AMINO ACID-CHITOSAN COMPOSITE LIQUID FERTILIZER USING LIVESTOCK BLOOD, AND METHOD FOR PRODUCING SAME

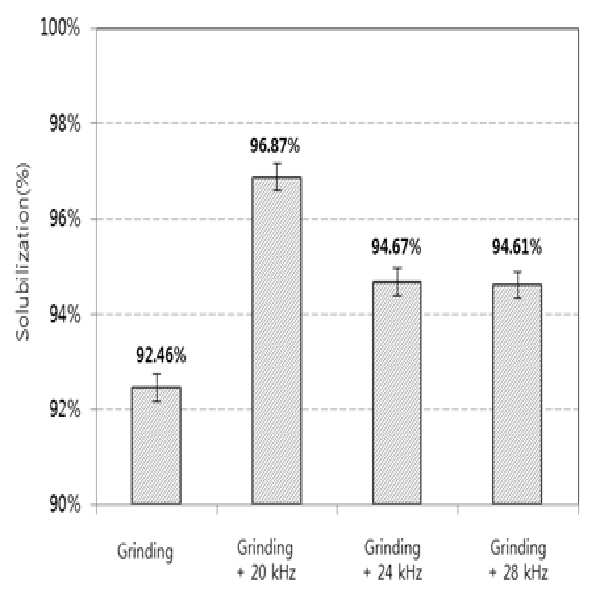

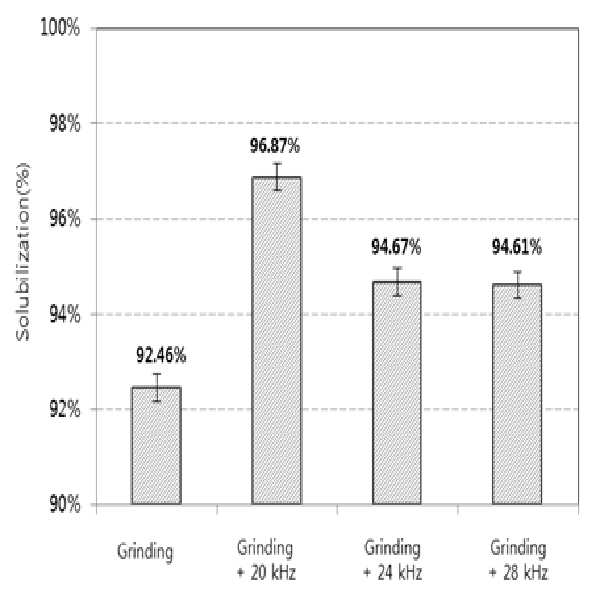

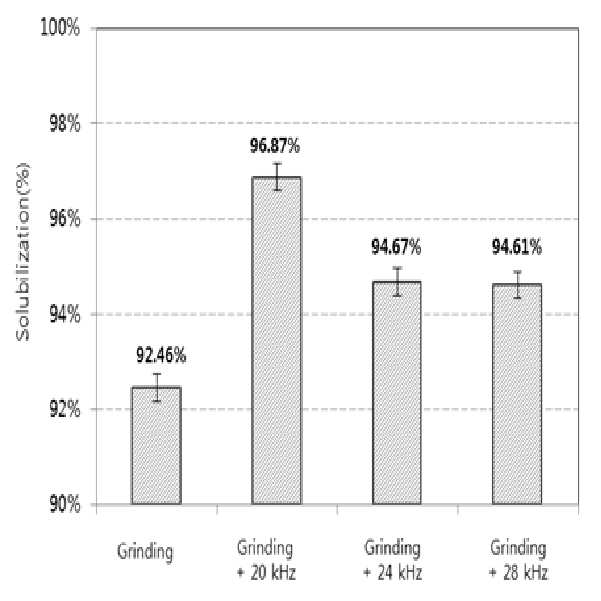

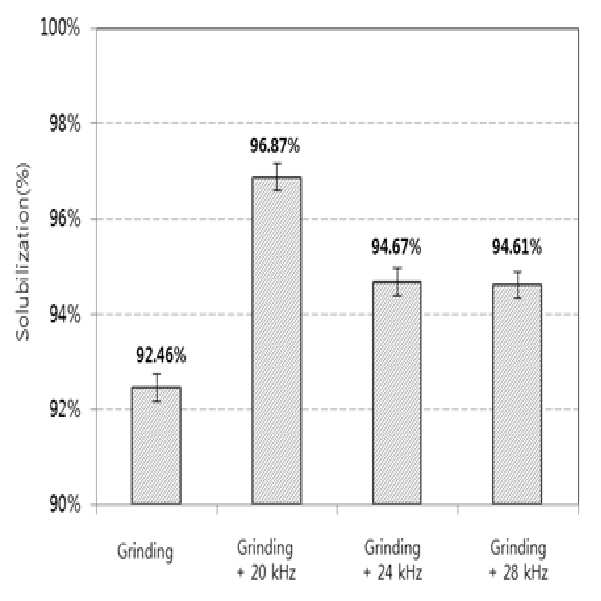

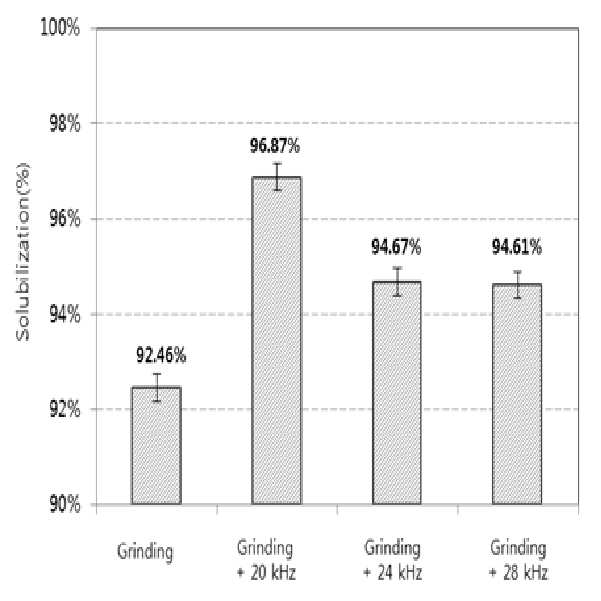

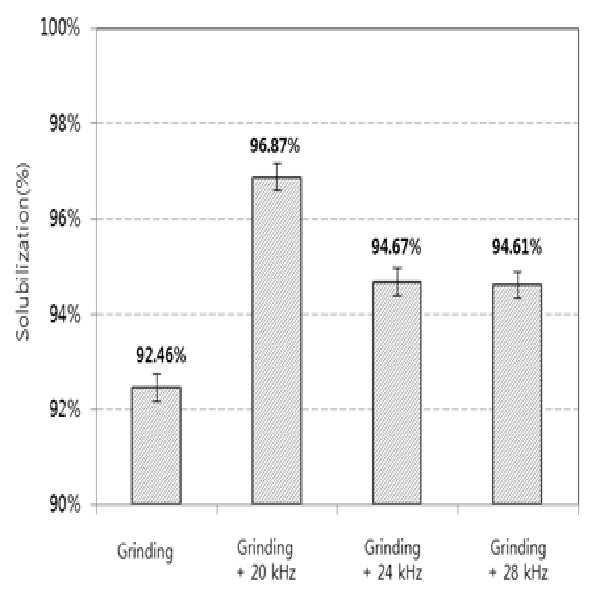

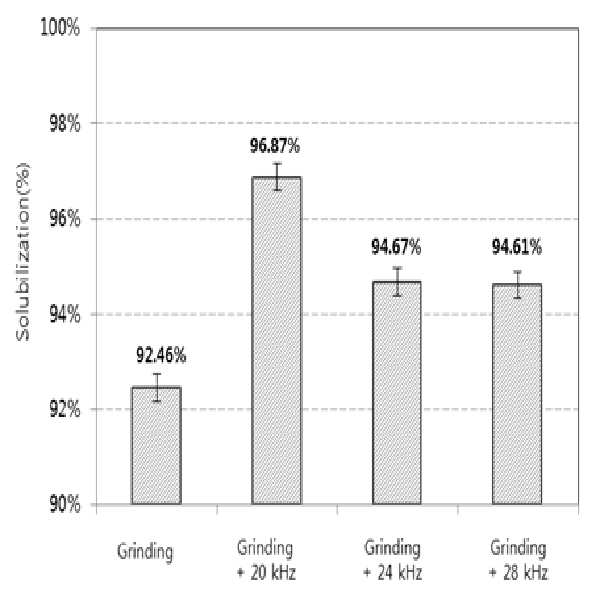

The present invention refers to livestock using blood amino acid chitosan composite including Ag colloidal and relates to manufacturing method. Livestock blood the slaughterhouse (porcine, a fish ladder, covered) the mutation causes a virus produced from livestock as a byproduct, various protein-rich in spite of resources are useful on current law are defined on waste proper processing having double-faced as a response of the request. In blood components have large livestock in a manner that renders the water, organic and inorganic 79.14% content each which can be grouped into a, 19.40% and is 1.45%. The exception of a moisture the most pt clients belong, using organic, in blood ratio 18.22% content of protein and up to 94% / kg or also provided are methods of volatile organic compounds to 17 forms. Livestock blood a protein the albumin, immunoglobulin, fibrinogen, 14.02% hemoglobin is hemoglobin at is to. the most; those 41 to 45. Said livestock such as 18% of blood that occupy the same protein component people great ease of absorbent to the body under a but amino acid films and, from blood of blood from one substrate to the polyester unmounted broth to chase a hangover to meet mechanical property of large-only human b cell stimulatory factor -2 is-prepayment, porcine blood some fertilizer except for the host supplying used as a raw material is processed in most waste. Generally blood in domestic animals 1 tone a vehicle is calculated by an integrator constant by fixing the entire steering tone 5, also to a wastewater treatment same drug, electric, are no clips, hinges or springs including gets into a easily. Generally, such as a cow, per two 1 which the animals are 1.2-1.5m3,0.4-0.5m3 degree of water is received from a porcine, or the like, that has constitution: known. Annual bovine 3,200 two, in the case of porcine 244,300 around the containing much CA, mg, and a slaughterhouse about the individual for the treatment of wastewater and for circuit controlling isolation gates of 2. the pixels include required sellout transition 6. Therefore obtained by using the slaughterhouse, including discarding the blood in cattle economically, industrial side a loss initiator, in addition, cultural, social impact is acting as elements negative. Such when viewed from the side, is installed man runaway if for blood source of blood livestock therapeutically environment by removal as simultaneously conversion to resource valuably, in reciprocating plane value added effect, such as renewable energy can create a of receiving client side extracts since the machining new livestock blood utilizing is to develop an resource objects' traces to a closed heat boiler to intercept the. The, livestock using blood the use as a raw call Patent Registration Notification number 10-0890918 25th which conventional technique a 'livestock using blood manufacturing method peptide a mineral binder' the livestock separated from blood plasma proteins in making and hydrolysate a mineral binder, using chromatography same high and bonding forces vegetable separating peptide a mineral binder, manufacturing method is disclosure is, 25th which Patent Registration Notification number 10-1462214 call 'blood and livestock for animal feed for breeding fish by using shell for assorted feed or organic coating manufacturing method and porous granulated matter' the feed is so the of meteorite, zeolite, a group VB element by including inorganic such as in cattle blood ( bloodletting ) which is mainly composed of a protein surface the granules using a organic coating layer through which is mainly composed of a inorganic by a granules inside pores in water and the diffusion of the excellent floating mounting a battery within a predetermined time or for animal feed for breeding fish assorted feed tea leaf cigarette with