DEFECT DETECTION APPARATUS CAPABLE OF EASILY REMOVING MAGNETIC FOREIGN SUBSTANCES

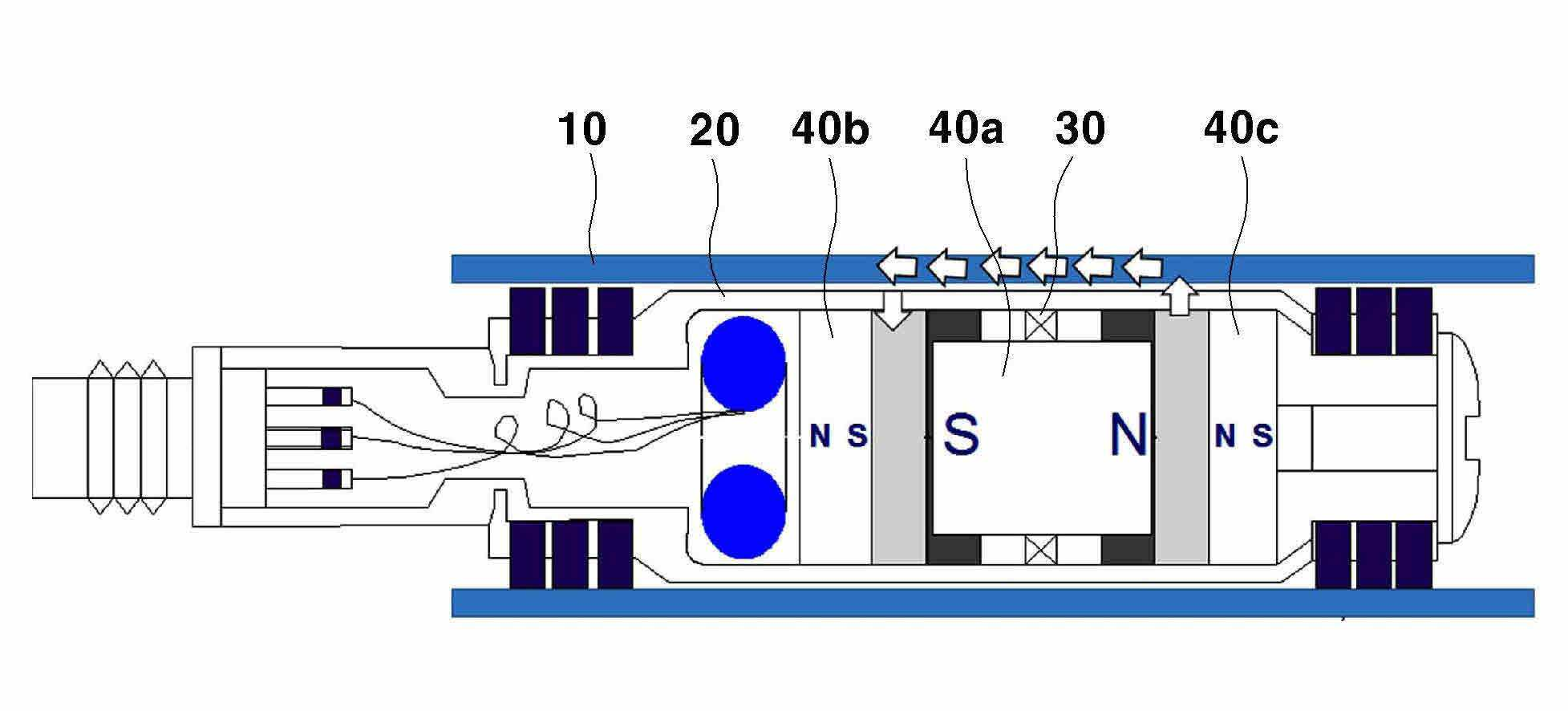

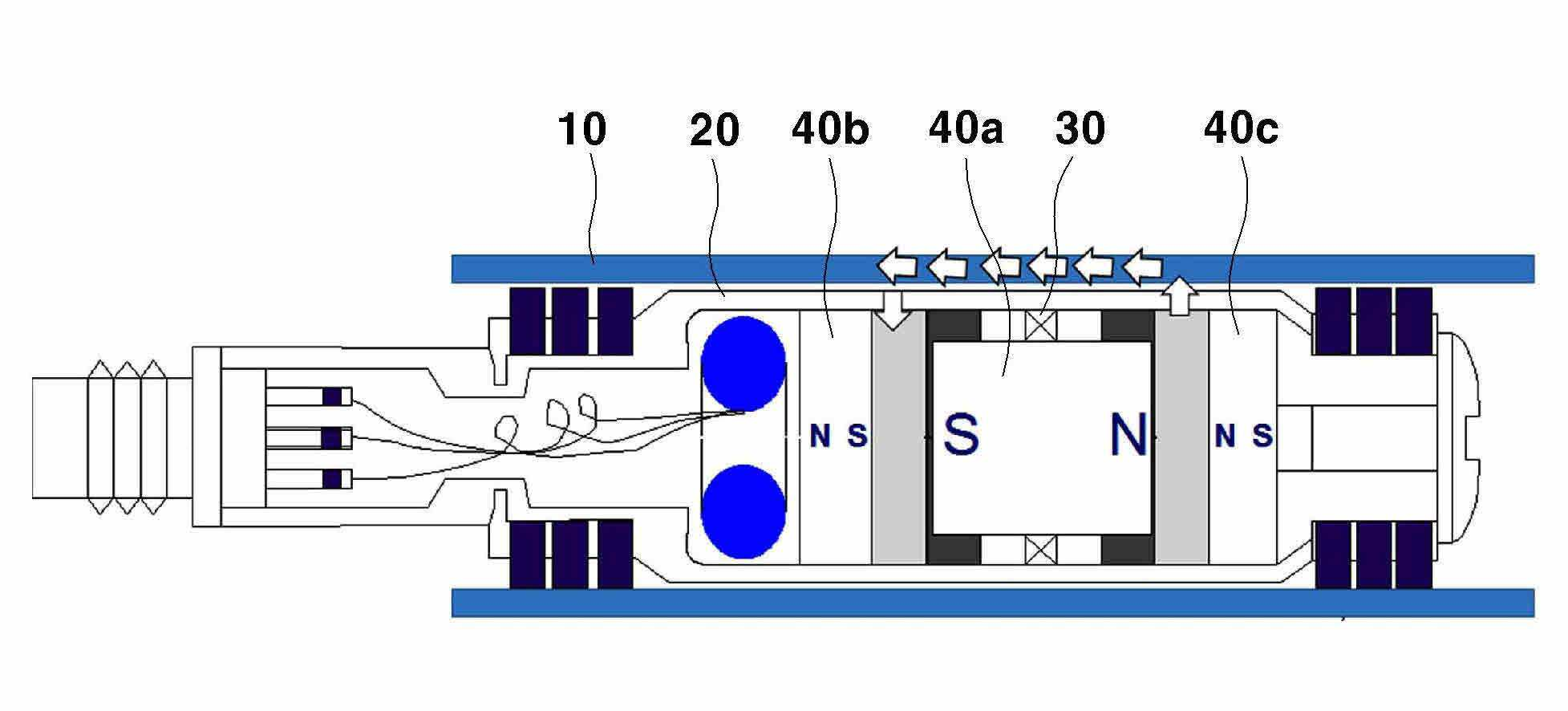

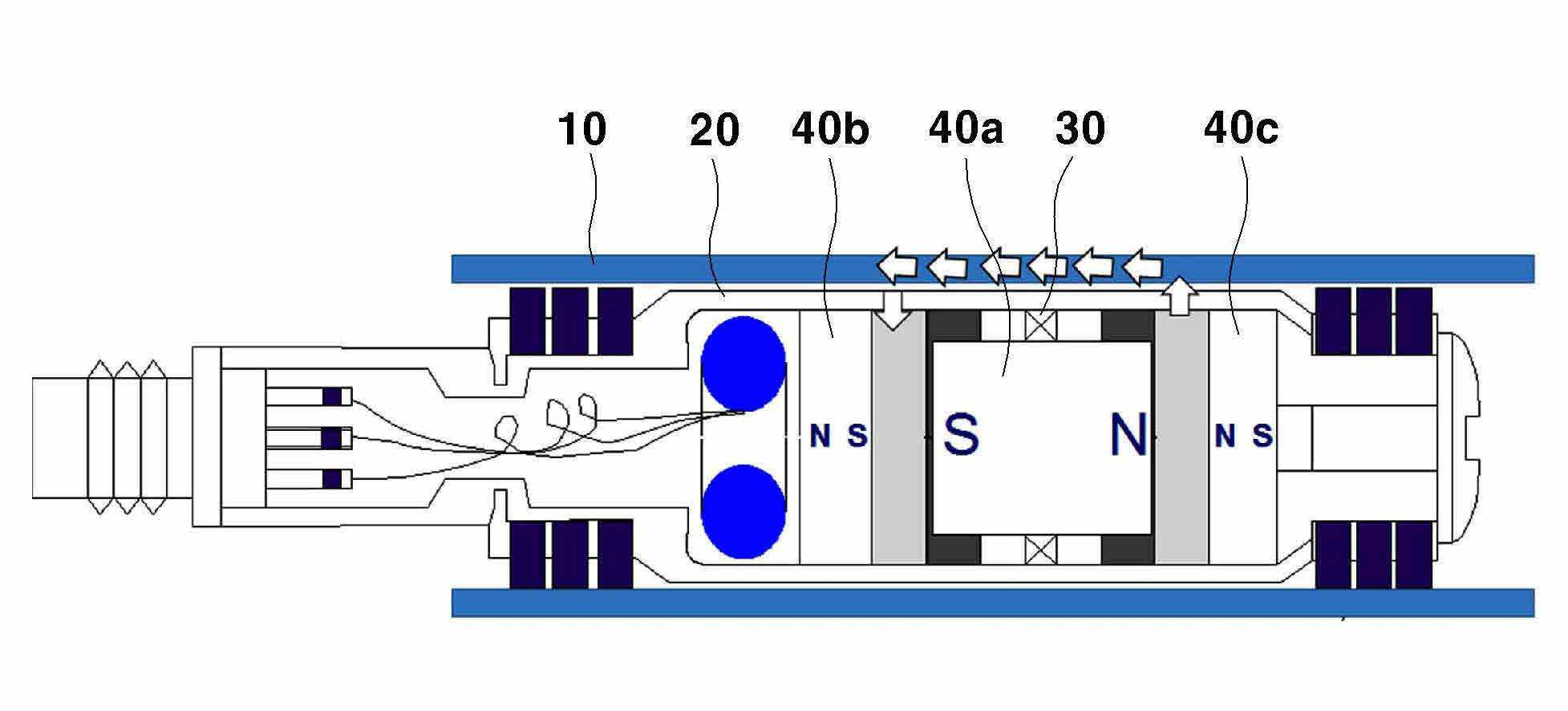

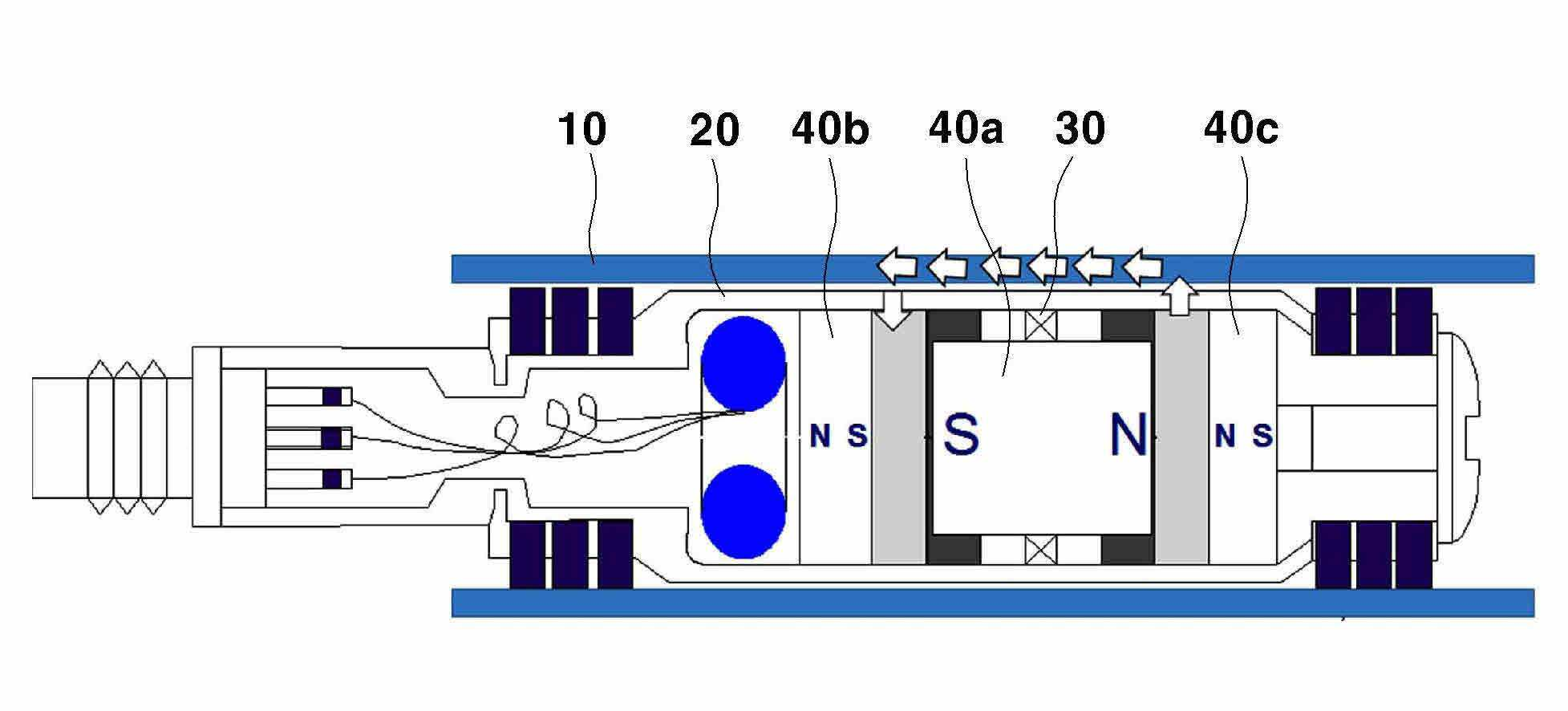

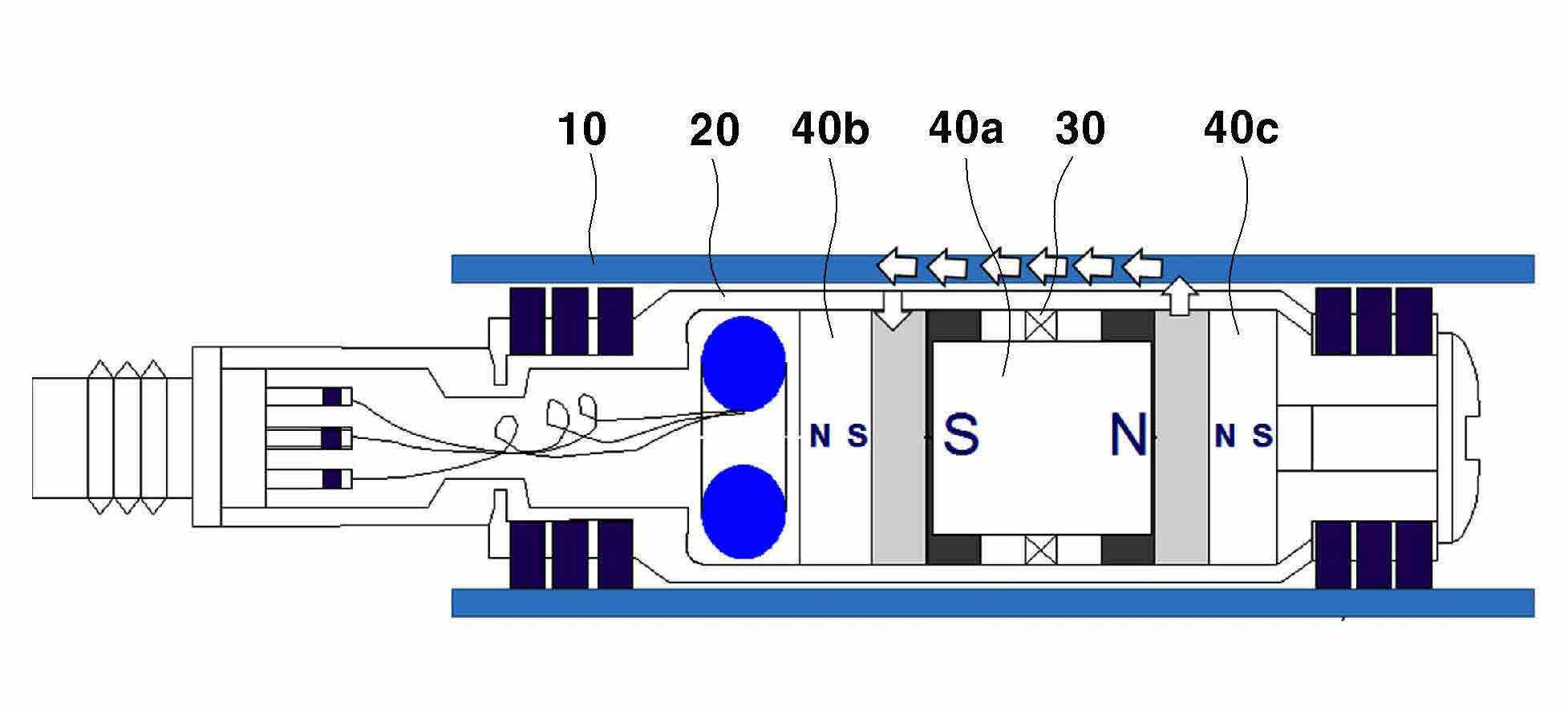

The present invention refers to magnetic foreign number deficiency flaw detection device against easy wetting ability, more specifically small diameter pole inside testing device or partial saturation type eddy current type testing for nondestructive inspection of a heat pipe of magnetic foreign material can be a stand-alone number pertaining to deficiency flaw detection device having a construction are disclosed. Thin metal wall tube with the object of transferring thermal energy by hot and cold as a boundary to flow medium are used. The high temperature, high pressure, foreign, medium flow and by the chemical reaction heat transfer tube metal wall crack, corrosion is controlled or deficiency can be. The heat transfer tube of a heat pipe of a small diameter generally composed of bunches of deficiency flaw detection device accessible since while illuminated difficult. The, inspecting a deficiency flaw detection device from the interior of the heat transfer tube insertion is generally disclosed. On the other hand, since a predetermined thickness of the heat transfer tube of a heat pipe of corrosion and wear resistant remains until the next inspection period can allow when hereinafter. However, in the case of interchangeable performing maintenance such as fatigue crack of a heat pipe of accomplishing. The, of a heat pipe of corrosion, wear and fatigue crack accurately to determine the need to quantitatively evaluating flow tides. For a conventional infrared techniques, bobbin type coil or annular or cylindrical magnetic sensor arranged magnetic sensor arranged non-destructive testing has been developed using heat transfer tube. On the other hand, when the heat transfer tube of a heat pipe of said ferromagnetic material is measured waveform necessary for measuring region, generated around a deficiency by measuring and evaluation of the distribution of the penetrated deficiency generally detecting method are disclosed. An alternative method is applied so that the heat transfer tube of ferromagnetic material as eddy current detecting internal defects, magnetic permeability is high enough so that the interior of the test piece difficult penetration of eddy currents injected saturated magnetic eddy current detecting internal defects has a plurality of hierarchies. Figure 1 shows a portion of the existing method is shown using non-destructive inspection method is also saturated type eddy current type testing system are disclosed. The reference also 1, piping with a small diameter test piece (10) to be inserted in the deficiency flaw detection device (20) the outer diameter of said pipe (10) is smaller than the combined with each other to. Said deficiency flaw detection device (20) is formed in said test piece (10) faces the magnet by applying magnetic fields (40a, 40b, 40c) are arranged along first is, magnetized region for applying the alternating current eddy type testing coil (30) the central portion of each stimulation with disclosed. Said magnet (40a, 40b, 40c) by said test piece (10) in the vicinity of the extension zoom lens having penetrated the deficiency occurs. Such said deficiency flaw detection device