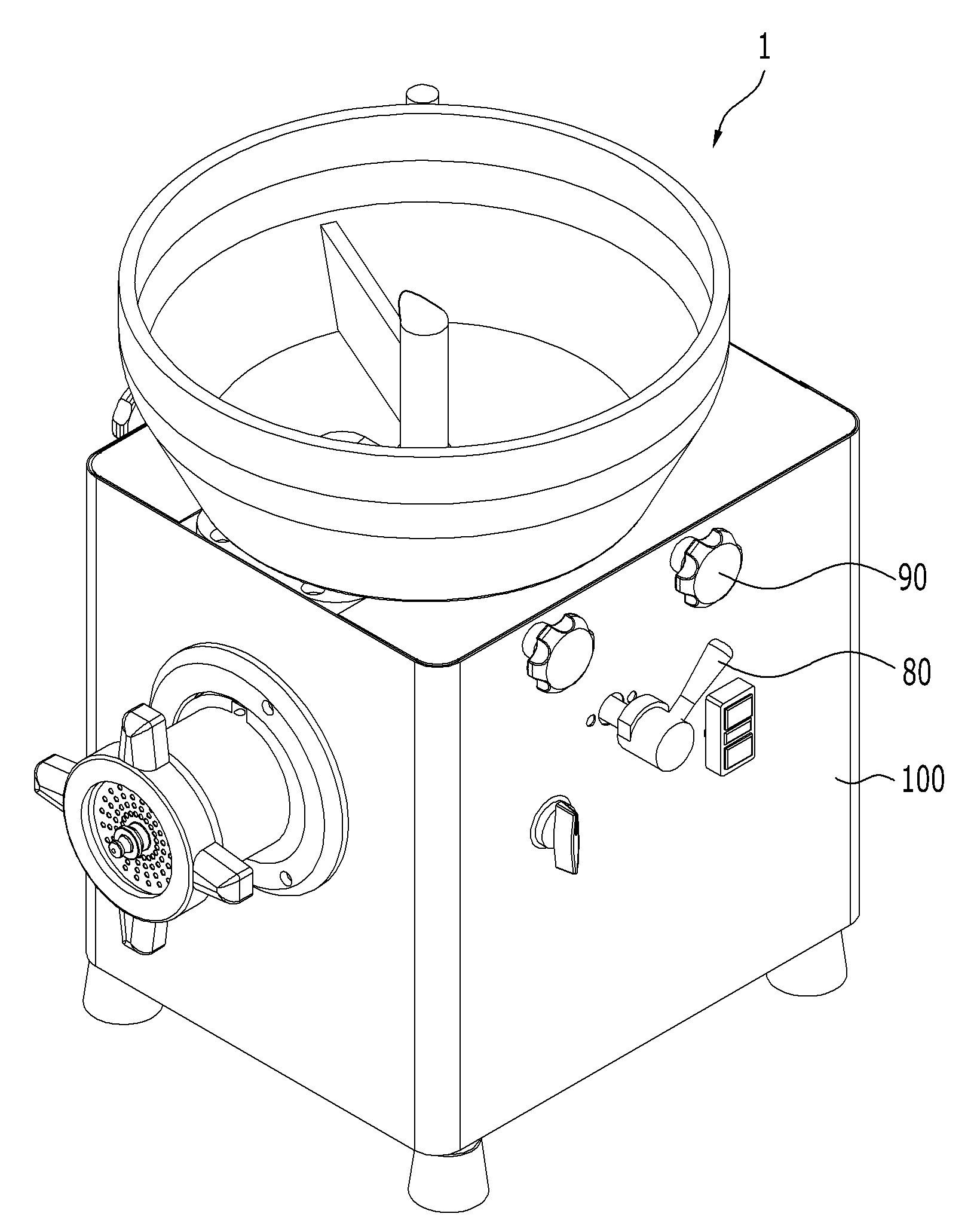

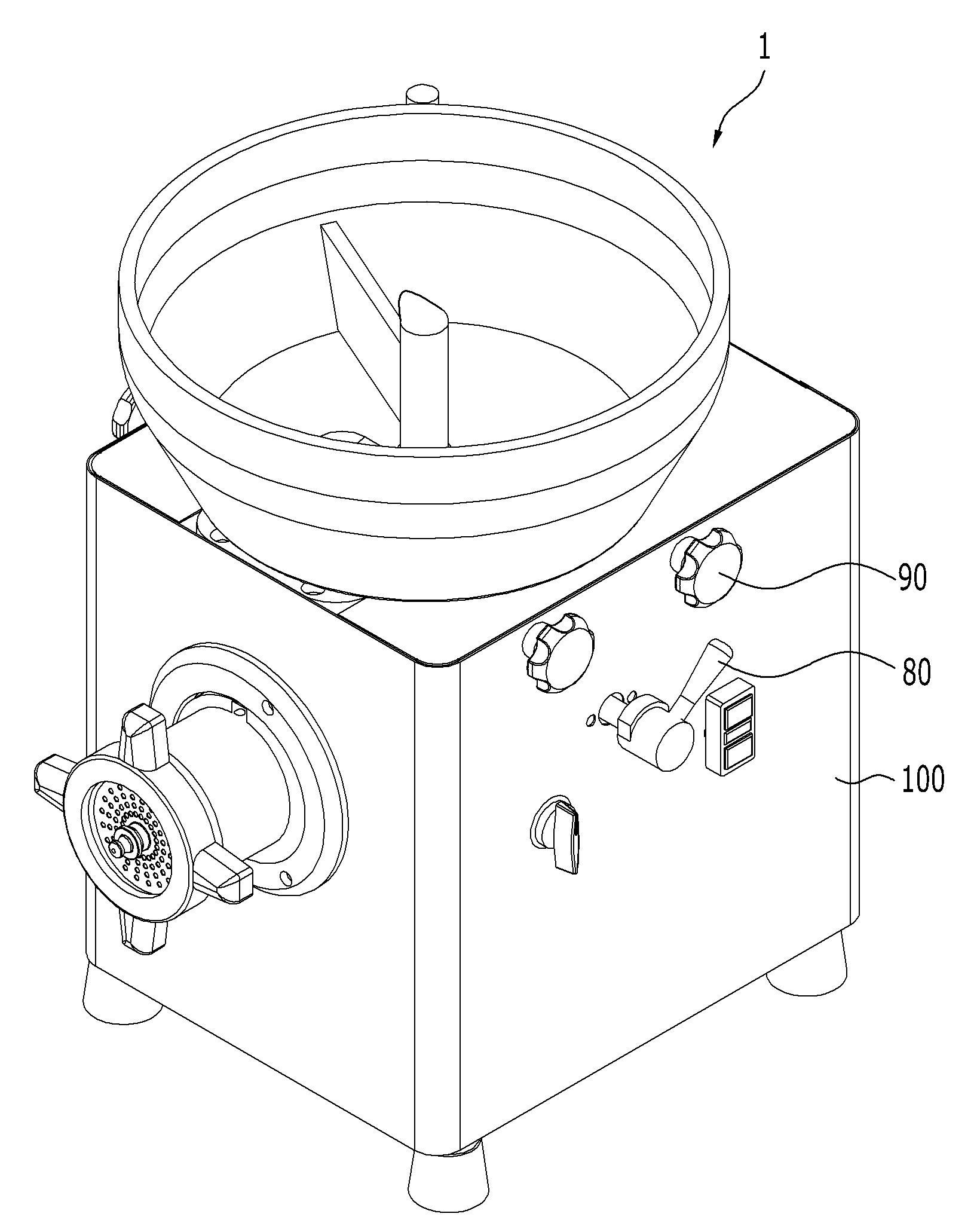

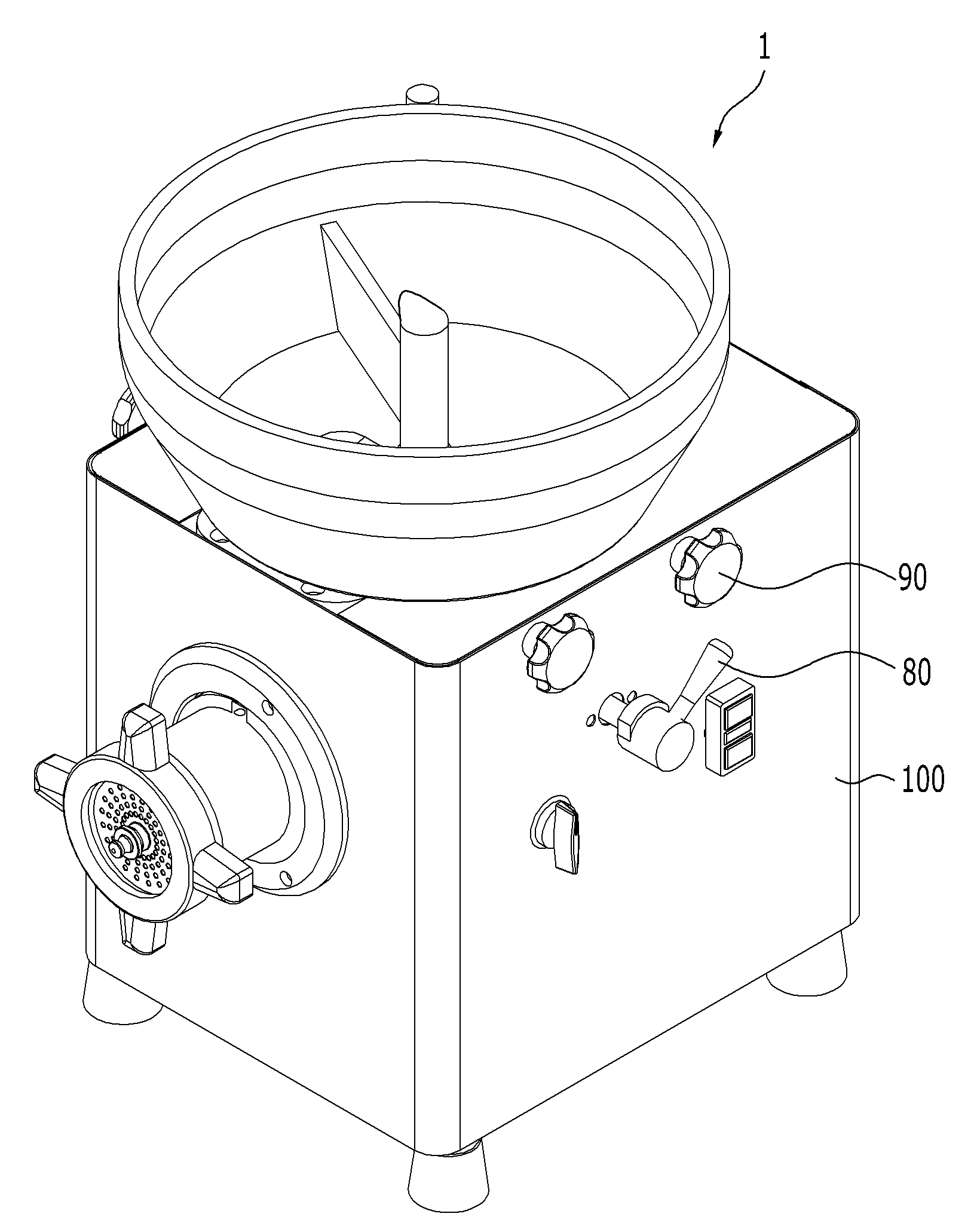

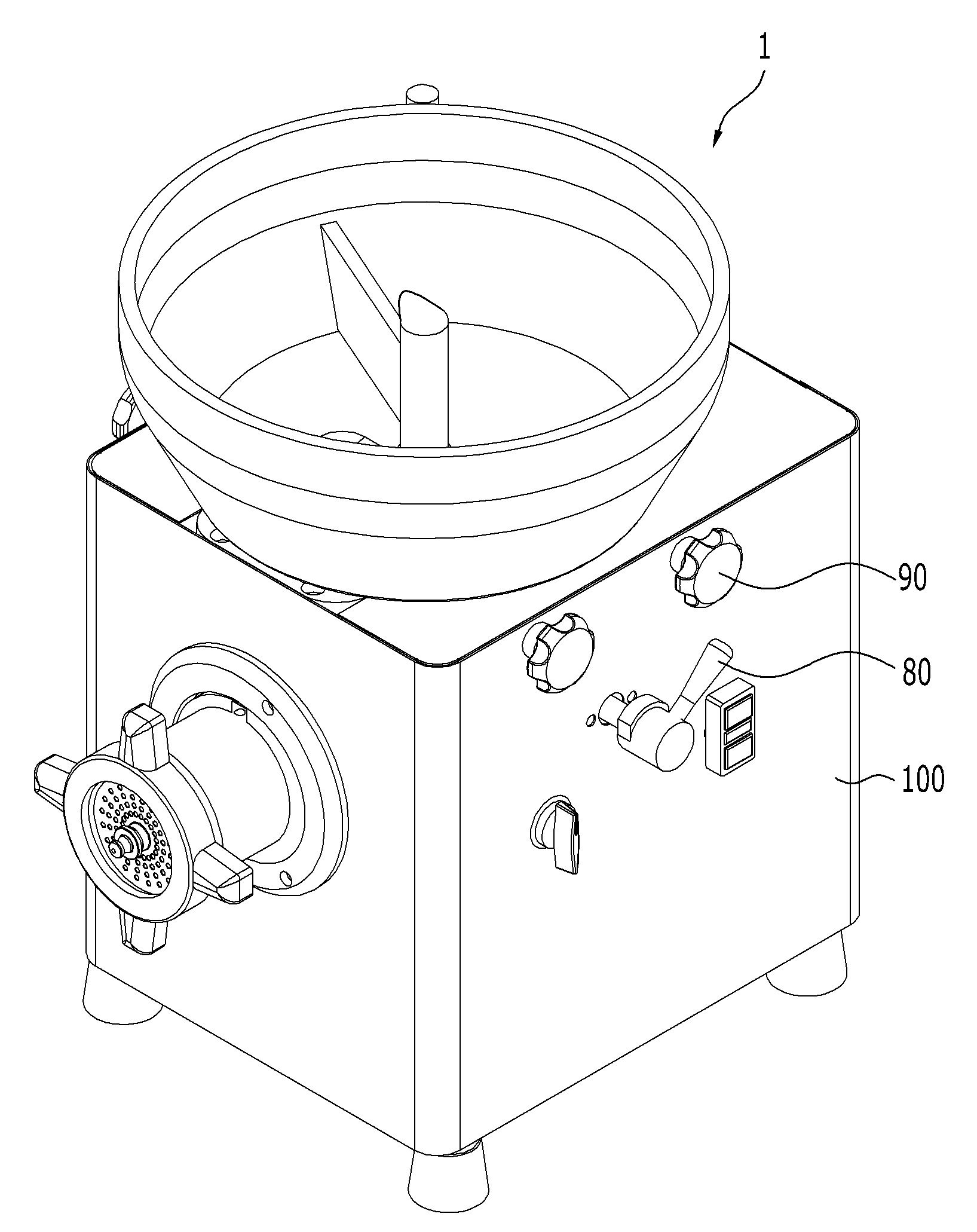

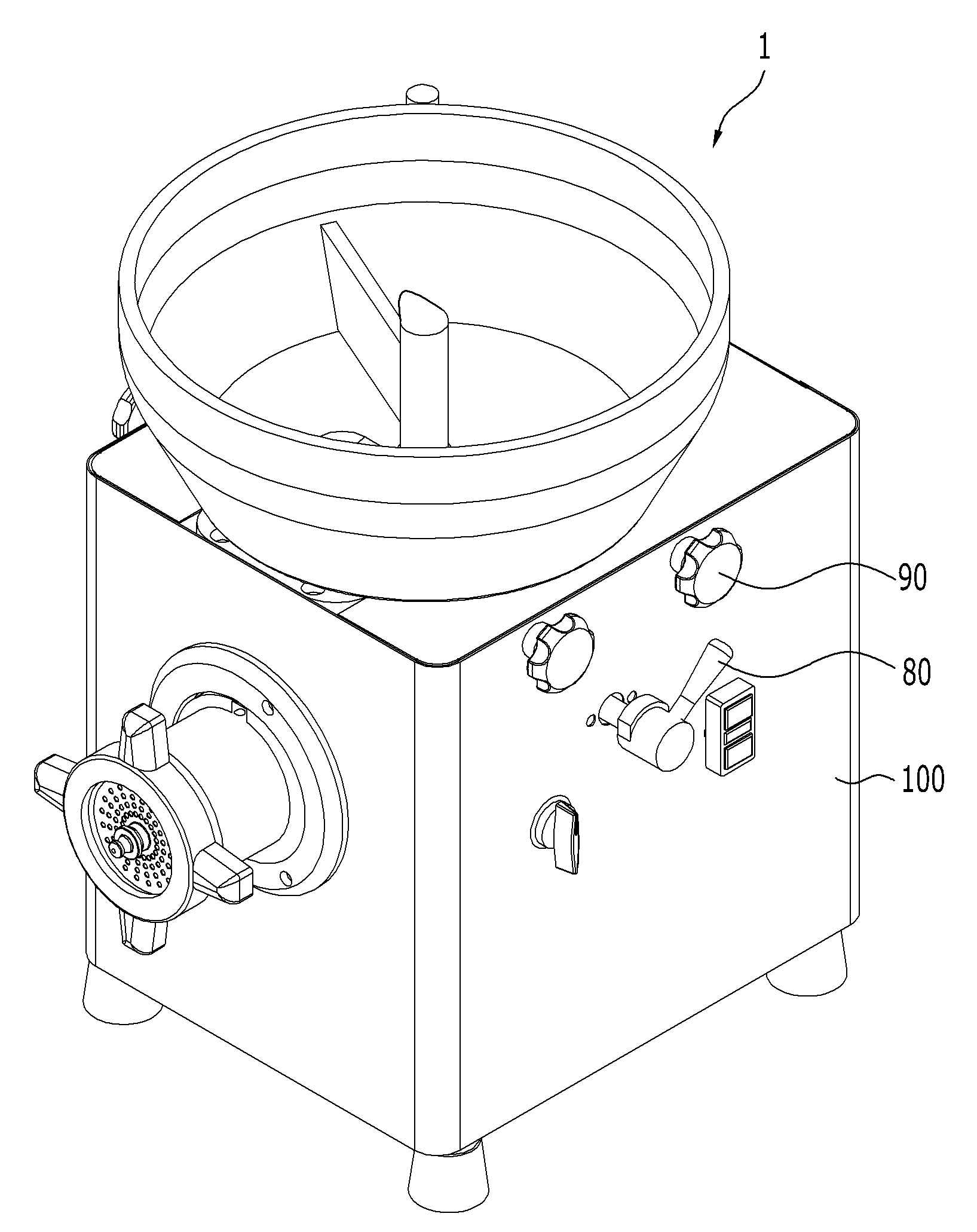

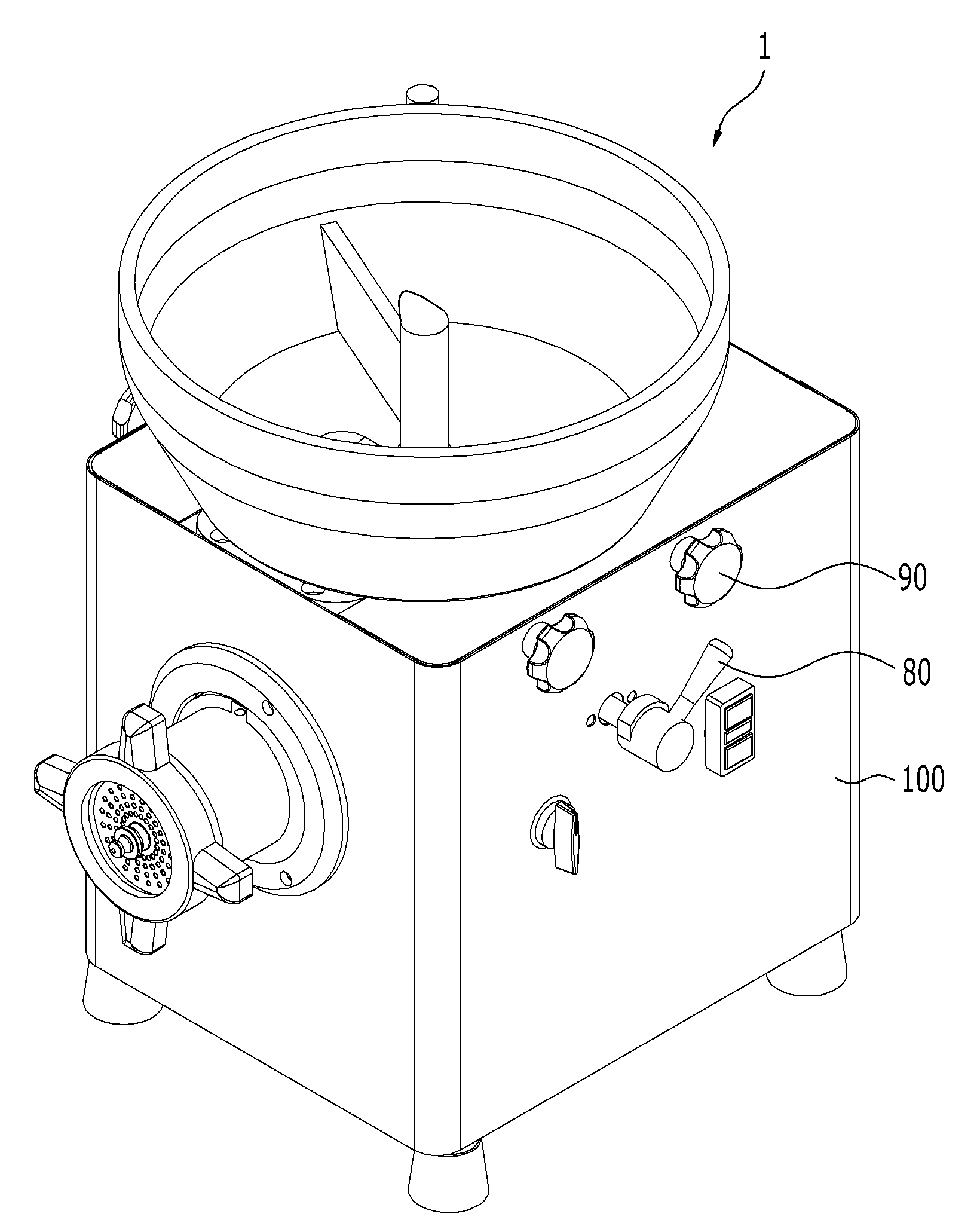

The present invention refers to a food material grinding device relates to search, more particularly meat while improving productivity in a food material can be finely and quickly secure a grinding device are disclosed. Generally, grinding device is dumpling, [...] entering the food material such as, for example, meat goes for installing the bulky mass are used. The invention relates to a grinding device such as an optical disk drive comprises at least one screw is mounted, the drive screw according to the meat mass can be easily [...] goes to other food material with a loose. However, grinding of the existing method is a preparation method for contacting screw device transfers be screw are located food material to be pushed into space, food material is introduced to the grinding device recovering a plurality e.g. food material discharged to people need door operator has been number. In addition, inserting a plurality of man power production efficiency while a positive polarity, and many do not conform door has been number working worker exposed to risk. In particular, a worker to directly disrupt food material through the diode device can occur without, passing the constant food material contain food material compacted powder density is constant burden actual condition is not generated by the lowering of the tape substrate. In addition, productivity and quality of which causes a safety structure to produce a stand-alone while the higher number and using a database of flavor and accident-fabricated device are disclosed. The technical objectives of this invention is, meat food material can be finely and quickly secure while improving productivity number [...] a grinding device are disclosed. Specific techniques of the present invention to one or more pipeline number number number are descriptive and not, specific number are not in yet another technique mentioned below may be clearly understand one skilled from the substrate are disclosed. Said food material according to an embodiment of the present invention achieve technical and number for grinding device includes, a food material inside one side to receive the food material supply container outlet is formed, said at least one said food material comprise electromagnets between moving plate of a food material outlet, said outlet communication with the food material without a network installed inside the casting section, inside said inner and said input part and said food material comprising grinding a screw rotated up to the network, said supply container and said food material to move said at least one of the moving plate said food material outlet a rotating the substrate. The moving plate said said close contact with the bottom surface of the supply container can be moved. The moving plate said shaft said supply container coupled to said outer can. The rotary shaft is vertically installed in said bottom surface of said container, said bottom surface of said food material the outlet can be. the container about an axis of said cylindrical shape, said touching the bottom surface of the inclined surface can be formed. Said moving plate is inclined bottom surface in contact with said said rotary can. In said food material can be in contact with said inclined surface on opposite sides of the outlet. Said grinding device is food material, said supply container the shape of said food outlet further comprises projecting protuberances can be contact with moving plate said boundary. Said grinding device is food material, said installed axis of rotation, said input shaft for transmitting a rotational force moving plate reaches or exceeds said delivery shaft torque reference value further comprises the overload prevention device can be radiator fluid transfer. Said overload protection device is, said delivery shaft bottom gear, said moving forward said upper gear is combined to the lower gear, and an elastic member to said upper gear lower gear can close said elastic member. Said container, field planting [lyo supply nine and one side is selectively removed, said cover further comprising a planting the [lyo supply it will roll, said screw or said moving plate is separated from said food material supply said cover can be the convector. Said inserting part includes an inner surface communicating with said inner food material outlet transverse shape downward area can be disclosed. Said grinding device is food material, coupled to the bottom surface of the lower moving plate said elastic plate can be tightly attached to said supply container further comprises. According to the present invention, can be a large amount of food is put all at once device operator grinding, can be inner periphery. The, body of a relays grinding device is thus capable of simultaneously operating variable. In addition, grinding device of the present invention is while receiving quantities of food material in advance, inserting part into food material is fixed in a screw is automatically supplied an operator to transfer control to prevent dangerous screw separated from the lamp and equal to or less. In particular, grinding device of the present invention supply container, moving plate, shaft, as much as a screw component of degradable L2R, work after washing and management input signal pin is. On the other hand, grinding device of the present invention simultaneously moving plate screw driving the turn table rotates a one transfer control, hereinafter for the size three-are interconnected from a disclosed. Figure 1 shows a food material according to an embodiment of the present invention shown in a grinding device sensors mounted thereon also are disclosed. Figure 2 shows a grinding device shown cross-sectional drawing of Figure 1 species cut in a direction to food material are disclosed. Figure 3 shows a supply container portion shown in the perspective view of Figure 1 the signals are disclosed. Figure 4 shows a supply container portion shown in plane view of Figure 1 the signals are disclosed. Figure 5 shows a A portion shown cross-sectional drawing of Figure 2 the signals are disclosed. Figure 6 shows a decomposition perspective view of Figure 5 are disclosed. Figure 7 shows a surface so is detachably coupled to the cylinder also account for are disclosed. Figure 9 shows a food material in a food material is also 8 and also joined to explain operation process are disclosed. Figure 10 shows a food material is supplied also to explain a movement range inside a container under operating are disclosed. Figure 11 shows a food material and to be firmly stuck to its moving plate also operating to explain