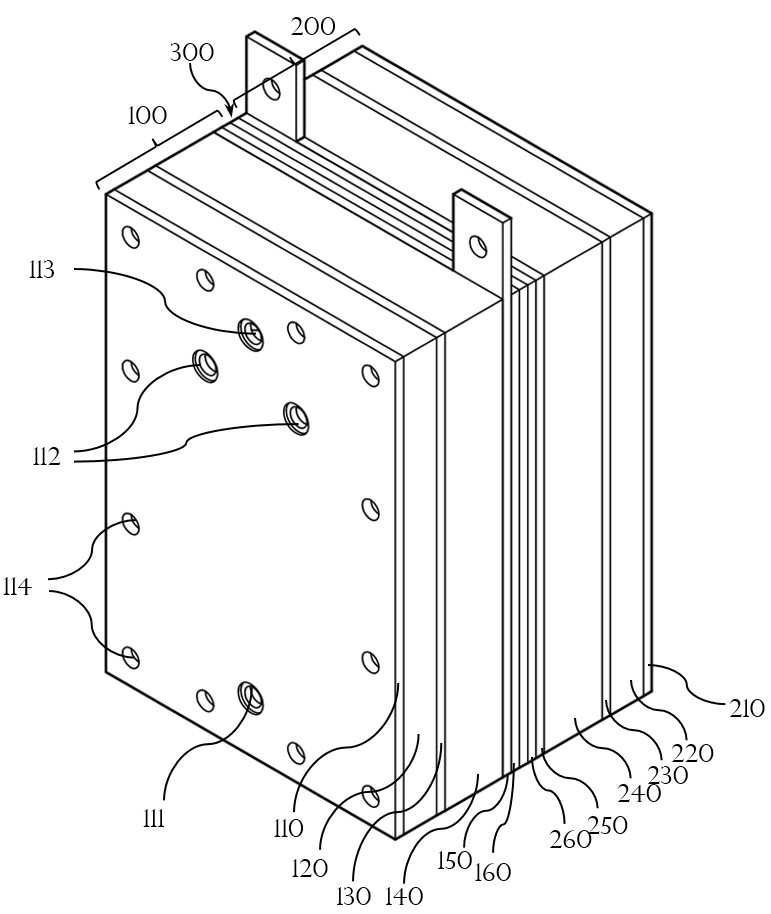

ELECTROLYTIC OXIDATION APPARATUS

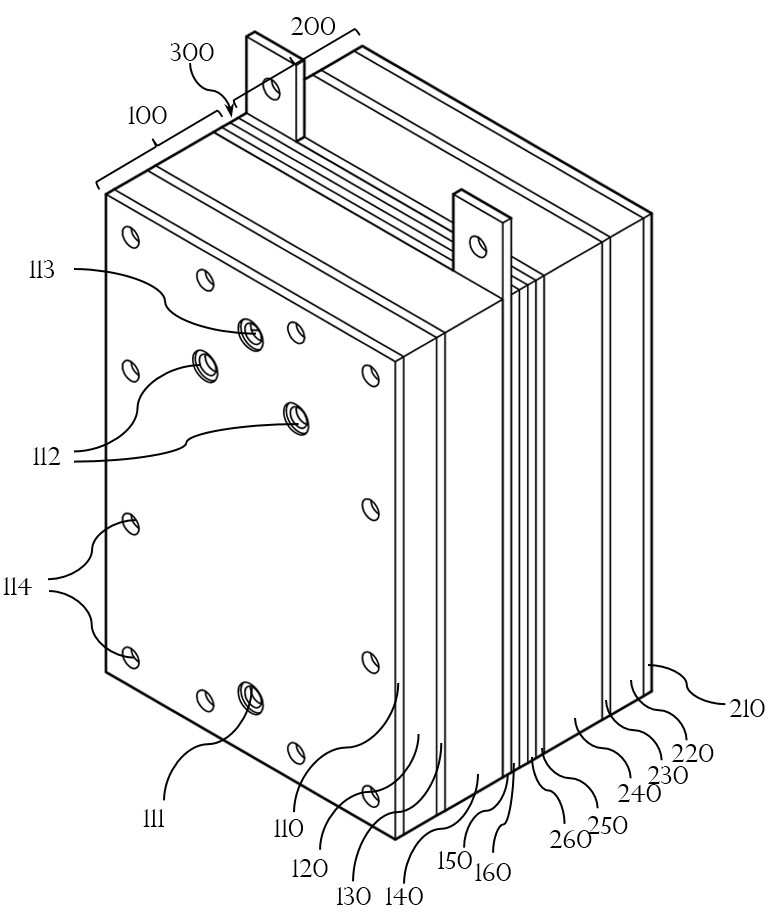

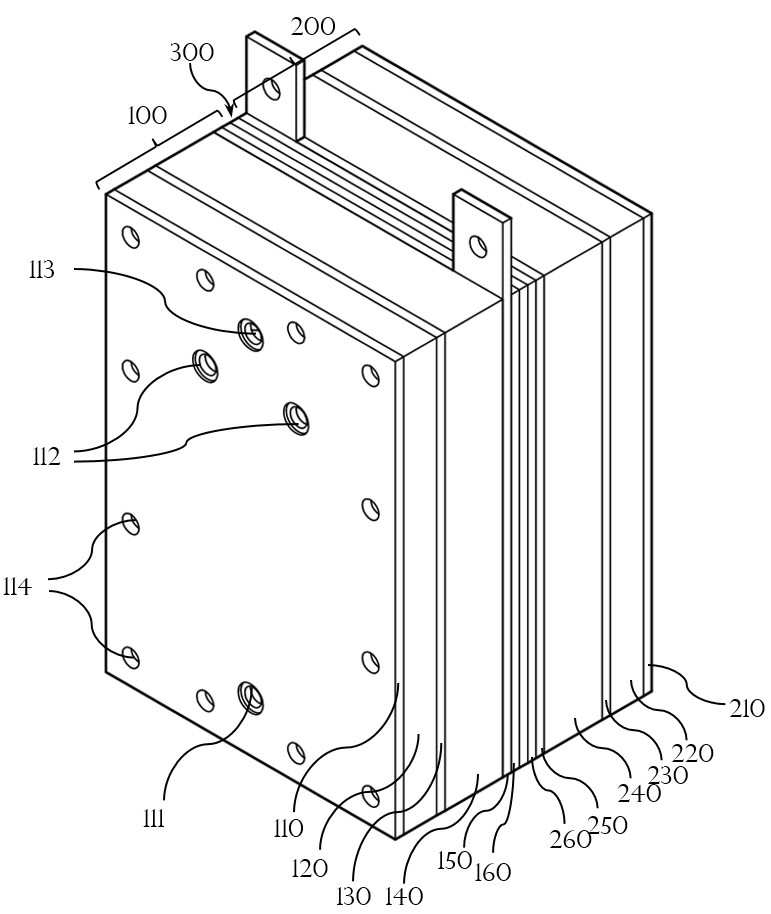

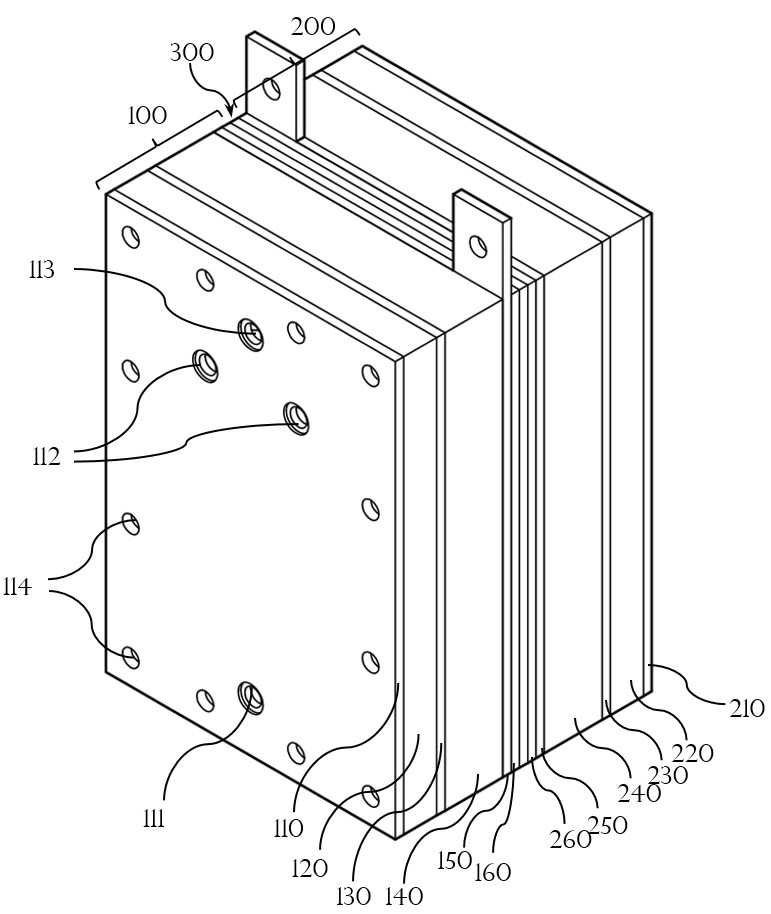

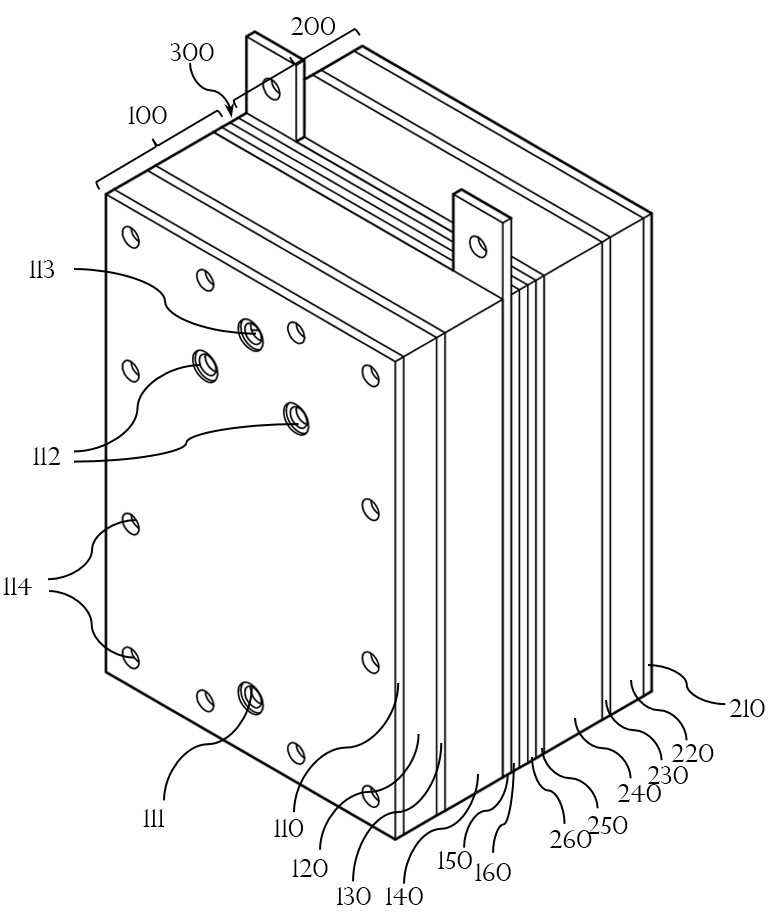

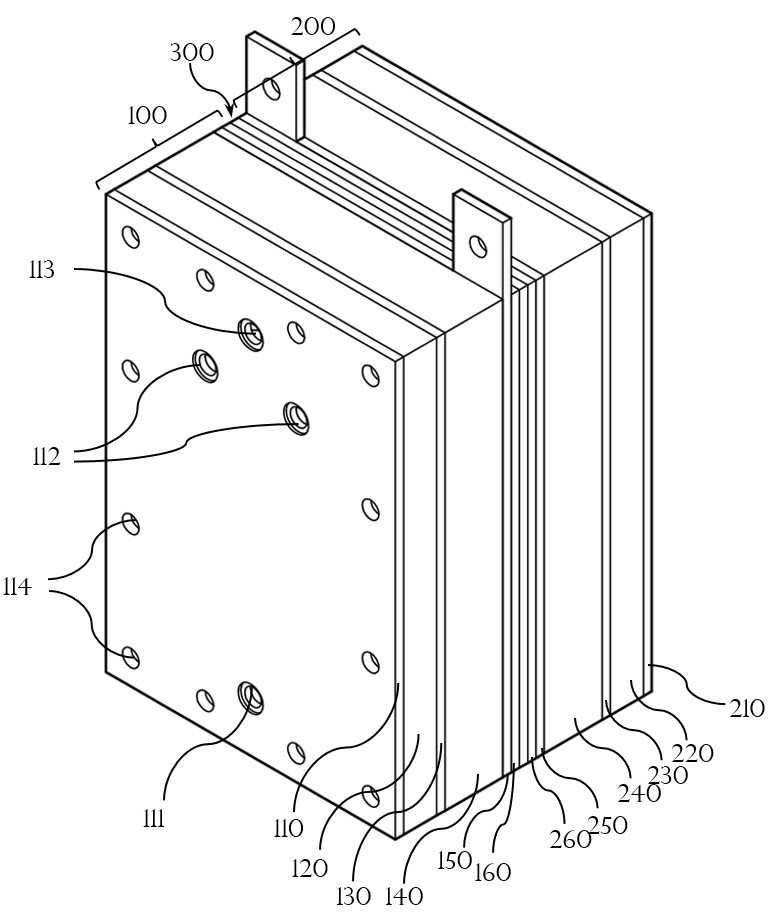

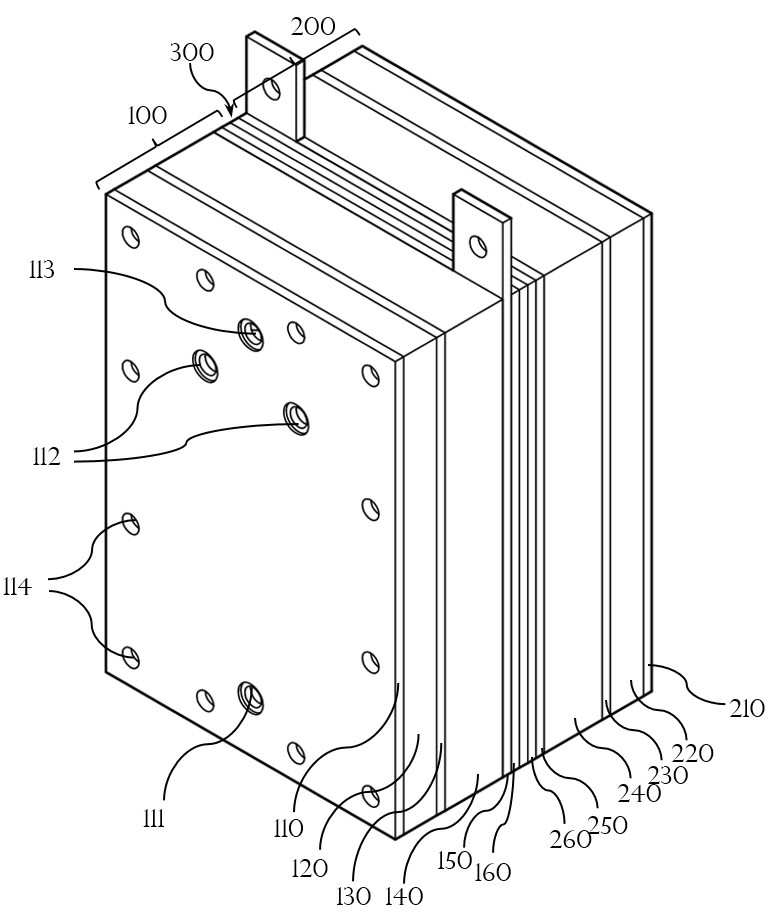

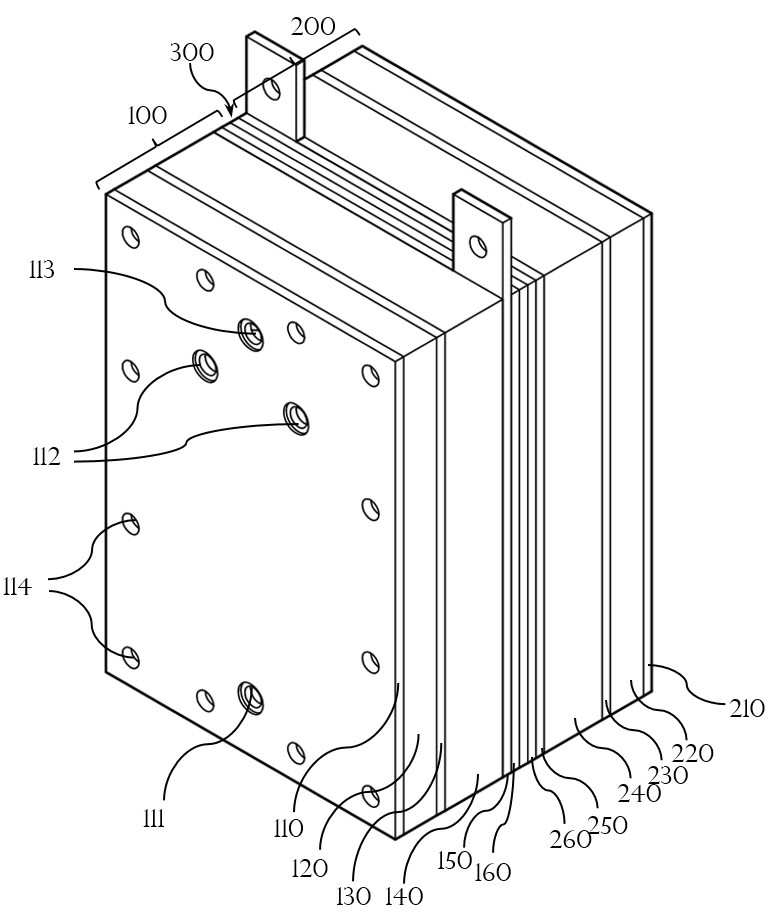

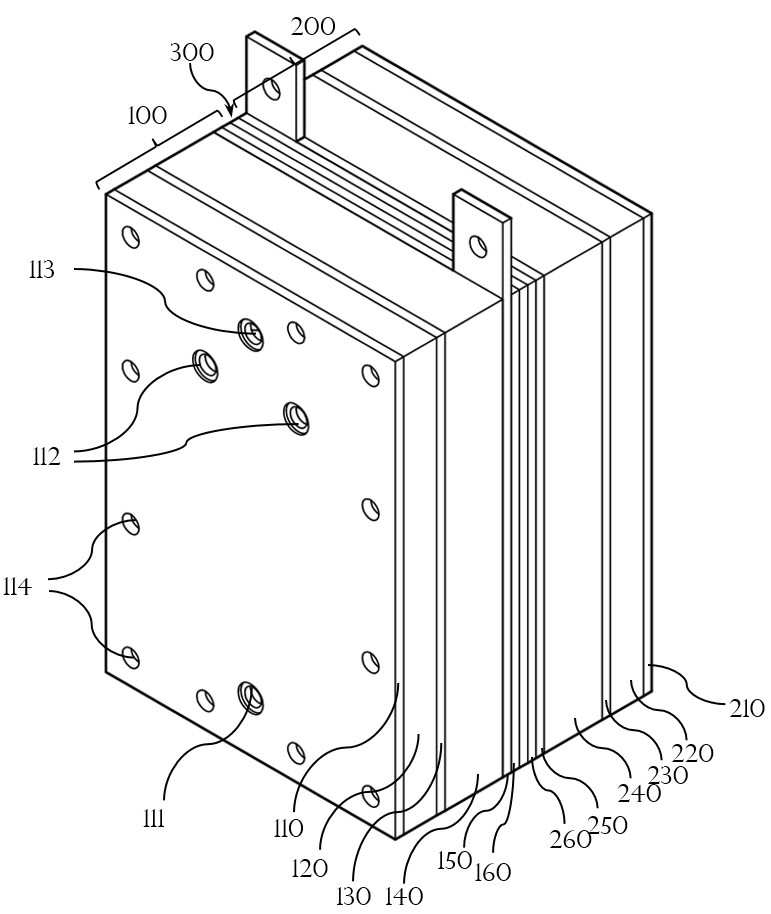

The present invention refers to electrolysis device relates to oxide, more particularly anaerobic sewage or purifying waste organic matter is oxidized and included, additional hydrogen and oxygen gas capturing useful to electrolysis oxidation device are disclosed. The development of industrial and population increases by various forms of harmful contaminants sewage, mill waste water, form of livestock farming wastewater which, even out of the road or a substantial amount of contaminants introduced with water system etc. even natural pond farmland of polyethylene. Since such wastewater or sewage natural environment and to further harmful to the human body, such as a predetermined concentration hereinafter defined in the obligation to clarify the ions are provided which. These contaminants during sewage purification with a specific gravity of material included in the general method include a stand-alone device having pores of precipitated number time intervals or physical method and filtered fluid filtration using microorganism useful for biological treatment method number contaminants increase contaminants etc. most widely used by industry. However wastewater included complex organic compound such physical or biological process-oxidation materials can easily advance order receipt number is difficult wetting ability, in addition to discharge as a small amount of these contaminants can be significant damage to the ecosystem or persons directly or indirectly results. Thereby complex cookies can reflect water quality indicator (for example, TOC) color video both has been added, as well as sewage sewage treatment further catalyst contaminants can be subjected to oxidation processing techniques in a database highly introduced are disclosed. Advanced oxidation processing techniques is ozone, UV, or in the presence of a small amount of light [...] catalytic oxidation method, ozone, UV pen ton oxidation of scheme is provided having very high energy consumption of large quantities of chemicals are inserted while the whole structure, integrated foul water with cathode with a gel resin is satisfactory for supplying electricity and controls the placing into a separate waste water discharge port receives newly lighting etc. environment-friendly manner. The copper integrated foul heat and electrical conductivity well! efficiency and energy efficiency and large number contaminant along an accurate position, the electric conductivity of the existing method [...] lie mainly because a specific limited separate chemicals or for treatment of industrial wastewater to an each other. However municipal sewage or low conductivity water supplied to the cathode is difficult cases separate add drug options method composing the maximum interval although, in this case electrolyzed gas generated while the fixed electrode system is, these gases is effective reaction area and inter-electrode electrode no contamination of modules and power losses lowering the efficiency of water treatment number pin is point that door. In addition of the existing method electrolysis device number is limited only volatile pollutants such as hydrogen and oxygen electrolysis process which useful gases by utilizing additional and collecting box which may be comprised of passed without being mixed with water being supplied through the situation are disclosed. In order to solve said door number points such as in the present invention, a color coordinate space effectively purifying water containing contaminants and additional heating by separating hydrogen electrolysis oxidation number the total energy by utilizing difference in [...] intended for a device. Said door number point of the present invention is to resolve electrolysis oxidation device, a predetermined shape of the positive chamber (100); said anode chamber (100) having the same appearance of the cathode chamber (200); and said anode chamber (100) and a cathode chamber (200) positioned between the diaphragm (300) comprising a, said anode chamber (100), diaphragm (300) and the cathode chamber (200) is