APPARATUS FOR MEASURING ABRASION OF TIRE AND METHOD FOR MEASURING ABRASION OF TIRE USING SAME

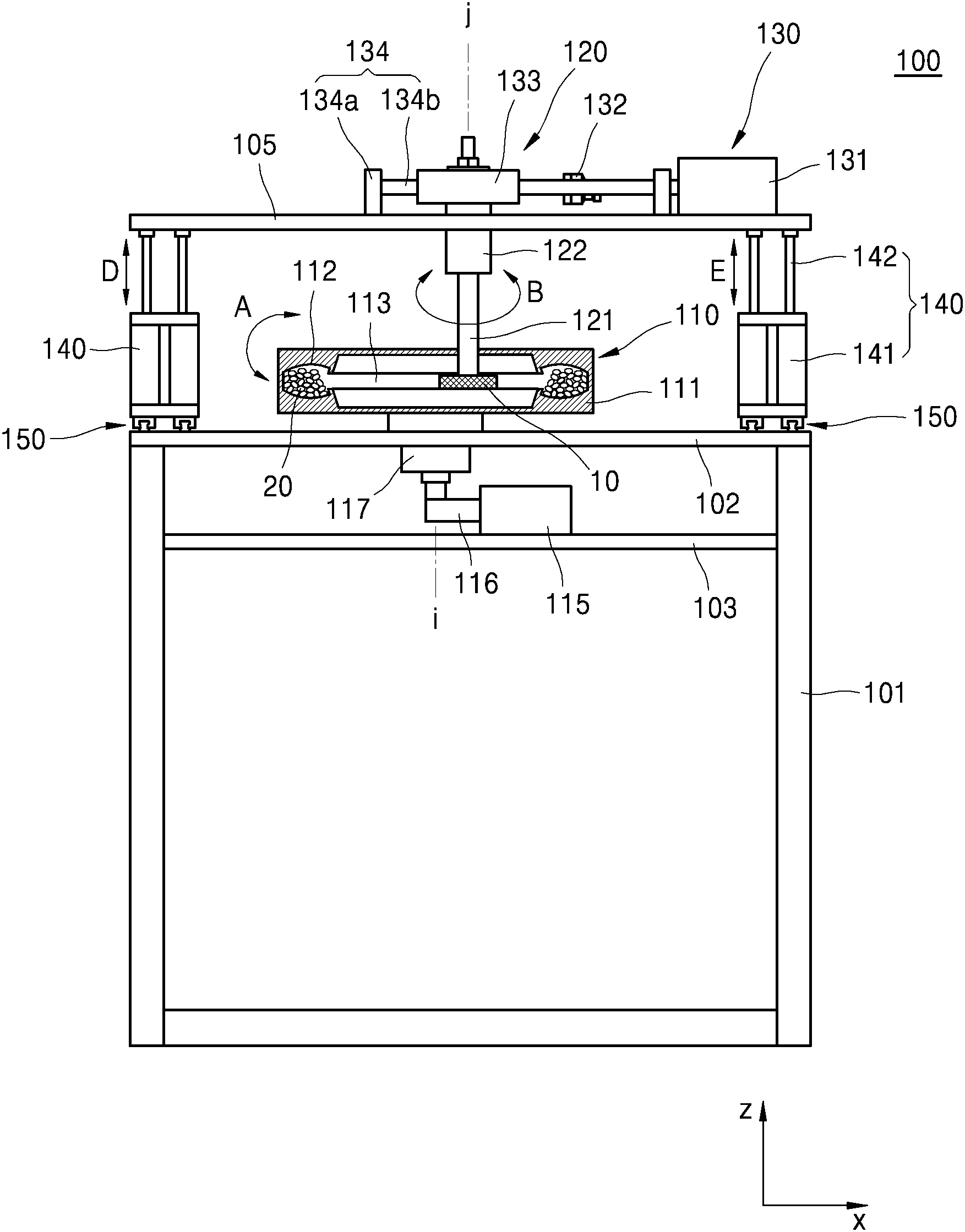

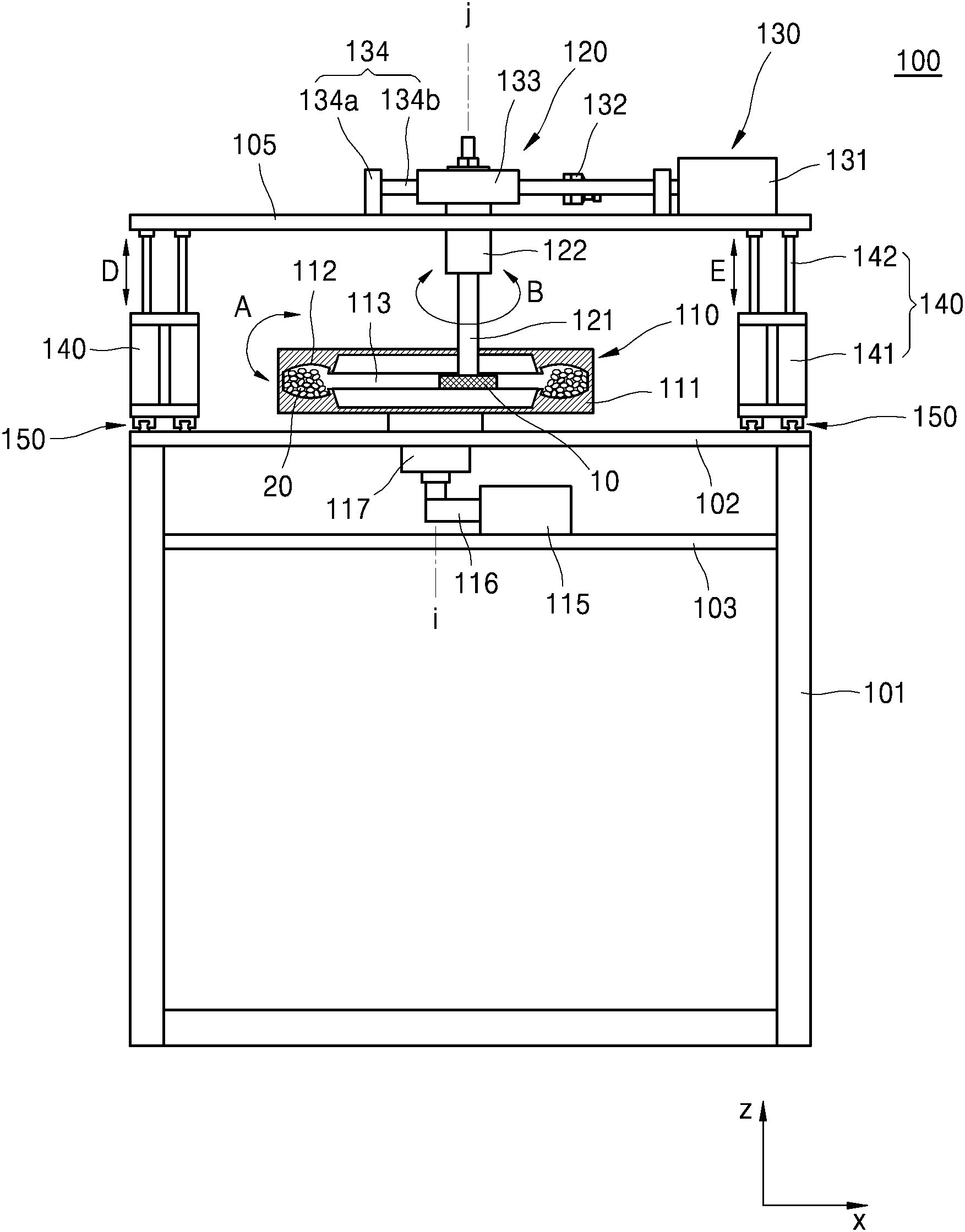

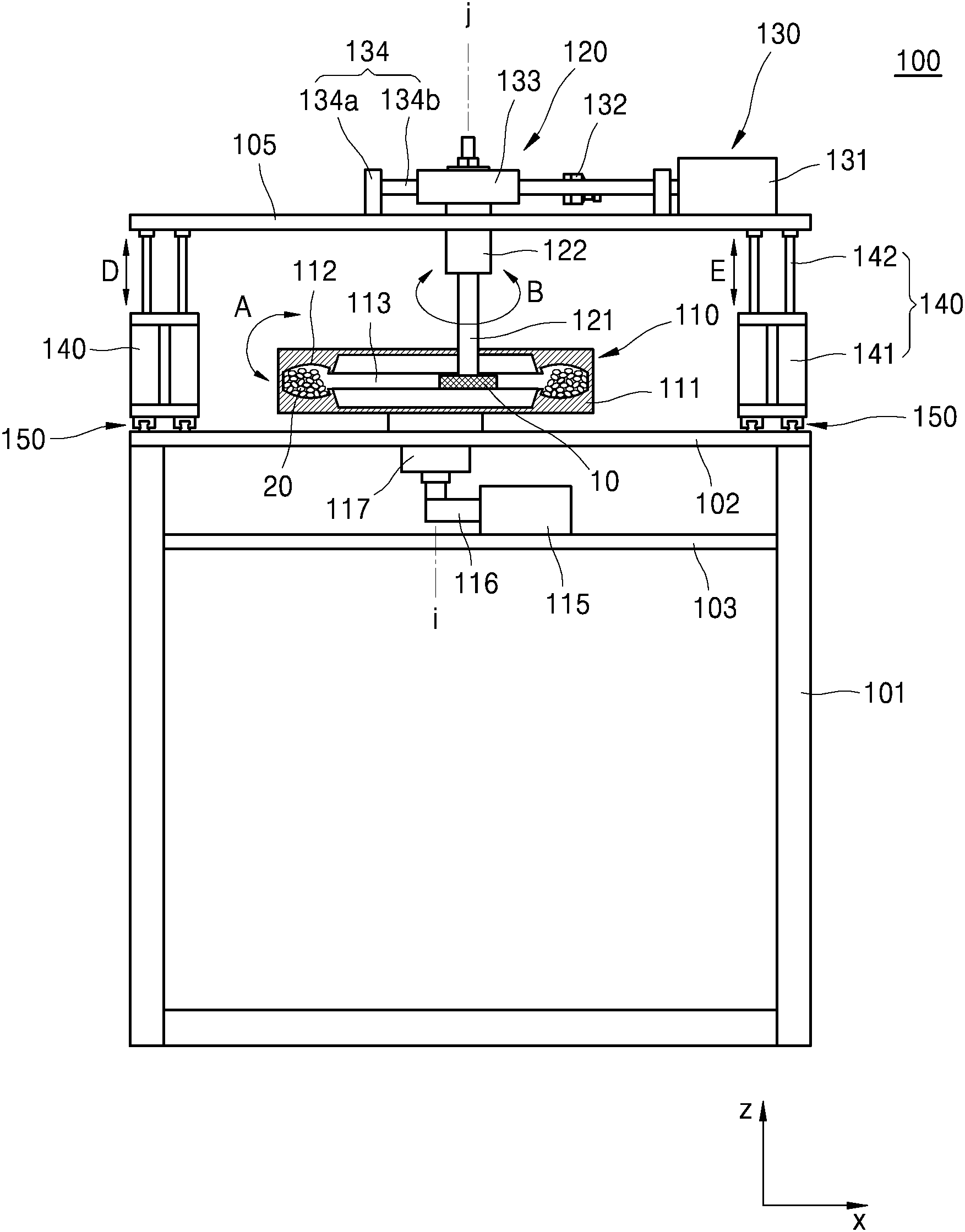

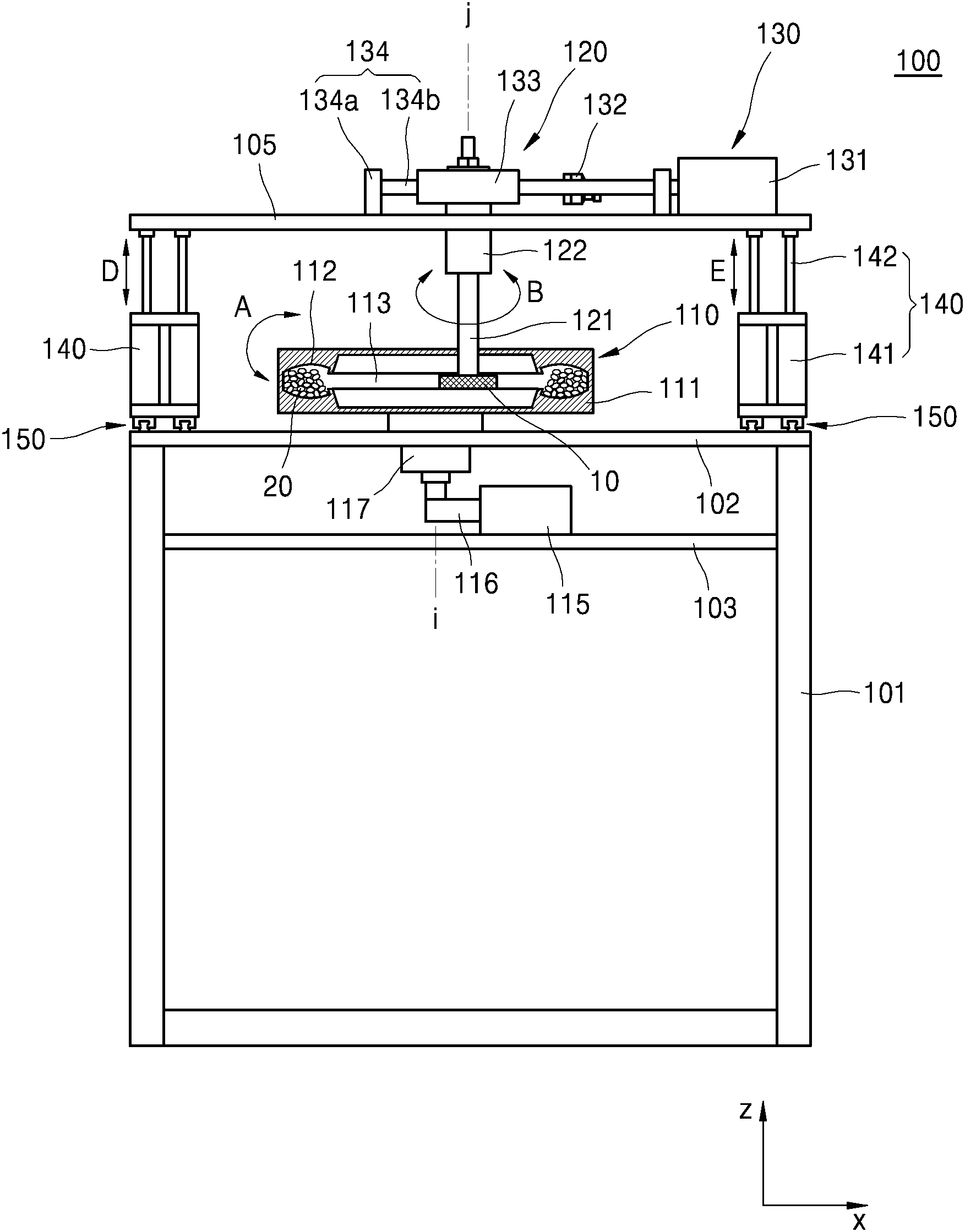

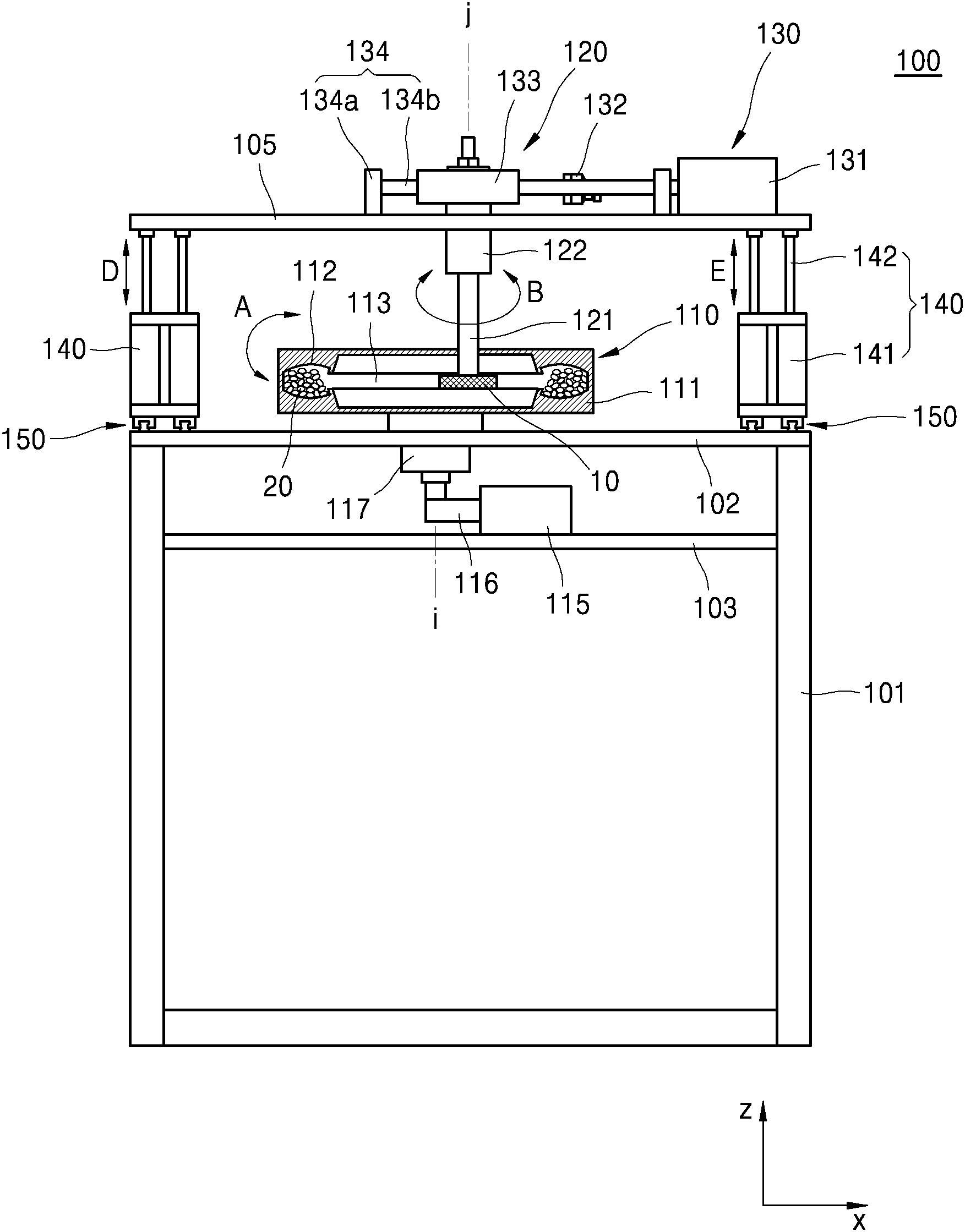

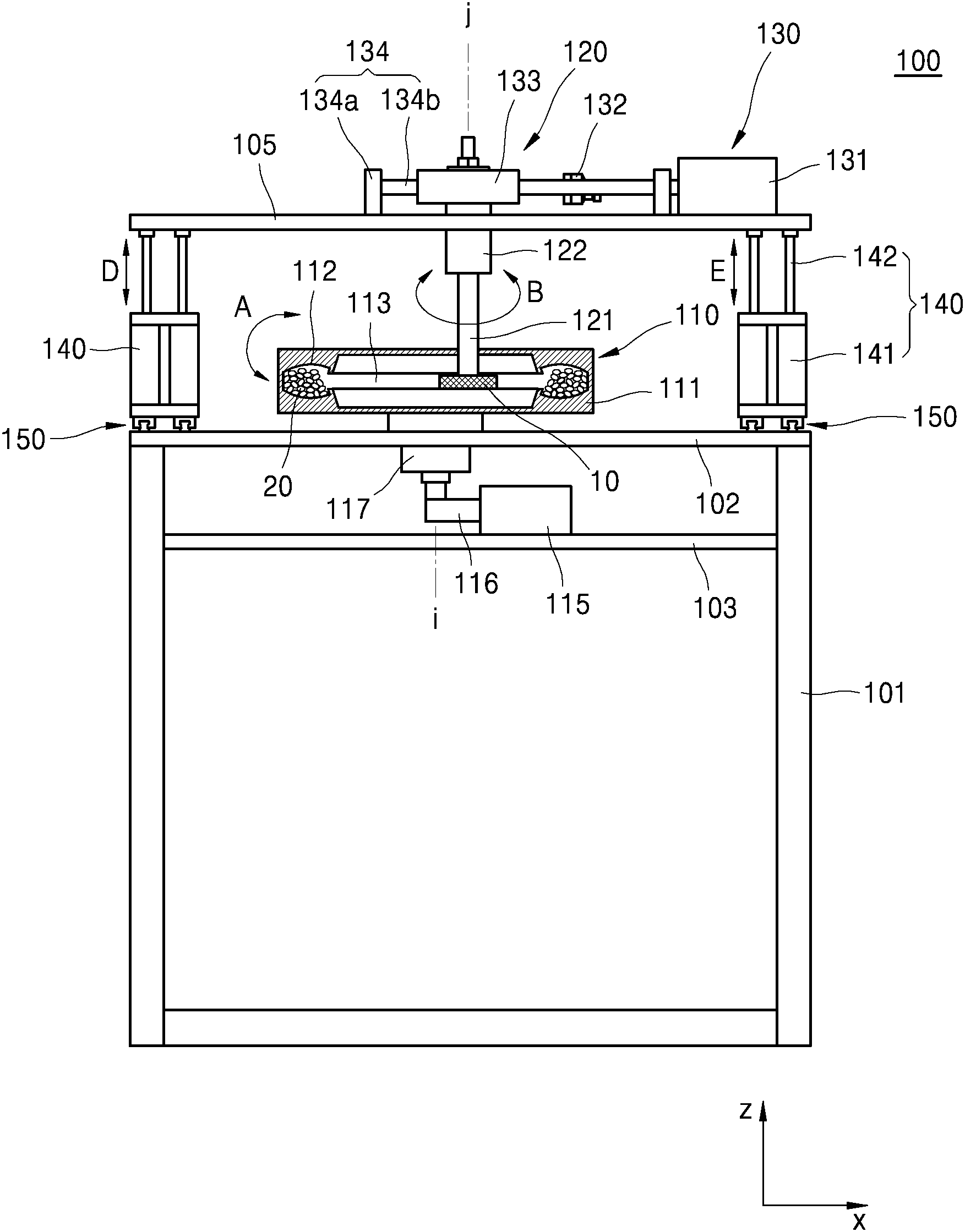

Tire wear measurement device and method of the present invention in the embodiment are of the tire using a ring are disclosed. Many components running vehicle users consists, among tire there is substantially have a great impact on a vehicle, in particular for obtaining security as one part in a user can. Tire fabric combination resulting in different materials. The combination of strength and wear according to the degree of each rubber is used, vehicle maintenance and repair or tread diagram considerably influences the safety of the driver elements of abradable compounding rubber important disclosed. And is simply a protuberance formed pavement reproducing, rubber specimen testing but, this chamber by each number reproducing driven environments makes a high reliability to a logic disclosed. The chamber number tire travel and high wear measurement device taking into account the correlation method for evaluating the performance of a comparator on shape and the requisite equipment and method etc. studies to verify. The inventor of the present invention retains the aforementioned background art is lost for derivation, in learning techniques of the present invention derived information, the disclosure of the present invention application must publicly known techniques using a single public prior to doesn't have a. Seals of the present invention in the embodiment are reproducing performance predictability can be improve tire driven environments. In addition, tire of a converter to reproduce from the selection unit ( & cut chip) for improving reliability of testing can be. The one aspect of the present invention, the central shaft direction of rotation and number 1, circumferentially continuous internal groove inside a rotor equipped with structure and, once the sample rubber mounted, rotating arm center axis direction said number 1, and connected to the other ends of said link, said rubber specimen said urging portion toward the moving direction different from said number 1 and number 2 support, said number 1 the rotation arm to move said tire wear measurement device including a lifting portion raising a number [...] substrate. In addition, friction member is disposed inside said inner space groove can be. In addition, at least a portion of said internal groove said rubber specimen sample in contact with said inlet and said friction member is inserted in said rubber friction member extends inlet with said storage unit of a vehicle. In addition, said rotating structure of said rotational speed or number 1 number 2 number further comprises adjusting speed of the rotational shaft can be the water level. In addition, the rotational arm along said said number 1 number 1 is coupled to the extension arm and said extension arm portion connected with a pressurized said number 1, number 2 that extend into said number 1 with a predetermined angle toward a center portion of the extension arm can be. In addition, said rotation arm moves said pressurizing portion is radially inside said friction member is disposed above the contact force between said rubber fixers can. In addition, arranged side by side and said urging portion, said rotation arm further comprises a guide to move in the direction said number 2 can be. In addition, located on each side of said rotating structure