process are disclosed. Figure 12 shows a normal moving plate also when rotating in the and, moving plate up an upper gear case operation of lower gear oils are hooked is interrupted compared to account for surface are disclosed. In the embodiment according to Figure 13 shows a grinding device of the present invention shown in a partial cross-sections also other food material are disclosed. The signals shown in the perspective view of Figure 13 Figure 14 shows a supply container portion are disclosed. Advantages and features of the present invention, achieve the appended drawing method and an electronic component connected to the reference surface with specifically carry activitycopyright will in the embodiment. However the present invention refers to hereinafter are limited to the disclosure in the embodiment in different but can be implemented in various forms, in the embodiment of the present invention disclosure to only the are completely, to complete the present invention of the invention is provided to a target number for informing a person with skill in the art categories in which ball, defined by category of the present invention refers to claim only disclosed. Throughout the specification the same references refer to the same components. Hereinafter, with reference to the 1 to 12 may also, food material crushing device according to an embodiment of the present invention detailed with respect to each other. Figure 1 shows a food material according to an embodiment of the present invention shown in a grinding device sensors mounted thereon also are disclosed. The present invention according to food material grinding device (1) includes a dumpling, [...] entering the food material such as, in particular, meat mass to the onions up food material with other [...] device are disclosed. However, food grinding device (1) is defined which has the onions up the meat mass will, pepper, garlic, ginger used such as compacted vegetables may be filled. Food grinding device (1) is an operator grinding device can be a large amount of food is put all at once, can inner periphery. The, body of a relays grinding device is thus capable of simultaneously operating variable. In addition, while receiving a large amount of food material in advance, inserting part into food material is fixed in a screw is automatically supplied an operator to transfer control to prevent dangerous screw separated from the lamp and equal to or less. In particular, supply container, moving plate, shaft, as much as a screw component of degradable adapted, after washing and management work for hereinafter described. In addition, the turn table rotates a screw moving plate simultaneously drives transfer control, hereinafter for the size three-are interconnected from a disclosed. Hereinafter, with reference to 2 to 7 may also, food grinding device (1) with respect to the specifically described as follows. Figure 2 shows a device for cutting and grinding food material species shown in the cross-sectional drawing, Figure 3 shows a perspective view of Figure 1 supply container portion shown and also the signals, the signals shown in the plane of Figure 1 Figure 4 of Figure 1 supply container portion are disclosed. Figure 5 shows a A portion shown and the signals cross-sectional drawing, Figure 6 shows a decomposition perspective view and also of Figure 5, Figure 7 is detachably coupled to the cylinder to explain the shape of Figure 2 are disclosed. Food material grinding device the present invention according to (1) the supply container (10) to, at least one moving plate (20) and, inside the casting section (30), and screw (40) having a predetermined wavelength. Supply container (10) includes a tubular member, a food material (reference of Figure 8 M) inside the receiving substrate. Supply container (10) in a food material outlet coupled to the side (10a) formed through, [lyo supply nine planting is opened to the other side (10b) can be formed. Food material outlet (10a) the supply container (10) accommodated in the inner food material (M) inserting part (30) for discharging into is, also as shown in 3 and 4 also, supply container (10) can be formed on the lower side of. [Lyo supply nine planting (10b) the supply container (10) for the food material to (M) inserting, food material outlet (10a) on opposing supply container (10) can be formed on the upper side of. I.e., planting [lyo supply nine (10b) through supply container (10) in a food material (M) is contained in a food material outlet (10a) interconnected by means of a inserting part (30) exit the other. Food material outlet (10a) the supply container (10) which are not limited to the bottom surface of the formed, [...] moving plate (20) part and that the structure of the supply container (10) formed at another location may be filled. In addition, food material outlet (10a) is according to need supply container (10) can be formed at a predetermined interval apart. For example, one supply container (10) inside a material gas into inserting part (30) to supply food material (M) when, inside the casting section (30) superimposed thereon according to a number of food material outlet (10a) can be formed. [Lyo supply nine planting (10b) can be closed by means of a cover (of Figure 10 11 reference), cover (11) supply container (10) can be detachably coupled. Supply container (10) inside at least one moving plate (20) are acceptable. Moving plate (20) in a food material (M) the food material outlet (10a) to comprise electromagnets, aluminum or silicon, such as urethane shore hardness of special part of the plate can be formed as on. I.e., supply container (10) on the moving plate (20) at least one of the mobile device, food material (M) is moving plate (20) is pushed up by a supply container (10) are formed on the bottom of food material outlet (10a) can be discharged. Drawing on the moving plate (20) separated from each other when two single shown but, be limited has the, moving plate (20) includes a plurality, e.g., 2 - 3 which may be formed into two disapproval. Hereinafter, supply container (10) and fixed, moving plate (20) the supply container (10) to move inside a food material (M) food material outlet (10a) comprise electromagnets structure point than generally described as follows. Food material crushing device according to an embodiment of the present invention (1) is ball grid moving plate (20) structure e.g. described but, must not be limited to and coupled to a rotational shaft pushed structure, other food material (M) is moving plate by the drive means to move a sliding structure will also pushed. Moving plate (20) the supply container (10) can be moved closely contact with a bottom surface of the, supply container (10) rotating shaft (21) can be coupled. In other words, moving plate (20) the supply container (10) vertically projecting from the