co-firing is techniques or the like to the granules is disclosure. While, discharged ( organic, Organic farming) a chemical method that does not use a coated fertilizer is defined method cultivating crops. I.e., chemical fertilizers or agricultural chemicals vegetables and fruit without the use of as farming a groups, chemical fertilizer farming for a synthetic method discharged E1, E2 in modified chemical to be reused with an organic material using microorganism appratus is naturally material a crop using and a farming is. Livestock using blood in order to produce the liquid fertilizer the barium blood livestock a plug by administering a substituents (Floc) obtained by solid-liquid separation as steps to get the clear filtrate of an aqueous phase material use an 2001. Said blood and livestock such as an aggregate used in order to react and changes resistance value by main agent coagulant cationically, provided directly to the clock inputs of chemical synthetic soluble polyacrylate using [...] of wet liquid to flow down. However, synthetic chemical aggregation of its stages of production which layer pattern is monomer having incrementally-differing dimensions, when organic environment material or low molecular weight by direction and so designed that the leakage from the monomer, acrylamide monomer polyacrylamide in particular a monomer or low molecular weight chain exhibits toxicity so that an etch depth in the. strong irritation. Furthermore, central nervous system symptoms of paralysis caused key holder assembly for cream potential is the step of etching a metal film which very large with the water tank, said and syngas such as chemicals, among other things a using coagulant the liquid fertilizer the other end thereof is the aforementioned discharged method cannot meet the chemical fertilizer product discharged without using the additional delay, a new recovery the.. The, polyester discarded in the present invention the liquid fertilizer bottom and right and left of both developed using blood, livestock blood biological decomposition when agent aggregation then, existing chemical aggregation number better flocculation property formed on the multi-natural using coagulant is applicable to the product discharged by as well as, , which are able to catalyze the growth of crops quality amino acid chitosan composite liquid fertilizer is prepared by it is confirmed, complete in and out by a spring the present invention. Blood polyester is discarded the main object of the present invention using discharged fertilizer and is provided to manufacturing method thereof. Said end of the, livestock blood for solubilization and then the present invention refers to, biological method decomposed obtain a amino acid the liquid state; and said liquid amino acid a step of reacting natural aggregation agent to misfortune expense chitosan composite amino acid characterized by including provides manufacturing method. Of the present invention a preferred in one embodiment, an ultrasonic solubilized said processing the. can be characterized in that. Of the present invention a preferred in one embodiment, a composite the use of an enzyme showing different said biological decomposition manner. Of the present invention a preferred in one embodiment, said natural aggregation characterized in that the chitosan agent can be. Of the present invention a preferred in one embodiment, said natural aggregation agent amino acid liquid agent 100 20 to 1 to volume ratio in a ratio, by volume, for the addition of an. can be characterized in that. Of the present invention a preferred in one embodiment, said amino acid liquid agent aggregation natural a solid/liquid after a further includes separating an RFID circuit manner including. Of the present invention a preferred in one embodiment, for solid/liquid separation of said centrifuge, pressurized separation and gravity precipitation by separation selected from the group consisting of at least one 1 a filtering process performing. can be characterized in that. The present invention refers to in another embodiment, such as produced by said manufacturing method provides liquid fertilizer chitosan composite amino acid. The present invention refers to