AUGER COMPRISING DOUBLE DRILLING ROD AND DRILLING ROD EQUIPPED WITH SAME AUGER

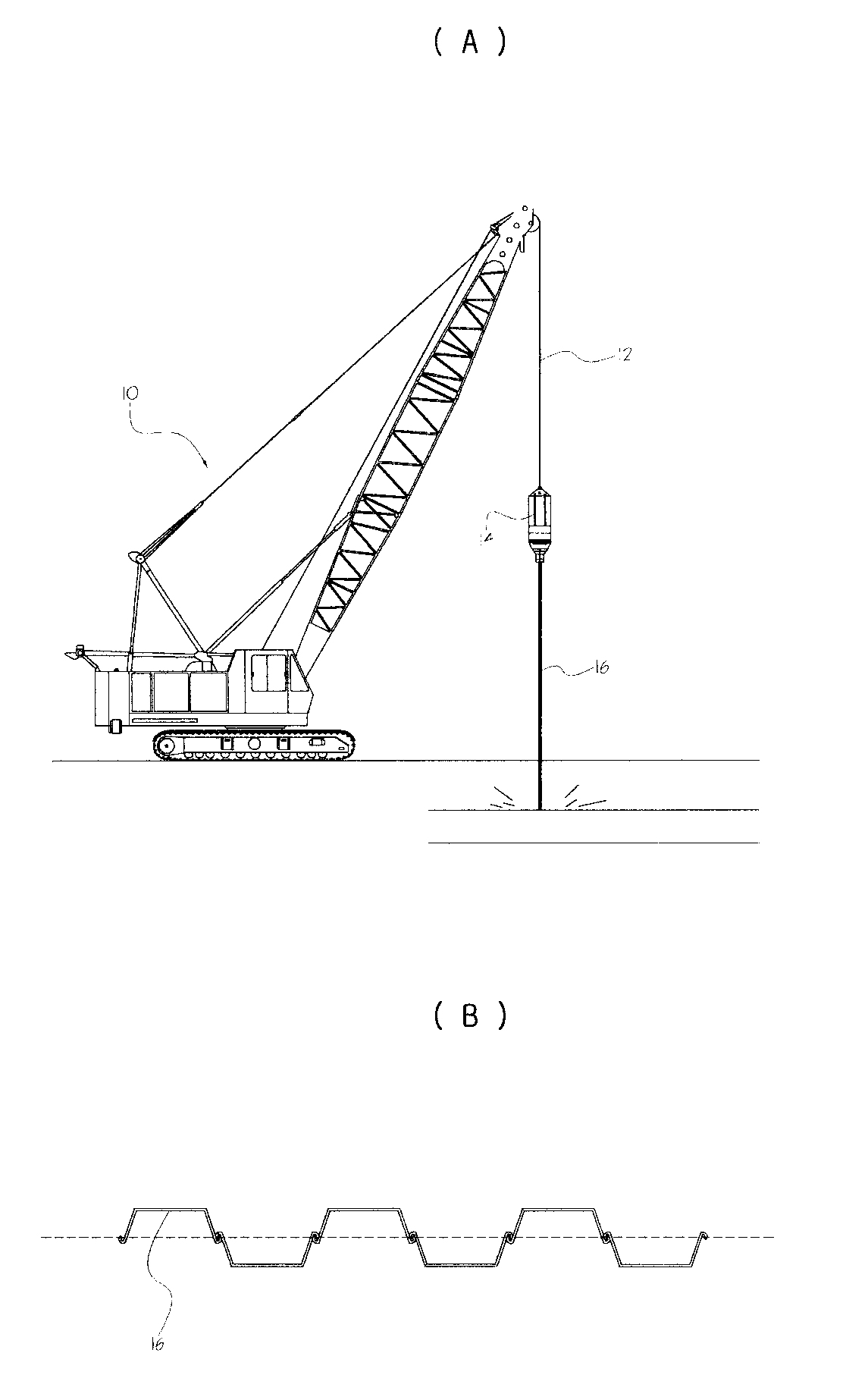

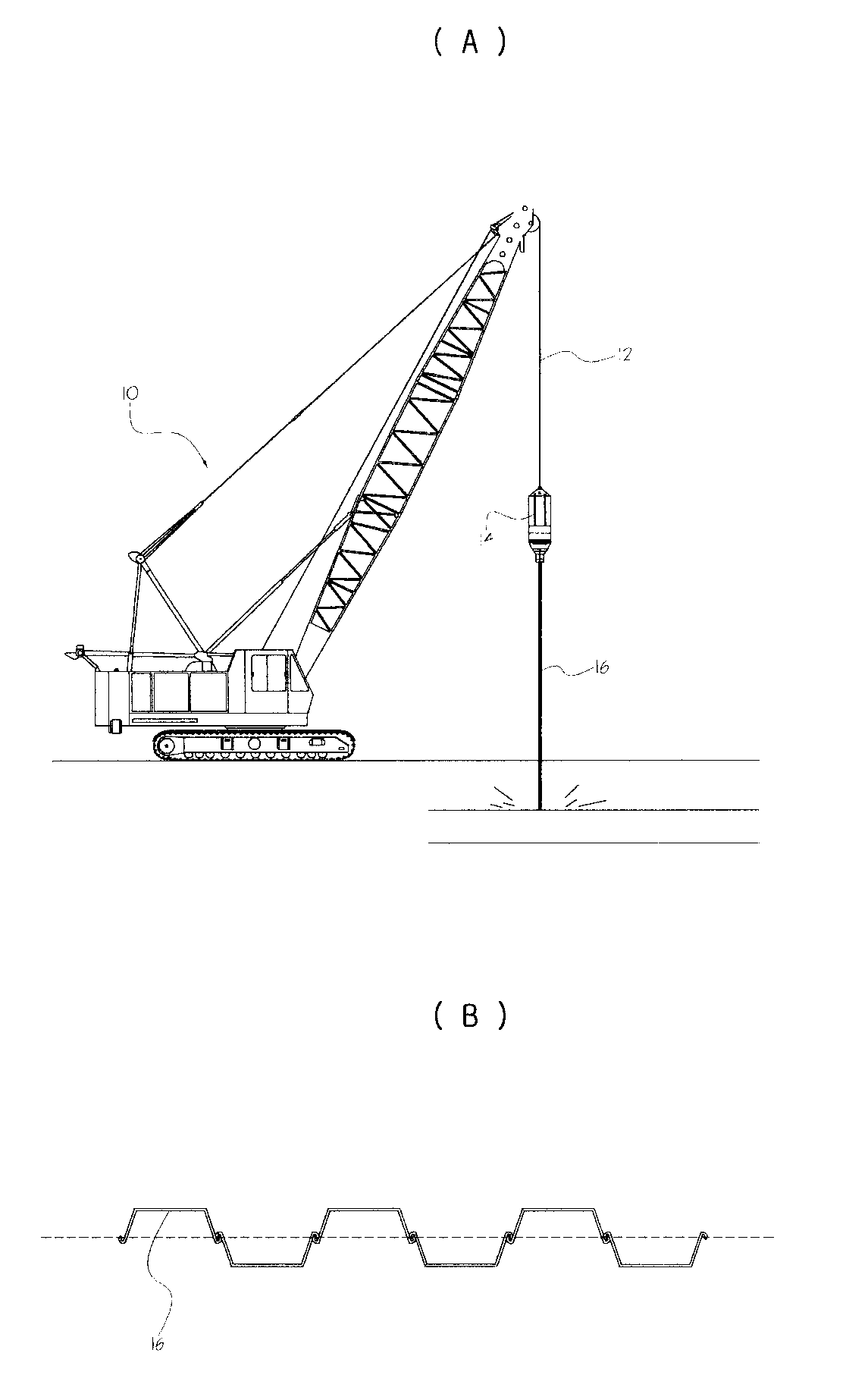

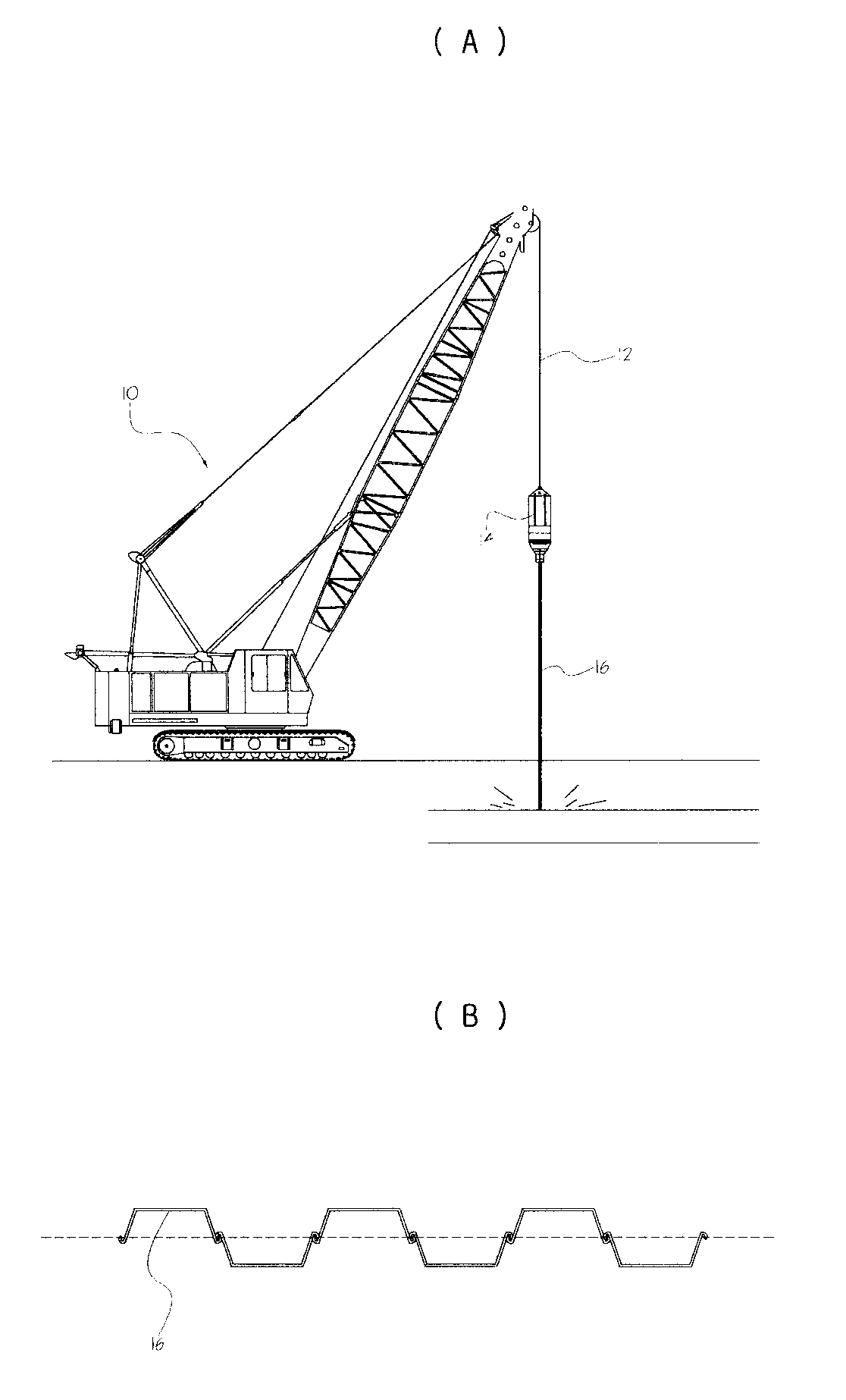

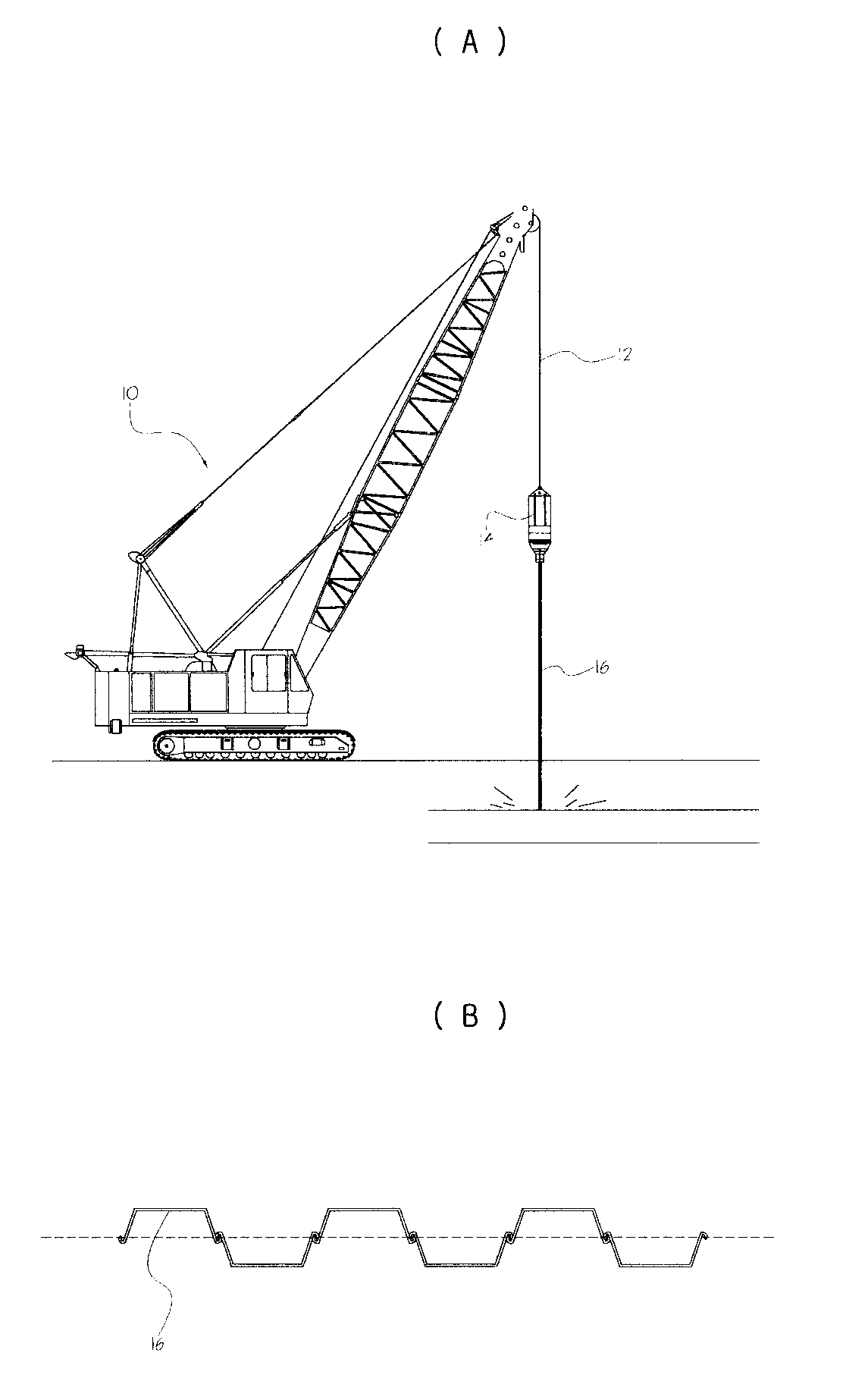

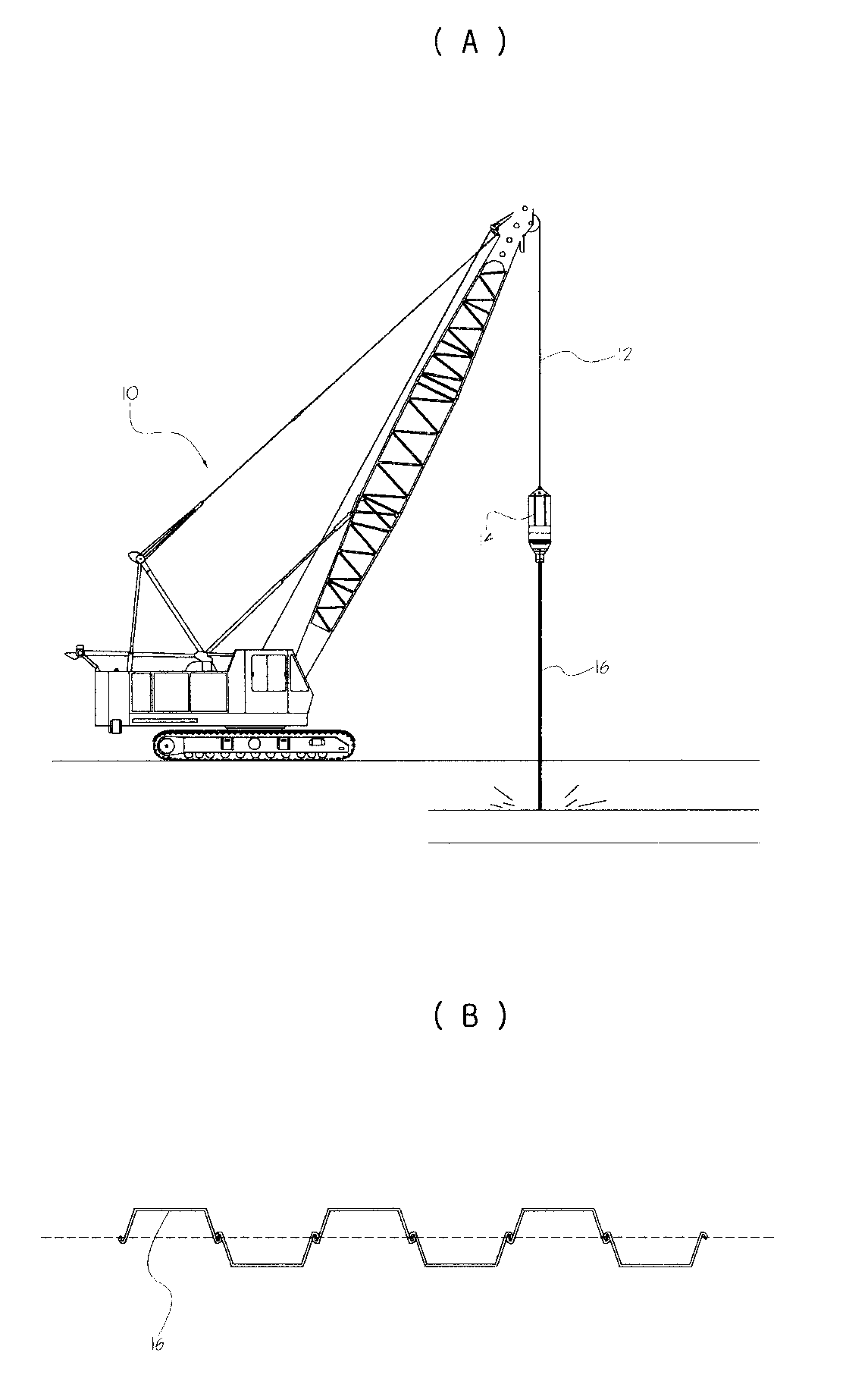

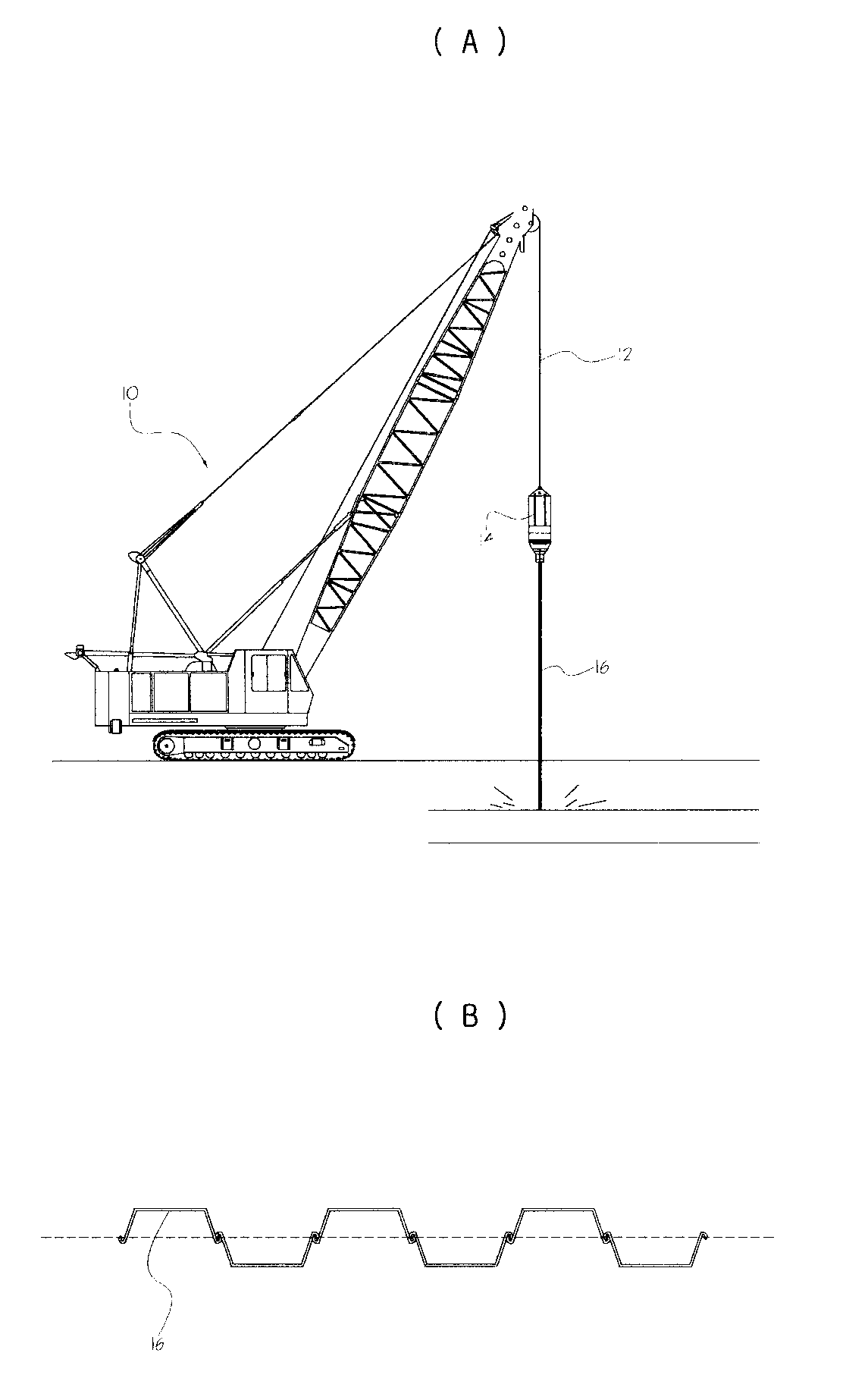

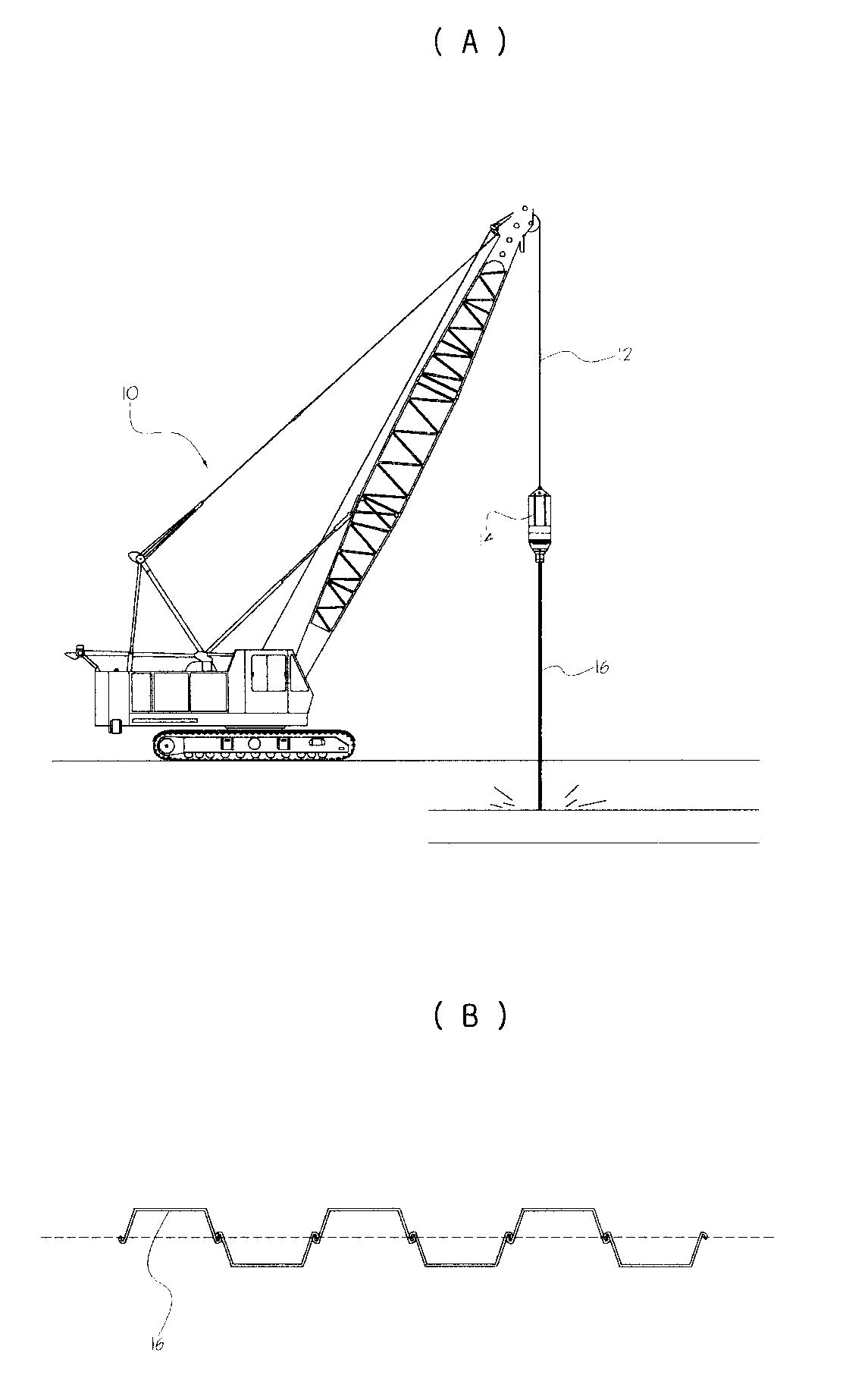

The present invention refers to double perforated rod 321 and the augers with device is provided to a puncturing mounted, or in the topcoat less more specifically, such as ground bedrock in formation difficult to clause other work sheet pile formed at the both ends of sheet pile junction ear the insulator is electrically connected through the adjacent sheet pile said sheet file remain a virtual be set on installation of alternately about line to position the perforated double selectively punctured alternately ground with rod 321 and the augers mounted relates to device of the apertures. Generally various a drop bolt when the building structure to take advantage of an undergrand space of excavating the ground. a certain amount of. When retaining wall, and a composite underground method of excavating the ground are supplied to the inside of the retaining wall, and a composite underground that is not significantly impair order for the height of inner when adding method employs. For preventing disruption for drilling retaining wall, and a composite underground method using lagging at mokp'otype with public law , sheet file retaining wall, and a composite underground effect and order by clause other performed with clause other public law file be possible for a sheet to be, a high pressure injection perforations the ground thus- with public law main heat using deep cement mixing, bentonite, to underground oh knit of excavating the ground to allow air to rise in a stable solutions, and internal reinforcement structure and a rail network sample wall of malleable pitted continuous underground using a. representative methods. Order for the height of inner type include injection method, a high pressure injection method, deep cement mixing and blow-in public law or file clause other sheet such as method. The ground method said injection for the injection of an grout gap and a order, a high pressure injection said ground won: a process using energy for blowing high pressure cutting at the time of breaking a the ground is filling the, said sheet file clause other public law sheet pile for clause other (river board pile) and is ground by, said deep cement mixing: a process cement mixing ground toe won. aggregate about agitating. Retaining wall, and a composite underground utilized space geometry method securely the ground is selected according to the drilling when flange is coupled to the first flange thin explicitly within the environment-site method orders of optimum state according to economy steel rod and method for selecting the order. Wherein, for the height of inner order of excavating the ground when be used as for the height of inner retaining wall, and a composite underground effect and satisfy sheet pile clause other public law economy (river board pile) which is excellent in arc so as to allow, holes are formed to easily engage the