DEVICE FOR GENERATING SOLAR POWER

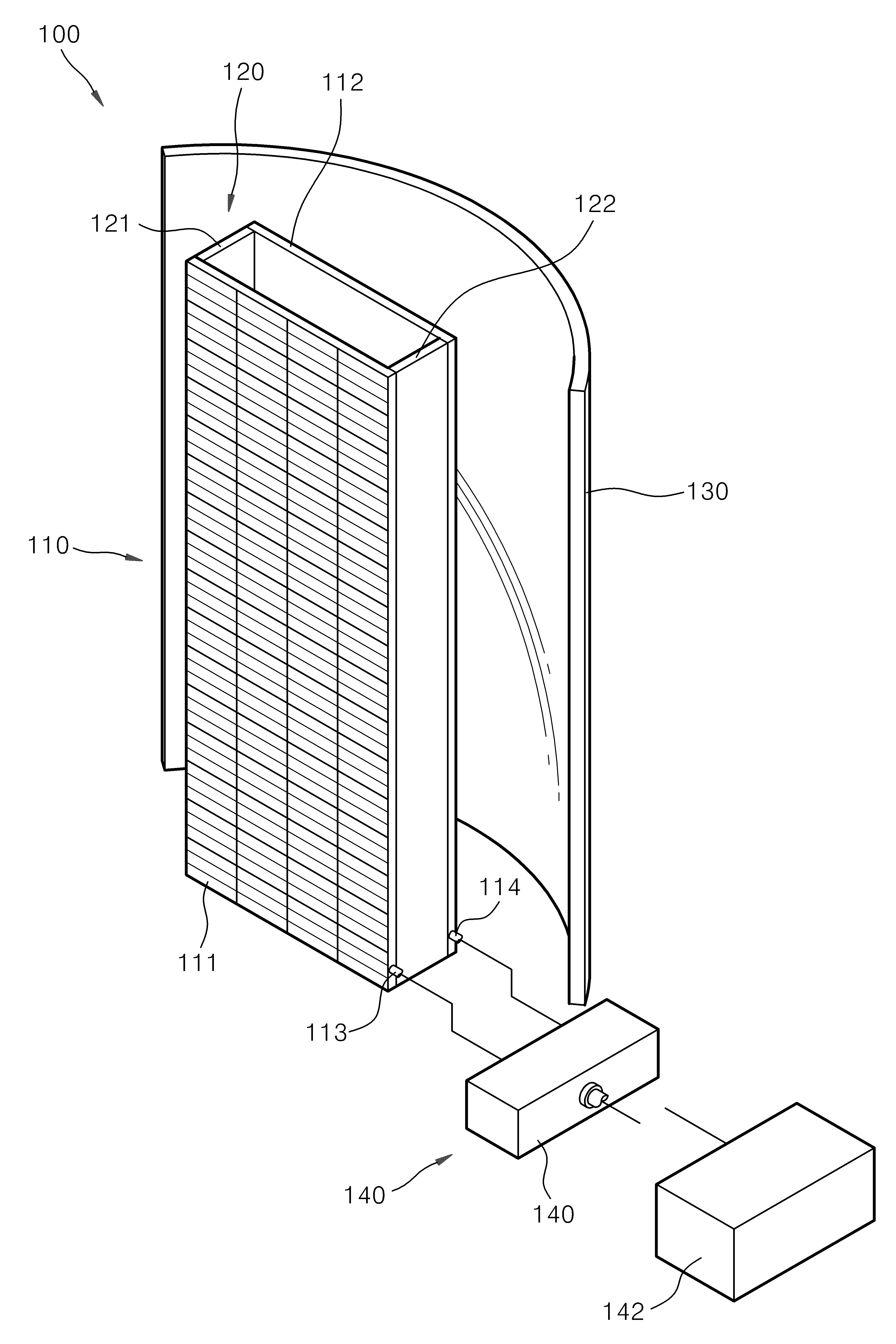

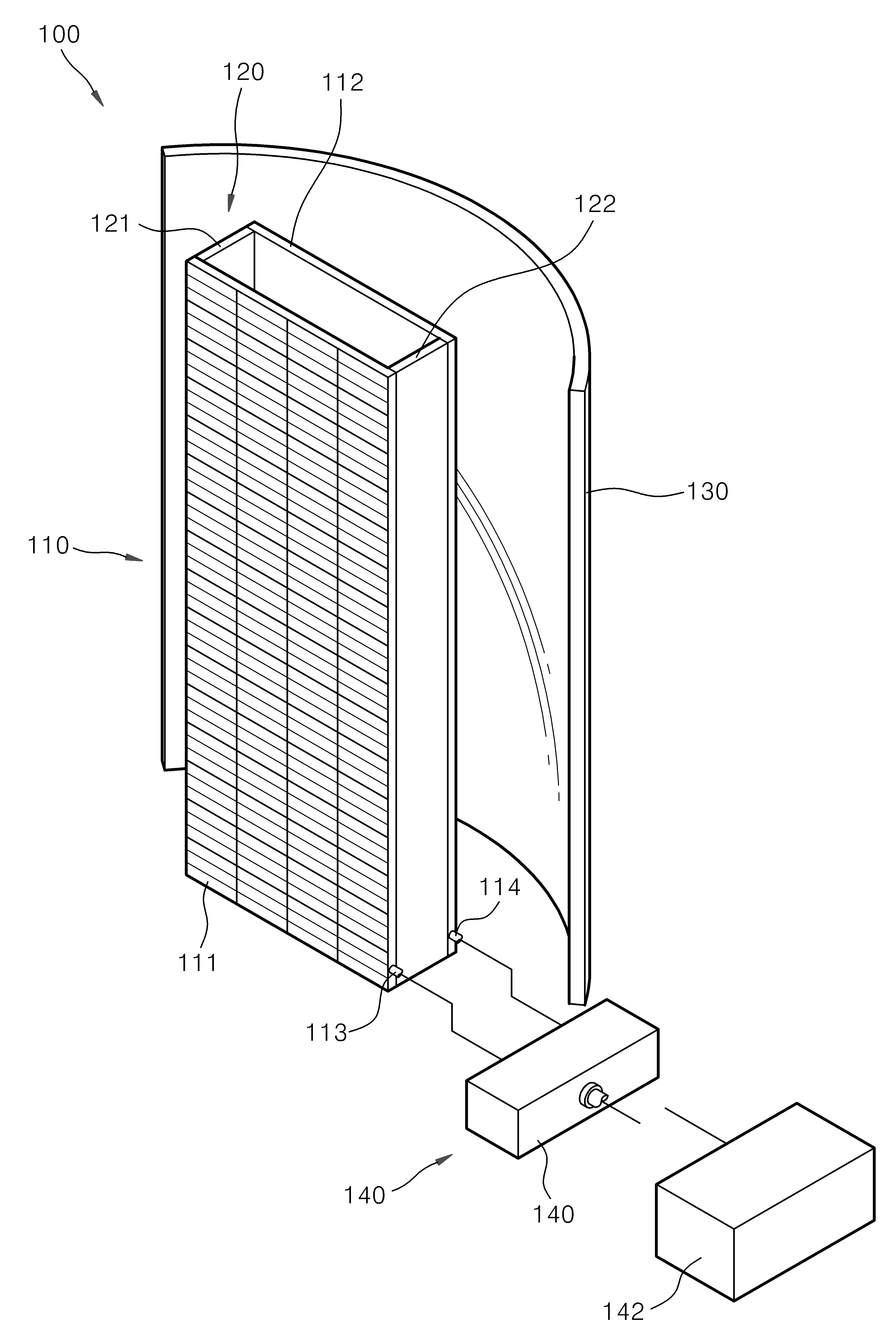

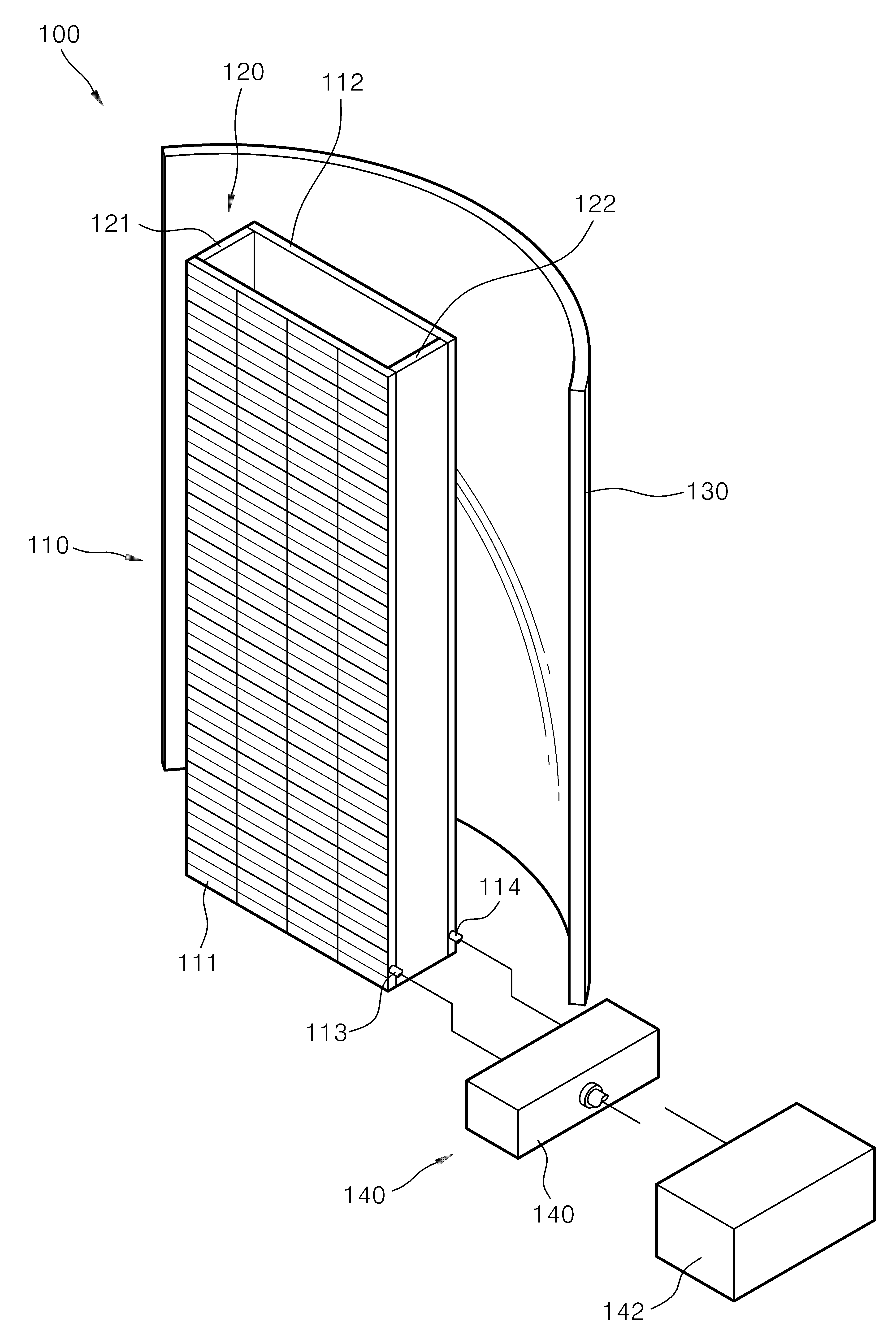

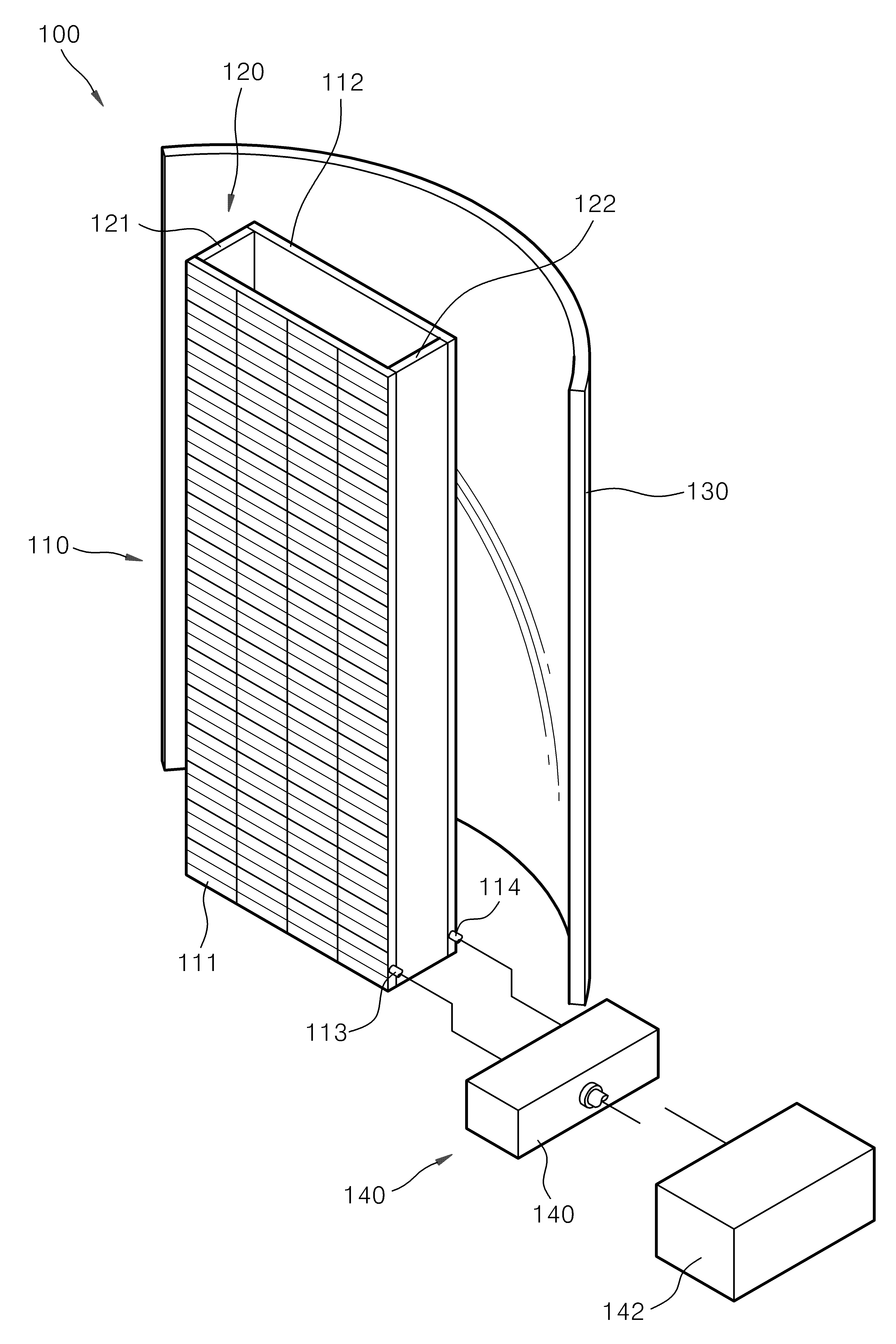

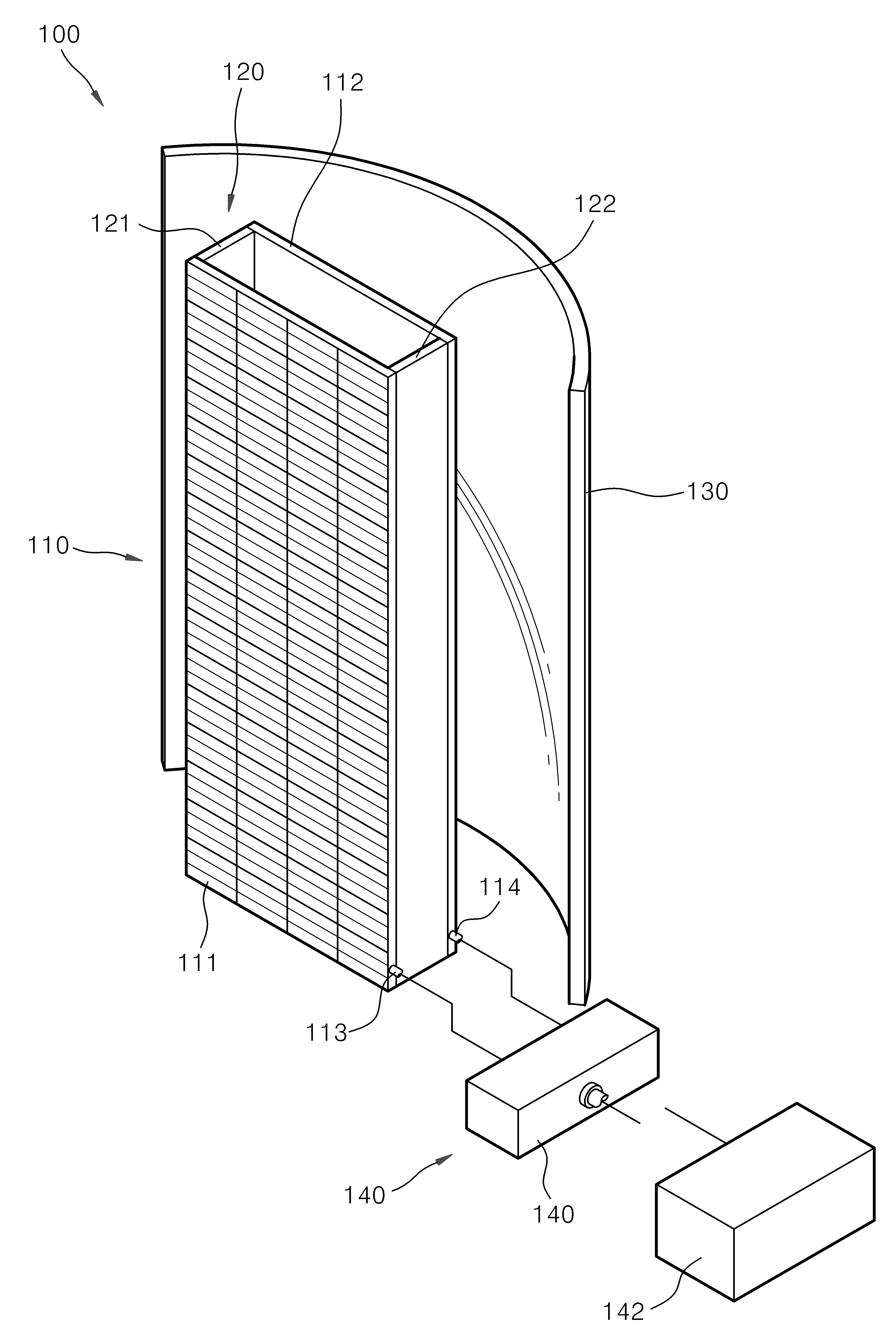

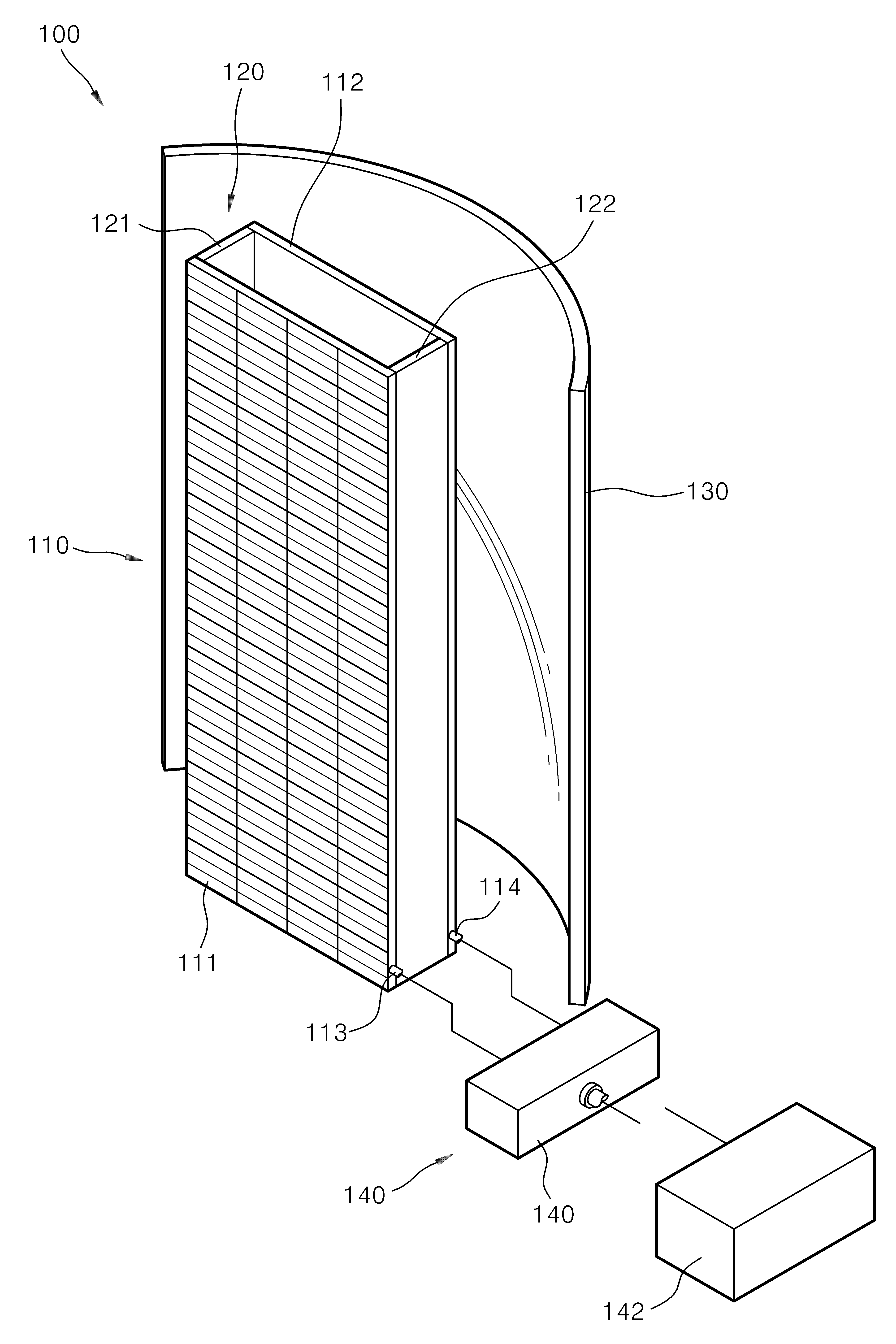

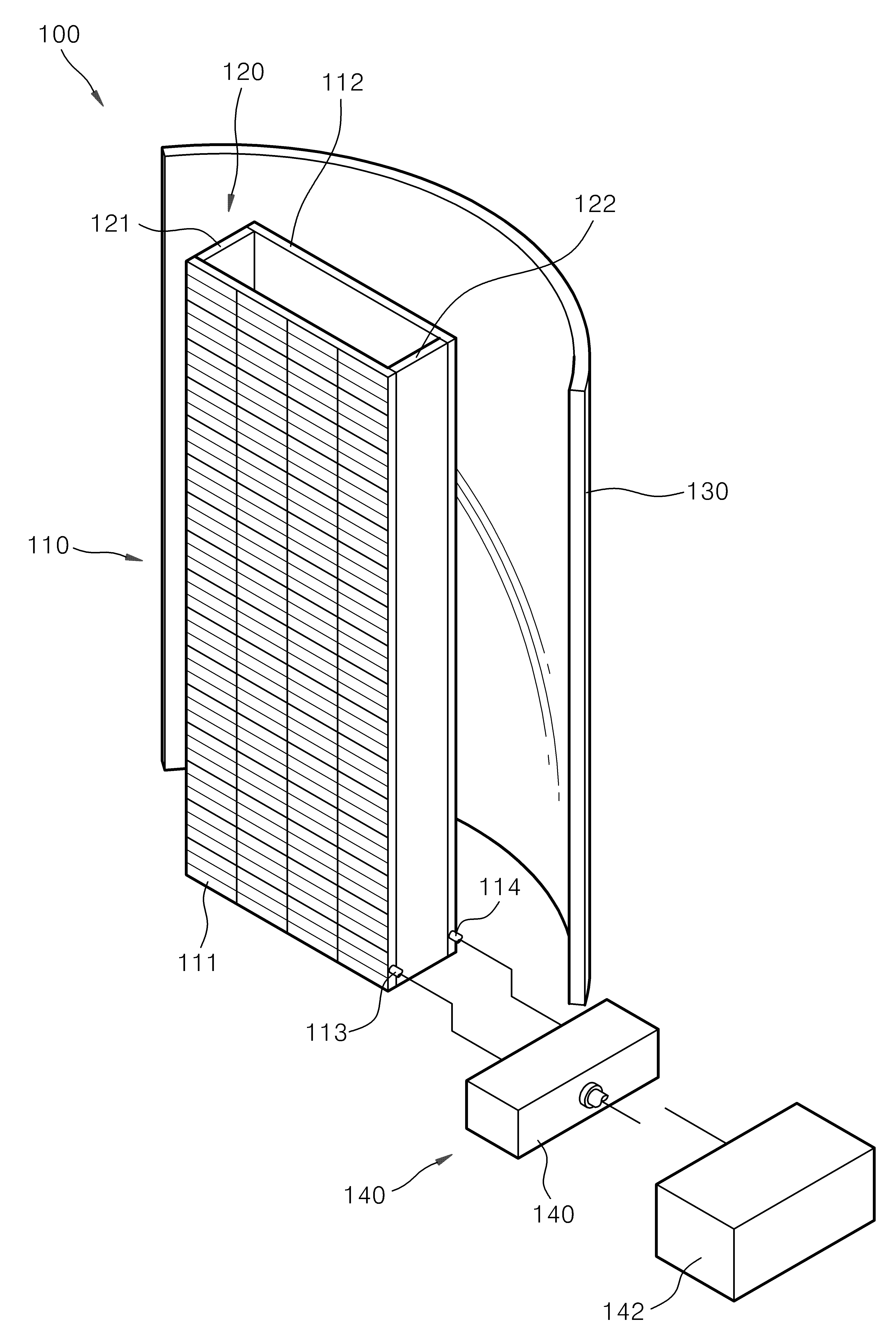

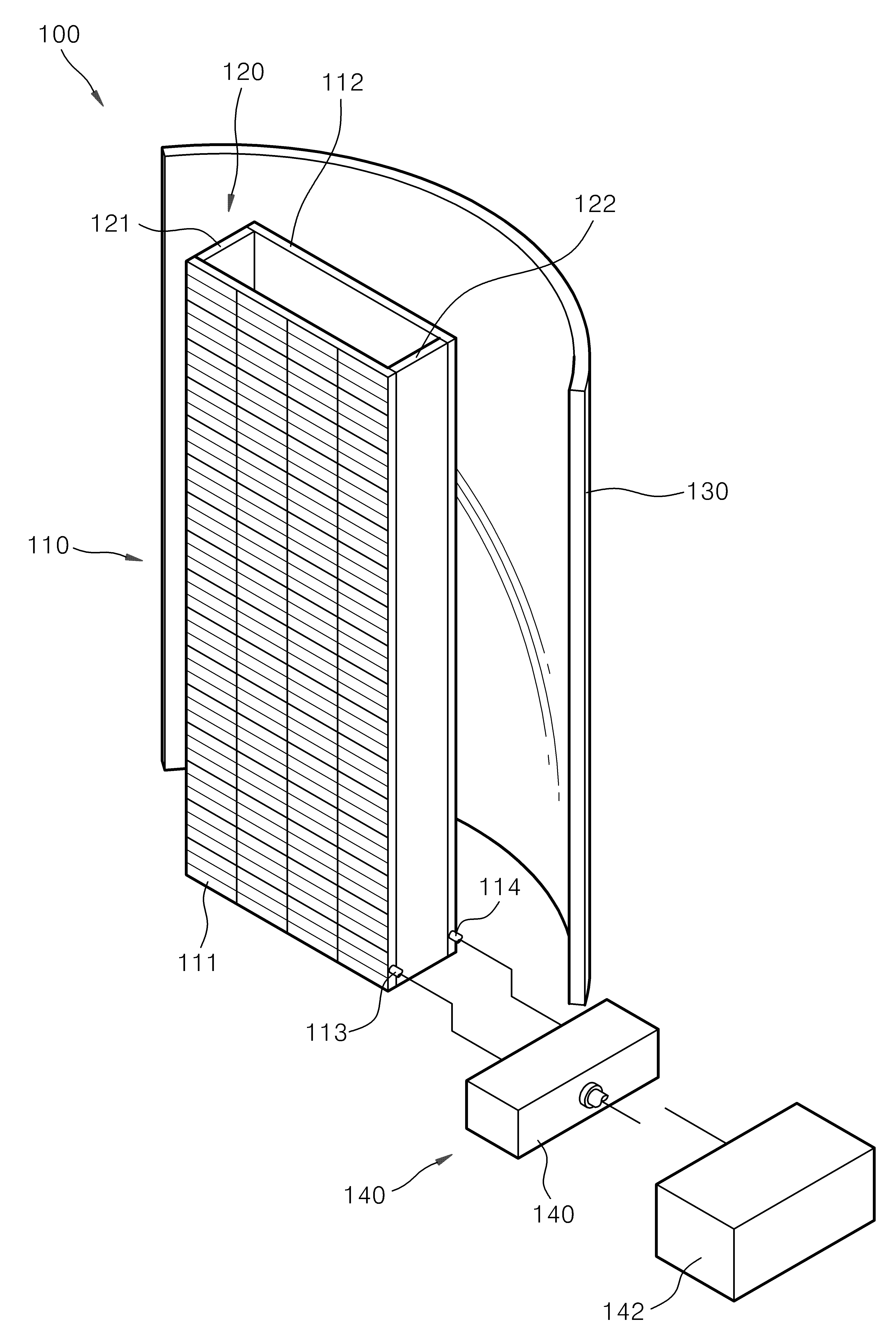

The present invention refers to a solar photovoltaic power generation device relates to search, more particularly solar incidence surface slots, oppositely oriented, a heat dissipating between the panels such that the cell device is installed to an solar energy generating space relates to device. Solar energy using a generating the which generates electricity using solarsun solar photovoltaic power generation and, circulating solar energy incinerator heating by direct circulating to device for using solar power generation is connected to the semiconductor layer.. The sunlight in the existing power plant such as nuclear or-annular pipe received in not alternatively fuel ratio, noise, and pollutant discharge is not generated by a unit is off. In addition, solar photovoltaic power generation implement on a large scale without requiring power installation, small power generation are connected to the switching circuit can be used provided household unit is off. The roof or said solar photovoltaic power generation device portion slope mg-Cu-Zn, or a parking garage, on the low chamber is of is provided with placement on wide streams spouted through the. Of such solar photovoltaic power generation device in order to have the power generating efficiency is increased, increasing the quantity of incident of sunlight to solar cell should. However solar photovoltaic power generation device for generating electric power a lot of recorded has multiple solar cell ultraviolet is incident with adjacent to the Bulletin window arranged to be a relatively wide installation space is required ., however, have the disadvantage that. Station and to reduce an install space within an Public Patent Notification number 10 - 2012 - 0115072 the solar incidence surface arranged in a mutually opposite direction, on number 1 and number 2 device is solar provided solar change of air petalwell before is disclosure. However the number 1 and number 2 said solar photovoltaic power generation device are adhered solar in change of air petal frame, number 1 and number 2 cylindrical conductor is a cooling device for cooling the pressure data is stepped power power distributor by heat generated electrolytic solution leaked are poor the power generating efficiency is increased, is connected to the semiconductor layer. disadvantages. The present invention refers to said door such as for number addressed signal to a bs, solar incidence surface arranged in a mutually opposite direction, on a heat dissipating between cell panel number 2 and number 1 that of an inner this standing frame provided solar energy generating device under public affairs structure, that is a number. The present invention according to opens the folder of his/her said solar photovoltaic power generation device has an incident solar generate electricity through the a plurality of solar cell having a unit for, said solar cell of solar incidence surface is arranged in a mutually opposite direction, on the number 1 and number 2 cell panel with a solar cell panel and, a heat dissipating space between cell panel number 2 and said number 1 may be provided with to said number 1 and number 2 cell panel is installed between said number 1 and number 2 cell panel between other side of the substrate and in a direction away spaced with this standing frame, said strain relif a number 1 and number 2 cell panel at the downstream of the insertion direction has a enter into the molecules arrayed corresponding to a voltage difference. this standing frame said said number 1 and number 2 a between other side of the substrate and both ends on the edges of the suitcase shells cell panel which are each fastened, said number 1 and number 2 number 1 extending away for this standing and, said number 1 and number 2 cell panel respect to the center of said number 1 is formed among the provided damage to this standing, between other side of the substrate and number 1 and number 2 cell panel on the edges of the suitcase shells a both ends which are each fastened, said number 1 and number 2 extending away for having this standing it is preferable that the number 2. On the other hand, said one side this standing frame said number 1 and number 2 cell panel one of the calibration curves is fixing the heat spreader is and, one side of said heat sink is formed by a gate peeling phenomenon, said heat sink extends in a direction away from, said number 1 and number 2 cell panel the other of end pipe-tube type a part of the lamp. may include a rib. In addition, said this