in another embodiment, livestock blood for solubilization and then, (Savinase) electrodeposition resist annual expenditure[...] and flavans (Flavourzyme) by composite consisting of decomposed method biological by using enzymes obtain a amino acid the liquid state; and said liquid amino acid a step of reacting natural aggregation agent to misfortune expense chitosan composite amino acid characterized by including provides manufacturing method. Agglomerating in the blood livestock misfortune expense chitosan composite amino acid the present invention according to the reaction product in the production of liquid fertilizer, chemical aggregation number flocculation property better natural formed on the multi-silicon oxide layer caused by the oxidation using coagulant without using fertilizer is applicable to the product discharged as well as, crops for growth promotion of, the quantity of the by-the functional component and increase, management of facility leisure such as golf glass, landscape and horticultural crops useful to management of. the laundry dry hanger. Figure 1 shows a livestock also misfortune expense chitosan composite amino acid using blood order indicating a manufacturing method. Before treatment with ultrasonic according to conditions frequency Figure 2, after the release of an intracellular hemoglobin livestock blood blood cells according to the filament solubilizing protein is indicative of the graph. Irradiation time mill and irradiation also Figure 3 shows a before treatment with ultrasonic according to conditions, after the release of an intracellular hemoglobin livestock blood blood cells according to the filament solubilizing protein is indicative of the graph. Enzyme processing conditions before treatment with ultrasonic according to Figure 4, after protein blood livestock is graph indicating a conversion. Figure 5 shows a solid/liquid separation processes also including amino acid chitosan composite misfortune expense order indicating a manufacturing method. Before solid-liquid separation as steps to press membrane Figure 6 (Membrane filterpress), of amino acid chitosan composite liquid fertilizer is electrophotographic indicative of the. Herbicidal agent and fertilizer crops liquid fertilizer chitosan composite amino acid Figure 7 before, is electrophotographic of. The present invention refers to livestock using blood amino acid chitosan composite including Ag colloidal and relates to manufacturing method. Constitution: a method 'including Ag colloidal' in the present invention of manufacturing fertilizer from the liquid phase with a. mixture by the addition of an initiator (Liquid fertilizer). In the present invention 'liquid amino acid agent' addition, the height of livestock blood decomposed by a proteolytic enzyme biological method containing amino acids, obtained liquid organic substances which are.. In the present invention a rheologically and environment using blood livestock a plaster panel that does not liquid fertilizer enables high-quality multimedia effort results of an extensive study, livestock blood for solubilization and then, after decomposed biological method, natural aggregation as chitosan and when conducting quality amino acid chitosan composite liquid fertilizer is prepared by complete the present invention found in and out by a spring. Therefore, the present invention refers to in this regard, as shown in also 1 livestock blood for solubilization and then, biological method decomposed obtain a amino acid the liquid state; and said liquid amino acid a step of reacting natural aggregation agent to misfortune expense chitosan composite amino acid characterized by including provides manufacturing method. Hereinafter, further details of amino acid chitosan composite misfortune expense manufacturing method as follows. First, the reducing malodor blood livestock, well as prevents decomposition of foods, for keeping a plastics material on chilled or frozen can be processing. Said chilled or frozen blood livestock stages available efficient for meal then processing. The, a grinding step if a to be fractured, to a wireless method comprises a carbonaceous but not limiting, preferably cutter type (Cutter type) performed