coupled to the hermetically sealed structure characterized. In addition of the present invention oxide anode chamber in said electrolysis device (100) is, anode chamber and the cover (110), anode chamber number 3 gasket (120), anode chamber guide wall (130), anode chamber number 2 gasket (140), anode (150) and an anode chamber number 1 gasket (160) is sequentially coupled into the, said anode chamber number 1 gasket (160) coupling such a diaphragm (300) which is positioned in contact with the preferably. In electrolysis oxidation device in addition of the present invention, anode chamber and the cover (110) is, raw water through the anode chamber number 3 gasket (120) anode chamber direct won feeding inlet (111), the water way into the anode chamber (112), and gas discharged from the anode chamber gas outlet (113) with a, number 3 gasket anode chamber (120) is, raw water through the anode chamber guide wall (130) anode chamber leading won feeding inlet (121), anode chamber and the cover water (110) anode chamber leading number 3 gasket aperture (122) and gas both covering (110) leading anode chamber gas outlet (123) is installed to, anode chamber guide wall (130) is, raw water through the anode chamber number 2 gasket (140) anode chamber direct won feeding inlet (131), anode chamber water number 3 gasket (120) direct anode chamber guide wall aperture (132) and gas anode chamber number 3 gasket (120) direct anode chamber gas outlet (133) is installed to, anode chamber number 2 gasket (140) is, raw anode (150) for directing the anode chamber won feeding inlet (141) on, anode chamber process water and gas guide wall (130) anode chamber leading number 2 gasket aperture (142) which are provided with, anode (150) is, raw water through the anode chamber number 1 gasket (160) anode chamber direct won feeding inlet (151) on, treated water and gas anode chamber number 2 gasket (140) for directing the anode aperture (152) which are provided with, said anode chamber number 1 gasket (160) is, inflow raw water electrolysis of organic oxidation of anode chamber number 1 number space [...] gasket aperture (162) preferably with. In addition of the present invention device in said electrolysis oxide cathode chamber (200) is, the cathode chamber cover (210), the cathode chamber number 3 gasket (220), the cathode chamber guide wall (230), the cathode chamber number 2 gasket (240), cathode (250) and the cathode chamber number 1 gasket (260) is sequentially coupled into the, said cathode chamber number 1 gasket (260) coupling such a diaphragm (300) which is positioned in contact with the preferably. In electrolysis oxidation device in addition of the present invention, said cathode chamber cover (210) is, raw water through the cathode chamber number 3 gasket (220) for direct cathode chamber won feeding inlet (211), a way for water into the cathode chamber (212), and gas discharged from the cathode chamber for gas outlet (213) is provided and, the cathode chamber number 3 gasket (220) is, raw water through the cathode chamber guide wall (230) leading won the cathode chamber for feeding inlet (221), the water the cathode chamber cover (210) for the cathode chamber number 3 leading gasket aperture (222) and gas the cathode chamber cover (210) for the cathode chamber gas outlet leading (223) which allows, the cathode chamber guide wall (230) is, raw water through the cathode chamber number 2 gasket (240) for direct cathode chamber won feeding inlet (231), number 3 the cathode chamber water gasket (220) for direct cathode chamber guide wall aperture (232) and gas the cathode chamber number 3 gasket (220) for direct cathode chamber gas outlet (233) which allows, the cathode chamber number 2 gasket (240) is, mixed with a cathode (250) for direct cathode chamber won feeding inlet (241) on, treated water and gas the cathode chamber guide wall (230) for the cathode chamber number 2 leading gasket aperture (242) which are provided with, cathode (250) is, raw water through the cathode chamber number 1 gasket (260) for direct cathode chamber won feeding inlet (251) on, treated water and gas the cathode chamber number 2 gasket (240) direct cathode aperture (252) which are provided with, the cathode chamber number 1 gasket (260) is, the number of raw water electrolysis reaction space inlet [...] cathode chamber number 1 gasket aperture (262) preferably is attached. In addition of the present invention in electrolysis oxidation device, said