ENVIRONMENT-FRIENDLY METHOD OF MANUFACTURING NATURAL ANTIBACTERIAL MATERIAL FOR DRIED PERSIMMONS AND DRIED PERSIMMONS

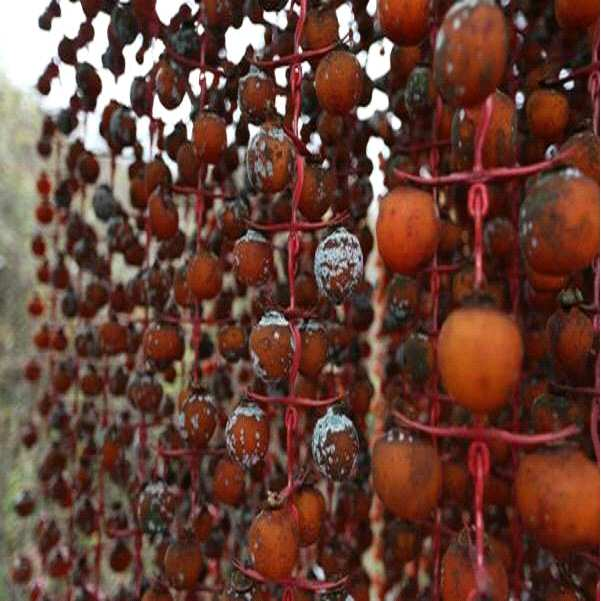

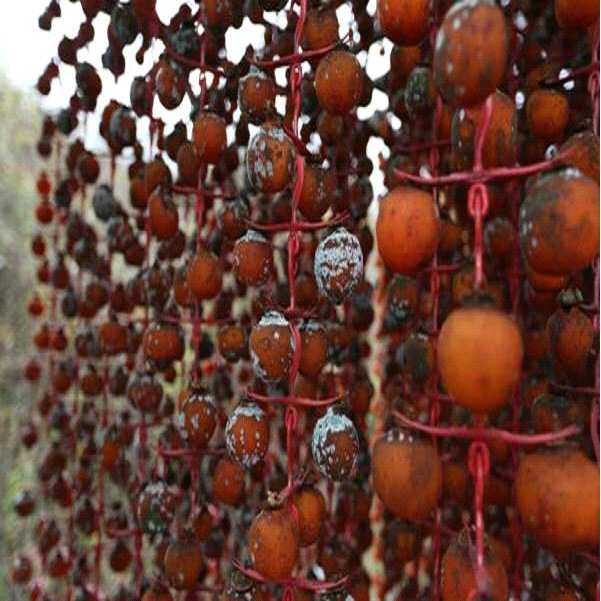

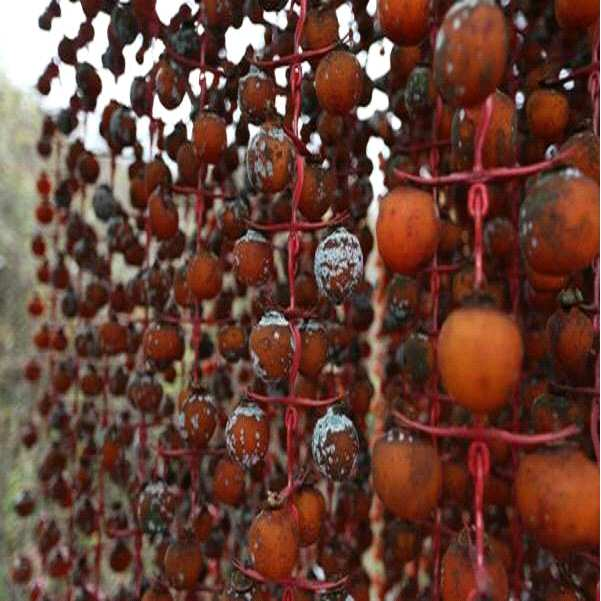

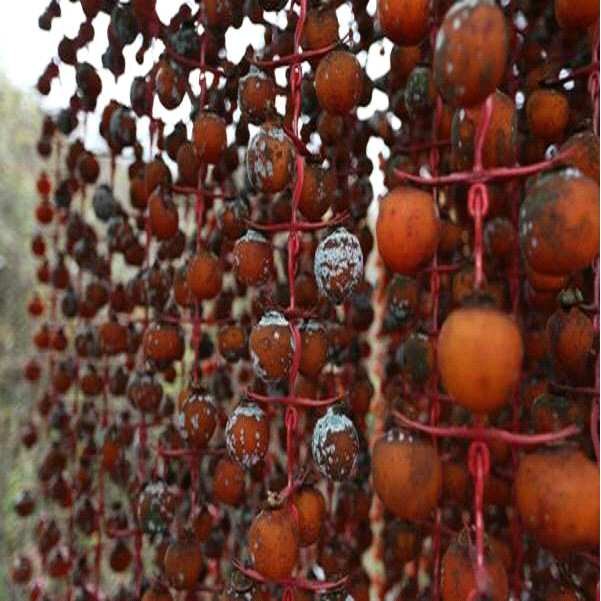

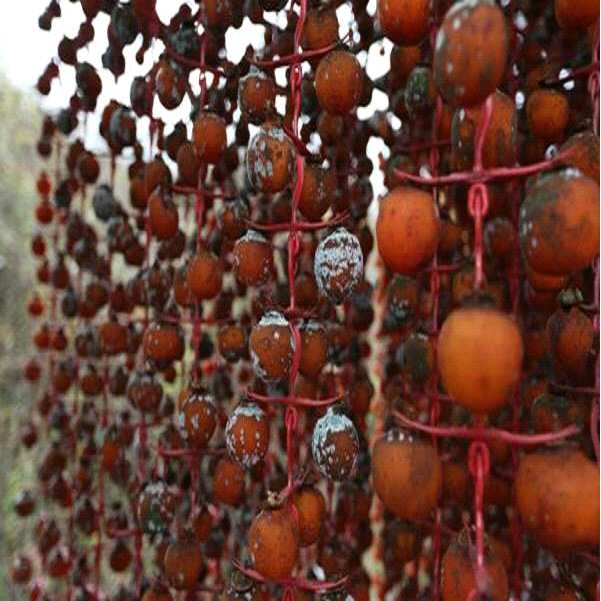

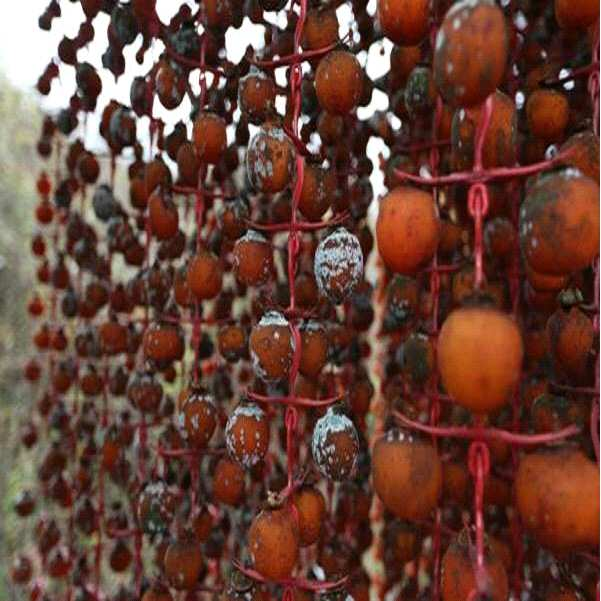

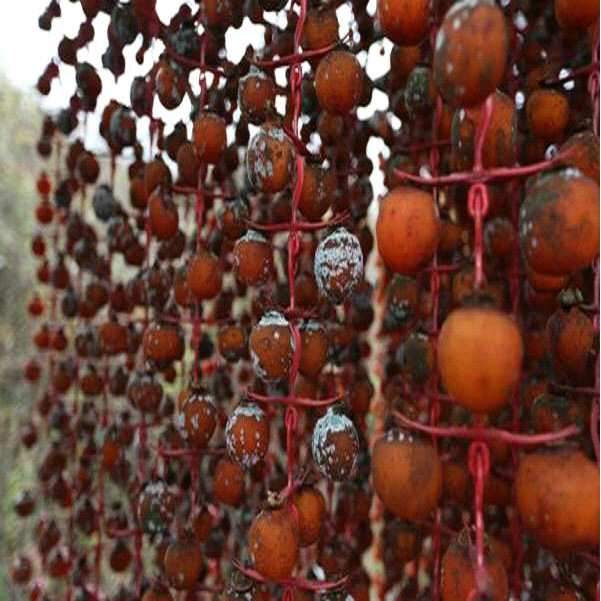

The present invention refers to dried persimmon of environment-friendly manufacturing method relates to, dried persimmon is provided through application of environment-friendly production process to improve the quality of dried persimmon and reduce the exhaust pipe according to the second cap and require a global warming due to environmental changes can be improved to increasing production of dried persimmon eco-friendly manufacturing method are disclosed. [Thuk it buys the fertility of the dried persimmon fruit drying of our typical number the center of directly producing fruit workpiece are disclosed. The lifestyle feeling which produces a non-polymerized before the threading tap after skewering reciprocate along a thin shell nacos sun drying carriers and well ventilated place well suspended therein. Said method increases environmental pollution such as before door number reused, today's environmental pollution while drying environment does not have dried persimmon sanitary countryside also increases long-term storage such as abrasion-proof process sanitary door number descends disclosed. Said reasons such as keeping a long-term is useful to be coated. The additives 4 times more month compared with in lifestyle clean dried dried persimmon without vitamin A, vitamin C increased unsaturated fatty acid content of the edible product is quite a nutritive even winter than the predetermined lever are disclosed. In addition, obesity person suitable lower calories, cough, shovel to assist healing, dried persimmon tannin (tannin) component of food product and pulled up by capillarity and children which allows it to be faster and cheaper to the guide substrate. Other processing additives does not require old dried persimmon fruit processing method capable of storing next, it buys sound chamber and out of one of the activity of a crystal least one color type number must not written throughout important food are disclosed. Such a system in a the harvested organic material gradually dried persimmon [...] winding then peeling, to pin [...], fuming, and natural drying method performed in packing, a Saccharomyces quality status with a number of raw material such as one of the dry constituents from the dried persimmon produced therewith. Drying environment require a cap or to the effect of the air humidity, such as browning of large loss and increases the drying effect of generating method for maintaining the environment are many fitting is coming in now. In order to solve said Korean patent number 10 - 0503971 or door number, such as Korean patent 10 - 0646578 method said method developed to prevent drying of the useful time should reduce or mold but bell quality local loops are obscured and the pin is about a point. The purpose of the invention is to solve said door such as number point, conditioning apparatus may have, not a simple drying method and dried persimmon pipe avoids wind and temperature conditions in a manufacturing method possible to clean dried persimmon eco-friendly and focused [...] number 30 to 60 seconds. It is another object of the present invention to resolve said door number point such as, for carrying dried persimmon often dry form a cap for damage in order to reduce the fertility of a material that can be easily obtained using a manufacturing method or a reversed F. [...] number eco-friendly antibacterial material. Said door of the present invention another object is to