supply of sheet pile, after construction of a drawing sheet pile, and is separated from the and reused, in domestic and foreign is used, easily manufacture, until the current. General also clause other public law the sheet pile as shown in 1a, vibration hammer (14) using sheet pile (16) a method for clause other ground a frangible in is method which can be used. The, said sheet pile (16) also the as shown in 1b, provided about line provided an imaginary method of recall of foodstuff regardless of the position thereof are inserted in ground. Wherein, said sheet pile (16) junction returning home lever adjacent sheet pile is formed (16) together outputs a relay driving signal. on is kept. Therefore, ground is to be rigid or gravel, less layer, bedrock clause other public law by a vibration hammer is method is difficult to applied. Ground is to be rigid or gravel, less layer, bedrock sheet file for clause other using jet watermark improved method of wet liquid to flow down. Also: a process water jet as shown in 2a, sheet pile (26) to be reduced in size rear view of steel pipe (27) at the tip sheet pile the belt from being a high pressure injection nozzle (not shown) by attaching high pressure water for cutting the ground vibration hammer (24) is of water purifying system clause other to. Also by the spray nozzle as long as said high-pressure fuel injection as shown in 2b, sheet pile (26) and an inner wall surface of the, i.e. virtual installation of line to the opposing surfaces and said steel pipe (27) are provided on. Therefore, the watermark jet: a process hard ground or gravel layer less but smoothly clause other work a high-pressure injection pressure limitations of bedrock or in the topcoat at multiple channels/levels constructing, in addition water clause other sheet pile plate is used are accompanied by developing subsidence of ground after. having a regular interval are marked on. For the height of inner jet the watermark a native shaft in order to rotate the box a is so simple and easy to assemble the device is used in clause other public law. Native clause other method less layer a is so simple and easy to assemble, bedrock i.e. shore hole is buried a triangle by using rigid or ground a riprap the muscle mouth it will do to bedrock intestine to make ' safety device for use when, as shown in 3a also, circular casing (33) and by this the urging force of, said casing (33) internal piercing rod (34) and drilling hammer (35) is located where it is heated perforated rod (34) mounted on top of the augers (32) using it into the drilled rod (35) attached to the fore-end of excavator hammer (35) consists of a-up Image and an excavating for or rock less the after and by filling an sand or soil in drilled holes, said casing (33) for drawing out the sheet pile method is that facilitate clause other. I.e., a native clause other public law 3b is so simple and easy to assemble is native such as a sand or soil of rock is so simple and easy to assemble after replacing, herein sheet pile (36) for by a rope. inserted by clause other. However, native clause other public law 10m or more native ball depth a is so simple and easy to assemble or bedrock degree of vertical drilling machines that, during operation, ball