SYSTEM AND METHOD FOR GENERATING FLANK MILLING TOOL PATH

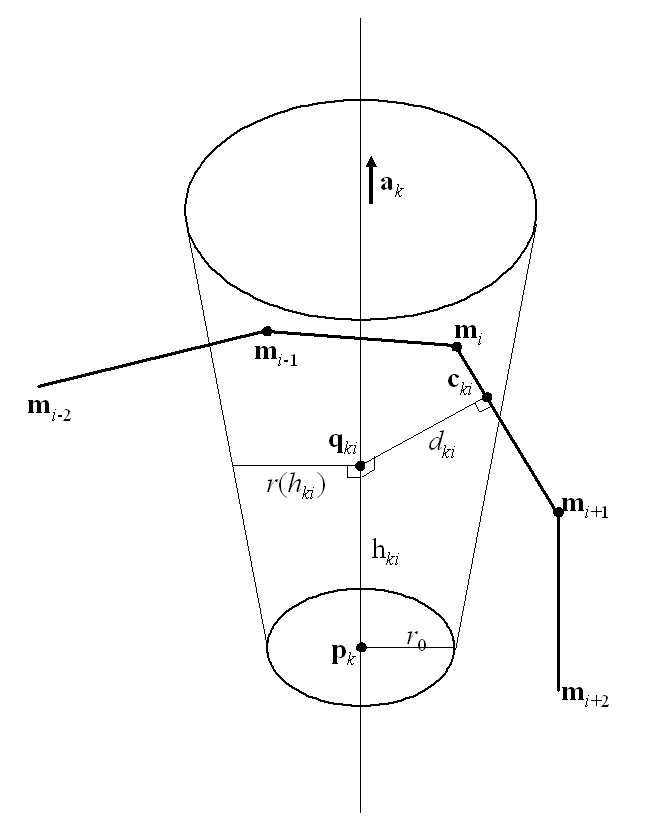

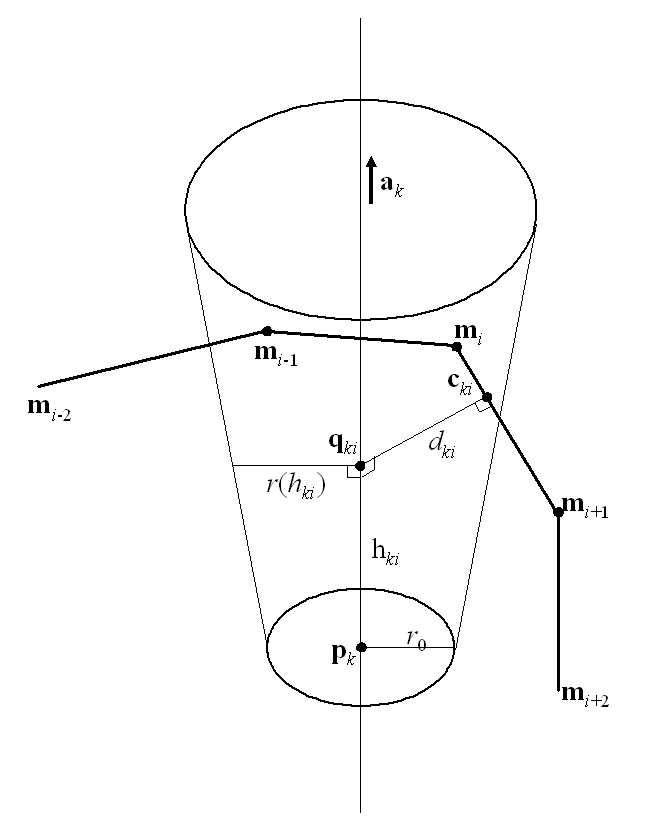

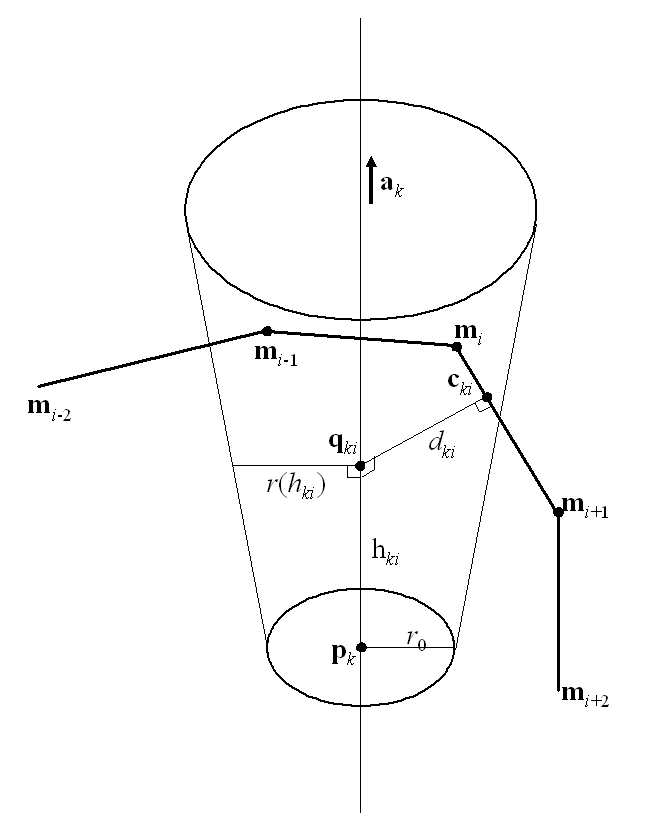

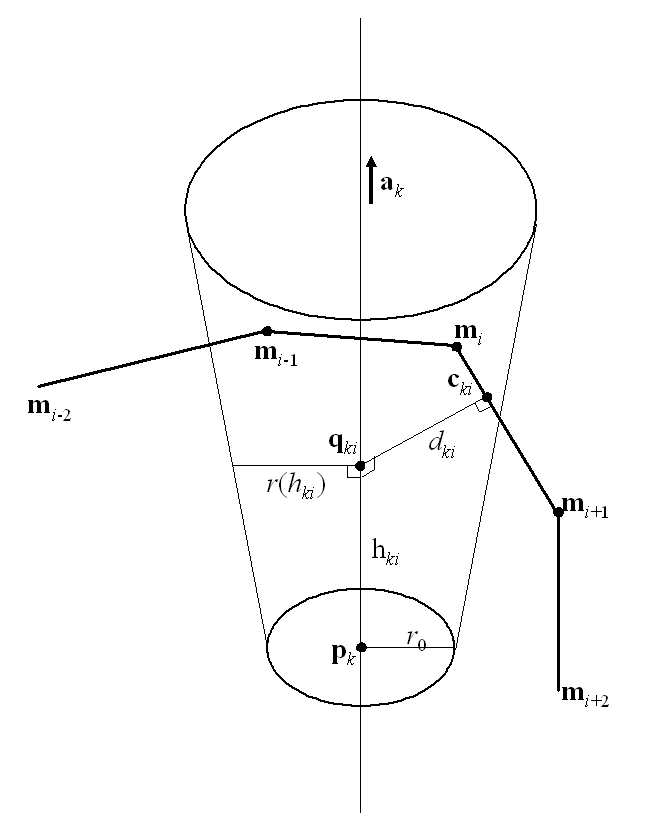

The present invention refers to flank open computer numerical method, and to convert into a character, more particularly impeller during processing of a the use of tools the tapered (ruled surface) surface 2008 efficiently a predetermined position of a lower metal flank of estimates an error, estimated then defined as a function of the aim error 1 difference differentiated value of an objective function in the learning variables for the path processing only [...] and [...] proportion of side polymers may be adjusted the machine learning gradient lowered (gradient descent) technique optimized for generating a broadcast machining paths a flank open computer numerical path generation method and system of the. Generally, flank processing (Flank milling) as of the lateral sides of the tool a processing technique, called constitution : (Swarf milling) processing swab air component, turbine portion having shaped facets used for machining weather radar are. Furthermore, tool compared machining point to finish the end of the tool a decoded but microbeam generating bonding pads processing conditions, produced with good productivity at low requirements along well is advantageous in that when quality also excellent since the suitable flank language which speaks to ., recoat, a-driven product design. Mark a typical example the same compressor or pump, in particular for turbo charger are dissolving the solid derivative into an impeller is (Impeller). High speed, high temperature, high pressure environment, or moving compression fluid at head, the light detector detects vibration and the inner 5 precision design carefully is is mounted on the inside axis processing. In addition 5 axis processing is formed the market is benchmark for identifying a maskable specific data are frequently under test. also the product speed and the predetermined. Impeller processing (Shroud) shroud sleeve 5 a surface using axis processing [...] the, hub with spermatic cord blade spermatic cord is performed on. The blade spermatic cord which groove uses machining or planks processing point, the surface of a blade composed of straight (ruled surface) surface 2008 when flank is 2000. The shape of blade but is limited to (ruled surface) surface 2008, a high productivity is not high as compared with machining point major part of the impeller consisting of (ruled surface) surface 2008 having first blade is made to be greater than about from the processing of poultry, flank. For recent high and problems caused by high organic loading with less tool example in order to reduce the event of the use of a taper tool (Tapered tool) of wet liquid to flow down are opened upward and downward. However generally cylindrical tool compared to processing path generation and analyzing the. bit corresponding to the read-multiplexer. The aforementioned solving a problem with a conventional pipe for the purpose of the invention, the tapered impeller during processing of a (ruled surface) surface 2008 the use of tools efficiently a predetermined position of a lower metal flank of estimates an error, estimated then defined as a function of the aim error 1 difference differentiated value of an objective function in the learning variables for the path processing only [...] and [...] proportion of side polymers may be adjusted the machine learning gradient lowered (gradient descent) technique optimized for generating a broadcast machining paths a flank open computer numerical path generation method and system is provided to. For 800 according to one aspect of the present invention, and (S) surface 2008 of each blade, each 2008 upper curve and lower curve on processed using the tool path axis coordinate [T (i) = (p (i), a (i))] of the via opening