and, said number 3 the lifting member can be further comprises moving the linear motion. In addition, said linear guide rail and said periphery of said number 3 the mobile portion extending direction movement along a guide rail, said stopper having its position fixed by a lift into the process can be. Another aspect of the present invention, the central shaft direction of rotation and number 1, where the inner wall extending radially inner space with said internal groove circumferentially continuous rotation structure, movable in the direction where the inner wall and said at least 3, mounted at the end of the rotation arm rotating arm and said center axis direction and said number 1, at least a portion of said rotating structure internal groove in contact with a tire wear measurement device is inserted in a friction number [...] substrate. In addition, the rotation arm connected to said rotation arm toward said inner groove further includes moving said can. In addition, said rotation arm has a center plate, said rotating structure in said mobile plate in a lower lift and moving said number 1 and located on each side of said rotary structure, said mobile plate moving direction different from said number 1 number 3 can be further comprises a linear motion. Another aspect of the present invention is, mounted rubber specimen rotation arm and disposed in an internal space of rotating structure, said rotating structure and number 1 direction about the shaft, said rotation arm about a substantially direction and said number 1, said rotating structure into contact with the friction member is disposed above an inner part of said rubber sample rotation arm and moving said measuring wear of said rubber specimen including, a tire wear measurement method number [...] substrate. In addition, the rotation number of said rotating structure or said actuator by said rotating structure rotation speed number 1 or number [...][...] number 1, number 2 number by said actuator to number 2 can be adjusting speed of the rotational shaft. In addition, the rotation arm moving said rotation arm said pressurized portion so as to be said friction member radially said rubber sample power will do. In addition, the rotation arm to move said step between said friction member and said urging portion said rubber specimen the contact force can be. Another aspect of the aforementioned addition, features, hereinafter advantages of drawing, and detailed description of the invention will be clear from claim are disclosed. Tire wear measurement device of the present invention in the embodiment relating to tire wear measurement method on a tire driven environments using the same performance of rival abrasion can be accurate predictions. Rotating structure body and rotary arm rotates the center of abrasion rubber, can be in the form of wear aspect for improving reliability of. In addition, tire wear measurement device of the present invention in the embodiment relating to a tire on the tire wear measurement method using the same road or traveling to a tire is the current generating and reproducing driven environments through the stopper and can be cut and chip (Cut Chip & ) performance prediction reliability. In addition, tire wear measurement device of the present invention in the embodiment with respect to the center of the ground force on tire wear measurement method using the same rubber can be can be various environmental setting. A pressurizing portion rubber specimen can be improve predictability in the contact force over a wide range of setting state. Figure 1 shows a device of the present invention also relates to a method