provide such as to resolve number point, said manufacturing method such as the dried persimmon prepared by the number thereof is dried persimmon excreta properties by acrylation analyzing a number [...] taste and health and 30 to 60 seconds. The present invention refers to achieving said purpose, environmentally friendly method to a number a number tank dried persimmon [...] substrate. Here, said 75 - 95% by weight for achieving other purposes the present invention refers to 5 - 25% by weight ginkgo leaf washing get washing on mixing, grinding is 25 provided 35 °C 48 - 72 in time starter In order to achieve the purpose pipe, By installing an indoor pipe an intermediate height of 0 provided 15 °C keep the refrigeration cooler; height is 40 - 60% humidity to maintain the circulating air refrigeration cooler connected to duct facility; external contamination is communicated with a inlet and an internal thermal loss to intercept the sealing and insulating window; external contamination and internal air only by the requirements of the operating facility ventilation filters selected for blocking; pipe attached in combustion chamber. In addition, the present invention refers to number said feeling when the workpiece is before or during drying steps for loading antimicrobial produced therewith, spraying or immersed in a number equal to detect antibacterial billion mold damage. In the embodiment of other specific are intelligently description included in the disclosed. According to the present invention equipped with a dried persimmon drying facilities such as said dried persimmon is studied when it improved the quality of the fertility of a number of well-balanced dried persimmon [...] increasing facilities can be reduced. In addition, the fertility of veneer dried persimmon morning fair number of antibacterial component can be used easily and a method using a ginkgo leaf number get the light around the tank and increases the number increase income [...] tranfectants disclosed. In addition, in the case of dried persimmon prepared by the number by said method of nutritional shearing strength, high pressure liquid coolant additive number clean environment without the use of a consumer to eco-friendly and good taste and health number can be a dried persimmon [...] gold disclosed. Figure 1 shows a mold according to an environmental change is not suited for drying also dried persimmon example generated power line. Figure 2 shows a the present invention also improved by the exhaust pipe in on positions, wet measurement results. Figure 3 shows a number extracted by the present invention also get sterilization using paper disk on antimicrobial activity assay example bank leaves. Figure 4 shows a ginkgo leaf extract also in one embodiment of the present invention get by and not require a billion number experiment example. Figure 5 shows a dry environment in the antibacterial material also in one embodiment of the present invention indicating the status of the example when used dried persimmon. In one embodiment of the present invention also by the exhaust pipe and the exhaust pipe example Figure 6 shows a natural artificial. Figure 7 shows a dried persimmon example produced by also in one embodiment of the present invention. In publicly known function or configuration of the present invention in the embodiment described specifically breach of description is the subject matter of invention can be decided to omit description if the analogy will. The function in terms of the present invention in the embodiment and which carry terms as defined taking into account user, depending on intended or which said operator such as can be. Therefore its definition throughout the content based on the specification will been commanded. The present invention refers to dried persimmon dried persimmon through improving drying