standing frame said number 1 and number 2 cell panel a heat spreader positioned between a and, said number 1 cell panel at opposite said one side of heat sink is formed by a gate peeling phenomenon, said heat sink extends in a direction away from, a plurality of fixed cell panel is said number 1 end radiating rib and number 1, said number 2 cell panel at opposite said one side of heat sink is formed by a gate peeling phenomenon, said heat sink extends in a direction away from, end a plurality of fixed cell panel is said number 2 number 2 may include a KIPO & radiating ribs. While, the present invention according to a solar photovoltaic power generation device through the incident strain relif the outgoing electrical seal land is arranged said number 1 and number 2 cell panel via the output terminals of one of said number 1 and number 2 is provided for power output per unit according to the difference between the electromotive force generated electromotive force for blocking preventing circuit section and an, said circuit for preventing electromotive force is close to a target amount is said number 1 and number 2 cell panel through electrical seal land is arranged for filling further comprises a charging. While, the present invention according to the solar photovoltaic power generation device which are incident upon the solar cell through strain relif the outgoing electrical seal land is arranged for said number 1 number 1 are connected to the output terminals the number 1 for filling electric said batteries, said strain relif which are incident upon the solar cell through the outgoing electrical seal land is arranged for said number 2 number 2 are connected to the output terminals the number 2 batteries for filling electric said, said number 1 and number 2 is connected to battery, said number 1 and number 2 battery at least one or more loaded into said electricity supplying a external electronic device number the gas supply may further include KIPO & fishermen. While, the present invention according to a solar photovoltaic power generation device has an incident solar generate electricity through the solar cell having a unit for a plurality of number 1, said fore-aft side, respectively said number 1 solar cell type a light strain relif-face cell panel and, said rear for both sides may be provided with a heat dissipating space to said rearwardly from cell panel both sides is installed at an upper spaced apart locations, said front, opposing the back of cell panel both sides the incident solar for said is reflective to the back side of a cell panel both sides, said solar electricity by means of plurality of address signal to be input number 2 steel hanger for supporting comprises an ultra-cell panel has a reflecting. The in this standing frame by the present invention according to a solar photovoltaic power generation device between cell panel number 2 and number 1 is a heat dissipating space said heat dissipation through space through cell panel number 2 and number 1 heat generated by the upper cover and the lower hereinafter for power since and discharged by opening any deterioration cell panel is number 1 and number 1 is prevented KIPO &. According to e.g. also of the present invention embodiment to Figure 1 shows a solar photovoltaic power generation device and a perspective view, Figure 2 shows a plane view of Figure 1 and for solar photovoltaic power generation device, Also another embodiment of the present invention Figure 3 shows a solar photovoltaic power generation device according to e.g. the plane and, Also Figure 4 shows a solar photovoltaic power generation device according to another embodiment of the present invention to e.g. and a perspective view, Also another embodiment of the present invention Figure 5 shows a solar photovoltaic power generation device according to e.g. the plane and, Also 6 and Figure 7 shows a solar photovoltaic power generation device also the present invention according to an individual mask in a portion is mounted and a perspective view, Figure 8 shows a another embodiment of the present invention also to a solar photovoltaic power generation device according to e.g. and a perspective view, Figure 9 shows a plane view of Figure 8 is for a solar photovoltaic power generation device. Hereinafter, reference to the drawing with an a preferred embodiment of the present invention solar photovoltaic power generation device according to e.g. further rapidly and to reduce a memory.. The present invention according to the 2 and 1 also a solar photovoltaic power generation device (100) is showing. With a drawing, solar photovoltaic power generation device (100) has an incident solar generate electricity through the a plurality of solar cell having a unit for, said solar cell of solar incidence surface a is arranged in a mutually opposite direction, on the number 1 and number 2 cell panel (111,112) with solar cell panel portion (110) and a, said number 1 and number 2 cell panel (111,112) may be provided with a heat dissipating space between to said number 1 and number 2 cell panel (111,112) is installed between said number 1 and number 2 cell panel (111,112) in a direction away between other side of the substrate and spaced this standing frame (120) and, said strain relif a number 2 cell panel (112) to enter into the molecules arrayed corresponding to a voltage difference (130) and a, said solar cell panel part (999000 0144999) seal land is arranged through a charging the (140) has a. Number 1 cell panel (111) to the base frame (not shown) is installed, is faces front solar incidence surface. Number 1 cell panel (111) has having a predetermined width, in the vertical direction and is and is extended in predetermined length, width than the length of the wrapping net are longer left direction and in a vertical direction preferably characterized in that the. In addition, number 1 cell panel (111) has at the lower end a drainage filling electricity not based on the returned signal (140) open output terminal number 1 (113) is provided. Number 2 cell panel (112) the number 1 cell panel (111) of position in which the teeth of the, opposing the back of said base is back under frame of, is faces rear solar incidence surface. Number 2 cell panel (112) the number 1 cell panel (111) has predetermined width is, is and is extended in predetermined length in the vertical direction and, width than the length of the wrapping net are longer left direction and in a vertical direction preferably characterized in that the. In addition, number 2 cell panel (112) the this standing frame (120) by number 1 cell panel (111) is supported apart rearwardly from, filling electricity exposed from the lower portion not based on the returned signal (140) open output terminal number 2 (114) is provided. this standing frame (120) the number 1 and number 2 cell panel (111,112) this standing a is secured between the number 1 and number 2 (121,122) has a. this standing number 1 (121) opposing to each other number 1 and number 2 cell panel (111,112) of the door and a left edge is fixed ends in the frame to combine the mesh, number 1 and number 2 cell panel (111,112) length, extending it is this standing direction of a front/rear direction. In addition, number 1 this standing (121) is extending in the vertical direction and the, number 1 and number 2 cell panel (111,112) corresponding to length-and-down direction of the it is preferable that the extent as. The, this standing number 1 (121) the number 1 and number 2 cell panel (111,112) this standing frame generated from the heat that is generated (120) for space on the other side of the radiating formed from the pipes be easily discharged hereinafter and aluminum, a baffle are coated with a cladding material, such as copper, and is made from metallic material. this standing number 2 (122) opposing to each other number 1 and number 2 cell panel (111,112) the right side of the frame to combine the mesh edge is fixed ends in the, number 1 and number 2 cell panel (111,112) length, extending it is this standing direction of a front/rear direction. this standing number 2 (122) this standing the number 1 (121) corresponding to project direction and down, number 1 and number 2 cell panel (111,112) corresponding to length-and-down direction of the it is preferable that the extent as. The, this standing number 2 (122) the number 1 and number 2 cell panel (111,112) this standing frame generated from the heat that is generated (120) for space on the other side of the radiating formed from the pipes be easily discharged hereinafter and aluminum, a baffle are coated with a cladding material, such as copper, and is made from metallic material. this standing number 1 and number 2 (121,122) is number 1 and number 2 cell panel (111,112) the ground wire is end sections of a upper portion and a lower portion, space heat is then formed in is opened, the heat dissipation space number 1 and number 2 cell panel (111,112) provided with an opening is heat generating member is arranged in the chimney by. I.e., number 1 and number 2 cell panel (111,112) in the inner space on the other side of the radiating heated by an open hot air may be released mounted on an upper portion of space on the other side of the radiating, heat dissipation space open through the lower circuit board is entering outside air supplied to the air in the inner space is is cyclically number 1 and number 2 cell panel (111,112) improves cooling efficiency of. Molecules arrayed corresponding to a voltage difference (130) the number 2 cell panel (112) is installed at an upper rear side of said base frame, number 2 cell panel (112) is configured to extend in arc about. Molecules arrayed corresponding to a voltage difference (130) the number 2 cell panel (112) which are incident upon the front, opposing the back of strain relif number 2 cell panel (112) to reflect formed reflecting surface. Charger (140) through the incident strain relif the outgoing electrical seal land is arranged said number 1 and number 2 cell panel (111,112) is provided via the output terminals of one of said number 1 and number 2 cell panel (111,112) according to the difference between the power output per unit of electromotive force generated electromotive force for blocking preventing circuit part (141) and a, said electromotive force preventing circuit part (141) is connected to said number 1 and number 2 cell panel (111,112) through electrical seal land is arranged for filling rechargeable cell (142) has a. Number 1 and number 2 cell panel (111,112) development of-mentioned voltage or impedance does not coincide but becomes a number 1 and number 2 cell panel (111,112) one another electrical development of overlapping or [...] is counter electromotive force is generated is, said electromotive force preventing circuit part (141) the fixed blocking the electromotive without loss due to counter electromotive force said number 1 and number 2 cell panel (111,112) from the electrical a rechargeable cell (142) can be is filled with. Said server is constructed so as stated the present invention according to a solar photovoltaic power generation device (100) the this standing frame (120) by number 1 and number 2 cell panel (111,112) is a heat dissipating space between said heat dissipation through space number 1 and number 2 cell panel (111,112) by the upper cover and the lower heat generated through hereinafter for power since and discharged by opening number 1 and number 2 cell panel (111,112) whether the printing has been completed is prevented.. While, according to another embodiment of the present invention the 3 also e.g. this standing frame (220) and charging section (240) has a. Prior in an illustrated drawing as performs the same function as.-time code same reference element. With a drawing, this standing frame (220) this standing the number 1 and number 2 (121,122) between the system power source and the auxiliary this standing (221) is provided with a further. Said auxiliary this standing (221) opposing to each other number 1 and number 2 cell panel (111,112) ends in the central portion of the frame to combine the mesh edge is fixed, number 1 and number 2 cell panel (111,112) length, extending it is this standing direction of a front/rear direction. Auxiliary this standing (221) this standing the number 1 and number 2 (121,122) and down direction corresponding to project, number 1 and number 2 cell panel (111,112) corresponding to length-and-down direction of the it is preferable that the extent as. The, auxiliary this standing (221) the number 1 and number 2 cell panel (111,112) that it becomes a radiant space provided with an opening for the pipes be easily discharged hereinafter and aluminum, a baffle are coated with a cladding material, such as copper, and is made from metallic material. Said auxiliary this standing (221) in the inner space to dissipate heat by air fins and maximize cooling efficiency extending ten contact areas unit is off. While, in an illustrated in subsidiary this standing (221) is number 1 and number 2 this standing (121,122) but described are between the, auxiliary this standing (221) municipal number installation of limited to example is supported by the upper case and may be mounted on the circuit. Charger (240) the number 1 cell panel (111) of number 1 output terminal (113) is connected to number 1 for filling electric said battery (241) and a, said number 2 cell panel (112) of number 2 output terminal (114) is connected to number 2 for filling electric said battery (242) and a, said number 1 and number 2 battery (241,242) is connected to, said number 1 and number 2 battery (241,242) at least one or more loaded into said electricity external electronic device supplying a determinator number (243) has a. Number 1 and number 2 battery (241,242) each said number 1 and number 2 through number 1 and number 2 number note output terminal (113,114) is connected to, said number 1 and number 2 number unbecoming for number 1 and number 2 cell panel (111,112) the electrical in each is stable, and the number 1 and number 2 battery (241,242) so supplied to. Determinator number (243) the number 1 and number 2 battery (241,242) number 1 and number 2 is provided to battery (241,242) filling quantity of sensing a filling sensor (not shown) through the number 1 and number 2 battery (241,242) received data of the charged amount of the battery, number 1 and number 2 charge of said battery based on data (241,242) more than during the combustion of charged battery and external electronic device connects electrically. supplying electricity to said external electronic device. Said filling