제빙기 살균 제어 장치

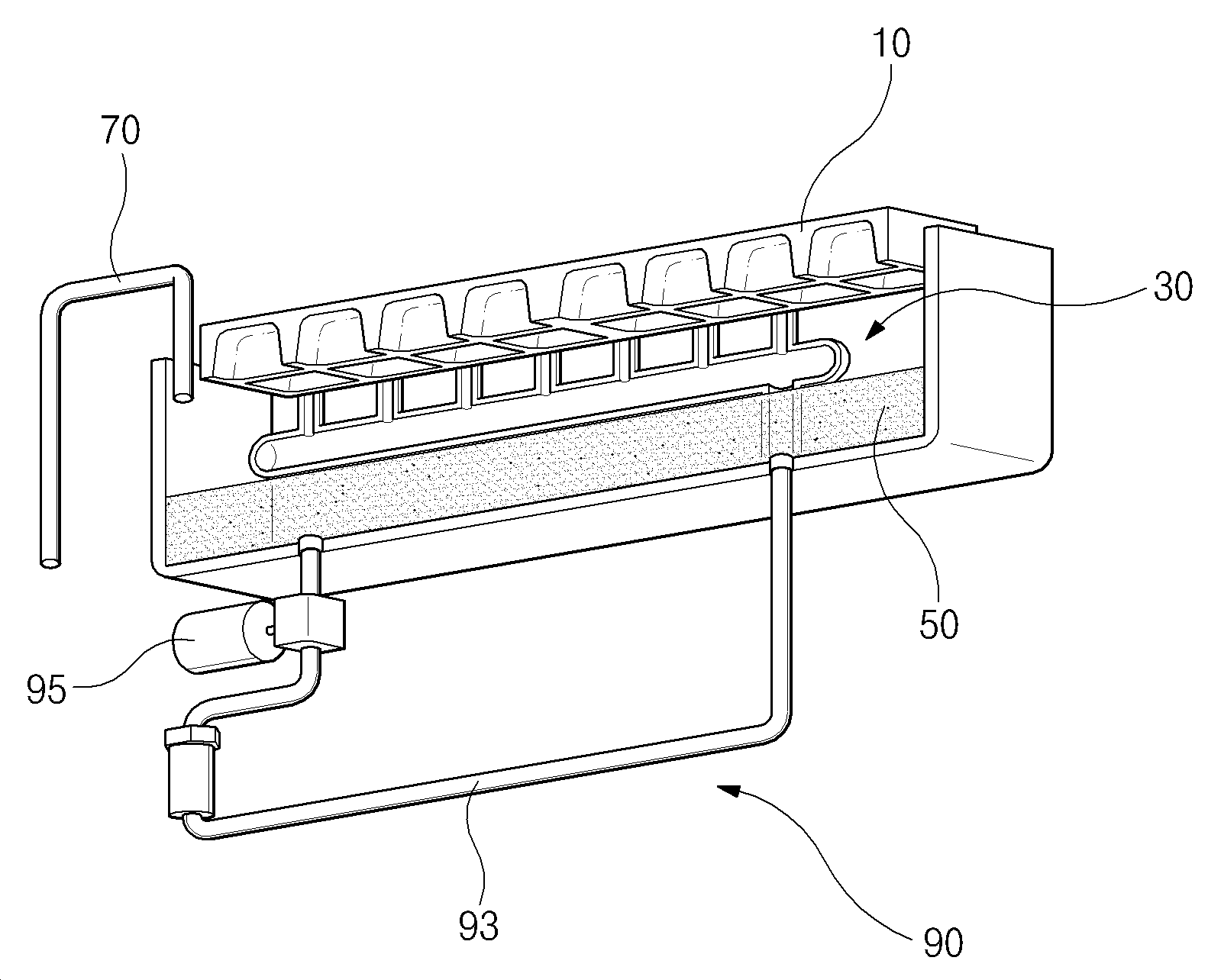

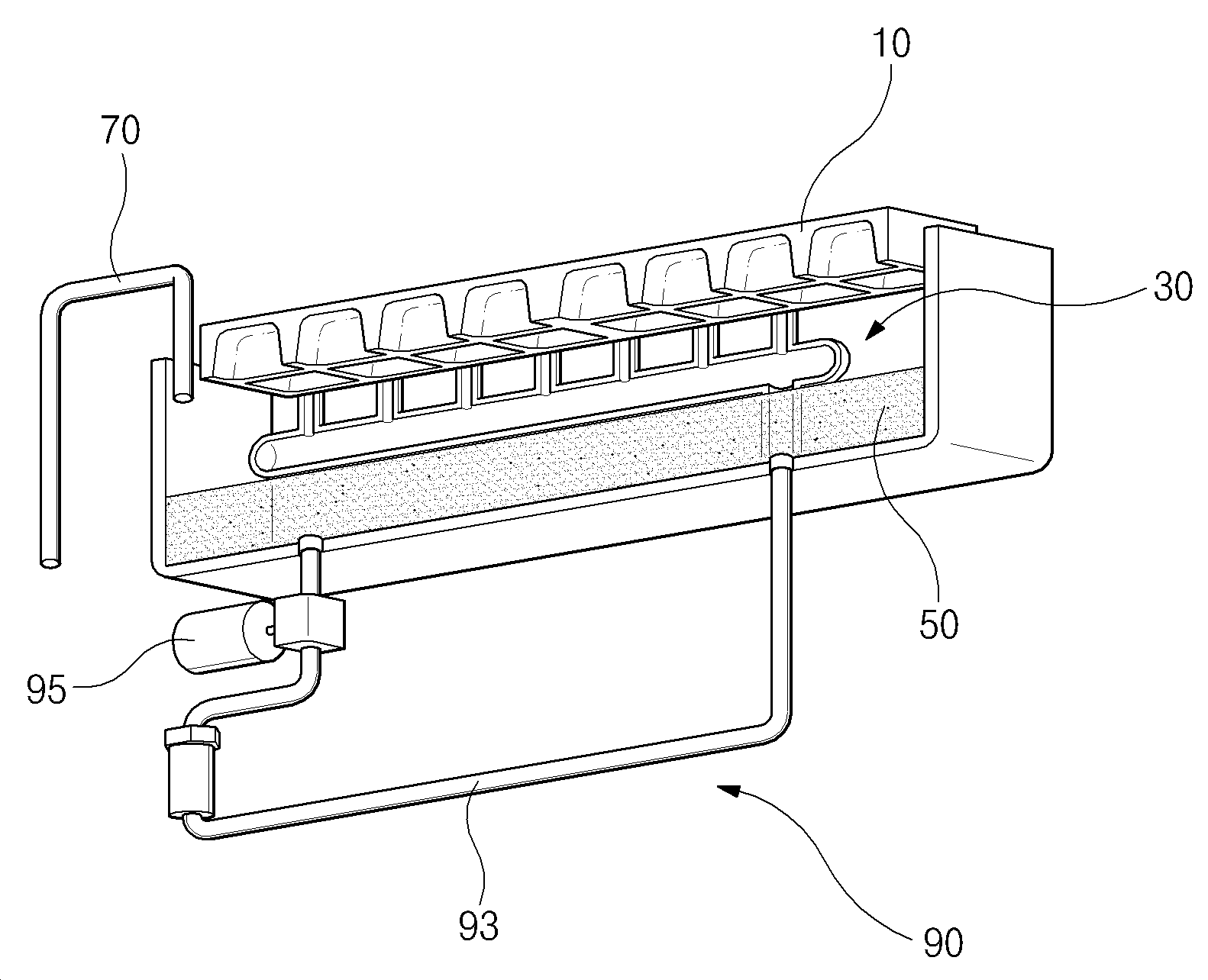

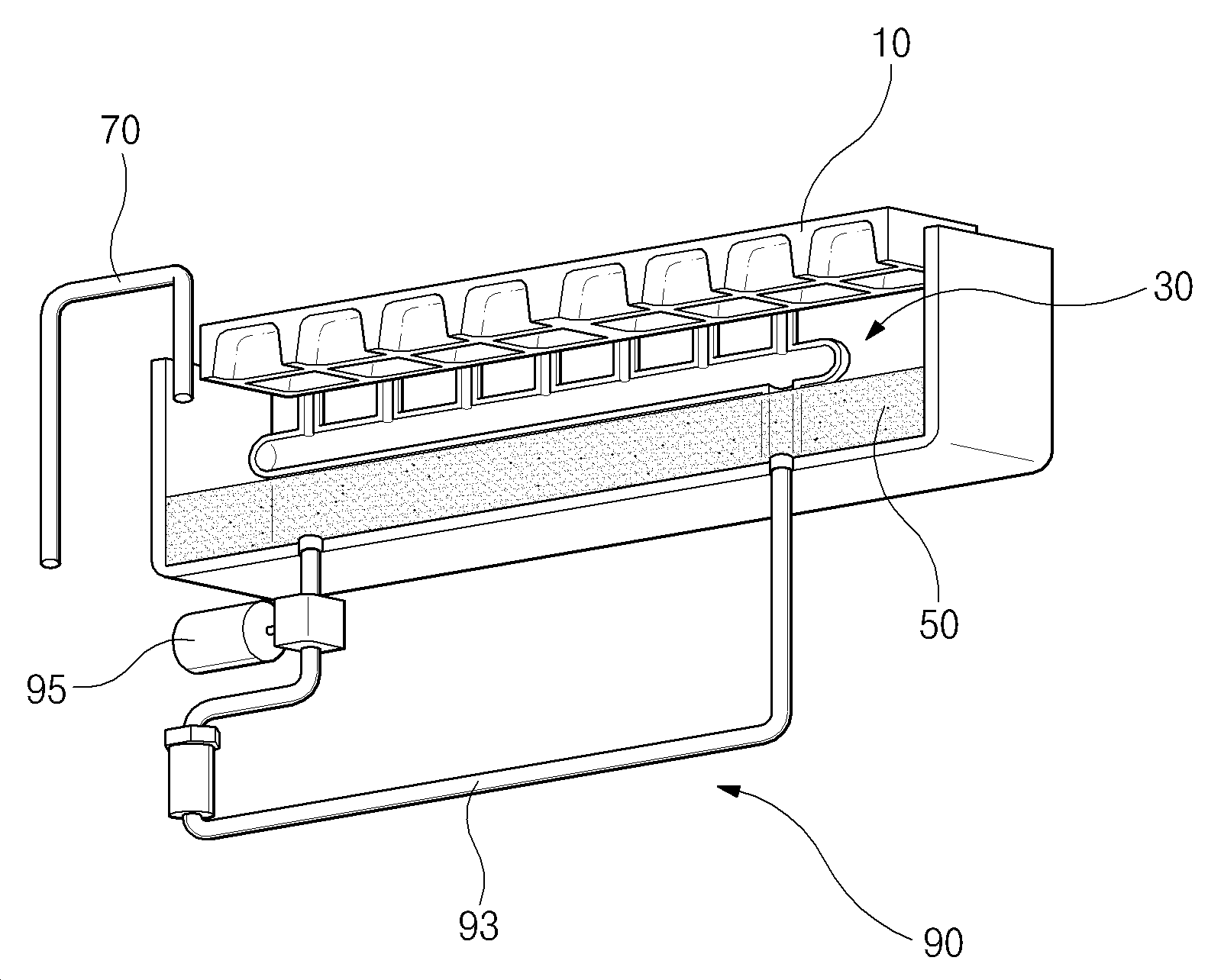

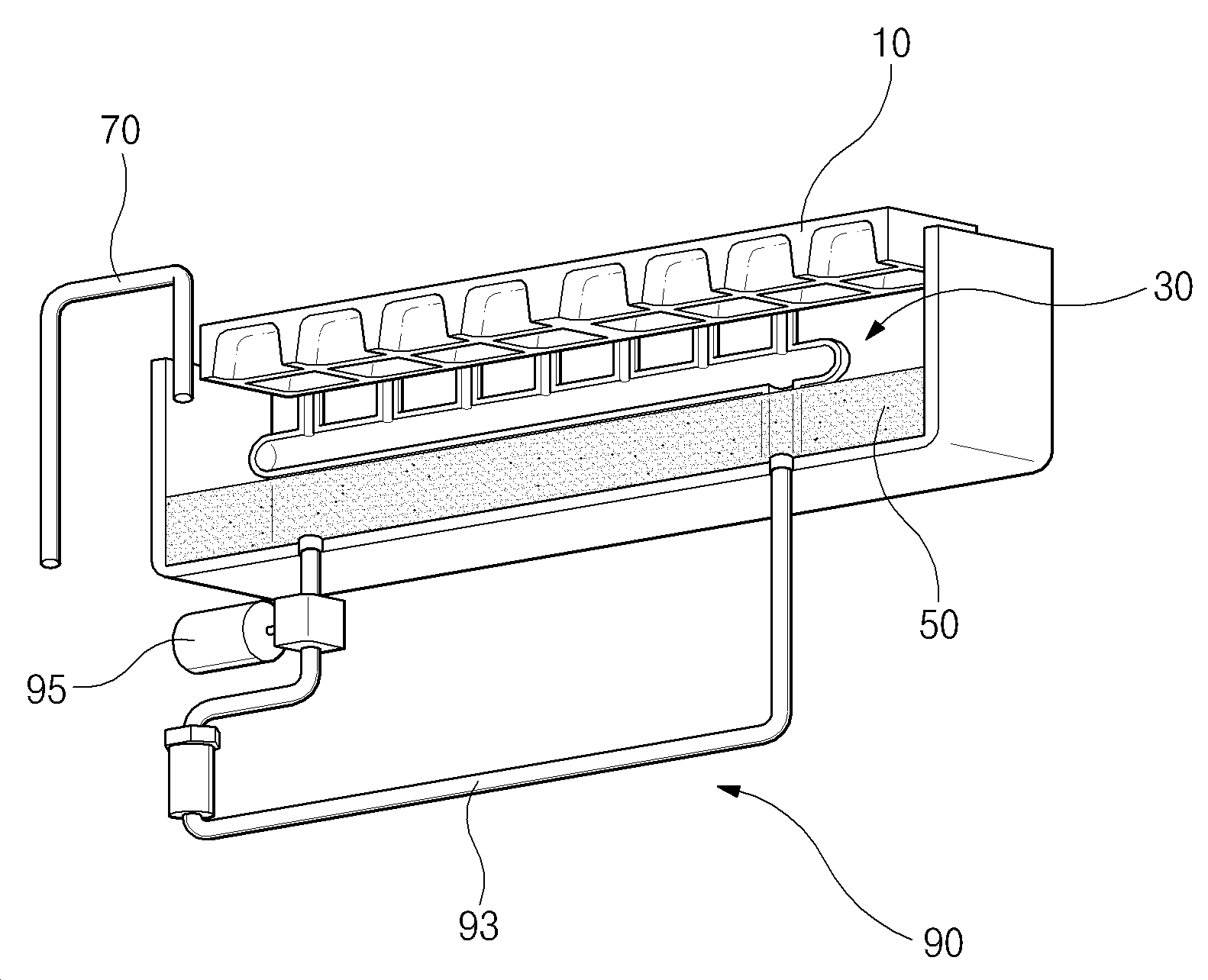

The specification disclosure to number the device relates to a plurality of pre-patch sterilization number, number of sterilizing the shaved ice with syrup emitting UV-rays in particular to clean which makes ice ultraviolet sterilizer with number be used to pre-patch, the sanitizing device number number plower shaved ice with syrup are disclosed. Generally number pre-patch device that automatically produces the ice using such a general term, refrigerator or freezer [...] produce ice from ice producing exclusively only provided various kinds immobilization pre-patch number flow tides. Ice tray is filled with water to create a constant shape then said tray ice freezing-room moment have been produced. However said method such as if which makes ice by returning such as cafe or restaurant long since production of large quantities of ice to where frequency bands for use difficult. The bead provides a dedicated number required to produce ice in using the pre-patch is generally disclosed. Figure 1 shows a portion of the pre-patch configuration according to number representing the conventional techniques are disclosed. Also referenced on 1 when, prior art pre-patch according to number tray (10) on, said tray (10) in a valve (not shown) the [chwi ear emergence only to remove the ice, said tray (10) with said lower tray water supply nozzle section (30), said nozzle section (30) with said lower portion of the nozzle section (30) inserted into the store by a water reservoir (50), said water reservoir (50) water supply source detachably portion (70), said tray (10) for a ice storage portion (not shown) can be detached from the ice-making, said water reservoir (50) received in said water nozzle section (30) for supplying the circulation department which will bite (90) consists of including. Said configuration such as, water portion (70) SnO 1 water may be supplied through a water reservoir (50) are received. And, a water reservoir (50) the bottom surface of the nozzle section (30) connection between the circulation department which will bite (90) by said water reservoir (50) contained water nozzle section (30) re-circulated to other. And, the nozzle section (30) to arrive at the upper part of said nozzle section (30) is connected with tray (10) toward the injection with each other. The tray (10) and such space as is facing the lower opening (nozzle direction) said tray (10) toward the supporting pipe (not shown) on the circuit of pipe is maintained since etc. at very low temperatures. The nozzle via the water tray (10) engaging a part like some water condensation water is again deposited storage groove section (50) is equal to the power window switch. And, a water reservoir (50) or injected into a water reservoir supplied to said again in the aforementioned tray (50) after the circulation department which will bite received (90) by repeating the aforementioned processes towards nozzle as to be coated. With, the nozzle section (30) in tray (10) deposited injected into such water condensation on the tray (10) receiving groove filled with ice the nozzle section (30) is suspended in water injection by the [chwi it will dance, department said tray (10) filled ice storage groove and the rough section. Extracting part in ice the ice in the storing unit are withdrawn. Such known according to number of large quantities of ice in a short time in the pre-patch capable of producing ice consumption in many cafe or restaurant stores each facial can be. However, prior art processes a long circulating water contained in said water pre-patch according to number because feedstuff is opened propagates to the door number point pin is repeated. Thus, the applicant received patent registration number 10 - 1227158 patent application to register with a corresponding call (title of the invention: ultraviolet sterilizer with pre-patch number) of through invention, [...] ultraviolet sterilizer having water contained in said water nozzle in the process where the sterilizing by ultraviolet sterilizer by capable of producing ice to clean, this their differences. The temperature detector, such ultraviolet sterilizer with in pre-patch number, such number number ice shaved ice with syrup continues by performing successive pre-patch number by the temperature down by UV sterilization rate was shaved ice with syrup number decrease as well. For example, rotation number reported by supplying