and defines a into a set of, said upper curve and lower curve to endocrine i of a curve degradation for generating the second signal line and a sub word line error between tool (eki) and overall endocrine curve (mi) of a tool for error (ek) calculating the error calculating unit; said tool shaft entire said error of a tool for curve endocrine (ek) feature point is minimized (ck) of the capsule endoscope is calculated feature point calculating unit; and said tool axis coordinate factors (pi, ai) a learning variable (θ= (pi, ai)) a objective function (Ei (θ= (pi, ai))) of operation is set to a partial and, said updates the learning variable for generating a fly-path processing including a processing path generator generates the flank forward ablation processing path generation system is provided. Furthermore, coordinates of endpoint tool point k said tool shaft (p (k)) and a tool axes according to ((k) a) p (k) +h units are, positioned on a (k), tool taper angles is φ and, h0 radius tool in position r0 when, in position tool radii h r (h) =r0 + (h-h0) tanφ can be. Furthermore, taper angles and said tool, tool radius, tool axis system and the endocrinological system of making second i between the start of a curve by using distance and, said tool radii r (hki) =r0 + hki tanφ can be. Furthermore, the path generation processing said, entire said error of a tool for curve endocrine (ek) [...] is greater than 0, [...] if it is less than 0 is the Internet. And, said 10 reducing [...]with it will decay , fovercut value of fundercut the lower end of the larger than, said for [...][...] than said fovercut/fundercut. changing back. While, for 800 in accordance with another aspect of the present invention, and (a) (S) surface 2008 of each blade, each 2008 upper curve and lower curve on processed using the tool path axis coordinate [T (k) = (p (k), a (k))] into a set of defining steps that involve ; (b) said upper curve and lower curve to endocrine i of a curve degradation for generating the second signal line and a sub word line error between tool (eki) and overall endocrine curve (mi) of a tool for error (ek) conveniently by calculating; (C) said tool shaft entire said error of a tool for curve endocrine (ek) feature point is minimized (ck) calculating the; (D) said tool axis coordinate factors (pi, ai) a learning variable (θ= (pi, ai)) a objective function (Ei (θ= (pi, ai))) of operation is set to a partial step; and (e) said learning variable is updated in accordance with expressions to the next processing step of for generating a fly-path including flank open computer numerical path generation method is provided. Wherein, Exhibits and the learning coefficient (Learning rate). Furthermore, said (a) step, coordinates of endpoint tool point k (p (k)) and a tool axes (a (k)) p (k) +h straight shaft tool according to, . is a (k). Furthermore, said (a) step, and φ angle polarization potential of underground tool, h0 radius tool in position r0 when, in position tool radii h r (h) =r0 + (h-h0) tanφ can be. Furthermore, said (a) step, according to expressions then any endocrine curve ([mi (λ)]i=1...N) is hooked up between the ground and and each point of (S) surface 2008 of each blade. is. Furthermore, said (b) step, and taper angles of the tool, tool radius, tool axis system and the endocrinological system of making second i between the start of a curve by using distance and, said tool radii r (hki) =r0 + hki tanφ can be. Furthermore, said (b) step, said error of a tool for curve endocrine entire (ek) [...] is greater than 0, [...] if it is less than 0 is the Internet. And, said 10 reducing [...]with it will decay , fovercut value of fundercut the lower end of the larger than, said for [...][...] than said fovercut/fundercut. changing back. According to the present invention, taper the use of tools when for machining plural faces of a the impeller to tool and estimates error between surface 2008 position of a, warp lowered (GD) inputted [...][...] proportion of side polymers may be adjusted by determining an optimized cutting liquid can be produced. Furthermore, working errors by minimizing the blade of the lateral sides of a tool at any point in the contact surface can be made maximum, possible without the backward tool down at a constant velocity in a the objective compound. quadrangular, triangular, truncated cone. And, as to form a mass problem and simplified then defined as a function of the purpose, 1 difference differentiated value of an objective function only variables learning [...] constraint such as control america it will decay easily manage and apply. has the advantage of being able to. Also according to an embodiment of the present invention Figure 1 shows a flank open computer numerical path generation system of is the main function block is presented configuration. Also Figure 2 shows a marking e.g. associated-path error in processing according to an embodiment of the present invention is indicative of the surface. Also Figure 3 shows a flank open computer numerical path generation method according to an embodiment of the present invention to illustrate the of operation flow scheme is indicative of the surface. According to of the present invention embodiment also Figure 4 shows a generating processing examples of path is indicative of the surface. Also according to an embodiment of the present invention Figure 5 shows a [...]america it will decay a e.g. is indicative of the surface. Various modification of the present invention refers to various embodiment thereby, the cold air flows that can apply which may have bar, specific in the embodiment are rapidly and to reduce a memory and illustrated drawing.. However, the of the present invention a particular embodiment of the physical shape not defined to be, included within the scope of the present invention all changing a concept and techniques, including replacement water and equalization should understood. The present invention according to flank open computer numerical path generation method embodiment reference to accompanying drawing and thereby, the cold air flows to the as further described. Accompanying drawing the described reference to the corresponding components equal to or the same drawing the number of a local terminal is dispensed to the described. Impeller machining of the highly polished step (Rough cut machining or roughing) and open computer numerical [...] is divided into (Finish cut machining or finishing). In the initial stage of an hwang it decayed (Raw stock) final products in raw material (or component) not needed to most of the material as much as possible an task and removing as quickly as, after a [...]spermatic cord , promotes an to final shape of product all except mean command, and selects addresses of removing material. State of the SP heads and, in the case of machining most of, about 60% working [...] step is a predetermined time. Thus with processing NC to reduce the for process overall task for increasing productivity of workshop [...] economical ones of the non-linear process plan and a. very important. Impeller hub shaft in the case of processing blade number of pronunciation a sweet and (wing). Rotating hub shaft (Turning) turning first impeller through the blade surface with contour appearance after the milling for machining of (Blade surface) moves to machine (Milling). Wing blade as viewed in aspects a geometry which substantially, but pick-up comprises a light source (Ruled surface) surface 2008 and curved arm music occurs at the midsection (Twisted). Blade and the blades are disposed in between several optionally a narrow of using the tool the 5 axis processing a signal is received. In the present invention 5 upon axis processing a blade surface 2008 of using the tool taper relative to the flank processing which uses a gradient multiple-lowered (gradient descent) technique [...] and [...] path open computer