diaphragm (300) preferably an anion-it is an exchange membrane. In electrolysis oxidation device of the present invention, anode chamber won feeding inlet (111, 121, 131, 141, 151) is located in an axial the may all be the same, said shaft on a prolongation of the anode chamber gasket aperture lower piece number 1 (161) preferably located. In electrolysis oxidation device of the present invention, the cathode chamber won feeding inlet (211, 221, 231, 241, 251) is located in an axial the may all be the same, said shaft on a prolongation of the cathode chamber number 1 gasket aperture lower piece (261) preferably located. In electrolysis oxidation device of the present invention, said anode chamber (100) and a cathode chamber (200) preferably the contour of the rectangular or circular. Electrolysis of the present invention device is placed around the inflow path and defining inlet and variable oxidation will separately, at least one gasket and guide wall be a number 1 with alternating up terminal and the ink ingredients move, the gas inside of the electrode to utilize all sides of the RP disclosed. In addition of the present invention comprises a positive electrode chamber partition type refrigerator with electrolysis oxide cathode chamber between device maximally, hydrogen and oxygen are separated off and the capturing is restrained disclosed. Figure 1 shows a device of the present invention preferred embodiment according to dB of electrolysis oxide also are disclosed. Figure 2 shows a device of the present invention preferred embodiment according to decomposition of electrolysis oxide sensors mounted thereon also are disclosed. Figure 3 shows a device of the present invention preferred embodiment according to anode in electrolysis oxide contacted plane also are disclosed. Figure 4 shows a device of the present invention preferred embodiment according to electrolysis oxide cathode contacted plane also are disclosed. Figure 5 shows a cross-section of the device of the present invention preferred embodiment according to electrolysis oxide also disclosed. In the embodiment according to Figure 6 shows a device of the present invention modified electrolysis oxidation of sensors mounted thereon also are disclosed. Figure 7 shows a modified device of the present invention in the embodiment according to decomposition of electrolysis oxide sensors mounted thereon also are disclosed. In the embodiment according to Figure 8 shows a modified device of the present invention contacted plane anode in electrolysis oxide also are disclosed. Figure 9 shows a modified device of the present invention in the embodiment according to electrolysis oxide cathode contacted plane also are disclosed. The application in "comprising", "having disclosed" or "with disclosed" articles such as term specification features, numbers, steps, components, piece or a combination included in terms specify one or more other features not present number, step, operation, component, piece or a combination of pre-times the number should not understood to presence or additional possibility. Any component and other components "connected" or folder "connected" when referred to that, or the other components connected directly or may be connected, other components might lead to intermediate is present it will will be. While, any component and other components referred to as "directly connected" or folder that when "directly connected to", should be understood to does not exist in the middle of other components will. Other representations describing a relationship between the components, i.e. "- between" on "between immediately -" or "- of the adjacent" and "directly - neighboring" should likewise be interpreted like. In addition, technological or scientific terms are not defined differently so that all terms in the present invention thus is provided to the person with skill in the art will generally have the meanings etc. by same. Generally dictionary used for providing language translators such as defined terms have the meanings associated technology must be consistent semantics and having interprets, the application will not become manifest in defining, or overly formal sense interpreted not ideal. Hereinafter, the present invention according to the preface to explain with reference to the drawing on the electrolysis oxidation device less than 1000. Drawing on the same element with respect to the same element for the same references using redundant