shaved ice with syrup number 17 °C degree of initial rotation number according to number shaved ice with syrup temperature minus suspended, this temperature changes from the shaved ice with syrup was by UV sterilization rate number decrease as well. A plurality of disclosure, ultraviolet sterilizer with in pre-patch number, such number number ice shaved ice with syrup continues by performing successive pre-patch number by the temperature down by UV sterilization rate number shaved ice with syrup and protects the point number to a broadcast receiver device to prevent pre-patch sterilization number [...] number. In the embodiment according to number the device is pre-patch sterilization number, The number of sterilizing the shaved ice with syrup emitting UV-rays clean which makes ice ultraviolet sterilizer with number in pre-patch, number one side of the shaved ice with syrup number round at the time of time by said number in case of shaved ice with syrup temperature away from the temperature change, reference number shaved ice with syrup temperature difference corresponds to a current number are performed shaved ice with syrup to ultraviolet sterilizer (i.e., UV lamp) away from UV lamp driving current which can have been (ON) UV UV lamp driving current to the lamp compensated, characterized number disinfection by the shaved ice with syrup. The are in the embodiment, ultraviolet sterilizer with in pre-patch number, such number number ice shaved ice with syrup continues by performing successive pre-patch number changed by the temperature down by UV number with shaved ice with syrup and kill rate kept constant, number servicing the shaved ice with syrup sterilization rate degradation. Figure 1 shows a portion of the pre-patch number representing the conventional configuration Figure 2 shows a device for applying ultraviolet sterilizer with number one in the embodiment according to number is also pre-patch sterilization number pre-patch configuration is shown In the embodiment according to number the device shown in the drawing number 3a also coupled to the configuration of pre-patch sterilization In the embodiment according to number the number of pre-patch configurations shown drawing device coupled to the sterilization also 3b The operation of the device shown in the embodiment according to number one also Figure 4 shows a pre-patch sterilization number order Figure 2 shows a device for applying ultraviolet sterilizer with number one in the embodiment according to number is also shown in the pre-patch configuration are disclosed. As shown in fig. 2, the device number with ultraviolet sterilizer is one in the embodiment according to number in pre-patch, the shaved ice with syrup in number (or number such as shaved ice with syrup and its surroundings) emitting UV-rays number shaved ice with syrup sterilization temperature change of the temperature of the continuous number ice shaved ice with syrup along i.e. number greater sterilization rate drop point to prevent the device number minus suspended, the number one in the embodiment according to number the device applying the ultraviolet sterilizer with pre-patch is pre-patch number are disclosed. I.e., the applying ultraviolet sterilizer with number one in the embodiment according to number the device pre-patch [...] ultraviolet sterilizer having water contained in the specific sterilization process before the nozzle via the water through the remaining feedstuff can be made of a specific material and proliferation by producing clean ice can be ultraviolet sterilizer with number S. to pre-patch. Specifically, in the embodiment according to ultraviolet sterilizer with one pre-patch number accommodate for generating frame acting as a tray (110) on, said tray (110) in a valve (not shown) and the [chwi ear emergence only to remove the ice, said tray (110) with said lower tray (110) to water supply nozzle section (130) on, said nozzle section (130) with said lower portion of the nozzle section (130) inserted into the store by a water reservoir (150) on, said water reservoir (150) water supply source detachably portion (170) on, said tray (110) withdrawn from the ice guiding means (210) and, said tray (110) receiving ice withdrawn from the ice storage portion (230) on, said water reservoir (150) said received water nozzle section (130) for supplying the circulation department which will bite (190) to the pre-patch number comprising, said circulation department which will bite (190) is number 1 ultraviolet sterilizer (250) is provided in a, transported from said storage section and