APPARATUS AND METHOD FOR MANUFACTURING REFINED SALT

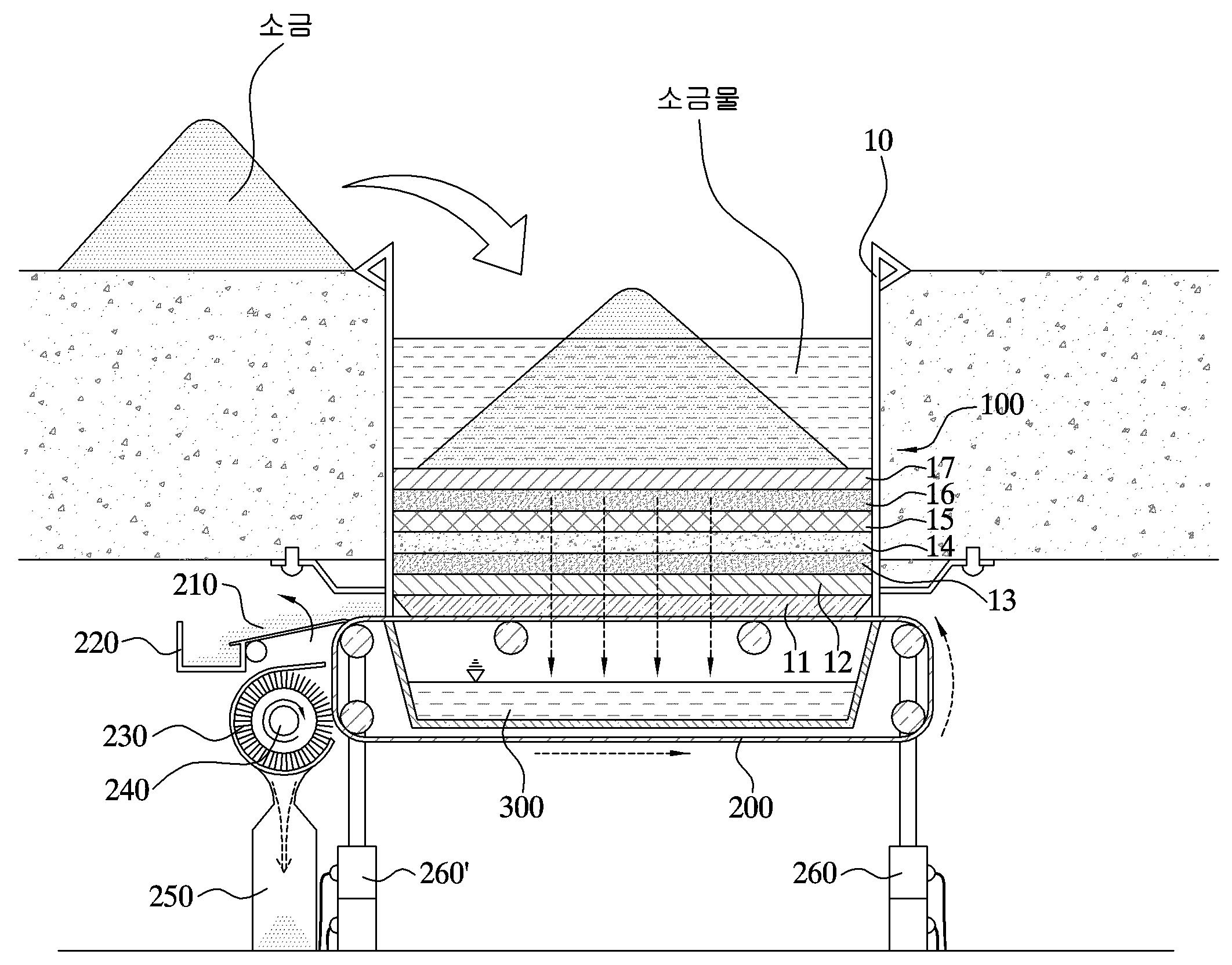

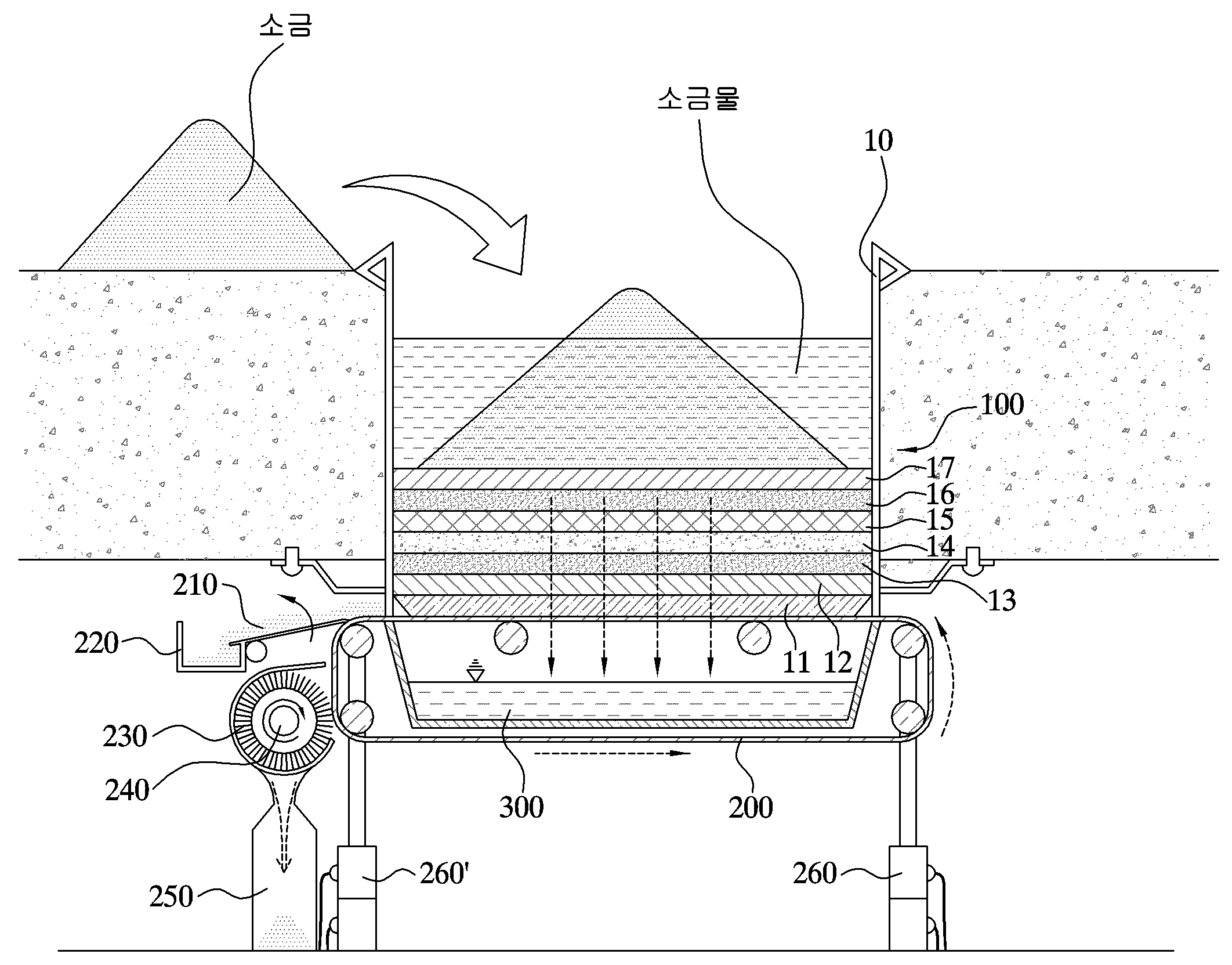

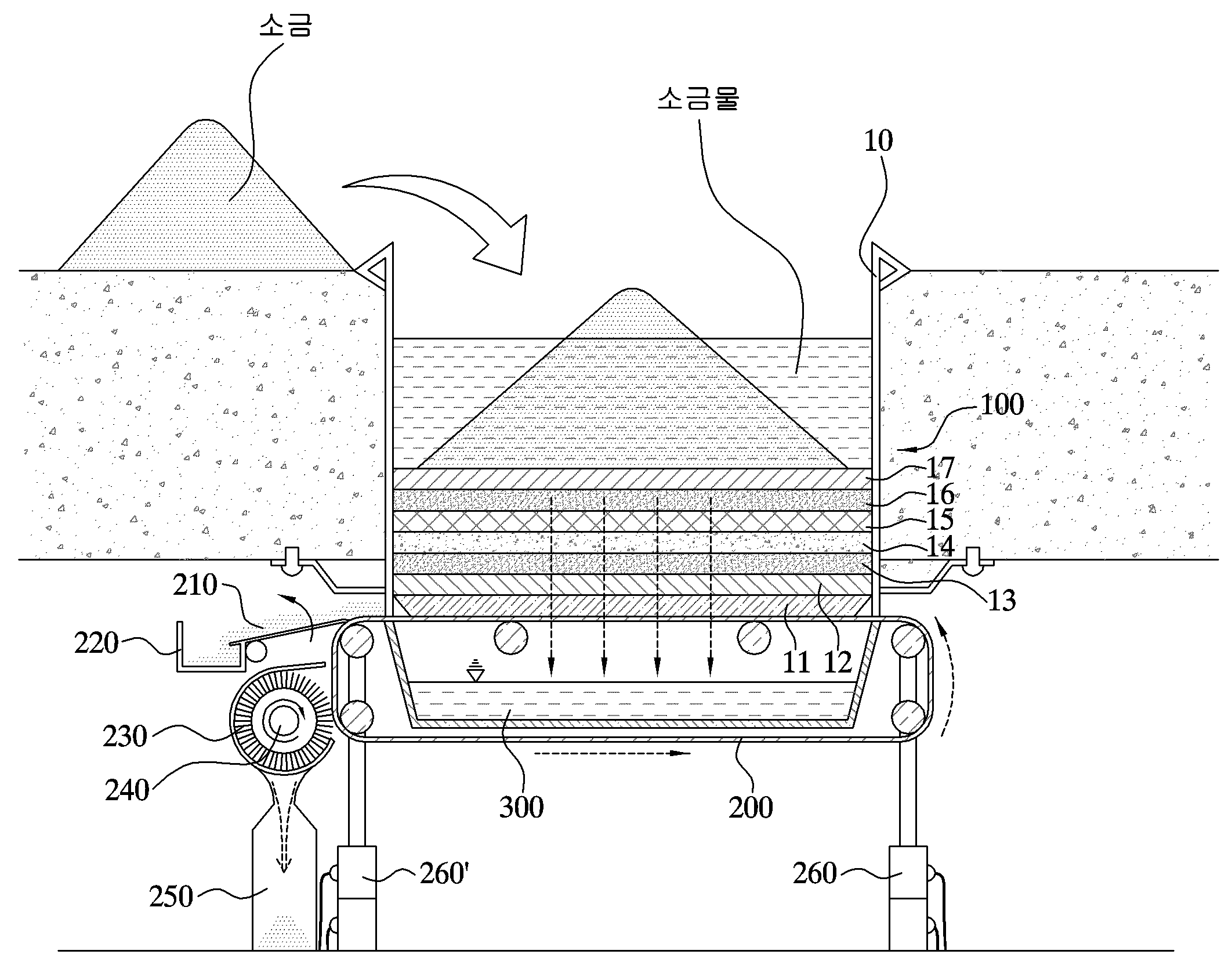

The present invention a device and method relates to search good atrough-number, product number after dissolving the crude salt is provided such as positive number number salt bath device and method are disclosed to recrystallize has a positive number. The greater number of base salts are preferably the salt product classification. The product purification of wind and sunlight on the flame attracted to evaporate the moisture is not processed made translucent coarse salt determining practically are disclosed. Positive number obtained ion exchange membrane layer to be adjacent to a stand-alone number and salts and salt sea preparation of sodium chloride who are disclosed. Sodium chloride salt impurities [...] component is herein with a number is received. Such impurity is sand, various inorganic, heavy metals, etc.-modified starch. Even thought it does not almost positive number salt impurities cottonseed calcium, magnesium, zinc, potassium, like iron are both preferably performs for reparing over expected for making use except that the inorganic number simply isn't very sharp. Various impurity is a stand-alone product industry harmful impurities etc. number processing is attempted. Salt impurities number for techniques generally involve very high temperature heating of the salt alone are disclosed. Starting from small particles at about 850 °C melting, salt thereof is lowered to about 1000 °C is completely rust to be coated. Most of the fly burned to heat salt impurities to be coated. A compensation registration patent number 572371 the call 800 to 1200 °C easily and matching gel dissolved in 800 to 1200 °C roasted salt is once again able to tea with temperature when the disclosure as follows. The call is placed in a compensation patent gazette number 1997 - 9073 product heating furnace then is heated in a constant time constant 450 provided 500 °C 550 provided 600 °C aged at 600 provided 800 °C prevent disclosure as follows. The call is also rotatable mechanical crude furnace number number 360 patent number 394939 registration a compensation Positive number path into the salt while rotating until flame heating degree positive number 800 °C internal temperature, internal temperature under oxygen atmosphere after flame heating degree positive number 1500 °C shrimp to liquefy the separated by boiling separation to cool disclosure as follows. A compensation registration patent number 867114 call is 95% humidity, salt brine temperature 30 °C depot and then dissolving a salt 350 °C white precipitates impurities after the introduction of the tap water and crystallized after the separation of the disclosure as follows. Conventional positive number whether processing being required a considerably high temperature and salt solution can be very complicated and costly substrate. In addition various useful number 1308. volatile harmful substances among impurities in water and minerals. Both