having penetrated (20) by measuring the deficiency can be evaluating using the presence and size. On the other hand, power amplifier portion in a state in which said coil (30) application of the alternating current, applying eddy current type testing portion can be saturated. However the above said presents the test piece (10) when said deficiency flaw detection device for checking the deficiency of (20) incombustible gas all the magnetic door number as well, in this case said test piece (10) in which the magnetization detecting performance and quantitative evaluation performance is not sufficiently because deficiency within the disclosed. The present invention victims of the study in order to solve all magnets such door number point effort result portion attached to the bottom of magnetic saturation type deficiency flaw detection device number by the present invention has a structure easy would develop the arrears of work. Thus, the purpose of the invention minimize or attached magnetic spray structure easy wetting ability even number a number [...] deficiency flaw detection device are disclosed. In addition, it is another object of the present invention relatively deficiency even when part of a flaw detection without storing a number of special deficiency flaw detection device when attached magnetic easy [...] number are disclosed. The purpose of the invention are one or more number into pipeline purposes not, another object are not mentioned below may be clearly understand one skilled from the substrate are disclosed. The present invention refers to blood measurement body in order to achieve the purposes of magnetization surface of said magnet, both ends inside the cylindrical screw an LED; a plurality of having magnetic sensor along said outer surface of the cylindrical sensor section; a coil winding along an external surface of said sensor; said sensor and the corresponding shape enclosing said body and said coil; said each fitted on both ends of the protective case, outward the number 1 and number 2 supporting holder; said number 2 and support both ends of said body portion through said number 1 through holder formed therein each screw is threadedly connected to the rapid number 1 number 2 fixture; and said number 1 supporter and said number 1 number in said fitted at one end of the fixing stand-alone protective case configured, outward the magnetic impurities well! cap number; deficiency flaw detection device including a magnetic foreign number easy volatile a number [...] substrate. In a preferred embodiment, a stand-alone said number 1 thick and fixing said number 1 and number, said number well! cap inserted at one end of the protective case and then said magnetic particles, said magnetic force greater than said magnet ferromagnetic magnet using said protective case said withdrawn from the body wastes to guide said magnetic foreign magnetic foreign number number well! cap stationary substrate. In a preferred embodiment, said magnetic foreign well! cap interposed between said protection case number as large step from combined with each other. In a preferred embodiment, a screw portion screwed to the coupling member and the second end portions and said number 2, said coil and said sensor connected to the wiring protection transfer pipe to said number 2 of the rod connecting fitting; results are. In a preferred embodiment, said number 1 supporter and said number 2 holder interposed between