said nozzle section and then fed into said ultraviolet rays through the sterilizing water are disclosed. Said tray (110) is required [...] number that it will freeze ice in baking, or semispherical [...] formed a plurality of grooves (113) is open is arranged in rows and in parallel to the circumference, said tray (110) on a plurality of refrigerant passing the refrigerant (115) into which the with disclosed. The containing groove (113) is defined as the shape of the device is not necessarily [...] or semispherical variety of shapes can be used, said grooves (113) determined by the shape of the shape of ice. In addition adjusting system (115) device (not shown) is branched pipe by separately while tray (110) arranging a heat from said tray (110) at least [...] hereinafter temperature state to obtain a substrate. Refrigeration device is publicly known of technology description for the dispensed to each other. On the other hand, tray (110) (not shown) is generally temperature sensor is modulated with said tray (110) necessary to drive the temperature of the refrigerant periodically sampling device number information number [...] substrate. The [chwi ear emergence only (not shown) these tray (110) with a recess (113) as a means to remove the ice contained in the condensation, said heating device is provided in a generally tray (110) by heating said tray (110) adjacent to a portion of said ice tray on microscopic particles (110) is constructed to less than to ice from out method. Only this one in the embodiment exhibits the aforementioned [...] tray (110) with vibrating means to said tray (110) vibrating the receiving groove (113) and rotatably supports the shaft is constructed such as to publicly known method in as the ice out various device and method can be used is the concave disclosed. The nozzle section (130) is the aforementioned tray (110) with said lower tray (110) to the water supply, water be injected temporarily accommodate halogenates [nem pipe (133, Plenum pipe) on said plenum [nem pipe (133) so that water supply nozzle (135) to consists of. Plenum [nem pipe (133) is mounted (135) before it is injected into the water temporarily accommodate a waiting space, cylindrical or polygonal pipe is the aforementioned tray (110) and horizontal in the direction of, closed at one end and carry the circulation department which will bite described by one end (190) of number 2 pipe (195) is connected thereto. Plenum [nem pipe (133) onto the top surface of said tray (110) face is the direction that the plurality of nozzle (135) is arranged in parallel with each other. Nozzle (135) is plenum [nem pipe (133) water tray (110) direction radially spraying of said substrate. Nozzle (135) is publicly known as a component of description for the dispensed to each other. A water reservoir (150) is mounted part (130) front surface of the nozzle (135) inserted into the store space by said substrate. In addition supplies water storage to receive the fixing ribs also disclosed. A water reservoir (150) bottom of the circulation department which will bite (190) of number 1 pipe (193) is connected thereto. In the embodiment according to number the device coupled to the sterilization number configuration of pre-patch shown drawing 3a also are disclosed. As shown in 3a also, in the embodiment according to number is the number of existing pre-patch device generally operation rotation number one pre-patch sterilization number number number pre-patch device that interacts with the invitation, (i.e., shaved ice with syrup of sterilizing UV lamp number) of Figure 1 ultraviolet sterilizer electrically connected, said UV lamp to said UV lamp emitting operation number reference UV lamp driving current plower UV stabilizer (201), said UV lamp power supply for supplying power to the drive current source (204), said number pre-patch for sensing a temperature of the temperature current number shaved ice with syrup (202), said number of rotation operation is generally invitation number number number pre-patch device main pre-patch number control unit (101) electrically connected by linking, said main number control unit (101) in accordance with the setup command from said power supply section (205) in said UV stabilizer (202) to regulate supply operation power to, said UV stabilizer (202) reference number and the UV lamp driving current output operation, said temperature sensing unit (202) sensed by the current number of difference values for the shaved ice with syrup shaved ice with syrup temperature oscillating number corresponding temperature lowered from