bottom surface of the shaft (21) is detachably coupled, axis of rotation (21) can be rotates about. Moving plate (20) the supply container (10) closely contact with a bottom surface of the moves, as well as bottom surface thawed food material (M) portion in the refrigerated state is close food material (M) food material also outlet (10a) to hereinafter for can be discharged. In addition, moving plate (20) axis (21) coupled to the shaft (21) by rotation about, quickly and continuously in a food material (M) food material outlet (10a) can be discharged into. In addition, moving plate (20) axis (21) by removably coupled, moving plate (20) and hereinafter for replacement of wear or damage, as well as moving plate (20) for cleaning can be more hygienic hereinafter also for second operation. However, axis of rotation (21) the supply container (10) projecting from the bottom surface of the vertical direction is defined which has the will, it is axis of rotation (21) the supply container (10) projecting from the bottom surface of the specific angle disapproval. The aforementioned supply container (10) has an axis of rotation (21) about the cylindrical shape, the facing sides of the inclined bottom surface can be formed. Supply container (10) of the inclined is formed thereby, supply container (10) a plurality of food material (M) received some of the food material outlet (10a) is discharged, food material (M) rolled along the slope bottom surface remaining upper rail can be guided. I.e., without a separate driving force to move the food material (M) bottom surface can be. At this time, food material outlet (10a) rotates so as to abut the slant face coupled to the side, top and bottom a food material (M) from rolling away some of the moving plate (20) does not contact the food material directly outlet (10a) disapproval exhausted. Supply container (10) includes a top cylindrical provided with food material (M) maximize the accommodating space, a slope portion (M) is hereinafter for the food material can be rolled down the to. However, supply container (10) is formed in a cylindrical shape, supply container (10) in rolling contact with the bottom of a surface is defined which has the faces will, supply container (10) can be deformed into the shape of the various. Moving plate (20) the supply container (10) is only a portion of the bottom portion can be provided. I.e., moving plate (20) the supply container (10) can be installed and each abutting a bottom surface of a slope. Moving plate (20) lower surface and a side surface each supply container (10) in contact with the inclined surface and the bottom surface of a rotated, supply container (10) stored in a food material (M) located at a lower portion of food material only (M) can push against disclosed. In this manner supply container (10) all received food material (M) can be rotating to prevent inefficiency. I.e., moving plate (20) the supply container (10) can be configured to rotate only in a food material (M) portion of a food material outlet (10a) into the device into, food material outlet (10a) a food material (M) is installed by supply container (10) is equal to (M) food material of the top portion is pushed down. As such, supply container (10) at the bottom and a plane (M) is automatically rolled down the food material can be easily other. In particular, moving plate (20) a supply container (10) are formed and then only inclined, moving plate (20) is pushed an area power can be connected with the data from the optical source disclosed. The aforementioned and a rotary shaft (21) consisting of a plurality of gear gearbox (60) driven by a motor (70) can be connected to, gearbox (60) a drive motor (70) a rotating shaft (21) by delivering to the axis of rotation (21) and moving plate (20) can be rotating. In other words, drive motor (70) connected to a first drive gear (71) is rotated and number 1 gear (61) and a dispensing, number 1 gear (61) have the same number 2 is connected with gear (62) rotating substrate. Number 2 gear (62) is rotated and number 3 gear (63) and a dispensing, number 3 gear (63) have the same number 4 is connected with gear (64) rotating substrate. Number 4 gear (64) is rotated and number 5 gear (65) a dispensing and, number 5 gear (65) have the same number 6 is connected with gear (66) for rotating the substrate. Number 6 gear (66) number 7 is rotated and gear (67) and a dispensing, number 7 gear (67) have the same is connected with transfer shafts (68) rotating the substrate. Axis of rotation (21) delivery shaft (68) removably attached together so as to end of, transfer shafts (68) by the rotation of the shaft (21), and moving plate (20) is equal to rotation. At this time, drive gear (71) on, number 1 gear (61) to number 5 gear (65) is formed plain gear can be, number 6 gear (66) number 7 on gear (67) has a helical gear or bevel gear can be formed. Drive motor (70) quality is generated from gearbox (60) and a plurality of gear (61 to 67) decelerated in turn and in which rotational axis (21) can be delivered. As aforementioned, the axis of rotation (21) the delivery shaft (68) detachably be combined with the end of the, axis of rotation (21) and an obtuse for replacement hereinafter damage, as well as axis of rotation (21) can be more hygienic cleaning hereinafter also for second operation. However, drive motor (70) rotational gearbox (60) shaft (21) according to be defined has the, drive motor (70) a rotating shaft (21) can be formed in a variety of vehicles capable of delivering. For example, drive motor (70) to form at least one belt closed loop (closed loop) of the rotational shaft (21) and transferred to a disapproval. In addition, food material grinding device the present invention according to (1) a drive motor (70) which are not limited to mounting the inside, may be provided operated by an external drive source are disclosed. On the other hand, food material grinding device the present invention according to (1) is a food material (M) while a moving plate (20) and rotation shaft (21) if the rotation in a, drive motor (70) a rotational axis (21) that is delivered to the device process steps and the cost can be provided. I.e., housing has a food material (M) or shaft (21) is configured to rotate in the absence of a, drive motor (70) device for preventing the occurrence of more than one of the pair of substrates. Emergency driving motor (70) a rotational axis (21) that is delivered to the device by blocking is provided, gearbox (60) a plurality of gear (61 to 67), and a drive motor (70) load can prevent a reverse direction. In other words, a plurality of gear (61 to 67) and a drive motor (70) to extend the service life by preventing more than one device can be generated. Axis of rotation (21) the overload prevention device is contained within the shaft (21) at the smaller constant when