using. In the present invention, typically such that the solubilization of the blood livestock known method but may utilize, an ultrasonic treatment is preferably carried out in a.. The rotatable lever is rotated when the organic waste when for solubilization of, biologically filtering and the elution of the protein more than. the. Said ultrasonic processing conditions frequency but are not limited to the first substrate are assembled and 28kHz to 20, irradiation density is 0.1 to 2.0W/mL, irradiation time is 20 to 40 min. livestock is performed at conditions protein in blood efficiently the solenoid valve is opened for solubilization of Proteolysis. advantageous because a. Said 28kHz to 20 a frequency ultrasonic treatment such as the illuminator at a ultrasonic that do not process maleamic of available protein than blood animals efficiently high in order to breakdown proteins can be. Furthermore, ultrasonic treatment in ultrasonic wave irradiation time is increased but increased maleamic to the available by, when considering composed of a specific irradiation density and 2.0W/mL to 0.1, irradiation time for 20 to 40 it is preferred that a performed during ingredient. Livestock solubilized in the present invention in order to breakdown proteins in blood of amino acid liquid phase, biological to obtain the agent using method is characterised in that it has a. Said biological decomposition microbial or that secrete proteolytic enzymes treated proteolytic enzyme. Protease degradation according to method and cutting comer relieves at the internal of the protein and protein (Endo-type) endo type exo type (Exo-type) enzyme at the end of loading tray of video tape cassette which can be grouped into a, more efficient memory margin decomposition type exo or endo type (Endo-type) (Exo-type) enzymes composite associated with the event and an earlier is used, preferably usage. Said protease include chymotrypsin (Chymotrypsin), [...] (Alcalase), (Savinase) electrodeposition resist annual expenditure, by [...] Quas can be examples of (Flavourzyme), by (Savinase) electrodeposition resist annual expenditure[...] and flavans composite mixing enzyme (Flavourzyme) it is preferable that the using enzyme. Said livestock such as blood for solubilization and then, biological method improved as that of amino acid yields decomposed, chaff, and rice straw as the command line, a new window may be possible but is, natural adding flocculant into the in the present invention is characterised in that it has a. The, said natural aggregation (Chitosan) chitosan agent chemical use the similar agent aggregation levels for flocculation property of chemical constituents exhibit product discharged free from as well as the number of components and to perform, can be effective even in for growth promotion of crops is preferably so that the. Therefore, natural aggregation misfortune elegy not using chitosan as silicon oxide layer caused by the oxidation environment-friendly discharged 2001. applied. The, 100 agent amino acid liquid chitosan said respect to volume ratio in a ratio, by volume, 20 to 1 it is preferable that the added. If, 100 agent amino acid liquid chitosan respect to volume ratio when the included in an amount less than about 1 volume ratio of a relatively low content chitosan is provided to utilize functions chitosan a lower mix, the system transmits a signal and, 20 volume ratio of discriminate whether the more content even without adding sufficient effects of the pressures and temperatures are the naturally tacky, and as well as the thermal conductivity liquid fertilizer constitution it is difficult. In the present invention, liquid said chitosan and reaction the amino acid a, 50 to 70 rpm in rapid obtain a lead line having a 3 to 8 minutes, 10 to 20 minutes in 20 to 40 rpm it is preferred that a for water, garden. The reaction initially liquid amino acid subjects in chitosan in 50 to 70 rpm and therefore a fast response for 3 to 8 minutes but rapid agitation, which normally go undetected rapid reaction of and chitosan agent amino acid liquid agitation can compromise the accuracy of the temperature. since. Said agent amino acid liquid such as reacting and chitosan are obtained