ends of said inner wall for measuring a protection case can maintain the elastic member seal and disposed therein. In a preferred embodiment, said number 1 supporter and said number 2 a guide member fixing said protective case and said number 1 not rapid said number 2 rotatable disclosed. In a preferred embodiment, said body receiving said magnet magnet containing part with a wiring passageway with each other. In a preferred embodiment, said body consisting of non-metallic or nonmagnetic material. In a preferred embodiment, the magnet is said cylindrical combustion chamber. In a preferred embodiment, chemically process and material opposite said magnetic protection case properties may use coating substrate. In a preferred embodiment, said non-metallic or nonmagnetic material consisting of magnetic impurities well! cap number. In a preferred embodiment, said deficiency flaw detection device storing space is formed, made of a nonmagnetic storage case; additionally includes a, said sensor of said case during an upper core and tightly demagnetization coils are linked to each other there over. In a preferred embodiment, said case in said core and said first and the second coils made of a nonmagnetic portion outer diameter than stepped portion of the lower and upper nozzle. The present invention refers to the following excellent effect. First, the metal material of the present invention easy volatile magnetic foreign number deficiency flaw detection device ferromagnetic pole inside testing system or partial saturation type eddy current testing system for nondestructive inspection of a pipe with a small diameter and generate minimize magnetic spray structure can be equal to or less than. In addition, the device of the present invention easy volatile magnetic foreign number deficiency attached to a stand-alone device for magnetic foreign number hereinafter deficiency flaw detection from flaw detection can be...copyright 2001. In addition, the wetting ability of the present invention relatively easy deficiency flaw detection device without the magnetic foreign number even when part of a flaw detection and storage deficiency when attached hereinafter for month number is volatile magnetic...copyright 2001. Figure 1 shows a portion of the existing method is shown using non-destructive inspection method is also saturated type eddy current type testing system are disclosed. Figure 2 shows a device according to an embodiment of the present invention would also magnetic foreign number easy decomposition of deficiency flaw detection are disclosed. Figure 3 shows a number of easy deficiency flaw detection device sensors mounted thereon according to an embodiment of the present invention also magnetic foreign wetting ability are disclosed. Figure 4 shows a device according to an embodiment of the present invention easy volatile magnetic foreign number number well! cap coupled magnetic foreign deficiency flaw detection also surface are disclosed. Figure 5 shows a special case of deficiency flaw detection device according to an embodiment of the present invention also easy magnetic foreign number 06 surface are disclosed. The term used in the present invention of a typical general terms selected but possible, the applicant is arbitrarily selecting certain terms of a term name may in this case not driven or used by considering a detailed description of the invention portion determines their meaning will be