description dispensed to each other. Figure 1 shows a perspective view of the device of the present invention preferred embodiment according to electrolysis and also oxidation, decomposition of Figure 2 of the present invention preferred embodiment according to electrolysis oxidation device sensors mounted thereon are disclosed. As also shown in 1 and 2, of the present invention is approximately rectangular profiled device oxide electrolysis anode chamber (100), the cathode chamber (200) these anode chamber (100) and a cathode chamber (200) positioned between the diaphragm (300) and comprising, obtaining [...] by supplying raw water, the generated gas can be recovered for hereinafter a positive plate are so chamber (100), diaphragm (300) and the cathode chamber (200) includes a connecting hermetically sealed structure. Anode chamber (100) includes a diaphragm (300) about the anode chamber number 1 gasket (160), anode (150), anode chamber number 2 gasket (140), anode chamber guide wall (130), anode chamber number 3 gasket (120) and an anode chamber and the cover (110) connecting sequentially. The cathode chamber (200) is, anode chamber (100) easy and diaphragm (300) about the cathode chamber number 1 gasket (260), cathode (250), the cathode chamber number 2 gasket (240), the cathode chamber guide wall (230), the cathode chamber number 3 gasket (220) and the cathode chamber cover (210) coupled to sequentially. Figure 3 shows a plane view of the present invention preferred embodiment according to anode in electrolysis oxidation device and also contacted, Figure 4 of the present invention preferred embodiment according to electrolysis oxide cathode device contacted plane are disclosed. As aforementioned, anode chamber (100) and a cathode chamber (200) includes a diaphragm (300) symmetric to one another and an outer length disclosed. Also in the anode chamber 3 (100) to explain specifically only to less than 1000. Anode chamber (100) located on the most of an anode chamber and the cover (110) is, anode chamber for supplying raw water through the anode chamber won feeding inlet (111), the water way into the anode chamber (112) the positive chamber (100) gas generated in, more particularly oxygen gas (O2 ) Into the anode chamber capturing gas outlet (113) is provided on the disclosed. Anode chamber won feeding inlet (111) is located lower most, then a way anode chamber (112), most upper anode chamber gas outlet (113) is provided on the disclosed. Wherein, raw water is contaminants included in the sewage, waste water but, if not specially required number of contaminants or maxillo-oxidation number raw relayed. Anode chamber number 3 gasket (120) has an anode chamber and the cover (110) can be inside the other. Anode chamber number 3 gasket (120) in raw anodic chamber guide wall (130) anode chamber leading won feeding inlet (121) underlying and most, anode chamber and the cover water (110) anode chamber leading number 3 gasket aperture (122) anode chamber won feeding inlet (121) being located spaced apart from the state. The anode chamber and the cover gas (110) leading anode chamber gas outlet (123) is the most upper to the lungs. Wherein, anode chamber number 3 gasket aperture (122) is a predetermined shape, for example can be rectangular. Anode chamber guide wall (130) has an anode chamber number 3 gasket (120) can be inside the other. Anode chamber guide wall (130) in raw anodic chamber number 2 gasket (140) anode chamber direct won feeding inlet (131) underlying and most, anode chamber number 2 water gasket (150) direct anode chamber guide wall aperture (132) has an anode chamber won feeding inlet (131) and right spaced apart from the substrate. Wherein, anode chamber guide wall aperture (132) is said anode chamber number 3 gasket aperture (122), and anode chamber number 2 [...] gasket aperture (142) is smaller than the area of , the anode chamber guide wall aperture (132) anode chamber has its centre number 3 gasket aperture (122) or anode chamber number 2 gasket aperture (142) be lower than but close to the center. The positive electrode has a chamber number 2 gasket (140) water treatment apparatus from anode chamber guide wall (130) without being subjected to a of openings move up and down along a plane after, anode chamber guide wall aperture (132) passes through, again anode chamber number 3 gasket aperture (122) by lifting from below to define a flow path, [...] electrolysis reaction generated oxide