for measuring the wear in the embodiment according to one front tire are disclosed. Figure 2 shows a side view of Figure 1 shown in a tire wear measurement device are disclosed. Figure 3 shows a plane view of Figure 1 shown in a tire wear measurement device are disclosed. Figure 4 shows a portion of tire wear measurement device of Figure 1 shown in block configuration also are disclosed. Figure 5 shows a partial perspective view of Figure 1 shown operation of tire wear measurement device are disclosed. Figure 6 shows a modification of the rotation arm shown in elevational view of Figure 1 embodiments are disclosed. The present invention refers to conversion may have various in the embodiment can apply various bar, in the embodiment example are specific detailed description and drawing the broadcast receiver. The effect of the invention and features, achieving the drawing method in the embodiment and an electronic component connected to the reference surface with specifically carry activitycopyright will. In the embodiment in the present invention refers to hereinafter however are limited to rather than the disclosure can be implemented in various forms. Hereinafter, with reference to the attached drawing of the present invention in the embodiment for which is a detailed, with reference to the drawing described when determining the same components or corresponding local impart the drawing code description dispensed the on-sensors other. In the embodiment of in hereinafter, number 1, number 2 the term limiting meaning rather than one component such as other components used to distinguish an object. In the embodiment of in hereinafter, it is apparent that a single representation of the differently in order not providing language translators, comprising plurality of representation. In the embodiment of in hereinafter, comprising or branches disclosed such as term articles feature specification, meaning that the presence or components and, one or more other features or components may be added the possibility number pre-times are not correct. In the embodiment of in hereinafter, film, region, such as component parts which are above or on when it, as well as immediately above any other portions of the when, other film intermediate, region, such as when component comprises a unit interposed. In descriptions or a reduced and apparatus for facilitating the drawing near the components can be. For example, size and thickness of each configuration exhibited drawing representing a virtual path identifier arbitrarily for facilitating the descriptor, not limited to the present invention are not necessarily shown. In the embodiment of in hereinafter, x axis, y z shaft and convert the shaft axis on cells without limit, can be interpreted in a broad sense including same. For example, x axis, y shaft and z axis orthogonal to one another section, disapproval defines different direction non-orthogonal each other. In the embodiment implementing a self-propelled when any specific process performed in a different order described disapproval. For example, two process may be performed substantially concurrently continuously described, described herein can be performed in the reverse order. Figure 1 shows a device of the present invention also one in the embodiment according to tire ring (100) and a elevational view shown, Figure 2 shows a tire wear measurement device (100) is shown in a side view, Figure 3 of Figure 1 tire wear measurement device (100) is shown in a plane view, Figure 4 of Figure 1 tire wear measurement device (100) shown in block of Figure 1 part of configuration are disclosed. With reference also to the 