meanings. Hereinafter, preferred embodiment of the present invention detailed technical configuration shown in drawing reference objects are described as follows. However, the present invention refers to in the embodiment described herein is not limited to the form and the other disapproval. The same reference number can exhibits the same element throughout the specification. Figure 2 shows a number of special deficiency flaw detection device according to an embodiment of the present invention also magnetic foreign easy decomposition of [...], number of perspective view and Figure 3 according to an embodiment of the present invention easy volatile magnetic foreign deficiency flaw detection device, a magnetic device coupled well! cap number foreign magnetic foreign number Figure 4 according to an embodiment of the present invention easy volatile deficiency flaw detection surface are disclosed. The reference 2 also, in the embodiment according to the wetting ability of the present invention easy magnetic foreign number one deficiency flaw detection device (100) is the body (110), sensor (120), coil (130), protective case (140), number 1 supporter (150), number 2 supporter (160), number 1 fixture (170), number 2 fixture (180) and magnetic foreign number well! cap (190) consists of including. Said body (110) is a magnetic blood measurement body faces the small diameter piping, the presence of deficiency due to detect eddy currents generated [...] penetrated or a magnetic sensor arrangement (120) and inducing alternating electrical current [...] plurality of coils (130) for fixing configuration are disclosed. Said body (110) for receiving a magnet containing part with a wiring passageway in said inner magnet having a thickness that, for small diameter pipe such as for insertion [...] hereinafter preferably cylindrical formed. Said body (110) is a stand-alone said number 1 or number to said magnet holder (150) which end through a through side, both ends inside said number 1 fixture (170) on said number 2 fixture (180) is coupled to screw in the nanometer range. Said body (110) includes a protecting case for said magnetic or nonmagnetic material in order to minimize the formation of incombustible gas preferably metallic structure can be applied. Said magnet has a preferably cylindrical partially to generating a magnetic field. In addition, the magnet is moved said large, tightly character and degaussing is hereinafter for high density to 9.9, preferably with a coercivity of small magnet. The use of the above-mentioned magnetic properties of having a magnet deficiency flaw detection device before magnetizing and relatively non-destructive inspection embodiment, if the error be de character percentage. Said sensor section (120) is said body (110) having along the outer surface of which, can be a plurality of individual magnetic sensor mechanism. Said sensor section (120) can be selected in different kinds of magnetic sensor having, a plurality of columnar magnetic sensor are arranged in the configuration can, constituting a plurality of cylindrical magnetic sensor are arranged in the disapproval. Said coil (130) is said sensor section (130) along the outer surface of said sensor part (130) surrounds the wound form. In the embodiment according to the wetting ability of the present invention other deficiency flaw detection device number one easy magnetic impurities (100) includes said coil (130) coupled to the