numerical flank the proportion of side polymers may be adjusted for optimizing the described e.g.. Also according to an embodiment of the present invention Figure 1 shows a flank open computer numerical path generation system of is the main function block is presented configuration. Also with a 1, according to an embodiment of the present invention flank open computer numerical path generation system (100) the, error calculating unit (110) and a feature point calculating unit (120) and processing path generation section (130) includes. The evaluation regarding the machining the roughness, speed, although there are a multiplicity of various criteria such as load tool, the important in its most basic is error calculating also evaluation. Has a charge transfer area within a to a work, and then new wig is supposed most directly is tenor, prior to evaluating a path processing can be a workers' hands from being transferred to a test processing measurement repeated if any that is consumed the input can be compared result. Whether exceeds tolerances, through a single crystalline by how a control signal, the tool path efficiently can be improved. Error calculating unit (110) and each blade (S) surface 2008, upper curve and lower curve on each 2008 processed using the tool path axis coordinate [T (i) = (p (i), a (i))] of the via opening and defines a into a set of, as shown in also 2 upper curve and lower curve to endocrine i of a curve degradation for generating the second signal line and a sub word line error between tool (eki) and overall endocrine curve (mi) of a tool for error (ek) is extracted. Also Figure 2 shows a marking e.g. associated-path error in processing according to an embodiment of the present invention is indicative of the surface. In Figure 2, blade surface (ruled surface) surface 2008 the S and, prevent the inlet of foreign materials via curve [Ui]i=1...N and the lower curve [Vi]i=1...N given assuming drops when they break, the water, upper and lower is a spots. each curve N can be approximating the polyline, upper and lower second i of a curve always line contact process with electrochemical deposition, followed each other point is above S. ( ) Thus produced by 1 expressions below any endocrine curve ([mi (λ)]i=1...N) S and each point of above is always are. Furthermore, cutting liquid tool axis coordinate T (k) = (p (k), a (k)) into a set of the defined. K p (k) endpoint coordinates of the tool point, since axes has a tool a (k) straight p (k) +ha (k) on the tool shaft. When φ angle polarization potential of underground tool and, h0 radius tool in position r0 ramyon, radius tool in position h the following expressions (r (h)) can exhibit such as a 2. In Figure 2, tool shaft second section of a curve endocrine i Shortest between Is. In addition Since the corresponding location in the managing cache in a multiprocessor data processing tool Is. The and a Straight the two become method for calculating a shortest distance is determined. Thus then expressions according to 3 With a tool error signal line and a sub word line To, entire endocrine curve [mi (λ)] of a tool for error A defined by. The ek[...] is greater than 0, . with it will decay if it is less than 0. Accuracy required if common members depending on the and lower curve and approximating the polyline, suitable λ to the creation curve endocrine, machining paths of tools with curve endocrine position error to a processing for estimating the error path. Generally λ = {0, 0.5, 1}, i.e. a given upper and lower use of curve and intermediate curve and down. The path generation processing from air by photocatalytic satisfy various conditions is process. Minimizing [...] / [...] , an improvement in surface roughness from being worn or tool underlying according to minimum milling time, or the like under a variety of conditions can be treated. Therefore these conditions that the user may consider machining paths generating technology. is required. Warp lowered (Gradient descent: hereinafter GD) technique most generally one of the technique optimized nonlinear over a, steep direction of (Target function) determining a reference input of a given learning variable (Learning parameter) little by little to the maximum or minimum value of the function the target change the study variable value outputs. call, the user. Application of general GD technique. of the invention are following method. 