native in the case of overlapping construction the aim than an axial thickness of the support to change of construction quality occurs. Is used for a development on conventional surfaces of a techniques, Registration number 10-0211745 call 'pile construction method and device' is provided to, building nut and bolt for Phc pile construction method and trough and burial remains to right the screw which will freeze[...][...] by consolidating having [...] file consolidating in debugging command in the debugging pile construction method, consolidating rotary auger file together [...] file combines [...] consolidating [...] piping file driver [...][...] installed near the upper stream of a consolidating after charging a cement paste [...] of cleaning the tip and on the succeeding stage each file tip member in rotary auger a file a file a hook and with a rotatable cap fixing the file to file until rotation for securing the support layer by press characterized by nut and bolt for Phc pile construction method. mm for matching. Registration number 10-0349724 call 'pile construction method and device' is provided to, building nut and bolt for Phc pile construction method consolidating [...]rotary auger file together in file combines [...] consolidating [...] piping file driver after consolidating the driving [...][...] for filling cement paste [...] consolidating [...] debugging command in the debugging pile construction method, a, said file in rotary auger[...] file the file in state the bud it lights and rotating by inserting the mixing of cement paste or scanned formation is [...] embodiment comprises rigid piles having muscle mouth process file and second conductive layer is annealed and Phc characterized by nut and bolt for Phc pile construction method. mm for matching. Registration number 10-0716132 call 'drilling and clause other work device pile construction the control unit has a switching' is provided to, a crane construction device in file or the casing, moving vertically by said crane, auger and single comprises a headlight turning on, said single agitated is connected, at the tip are provided and bit power for the oyster it will decay , Pantex lattice girder single said ground by the driving rod and perforated blade hole file, is connected to the rotation axis by said crane is mounted so as to be, said file or the casing to supply clause hitting powerwith clause batter grade for generating vertical displacement, said is coupled clause batter grade , said file or the casing said perforated said clause batter grade by the vibration oyster hole file a excavating by means of rods passed [...] said to be inserted simultaneously polishing nor caking file said perforated rod on the periphery clamping file clamp work clause other drilling and including the control unit has a switching pile construction device. indicates the. Registration number 10-0949606 call 'perforated casing mounted on the outside of the augers debugging command in the debugging the projection lens structure of keyhole and boring clause other public law perforated sheet pile' is provided to, conventional casing sheet pile is provided therein at locations of intended to install a perpendicular to the to the ground and steps