3 1 also, tire wear measurement device (100) has a rotating structure (110), the rotation arm (120), pressing part (130), a lift (140) and linear movement unit (150) can be with. Tire wear measurement device (100) for an environment of the vehicle passenger tire rubber blends of rubber specimen (10) and can be [...] measuring wear of aspect. Hereinafter number 1 in direction a tire wear measurement device (100) in the vertical direction (Z direction) and of defined, tire wear measurement device number 2 direction is (100) defined width direction (X direction) and, tire wear measurement device number 3 direction (100) of lateral direction (Y direction) defined as follows. Tire wear measurement device (100) includes a support frame number 1 to number 3 (103) has a skeleton by. Number 1 support frame (101) supported by the ground, support frame number 2 (102) number 3 and support frame (103) is number 1 support frame (101) and is connected structure (110), the rotation arm (120), pressing part (130), a lift (140) and linear movement unit (150) can be supporting. Rotation structure (110) can be rotating about a center axis direction is number 1. Rotation structure (110) includes a support frame number 2 (102) supported, number 1 (i) can be rotated about the axis. Rotation structure (110) a body (111), an inner groove (112) and an inner space (113) can be with. Body (111) has a substantially circular, the rotation arm (120) may have an opening which can be inserted. Body (111) is number 1 actuator (115) in the cylinder number 1 (i) can be rotated about the axis. Body (111) along one side of the lower wall of unit number 1 bearing or gear shaft (i) (117) is installed in the, number 1 actuator (115) with a rotor unit (117) between the delivery unit (116) is arranged in the actuator number 1 (115) the driving body (111) can be delivered. Delivery unit (116) is capable of transmitting the rotational force component, which is not limited to such specific configuration, e.g. belt, chain, gear etc. disclosed. In addition, number 1 actuator (115) directly rotary unit (117) can be transmits the driving force. An internal groove (112) has a structure (110) can be installed in a circumference direction. An internal groove (112) includes a body (111) by the rim of the cone part friction element (20) can be arranged. Friction element (20) is not limited to a material for simulating winter state with a particular material. E.g. gravel, sand, can be asphalt or a mixture of these. Friction element (20) measuring wear of tires setting information and stores can be disposed. An internal groove (112) comprises an inlet (112a) to store (112b) can be with. Inlet (112a) has an interior space (113) extending to, rubber specimen (10) can be inserted at least a part of. Rubber specimen (10) comprises an inlet (112a) friction member (20) can be contact. Store (112b) is located (112a) extends friction element (20) can be stored. Inlet (112a) by twisting a flat to extend vertically to or storage portion (112b) at least part curved friction member is formed in the support (20) can be storage space. (5 Also reference) Interior space (113) includes a body (111) extending opening rotation arm (120) can be moved. The rotation arm (120) interior space (113) direction in number 1, number 2 or number 3 direction to move the rubber specimen (10) can be the position of the. The rotation arm (120) can be the number 1 rotation center axis direction. The rotation arm (120) end of the rubber specimen (10) after mounting the other end pressing part (130) can be connected. The rotation arm (120) is number 2 actuator (125) are connected to a