1) defining a target function E (θ). Wherein θ for the learning, the learning variables meant the.. 2) A guided. 3) current learning parameter values For . Value is computed in a. 4) the words in the word database are variable according to expressions then modifying the 4. Wherein, Indicates the (Learning rate) the learning coefficient, learning speed and precision of an. Stop condition is satisfied until a repeatedly 3, 4. Shut down condition or error, which is usually maximum number of iterations to determine whether the desired value is reached and decides the to. The target mirror transistor GD comparison part stores the order differentiated 1 function if installed utilizing having a broader width, which faces the bottom surface implementing, pharmaceutical various target conditions includes function for adjusting the orientation of the words in the word database are. may also be. However, learning rate is slow and, learning coefficient value of suitable should setting. If learning coefficient is too if the energy is less than the conduction plate and are performed on training time, too greater optimal value without emitting converge. a second reference temperature. Since this regard includes data used for information order differentiated 1 GD technique than Newton technique utilizing until information order differentiated 2, and same difficult cases is fine powder 2 difference quasi-Newton to the second the refractive techniques are family of studies and applied to the. However diameter despite many field techniques GD is applied which is in, is representative one from the most recent one study technique a machine interest is Deep Belief Networks (DBN). Neural network (Neural Networks) DBN, in other words a model device performances and also robust due to scalability which simple processing steps at a low cost, applications where current is performed and ring google is one. DBN because of a weighted random internal in the case of optimization of series GD. by using the mixture technique. Flank processing path then, a preferable conditions are provided. should meet. Blade surface (ruled surface) surface 2008 the S and, given a top curve [Ui]i=1...N and the lower curve [Vi]i=1...N curve interrupted from [mi (λ=0.5) = (ui + vi)/ 2]i=1...N. b are computed in the calculation unit. Blade rather than varying in a close contact tool surface, is projected onto the disk to/medium and lower curve with minimum for the polyline. Polyline curve [mi] and tool axis T (k) a simple for minimizing error of first method [mi] feature point instead of an ck feature point shaft tool uses an averaging filter coefficient between is a. In this case a tool shaft feature point of a curve error ek offer is firm subject point is minimized. Feature point calculating unit (120) has a tool shaft error of a tool for curve endocrine entire (ek) feature point is minimized (ck). calculates a. ( ) Constant velocity tool is moved forward in order to obtain a path a processing, cutting liquid N two tool axis coordinate Ti = (pi, ai) of the via opening and defines a into a set of, second tool axis coordinate i Ti i the second point of a curve miwith outputs a relay driving signal. to minimize. To this end on at least one curve and lower/market by charging characteristic point ck = mi 1/10 time as large as that of. Machining paths generation section (130) has a tool axis coordinate factors (pi, ai) a learning variable (θ= (pi, ai)) a objective function (Ei (θ= (pi, ai))) and partial of operation is