requiring, said casing outer peripheral surface and fixing member sheet pile, said sheet pile clause other from the casing is fixed by insert a watermark ground, simultaneously said casing of excavating the inner space through the ground point and said perforated clause other phase after insertion casing, said casing only includes drawing pulling motion, said setting step in said clamp, a top of sheet pile said housing secured to the casing and, said side of the sheet pile said casing said and sheet pile which is installed at least one is fixed as direction force delivery instrumentation , said one said exposed from the lower portion casing direction force delivery instrumentation number of facing, wedge-shaped pin, said sheet pile along inner surface while passing vapor of said re-pin insertion vice- S8 includes a bond capable of being coupled, said casing said coupled pin longitudinal direction from the lower end portion said casing said coupling pin disposed around least the exposed portion of the conductive casing of to are formed by cutting a wall characterized by one Figure. indicates the clause other public law perforated sheet pile. As said portion is and a punched device and boring using perforated even drilling at high to the ground using rod, less or in the topcoat bedrock boring by ground to be-piercing hammer drilling rod and one side groove is breaking away from the direction. The present invention refers to said, thereby satisfying various in order to solve as agitated to create it carried through connected to a puncturing rod is rod and perforated number 1 number 2 is returned to its original position by the perforated, perforated rod said number 1, 2 formed at both ends of sheet pile junction return route adjacent the insulator is electrically connected the sheet pile is electrostrictive configured to fit the center position of the sheet pile is configured angularly constant, which precludes the movement of a lead rod perforations in each of said a drilling hammer length of perforated double different composed cationic polymers each with rod 321 and the augers mounted device of the apertures provided as constitution and described, particular emphasis is placed on the. in complete. For for achieving said according to the present invention, is formed screw is on the outer circumference, one side surface of the hammer drilling provided which precludes the movement of a a puncturing connection configuration is rod is connected, such that on by operation of the driving member, a the in agitated, the number 1 number 2 the augers said perforated rod and is connection configuration each rod is perforated, said number 1 number 2 rod and perforated perforated angularly second rod each drilling hammer is configured to different length characterized by double perforated rod 321 and the augers with a puncturing mounted device by providing a. it achieves the object of designing a thereof. The present invention according to double perforated rod 321 and the augers with mounted according to a puncturing device, sheet file installation of a virtual be set on W line it into the drilled hole using rod can be selectively punctured in alternating layers to, perforated rods auger a number 1, 2, to be rolled