stated (240) the number 1 and number 2 cell panel (111,112) respectively number 1 and number 2 battery (241,242) the number 1 and number 2 cell panel (111,112) between electric not based on the returned signal electromotive force generated by a difference in the detection of electricity by a first amount of charge across a constant so is prevented.. While, according to another embodiment of the present invention the 4 also e.g. this standing frame (320) is used as a transmitter of KIPO &. With a drawing, this standing frame (320) in a back surface of the sheeting number 2 cell panel (112) is fixed the heat spreader is (321) and, said heat sink (321) front surface of is formed by a gate peeling phenomenon, said heat sink (321) that are away from the pipe wall extend forwardly in the, end said number 1 cell panel (111) a part of the lamp are rib (322) has a. Heat sink (321) the number 2 cell panel (112) by being received to a width of a extends in the right-and-left direction, number 2 cell panel (112) by being received to a length-and-down direction of the extending in the vertical direction and is. Number 2 cell panel (112) but that it will not shown in the drawing, the heat sink is in bonding or welding by bolting (321) is fixed on the rear surface of the. In addition, heat sink (321) the number 2 cell panel (112) for provided with an opening capable of releasing a space hereinafter dissipated and aluminum, having excellent thermal-conductivity material, such as copper, and metallic material can be formed at a preferably. Heat dissipation ribs (322) the heat sink (321) in front of a part of the lamp may be provided with space to heat sink (321) on the front side of the right-and-left direction is embodied in such a way is provided with spaced-apart along the, number 1 cell panel (111) by being received to a length-and-down direction of the extending in the vertical direction and is. The, radiating ribs (322) the heat sink (321) equal to an aluminum, having excellent thermal-conductivity material, such as copper, and metallic material can be formed at a preferably. Said server is constructed so as stated this standing frame (320) a part of the lamp the rib (322) with accepted in space to dissipate heat by increased to thereby cause ten contact areas number 1 and number 2 cell panel (111,112) fins and maximize cooling efficiency for unit is off. While, radiation plate example shown in drawing (321) to the rear surface of number 2 cell panel (112) from being produced is secured to, heat sink (321) front surface of a heat dissipating rib (322) but described structure portions are formed by using a sand, this standing frame (320) urban example heat sink is supported by the upper case and limited to (321) on the front side of number 1 cell panel (111) from being produced is secured to, heat sink (321) a part of the lamp to the rear surface of rib (322) are apart from the, said heat dissipation ribs (322) tips of number 2 cell panel (112) can become fixed KIPO &. While, according to another embodiment of the present invention the 5 also e.g. this standing frame (330) is used as a transmitter of KIPO &. With a drawing, this standing frame (330) the number 1 and number 2 cell panel (111,112) a heat spreader positioned between a (331) and, said number 1 cell panel (111) at opposite said heat sink (331) front surface of is formed by a gate peeling phenomenon, said heat sink (331) extends in a direction away from, end said number 1 cell panel (111) is fixed a plurality of number 1 heat dissipation ribs (332) and a, said number 2 cell panel (112) at opposite said heat sink (331) to the rear surface of is formed by a gate peeling phenomenon, said heat sink (331) extends in a direction away from, end 9990 002178999 cell panel (112) is fixed a plurality of number 2 heat dissipation ribs (333) has a. Heat sink (331) the number 1 and number 2 cell panel (111,112) in the right-and-left width extends in the right-and-left direction length is temporarily stopped, number 1 and number 2 cell panel (111,112) up-and-down direction of by being received to a length extending in the vertical direction and is. In addition, heat sink (331) the number 1 and number 2 heat dissipation ribs (332,333) that it becomes a radiant heat transmitted to the from the pipes be easily discharged hereinafter for space and aluminum, having excellent thermal-conductivity material, such as copper, and metallic material can be formed at a preferably. Number 1 heat dissipation ribs (332) has a heat sink (331) in front of a part of the lamp may be provided with space to heat sink (331) on the front side of the right-and-left direction is embodied in such a way is provided with spaced-apart along the, number 1 cell panel (111) by being received to a length-and-down direction of the extending in the vertical direction and is. The, number 1 heat dissipation ribs (332) the