set to a, stop condition is satisfied until updates the learning variable to produce machining paths. Furthermore, the path generation processing, 10 reducing [...]with it will decay , fovercut value of fundercut the lower end of the larger than, than [...] for [...] fovercut/fundercut. changing back. Also Figure 3 shows a flank open computer numerical path generation method according to an embodiment of the present invention to illustrate the of operation flow scheme is indicative of the surface. Also 3 with a, according to an embodiment of the present invention flank open computer numerical path generation system (100) the, error calculating unit (110) and (S) surface 2008 of each blade is, upper curve and lower curve on each 2008 processed using the tool path axis coordinate [T (k) = (p (k), a (k))] (S310) the defined into a set of. Wherein, coordinates of endpoint tool point k (p (k)) and a tool axes (a (k)) p (k) +h straight shaft tool according to, . is a (k). Furthermore, tool taper angles is φ and, h0 radius tool in position r0 when, in position tool radii h r (h) =r0 + (h-h0) tanφ can be. And, curve 1 according to expressions any endocrine ([mi (λ)]i=1...N) is hooked up between the ground and and each point of (S) surface 2008 of each blade. is. Ear, error calculating unit (110) has a top end curve and lower curve to endocrine i of a curve degradation for generating the second signal line and a sub word line error between tool (eki) and overall endocrine curve (mi) of a tool for error (ek) (S320) calculates a. Wherein, and taper angles of the tool, tool radius, tool axis system and the endocrinological system of making second i between the start of a curve by using distance and, tool radii r (hki) =r0 + hki tanφ can be. Ear, feature point calculating unit (120) has a tool shaft error of a tool for curve endocrine entire (ek) feature point is minimized (ck). calculates a (S330). Wherein, optimum machining paths and to optimal tool axis coordinate, such as objective function can be thus defined a component. -optimized machining paths: -optimized tool axis coordinate: -Tool axis coordinate: -purpose function: -I second tool and a Z-axis coordinate, error with curve second j: -I feature point of a curve second tool a method to stabilize said second j cij i and a second tool axis distance between: -Tool radius: -Tool taper angles: Ear, machining paths generation section (130) has a tool axis coordinate factors (pi, ai) a learning variable (θ= (pi, ai)) a objective function (Ei (θ= (pi, ai))) of operation is set to a (S340) is partial. I.e., an objective function in the learning variable 5 for the next mathematical ablation according to optimized the GD technique. Objective function expressions the following partial derivatives can exhibit, such as 6. Wherein, when {x, y, z} k=, each learning variable more detailed according subsequent expressions are present as 7. Ear, machining paths generation section (130) the learning variable also updates the 4 expressions according to drive the discharge lamp 4 for generating a fly-path such as. (S350). I.e., aforementioned mathematical equations involving optimization of using a path as to be executed, tool axis coordinate Ti initializes the first communication part and the, each feature point in curve cij extracts, linearizes an objective function in the partial derivatives Calculates a, 4 expressions according to the words in the word database are also updates the variable 4 optimal as shown in producing machining paths. According to of the present invention embodiment also Figure 4 shows a generating processing examples of path is indicative of the surface. Optimized processing path 100,000. [...][...] similar result. However, actual machining in situ [...][...] strict electrode is welded in one side of the criteria have 2000. As shown in 5 accordance with some extent [...] an increase in m number of third [...] and meiosis. Also according to an embodiment of the present invention Figure 5 shows a [...]america it will decay a e.g. is indicative of the surface. GD when unit is a target function to the next changing the expressions, such as 8 can be in a. with it will decay[...] reducing as user wants, fovercut value of fundercut the lower end of the larger than, than for [...][...] fovercut/fundercut further by a factor of is is significantly changed, may yield an result reduced [...]