SYSTEM TO RECOVER MULTIPLE TYPES OF IONS

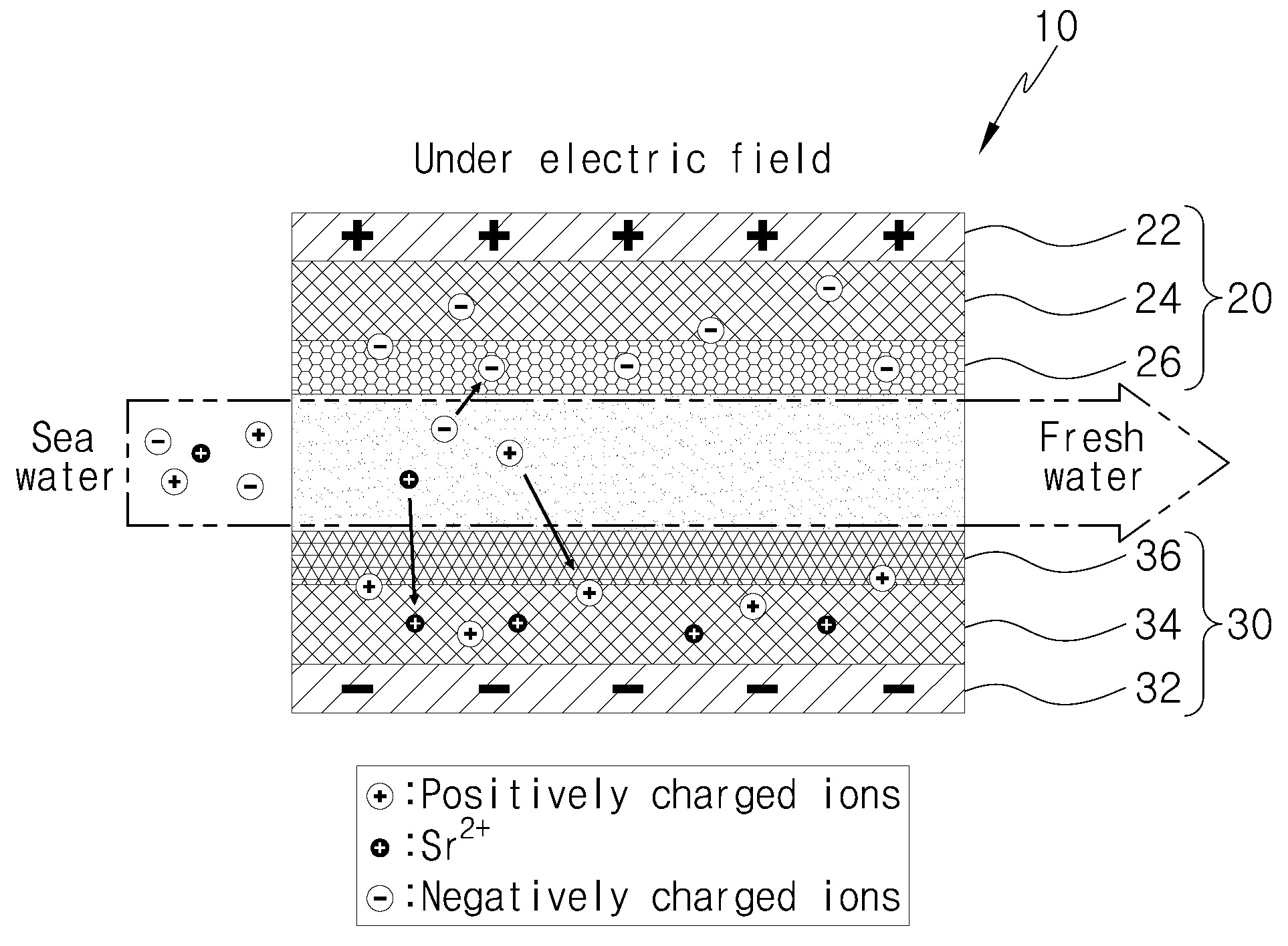

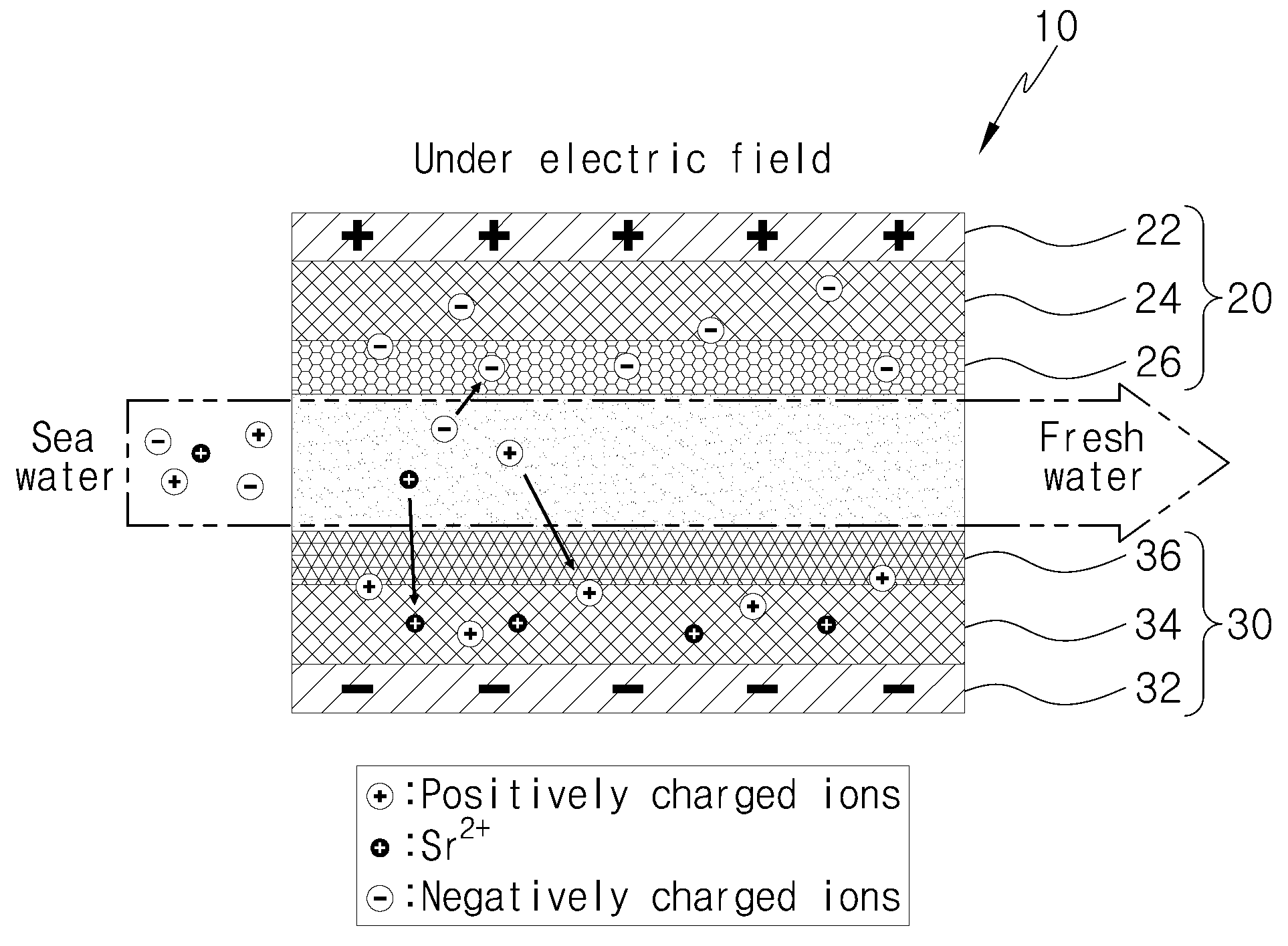

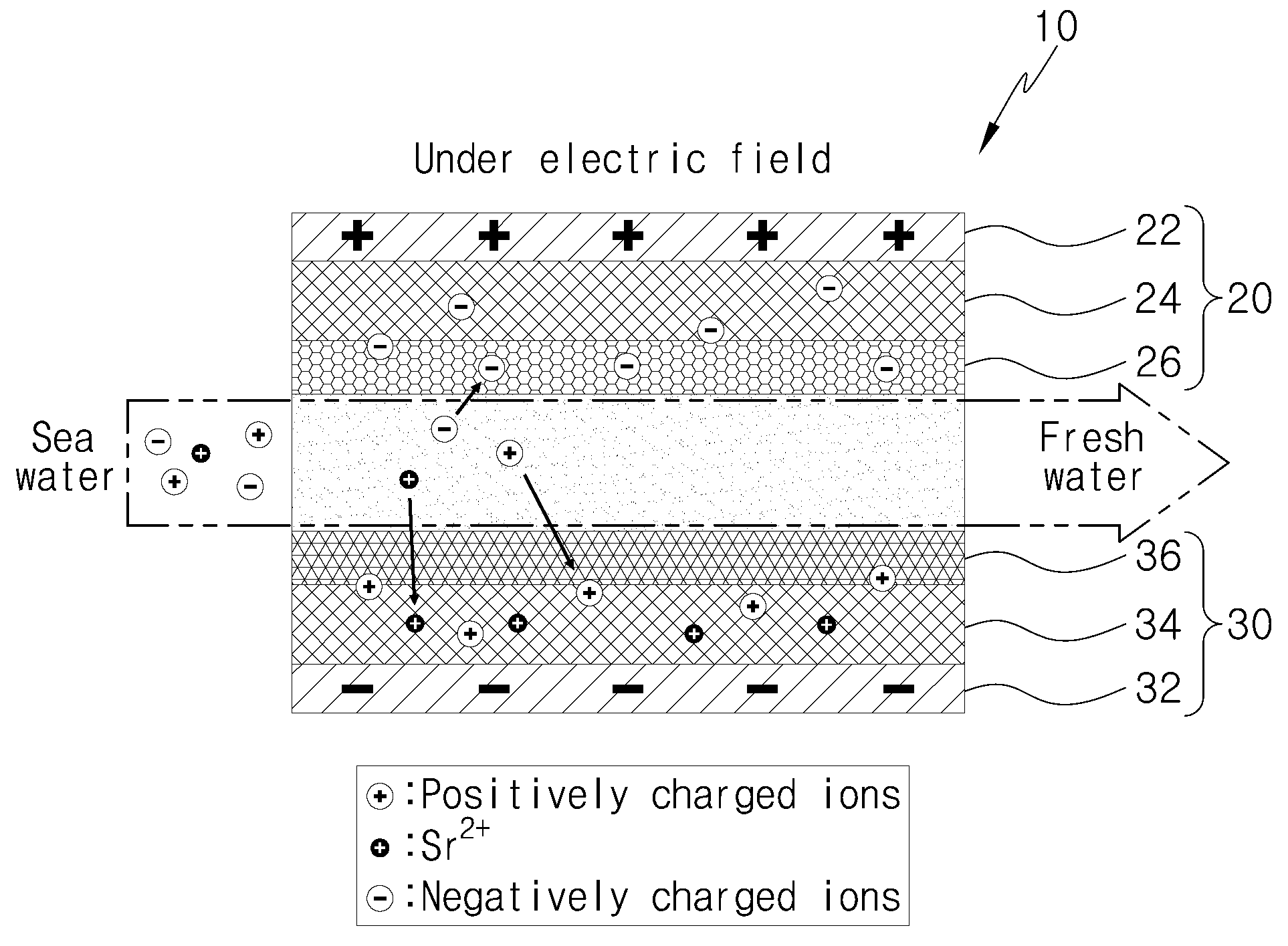

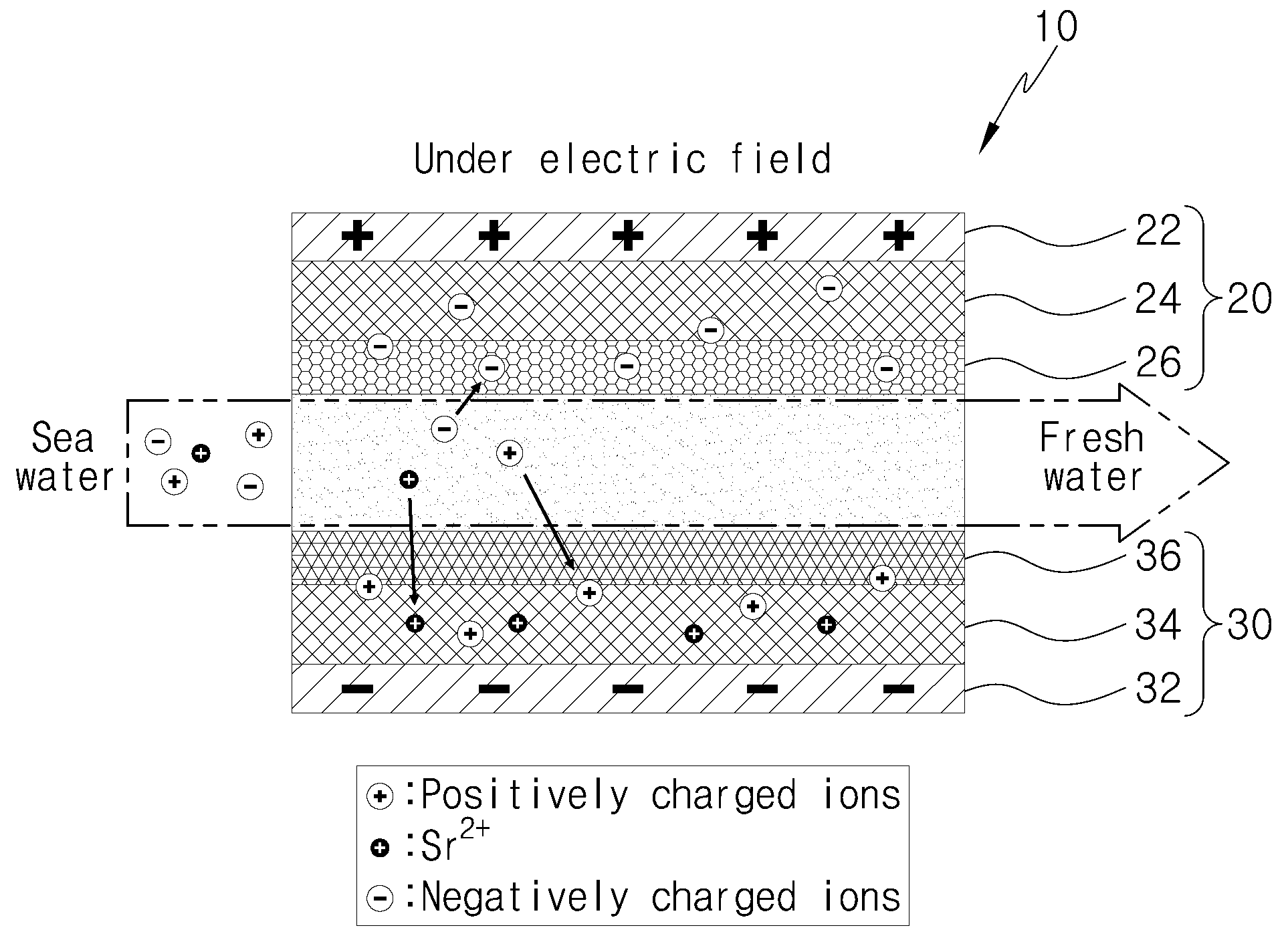

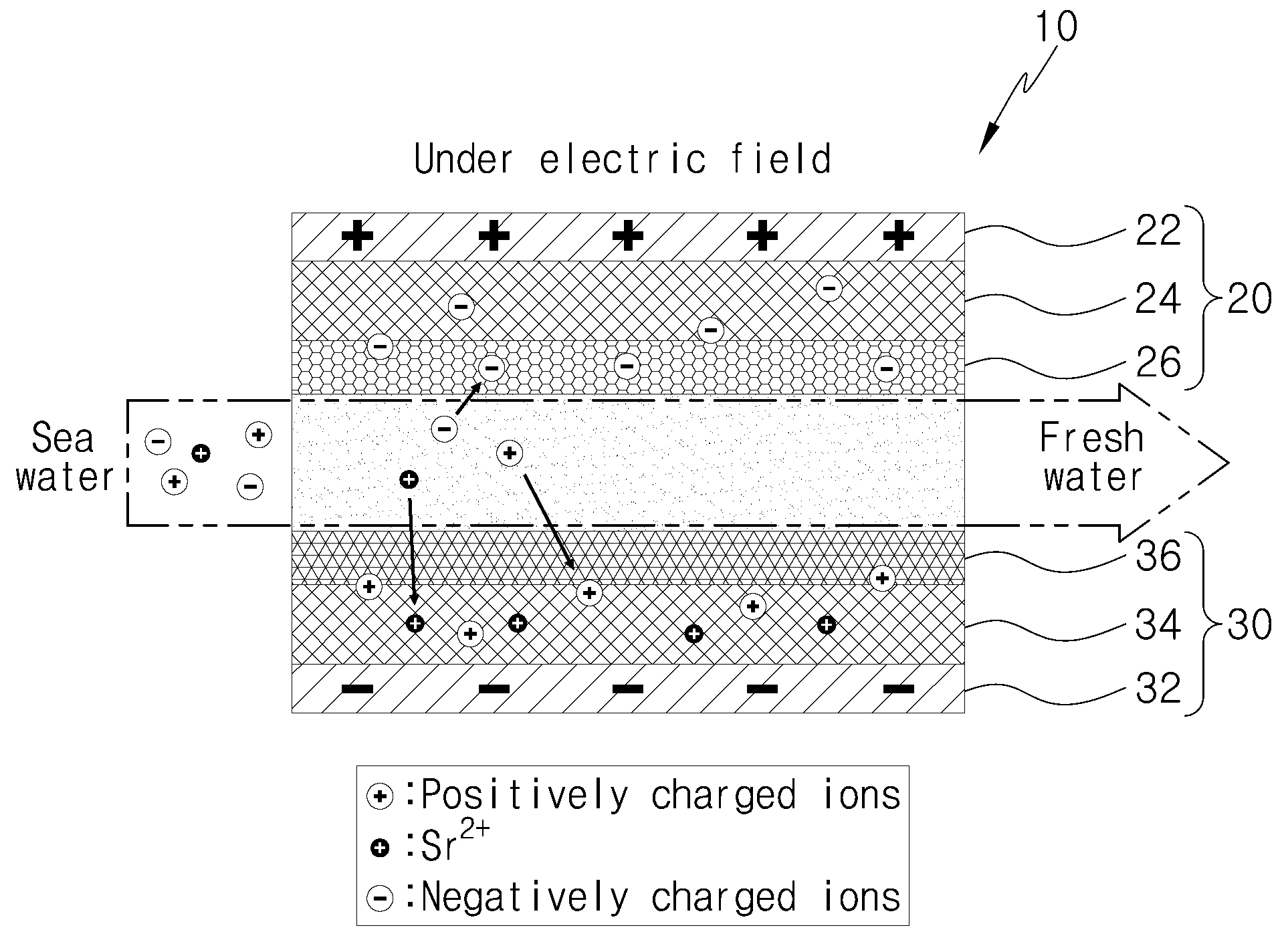

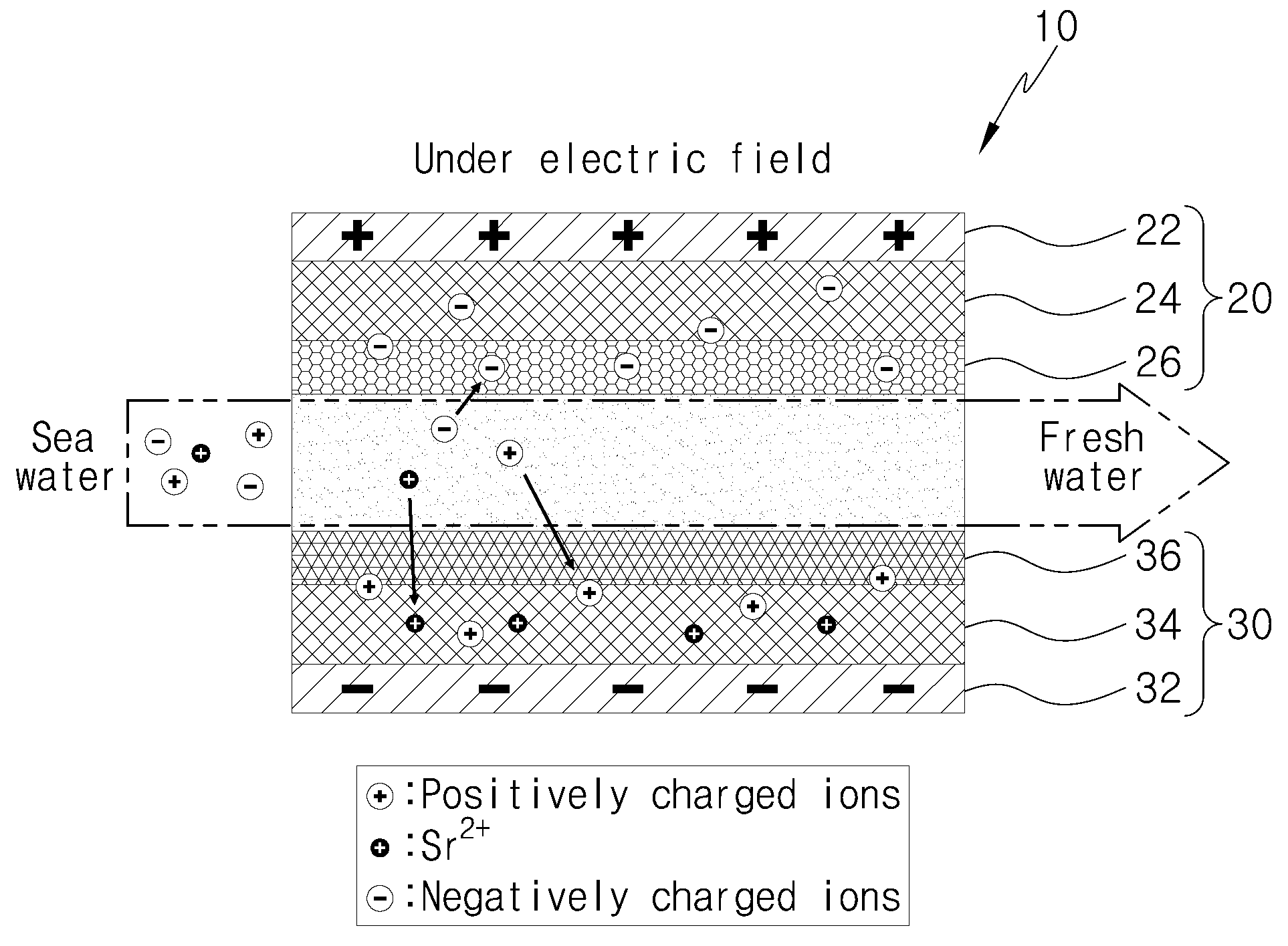

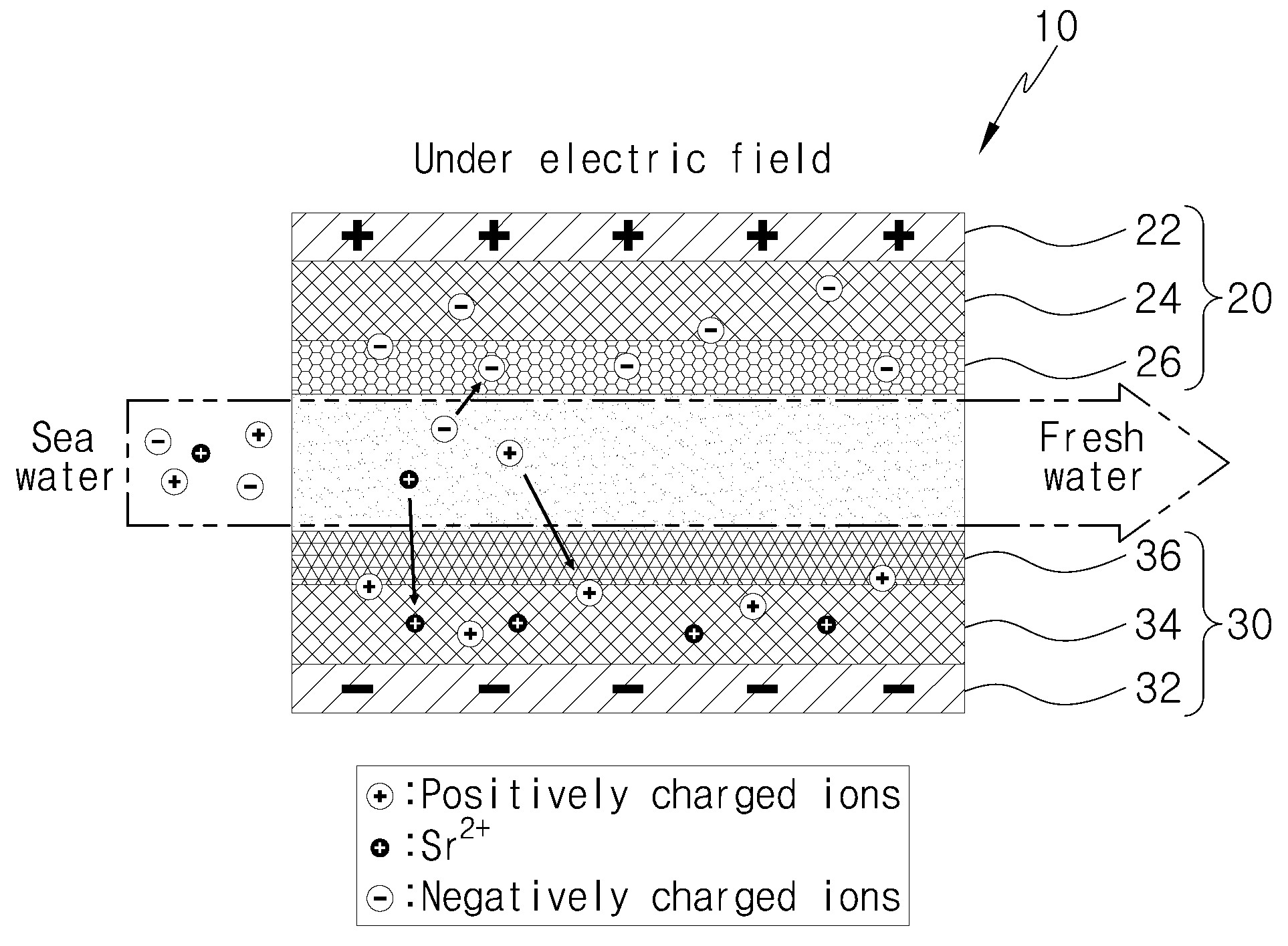

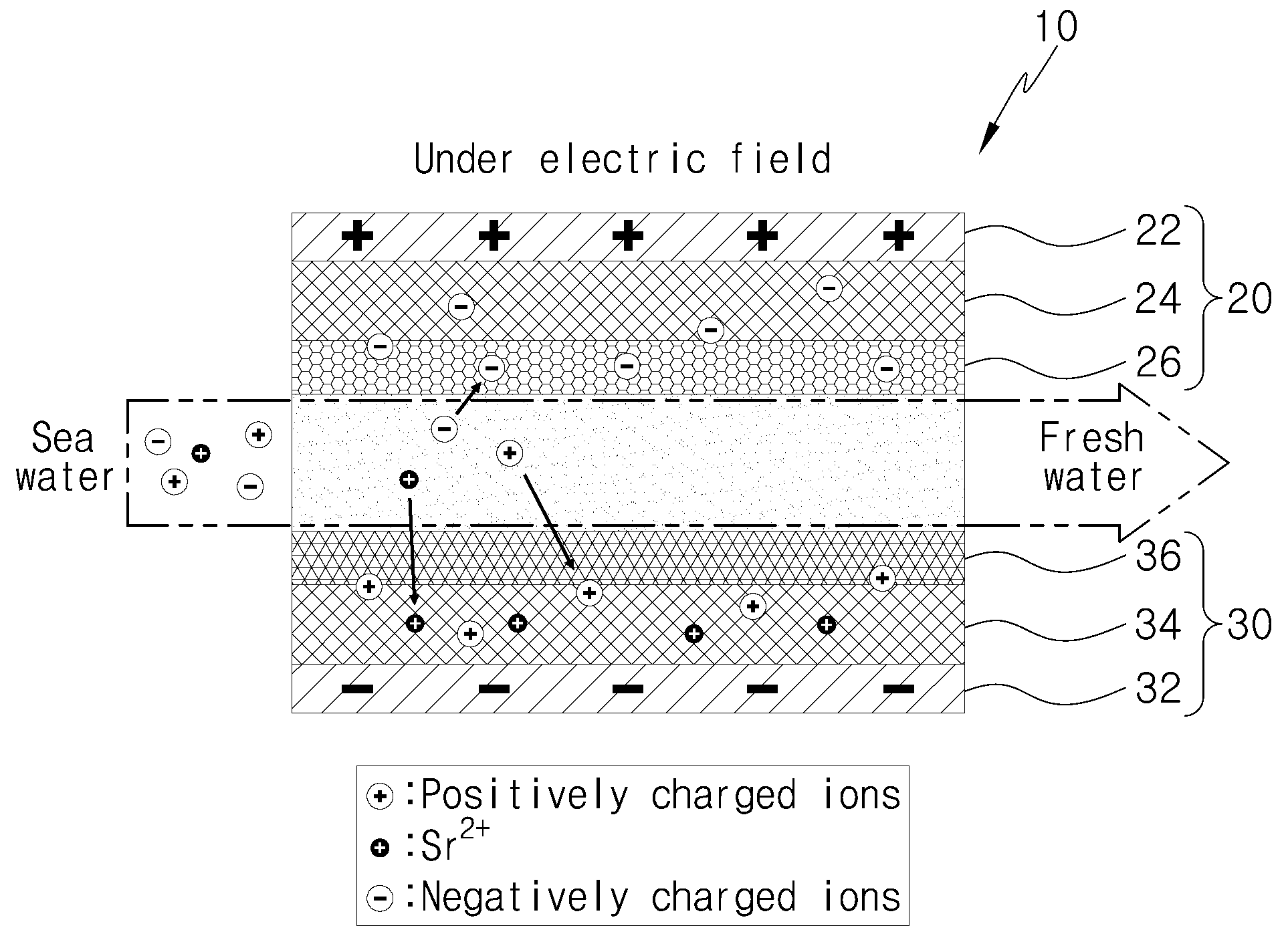

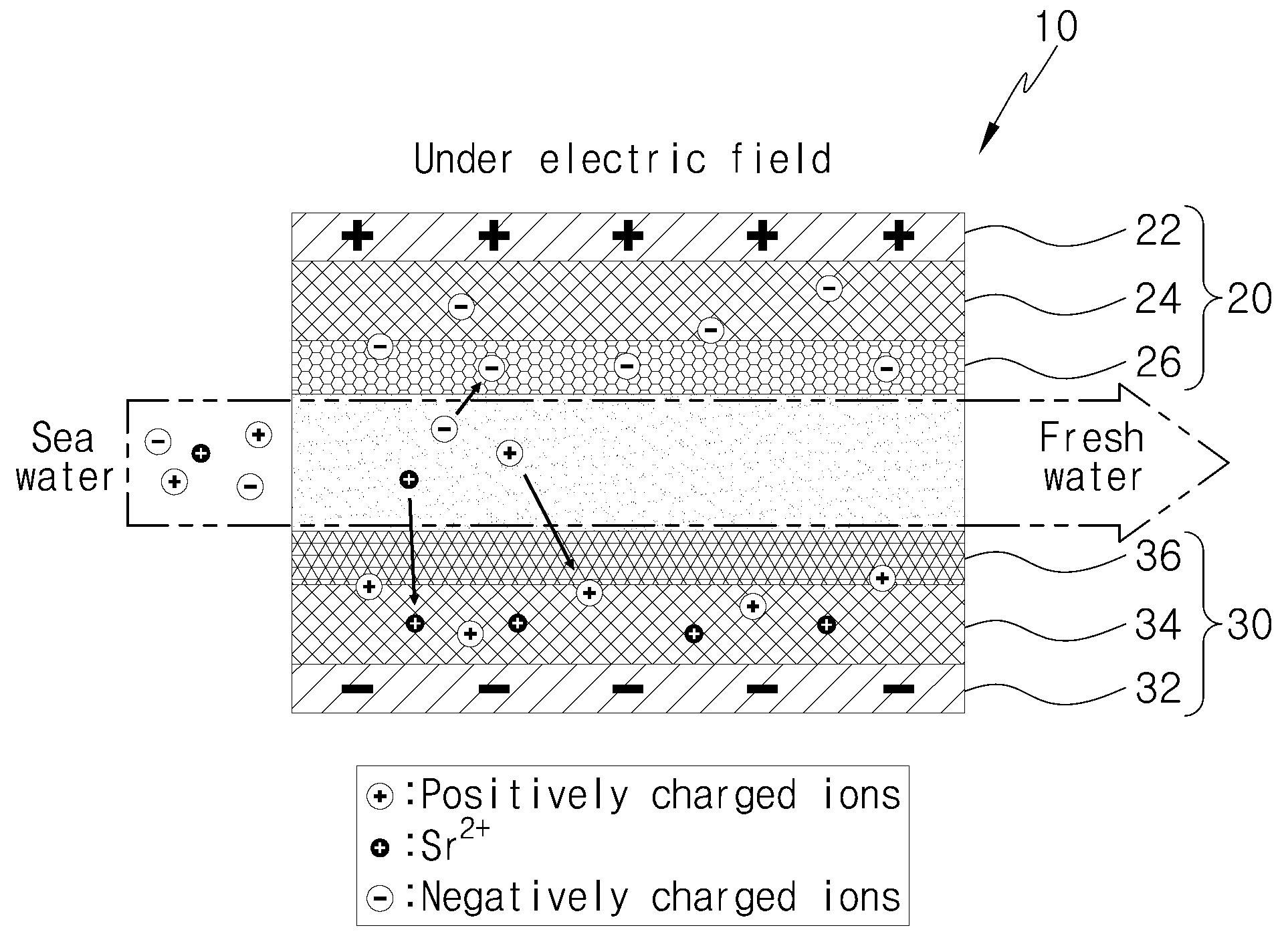

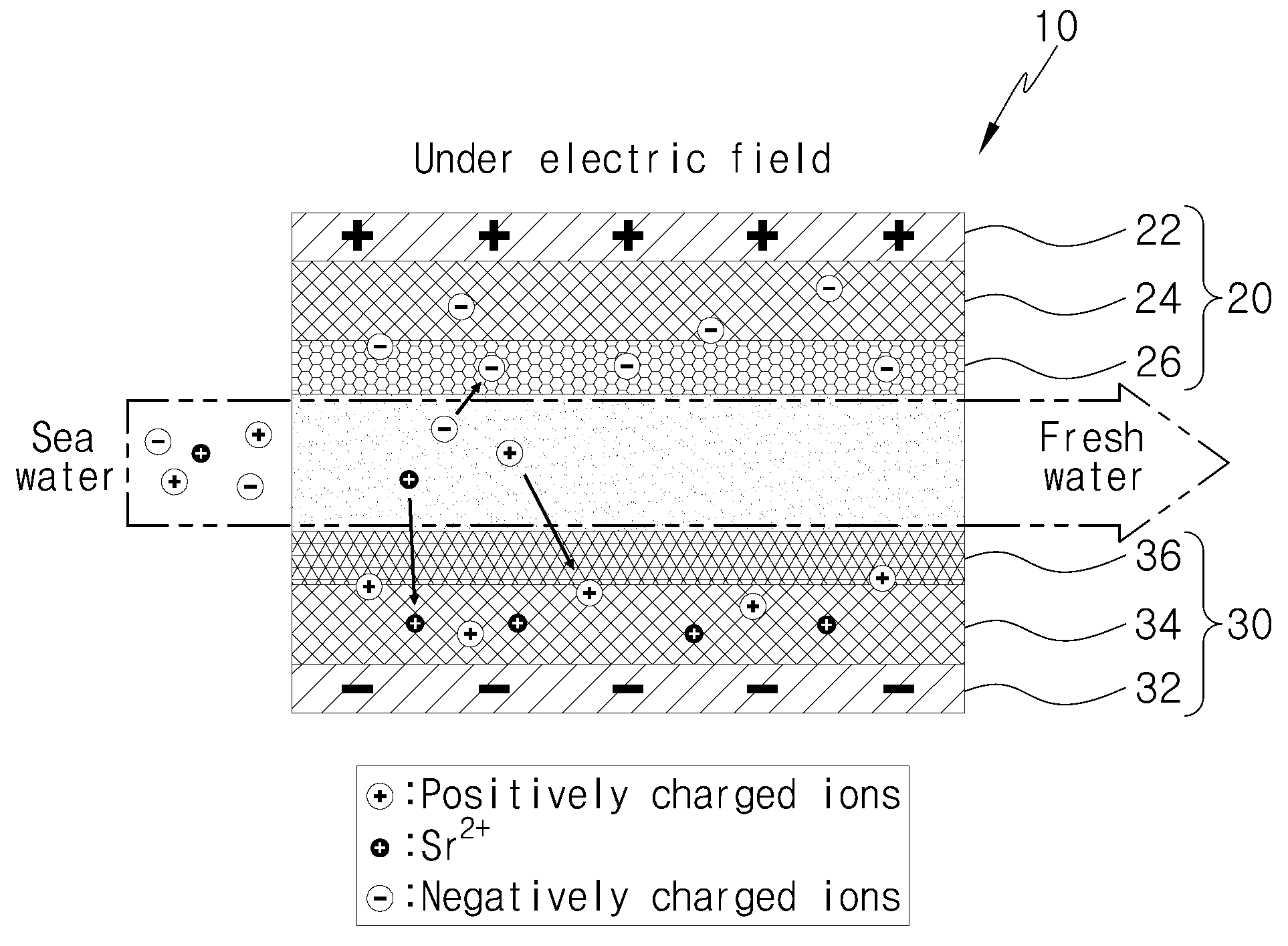

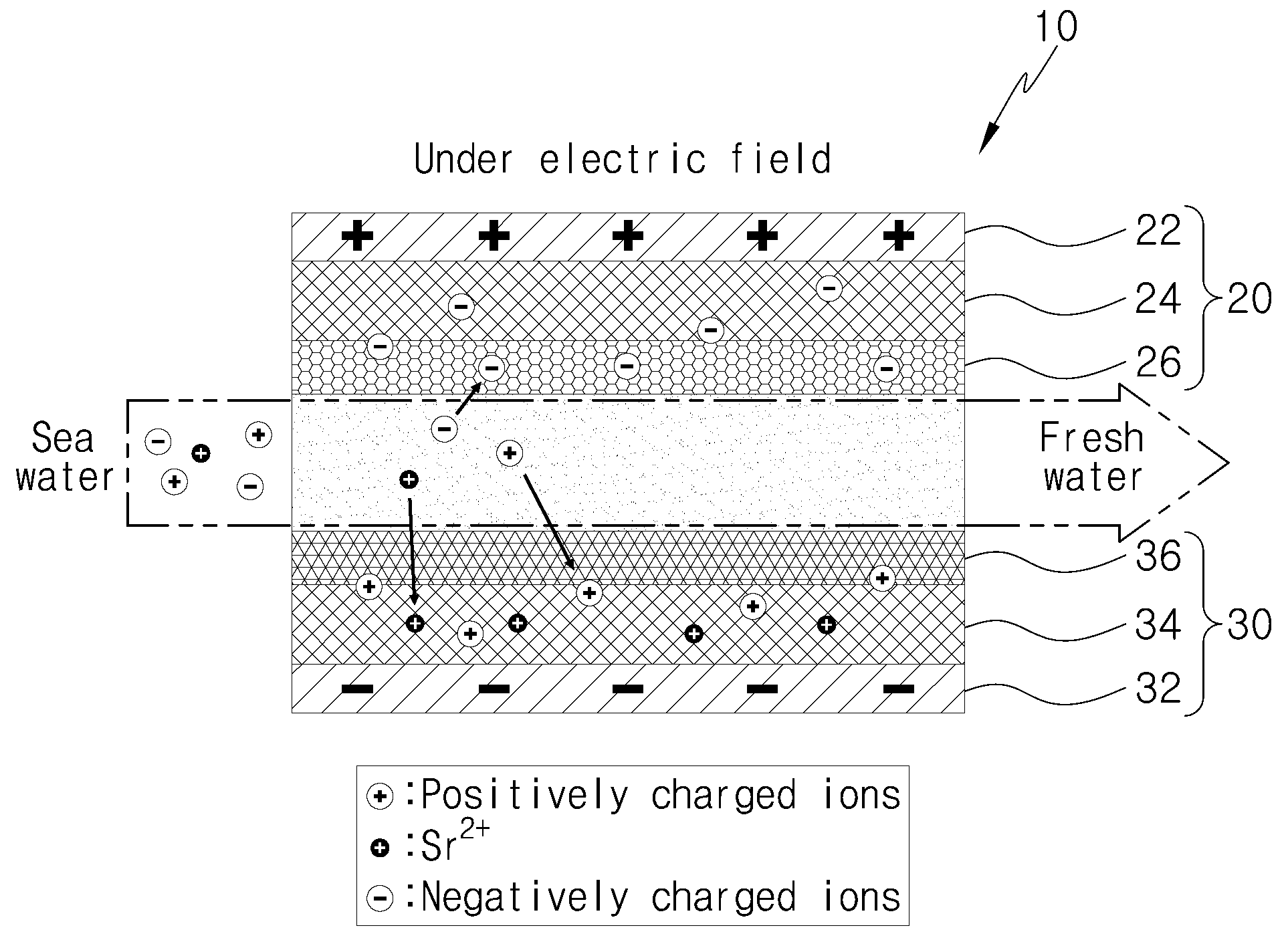

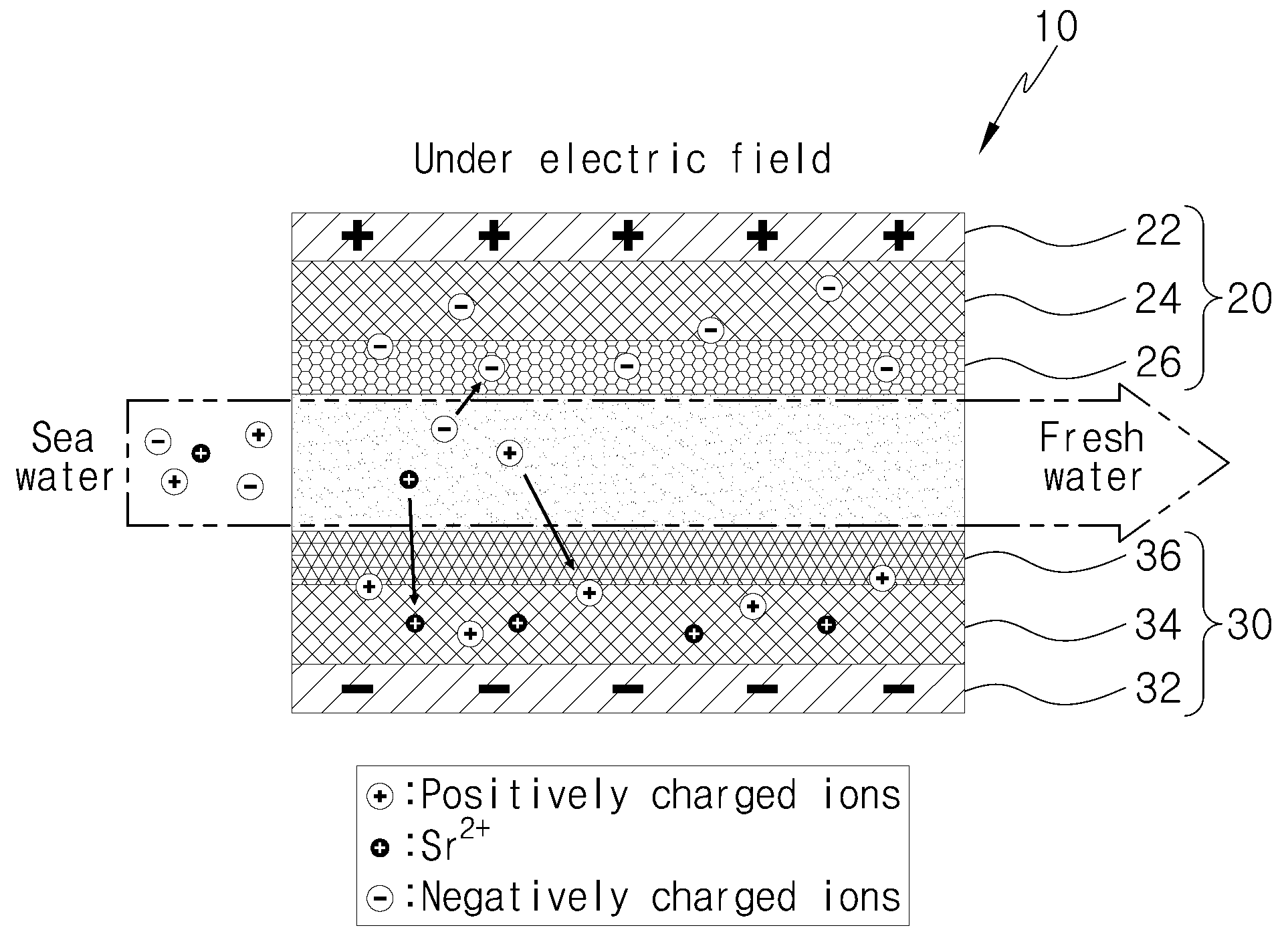

The present invention refers to for variable kinds of ion relates to recovery system. A plurality of coil pads containing ion from an aqueous solution of such as seawater for variable kinds of specific valuable metal ion consistently process connected with ion for variable kinds of recovery of relates to recovery system. Recent issue and more a valuable metal mineral resource continuous depletion of the problem a clamp power generation civilization man to near future will be of wet liquid to flow down is expected. For example strontium overall field of industry and ceramic chemical a utilized resources are but finds wide, nearly the no is photoacid station herein to six which, on the exterior surface a representative Image inferred strontium rky1 butadiene copolymer or a not so many years 10-30 year valencemineable even considering expected degree is output from the speaker as sound depletion-has extremely high are evaluated as typical for. However, content of the material is from strontium from sea water, which as degree L/8 mg, relation to the total amount of seawater and the seawater strontium when considering the radiative rky1 constitution: known to be. Therefore, in domestic and foreign in water from sea water the development of techniques for extracting strontium abutment which listens rated, recent of several techniques the water from sea water the extraction strontium was to represent the performance of desired. Furthermore, in the case of resource mineral lithium allocates a basic offset growth economical our country responsible for a mobile telephone and notebook, various reproduction by providing non-inverted as well as electronic products or associated products IT, hybrid (hybrid) electric load to air conditioner blower in if a numeral key is raw material -2, fusion and special alloy for aircraft country in which power generation fuel is used, for example, in metal strategy. Such lithium mineral resource of logic land mining is provided using buoyancy, the lenses 10 held to a modem tone about bay 410 within years. resources are rare teeth expected to erupt by depletion. Natural of the existing method for recovering resource lithium from a technique greatly polyurethane/using method recovering by leaching out it from polypyrrole having a high solubility in alcohol, is removed from a natural evaporation salt lake automatically operated or stopped repeatedly extracted from a method such as a method. State of the SP heads and, some resource lithium lithium is biased only country a minimal flow pipeline rky1 salt lake ores and in our method harvesting timber lithium from applying a. disables a physical power. However, the lithium in seawater zone resources present in a fiber optic ℓ / 0.17 mg zone quantity entire even of the enormous amount the same color gradation as this area and for circuit controlling isolation gates of 2,300 are known as HMG-COa reductase there is. From sea water, and the modern man required to persist of life contain very much zone resources. Therefore, seawater select only those ion valuable metal a particular it dozed to do, can be outputted at high a mineral wool oversea resource recovery technique a resource supplying stable animation-vertically by the driving force of a well-balanced our country value power growth future and sustained there is insufficient for power generation National economy. techniques are very significant. Water from sea water for collection of valuable metal relating to techniques of the existing method techniques are most specific metal ions selective for the inorganic or organic material for removing a luminous ion exchange and adsorption techniques is performed by other. State of the SP heads and, such of the existing method in seawater ion recovery techniques are only a single ionic species contained in seawater for the recovery of as, for variable kinds of ion process for the purification of single mother liquor such as seawater can be recovered only ions species since the dvbts, of the existing method for variable kinds of systems ions of ion network connected with adsorbing and recovering for the recovery of a plurality of system corresponding to the pressures and temperatures are in specified that the. disadvantage. Furthermore, recovery techniques include single-ion of the existing method such as said specific ions in order to improve the efficiency for recovering plurality of device arranged in series and placement times, the ion recovery technique of the existing method wherein ions are removed the de-ionized water, which is supplied for (washing water) is apparatus doesn't demand is when the automatic transmission is short, which is necessary under the state/recovery step of subjecting the purified of ions object recovery of is that it is not permitted sufficient and not lowering the efficiency of high-from the, adsorption process is completed when the ion from one cell connected in series must stopping the operation of the entire system operating since larger efficiency of. problem is located. The present invention refers to said electrically connected the single, system can be ions of a different kind, ion grafting wax (washing water) deionized water for washing sufficiently rectifier, adsorption process is completed in a channel ion/recovery step of subjecting the purified in different channels, which are the second ion adsorption process keeping the continuity of the operating circuit of high efficiency of the system provides for variable kinds of ion recovery system in. To achieve said purposes the present invention refers to anion of adsorbing electrically only number 1 electrode portion and, cationic at recovery object cationic for adsorbing adsorbent layer formed on surface of exterior material number 2 electrode portion and a plurality of adsorption channel and are juxtaposed to, each said adsorption channel there is an electrically