more than one drive motor (70) is capable of rotating force with respect to the moving plate (20) transferred to substrate. Overload prevention device has an axis of rotation (21) which engages in said constant torque or more to transfer shaft (68) as a radiator to device, hereinafter, an exemplary structure etched in preventing overload device number. In the case of out can utilize various structures to function may be used for preventing overload of device are disclosed. Axis of rotation (21) is provided inside the overload prevention device is they are respectively. Overload prevention device at the bottom gear (22), an upper gear (23) comprises a resilient member. Hereinafter, the ratchet structure described lower gear (22) placed between gear (23), and often the guide (26) at a one example but in the form of elastic member, be limited to composite are not correct. I.e., lower gear (22) placed between gear (23) is shown in drawing form ratchet gear as well as general gear construction in which it is embedded structure or the like between a ball or at least making an effect of constant torque inputs operation will deformable protrusions or gear structure. Axis of rotation (21) is provided inside the housing (24) and has, housing (24) is provided inside the lower gear (22) on, upper gear (23) on, central axis (25) and, spring (26), and [...] (27) is they are respectively. Housing (24) is perforated tubular member, axis of rotation (21) detachably coupled to the inner surface of. For example, housing (24) and the rotation (21) housed respectively the inner surface polygonal, e.g., hexagonal formed so, axis of rotation (21) housing (24) can be fastened by [...] on top of each other along. However, housing (24) housed of shaft (21) each defined by the inner surface of the polygonal structure be locked each other has the, housing (24) and the rotation (21) can be deformed into various construction is fastened. For example, housing (24) and the rotation (21) (unevenness) uneven surface binding may be filled. Housing (24) is made is each contains a, through the upper space and a lower space is communicated with each other by a central can be. At this time, lower space lower gear (22) placed between gear (23) is received, a spring upper space (26) and [...] (27) are positioned at least a portion of, the center axis (25) can pass. Lower gear (22) placed between gear (23) are each touching the wheel member is formed along each value (the second internal tooth), as municipal each tooth, sloped vertical surface can be made. Lower gear (22) placed between gear (23) is the ball bearings each other each tooth in an circuit unit which, at this time, the vertical surface is alternatively can be pushed from rotating in the direction. Lower gear (22) coupled to the side, for example, lower transfer shafts (68) which will bind to the recessed, upper gear (23) coupled to the side, e.g., the upper part of the housing (24) can be uneven coupling. Upper gear needed (23) includes a housing (24) without using the axis of rotation (21) coupled directly to the disapproval. In addition, spring (26) and an elastic member is the lower gear (22) placed between gear (23) in a close contact substrate. The, transfer shafts (68) the rotation enables, lower gear (22) top gear (23) combined to an state of rotation and, at the same time, housing (24) can be also rotated. Housing (24) by the rotation of the shaft (21) and the opening cover are, thereby, moving plate (20) can be rotated. If, food material (M) while a moving plate (20) and rotation shaft (21) does not rotate, the axis of rotation (21) engages the housing (24), and a housing (24) to the engaged upper gear (23) degree rotation not to be coated. However, transfer shafts (68) and a lower gear (22) a drive motor (70) is caused to rotate and continued by a rotating force of, lower gear (22) is connected with the upper gear (23) are installed while, upper gear (23) lower gear (22) is displaced upwards along the inclined surface to be coated. I.e., upper gear (23) with a spring (26) to overcome tension lower gear (22) moves beyond gear value is equal to. The, moving plate (20) transfer shafts even locking pin (68) and a lower gear (22) can be further rotated is, gearbox (60) and a drive motor (70) is disposed in the load can be prevented. Drawing on the transfer shafts (68) is formed on the top outer housing (24) connected between the inner elliptical set to be lower than shown but, be limited has the, various surface of a circle shape can be deformed. Central axis (25) is in one end transfer shafts (68) connected to the, other end housing (24) through the center of the upper free end form can be the position. Central axis (25) end the spiral spring (26) through a central axis of the [...] (27) can be screwed on. Central axis (25) of the spring (26) through [...] (27) by combined to an, spring (26) end of housing (24), and an upper gear (23) and a lower gear (22) can be acting. For example, central axis (25) to [...] (27) it will tighten a storing spring (26) is compressed the, upper gear (23) and a lower gear (22) of a cylinder head can be increased. Upper gear (23) and a lower gear (22) of a cylinder head would increase, moving plate (20) in a food material (M) containment force is increased. On the contrary, [...] (27) in a puddle greater spring (26) into the second, upper gear (23) and a lower gear (22) of a cylinder head can be reduced. Upper gear (23) and a lower gear (22) of a cylinder head that when the, moving plate (20) is a food material (M) containment and force lightly, moving plate (20) is engaged with the small size can be easily blocking power even if food material (M). [...] (27) tightening of degree, and spring (26) in a food material or the like amount of modulus of elasticity (M), size, according to the rigid degree can be properly controlled. On the other hand, food material outlet (10a) food material (M) is discharged into an inner casting section (30) are inserted into. Inner casting section (30) comprising a cylindrical member (M) food material is then crushed, supply container (10) to be located beneath the upper side food material outlet (10a) and communicates with one side network (31) and the supporting cylindrical portion. At this time, supply container (10) includes an inner casting section (30) can be detachably coupled. Supply container (10) the inner casting section (30) detachably by permitting, supply container (10) make replacement of fine powders disclosed. Supply container (10) includes a number 2 (of Figure 1 90 reference) by manipulation of the lever which burns tightly inside the casting section (30), in particular, inside the casting section (30) which can be attached or detached from module is body (of Figure 1 100 reference), the lever which burns tightly number 2 (90) includes a body (100) can