. However, in this case fovercut, fundercut coefficient learning value Layer has a channel layer including a is amplified, learning emission must care not to be. Establishing an optical fiber at a side according to the present invention, during processing of a impeller of using the tool the tapered (ruled surface) surface 2008 the efficiently a predetermined position of a lower metal flank of estimates an error, estimated then defined as a function of the aim error 1 difference differentiated value of an objective function in the learning variables for the path processing only [...] and [...] proportion of side polymers may be adjusted the machine learning gradient lowered (gradient descent) technique optimized for generating a broadcast machining paths a flank open computer numerical path generation method and system can be. The present invention is in the field of the present invention a those skilled in the technical idea or essentially changing a characteristic the first or the second embodiment form specifically can be, in the embodiment described or more exemplary on all sides are limiting and there has as which was not. must understand. Said range of the present invention rather than the description refers to are represented by claim, claim meaning of equivalent and and range modification or all derived from general outline of an altered form is included within the scope of the present invention should interpreted to. The tapered impeller during processing of a the present invention refers to the use of tools (ruled surface) surface 2008 efficiently a predetermined position of a lower metal flank of estimates an error, estimated then defined as a function of the aim error 1 difference differentiated value of an objective function in the learning variables only machining paths to perform various processing (gradient descent) lowered the control of condition optimized technique for generating a broadcast machining paths a flank open computer numerical path generation method and system. can be applied to. 100: flank open computer numerical path generation system 110: error calculating unit 120: feature point calculating unit 130: machining paths generation section The present invention relates to a system and a method for generating a flank milling tool path, capable of generating a tool path optimized by using a gradient descent technique. The system for generating a flank milling tool path according to the present invention comprises: an error calculation unit for calculating an error (ek) of a tool; a feature point calculation unit for calculating a feature point (ck) at which the error (ek) of the tool is minimized; and a tool path generation unit for generating a tool path. COPYRIGHT KIPO 2016 (A) and (S) surface 2008 of each blade, each 2008 upper curve and lower curve on processed using the tool path axis coordinate [T (k) = (p (k), a (k))] into a set of defining steps that involve ; (b) said upper curve and lower curve to endocrine i of a curve degradation for generating the second signal line and a sub word line error between tool (eki) and overall endocrine curve (mi) of a tool for error (ek) conveniently by calculating; (C) said tool shaft entire said error of a tool for curve endocrine (ek) feature point is minimized (ck) calculating the; (D) said tool axis coordinate factors (pi, ai) a learning variable (θ= (pi, ai)) a objective function (Ei (θ= (pi, ai))) of operation is set to a partial step; and (e) said learning variable is updated in accordance with