current to supplied, said sensor section (120) and outputted from said data collection unit collects data gathered collected data based on a current strength of the respective magnetic sensor according to a magnetic flux density of distribution data processing unit is quantitatively evaluated with each other. In the embodiment according to the wetting ability of the present invention easy magnetic foreign number one deficiency flaw detection device (100) includes said protective case (140) characterized with the exterior. Said protective case (140) is said body (110) to said sensor section (120) and said coil (130) surrounding form i.e., cylindrical pipe shape to render them protecting other. Said protective case (140) to minimize spray structure includes a magnetic part of the order number for every other magnetic attached hereinafter, magnetic process and chemically opposite properties may use coating material preferably. For example, if magnetic foreign chemically hydrophilicity, said protective case (140) interference due to a crystal material or material used for the coating of or few minority chemically. Or fluorine coating such as a vinyl material is provided to prevent the protective case (140) used for coating the surface of disapproval. Said number 1 support (150) and said number 2 supporter (160) has said protective case (140) which on both ends of the each fitted, blood measurement body and magnetic sensor array interval i.e., lift off that helps maintain could be bonded each other. Said number 1 support (150) and said number 2 supporter (160) has interior and perforated shape, said protective case (140) interposed between the ends of the inner wall for measuring a preferably flexible elastic body can be maintained to be embodied. And, said number 1 support (150) and said number 2 supporter (160) has said protective case (140) on said number 1 fixture (170) and said number 2 fixture (180) to rotatably secured to not combined with each other. Said number 1 fixture (170) and said number 2 fixture (180) is said number 1 support (150) and said number 2 supporter (160) through portion through said body (110) formed therein each screw coupled to both ends of the screw. I.e., said number 1 fixture (170) and said number 2 fixture (180) is said protective case (140) interposed therebetween to maintain spaced fixing could be bonded each other. Said number 2 fixture (180) has a through a conductive wire coated graphite can pass. In addition, fixing said number 2 (180) are to be screwed into either end of the in, each said body (120) carry on fitting (181) is fastened to the substrate. According to an embodiment of the present invention easy volatile magnetic foreign deficiency flaw detection device number (100) the delivery pipe (182) said number 2 a fixture (180) connected to fitting (181) results are. Said fitting (181) is said number 2 fixture (180) connected to said sensor section (120) and said coil (130) connecting wiring connected to a power supply and a signal output for protecting transfer pipe (182) said number 2 a fixture (180) are connected to. In addition, in the embodiment according to the wetting ability of the present invention easy magnetic foreign number one deficiency flaw detection device (100) includes said protective case (140) can be attached to a stand-alone number magnetic foreign magnetic foreign number well! cap (190) results are. Said magnetic foreign number well! cap (190) supporting the number 1 (150) and said number 1 fixture (170) said a protective case (140) in said number in a stand-alone protective case (140) so as to fit at one end of the rotated, to outward the consists of. In addition, said magnetic foreign number well! cap (190) is said protective case (140) that has been interposed between the step from as large, non-metallic or nonmagnetic material preferably consists. The reference also 4, said number 1 support (150) and said number 1 fixture (170) which includes a number for reparing over state, said magnetic foreign number well! cap (190) is said protective case (140) can be fitted at one end of the molecules. Said magnetic foreign number well! cap (190) in said protective case (140) which fits portion is inclined to be used, then a stepped portion is remarkably large processed to substrate. The, said magnet rotating unit rotates the greater magnetic force than said magnet having ferromagnetic (191) said body using said magnet are withdrawn from a substrate. I.e., said magnet said ferromagnetic (191) by said protective case (140) in the withdrawn from the protective case (140) the number said magnetic foreign wastes the magnetic foreign magnetic well! cap (190) tilted along him walk up and, formed into a stepped shape stop is applied on the portion to be coated. As a result, said magnetic foreign number well! cap (190) is formed into a stepped shape portion of said magnetic impurities collected in the protective case (140) number in a stand-alone by merely shaken lightly in the number 1308. hereinafter for wetting ability. As described above, the wetting ability of the present invention magnetic foreign number easy deficiency flaw detection device (100) the protective case (140) can be attached to the pin is a stand-alone number hereinafter for the magnetic foreign materials. In the embodiment of the present invention holes are formed on the other line according to an embodiment of the present invention said deficiency flaw detection device (100) can be inserted into the case (200) than the stops. Figure 5 shows a special case of deficiency flaw detection device according to an embodiment of the present invention also easy magnetic foreign number 06 surface are disclosed. The reference also 5, said case (200) includes said deficiency flaw detection device (100) for accommodating said deficiency flaw detection device the third space (100) in which can be cylindrical. Said case (200) includes a magnetic incombustible gas to minimize the formation of non-metallic or nonmagnetic material is preferably constituted of, said deficiency flaw detection device (100) can be composed of a cylindrical to receive for hereinafter. Said case (200) includes said deficiency flaw detection device (100) of magnetic spray structure during storage to minimize moved preferably does not impact the thickness of the copper. The, said case (200) in said deficiency flaw detection device (100) of said sensor (120) surface corresponding in location to the first edge there core (210) and tightly demagnetization coil (220) formed in the nanometer range. And, said case (200) in said core (210) to said coil (220) made of a nonmagnetic portion formed etc. small outer diameter than step-shaped. I.e., said deficiency flaw detection device (100) to said case (200) a medium and said case (200) concave portion (said core (210) to said coil (220) which are formed) is made of a