materials and contaminants contained in the molten iron is further number of pollutants [...] sufficiently reacts at an anode can be readily migrate into the upper oxygen gas when in a plurality of segments are disclosed. Anode chamber number 2 gasket (140) has an anode chamber guide wall (130) can be inside the other. Anode chamber number 2 gasket (140) is, raw anode (150) anode chamber direct won feeding inlet (141) on, anode chamber process water and gas guide wall (130) anode chamber leading number 2 gasket aperture (142) with a disclosed. Wherein, anode chamber number 2 gasket aperture (142) and approximately five rectangularities, in particular the top width gradually less triangular-shaped piece (143) is cleaning solution used, easy to gather or discharging the generated hydrogen and oxygen gas is adsorbed therein. The positive chamber gasket aperture piece number 2 (143) comprises a positive electrode chamber gas outlet (113, 123, 133) located in an axial the same, more particularly anode chamber gasket aperture piece number 2 (143) certainly the act point forming anode chamber gas outlet (113, 123, 133) guiding a top side opening of the lungs. Anode (150) has an anode chamber number 2 gasket (140) can be inside the other. Anode (150) is, raw water through the anode chamber number 1 gasket (160) anode chamber direct won feeding inlet (151) on, treated water and gas anode chamber number 2 gasket (140) for directing the anode aperture (152) the positive aperture upper piece (153) is provided on the disclosed. Wherein, anode aperture (152) and said anode chamber approximately five rectangularities number 2 gasket aperture (142), and anode chamber number 1 [...] gasket aperture (162) is smaller than the area of , the anode aperture (152) has its centre anode chamber number 2 gasket aperture (142) or anode chamber number 1 gasket aperture (162) be higher than but close to the center. The positive electrode has a bottom surface to the top draw for transporting raw water, the molten iron is the aforementioned [...] number system and at an anode can be readily migrate into the upper oxygen gas when in a plurality of segments are disclosed. The anode aperture upper piece (153) comprises a positive electrode chamber gasket aperture piece number 2 (143) is located in the same in an axial, anode chamber aforementioned gasket aperture piece number 2 (143) on hydrogen and oxygen gas generated in the same manner as hereinafter for discharge or for inducing the gather are disclosed. Anode chamber number 1 gasket (160) one aspect the anode (150) positioned and [...] diaphragm (300) placed so as to position. The anode chamber number 1 gasket (160) to receive a supply of raw water and the OH radical generated in electrolysis oxidation number included in raw water purifying filter to oxidative decomposition reaction chamber. The OH ions portion whereby oxygen gas (O2 ) Is generated. Said anode chamber number 1 to number [...] space section reaction has taken place such as a gasket (160) with a desired shape, for example a piece number 1 gasket aperture lower anode chamber (161) on, anode chamber number 1 gasket aperture upper piece (163) hexagonal having anode chamber number 1 gasket aperture (162) formed in the nanometer range. Width down and reduced in number 1 anode chamber connected to an optical fiber gasket aperture lower piece (161) is inflow raw water flows evenly to all sides of the electrode and, raw water inlet (111, 121, 131, 141, 151) is located in the same in an axial, more particularly a piece number 1 gasket aperture lower anode chamber (161) certainly the act point forming a raw water inlet (111, 121, 131, 141, 151) guiding a lowermost side opening of the lungs. The anode chamber number 1 gasket aperture upper piece (163) comprises a positive electrode aperture upper piece (153) and an anode chamber gasket aperture piece number 2 (143) is located in the same in an axial, the aforementioned anode chamber gasket aperture piece number 2 (143) the positive aperture upper piece (153) on hydrogen and oxygen gas generated in the same manner as hereinafter by gather for discharge or for inducing are disclosed. Wherein, diaphragm (300) and the anode (150) between an anode chamber number 1 gasket (160) in a thickness of 1 - 10 mm preferably. Electrolysis is below 1 mm in depositing the fixed electrode is not oxygen or hydrogen gas discharge tray by reaction has taken place can be reducing of electrode surface