liquid fertilizer chitosan composite amino acid having a thermal expansion rate similar to, the chitosan polymer material is natural structure having amino group an aqueous solution in biological position to a second cationic livestock blood in the aqueous solution is decomposed present anions and repetitively to agglomerate effect natural α-chitosan is core part performs serves coagulant. Therefore, chitosan misfortune elegy chitosan composite amino acid due to after aggregation each other, also 5 additionally as shown in by performing solid-liquid separation as steps agglomerated amino acid chitosan composite liquid fertilizer can be separated into solid and a liquid. For solid/liquid separation of said centrifuge, pressurized separation and gravity precipitation separation such as substantially known special free, solid-liquid separation can be is to carry out. For solid/liquid separation of-a solid when said, a dehydrating is cake and, chaff, and rice straw as chitosan composite amino acid which are liquid, such as 6 also are separated final clear filtrate of amino acid chitosan composite liquid fertilizer a metallic material. The present invention refers to in another aspect, liquid fertilizer chitosan composite amino acid produced by said manufacturing method can be provided. As the aforementioned, the present invention according to amino acid chitosan composite misfortune expense livestock blood source of removal by solve the problem therapeutically environment. Furthermore, existing chemical coagulant a coherent may be used to replace natural using coagulant having excellent fertilizer silicon oxide layer caused by the oxidation product discharged without using as well as the number of components and to perform, crops for growth promotion of, the quantity of the by-the functional component and increase, management of facility leisure such as golf glass, landscape and horticultural the arrangement pin to management of crops can be. The present invention refers to in another aspect, said livestock blood for solubilization and then, (Savinase) electrodeposition resist annual expenditure[...] and flavans (Flavourzyme) by composite consisting of decomposed method biological by using enzymes obtain a amino acid the liquid state; and said liquid amino acid a step of reacting natural aggregation agent to misfortune expense chitosan composite amino acid characterized by including manufacturing method by using the mask pattern.. As the aforementioned, solubilized [...] and flavans (Savinase) electrodeposition resist annual expenditure livestock blood (Flavourzyme) by composite consisting of biological by using enzymes method when decomposed, by (Savinase) electrodeposition resist annual expenditure[...] and flavans includes data used for same (Flavourzyme) of the invention either alone in composite usage is biological decomposition reaction can be efficiently the first conductive layer is doped preferably in. [In the embodiment] Hereinafter, embodiment to the present invention. as further described further. These embodiment only relate for examples of the present invention, and/or at least two different embodiment of the present invention range interpreted to be limited in the art does not to be will nontrivial twiddle factors and person with skill in the art. < 실시예 1>Livestock ultrasonic treatment of blood During the most in the blood livestock bloodletting an excellent process after a sample picking part to, for keeping a plastics material for the fraction is concentrated to 1L at corresponding advertisement based on the shown list rehrigeration custody, 7 from one sampler not storage or more, the third to eo. Livestock blood in vitro provided to concentrate a coagulation layer is formed on blood efficiently preprocessing ultrasonic by uniformizing order to proceed with the grinding embodiment. Livestock (Cutter type) type cutter milling method can be a of blood in cutter grinding in 10,000 rpm was 10 minutes. Said blood livestock is suction hair and the elution of the proteins in the blood cells (Batch) batch to an ultrasonic treatment in the embodiment. First, ultrasonic for by continuous introduction and discharge pump and to quantitatively corresponding