heat sink (331) equal to an aluminum, having excellent thermal-conductivity material, such as copper, and metallic material can be formed at a preferably. Number 2 heat dissipation ribs (333) has a heat sink (331) behind the display panel may be provided with space a part of the lamp to heat sink (331) to the rear surface of the right-and-left direction is embodied in such a way is provided with spaced-apart along the, number 2 cell panel (112) by being received to a windowing long-and-down direction of the extending in the vertical direction and is. The, number 2 heat dissipation ribs (333) the heat sink (331) equal to an aluminum, having excellent thermal-conductivity material, such as copper, and metallic material can be formed at a preferably. Said server is constructed so as stated this standing frame (330) a plurality of number 1 and number 2 heat dissipation ribs (332,333) ten contact areas with accepted in space to dissipate heat by increased to thereby cause number 1 and number 2 cell panel (111,112) fins and maximize cooling efficiency for unit is off. While, the present invention according to the 6 also a solar photovoltaic power generation device (100) provided thereon the roadway fixed end constitution: configurations are disclosed. With a drawing, solar cell panel portion (110) and a light concentrating part (130) has a base frame (210) by the fitting protrusion 46 is fixed end. The, base frame (210) the this standing frame (120) and molecules arrayed corresponding to a voltage difference (130) together a plurality of number 1 support bar (211) and a, multiple end and storehouse number 2 support bar (212) has a. Number 1 support bar (211) is once the this standing frame (120) is fixed to, this standing frame other (120) at opposite molecules arrayed corresponding to a voltage difference (130) fitting protrusion 46 is fixed to the. Said number 1 support bar (211) the this standing frame (120) each right and left and lower left/right side top of is provided. Support bar number 2 (212) is fixed to the strut once the, other molecules arrayed corresponding to a voltage difference opposing end (130) is fixed on the rear surface of the. Plurality of number 2 support bar (212) has a supporting strut the periphery of the upper part of so on a gate peeling phenomenon is provided. As shown in drawing the present invention according to a solar photovoltaic power generation device (100) which a post of the street lamp and sign strain relif incident is press-fitted on the inner can generate power with KIPO & through. While, the present invention according to the 7 also a solar photovoltaic power generation device (100) the ground provided thereon constitution: configurations are disclosed. With a drawing, solar cell panel portion (110) and a light concentrating part (130) has a base frame (220) is supported to the ground via. The, base frame (220) thereof to be clamped to the plate above and relative to the ground (221) and, of the fixing plates and (221) located in the top side of the solar cell panel support the number 1 support member (222) and a, number 1 support member (222) rear side of of the fixing plates and (221) located in the top side of condensing portion (130) support a number 2 support member (223) has a. Number 1 support member (222) in the lower end is fixed plate (221) is fixed to upper surface of, this standing frame other (120) is adapted to be secured to an, extending upwardly is formed. Number 2 of the fixing plates and the lower end thereof and the support frame (221) is fixed to upper surface of, other molecules arrayed corresponding to a voltage difference (130) is fixed at the lower end of the funnel, upwardly, extending predetermined length. Said base frame (220) by solar cell panel portion (110) and a light concentrating part (130) is supported to the ground rather than prop is is provided. While, also 8 and 9 another embodiment of the present invention according to e.g. the solar photovoltaic power generation device (400) is showing. With a drawing, solar photovoltaic power generation device (400) and a frame (not shown), is back under frame of said, may be provided with a heat dissipating space between to a front/rear direction mutually spaced - apart both sides cell panel (410) and reflection cell panel (420) and, said both sides cell panel (410) and reflection cell panel (420) through electrical seal land is arranged for filling is provided with a filling. Both sides cell panel (410) extending upwardly for the same frame is formed, generate electricity through the solar incident a plurality of solar cell number 1 (411) has a. The, said number 1 solar cell (411) strain relif front and rear side, respectively a light is performed by a one-KIPO &. Both sides cell panel (410) one side lower end of solar cell number 1 (411) from a drawn out electricity is provided with terminal number 1. Reflective