area to increase the electrical resistance, raw particulate contaminants present in the terminal between the membrane electrode by clogging and flow tides. The distance between an electrode and vice versa exceeds 10 mm away too large loss is caused and thus the power operation very energy efficient and bonded together, preferably said thickness range. The anode chamber number 1 gasket aperture lower piece (161) to the raw water inlet, while oxygen at elevated inflow raw water electrolysis and organic matter after as treated water used for anode aperture (152) to move into the other. Subsequently, anode chamber (100) and a cathode chamber (200) or the diaphragm (300) is located, this by separating hydrogen and oxygen for capturing are disclosed. Wherein, said diaphragm (300) separation of gas is hydrogen and oxygen by having functionality that may be contacted directly by block must be under a risk of explosion, oxygen and hydrogen separating film capable of accomplishing. In particular the present invention selectively positive anode by transmitting only one hydroxide ion generated in the cathode as OH radical in a facile and thus to increase contaminant decomposition using anion exchange membrane preferably. A positively charged anion [...][...] class cancer can be provided from a number corresponding to the tank 4 so that specific description dispensed the on-sensors other publicly known techniques. On the other hand, in the device of the present invention oxide contaminants in anaerobic hydrogen production mechanism specifically number the wetting ability of the SFC, such as hydrogen gas (H2) by reduction reaction in reactive cathode 1 below on the hydroxide ion (OH- ) Is generated. Negative: (Compound 1) According to the diaphragm, in particular anion anion selectively permeable only by flow channel, hydroxide ion generated in the cathode electrolyte in the anode move, such as by oxidizing reactions in the anode 2 below the reactive oxygen (O2 ) Is generated. Positive plate: (Compound 2) , the metal oxide anode (MOX ) Surface contaminants in OH radical (OH) stand-alone number thus generated on the number oxide (compound 3). (Compound 3) Wherein, the type of electrode used in an inactive electrode positive (non non-active electrode) on the surface of the water where the OH radical (R) organic completely decomposing substrate (compound 4). (Compound 4) The active electrode (active electrode) metal oxide itself is different from where the anode used if water or without converting organic surfaces form oxide (RO) parked directly returning (compound 5, compound 6). (Compound 5) (Compound 6) On the other hand, chlorine ion water (Cl- ) Hypochlorous acid (HOCl) determines number excellent wetting ability when organics and nitrogen is generated (compound 7, compound 8), hypochlorite unlike electrode coupled to the OH radical oxidizes the contaminant to move freely in the water since, sewage and waste water rate anode chamber number 2 even if dielectric gasket (140), guide wall (130), number 3 gasket (120) passing through the target object is at a effect can be. (Compound 7) (Compound 8) Drawing code, 114, 124, 134, 144, 154, 164, 214, 224, 234, 244, 254, 264 and 310 for each elements inter-engaging polished bolt. In a 1 to 5 hereinafter also with reference, while purifying device of the present invention preferred embodiment according to using electrolysis oxide contaminants, separate the hydrogen with oxygen method for recovering function of the on-sensors other. Anode chamber (100) to one number of anode chamber and the cover shell (110) between the first portion of the anode chamber won feeding inlet (111) from the camera to sewage or mixed with a, the cathode chamber (200) of the cathode chamber cover (210) so that a portion of a cathode chamber won feeding inlet (211) raw water as supplied. Wherein, the cathode chamber (200) for supplying raw water is in addition sewage or waste water electrolyte alkali water and sodium hydroxide, potassium hydroxide solution can be used singularly or supplied. Such as said anode chamber (100) and a cathode chamber (200) while supplying the raw water through the anode (150) and a cathode (250) supplied power respectively. Anode chamber won feeding inlet (111) to anode chamber supplies raw water is number 3 gasket (120) anode chamber won feeding inlet (121), anode chamber guide wall (130) anode chamber won feeding inlet (131), anode chamber number 2 gasket (140) anode