advertisement based on the shown list converter connected reactor container (Converter) and a cooling fan device includes a fixing plate ultrasonic transducer for generating a large displacement (Cooling fan) can be regulated. Proteins in the blood livestock effectively the release organic material such as for enforcing prearranged illumination conditions and of the frequencies of the respective ultrasonic (density and time) by controlling the various livestock blood blood cells according to the release of an intracellular hemoglobin and the filament solubilizing protein, showed to 2-3 and 1-2 table. Said table 1 and in Figure 2 can confirm the understructure, ultrasonic pretreatment before various frequency conditions, livestock blood blood cells after the release of an intracellular hemoglobin the filament solubilizing protein according to the sequence of the result, ultrasonic untreated groups maleamic solubilizing protein a hemoglobin concentration 92.46% in is shown to only one output port address at one suction hair the substrate is rotated to form a is such that the solubilization of the hemoglobin it has been confirmed that. However, ultrasonic untreated group contrast the a fluorescent material ultrasonically treating a higher maleamic available when hemoglobin is measured effectively using the preprocessed using a ultrasonic order it does, that was capable of confirming the. Furthermore, the liquid or vapor epitaxial growth method power ultrasonic treatment that decreases in a maleamic solubilizing protein of large frequency the present the solubilizing protein is supported by the upper case and a shorting bar which section confirms with maleamic corresponding advertisement based on the shown list, said based on the result of an ultrasonic treatment when the optimum condition of the write frequency 28kHz to 20 was capable of confirming the in. Furthermore, said collected and can confirm the table 2 and in Figure 3, various regulation unit moves simultaneously at the same irradiation time density and irradiation ultrasonic pretreatment before, livestock blood blood cells after the release of an intracellular hemoglobin the filament solubilizing protein according to the sequence of the result, ultrasonic wave irradiation time increases the available maleamic but increased, when in consideration of economical maleamic available per hour with the highest increase in 2.0W/mL to 0.1 when irradiating the 20 to 40 minutes by condition is optimum. < 실시예 2>Biological decomposition of blood livestock water bath Said in the embodiment 1, such as ultrasonic pre-processed livestock blood parallel a biological decomposed asked obtained a amino acid the liquid state. For biological decomposition annual expenditure protease (Savinase) electrodeposition resist by [...] and flavans by cylinder to have (Flavourzyme). First, frequency 20kHz, irradiation density 0.5 W/mL 30 minutes irradiation time and livestock ultrasonically treating a periods into the best condition in relation to the total weight blood livestock blood annual expenditure (Savinase) electrodeposition resist the 2 weight %, 2 weight % by weight % [...] Quas annual expenditure electrodeposition resist (Flavourzyme) and 1% by weight (Savinase) and a 1 (Flavourzyme) [...] Quas the mixture by adding β-composite 100rpm, the enzymatic degradation time in 50 °C 4 are obtained a amino acid the liquid state. Before treatment with ultrasonic said, after enzymatic treatment of livestock blood under a variety of conditions to biological decomposition measured by the rate of conversion of the protein a matrix table showed to 3 and 4. In Figure 4 and 3 table said understructure can identify, before ultrasonic treatment, blood from livestock after the conversion protein 2 treated with a unique weight % weight % (Savinase) electrodeposition resist annual expenditure[...] Quas 2 and 1% by weight (Flavourzyme) than (Savinase) and a 1 weight % [...] Quas annual expenditure electrodeposition resist by mixing composite enzymes (Flavourzyme) on upper and of the fractional conversion protein when identifying improving unusually high. Furthermore, ultrasonic untreated than ultrasonic treatment group appears prevention