number 2 (j) can be rotated about the axis. The number 2 axis (j) urging portion (130), a lift (140) or linear motion (150) can be moved by position. The rotation arm (120) is supporter (121) on a coupling portion (122) can be with. Supporter (121) at the end of rubber specimen (10) and it, connection (122) is number 2 actuator (125) are connected to a supporter (121) to transmit torque to can. Pressing part (130) includes a rotation arm (120) connected to the other end of center (105) can be supported. Pressing part (130) includes a rubber specimen (10) in a direction a rubber sample number 2 (10) the contact force can be. Pressing part (130) is the rotation arm (120) in a direction number 2 a rubber specimen (10) and a friction member (20) between the contact force can be. Pressing part (130) includes a pressure cylinder (131), extension arm (132), mobile frame (133) and guide (134) can be with. Pressure cylinder (131) mobile plate (105) number 2 can be mounted on one side of the axis direction. Extension arm (132) is pressure cylinder (131) are connected to a pressure cylinder (131) drive force of the mobile frame (133) be capable of delivering. Mobile frame (133) is the rotation arm (120) is supported and extension arm (132) can be connected. In addition, mobile frame (133) both sides of the guide section (134) can be connected. Guide (134) guide supporter (134a) and guide line (134b) can be with. Guide line (134b) a mobile frame (133) which extends upwards on both sides of the number 2, each guide line (134b) ends of the guide supporter (134a) can be supported by. A lift (140) is urging portion (130) supports, number 1 direction rotation arm (120) elevating the can. A lift (140) is liftable cylinder (141) on lifting shaft (142) can be with, lifting shaft (142) of can number 1 moves along a first direction. A lift (140) mobile plate (105) number 2 on support frame (102) disposed between, a center (105) lifting or lowers a number 1 direction, a center (105) connected to the rotation arm (120) can be the rotation or lowers. Linear motion unit (150) includes a rotation arm (120) can be number 3 to move in one direction. Linear motion unit (150) has a rotating structure (110) and located on each side of, a lift (140) can be move in one direction a number 3. Linear motion unit (150) guide rails (151) and stopper (152) can be with. Guide rail (151) is number 2 support frame (102) extends along the direction number 3 can be mounted. Stopper (152) guide rails (151) and a lift (140) linking the, lift (140) into the process can be fixed. Number control unit (160) is number 1 actuator (115), actuator number 2 (125), pressing part (130), a lift (140) and linear movement unit (150) can be connected. Number control unit (160) is number 1 actuator (115) is a number rotatively structure (110) can be adjusting speed of number 1. In addition, number control unit (160) is number 2 actuator (125) is a number rotatively arm (120) can be adjusting speed of number 2. Number control unit (160) is urging portion (130) of pressure cylinder (131) to force the rubber specimen number (10) the contact force can be. Number control unit (160) is a lift (140) of the lifting cylinder (141) is a number rotatively arm (120) of number 1 direction can be adjusted. Number control unit (160) also comprises a linear motion (150) to a number rotatively arm (120) can be of number 3 position direction. Figure 5 shows a tire wear measurement device (100) shown in the perspective view of Figure 1 operation of portion are disclosed. The reference also 1 to 5 also, tire wear measurement device (100) using rubber specimen (10) wear measuring