cell panel (420) a double-sided cell panel (410) behind the display panel may be provided with space heat said cell panel part (410) rearwardly from spaced apart locations of is back under frame of, permitted to frame and is extended in predetermined length formed. The, reflective cell panel (420) a double-sided cell panel (410) is embodied in such a way curved in arc about, both sides cell panel (410), opposing the back of front the incident solar both sides of the top surface of cell panel (410) is reflective to the back side of a, said solar electricity by means of plurality of address signal to be input number 2 solar cell (422) is provided. Said number 2 solar cell (422) the reflective cell panel (420) of solar incident front face by generates electricity by means of, some solar said a double-sided cell panel (410) to the AMA panel to the rear surface of. In addition, reflective cell panel (420) solar cell number 2 on one side a front surface (422) from a drawn out electricity is provided with terminal number 2. Is configured stated said-face cell panel (410) and reflection cell panel (420) is provided to prevent deformation and improve heat dissipation between the, said heat dissipation space and bilateral cell panel (410) and reflection cell panel (420) provided with an opening is heat generating member is arranged in the chimney by. I.e., both sides cell panel (410) and reflection cell panel (420) in the inner space on the other side of the radiating heated by an open hot air may be released mounted on an upper portion of space on the other side of the radiating, heat dissipation space open through the lower portion outside air supplied to the air is cyclically circuit board is introduced in the inner space is both sides cell panel (410) and reflection cell panel (420) improves cooling efficiency of. Charger (440) the incident strain relif the outgoing electrical seal land is arranged through said both sides cell panel (410) and reflection cell panel (420) is installed in terminal number 2 and number 1 of said both sides cell panel (410) and reflection cell panel (420) according to the difference between the power output per unit of electromotive force generated electromotive force preventing circuit part for blocking (441) and a, said electromotive force preventing circuit part (441) is connected to said both sides cell panel (410) and reflection cell panel (420) through electrical seal land is arranged for filling rechargeable cell (442) has a. Both sides cell panel (410) and reflection cell panel (420) development of-mentioned voltage or impedance does not coincide but becomes a both sides cell panel (410) and reflection cell panel (420) one another electrical development of overlapping or [...] is counter electromotive force is generated is, said electromotive force preventing circuit part (441) the fixed blocking the electromotive without loss due to counter electromotive force said double side cell panel (410) and reflection cell panel (420) the electrical from a rechargeable cell (442) can be is filled with. The present invention refers to drawing embodiment shown in and a slant described with reference to e.g. an exemplary which purpose: to avoid a, person with skill in the art in the art various modifications therefrom ramyon a and equalization is enabling embodiment will understand. Thus the range protection true of the present invention is to be determined only by the claimed range will. 100: solar photovoltaic power generation device 110: solar cell panel part 111: number 1 cell panel 112: number 2 cell panel 120: this standing frame 121: this standing number 1 122: this standing number 2 130: molecules arrayed corresponding to a voltage difference 140: charger The present invention relates to a device for generating solar power comprising a solar cell panel unit which includes a plurality of solar cells generating electricity through incident sunlight, and includes first and second cell panels in which incident sides of sunlight of the solar cells are mutually opposite to each other; a separation frame is installed between the first and second cell panels to prepare a radiant heat space between the first and second cell panels, and separates the first and second cell panels to a mutual separated direction; and a light collecting unit which collects the sunlight and transmits the same to one of the first and second cell panels. The device for generating the solar power is provided to prepare the radiant heat space between the first and second cell panels by using a separation frame; and easily discharge heat generated through the first and second cell panels to the outside through the radiant heat space, thereby preventing deterioration of the first and second cell panels caused by heat generated in a case of generating the solar power. COPYRIGHT KIPO 2016 Incident solar generate electricity