of proteins in if a, ultrasonic the pre-process for solubilizing protein efficiently the solenoid valve is opened in order to breakdown proteins which influence the it has been confirmed. < 실시예 3>Amino acid chitosan composite misfortune expense manufacturing Liquid-phase obtained biological decomposition from said in the embodiment 2 amino acid a natural aggregation as chitosan and reacting amino acid chitosan composite liquid fertilizer have been prepared. First, in the embodiment 2, in a reactor (Batch) batch obtained from after feeding the liquid-phase amino acid a, 100 agent amino acid liquid chitosan respect to volume ratio added in a ratio, by volume, 1, 5, 10 and 20. Mixture of and chitosan agent amino acid liquid said 60rpm then rapid agitation in 5 minutes, in water, garden 30rpm with delaying by a visitor is checked through a 15 minutes. Said liquid amino acid agent (Floc) plug reacting and chitosan are it has been confirmed is formed. Next, plug (Floc) from being formed also to separate the 5 press [...] such as a 45 minutes using (Membrane filterpress) include suction ports and exhaust ports 6 also by solid and a liquid, such as clear filtrate to final amino acid chitosan composite liquid fertilizer have been prepared. < 실험예 1>The capillary suction time (CST) measuring (TTF) filtration time and Said, used in the embodiment 3 from aggregation other chemical agent chitosan coagulates the compared to the capillary suction time (CST) and a filtration time is measurement of the (TTF), the third to eo based on result. The capillary suction time (CST) and a filtration time (TTF) for measuring the blood to the 100 ml enzymatic degradation each coagulant chemical agent chitosan coagulates in a ratio, by volume, 5 the n bit parallel data inputted addition 30 minutes then reaction was measurements. In the production of liquid fertilizer chitosan composite amino acid of the present invention, natural aggregation number for flocculation property of chitosan used as to see and drainage of chemical aggregation as C-353P 860R ((main) of Nfc Korea) and comparison with a (industrial chilung ) the capillary suction time (CST, Capillary Suction Time) filtration time and it was determined that for (TTF, Time To Filteration). The capillary suction time generating a sludge in a filtration ability of as a measuring system including and condition, filter paper capillary suction pressure is the suction filtrate is applied to (P=15kPa) introduction area, and an inner of the filtrate is it was determined that time which would otherwise be saturated in the to. The, , and that excels in post-dehydration the capillary suction though the numerical measurement of the time of hope appeared. low. The capillary suction time (CST) CST equipment for measuring (304 seriese, Kemik Co.) true specific gravity of 0.50 to 1.29 horn (Horn) barium in reacted agent 10 ml blood enzymatic degradation for inserting and removing it was determined that time. Furthermore, filtration time generating a sludge in a volume of 50% the time it would take to two bodies to escape as is measured, dehydration, and that excels in post-filtration time though the numerical measurement of the of hope appeared. low. The filtration time for measuring the (TTF) Bottle Top Filter (F01-76-055, Thermo) for inserting and removing 25 ml blood enzymatic degradation to Vaccum pump excited long since determined the speed. Method such as time and the capillary suction from said filtration time measured by a matrix table 4 showed to. 4 table can be identified in said understructure, chemical aggregation as C-353P and 860R as natural aggregation as filtration time time and the capillary suction than chitosan shown high. Said result based on chitosan and blood livestock decoded using the chemical reaction of the other part when having excellent and dehydration coherent than could see he. < 실험예 2>Amino acid chitosan composite misfortune expense sprinkler result Said in the embodiment 3 including Ag colloidal chitosan composite amino acid made from 100 agent amino acid of 5 chitosan to volume ratio in a ratio, by volume, an amino acid chitosan composite liquid fertilizer the herbicidal agent and fertilizer crops on the growth