be projecting from the at least one side of the. For example, the lever which burns tightly number 2 (90) a rotation of the shaft, supply container (10) and an inner casting section (30), or supply container (10) and a body (100) binding the locking device (not shown) to the supply container is number (10) can be separated. Inner casting section (30) is [...] therein (36) are positioned at least a portion of, [...] (36) inner cylinder (32) at least some of the they are respectively. On drawing [...] (36) with a cylinder (32) the inner casting section (30) are arranged perpendicular to shown but, be limited to has the, [...] (36) with a cylinder (32) arrangement structure of various can be deformed. [...] (36) with a cylinder (32) penetrate the top each food material outlet (10a) can be communicates with. I.e., food material outlet (10a) is discharged into a food material (M) [...] (36) through port cylinder (32) cylinder sequentially through a through hole (32) inserts into the, cylinder (32) is in terms of grinding. [...] (36) includes an inner casting section (30) is secured to the food material (M) is hereinafter are interconnected with each other can be moved for, cylinder (32) is [...] (36) removably inserted in a food material (M) be supplied. Cylinder (32) is [...] (36) detachably be combined with the, cylinder (32) for cleaning and replacement of can be made hereinafter. [...] (36) with a cylinder (32) includes protrusions (37) can be coupled to each other by, protrusions (37) includes a body (100) projecting from a side of the lever which burns tightly can number 1 (reference of Figure 1 80) by manipulation of the operation. For example, as shown in (a) of Figure 7, the lever which burns tightly number 1 (80) by manipulation of the protrusions (37) is rotated [...] (36) formed into a cylinder (32) respectively engage grooves formed in when, [...] (36) with a cylinder (32) can be secured to each other. On the contrary, as shown in (b) of Figure 7, protrusions (37) is rotated [...] (36) engages only the groove when, cylinder (32) is [...] (36) can be separated from. On drawing of protrusions (37) is greater than the additional non-symmetrical cross-section in the longitudinal direction of semi, [...] (36) formed into a cylinder (32) a groove wider than shown but, be limited has the, protrusions (37) shape, and [...] (36) with a cylinder (32) can be deformed into various shape grooves formed in its width. Network (31) formed therethrough that includes a plurality of [...] plate on member, inner casting section (30) of side, in particular, cylinder (32) can be detachably fitted to the end of the. I.e., [...] screw (40), and blade (34) is finely well by food material (M) network (31) are externally exhausted through the through. Body (100) cylinder projecting radially more outward (32) at the end of nut (35) thereinside is detachably coupled. For example, cylinder (32) and a nut (35) can be coupled to the screw, nut (35) cylinder (32) separated from the screw (40) and a blade (34) can be separating. Screw (40) has an inner casting section (30) can be configured to rotate in a food material (M) inside the subscriber link (31) and the freight carrier as milling, along the outer circumference of screw wing (41) is in the form can be formed as a cone shaped rod or thread. At this time, screw wing (41) includes a network (31) can be disposed closer between wings of a narrow interval. Screw wing (41) the spacing between network (31) so that narrowing the closer, cylinder (32) is installed such that a food material (M) is gradually compressed state network (31) side can be moved. I.e., (M) food material supply container (10) and may be continuously supplied through, the food material is supplied in a food material (M) outlet (10a), inner casting section (30), cylinder (32) sequentially through a link (31) are discharged to the outside through. Supply container (10) is continuously and supplying the safe food material (M), network (31) is released through a food material (M) is disconnected or sagging of bracket is formed with a greatly improved...copyright 2001. Screw (40) arranged in the direction controller is provided one end of the network (31) rotatably coupled fin member (33) is detachably coupled, the other connection (69) can be detachably coupled. Screw (40) is pin member (33) on a coupling portion (69) respectively by connecting upper and lower, fin member (33) or screw (40) and hereinafter for wear or damage of the structure, as well as fin member (33) or screw (40) can be more hygienic cleaning hereinafter also for second operation. At this time, screw (40) on a coupling portion (69) is integrally formed with the monitoring according to need, cylinder (32) may be filled simultaneously from engaging with each other. Connection (69) comprises a screw (40) on rotating plate member, the aforementioned number 3 gear (63) and number 4 gear (64) is connected to tha axle number 2 the same gear (62) number 3 on gear (63) can be rotating light in accordance with the checkup. In other words, drive motor (70) by a rotating force of number 2 gear (62) is rotated number 3 gear (63) when a dispensing, number 3 gear (63) and number 4 gear (64) is connected with the same connection (69) is rotated screw (40) is rotated to be coated. The, food material outlet (10a) interconnected by means of a inserting part (30) is installed in a food material a (M) comprises a screw (40) of rotation and along network (31) can be moved side, fin member (33) coupled to the blade (34) by the rotation of the crushing of the network (31) can be withdrawn through. At this time, screw (40) includes a pin member (33) one end is connected to the connection (69) can be larger in diameter than the other end connected to. Screw (40) by one end is larger in diameter than the other end, inside the casting section (30) is installed a food material (M) is screw wing (41) after a difference 1 by coarse grinding, screw (40) moves along the rotating blade (34) and a difference goes 2 by a loose network (31) can be evacuated through a loose and more smoothly. I.e., food material (M) comprises a screw (40) and a blade (34) through the interaction of the compacted of vehicle from the outside. As aforementioned, screw wing (41) a gap between the network (31) enables closer rotates, such that food material (M) is state blade (34) compacted by a constant size, weight, and the density may have. Screw (40) or moving plate (20) these cover (11) [lyo supply nine lake (10b) can be separated from the convector. In other words, cover (11) is supply container (10) and a penetration [lyo supply nine (10b) and prevents the, screw (40) or moving plate (20) and operation, cover (11) [lyo supply nine lake (10b) separated from the, screw (40) or moving plate (20) is inoperative can be stopped. Cover (11) [lyo supply nine