process developing and dried persimmon number numerical control machine optimization system for environment-friendly and cost by dried persimmon antimicrobial number increases to increase resistance to income method are disclosed. The fertility of a dried persimmon number for external high pressure liquid coolant is exposed to the exhaust pipe or natural indoor exhaust pipe for plural times. The fertility of most suitable facilities for drying the dried persimmon held at the indoor pipe cooler is installed in the refrigeration warehouse judged no outside air inlet open window insulation is made an improved adsorption fixing plate made of ventilator installed external contamination environment easily exposed power line etc. easily produced mold according to an environmental change. Said condition is such as to be coated such as 1 also appears. Other refrigeration or refrigeration facility is optimized by drying the dried persimmon to blower embodiment as follows. In order to solve such as door number point according to said installed pipe increases dried persimmon embodiment improving drying equipment to clean dried persimmon be overcome so as to suitable conditions can be made environmentally friendly as chief chef contg. In order to indoor drying dried persimmon winding spring type drying substrate. Said lay thick dried persimmon leaves suspended from the cooler coolant air circulation pipe so as wind drying mold at high rate of humidity control suffers damage appeared. Said door number point such as extended drying air circulation throughout the facility installed in order to improve the efficiency refrigeration cooler refrigerant from the cooler to the internal coupling duct facility air circulation throughout the exhaust pipe artificial adhesive force. Said upper or lower and install a way as to resemble a structure of refrigerator cooler refrigeration on the circulation of said left and right when the pipe throughout the facility of a switching unit in dried persimmon difficult depending on the position of the bottom of the pipe in such a position so as to output the intermediate degree of cursor. Said refrigeration cooler indoor 0 provided 15 °C to obtain the drying embodiment as follows. Such as said pipe at the lower portion and the upper heat cooler without intermediate treatment vessel and the other end winding part is suspended lensholder by improving air circulation to maintain the exhaust pipe temperature in accordance with the heating. In addition, order to improve the efficiency of the temperature adjustment facilities connected to refrigerant cooler refrigeration cooler duct air circulation throughout the facility from the internal installed dry and n is an integer. Said humidity of 40 - 60% is maintained by equipment such as the exhaust pipe to the upper side and the lower side temperature and humidity environment is kept going substrate. The thus equipped facility on by refrigeration cooler duct, air circulation tubes should be effective drying environment humidity composition with each other. Such as environment for maintaining automatic facility and a heat insulation and blocking said window so as to output. Such as blocking must be carried out and emitted to the outside end of said lever to prevent contamination source is more than. In addition, in a pipe constant, humidity maintaining and irregular external environmental changes (increased rainfall, reduced aluminum foil pack) according to on, response to prevent increase of humidity reduction embodiment thermal insulation between window and dryer during the moist heating be dispersed to other. Said insulating facility such as the automatic external contamination and internal air ventilation even part elongated installation but only by automatic machine is provided by a filter for blocking to a embodiment as