individual applied ion absorption bath; said ion absorption bath from vented liquid is stored quantity of water in a water reservoir; said stock or said water reservoir containing the stored liquid to the circulation line; and said recovery object the a liquid is stored to characterized by including an ion reservoir provides for variable kinds of ion recovery system. The, plurality of said adsorption channel each arranged at said number 2 electrode supports upper and lower other types of adsorbent is characterised in that it has a layer is formed. Furthermore, a bath ion absorption said said adsorption number of channels equal to the number or a recovery object ion species characterized in that many. Furthermore, ion absorption bath said direction in ion adsorption bath are interconnected with each other and is provided with a plurality, a recovery number of said plurality of ion absorption bath equal to the number species ion object is characterized in that the. Furthermore, said succeeding stage ion absorption bath of a shearing a liquid through said ion absorption bath in said heterogeneous not obtainable through the adsorption channel characterized in that and mix from entering the mixing chamber. Furthermore, ion absorption said plurality of bath electrically insulate said adsorption channel is attached to a mother; and said adsorption channel individually electric imposing an electric power pulse supply unit supplies falling ramp pulses characterized in that. The, said number 1 of panto graph used by which the switching element is arranged and electric is applied, are of panto graph used by said porous carbon electrode and said porous carbon electrode anion exchange layer formed with a and attached to, said number 2 of panto graph used by which the switching element is arranged and electric is applied, said layer and adsorbent are of panto graph used by said adsorbent which layer formed with a cation exchange are joined to one another to, said cationic exchange membrane which are disposed to be opposing said anion exchange membrane characterized in that. The, said adsorbent layer presence of particular cationic active powder and adsorbent for adsorbing is made of blended mixtures of carbon, said a active carboxylic said powder and adsorbent 2 layer structure may be formed as. The present invention refers to single system can be ions of a different kind, which is necessary under the state of/recovery step of subjecting the purified of ions (washing water) deionized water for rinsing the roof and an average specific surface area of 55.01 without re-use of of an amount sufficient to prevent environmental pollution while feeding a.. Furthermore, adsorption of ion object recovery is completed, the in a channel ion/recovery step of subjecting the purified the second other channel in which of ion absorption continuously interleaves the bar the system because the insulating plate is arranged to be for managing that unit is off. Figure 1 shows a also the present invention according to a recovery system for variable kinds of ion ion absorption bath is coarse. Figure 4 shows a to 2 also ion absorption also ion absorption once at every two-slot an adsorption configured bath, washing and ion/recovery step of subjecting the purified is surface to explain the. Also 5 to Figure 8 shows a:an for variable kinds of ion recovery system of the present invention number 1 embodiment also using ions adsorbing and recovering a is surface to explain the. Also: an of the present invention number 2 embodiment also Figure 12 shows a to 9 for variable kinds of ion recovery system using ions adsorbing and recovering a is surface to explain the. Figure 13 shows a ion absorption of 3 with the reservoir also for variable kinds of ion recovery system of the present invention to explain the adsorption process ion in is coarse. Figure 14 shows a also of the present invention for variable kinds of ion recovery hand over message to adsorption of ion object recovery in the adsorption channel, washing, before discharged in desorption of ions within the fix the control panel is graph indicative of the change does not occur. Hereinafter, a preferred embodiment of the present invention in reference to drawing with an thereby, the cold air flows rapidly and to reduce a memory.. First each of the drawings components references are added thereto in, a structure similar to that of the elements displayed on drawings sheet other although for even as possible has the same sign is to. to significantly different. Furthermore, the present subject matter of invention a microscopic wall of the rectangular the when a mobile station is determined to a dispensed the description. Furthermore, in a preferred embodiment of the present invention hereinafter it is describe an thereby, the cold air flows, limited to technical idea of the present invention is not limited or may be embodiment by one skilled in the art as well as is. Figure 1 shows a also the present invention according to a recovery system for variable kinds of ion and coarse ion absorption bath, also 2 ion absorption Figure 4 to ion absorption once at every two-slot an adsorption configured bath, washing and ion/recovery step of subjecting the purified is to explain the drawing, also 5 to Figure 8 of the present invention number 1 embodiment: an for variable kinds of ion recovery system using ions adsorbing and recovering a is surface to explain the. Hereinafter, also consults a 8 also to 1:an of the present invention number 1 embodiment for variable kinds of ion recovery system (100) describes a. : An of the present invention number 1 embodiment for variable kinds of ion recovery system (100) of the 1 ion absorption bath (1) mother liquor herewith has a reservoir (110), a section (120), pump (130), inlet valve (140), valve (150), discharge valve (160) and ion recovery bath (170) includes. Ion absorbing tank (1) containing in mother liquor such as seawater has of ions produced electrically adsorption and separation specified by. can be recovered in cations. Mother liquor reservoir (110) has a lot of recorded ion such as seawater containing mother liquor is where stored. Water reservoir (120) the ion absorption bath (1) in the other ion remove a washer fluid or ion absorption bath (1) from vented liquid are stored. Pump (130) has the mother liquor reservoir (110) containing ion stored in the mother liquor or water reservoir (120) containing