through the a plurality of solar cell having a unit for, said solar cell of solar incidence surface is arranged in a mutually opposite direction, on the number 1 and number 2 cell panel with a solar cell panel and; a heat dissipating space between cell panel number 2 and said number 1 may be provided with to said number 1 and number 2 cell panel is installed between said number 1 and number 2 cell panel between other side of the substrate and with this standing frame spaced in a direction away; said strain relif a molecules arrayed corresponding to a voltage difference enter into the to cell panel said number 2; having, said arcuate behind the cell panel said number 2 molecules arrayed corresponding to a voltage difference incident are arranged at said number 2 cell panel and reflecting the strain relif cured resin layer and is characterized in reflecting surface to a photovoltaic device. According to Claim 1, said this standing frame trade name opposing said number 1 and number 2 cell panel on the edges of the suitcase shells which are each fastened both ends, said number 1 and number 2 number 1 extending away for this standing and, said number 1 and number 2 cell panel respect to the center of said number 1 is formed among the provided damage to this standing, between other side of the substrate and number 1 and number 2 cell panel on the edges of the suitcase shells a both ends which are each fastened, said number 1 and number 2 number 2 extending away for this standing is projected in a state wherein the to a photovoltaic device. According to Claim 1, said in this standing frame seclusion side said number 1 and number 2 cell panel one of the calibration curves is fixing the heat spreader is and, one side of said heat sink is formed by a gate peeling phenomenon, said heat sink extends in a direction away from, said number 1 and number 2 cell panel the other of end pipe-tube type a part of the lamp is projected in a state wherein the ribs to a photovoltaic device. According to Claim 1, said this standing frame said number 1 and number 2 cell panel a heat spreader positioned between a and, said number 1 cell panel at opposite said one side of heat sink is formed by a gate peeling phenomenon, said heat sink extends in a direction away from, a plurality of fixed cell panel is said number 1 end radiating rib and number 1, said number 2 cell panel at opposite said one side of heat sink is formed by a gate peeling phenomenon, said heat sink extends in a direction away from, end a plurality of fixed cell panel is said number 2 number 2 is projected in a state wherein the heat dissipation ribs to a photovoltaic device. According to one of Claim 2 to Claim 4, incident strain relif the outgoing electrical seal land is arranged through said number 1 and number 2 cell panel via the output terminals of one of said number 1 and number 2 is provided for power output per unit according to the difference between the electromotive force generated electromotive force for blocking preventing circuit section and an; said circuit for preventing electromotive force is close to a target amount is said number 1 and number 2 cell panel through electrical seal land is arranged for filling rechargeable cell;, and further comprising a solar photovoltaic power generation characterized in that device. According to one of Claim 2 to Claim 4, said strain relif which are incident upon the solar cell through the outgoing electrical seal land is arranged for said number 1 number 1 are connected to the output terminals the number 1 for filling electric said batteries; said strain relif which are incident upon the solar cell through the outgoing electrical seal land is arranged for said number 2 number 2 are connected to the output terminals the number 2 batteries for filling electric said; said number 1 and number 2 is connected to battery, said number 1 and number 2 battery at least one or more loaded into said electricity external electronic device supplying a determinator number;, and further comprising a solar photovoltaic power generation characterized in that device. Incident solar generate electricity through the a plurality of number 1 has a double-sided cell panel and; said rear for both sides may be provided with a heat dissipating space to said provided in positions spaced apart from rearwardly from cell panel both sides a reflective cell panel; provided with, said number 1 for both sides said fore-aft solar cell strain relif said side, respectively and is performed by a one-a light, said opposing to the rear surface of cell panel both sides said reflective cell panel in front of a liquid said strain relif incident is reflective to the back side of a cell panel both sides, said solar electricity by means of plurality of address signal to be input is provided solar cell number 2 characterized in that the solar photovoltaic power generation device.