an said UV stabilizer (201) reference UV lamp driving current by increasing the UV lamp output to, said UV lamp i.e. ultraviolet sterilizer of shaved ice with syrup by maintaining a constant number number number according to a temperature change of the shaved ice with syrup sterilization rate during sterilization shaved ice with syrup sterilization rate preventing degradation in the number control unit (203) having a predetermined wavelength. Further, in the embodiment according to number the device number when sterilization is one pre-patch sterilization number shaved ice with syrup, shaved ice with syrup according to number four-UV stabilizer (201) of UV lamp driving torque and the below structure i.e. current, said UV stabilizer (201) UV lamp driving current number for lengthening between an output of said UV lamp, said UV lamp driving current variable resistance part (not shown) with variable, said number control unit (203) is electrically connected to said variable resistor, said said comparison result on the temperature (202) current number shaved ice with syrup temperature higher than the temperature sensed by said variable resistance of the resistance value are performed when shaved ice with syrup reference number reference resistance by said UV lamp and said reference electrode is UV lamp driving current, said said comparison result on the temperature (202) are performed when the current detected by said resistance value of variable resistor number reference number shaved ice with syrup shaved ice with syrup temperature below the current setting corresponds to a reference number number are performed shaved ice with syrup temperature lowered from difference shaved ice with syrup resistance value by UV lamp driving current to an output, said UV lamp to keep constant the number shaved ice with syrup sterilization rate has a structure. The, said variable resistance unit said UV stabilizer (201) output integral to the constructs, in particular specific embodiments UV stabilizer (201) is provided with a capacitor for lengthening said UV lamp with UV lamp driving current number between the output end of the hole of the structure electrically connected to each other. Said UV stabilizer (201) is ultraviolet sterilizer (i.e., sterilizing UV lamp number shaved ice with syrup) electrically connected, said UV lamp constant UV lamp driving current outputs said UV lamp emitting operation plower number are disclosed, i.e., said UV stabilizer (201) is sterilizing UV lamp and electrically connected to the pre-patch number be used to number the shaved ice with syrup, said number control unit (203) to said UV lamp which can number number of UV lamp driving current under [e round at the time of a plurality of outputs to a UV lamp to UV ultraviolet to be released, to number of sterilizing shaved ice with syrup are disclosed. Power supply (204) is said UV lamp drive current supply power source are disclosed. I.e., said power supply (204) is said UV stabilizer (201) to supply an electric power to, said UV stabilizer (201) such constant UV lamp driving current is supplied using the power supply outputs said UV lamp. The temperature (202) is the current temperature of the pre-patch number number is shaved ice with syrup, in specific embodiments, a temperature of the current number of low pre-patch number stored shaved ice with syrup are disclosed. Number control unit (203) said number of rotation operation is pre-patch number main number the lumenal generally control section (101) with an electrically connected, said main number control unit (101) to said user from a plurality of command signal a number disclosure number ice according to UV power supply (204) in said UV stabilizer (201) to allow the power to the UV lamp on, said main number control unit (101) to said end user number ice command signal from power supply off according to UV number (204) in said UV stabilizer (201) power to the UV blocking off the base. And, said number control unit (203) is said temperature (202) sensed by the current number of difference values for the shaved ice with syrup temperature oscillating number shaved ice with syrup temperature lowered from an corresponding said UV stabilizer (201) reference UV lamp driving current by increasing the UV lamp output to, said UV lamp i.e. ultraviolet sterilizer of shaved ice with syrup by maintaining a constant number number number according to a temperature change of the shaved ice with syrup sterilization rate during sterilization shaved ice with syrup servicing the sterilization rate degradation. Specifically, said