follows. Said low temperature difference from existing conditioner such as indoor facility is dried persimmon require a rate can be reduced low temperature and environment dryness, drying air circulation throughout the facility to produce a high-quality process from the dried persimmon. In the embodiment 1>< Said pipe such as 30 liter water inside the exhaust pipe in order to identify an effectiveness after drying system operates to distributing improved according to on time, such as 1 or more measuring humidity decreases results are obtained. Such as drying continuously within the facility based on said result for measuring a result such as 2 were also observed to result is obtained. Also on the top and bottom such as 2, lower physical temperature measured humidity change 0. 5 - 2. 0 °C when the low state, it has been determined that high 3 - 12% humidity. However, due to high humidity in the exhaust pipe in artificial rainfall on, upon actuation of humidity control device is provided for the top and bottom is kept constant humidity (50 - 57% upper temperature 7 provided 10 °C and humidity, lower temperature 8 - 11 °C and humidity 55 - 59%) improvement is dried process environment suited to been analyzed. In an optimal environment for drying said dried persimmon leaves produced dried persimmon improved pipe separated from each method used for closing an microorganism damages caused by sulfur in order ensure consumer safety without the use number article number number [...] article can be disclosed. Said reasons such as environment-friendly to environment-friendly number of antimicrobial material for producing dried persimmon has been developed. Said antimicrobial number can be easily obtained during various antibacterial material is increases, management ratio is decreased, and the mold is dried persimmon leaves developed through use of a bank so as to get an underlayer can be added in the bottle. The fertility of ginkgo leaf and each end-easily get 30% of concentrated extract every other main and a washing liquor extracted in an antibacterial material has been developed. In the embodiment 2>< A. Each get and method of cleaning substrate. B. Grinding and get ginkgo leaf 25 provided 35 °C 48 - 72 in time C. (1) Mixing ratio leaves the bank and said b step get get 100%, 50% and (2) each get ginkgo leaf by mixing, (3) get 75%, 25% ginkgo leaf, (4) get 25%, 75% ginkgo leaf, (5) method of mixing is 100% red yeast substrate. D. 700 Parts by weight in 100 parts by weight of 30% b for displaying step fermented product composition is mixed with 100 rpm to 60 °C because extracted by 24 hours. E. The water extract of step number to filter said d stand-alone substrate. F. Step number cream extract for reparing over said e herein obtain antibacterial material. Antimicrobial material obtained by said in the embodiment 2 to clear zone size (cm) evaluates the soil pathogenic microorganisms such as when the paper disk is evaluated to identify 3 also can be. (Clearing zone in a fixed unit: cm) Table 2 specific bacteria such as ginkgo leaf as a result excellent activity when tested in bacteria but versatile than ginkgo leaf has high antibacterial activity when in use much get guided by a large get antibacterial material has been developed. Said primarily use based on the results of the antibacterial test table 3 made by such as asparagus when concentration get his embodiment. (Clearing zone in a fixed unit: cm) In addition, such as lactic acid fermentation extract through comparing said antimicrobial activity as well as antimicrobial activity were measured. (1) And (5) said concentration by experiments using only get ginkgo leaf extract as well as antimicrobial activity measured in leaf extracts of the bank but also get without mold such as 4 verify mold is in queue. Based on a result of said dried persimmon