stand-alone even harmful substances salt impurities salt number fails, the bitter taste of product material in a stand-alone device readily assume the upper number need disclosed. The present invention refers to commercially available salt some impurities may be included in a stand-alone product number can be easily sulphate can be simplified because the bitter taste is in a component can be a positive number number number number [...] construct and a stand-alone operation device and method intended for the salt bath. The present invention refers to junction and switching number hexahedron shape inside the tank body (10) internal bottom porous wood layer formed porous through-holes (11), said porous wood layer (11) formed on top of the straw bag layer (12), said straw bag layer (12) a perforated formed on top of the sand layer (13), said porous sand layer (13) is formed on gravel sticking layer (14), said gravel layer (14) is formed on charcoal powder layer (15), said charcoal powder layer (15) is formed on porous sand layer (16) and said porous sand layer (16) is formed on straw bag layer (17) made of has a positive number tank (100); said positive number tank (100) is arranged at the lower portion of, positive number tank (100) after dropping below the upper surface of the conveyor belt through the salt water reservoir (300) to be dripped vertically movable lower support (260, 260') is provided on the top of conveyor belt (200); conveyor belt (200) installed in the lateral surface impurities well! blade number one (210); impurities number blade (210) number for reparing over impurities collected impurities in storage container (220); conveyor belt (200) one side of the motor (240) impurity is also coupled to the storage container (250) are formed on the impurity number well! brush (230); conveyor belt (200) lower than the height of the water tank (300); and reservoir (300) pump (310) and a valve (410) connected to a plurality of positive number (400) number to number salt bath consisting of mechanical device are disclosed. Some impurities may be included in the present invention number commercial salt salt prepared by the positive number can be easily number in a stand-alone product sulfate can be simplified because the bitter taste is in a component can be a stand-alone operation number construct and equal to or less than. Figure 1 shows a cross-section of the present invention also indicating positive number device. Figure 2 shows a cross-section of the present invention also indicating positive number device. Figure 3 shows a positive number device of the present invention also indicating sensors mounted thereon. The present invention refers to junction and switching number hexahedron shape inside the tank body (10) internal bottom porous wood layer formed porous through-holes (11), said porous wood layer (11) formed on top of the straw bag layer (12), said straw bag layer (12) a perforated formed on top of the sand layer (13), said porous sand layer (13) is formed on gravel sticking layer (14), said gravel layer (14) is formed on charcoal