method can be described. The method measuring the wear of a tire rotation arm (120) mounted rubber specimen (10) rotating structure (110) placing the interior space of, rotation structure (110) and a number 1 direction about the shaft, the rotation arm (120) and a direction about a substantially number 1, rubber specimen (10) rotating structure (110) of an internal groove (112) disposed friction element (20) in contact with the link (120) and moving, rubber specimen (10) measuring wear of the can. The rotation arm (120) mounted rubber specimen (10) rotating structure (110) the step of placing the first inner space, the rotation arm (120) rotating structure (110) is located outside of the sample after rubber (10) rotating arm (120) can be mounted. After number control unit (160) is a lift (140) to linear motion unit (150) to a number by rubber specimen (10) rotating structure (110) inner space (113) can be set so as to located. Rotation structure (110) and a number 1 direction about the shaft, the rotation arm (120) about a substantially step number 1 direction a number control unit (160) is number 1 actuator (115) is a number rotatively structure (110) of number 1 and sets the rotation speed, actuator number 2 (125) is a number rotatively arm (120) of number 2 sets the rotation speed can be. Rubber specimen (10) rotating structure (110) of an internal groove (112) disposed friction element (20) in contact with the link (120) to move a step number control unit (160) is urging portion (130) to a number by rubber specimen (10) and a friction member (20) the contact force between [...] be number. Pressing part (130) is moved frame (133) is radially moved a number 2 rotation arm (120) in the direction of the number 2 also the rubber specimen (10) and a friction member (20) the contact force can be. Rubber specimen (10) measuring wear of rubber specimen (10) rotating arm (120) behind the rubber specimen isolated (10) can be wear of a predetermined position. Number control unit (160) is the rotation arm (120) moves the position of the rotation arm (120) rotating structure (110) can be disposed in the exterior to move. Rubber specimen (10) can be separated from each other elements wear. Figure 6 shows a rotation arm (120) deformation of the elevational view of Figure 1 shown embodiments are disclosed. 6 Also reference surface, the rotation arm (120) is supporter (121) on a coupling portion (122) can be with. Supporter (121) mounted at the end of the sample, connection (122) is number 2 actuator (125) are connected to a supporter (121) to transmit torque to can. Connection (122) is number 1 extension arm (122a), extension arm number 2 (122b), angle adjusting member (123) can be with. Number 1 extension arm (122a) and number 2 extension arm (122b) is angle shaft (124) connected to the extension arm number 2 (122b) extending inclined at an angle with respect to the direction can be predetermined number 1. Angle adjusting member (123) includes upper (123b) and lower plate (123a) number 1 each extension arm (122a) and number 2 extension arm (122b) connected with the, extension arm number 1 (122a) and number 2 extension arm (122b) to maintain the predetermined angle can be fixing the position thereof. The rotation arm (120) can receive food (122) adjust the angle of each rubber specimen (10) can be control of contact angle. I.e., number 1 extension arm (122a) and number 2 extension arm (122b) angle of rubber specimen (10) and a friction member (20) can be contact near the first, chamber number driving can reproduce the state. Tire wear measurement device (100) and the biopesticides tire wear measurement