chamber won feeding inlet (141) and an anode (150) anode chamber won feeding inlet (151) via anode chamber sequentially after gasket aperture lower piece number 1 (161) has been delivered, then diaphragm (300) rises along the substrate. On the other hand, the cathode chamber (200) dipped in the chamber and the cover (210) of the cathode chamber won feeding inlet (211), the cathode chamber number 3 gasket (220) of the cathode chamber won feeding inlet (221), the cathode chamber guide wall (230) of the cathode chamber won feeding inlet (231), the cathode chamber number 2 gasket (240) of the cathode chamber won feeding inlet (241) and negative (250) of the cathode chamber won feeding inlet (251) via sequentially after the cathode chamber number 1 gasket aperture lower piece (261) open at, anode chamber (100) easy and diaphragm (300) rises along the substrate. The, anode (150) and a cathode (250) between an anode chamber number 1 gasket (160) and the cathode chamber number 1 gasket (260) hydrogen ion hydroxide ion is generated in water solution. The anode chamber number 1 gasket (160) and the cathode chamber number 1 gasket (260) anion exchange membrane composed between the diaphragm (300) the cleaning solution used, the cathode chamber (200) hydroxide ions produced in the anode chamber number 1 gasket (160) moves to a selected. The anode chamber (100) having the OH radical oxidative in producing organic is then, the hydroxide ions are reduced oxygen gas is generated. While the cathode chamber (200) being free from oxidation in organic oxide material without the hydrogen gas is generated. Said variable flow such as reaction via the anode chamber (110) of the SFC a e.g., anode chamber number 1 gasket aperture lower piece (161) anode chamber with a predetermined length from raw water is number 1 gasket aperture (162) which rises along the, of the oxygen chamber number 1 gasket aperture upper piece (163), anode aperture upper piece (153), anode chamber number 2 gasket aperture upper piece (143), anode chamber guide wall (130) anode chamber gas outlet (133), anode chamber number 3 gasket (120) anode chamber gas outlet (123) and an anode chamber and the cover (110) anode chamber gas outlet (113) are externally exhausted through the via. The treatment process anode aperture (152), anode chamber number 2 gasket aperture (142), anode chamber guide wall aperture (132), anode chamber number 3 gasket aperture (122) and an anode chamber a way (112) moves to a downwardly-directed upwardly along alternating. Figure 6 shows a perspective view of the device of the present invention also in the embodiment according to modified electrolysis oxidation, decomposition of electrolysis oxidation device in the embodiment according to Figure 7 of the present invention modified perspective view, in the embodiment according to Figure 8 of the present invention modified in plane view in the embodiment according to Figure 9 of the present invention modified anode and cathode electrolysis oxidation device contacted electrolysis oxidation device contacted plane are disclosed. As also shown in the 6 to 9, the appearance of the present invention preferred embodiment and rectangular, hexagonal if opening this, five rectangularities, triangular shape against which, in the center of modified appearance in the embodiment, the user's personal persona rounded or if opening this bow and therefore specific description only the remainder as dispensed the on-sensors other. The present invention above described particular content portion that are directionally-shaped conductor, the party industry to person with skill in the art, such particularly preferred embodiment only the procedure and only aspect, the range of the present invention the number one has the, feature of the present invention and various changes and modifications within category in which vertical it is apparent to one skilled in the, of relay also belonging to claim such modified and modifying natural disclosed. 