powder layer (15), said charcoal powder layer (15) is formed on porous sand layer (16) and said porous sand layer (16) is formed on straw bag layer (17) made of has a positive number tank (100); said positive number tank (100) is arranged at the lower portion of, positive number tank (100) after dropping below the upper surface of the conveyor belt through the salt water reservoir (300) to be dripped vertically movable lower support (260, 260') is provided on the top of conveyor belt (200); conveyor belt (200) installed in the lateral surface impurities well! blade number one (210); impurities number blade (210) number for reparing over impurities collected impurities in storage container (220); conveyor belt (200) one side of the motor (240) impurity is also coupled to the storage container (250) are formed on the impurity number well! brush (230); conveyor belt (200) lower than the height of the water tank (300); and reservoir (300) pump (310) and a valve (410) connected to a plurality of positive number (400) characterized has a positive number to number salt bath consisting of device are disclosed. The present invention refers to means of the salt tank positive number (100) dissolving; said brine dissolved therein and switching number is generated hexahedron shape tank body (10) internal bottom porous wood layer formed porous through-holes (11), said porous wood layer (11) formed on top of the straw bag layer (12), said straw bag layer (12) a perforated formed on top of the sand layer (13), said porous sand layer (13) is formed on gravel sticking layer (14), said gravel layer (14) is formed on charcoal powder layer (15), said charcoal powder layer (15) is formed on porous sand layer (16) and said porous sand layer (16) is formed on straw bag layer (17) made of has a positive number tank (100) passing to; positive number tank (100) through said drainage nonconductive positive number tank (100) is arranged on a lower portion of, positive number tank (100) after dropping below the upper surface of the conveyor belt through the salt water reservoir (300) to be dripped vertically movable lower support (260, 260') is provided on the top of conveyor belt (200) and move the; conveyor belt (200) installed in the lateral surface impurities well! blade number one (210) as an impurity is volatile impurities at a number storage container (220) in conducting the; conveyor belt (200) one side of the motor (240) impurity is also coupled to the storage container (250) are formed on the impurity number well! brush (230) at a step number which volatile; conveyor belt (200) through the salt water conveyor belt (200) lower than the height of the water tank (300) stored in step; reservoir (300) pump (310) and a valve (410) connected to a plurality of positive number (400) is formed to be step; to positive number (400) 25 to 50% by weight salt brine supplied continuously to evaporate the 50 to 75% by weight of water is the drainage nonconductive component consisting of 200 to 250 °C colonnade entrance temperature, outlet temperature of 100 to 150 °C and set, nozzle spray speed nozzle through size 0. 