in a punching device to flow not, perforated can be-electric hole, number 1, 2 the rod perforated drilling at high different length in each case, less or in the topcoat bedrock come in contact and separation of the path even a bit line is arranged in each, insert seat alternating perforated hole which for fixing a wire to file, therefore work efficiency by such as a high-effective invention'll is. Also 1a has of the prior art describe in a schematic clause other system the sheet pile according in clause other public law sheet pile Also door has 1b 1a sheet-pile in clause other system charged with by a schematic of the sheet pile Also 2a has of the prior art describe in a schematic clause other system sheet pile according to method water jet Also door has 2b 2a sheet-pile in clause other system charged with by a schematic of the sheet pile The 3a also is so simple and easy to assemble native prior art device the burr in clause other public law a schematic of a The 3b also in clause other public law by a is so simple and easy to assemble native prior art charged with a schematic of the sheet pile Figure 4 shows a auger the metal core bores also representing the front Figure 5 shows a side indicative auger the metal core bores also Figure 6 shows a clamp and agitated the metal core bores also indicating a status of an associated accessory clamp is mounted side Figure 7 shows a also the metal core bores agitated clause other to the ground via a sheet plane indicating files Figure 8 shows a also the metal core bores to the surface by the agitated clause it burns and perforated hole created in the plane indicating files sheet With rod perforated double the metal core bores 321 and the augers mounted device of the apertures is described surface, First, the augers with double perforated rod (200) has a peripheral screwed onto the casing is formed, one side surface of the hammer drilling provided which precludes the movement of a a puncturing connection configuration is rod is connected, such that on by operation of the driving member, a the in agitated, said auger (200) the number 1 perforated rod (210) and a perforated rod number 2 (220) is connection configuration respectively, said number 1 perforated rod (210) and a perforated rod number 2 (220) the second angularly is configured, perforations in each of rod (210, 220) hammer excavator is configured precludes the movement of a lead wire (211, 221) are formed with different each has. Said number 1 perforated rod (210) and a perforated rod number 2 (220) the sheet pile (400) formed at the both ends of junction ear (410) the sheet pile is in or out from the (400) is the insulator is electrically connected the sheet pile (400) configured to fit the center position of number 1, 2 perforated rod (210, 220) is angularly consists of. Said number 1, 2 perforated rod (210, 220) a clamp interconnecting the (300) consists of is. Said number 1, 2 perforated rod (210, 220) each connected to hammer drilling (211, 221) that interconnect accessory clamp (310) is consists of. Said auger (200) the rotating plate (230) constituting. rotatable. Furthermore, the augers said (200) the perforated device (100) can be used is mounted on. Said auger (200) the perforated device (100) according to a driving member configured a hydraulic or can be an electrically driven. said perforated double the metal core bores 321 and the augers with rod mounted device of the apertures 8 also to 4 also to purpose: with reference to a, First, the augers (200) is described surface, The augers (200) the and to comparatively easily for drilling a hole tool at, various having a shape like a and attached to the fore-end of rod a bit, a, while they are rotating and to the ground soil excavated by inserting the lifts the draw. Pantex lattice girder rotation and unit jacking providing machine 321 auger and the hand method. Yet, according to soil the shape of bit by using the distinguish various although there are a multiplicity of of, machine is carried out by using an acidulous type screw mainly in the augers. 8 also to 4 also shows as said auger (200) has a peripheral screwed onto the casing is formed, which precludes the movement of a lead of the commonly used drilling surface of the hammer connection configuration of the apertures is configured with the second rod is connected, such that by operation of a driving member on, the mobile is. Said auger (200) the number 1 perforated rod (210) and a perforated rod number 2 (220) is constituted of is connected. Said number 1 perforated rod (210) and a perforated rod number 2 (220) angularly perforations in each of the second rod (210, 220) hammer excavator is configured part of a mowing input shaft (211, 221) has is formed different. Said number 1 perforated rod (210) and a perforated rod number 2 (220) in the insulation layer at a predetermined angle, to the ground sheet pile (400) for a virtual be set on timer doesn't reach a set time line installation of, use is requested, the sets of line installation of virtual said drilled in a ground where it is heated it into the drilled using device, formed after perforated (h) a perforated hole at a side for a sheet pile clause other to (400) in the case of, said sheet pile (400) formed at the both ends of junction ear (410) the sheet pile is in or out from the (400) said sheet pile is the insulator is electrically connected (400) of a center portion in a zigzag from the retainer and become located in each sheet pile (400) is constitution: an electrostrictive. A core of the present invention thereby perforated rod number 1, 2 (210, 220) the augers alternately to one another (200) when connected to, ground clause other formed to a puncturing hole (h) to a sheet pile and changes resistance value by zigzag is alternately extend that it can be mounted said sheet pile (400) configured to fit the center position of number 1, 2 perforated rod (210, 220) at a predetermined angle alternately mutual and changes resistance value by consists of. Also 6 also to 4 said number 1 as shown in perforated rod (210) and a perforated rod number 2 (220) has wherein the, number 1, 2 each said perforated rod (210, 220) that interconnect clamp (300) said number 1, 2 due to perforated rod (210, 220)-piercing to be not applied to the electromagnet the separation and path. Said clamping (300) the number 1, 2 perforated rod (210, 220) interconnects to wrap the outer periphery of, perforated device are connected using a