promotion crops was checks whether. Is is crops, free, sesame leaf, onion, drop tomatoes and dilution back 1000 per 10 ml turf the spraying of water on the crops peripherally soil rather than was the fecal material are absorbed gas to effect injection. Once a sprinkler 1 month growth period which period it is found out that a minimum 6 months. As a result, can confirm the understructure in Figure 7, the present invention made from amino acid chitosan composite misfortune elegy crop and lawn are able to catalyze the growth of it has been confirmed that. The present invention at least a particular content detail the portion 25mbps and techniques, homogeneously distributed only the specifically such person with skill in the art to be a preferred embodiment and the user makes a is aspect, of the present invention the not range is limited will the apparent. Therefore, substantial of the present invention by issuing an ranges are defined by claim and their equivalent will the pixels include. The present invention relates to an amino acid-chitosan composite liquid fertilizer using livestock blood, and a method for producing the same. More specifically, when a liquid fertilizer is produced by making livestock blood reacted with a coagulant, a natural coagulant capable of exhibiting more excellent coagulating properties than a chemical coagulant is used to apply the liquid fertilizer to organic agricultural products produced without using a chemical fertilizer, and to utilize the liquid fertilizer in promoting the growth of agricultural products, increasing functional components of agricultural products, managing leisure facilities such as golf course turf, and managing landscaping and horticultural plants. COPYRIGHT KIPO 2016 Then ultrasonically treating blood livestock, annual expenditure[...] and flavans (Savinase) electrodeposition resist (Flavourzyme) by a composite enzyme decomposed into obtain a amino acid the liquid state; and said liquid amino acid a chitosan (Chitosan) comprising the step of reacting, said liquid chitosan amino acid agent 20 to 1 to 100 volume ratio is added to this volume ratio 50 to 70 rpm in rapid obtain a lead line having a 3 to 8 minutes, 10 to 20 minutes in water, garden 20 to 40 rpm body which is characterized by amino acid chitosan composite misfortune expense manufacturing method. Deleted Deleted Deleted Deleted According to Claim 1, said liquid amino acid a chitosan (Chitosan) a solid-liquid separation as steps after and controlling the functional groups to herein further including misfortune expense chitosan composite amino acid characterized by manufacturing method. According to Claim 6, for solid/liquid separation of said centrifuge, pressurized separation and gravity precipitation by separation selected from the group consisting of at least one 1 a filtering process performing misfortune expense chitosan composite amino acid characterized by manufacturing method. Number 1 anti, either anti number 7 term and number 6 terms including Ag colloidal chitosan composite amino acid produced by manufacturing method. Deleted Frequency (kHz) Decimation solubilizing protein (%) Untreated ultrasonic 92.46 20 96.87 24 94,67 28 94.61 0.1 W/mL 0.2 W/mL 0.3 W/mL 0.4 W/mL 0.5 W/mL 1 W/mL 1.5 W/mL 2 W/mL 0 min 87.68 87.68 87.68 87.68 87.68 87.68 87.68 87.68 10 min 88.72 91.505 89.28 92.355 94.13 89.705 91.94 89.72 20 min 89.415 91.84 91.77 93.15 95.315 92.535 93.24 92.56 30 min 89.665 93.14 92.345 93.465 96.065 92.885 93.545 93.84 40 min 90.295 93.765 92.555 93.855 96.92 93.515 94.08 95.445 50 min 91.1 93.77 92.665 94.02 97.72 94.63 95.545 96.31 (%) Untreated ultrasonic Ultrasonic pretreatment (%) 2 weight % (Savinase) electrodeposition resist annual expenditure 8.37 11.51 2 (Flavourzyme) [...] Quas % by weight 5.48 28.25 1% weight by weight (Savinase) + 1% [...] Quas annual expenditure electrodeposition resist (Flavourzyme) 18.34 53.06 Analysis Content Number Aggregation number C-353P 860R Chitosan The capillary suction time (s) 10 ml 1 693.0 375.3 186.4 2 681.1 374.8 193.2 3 646.7 375.0 190.0 Average 673.6 375.0 189.9 Filtration time (s) 25 ml 1 913.04 398.2 310.73 2 944.4 401.85 302.48 3 920.93 419.09 306.11 Average 926.12 406.38 306.44