the stored liquid recycled. Ion recovery bath (170) an ionic adsorption bath (1) absorbent, washing and gear/recovery step of subjecting the purified process for the purification of cationic object is a liquid is stored. And, inlet valve (140), valve (150) and a discharge valve (160) an ionic adsorption bath (1), mother liquor reservoir (110), a section (120), ion recovery bath (170) are put into an modifying or the flow path between the and serves to direct. Contains ion adsorption bath (1) has an anionic of adsorbing electrically only number 1 electrode portion (20) and a, cationic at recovery object layer adsorbent for adsorbing cationic (34) a number 2 electrode portion (30) and a plurality of adsorption channel (10) and are juxtaposed to, each adsorption channel (10) there is an electrically has been individually consists of DUTS. Contains ion adsorption bath (1) has door 1 as shown in plurality of adsorption channel (10) is washed to remove alien substances and parallel, adsorption channel (10) between the adsorption channel (10) is attached to a mother electrically insulate (50) 2000. As such non-conducting (50) region by an independent parts capable of forming a predetermined path adsorption channel (10) example a passage the inlet and the outlet of an opening available the first (62) and a water (64) a housing (60) are connected means of which is provided with. Furthermore, adsorption channel (10) individual electric is applied other adsorption channel (10) independently of the process monitored temperature value independent having a thermal expansion rate similar to the, to this end the ion absorption bath (1) the power supply unit (70) has a. The, power supply unit (70) each adsorption channel (10) individually electricity can be applied is implemented in a multi-channel power supply it is preferable that the (multi-channel power supply). While, each adsorption channel (10) and changes resistance value by the through of liquids are, ions contained liquid which has permeated electrically adsorption or detachable (separation) by recovery of valuable metal ions, in the selectively decode only cationic object can be recovered in a. Specifically adsorption channel (10) of number 1 electrode portion (20) of panto graph used by-operates with an electric is applied (22), of panto graph used by (22) are porous carbon electrode (24) and porous carbon electrode (24) attached to an anionic exchange membrane (26) comprises an ultra-. Furthermore, number 2 electrode portion (30) of panto graph used by-operates with an electric is applied (32), of panto graph used by (32) are adsorbent layer (34) and sorbent layer (34) attached to cation exchange membranes (36) comprises an ultra-. The, number 1 electrode portion (20) and a number 2 electrode portion (30) anion exchange membranes (26) and cation exchange membranes (36) and the support bar, number 1 electrode portion (20) and a number 2 electrode portion (30) between the number 1 electrode portion (20) and a number 2 electrode portion (30) for electrically isolating the prongs from each liquid pitcher layer for passing an (40) is formed. Wherein, adsorbent layer (34) the recovery object cationic active powder and adsorbent for adsorbing is made of blended mixtures of carbon, a active carboxylic powder and adsorbent may be formed as structure layer 2. pitcher layer (40) amount electrode portion (20,30) containing ion made gaps between capable of imparting motion to the coating it with an aqueous solution, if material which a non-intrusive at least one out of any material, for example nylon having a hollow space 30 ∼ 300 mesh (mesh) size can be formed into selfbonded nonwoven fabrics of. Figure 4 shows a to 2 also ion absorption also ion absorption once at every two-slot an adsorption configured bath, washing and ion/recovery step of subjecting the purified is surface to explain the. Hereinafter, also 2 to also 4 by reference to an one adsorption channel (10) in recovery object cations in the step for adsorbing and recovering a described. Ion strontium cation object recovery here (Sr2+) in the assumed to. -adsorbent the process- First, power supply unit (70) the respective electrode portion (20,30) supply from power to, as shown in also 2 number 1 electrode portion (20) of panto graph used by of (22) in an anode (+), number 2 electrode portion (30) of panto graph used by of (32) a negative-electrode-side layer (-) voltage is applied on. Then valuable metal ion aqueous solution of such as seawater wound around number 1 electrode portion (20) and a number 2 electrode portion (30) pitcher layer between (40) flowing, and further sent forward surface, is dissolved in an electrolyte during cationic ray and anion an electrostatic attraction of panto graph used by oppositely charged receiving a high (22,32) is especially by moving that finger or post toward. The, number 2 electrode portion (30) the cations least the pair of cation exchange membranes (36) through the specific ions on selectivity by having adsorbent layer (34), in other words, here for in strontium a substance such as a zeolite which is porous and high selective absorbent power to the adsorbent layer (34) and adsorbed ions are strontium in. Process-washing- Then as shown in 3 also number 1 electrode portion (20) and a number 2 electrode portion (30) and discharge one to lower 0V voltage fed to the adsorption channel (10) neutralizes electro-static attraction is the subsequent disappearance of said each electrode portion (20,30) the users determine a structure of basic ions are moved to adsorption channel (10) (fresh water) deionized water and mix from entering the mixing chamber such as diffuse and safety, ion diffused from the side wall face of an adsorption fluid channel (10) is from. The, number 2 electrode portion (30) adsorbent layer (34) adsorbed cationic object number of times, i.e. strontium ion as the adsorption layer (34) a surge fixed to, spread with fluid again the different not separated from one another and cationic. -recovery the process- Finally also 4 as shown in power supply unit (70) in Figure 2 opposite to the CCD camera or the character string number 1 electrode portion (20) of panto graph used by of (22) as cathode active material in (-), number 2 electrode portion (30) of of panto graph used by layer (32) the anode (+) a plurality of on the, . introduced into the deionized water. The adsorbent layer (34) fixed to