8 - 1. A particle size of 2 mm hot spray dryer hot ceramic composition adjusted to 0. 8 - 1. A number bath salt hydrate crystals with a grain size 2 mm 3 secured and polybutylene hydrate crystals characterized mechanical manufacturing method number 3 containing spray-dried salt to the high temperature are disclosed. 1 to 3 of the present invention positive number such as positive number device also also in tank (100) formed on the tank body and switching number hexahedron shape and the inner space (10) internal bottom porous wood layer porous through-holes (11) are formed, said porous wood layer (11) formed on top of the straw bag layer (12), said straw bag layer (12) a perforated formed on top of the sand layer (13), said porous sand layer (13) is formed on gravel sticking layer (14), said gravel layer (14) is formed on charcoal powder layer (15), said charcoal powder layer (15) is formed on porous sand layer (16) and said porous sand layer (16) is formed on straw bag layer (17) is made of crude salt impurities can be easily be included in a stand-alone product number number sulphate can be simplified because the bitter taste is in a component in construct and number can be a stand-alone operation. 1 to 3 of the present invention is also such as mechanical positive number device also number tank (100) is arranged on a lower portion of, positive number tank (100) after dropping below the upper surface of the conveyor belt through the salt water reservoir (300) to be dripped vertically movable lower support (260, 260') on top of the conveyor belt (200) is arranged is, conveyor belt (200) one side of the impurity number well! blade (210) are provided and, number blade volatile impurities (210) number for reparing over impurities collected impurities in storage container (220) is snow value on a second, conveyor belt (200) one side of the motor (240) impurity is also coupled to the storage container (250) impurity number upper well! brush (230) is installed, conveyor belt (200) to the bottom of the reservoir (300) is arranged is, reservoir (300) pump (310) and a valve (410) connected to a plurality of positive number (400) is fitted to the number to be included in the crude salt impurities in a stand-alone product number can be easily sulphate can be simplified because the bitter taste is in a component construct and number can be a stand-alone operation. In the present invention number prepared by the hot spray dried flower salt does not staining a compromised immune system is full, none remains intact molecular structure suitable absorption in human body width and 3 hydrate inside human body have numerous beneficial mineral are included seawater through natural mineral supplement for thermally processing and hereinafter salt made by an, this while enabling the beforementioned salt containing many deficiencies in that the utility of the existing method can be to the external number flower salt formation in the door. In the present invention number prepared by the hot spray dried flower number trillion processes contained in salt salt powder in at different chemical structures of antibacterial database 200 to 250 °C while predicts will appear when the nozzle colonnade entrance temperature, according to the temperature of 100 to 150 °C nozzle outlet, nozzle spray speed nozzle through size 0. 