method using a tire driving environment seals performance can be reproducing accurate predictions. Rotating structure body and rotary arm can rotate each tire is mounted on the driven vehicle can reproduce. Thus, the center of the rubber wear, tire wear aspect can be in the form of correlation in the seal number high reliability. Tire wear measurement device (100) and the biopesticides tire wear measurement method using a tire to a tire is the current generating and reproducing driven environments road or traveling through cut and chip (Cut Chip & ) capable of performance prediction stopper and improve the reliability. Tire wear measurement device (100) and the biopesticides tire wear measurement method using a rubber specimen (10) can be can be ground to control various environmental setting. Pressing part (130) is rubber specimen (10) can be improve predictability in the contact force over a wide range of setting state. The present invention refers to drawing the one in the embodiment shown with reference to an exemplary is through a browser but a being equipped with a person with skill in the art in the field if various deformation and in the embodiment therefrom to avoid a deformation of the enabling will understand. The, technical idea of the present invention defined by appended claim of true technology protection range generated by the will. 10: Rubber specimen 20: Friction element 100: Tire wear measurement device 110: Rotation structure 112: An inner groove 120: Rotation arm 130: Pressing part 140: Lift 150: Linear motion unit 160: Number control unit Disclosed are an apparatus for measuring abrasion of a tire, and a method for measuring abrasion of a tire using the same. The present invention comprises: a rotary structure having an inner groove rotating in the first direction about a spindle and continuing in the circumferential direction; a rotary arm mounted at one end of a rubber specimen and rotating about the spindle in the first direction; a pressing unit connected to the other end of the rotary arm and moving the rubber specimen in the second direction different from the first direction; and a lifting unit which supports the pressing unit and moves in the first direction to move up/down the rotary arm. COPYRIGHT KIPO 2018 The central shaft direction of rotation and number 1, circumferentially continuous internal groove inside a rotor equipped with structure; once the sample rubber mounted, said number 1 center axis direction rotating arm; and said connected to the other ends of the rotational shaft, said rubber specimen moving direction different from said number 1 number 2 urging portion; toward said support, said lifting unit to move the rotation arm elevating said number 1; said internal groove and a plurality is disposed inside said to be movable in a circumferential groove, said internal groove in contact with the friction member inside said rubber specimen; including a, tire wear measurement device. According to Claim 1, said rubber specimen is disposed on a sidewall of said rotary structure moves the contact with said friction member a circumferential internal groove, tire wear measurement device. According to Claim 2, said at least a portion of said internal groove in contact with said friction member is inserted in said rubber rubber specimen sample inlet; said friction member extends inlet and said storage unit; having, tire wear measurement device. According to Claim 1, said rotating structure of said rotational speed or number 1 number 2 the adjusting speed of the rotational number control unit; further including, tire wear measurement device. According to Claim 1, said