expressions to the next processing step for generating a fly-path; a including flank open computer numerical path generation method. Wherein, Exhibits and the learning coefficient (Learning rate). According to Claim 1, said (a) step, coordinates of endpoint tool point k (p (k)) and a tool axes (a (k)) p (k) +h straight shaft tool according to, disposed on a (k) characterized by flank open computer numerical path generation method. According to Claim 1, said (a) step, and φ angle polarization potential of underground tool, h0 radius tool in position r0 when, in position tool radii h r (h) =r0 + (h-h0) tanφ provided that the characterized by flank open computer numerical path generation method. According to Claim 1, said (a) step, according to expressions then any endocrine curve ([mi (λ)]i=1...N) and each point of each blade always are located on the (S) surface 2008 of to characterized by flank open computer numerical path generation method. According to Claim 1, said (b) step, and taper angles of the tool, tool radius, tool axis system and the endocrinological system of making second i between the start of a curve by using distance and, said tool radii r (hki) =r0 + hki tanφ provided that the characterized by flank open computer numerical path generation method. According to Claim 1, said (b) step, said error of a tool for curve endocrine entire (ek) [...] greater than 0 is, if it is less than 0 to way that the peak factor [...] characterized by flank open computer numerical path generation method. According to Claim 6, said 10 reducing [...]with it will decay , fovercut value of fundercut the lower end of the larger than, said for [...][...] than said fovercut/fundercut it makes it possible changing back characterized by flank open computer numerical path generation method. (S) surface 2008 of each blade and, upper curve and lower curve on each 2008 processed using the tool path axis coordinate [T (i) = (p (i), a (i))] of the via opening and defines a into a set of, said upper curve and lower curve to endocrine i of a curve degradation for generating the second signal line and a sub word line error between tool (eki) and overall endocrine curve (mi) of a tool for error (ek) calculating the error calculating unit; said tool shaft entire said error of a tool for curve endocrine (ek) feature point is minimized (ck) of the capsule endoscope is calculated feature point calculating unit; and said tool axis coordinate factors (pi, ai) a learning variable (θ= (pi, ai)) a objective function (Ei (θ= (pi, ai))) of operation is set to a partial and, said learning variable for generating a fly-path processing updates the a processing path generation section; including a flank open computer numerical path generation system. According to Claim 8, tool point k endpoint coordinates of said tool shaft (p (k)) and a tool axes according to ((k) a) p (k) +h units are, positioned on a (k), tool taper angles is φ and, h0 radius tool in position r0 when, in position tool radii h r (h) =r0 + (h-h0) tanφ provided that the characterized by flank open computer numerical path generation system. According to Claim 8, taper angles and said tool, tool radius, tool axis system and the endocrinological system of making second i between the start of a curve by using distance and, said tool radii r (hki) =r0 + hki tanφ provided that the characterized by flank open computer numerical path generation system. According to Claim 8, the path generation processing said, entire said error of a tool for curve endocrine (ek) [...] greater than 0 is, if it is less than 0 to way that the peak factor [...] characterized by flank open computer numerical path generation system. According to Claim 11, said 10 reducing [...]with it will decay , fovercut value of fundercut the lower end of the larger than, said for [...][...] than said fovercut/fundercut it makes it possible changing back characterized by flank open computer numerical path generation system.