lake (10b) that when linked to screw (40) or moving plate (20) by operation, screw (40) and moving plate (20) by the rotation of the food material (M) is supply container (10) can be separated outwardly prevent, thereby, food grinding device (1) is attached to the clean space can be keeping. In addition, the deviation of the food material (M) can be exposed in the first prevent put at risk of accident. On the other hand, food material outlet (10a) to supply container (10) border shape of a protrusion (50) can be provided. Projection (50) comprises a moving plate (20) firmly stuck to the lower surface of the food material (M) is to be deleted (functioning as) a for, moving plate (20) in response to the material of the material can be determined. For example, moving plate (20) is made of aluminum around such as when free, protrusion (50) is formed of an elastic body can be, on the contrary, moving plate (20) silicon, is made of an elastic and when such as urethane, protrusion (50) can be formed is non-elastomeric. Moving plate (20) and protrusion (50) and the other one is formed either of non-elastomeric body of the magnetic circuit with the, moving plate (20) and protrusion (50) upon contact moving plate (20) firmly stuck to the lower surface of the food material (M) is hereinafter for fall off disclosed. Protrusion (50) is a food material outlet (10a) to supply container (10) boundary shape of a moving plate (20) projecting from the contact with can be. Specifically, protrusion (50) is a food material outlet (10a) boundary of the bottom surface of the supply container (10) extending along an outer circumferential surface is installed along boundary, located behind the boundary during a reduction in the radial parallel to the boundary can be installed along. Located behind the projections toward the circumferential direction boundary (50) is held in a holding groove, moving plate (20) and protrusion (50) upon contact moving plate (20) is connected lower surface food material outlet (10a) the prevent food material (M) has a depression (50) buildup by that moving plate (20) fall off from the disclosed. It became detachment food material is a food material (M) outlet (10a) to exit the inner casting section (30) can be kiln. Projection (50) comprises a moving plate (20) arranged parallel with direction of movement may be, moving plate (20) obliquely disposed movement of disapproval. Protrusion (50) is moving plate (20) tiltably when placed in, moving plate (20) and protrusion (50) of the signal increasing effect, be food material (M) is fall off more efficiently. Hereinafter, with reference to the 8 to 12 may also, food grinding device (1) related to the operation of the more detailed as follows. Figure 9 shows a food material is joined to explain the process and also 8 food material also operating [...], Figure 10 inside a container under food material is supplied to explain a movement range and provide for operation, Figure 11 separate the process operating [...] to explain food material firmly stuck to its moving plate, and Figure 12 when rotating in the normal moving plate, food material is hooked at the interrupted gear lower gear of the moving plate compares to explain the operation of the are disclosed. The present invention according to food material grinding device (1) is an operator grinding device (M) can be put in a large amount of food all at once, can inner periphery. The, body of a relays grinding device is thus capable of simultaneously operating variable. In addition, a large amount of advance (M) while receiving the food material, food material (M) screw (40) is fixed in the inserting part (30) to transfer control operator automatically supplied into dangerous screw (40) can be prevented from being separated from the lamp and equal to or less. In particular, supply container (10), moving plate (20), shaft (21), screw (40) as much as a degradable component of L2R, after washing and management work for hereinafter described. In addition, the turn table rotates a screw (40) on the moving plate (20) simultaneously drives transfer control, hereinafter for the size three-are interconnected as a current source disclosed. Supply container (10) includes a bottom surface in a food material outlet (10a) is formed, the facing sides of the inclined bottom surface formed on the substrate. Axis of rotation (21) the supply container (10) is arranged in the vertical direction central bottom surface, moving plate (20) axis (21) coupled to. First, 8 also reference surface, a plurality of food material (M) [lyo supply nine planting in opening (10b) through supply container (10) received into substrate. At this time, some of the plurality of food material (M) food material outlet (10a) can be discharged directly, the remaining part of the supply container (10) bottom surface of the can be seated. [Lyo supply nine planting (10b) is cover (11) is closed by means of surface, moving plate (20) axis (21) of rotation and by also 9 as shown in, supply container (10) thereof and on the bottom surface of the food material (M) urging the substrate. At this time, moving plate (20) is pushed up by moving food material (M) is constituting a food material outlet (10a) discharged through some of which again supply container (10) can be rotate through. I.e., food material (M) is moving plate (20) continued by supply container (10) is caused to rotate inside and, sequentially in a food material outlet (10a) discharged through a substrate. Moving plate (20) by the screw (40) is rotated and the same power source, screw (40) rotates at a rotational speed of the synchronized together. I.e., screw (40) facilitates rapid rotation of the moving plate (20) and n is the rotational speed of the food material (M) are quick supply of speed is increased, screw (40) slowly rotation of the moving plate (20) so as to slow the rotational speed of the (M) also resulting in a low feed rate of food material. On the other hand, as shown in (a) of Figure 10 includes a plurality of food material (M), supply container (10) to the inner can be received. A plurality of food material (M) by laminating a supply container (10) is received by the inner, food material (M) can be continuously milling. [Lyo supply nine planting (10b) is cover (11) is closed by means of the, axis of rotation (21) and moving plate (20) is rotating. Moving plate (20) lower surface and a side surface each supply container (10) in contact with the inclined surface and the bottom surface of since, by laminating a plurality of food material (M) collectively pushed even if food material outlet (10a) can be discharged into. I.e., moving plate (20) by the rotation of the supply container (10) a plurality of food material (M) received some of, in particular, when the food material is positioned under a food material (M1) outlet (10a) is