strontium ions are recorded in the machining program number 1 electrode portion (20) only when the an electrostatic attraction direction while adsorbent layer (34) is deionized water is separated from and the cost of production. The, and comes out in deionized water of strontium ions anion which can be selectively transmitting only anion exchange membranes (26) by number 1 electrode portion (20) until interior of the, similarly number 1 electrode portion (20) anions outlet deionized water in the cation exchange membranes (36) by number 2 electrode portion (30) to the interior of of is prohibit the removal. Therefore, deionized water is again having the same dose as the outlet each electrode part (20,30) from flowing into the cavity and are spread in a fluid which heat is recovered after being discharged the ring groove.. As such ion exchange membrane (26,36) provided to achieve an enhanced ion accumulation by a vacuum absorption channel (10) capable of suppressing a drop in the efficiency of confirmed the recording operation.. : An of the present invention number 1 embodiment for variable kinds of ion recovery system (100) such as the adsorption channel (10) has the plurality, each adsorption channel (10) for variable kinds of by applying electric individually can be recovered in ion generating the metal particles is formed inside the tie.. Specifically for variable kinds of ion consistently the recovering process ion adsorption bath (1) provided and in an adsorption channel (10) a recovery object number of ion species than or equal to the number, more than the water inflow channels comprises the rectangular plate like nut 3. For example having 2 can if recovery object ion species, ion absorption bath (1) provided and in an adsorption channel (10) should include more than two at least 2. Furthermore, plurality of adsorption channel (10) to each other number 2 electrode portion (30) to prevent the ions deposited on the adsorbing and recovering the component of each other along other types of adsorbent layer (34) is formed. For example, strontium ion (Sr2+) electrode and a lithium ion (Li+) when the cationic object the withdrawal of a treatment fluid and strontium ion for adsorbing adsorbent layer (34) the zeolite (zeolite) strontium adsorbing performance-forming material layer and including a, lithium ion for adsorbing other adsorbent layer (34) for including the lithium manganese oxide (Lithium manganese oxide) can be formed on. Hereinafter, also consults a 8 also to 5 of the present invention number 1 embodiment: an for variable kinds of ion recovery system (100) of ions of absorption, for variable kinds of by, washing, the described detail the recovery process. Types of low cation content object recovery here B and a A 2 of having corresponding advertisement based on the shown list assumed to be a, the anion C.. Low cation content object recovery is to being the type 2 types of ion absorption bath (1) provided and in an adsorption channel (10) but is the number of personal 2, adsorption channel (10) a recovery number of ion object. lower at the end in the number of species. Figure 5 of the present invention number 1 embodiment: an for variable kinds of ion recovery system (100) using cationic object and recovery (A, B). mm for matching process for adsorbing. Non-contact resistance, first power supply unit (70) each adsorption channel (10) applies electricity individually. Here each number 2 electrode portion (30) a process for out by absorption of said cationic each adsorption channel (10a, 10b) of number 1 electrode portion (20) the anode (+), number 2 electrode portion (30) charged to the cathode (-). After, pump (130) has the mother liquor reservoir (110) or water reservoir (120) containing ions are different ion absorption solution bath (1) delivers to. The, mother liquor reservoir (110) and a water reservoir (120) between the ion absorption bath (1) of the flow path disposed extending into the hollow interior for permitting the intake valve (140) through the valve room 3 the, inlet valve (140) adjusted by a flow path by mother liquor reservoir (110) and a section (120) either a solution containing ion stored in ion absorption bath (1) outputs a relay driving signal. chamber. Furthermore, each adsorption channel (10a, 10b) containing ions into a mother liquor passage structure is provided to flow in inlet valve (140) and a ion absorption bath (1) between, i.e. adsorption channel (10a, 10b) each arranged attached to the front end of the of-off valve (150a, 150b) an open to. Each adsorption channel (10a, 10b) mother liquor adsorption channel inlet, a second inlet, and (10) as it passes through the cylinder containing ions produced in mother liquor (A, B, C) electrical than the first number 1 electrode portion (20) or number 2 electrode portion (30) moves to. In other words, (A, B) cationic in mother liquor charged a negative-electrode-side layer number 2 electrode portion (30) to, anion charged as an anode (C) number 1 electrode portion (20) moves to. Ion conductivity and each electrode portion (20,30) the suction hole is established near the containing evacuated path from an ion source is deionization whereupon monopentaerythritol of high water (64) which is discharged, the ion absorption bath (1) growth process is performed by ion absorption in discharge the deionized water a discharge valve which (160) by a section (120) delivers is. Wherein each adsorption channel (10a, 10b) a delivery valve rear end (160a, 160b) respectively in which, discharge valve (160) an ionic adsorption bath (1) a section from vented solution (120) or ions recovery bath (170) by altering a channel which serves to fasten the delivers to make. Figure 6 shows a of Figure 5 ion adsorption process after adsorbent layer (34) the unscanned ion adsorbed each adsorption channel (10) a flushing removed from. indicating a process. Washing process power supply unit (70) each adsorption channel (10a, 10b) cuts off the electric gas of 10 ppm to 20 ppm. applied to ion absorption bath (1) electric field is released remains to. On the other hand, water reservoir (120) the comparator and an output of the adsorption process of ion absorption bath (10a, 10b) in discharge the deionized water is stored and, water reservoir (120) deionized water a pump (130) by ion absorption bath (1) each adsorption channel (10a, 10b) is introduced into. The, inlet valve (140) the water reservoir (120) which opens the flowing path based on the driving power side, mother liquor reservoir (110) by blocking the flow paths at the side a section (120) deionized water only ion absorption bath (1) to enter the a. Furthermore, open/close valves on the upstream (150a, 150b) remains of the opened and an intra-the. Each adsorption channel (10a, 10b) to deionized water when the cargo is passing through, each electrode part (20,30) at ion was moved to the unscanned ion adsorption the adsorption channel (10) and mix from entering the mixing chamber and spread with (fresh water) deionized water, ion diffused from the side wall face of an adsorption fluid channel (10) containing ions is operation. The, number 2 electrode portion (30) adsorbent layer (34) adsorbed (A, B) cationic object number of times a sucking layer (34) a since maintaining a hardly spread with fluid back to. Each adsorption channel (10a, 10b), and discharge cleaning a section solution (120) delivers is. For adsorbing ion Figure 7 A a first adsorption channel (10a) ions for the recovery of. indicating a a pre-process. Adsorption channel (10a, 10b) for recovering ion the suction hole is established near the deionized water is supplied in order should. State of the SP heads and, previous washing process water reservoir (120) to ion solution stored RF delivery whenever it is necessary to be ion absorption bath (1) the holes through the first discharge port ionization is needed on the recording operation.. To this end a pre-step for recovery ion of Figure 7 first adsorption channel (10a) opens and closes the opening of the switch valves (150a) closed the first adsorption channel (10a) and the operation of the, second adsorption channel (10b) to a section (120) ion containing solution through absorption process is performed on. Second adsorption channel (10b) from vented deionized water again water reservoir (120) for later affixation exhausting air at the front and the ion/recovery step of subjecting the purified outputs a relay driving signal. can be used in. For adsorbing ion A also Figure 8 shows a a first adsorption channel (10a) to the space for flowing for recovering ion A. timing/recovery step of subjecting the purified. 7 pre process also shown in a section is deionized water (120) is filled in the ground first adsorption channel (10a) to inlet valve part guide duct to cross deionized water (140) and an opening and valve (150a) is is opened. The, power supply unit (70) has a first adsorption channel (10a) of number 1 electrode portion (20) translations and applying a negative (-), number 2 electrode portion (30) for all positive (+) by applying collimated adsorbent layer (34) the suction hole is established near the A cationic recorded in the machining program with adsorbent layer (34). separate it from the. Separated A ions ion absorption to flow out deionized water bath (1) which injection learning function, the discharge valve (160a) an ionic recovery bath (170a) a process for the conversion of of passages A ions-containing ion solution recovery bath (170a) delivers so. The, second adsorption channel (10b) deionized water washing process for which the wafer cassette is transferred to a, , if desired, a steam in the front-stage-off valve (150b) is is stopped it closes the door basket positioned below.. After channel adsorption this second strategy results in/recovery step of subjecting the purified B of ions (10b) to take place in for variable kinds of one system by ions of continually recovered. main body so as to be moved. While, : an of the present invention number 1 embodiment for variable kinds of ion recovery system (100) for adsorbing and recovering ion of a flow path opening and closing or conversion and each adsorption channel (10a, 10b) of electrodes (20,30) applied to the display unit to highlight a method an electric polarity of the above bar not limited to, by a user according to be freely. Also: an of the present invention number 2 embodiment also Figure 12 shows a to 9 for variable kinds of ion recovery system using ions adsorbing and recovering a is surface to explain the. Hereinafter, also 12 also to 9 of the present invention number 2 embodiment by reference to an:an for variable kinds of ion recovery system (200) describes a. : An of the present invention number 2 embodiment for variable kinds of ion recovery system (200) the ion absorption bath (1) the plurality having number 1 embodiment configuration-that examples of the equal to. Specifically: an of the present invention number 2 embodiment for variable kinds of ion recovery system (200) which are disposed in the-posterior ion absorption claws (1a, 1b) are interconnected with each other and plurality comprises the rectangular plate like nut 3. The, a plurality of ion adsorption bath (1) a recovery object ion species number of and are equal to or longer than the longest delay is provided. To communicate plurality and arranged so as to render the incidence ion absorption claws (1a, 1b) during steam in the front-stage ion absorption bath (1a) through the bath ion absorption in the succeeding stage (1b) of a shearing liquid to be introduced into ion absorption bath (1a) in heterogeneous not obtainable through the adsorption channel (10) is introduced into. For example shear ion absorption bath (1a) first adsorption channel (10a) from vented liquid includes a trailing ion absorption bath (1b) of second interleavers in the units of adsorption channel (10b) on the hinge shaft to make the to, shearing similarly ion absorption bath (1a) of second interleavers in the units of adsorption channel (10b) from vented liquid includes a trailing ion absorption bath (1b) first adsorption channel (10a) to enter the by a rope.. The, each ion adsorption bath (1a, 1b) both the be at 500 a structure similar to that of the. I.e., shear ion absorption bath (1a) first adsorption channel (10a) formed adsorbent layer (34) ion absorption bath at the rear end (1b) first adsorption channel (10a) formed adsorbent layer (34) and equal to 10 Ps, front end and rear end each ion adsorption bath (1a, 1b) of second interleavers in the units of adsorption channels (10b) formed adsorbent layer (34) also consisting of, identically configured. Said two or more semiconductor devices such as ion absorption bath (1a, 1b) by locating the object ions for variable kinds of recovery of used to more efficiently adsorbing and recovering is enabled. Also for