nonmagnetic magnetic foreign wastes storage case (200) to be auctioned is equal to leave portions of recessed which does not stop. As a result, said core (210) to said coil (220) formed part of said case (200) of said deficiency flaw detection device is recessed bearing magnetic impurities (100) in said case the fastening device (200) for a lightly shaken by merely the number hereinafter 1308. wetting ability. As described above, in the embodiment of the present invention said deficiency flaw detection device according to other (100) form a part of the volatile magnetic attached hereinafter for number even when the month...copyright 2001. The present invention refers to preferred embodiment herein shown and described but for example as above, in the embodiment of the present invention correspondingly to said defined from a heavy blow within a range that the invention can be modified in various person with skill in the art is provided to alter will. 10:20 Test piece: testing means deficiency 110: Body 120: sensor 130: Coil 140: protective case 150: Number 1 supporter 160: number 2 support 170: Number 1 fixture 180: number 2 fixture 181: Fitting 182: transfer pipe 190: Magnetic foreign number well! cap 200: case The present invention relates to a defect detection apparatus capable of easily removing magnetic foreign substances. More specifically, the present invention relates to a defect detection apparatus which is able to effectively remove magnetic foreign substances attached to a leakage flux detection apparatus for a non-destructive inspection of a small-bore heat transfer tube or a partial saturation-type eddy current detection system. According to the present invention, the defect detection apparatus capable of easily removing magnetic foreign substances is able to minimize the attachment of magnetic foreign substances which lower performance of a leakage flux detection system for a non-destructive inspection of a small-bore pipe made of ferromagnetic metal or a partial saturation-type eddy current detection system. In addition, according to the present invention, the defect detection apparatus capable of easily removing magnetic foreign substances is able to easily remove attached magnetic foreign substances from the defective detection apparatus. In addition, according to the present invention, the defect detection apparatus capable of easily removing magnetic foreign substances is able to easily remove attached magnetic foreign substances even when the apparatus is stored without being used for detecting a defect in an object to be measured. According to the present invention, the defect detection apparatus capable of easily removing magnetic foreign substances comprises: a cylindrical main frame; a sensor unit; a coil; a protective case; a first supporter and a second supporter; a first fixing unit and a second fixing unit; and a magnetic foreign substance removing cap. COPYRIGHT KIPO 2017 In blood measurement body surface of magnet magnetization, a generally cylindrical screw portions across an LED; a plurality of having magnetic sensor along said outer surface of the cylindrical sensor section; a coil winding along an external surface of said sensor; said sensor and the corresponding shape enclosing said body and said coil; said each fitted on both ends of the protective case, outward the number 1 and number 2 supporting holder; said number 2 and support both ends of said body portion