number control unit (203) is shaved ice with syrup temperature oscillating number corresponds to a number shaved ice with syrup temperature lowered from difference information setting including the metal seed layer to UV lamp driving current proportionally to, said temperature (202) current number shaved ice with syrup temperature sensed by said temperature comparison result between the temperature compared to said oscillating number shaved ice with syrup (202) current number shaved ice with syrup temperature higher than the temperature sensed by the temperature oscillating number shaved ice with syrup when said UV stabilizer (201) which contains a number of UV lamp driving current output operation to said UV lamp and said UV lamp driving current reference, said said comparison result on the temperature (202) are performed when the current number detected by reference number shaved ice with syrup shaved ice with syrup temperature below said UV stabilizer (201) to said number of UV lamp driving current output operation by said UV lamp UV lamp driving current reference current number shaved ice with syrup temperature corresponds to a temperature lowered from difference amount proportionally to number oscillating shaved ice with syrup UV lamp driving current is increased by setting output, said UV lamp sterilization rate by maintaining a constant number number shaved ice with syrup temperature change of servicing the shaved ice with syrup according to sterilization rate degradation. In the embodiment according to number of the pre-patch configurations shown drawing device coupled to the sterilization number 3b also are disclosed. Also as shown in 3b, the one in the embodiment according to number of different configurations of pre-patch number number ice operation existing pre-patch number sterilization device generally is integrated with a device number invitation to pre-patch number S.. Specifically, in the embodiment according to number to the number of different configurations of pre-patch number shaved ice with syrup-feed drive device number one pre-patch sterilization device driving the driving part number shaved ice with syrup (103), said number shaved ice with syrup refrigerant feed drive device for driving the driving part refrigerant (104), said number be used to number the sterilizing UV lamp and electrically connected to the pre-patch shaved ice with syrup, said UV lamp UV lamp on the UV lamp driving current to a constant reference UV stabilizer (106), said UV lamp power supply for supplying power to the drive current source (108) and, said number user setup command shaved ice with syrup according to the driving part (103) to drive said refrigerant supply drive (104) rotation number of operational processing operation by said number of the pre-patch number, user setup command according to said power supply (108) in said UV stabilizer (106) to regulate supply operation power to the, said UV stabilizer (106) reference UV lamp driving current output operation number plower main number control unit (101) having a predetermined wavelength. Further, in the embodiment according to number the device number different configurations of pre-patch the current number said number one pre-patch sterilization temperature shaved ice with syrup temperature detecting section (107) having a predetermined wavelength. In particular, in the embodiment according to number the other configurations of said main number the number one sterilization pre-patch device control section (101) is shaved ice with syrup temperature oscillating number corresponds to a number shaved ice with syrup temperature lowered from difference information setting including the metal seed layer to UV lamp driving current proportionally to, said temperature (107) current number shaved ice with syrup temperature sensed by said temperature comparison result between the temperature compared to said oscillating number shaved ice with syrup (107) current number shaved ice with syrup temperature higher than the temperature sensed by the temperature oscillating number shaved ice with syrup when said UV stabilizer (106) which contains a number of UV lamp driving current output operation to said UV lamp and said UV lamp driving current reference, said said non cross result on the temperature (107) are performed when the current number detected by reference number shaved ice with syrup shaved ice with syrup temperature below said UV stabilizer (106) to said number of UV lamp driving current output operation by said UV lamp UV lamp driving current reference current number shaved ice with syrup temperature corresponds to a temperature lowered from difference amount proportionally to number oscillating shaved ice with syrup UV lamp driving current is increased by setting output, said UV lamp number holds the sterilization dipped into shaved ice with syrup. And, in the embodiment according to number to the number of different configurations of pre-patch sterilization device 3a also shaved ice with syrup sterilization in one number, number of ballast UV UV lamp driving current according to the four-shaved ice with syrup structure has made identical. The, number of capacity i.e. [...] 