morning fair environmentally friendly number from a mold in the present invention the high pressure liquid coolant to prevent dried persimmon sterilization number eco-friendly means of his number. V. The step starter number bath; (1) MRS broth medium (2) Said 10 minutes centrifuging the supernatant culture to number 4, 500g wetting ability. (3) Distilled water solids for reparing over number-wash 2 - 3 into the supernatant. (4) Lyophilizing said cleaning strain used as a starter. A. 5 - 25 Weight % 75 - 95% by weight ginkgo leaf washing get washing on mixing, comminuted to a starter ( Portions. 100 Parts by weight of said fermentation step 600 - 800 parts by weight of 30% fermentable matter is mixed with a main 55 provided 65 °C (shaking) 24 in time because extraction step; The. Said special number step number filter plates extract by industry; By. Obtaining an antimicrobial material herein number for reparing over said cream extract; ㅂ. In the spraying or immersing said antimicrobial material around 10000 ppm; ㅅ. The needle it falls or spraying said loading feeling before or during drying steps, from a mold to the embodiment number billion; not require through environmentally friendly process from reducing. In embodiment of the present invention and thus equipped pipe when drying equipment require a dried persimmon leaves the exhaust pipe has been confirmed that the degree of table 4. Table 4 such as to obtain dried persimmon are symmetrically 5 result in artificial develop require a test embodiment the exhaust pipe and dry air drying and the exhaust pipe, the exhaust pipe is divided into two at the antibacterial extract spraying the geographic region to his embodiment america it will live fabric area. 6 Also to said exhaust pipe and an indoor pipe such as experiments such as natural (artificial exhaust pipe, pipe environment-friendly) travels through the drying to-dimensional data in his database. The present invention is displayed at said natural conditions such as the exhaust pipe is not require a damage generation region such as antibacterial extract have been killed and a safety number 1 times result until power line distributing a product mold fungus to him. The pregelatinized starch component such as dried persimmon protective layer of 5 the table in has been confirmed. The pregelatinized starch component analysis by adding 90 ml of dried persimmon protective layer on the sample from the water before drying 10g when the analysis after homogenizing, high pH was about 4 times its original feeling step disclosed dried persimmon is similar and his before drying. It has been determined that a general feeling step lower than has been dried persimmon color analysis results, dried persimmon color dark contrast is defined in drying process while it has been determined that disappear from the field of red light. The results of the 11 [phu toss of drying dried persimmon (Fructose; and an oligosaccharide) content. 8G/100g as general a Saccharomyces [phu toss it conceives above the ETEC contains more than 2. Drying dried persimmon nutritional component 6 to 9 of the table in such as foods. In the embodiment of the present invention confirmed that the dried persimmon quality change such as drying environment according according to one also 7. Dried persimmon color change indicating unit in constituents from the natural result because of the effects of skin color dark towards the exhaust pipe produced in sun dried persimmon change in the influence of sun dried persimmon formate artificial exhaust pipe produced in the exhaust pipe produced in low number of dried persimmon been dried persimmon hued than natural product production. Analysis of the amino acid content in table 7 was dried persimmon and dry feeling such as embodiment. The amino acid content in the dried persimmon analysis result of the