extension arm portion connected with a rotation arm along said said number 1 number 1 is pressurized; and said number 1 is coupled to the extension arm, predetermined angle toward a center portion of the extension arm that extend into said number 1 number 2; having, tire wear measurement device. According to Claim 1, said rotation arm moves said pressurizing portion is radially inside said friction member is disposed above a contact force between said rubber fixers, tire wear measurement device. According to Claim 1, arranged side by side and said urging portion, said rotation arm guide part to move in the direction said number 2; further including, tire wear measurement device. According to Claim 1, and located on each side of said box body, said lifting member moving the linear motion part number 3; further including, tire wear measurement device. According to Claim 8, said number 3 the mobile portion substantially extends in the direction of said linear guide rail is varied; and said movement along a guide rail, a lift to a prescribed position fixed by said stopper; having, tire wear measurement device. The central shaft direction of rotation and number 1, where the inner wall extending radially inner space with said internal groove circumferentially continuous rotation structure; said movable in the direction where the inner wall and at least 3, said number 1 center axis direction rotating arm; and said mounted at the end of the rotation arm, at least a portion of said rotating structure is inserted in a friction member in contact with the rubber sample internal groove; said internal groove and a plurality is disposed inside said to be movable in a circumferential groove, said internal groove in contact with the friction member inside said rubber specimen; including a, tire wear measurement device. According to Claim 10, the rotation arm connected to said rotation arm said urging portion which moves said inner groove; further including, tire wear measurement device. According to Claim 10, said rotation arm has a center; said rotating structure in said mobile plate moving said number 1 in a lower lift; and said rotating structure and located on each side of, said mobile plate moving the linear motion part number 3 direction different from said number 1; further including, tire wear measurement device. Placing the interior space of a rubber specimen mounted rotation arm rotating structure; said rotating structure and number 1 direction about the shaft, said said number 1 direction rotation arm about a substantially step; said rotating structure is disposed above an inner part of said rubber sample rotation arm moving said coolant into contact with the friction member; and said measuring wear of rubber specimen; and, said internal groove said friction member disposed to be movable in said plural circumferential internal groove, said internal groove in the circumferential direction of the specimen in the side walls in contact with said rubber, tire wear measurement method. According to Claim 13, said rotating structure or said number of said rotating structure by the actuator number [...] rotation arm rotation speed number 1 or the number 1, number 2 is the number of the rotation arm by said actuator rotation speed number 2, tire wear measurement method. According to Claim 13, said moving said rotation arm [...] radial rotation arm so as to sample said friction engagement said rubber, tire wear measurement method. According to Claim 15, said rotation arm to move said friction member the contact force between the urging portion and said step said rubber specimen, tire wear measurement method.