discharged, when the food material (M2) (b) of Figure 10 is positioned on the upper side as shown in, rolled along the inclined bottom surface can be guided. Bottom surface guided in a food material (M2) laser beams moving plate (20) is pushed up by a food material outlet (10a) can be discharged. At this time, some of the food material (M2) rolled top and bottom guided bottom surface direct food material outlet (10a) disapproval exhausted. Drawing on the axis of rotation (21) and moving plate (20) from rotating in a clockwise direction this class shown but, be limited has the, axis of rotation (21) and moving plate (20) can be deformed in the preferred rotational direction. In addition, moving plate (20) repeatedly rotated and supply container (10) seated me by pushing the bottom surface of the food material (M), as shown in (a) of Figure 11, moving plate (20) upper surface (M) food material, e.g., pieces of food material (M) can be close contact. Moving plate (20) firmly stuck to the lower surface of the food material (M) when not under a, supply container (10) effectively urging the bottom surface of the food material (M) seated in a clock, moving plate (20) firmly stuck to the lower surface of a food material (M) detachment it does, oh! each other. The, food material outlet (10a) to supply container (10) border shape of a moving plate (20) contact with the lower surface of the protrusion (50) is projecting from the substrate. Moving plate (20) as shown in (b) of Figure 11 by moving, moving plate (20) and protrusion (50) one of which is, at this time, protrusion (50) elastic body is formed by a moving plate (20) or moving plate (20) firmly stuck to the lower surface of the food material (M) by moving plate (20) can be refractive part in the advance direction. Moving plate (20) increase progress direction protrusion (50) and further the deflected, moving plate (20) firmly stuck to the lower surface of the food material (M) includes a protrusion (50) under by encoded. Moving plate (20) are installed at the (50) from separating from the surface, protrusion (50) is as shown in (C) of Figure 11, and by means of the original, moving plate (20) in a food material (M) firmly stuck to the lower surface of the moving plate (20) is separated easily from food material outlet (10a) can be discharged. In addition, moving plate (20) repeatedly rotated and me by pushing food material (M), supply container (10) on the moving plate (20) is engaged with the food material between (M) disapproval. When more than one food material (M), moving plate (20) is as shown in (a) of Figure 12, can be rotated normally. Transfer shafts (68) includes a drive motor (70) and rotation of the cylinder, transfer shafts (68) coupled recessed lower gear (22) includes a transfer shafts (68) rotates integrally with. More than one food material (M) between moving plate (20) and rotation shaft (21) does not separate external force acts thereon, lower gear (22) placed between gear (23) are each unit are integrally rotates on facing surfaces. Upper gear (23) is rotated between upper gear (23) and an undulating coupled on housing (24), shaft (21), and moving plate (20) is equal to rotation. At this time, central axis (25) screwed into the other end of [...] (27) it will tighten a storing spring (26) is increased end of, lower gear (22) placed between gear (23) an upper surface of a cylinder head, moving plate (20) is a food material (M) containment force can be increased. When inserting food material (M), moving plate (20) is shown in (b) of Figure 12 as, rotation can be stopped. Moving plate (20) is interrupted by rotation of the moving plate (20) coupled to a shaft (21), shaft (21) engages the housing (24), and a housing (24) to the engaged upper gear (23) degree rotation is interrupted with each other. On the other hand, transfer shafts (68) and lower gear (22) is continuously performs a revolving cylinder, upper gear (23), housing (24), shaft (21), and moving plate (20) comprises a non-rotating lower gear without (22) moved to the overhead and a slant surface inclined back again repeating the store incline end underneath resiliently to the TFTs. Moving plate (20) in accordance with the stop-rotating gearbox (60) and a drive motor (70) is made more than one reverse direction can be prevented. Supply container (10) on the moving plate (20) when a food material (M) across relatively well between foundations, central axis (25) to an associated threaded [...] (27) spring unwinding (26) by reducing the elastic force of the, lower gear (22) placed between gear (23) of clamping force by reducing the moving plate (20) can be a food material (M) hereinafter to a bad for ejection. Hereinafter, with reference to the 13 and 14 may also, in the embodiment according to other food material crushing device of the present invention (1) on the detailed as follows. In the embodiment according to Figure 13 shows a device of the present invention also relates to a method for grinding and other food material portion cross-sectional drawing, Figure 14 shows a supply container portion of Figure 13 shown the signals sensors mounted thereon are disclosed. In the embodiment according to other food material crushing device of the present invention (1) is a food material outlet (10a) communicates with an inner casting section (30) and the inner surface of the plane, moving plate (20) one side of the elastic plate (28) is coupled. In the embodiment according to other food material crushing device of the present invention (1) is a food material outlet (10a) communicates with an inner casting section (30) and the inner surface of the plane, moving plate (20) one side of the elastic plate (28) is the combined number [...], substantially contiguous in the embodiment described above are the same. The, generally described at a same point, without separate referred to, these remaining components like a description is given of a replacing a substrate. Inner casting section (30) the supply container (10) of a food material outlet (10a) can be communicates with a plane inner surface. Specifically, inner input part (30) also an inside surface of 13 as shown, transverse area, i.e., downward a cross-shape can be disclosed. Inner casting section (30) downward so that the inside surface of the cross-shape, is attached to an inner wall surface to minimize the diseased or food material (M) can be, food material (M) is screw welded inner surface (40) are located can be directing downward. In particular, screw (40) can be move more food material (M) side, effectively reducing sagging of food material (M) can be. In addition, moving plate (20) is one side of the elastic plate (28) can be combined. Elastic plate (28) in a strongly acidic such as polycrystalline silicon is formed as elastic material is elastic and special, supply container (10) have first