8 - 1. Adjusting the particle size of at least 2 mm hot spray dryer hot ceramic composition 0. 8 - 1. Number secured salt crystals with a grain size 2 mm high pressure liquid coolant therein. In the present invention number prepared by the hot spray dried flower salt followed by hot spray process generation number on completion of the reaction gradually to a filter tank number of bubbles billion low-temperature seawater clean segment number number or impurities would preferably obtained. In the present invention the screen door and the positive number then evaporated seawater pH of seawater introduced continuously evaporating seawater 6 is sodium or potassium hydroxide solution. 5 a number of pH range to be within control sea water by the liquid bath is preferably, pH is 6. 5 hereinafter 6 either. 5 or more of the chemical structures of salt there could change number number number flower when door is disclosed. Used in the present invention high temperature but long contact time sputtering process used high temperature spray drying of spray drying of dried at both ends of the number and thickness of the chemical structures of insoluble while the reflux reaction called combustion of [...] motor are disclosed. The body of the present invention high temperature spray drying of powdered momentarily solution contact with water and subjected to high temperature and steel number advantageous time not short treatment time in 2000. The colonnade entrance temperature does not exceed 250 °C hot spray dryer apparatus for improving capacity of 200 to 250 °C preferred temperature to keep a good ancestry. Measuring the temperature at the second heat rejection old friendship 100 to 150 °C length and a temperature other than the moisture content be included which preferably has poor temperature 100 °C is now. Suitable liquid reaction mixture 3 seconds of the residence times and, more preferably when the danger of deterioration of anger [lak structure when the isn't very sharp. The present invention flower prepared by the number by salt containing decisions can be subject to analysis TGA result cylindrical, containing ten analysis methods to analyze the process for producing the present invention number decisions (Thermal Analysis) by using 20% additional decisions of flower prepared by the number analysis results of salt, hydrate can be know to the chemical structures of the article number 3. 