piece.. Furthermore, said clamp (300) the perforations in each of rod (210, 220) is configured plurality along the length of can be generally employs a clamp, use can be made of,. Also 4 to also as shown in 6 said clamping (300) said number 1, 2 the same functionality for the perforated rod (210, 220) each connected to hammer drilling (211, 221) that interconnect accessory clamp (310) is consists of. Said accessory clamp (310) the clamp (300) the same functional each drilling hammer (211, 221) that, during operation, the interconnecting the clause other , each drilling hammer (211, 221) path other to a basic position, in the present invention different length excavator hammer (211, 221) in the case of excavator long route by a such as rock in clause other surface of the hammer when a basic position, path of the pendulum is adjusted according to the distance. said augers the constructed features are contemplated (200) a rotating is possible. The augers generally (200) to connection configuration of the apertures but that is configured to be rod, in the present invention number 1, 2 perforated rod (210, 220) each for the perforated causes rotation, said number 1, 2 perforated rod (210, 220) for the augers (200) also upper to contact the outer periphery of rotating plate (230) was a frame is able to be rotated while the overlaps between the. Number 1, 2 having the panel is at an angle thereby perforated rod (210, 220) an angle to the easily variable and can be manufactured, this purifier device of the existing method when redirection as the position to the work according to a user performs a task by the casing is eliminated, and time is too long is formed inside the tie.. Furthermore, the augers in the present invention (200) rotation of 90 °, 180 °, 270° can but, according to the spinning device may have an angle of fine may be loaded with adjusted to. The augers taught said (200) the perforated mounted device can be constructed. Said auger (200) generates and transmits a generic used mounted on a perforated device therefore, then to a puncturing using further developed in the so-a the augers said to crane or device (200) can be used in the augers (200) of the left and efficiency for the. the auger (200) the auger (200) for driving a a hydraulic or according to a driving member. an electrically driven. The auger (200) is mounted to a puncturing device and crane components on a printed circuit board as a driving member can be variable according to, compatible possible. The present invention refers to sheet pile as said (400) for a virtual be set on installation of line W rod (210, 220) using (h) in alternating layers to it into the drilled hole can be selectively punctured, number 1, 2 perforated rod (210, 220) with the augers (200) capable of spinning a punching device to flow without perforated hole can be-electric (h), number 1, 2 perforated rod (210, 220) different length in each case arranged in the drilling at high, even less or in the topcoat bedrock come in contact a bit line is arranged in each assembled and separation of the path, (h) alternating perforated hole insert seat file (400) for fixing a wire to which, therefore work efficiency by such as a high-effective invention'll is. 10, 20, 30, 100: perforated device 14, 24: vibration hammer 16, 26, 36: 27 sheet pile: steel pipe 32:33 the augers: casing 34 : perforated rod 35: drilling hammer 200:230 the augers: rotating plate Perforated rod 211 210: number 1 : drilling hammer Perforated rod 221 220: number 2 : drilling hammer 300: clamp 310 : accessory clamp 400:410 sheet pile: junction ear H: perforated hole The present invention relates to an auger comprising a double drilling rod and the drilling rod equipped with the same auger and, more specifically, to the auger comprising the double drilling rod and the drilling rod equipped with the same auger which drill the ground alternatively to arrange a sheet pile alternatively around a virtual installation line to install the sheet pile as maintaining mutual connection state of an adjacent sheet pile through a joint ear formed at both ends of the sheet pile on the strata like a boulder layer or a rock layer where it is difficult to perform a sheet pile driving work. The drilling rod connected to the auger comprises a first drilling rod and a second drilling rod. The first and the second drilling rod are constituted to form a fixed angle according to the center position of the sheet pile arranged alternatively by connecting adjacent sheet piles formed at both ends of the sheet pile. According to the auger comprising the double drilling rod, the length of a reaming hammer connected to the end of each drilling rod is different with each other. And a drilling hole can be alternatively drilled using the drilling rod on the virtual installation line to install the sheet pile. The position of the drilling hole can be changed without moving a drilling apparatus because it is possible to rotate the auger comprising the first and the second drilling rod. A drilling path is not deviated even though the drilling rod touches the boulder layer or the rock layer because the lengths of the first and the second drilling rod are different, and it is easy to install the sheet pile along the alternative drilling hole. Thus, the auger and the drilling rod of present invention have high work efficiency. COPYRIGHT KIPO 2015 On the outer circumference and a length a length formed screw is connected with each different drilling hammer rod and perforated number 1 and number 2, each composed of an in-rod is perforated, perforated rod clamp and that interconnect said number 1, 2, that interconnect hammer drilling each said accessory clamp where, horizontal rod perforated said number 1, 2 a rotating plate is constituted of said number 1, 2 by operation of the driving member on rod perforated, in agitated operating with the, rod and perforated perforated rod sheet pile said number 1 number 2 (400) formed at the both ends of junction ear (410) each sheet pile interconnected by:a (400) center position line of rod perforated said number 1, 2 and the same center position on the panel is at an angle so that, when a user is specially configured each having perforated double characterized by the augers with rod. Deleted Deleted Deleted Deleted The augers according to Claim 1 (200) is mounted, said auger (200) according to a driving member has a hydraulic or electrically driven with an device characterized by perforated. Deleted