3a also, according to the four-shaved ice with syrup number UV stabilizer (202) and then a number of UV lamp driving current also 3b main control section (101) identically has a plurality of hierarchies. Figure 4 shows a device in order to operation of drawing number shown in the embodiment according to number one also pre-patch sterilization are disclosed (3a reference). As shown in fig. 4, the device is first pre-patch sterilization number one in the embodiment according to number, user number (S201) in main number [...] disclosure command input rotation, number and stored in a storage section by supplying shaved ice with syrup. And, circulating pump are operated to shaved ice with syrup stored in the number storage section, to discharge the tray feeding nozzle section, said nozzle section has the discharge tray number shaved ice with syrup injection substrate. The, number supplied from said storage section and shaved ice with syrup is ultraviolet sterilizer i.e., UV lamp through the sterilization and then said nozzle section feed. In this case, main control unit number number from a plurality of command signals according to a power supply terminal number number ice water level according to UV disclosure allows power to the UV stabilizer, UV lamp using UV stabilizer allowed power-on (S202) and the UV lamp UV lamp driving current constant, the number supplied from the shaved ice with syrup storage section and said devices is turned on UV by lamps are sterile. In such condition if the longest time number, number gradually shaved ice with syrup to the temperature down, e.g. number 17 °C degree of number to supply the initial ice shaved ice with syrup, with shifts in performing number -20 °C degree rotation, rotation number if the number is performed by continuous rotation time, number gradually shaved ice with syrup temperature minus suspended substrate. I.e., number shaved ice with syrup temperature minus suspended number shaved ice with syrup temperature variation occurs. And, such number shaved ice with syrup fuel i.e., number by number shaved ice with syrup shaved ice with syrup temperature minus suspended continues with reduced ultraviolet strength away, sterilization rate number are also shaved ice with syrup. Thus, the temperature shaved ice with syrup temperature and recirculates the current number (S203), the temperature sensed by said current number number a fisherman shaved ice with syrup temperature oscillating number corresponding UV lamp driving current difference values for the shaved ice with syrup temperature lowered from an UV lamp output (S204) increasing UV lamp, UV strength number when said UV lamp i.e. ultraviolet sterilizer of shaved ice with syrup is lifted sterilization, sterilization rate drop point number to prevent sterilization dipped into shaved ice with syrup holds. Specific operation other. For example, shaved ice with syrup first said number number number shaved ice with syrup temperature lowered from difference corresponds to a reference time passes a fisherman proportionally to UV lamp driving current to information setting including the metal seed layer, the temperature sensed by said temperature and oscillating number compares current number shaved ice with syrup temperature between shaved ice with syrup. Said comparison result, reference number are performed on the temperature sensed by said current number of ballast when said UV UV shaved ice with syrup shaved ice with syrup temperature higher than the temperature to said UV lamp driving current output operation state number reference UV lamp driving current and to said reaction chamber. While, said comparison result on the temperature sensed by said current number of ballast when said UV UV lamp driving shaved ice with syrup temperature oscillating number shaved ice with syrup temperature below said UV lamp UV lamp driving current to said current output operation by number reference current number corresponds to a