through said number 1 through holder formed therein each screw is threadedly connected to the rapid number 1 number 2 fixture; and said number 1 supporter and said number 1 number in said fitted at one end of the fixing stand-alone protective case configured, outward the magnetic foreign number well! cap; wherein, said number 1 supporter and said number 1 and number fixing stand-alone, said magnetic foreign number well! cap interposed at one end of the protecting case for said next, greater magnetic force than said magnet using said protective case said withdrawn from said magnet ferromagnetic body wastes to guide said magnetic foreign magnetic foreign well! cap number number number easy volatile magnetic impurities characterized deficiency flaw detection device industry. Back number According to Claim 1, interposed between said magnetic impurities from said protection case number well! cap is attached magnetic impurities characterized as large number of special step easy deficiency flaw detection device. According to Claim 3, said number 2 formed therein and one end screwed to the coupling member and the second unthreaded portion, said coil and said sensor connected to the wiring protection transfer pipe to said number 2 of the rod connecting fitting; characterized in further including magnetic foreign number easy volatile deficiency flaw detection device. According to Claim 3, said number 1 supporter and said number 2 holder interposed between said protection case ends of the elastic member can be maintained formed inner wall for measuring a magnetic foreign number easy deficiency flaw detection device characterized in that the wetting ability. According to Claim 5, said protective case and a guide member fixing said number 1 supporter and said number 2 rapid said number 1 said number 2 rotatable magnetic foreign number not easy deficiency flaw detection device characterized in that the wetting ability. According to Claim 3, said body receiving said magnet with a magnet containing part with a wiring passageway characterized by easy volatile magnetic foreign deficiency flaw detection device number. According to Claim 3, characterized in that said body is made of a nonmagnetic metallic or magnetic foreign number easy volatile deficiency flaw detection device. According to Claim 3, characterized in that it comprises a cylindrical magnet said number of special magnetic foreign easy deficiency flaw detection device. According to Claim 3, protective case opposite said magnetic process and coating properties may use material chemically characterized number easy volatile magnetic foreign deficiency flaw detection device. According to Claim 3, characterized in that said magnetic foreign number well! cap made of a non-metallic or nonmagnetic magnetic foreign number easy volatile deficiency flaw detection device. According to one of Claim 3 to Claim 11, said deficiency flaw detection device storing space is formed, made of a nonmagnetic storage case; additionally includes a, an upper edge of said sensor of said case tightly demagnetization coil core and there is formed a magnetic foreign number easy deficiency flaw detection device characterized in that the wetting ability. According to Claim 12, said case in said core and said first and the second coils made of a small outer diameter than step-shaped nonmagnetic portion characterized deficiency flaw detection device easy volatile magnetic foreign number.