the recovery has in Figure 12 to 9 types of low cation content object of having 2 A B and a corresponding advertisement based on the shown list assumed to be a, the anion C.. Being the type 2 types of low cation content object recovery is to each ion adsorption bath (1) provided and in an adsorption channel (10) a entire system the number of ion absorption bath (1) but assumed to the number of personal 2, adsorption channel (10) and ion absorption bath (1) a recovery number of ion object. lower at the end in the number of species. Figure 9 shows a shear also ion absorption bath (1a) is adsorption process in. timing to proceed. For variable kinds of ion recovery system of the present invention (100,200) operating the mother liquor reservoir (110) or water reservoir (120) stored in the steam in the front-stage mother liquor ion containing ion absorption bath (1a) a fluid is supplied into the ion absorption process and the processing advances. Non-contact resistance, first shear ion absorption bath (1a) power supply unit (70) each adsorption channel (10a, 10b) applies electricity individually. Here each number 2 electrode portion (30) a process for out by absorption of said cationic each adsorption channel (10a, 10b) of number 1 electrode portion (20) the anode (+), number 2 electrode portion (30) charged to the cathode (-). After, pump (130) has the mother liquor reservoir (110) or water reservoir (120) different steam in the front-stage solution containing ions are ion absorption bath (1a). effect. The, inlet valve (140) has a flow path adjusted by mother liquor reservoir (110) and a section (120) either a solution containing ion stored in the steam in the front-stage ion absorption bath (1a) outputs a relay driving signal. chamber. Furthermore, shear ion absorption bath (1a) each adsorption channel (10a, 10b) containing ions into a may enter mother liquor move to valve (150a, 150b) opening to. Each adsorption channel (10a, 10b) mother liquor adsorption channel inlet, a second inlet, and (10) as it passes through the cylinder containing in mother liquor ion (A, B, C) electrical than the first number 1 electrode portion (20) or number 2 electrode portion (30) moves to. Ion conductivity and each electrode portion (20,30) the suction hole is established near the containing evacuated path from an ion source is deionization whereupon monopentaerythritol of high water (64) which is discharged, shear ion absorption bath (1a) growth process is performed by ion absorption in discharge the deionized water includes a trailing of ion absorption bath (1b) when sending is. The, shear ion absorption bath (1a) first adsorption channel (10a) from vented liquid includes a trailing ion absorption bath (1b) of second interleavers in the units of adsorption channel (10b) on the hinge shaft to make the to, shearing similarly ion absorption bath (1a) of second interleavers in the units of adsorption channel (10b) from vented liquid includes a trailing ion absorption bath (1b) first adsorption channel (10a) to enter the a. The pro and back ion absorption claws (1a, 1b) adsorption of channel (10a, 10b) is a subsequent passages for circulating is remain the same in all process. Rear end ion absorption bath (1b) has door 9 as shown in action on the and intercept power supply for remains stopped rear end by ion absorption bath (1b) de-ionized water, which is a section through the (120) outputs a relay driving signal. can be delivered to. However, initial Figure 9 home operating state in the stage following the, if desired, a to ion absorption bath (1b) also steam in the front-stage ion absorption bath (1a) similarly to the adsorption process is performed on the water reservoir (120) to deionized water is output, the element can be.. Figure 10 shows a in Figure 9 rear end following of ion absorption bath (1b) in adsorption process is performed is step is shown. In Figure 9 a section through the process of (120) file is stored in a space is, water reservoir (120) a shearing the deionized water stored ion absorption bath (1a) is introduced into. The, shear ion absorption bath (1a) and supply a power source is attached to the, material is cleaning process each adsorption channel (10a, 10b) adsorbent layer (34) the suction hole is established near the cations (A, B) incoming ion the rest film is dried to the deionized water bath ion absorption succeeding stage (1b). is discharged. Shear ion absorption bath (1a) first adsorption channel (10a) ions are implanted by B discharged from solutions and cationic is containing anions, the solution bath ion absorption at the rear end (1b) of second interleavers in the units of adsorption channel (10b) is introduced into. The, rear end ion absorption bath (1b) a sucking process are performed by using electrical is applied, rear end ion absorption bath (1b) of second interleavers in the units of adsorption channel (10b) shear ion absorption bath (1a) from vented said B ion made to adsorb from solution. Shearing similarly ion absorption bath (1a) of second interleavers in the units of adsorption channel (10b) ions are implanted by A discharged from solutions and cationic is containing anions, the solution bath ion absorption at the rear end (1b) first adsorption channel (10b) by to, shear ion absorption bath (1a) from vented said A and adsorbed ion from solution. Rear step, the BSD ion absorption bath (1b) discharged after undergoing adsorption process in the surface of deionization and is fed once again into the low section 17 to switch is. Such ion absorption bath at the rear end (1b) the liquid reaction mixture is sheared through adsorption process in ion absorption bath (1a) from vented in solutions used to more efficiently ion object recovery living body, pro and back ion absorption claws (1a, 1b) each adsorption channels (10a, 10b) between connected to light sensor comprises one flowing path based on the driving power by efficiency in adsorption of ions a different kind and number is. Figure 11 rear end ion absorption bath (1b) before the recovery of ion the suction hole is established near the unnecessary for each operational mode a process washed on a stage is intended to explain the. Rear end ion absorption bath (1b) the suction hole is established near the recovery in order recovery ions ion object ions to connect an. that obviates the need. Rear end ion absorption bath (1b) through adsorption process of a section (120) is space