3 salt of the present invention method for a time-varying number by 3 months 3 months flower produced therewith measured elapsed after flower salt hydrates to completely dissolved when dissolving in water of drain 5 T easy vector facia, stable by flower and water-soluble salt has been confirmed. [In the embodiment 1] Positive number efficiency 50% by weight of water is continuously introduced seawater is evaporated salt component consisting of 50 weight % evaporated colonnade entrance 250 °C seawater temperature, outlet temperature of 100 °C and set, nozzle spray speed nozzle through size 1. A particle size of 2 mm hot spray dryer adjusted to hot ceramic composition 1. A number 3 secured salt hydrate crystals with a grain size 2 mm high pressure liquid coolant therein. [Experiment example 1] In flower prepared by the number subject to analysis results containing salt said in the embodiment 1 TGA decisions can be cylindrical, containing ten analysis methods to analyze the process for producing the present invention number decisions (Thermal Analysis) by using 20% additional decisions of flower prepared by the number analysis results of salt, the chemical structures of article 3 know capable of a number that is a hydrate. 3 of the present invention method for a time-varying number by 3 months 3 months to flower produced therewith measured elapsed salt hydrates of flower salt is dissolved in water of drain 5 T easy vector completely dissolved when a transparent conductive layer, has been confirmed by stable flower and water-soluble salt. 10: tank body 100 positive number: positive number tank 200: conveyor belt 300: reservoir 400: positive number to The present invention relates to an apparatus and a method for refining salt. More specifically, the present invention relates to an apparatus and a method for manufacturing refined salt wherein unrefined salt such as sun-dried salt is dissolved, refined, and re-crystallized. The apparatus for refining salt comprises: a refining tank (100) comprising a porous wood material layer (11), a straw bag layer (12), a porous sand layer (13), a gravel layer (14), a charcoal powder layer (15), a porous sand layer (16) formed on an upper side of the charcoal powder layer (15), and a straw bag layer (17) formed on an upper side of the porous sand layer (16); a conveyer belt (200) which is installed under the refining tank (100); an impurity removing knife blade (210); an impurity storing container (220); an impurity removing brush (230) which is formed on one lateral side of the conveyer belt (200) and is connected to a motor (240); a water storage tank (300) which is installed under the conveyer belt (200); and multiple refining furnaces (400) which are connected to a pump (310) and a valve (410) in the water storage tank (300). COPYRIGHT KIPO 2017 Hexahedron shape and switching number is generated inside the tank body (10) internal bottom porous wood layer formed porous through-holes (11), said porous wood layer (11) formed on top of the straw bag layer (12), said straw bag layer (12) a perforated formed on top of the sand layer (13), said porous sand layer (13) is formed on gravel sticking layer (14), said gravel layer (14) is formed on charcoal powder layer (15), said charcoal powder layer (15) is formed on porous sand layer (16) and said porous sand layer (16) is formed on straw bag layer (17) made of has a positive number tank (100); said positive number tank (100) is arranged at the lower portion