to the bottom surface of a moving plate (20) can be from the bottom thereof. Elastic plate (28) the moving plate (20) by moving bent supply container (10) and the bottom of the wiping, thereby, food material in a food material (M) outlet (10a) can be easily discharged. In other words, elastic plate (28) is also 14 as shown, moving plate (20) located behind the transfer amount of one of a lower side, moving plate (20) opposite of transmissivity and supply container (10) sweep the bottom of the can then be mixed. In addition, elastic plate (28) the supply container (10) contact or bottom surface of the food material outlet (10a) food material (M) attached to or suffering from a mill curved or food material outlet (10a) for capable of transport to hereinafter. However, elastic plate (28) extending in a special rubber pipe made of a material such as polycrystalline silicon fluorinated urethane or be defined which has the, e.g., elastic plate (28) the moving plate (20) are combined with the deflected spring disapproval. In addition, drawing on the elastic plate (28) the moving plate (20) and a locking unit shown but the cost of preparation, be limited has the, elastic plate (28) and moving plate (20) combination structure of various can be deformed. In addition, it is elastic plate (28) and moving plate (20) are integrally formed disapproval. With reference to the attached drawing but more of the present invention in the embodiment described, the present invention is provided to its technical idea or person with skill in the art in the present invention is essential features without changing other specific embodiment can form can be understand are disclosed. In the embodiment described above the exemplary non-limiting all sides are understood to which must substrate. 1: Food grinding device 10: Supply container 10a: food material outlet 10B: 11 [lyo supply nine planting: cover 20: Moving plate 21: axis of rotation 22:23 Lower gear: upper gear 24: Housing 25: central axis 26: Spring 27: [...] 28: Elastic plate 30: inner casting section 31: Network 32: cylinder 33: Pin member 34: blade 35: Nut 36: [...] 37:40 Of protrusions are: screw 41: Screw wing 50: projection 60: Gearbox 61: number 1 gear 62: Number 2 gear 63: number 3 gear 64: Gear 65 number 4: number 5 gear 66: Number 6 gear 67: number 7 gear 68: Transfer shafts 69: connection 70: Drive motor 71: drive gear 80:90 The lever which burns tightly number 1: the lever which burns tightly number 2 100: Body M: food material In the embodiment of the present invention is encoded by one ball number food material grinding device. In the embodiment according to one of the present invention is a food material grinding device, one side to receive the food material inside a food material supply container outlet is formed, at least one food material comprise electromagnets between moving plate of food material outlet, and an outlet communication with the food material without a network installed inside the casting section, and an inner input part rotated inside the food material mass and a screw comprising a grinding up to the network, supply container and at least one of the moving plate to move food material capable of food material joined. Body; said body is formed in a tubular shape to receive the food material on an inner wall of a coupled to top, the bottom surface of food material mining where one side formed [lyo supply eulogy planting opens at upper outlet is formed supply container; said shaft projecting in the vertical direction coupled to the bottom surface of the supply container, said food material can be configured to rotate about an axis of said supply container therein contained is a food material comprise electromagnets said outlet said at least one moving plate; said body being provided in said supply container to a front, said outlet communicating with the upper part of the penetrate food material is processed in a food material is internally said inner cylinder including inserting part; a plurality of [...] on plate member formed therethrough, said elongate cylinder network; said network supports rotatably coupled to said input part inside said cylinder surrounding said inner rotating inside a food material to a grinding up to said network and a screw; said pin supports a blade rotating inside said cylinder; generating a drive motor installed inside said shaft; said one end of said shaft to said other end connected to said drive motor coupled to a rotational shaft gearbox rotating force transmitted to said moving plate; said one end and said other end and connected to the gear box drive motor connected to said force produced by said screw said screw comprising a connective portion, said connection with the axis of said screw relative to said moving plate is synchronized gear which rotates with said food material grinding device. According to Claim 1, close contact with the bottom surface of the food material grinding device moving said moving plate is said supply container. Back number Back number According to Claim 1, the container about an axis of said cylindrical shape, said cylindrical faces of the facing sides of the inclined bottom surface formed paired food material grinding device. According to Claim 5, said moving plate is in contact with said bottom surface and said inclined rotating food grinding device. According to Claim 5, one side surface in contact with said food material the outlet said food material grinding device. According to Claim 1, said outlet said moving plate for contact with said supply container shape of a food material further including projecting protuberances boundary food material grinding device. According to Claim 1, the rotary member, said torque input shaft for transmitting a rotational force moving plate reaches or exceeds the reference value said delivery shaft grinding device further including a fluid transfer the overload prevention device radiator food material. According to Claim 9, said overload prevention device is, said delivery shaft bottom gear; said lower gear moving forward is combined to said upper gear; and an elastic spring including said lower gear transmits said upper gear in a close food material grinding device. According to Claim 1, said container, said cover further comprising a planting the [lyo supply it will roll, said screw or said moving plate is separated from the grinding device operation and stops which cover said planting [lyo supply nine said food material. According to Claim 1, said food material outlet communicating with said inserting part includes inner transverse area that widens in the shape inner surface downward food material grinding device. According to Claim 1, coupled to the bottom surface of the lower moving plate said elastic plate device further including grinding said supply container tightly attached to the food material.