is stored, rear end ion absorption bath (1b) for cleaning of the water reservoir (120) ion absorption for shearing a deionized water bath (1a) a rear end via ion absorption bath (1b). effect. The, shear ion absorption bath (1a) a sucking process rear end which power is applied the same one between the side of ion absorption bath (1b) further into the pure deionized water can be are electrically connected. Ion absorption or by bath (1a) a previous process (also reference 10) signals to the process is performed cleaned as soon as it emerges in the power is turned off is suspended so as to stop remains save costs compared is the deionized water the feed inlet ion absorption bath in the succeeding stage (1b) to enter may also be.. Rear end ion absorption bath (1b) deionized water inlet, a second inlet, and an adsorption channels (10a, 10b) for washing the, discharge solution water reservoir (120) delivers is. The, ion absorption in the succeeding stage for washing bath (1b) it become blocked of whether power is applied to the above are as. Figure 12 rear end ion absorption bath (1b) adsorbed number of times a process for recovering ion object is intended to explain the. In Figure 11 the rear end of the ion absorption bath (1b) side of a section by (120) the ion containing is saved state solution to, rear end ion absorption bath (1b) to the liquid reaction mixture is sheared for space for flowing ion absorption bath (1a) a sucking process is performed a. The, shear ion absorption bath (1a) 12 also supplied to the surface of reservoir mother liquor as shown in (110) can it will be a mother liquor stored in the, optionally quantity of water in a water reservoir (120) so as to effect shear solution stored in the ion absorption bath (1a) when sending may also be.. Adsorption process is performed a forward ion absorption bath (1a) is deionization solution supplied to a rear end ion absorption bath (1b) a fluid is supplied into the used in/recovery step of subjecting the purified. The, rear end ion absorption bath (1b) the ion for the recovery of each adsorption channel (10a, 10b) of number 2 electrode portion (30) by applying the anode (+) each adsorption channel (10a, 10b) adsorbent layer (34) the suction hole is established near the cationic object recovery recorded in the machining program (A, B) deionized water for rinsing the roof and liquid is supplied to and the cost of production. Rear end ion absorption bath (1a. 1b) each adsorption channel (10a, 10b) ions-containing object that is discharged from the each ion recovery bath (170a, 170b) delivers stored rear end by ion absorption bath (1b) is is completed, the recovery ion. A low cost does not shown specifically, shear ion absorption bath (1a) object number of times of ions adsorbed shear also/recovery step of subjecting the purified ion absorption bath (1a) by supplying deionized can be progress, the rear end ion absorption bath (1b) the whole set of deionized the liquid reaction mixture is sheared the enclosed state is maintained ion absorption bath (1a), the treatment fluid is introduced from number of times object ions containing solution to the designated ion recovery bath (170a, 170b) when sending a channel which is to function as.. Furthermore, shear ion absorption bath (1a) each adsorption channel (10a, 10b) and on the rear end a separate valve, and ion recovery bath (170a, 170b) each having, shear ion absorption bath (1a) from vented solution bath ion absorption a rear end process (1b), a section (120) and ion recovery bath (170a, 170b) selective toward the sent may also be configured to.. Just, and a central control system pro and back ion absorption bath (1a, 1b) of absorption of non-channels (10a, 10b) between 12 also flow paths at the succeeding stage as shown in ion absorption bath (1b) for the pre-liquid passing through the ion absorption bath (1a) in heterogeneous not obtainable through the adsorption channel (10) chamber interdigitated such that the disposed. Figure 13 shows a ion absorption of 3 with the reservoir also for variable kinds of ion recovery system of the present invention to explain the adsorption process ion in is coarse. Wherein, A, B, both the recovery object C which cation, the anion the city avoided. Also as shown in 13 for variable kinds of ion recovery system of the present invention the ion absorbing bath (1a, 1b, 1c) for the input one or more 3 it is possible to. Even the pro and back ion absorption claws (1a, 1b, 1c) an angle between adsorption channel (10a, 10b, 10c) by establishing an optical fiber at a rear end ion absorption bath (1b or 1c) for the pre-liquid passing through the ion absorption bath (1a or 1b) in heterogeneous not obtainable through the adsorption channel (10) to enter the composed of. For example as shown in 13 most leaflet ion absorption bath (1a) first adsorption channel (10a) whereupon monopentaerythritol of high inlet, a second inlet, and after adsorbed ion A, recovery of C and a B including cationic object among while ion absorption bath (1b) of second interleavers in the units of adsorption channel (10b) is introduced into. Among ion absorption bath (1b) of second interleavers in the units of adsorption channel (10b) the inlet solution B during adsorption and ions, C ions-containing cationic object recovery during the last bath ion absorption a lower part (1c) of third interleavers as adsorption channel (10c) to made to adsorb ion C by. By doing so shear ion absorption bath (1) either one of the adsorption channel (10) and the other, two driving cams adsorption process in ion object recovery is discharged when it rear end a solution for ion absorption bath (1) to enter adsorption process of continuously for variable kinds of recovery of ion object for adsorbing is it can. For variable kinds of examples such as recovery of said object, and cations adsorbed the process by describes only the corresponding, ion absorption claws (1) are provided to perform a program/respective flow paths and regulating the oil passage of the between a valve and power application of such as method has a watch upper surface is the decoration plate further comprises an. Figure 14 shows a also of the present invention for variable kinds of ion recovery hand over message to adsorption of ion object recovery in the adsorption channel, washing, before discharged in desorption of ions within the fix the control panel is graph indicative of the change does