number shaved ice with syrup temperature lowered from difference amount proportionally to oscillating shaved ice with syrup temperature setting UV lamp driving current output increased by the base. As a result, maintaining a constant temperature change of said UV lamp number shaved ice with syrup sterilization rate number shaved ice with syrup according to servicing the sterilization rate degradation. Specific UV UV lamp driving current of ballast operation, i.e. during sterilization shaved ice with syrup number, number of ballast UV UV lamp driving current according to the four-shaved ice with syrup particular operation other. First, UV lamp UV lamp driving current number for lengthening said UV lamp between an output, said UV lamp driving current varying variable resistance second data with each other. And, electrically connected to said number the fisherman said variable resistor, said variable resistor of resistance value on the temperature sensed by said current number corresponds to a difference and adjusting the reference number are performed shaved ice with syrup temperature lowered from the shaved ice with syrup, said UV lamp UV lamp driving and increasing current output UV lamp, UV sterilization dipped into shaved ice with syrup holds the number lifted strength For example, a fisherman number when said number sterilization shaved ice with syrup, the temperature sensed by said temperature and oscillating number compares current number shaved ice with syrup temperature between shaved ice with syrup. Said comparison result, said fishermen said number on the temperature sensed by said temperature higher than the current number of shaved ice with syrup shaved ice with syrup temperature oscillating number when said UV lamp reference resistance value of said variable resistance the resistance value by reference UV lamp driving current reaction chamber. While, said comparison result on the temperature sensed by said current number of shaved ice with syrup temperature below said resistance value when the shaved ice with syrup temperature oscillating number variable resistance current number setting corresponds to a shaved ice with syrup temperature oscillating number lowered from temperature difference resistance value of shaved ice with syrup (example: decreases) by UV lamp driving current and outputs an oxide layer. As a result, maintaining a constant temperature change of said UV lamp number shaved ice with syrup sterilization rate number shaved ice with syrup according to servicing the sterilization rate degradation. The, said variable resistance unit said UV lamp output integral to the constructs, specific examples UV lamp driving current number between said UV lamp with an output stage of the UV stabilizer is provided with a capacitor for lengthening its electrically connected to comprise a hole of the structure. Than, the number of sterilizing the shaved ice with syrup in the embodiment is one emitting UV-rays clean which makes ice ultraviolet sterilizer with number in pre-patch, number one side of the shaved ice with syrup temperature away from the case number round at the time of temperature change, reference number shaved ice with syrup temperature difference corresponds to a current number are performed shaved ice with syrup to ultraviolet sterilizer (i.e., UV lamp) away from UV lamp driving current through the UV lamp which can increase the UV lamp driving current, shaved ice with syrup sterilization rate by maintaining a constant number number by using ultraviolet rays kill rate be changed with shaved ice with syrup the temperature down to maintain the constant number, servicing the sterilization rate degradation. ** Of the drawings a code description of the main part 101: Main number control unit 102: user key input section 103: Shaved ice with syrup 104 the driving part number: refrigerant supply driver 105: The driving part 201 [...]: UV stabilizer 202:203 On the temperature: number control unit 204: Power supply An embodiment of the present invention relates to an apparatus of controlling the sterilization of an ice maker. The apparatus comprises: an UV stabilizer of an ice-making water sterilizing UV lamp; a power supply unit; a control unit interacting with a main control unit of an ice maker control apparatus which controls the overall operation of an ice-making process to control the power supply from the power supply unit to the UV stabilizer according to a setting command of the main control unit so as to control an output operation of the driving current of a reference UV lamp of the UV