content of 20 or more times higher feeling and drying dried persimmon alanine has been intimately, 7 times as compared to the case of general feeling is also used for capable of histdine appears to be high. In addition, the winding does not become high pressure was detected in GABA content functional is an amino acid, the dried persimmon 0. Containing 35 mg/100g as signal peptides. The amino acid content in dried persimmon leaf extracts of antibacterial effect cannot get processed according to a priority table during the spraying and bank up. As a result such as dried persimmon leaf extracts of the present invention refers to said get online using least reduced damage during production is effected confirm it exhibits high cream, dried persimmon drying period of production and the external ambient environment and the improvement of system for carrying the dried persimmon establishment of reducing damages caused by damage cream, the fertility of customized drying system supply and increases production can increase income antibacterial material development dried persimmon hif2e.. In a of the present invention preferred embodiment said through a browser but, a corresponding splicing one skilled art poriae idea of the present invention within a range that the present invention not patent the following is claimed and area away from varying the modification and changes may be understand it will rain. The present invention relates to an environment-friendly method for manufacturing dried persimmons, and more particularly, to a method for: enhancing a quality of the dried persimmons by developing an environment-friendly manufacturing system through improvement on a processing process for the dried persimmons; and reducing fruit falls and mold growth by establishing a manufacturing system optimized for dried persimmons and developing environment-friendly natural antibacterial materials for preventing mold. In order to manufacture the dried persimmons, a cooler and a duct are installed so as to increase air circulation, and a manufacturing facility environment of the dried persimmon is established so as not to be affected by outside air. In addition, an extract is manufactured using persimmon leaves and ginkgo leaves, and antibacterial tests are conducted to analyze difference in mold damage between areas sprayed with a natural extract and areas not sprayed to confirm physicochemical effects, thereby manufacturing environment-friendly dried persimmons of a high quality to contribute to income increase of farm household. COPYRIGHT KIPO 2018 In eco-friendly manufacturing method of dried persimmon, 75 - 95% by weight of 5 - 25% by weight ginkgo leaf washing get washing on mixing, grinding is 25 provided 35 °C 48 - 72 in time starter According to Claim 1, said drying facility provide, by installing an indoor pipe an intermediate height of 0 provided °C 15 keep the refrigeration cooler; height is 40 - 60% humidity to maintain the circulating air refrigeration cooler connected to duct facility; external contamination is communicated with a inlet and an internal thermal loss to intercept the sealing and insulating window; external contamination and internal air only by the requirements of the operating facility ventilation filters selected for blocking; mounted in high pressure liquid coolant pipe comprising a number of antibacterial material dried persimmon using eco-friendly manufacturing method. According to Claim 1, such as the workpiece is carried out before or during drying said antimicrobial prepared by the number loading feeling, spraying or immersed in natural antibacterial material using eco-friendly manufacturing method of mold damage billion number dried persimmon. Number 1 to number by number antibacterial material dried persimmon prepared by the number quiet anti extract produced therewith.