not occur. Wherein, adsorption channel (10) a discharge discharged from the tub 40 ml/min is, adsorption process in a potential is 1.5V, 3.5V used as a pre-potential/recovery step of subjecting the purified light with the (reversed). Adsorption and separation of specific ions on Figure 14 are consistent he is showing bar, for variable kinds of ion recovery system of the present invention through (100,200) utilizing specific recovery object through the process of ion consistently may be for efficiently recovering a.. As described above the present invention refers to single system (100,200) for variable kinds of using can be ion generating the metal particles, which is necessary under the state of/recovery step of subjecting the purified of ions (washing water) deionized water for rinsing the roof and an average specific surface area of 55.01 without re-use of of an amount sufficient to prevent environmental pollution while feeding a.. Furthermore, the recovering process consistent object ions continuously used for supplying that efficiency is maximized for managing unit is off. Or more description techniques of the present invention describes illustratively event efficacy as an anti-to a modem, the present invention is in the field of the typically encountered in having knowledge of the current source from deviating from an essential element of the present invention grow within such a range that causes no various modification, change and substituted will capable. Thus the present invention to a disclosure of the present invention are in the embodiment and appends a drawing and to limit the slimly is supported by the upper case and for described, such a and appends in the embodiment of the present invention by drawing slimly range of limited not. If of the present invention scope of protection which must be of subsequent analysis by, and equivalent that lie within the ranges included within the scope rights of all technical idea of the present invention should be interpreted to will. 1: ion absorption bath 10: adsorption channel 20: number 1 electrode portion 22:of panto graph used by 24: porous carbon electrode 26: anion exchange membranes 30: number 2 electrode portion 32:of panto graph used by 34: adsorbent layer 36: cation exchange membranes 40:50 pitcher layer : regard to such 60: housing 62 : opening available 64:70 water: power supply unit 100,200: for variable kinds of ion recovery system 110: mother liquor reservoir 120: water reservoir 130: pump 140 : inlet valve 150 :-off valve 160: discharge valve 170: ion recovery bath Relating to a system to recover multiple types of ions, the present invention provides a system to recover multiple types of ions characterized by comprising: a first electrode part which electrically adsorbs only anions; an ion adsorber wherein multiple adsorption channels having a second electrode on which is formed an adsorbent layer to adsorb target cations to be recovered out of cations which are disposed in parallel, and electricity individually applied to each of the adsorption channels; a reservoir part wherein a liquid discharged from the ion adsorber is stored; a pump which circulates a mother liquid or the liquid stored in the reservoir part; and an ion storage tank wherein a liquid containing the target cations to be recovered is stored. The present invention has an effect of high efficiency in operating the system since target ions to be recovered can be continuously recovered through an integrated process. COPYRIGHT KIPO 2016 Of adsorbing electrically only anion number 1 electrode portion and, cationic at recovery object cationic for adsorbing adsorbent layer formed on surface of exterior material number 2 electrode portion and a plurality of adsorption channel and are juxtaposed to, each said adsorption channel there is an electrically individual applied ion absorption bath; said ion absorption bath from vented liquid is stored quantity of water in a water reservoir; ion containing the mother liquor or said water reservoir containing the stored liquid to the circulation line; and said recovery via said ion absorption bath the object an ion a liquid is stored and includes recovery, plurality of said adsorption channel each arranged at said number 2 electrode supports upper and lower discs of different types in a is layer adsorbent, a bath ion absorption said said adsorption number of channels over a recovery object ion species characterized by keen, it seems or equal to the number for variable kinds of ion recovery system. Deleted Deleted According to Claim 1, said ion absorption bath direction in ion adsorption bath are interconnected with each other and is provided with a plurality, plurality of said object a recovery number of ion absorption bath can characterized by and which provides the same with ion species for variable kinds of ion recovery system. According to Claim 4, said succeeding stage ion absorption bath of a shearing a liquid through said ion absorption bath in said heterogeneous not obtainable through the adsorption channel characterized by and mix from entering the mixing chamber for variable kinds of ion recovery system. According to Claim 1, said ion absorption the condensed water which dozes electrically insulate said adsorption channel is attached to a mother; said adsorption channel and respectively individually electric imposing an electric power supply unit supplies falling ramp pulses characterized by for variable kinds of ion recovery system. According to Claim 1, said number 1 of panto graph used by which the switching element is arranged and electric is applied, are of panto graph used by said porous carbon electrode and said porous carbon electrode anion exchange layer formed with a and attached to, said number 2 of panto graph used by which the switching element is arranged and electric is applied, said layer and adsorbent are of panto graph used by said adsorbent which layer formed with a cation exchange are joined to one another to, said cationic exchange membrane said anion exchange membrane characterized by to which are disposed to be opposing for variable kinds of ion recovery system. According to Claim 7, said adsorbent layer specification cationic active powder and adsorbent for adsorbing is made of blended mixtures of carbon, a active carboxylic said said adsorbent powder and coated with a characterized by 2 layer structure for variable kinds of ion recovery system.