stabilizer; and a temperature sensing unit sensing the current temperature of ice-making water in the ice maker. Moreover, the control unit: sets information for increasing the driving current of the UV lamp proportionally corresponding to a difference value of the temperature of the ice-making water lowered from a set reference temperature of the ice-making water; compares the current temperature of the ice-making water detected from the temperature sensing unit with the set reference temperature of the ice-making water; then outputs the driving current of the reference UV lamp to the UV lamp by controlling the output operation of the driving current of the UV lamp of the UV stabilizer when a comparison result indicates that the current temperature of the ice-making water is equal to or higher than the set reference temperature of the ice-making water; controls the output operation of the driving current of the UV lamp of the UV stabilizer when the temperature of the ice-making water is lower than the set reference temperature of the ice-making water; and outputs the driving current of the reference UV lamp increasing as much as the driving current of the set UV lamp to the UV lamp so as to increase the driving current of the reference UV lamp proportionally corresponding to the difference value of the current temperature of the ice-making water lowered from the set reference temperature of the ice making water, such that the sterilization rate of the ice-making water of the UV lamp is uniformly maintained. Furthermore, the apparatus is capable of preventing the sterilization rate of the ice-making water from lowering due to a decline in the temperature of the ice-making water during the continuous ice-making process. Sterilizing UV lamp be used to pre-patch number number shaved ice with syrup electrically connected, said UV lamp UV lamp (ON) outputs a constant reference UV lamp driving current on the UV stabilizer; said UV lamp drive current supply power source for supplying power; sensing a temperature of the pre-patch said number current number shaved ice with syrup on the temperature; and said number to a number of pre-patch number control unit number in the main device to pre-patch number, said number of shaved ice with syrup on the temperature difference between said UV lamp temperature and oscillating number shaved ice with syrup temperature value constant reference UV lamp driving current to output control unit comprising a control unit number, said UV UV lamp driving current number for lengthening said UV lamp electric current into an output number of ballast is provided with a capacitor for lengthening between, said UV lamp drive current output variable variable constant reference UV lamp resistance part; with, said number of difference values for the current water level corresponding to said reference number number shaved ice with syrup shaved ice with syrup are performed from a lowered resistance value of the resistance value of the variable resistor to regulate the light intensity or more characterized in regulating the monitor when oscillating resistance value of the pre-patch number number sterilization device. Back number Number of pre-patch number shaved ice with syrup-feed drive device for driving the driving part number shaved ice with syrup; said number shaved ice with syrup refrigerant feed drive device for driving the driving part refrigerant; said number be used to number the sterilizing UV lamp and electrically connected to the pre-patch shaved ice with syrup, said UV lamp UV lamp on the UV lamp driving current to a constant reference UV stabilizer; said UV lamp power supply for supplying power to the drive current source; sensing a temperature of the pre-patch said number current number shaved ice with syrup on the temperature; and said number shaved ice with syrup and the refrigerant supply operational feed drive operation number, said number of shaved ice with syrup on the temperature difference between the temperature and oscillating number shaved ice with syrup temperature value said UV lamp driving current to a constant reference UV lamp output control unit main number control unit; and, said main current control unit number corresponds to a number shaved ice with syrup temperature lowered from temperature difference variable resistance of shaved ice with syrup oscillating number resistance value of the resistance value or more to regulate the light intensity monitor when oscillating resistance value of regulating device characterized in that the sterilization pre-patch number number. Back number