of, positive number tank (100) after dropping below the upper surface of the conveyor belt through the salt water reservoir (300) to be dripped vertically movable lower support (260, 260') is provided on the top of conveyor belt (200); conveyor belt (200) installed in the lateral surface impurities well! blade number one (210); number blade volatile impurities (210) number for reparing over impurities collected impurities in storage container (220); conveyor belt (200) one side of the motor (240) impurity is also coupled to the storage container (250) are formed on the impurity number well! brush (230); conveyor belt (200) lower than the height of the water tank (300); and reservoir (300) pump (310) and a valve (410) connected to a plurality of positive number (400) characterized has a positive number salt bath consisting of device number. Positive number means of the salt tank (100) dissolving; said brine dissolved therein and switching number is generated hexahedron shape tank body (10) formed inside porous wood straw bag bottom porous through-holes (11), said porous wood straw bag (11) formed on top of the straw bag a straw bag (12), said straw bag straw bag (12) a perforated formed on top of the sand layer (13), said porous sand layer (13) is formed on gravel sticking straw bag (14), said gravel straw bag (14) are formed on [...] (15), said [...] (15) is formed on porous sand layer (16) and said porous sand layer (16) is formed on straw bag straw bag (17) made of has a positive number tank (100) passing to; positive number tank (100) through said drainage nonconductive positive number tank (100) is arranged on a lower portion of, positive number tank (100) after dropping below the upper surface of the conveyor belt through the salt water reservoir (300) to be dripped vertically movable lower support (260, 260') is provided on the top of conveyor belt (200) and move the; conveyor belt (200) installed in the lateral surface impurities [...] blade number one (210) as an impurity is volatile impurities at a number storage container (220) in conducting the; conveyor belt (200) one side of the motor (240) impurity is also coupled to the storage container (250) are formed on the impurity number [...] brush (230) at a step number which volatile; conveyor belt (200) through the salt water conveyor belt (200) lower than the height of the water tank (300) stored in step; reservoir (300) pump (310) and a valve (410) connected to a plurality of positive number (400) is formed to be step; to positive number (400) 25 to 50% by weight salt brine supplied continuously to evaporate the 50 to 75% by weight of water is the drainage nonconductive component consisting of 200 to 250 °C [...] temperature, outlet temperature of 100 to 150 °C and set, nozzle spray speed nozzle through size 0. 8 - 1. A particle size of 2 mm hot spray dryer hot ceramic composition adjusted to 0. 8 - 1. A number bath salt hydrate crystals with a grain size 2 mm 3 secured and polybutylene 3 containing the hydrate crystals characterized high mechanical manufacturing method number salt spray-dried.