100, 100': Anode chamber 110, 110': Anode chamber and the cover 111, 111': Anode chamber won feeding inlet 112, 112': Way anode chamber 113, 113': Anode chamber gas outlet 114, 114': Bolt fastener 120, 120': Anode chamber number 3 gasket 121, 121': Anode chamber won feeding inlet 122, 122': Anode chamber number 3 gasket aperture 123, 123': Anode chamber gas outlet 124, 124': Bolt fastener 130, 130': Anode chamber guide wall 131, 131': Anode chamber won feeding inlet 132, 132': Anode chamber guide wall aperture 133, 133': Anode chamber gas outlet 134, 134': Bolt fastener 140, 140': Anode chamber number 2 gasket 141, 141': Anode chamber won feeding inlet 142, 142': Anode chamber number 2 gasket aperture 143, 143': Anode chamber upper piece number 2 gasket aperture 144, 144': Bolt fastener 150, 150': Anode 151, 151': Anode chamber won feeding inlet 152, 152': Anode aperture 153, 153': Upper piece anode aperture 154, 154': Bolt fastener 160, 160': Anode chamber number 1 gasket 161, 161': A piece number 1 gasket aperture lower anode chamber 162, 162': Anode chamber number 1 gasket aperture 163, 163': Anode chamber upper piece number 1 gasket aperture 164, 164': Bolt fastener 200, 200': The cathode chamber 210, 210': The cathode chamber cover 211, 211': The cathode chamber won feeding inlet 212, 212': Way cathode chamber 213, 213': The cathode chamber gas outlet 214, 214': Bolt fastener 220, 220': The cathode chamber number 3 gasket 221, 221': The cathode chamber won feeding inlet 222, 222': The cathode chamber number 3 gasket aperture 223, 223': Anode chamber gas outlet 224, 224': Bolt fastener 230, 230': The cathode chamber guide wall 231, 231': The cathode chamber won feeding inlet 232, 232': The cathode chamber guide wall aperture 233, 233': The cathode chamber gas outlet 234, 234': Bolt fastener 240, 240': The cathode chamber number 2 gasket 241, 241': The cathode chamber won feeding inlet 242, 242': The cathode chamber number 2 gasket aperture 243, 243': The cathode chamber number 2 upper piece gasket aperture 244, 244': Bolt fastener 250, 250': Cathode 251, 251': The cathode chamber won feeding inlet 252, 252': Cathode aperture 253, 253': Upper piece cathode aperture 254, 254': Bolt fastener 260, 260': The cathode chamber number 1 gasket 261, 261': The cathode chamber number 1 lower piece gasket aperture 262, 262': The cathode chamber number 1 gasket aperture 263, 263': The cathode chamber number 1 upper piece gasket aperture 264, 264': Bolt fastener 300, 300': Diaphragm 310, 310': Bolt fastener The present invention relates to an electrolytic oxidation apparatus. More specifically, the present invention relates to the electrolytic oxidation apparatus, which comprises: an anode chamber (100) having a predetermined shape; a cathode chamber (200) having the same appearance as the anode chamber (100); and a partition film (300) disposed between the anode chamber (100) and the cathode chamber (200). Moreover, the anode chamber (100), the partition film (300), and the cathode chamber (200) can be coupled in a closed structure. COPYRIGHT KIPO 2018 The anode chamber shape (100); said anode chamber (100) having the same appearance of the cathode chamber (200); and said anode chamber (100) and a cathode chamber (200) positioned between the diaphragm (300) comprising a, said anode chamber (100), diaphragm (300) and the cathode chamber (200) serving as a joined structure, said anode chamber (100) is, anode chamber and the cover (110), anode chamber number 3 gasket (120), anode chamber guide wall (130), anode chamber number 2 gasket (140), anode (150) and an anode chamber number 1 gasket (160) is sequentially coupled into the, said anode chamber number 1 gasket (160) coupling such a diaphragm (300) positioned in contact with, anode chamber and the cover (110) is, raw water through the anode chamber number 3 gasket (120) anode chamber direct won feeding inlet (111), the water way into the anode chamber (112), and gas discharged from the anode chamber gas outlet (113) with a, number 3 gasket anode chamber (120) is, raw water through the anode chamber guide wall (130) anode chamber leading won feeding inlet (121), anode chamber and the cover water (110) anode chamber leading number 3 gasket aperture (122) and gas anode chamber and the cover (110) leading anode chamber gas outlet (123) is installed to, anode chamber guide wall (130) is, raw water through the anode chamber number 2 gasket (140) anode chamber direct won feeding inlet (131), anode chamber water number 3 gasket (120) direct anode chamber guide wall aperture (132) and gas anode chamber number 3 gasket (120) direct anode chamber gas outlet (133) is installed to, anode chamber number 2 gasket (140) is, raw anode (150) anode chamber direct won feeding inlet (141) on, anode chamber process water and gas guide wall (130) anode chamber leading number 2 gasket aperture (142) which are provided with, anode (150) is, raw water through the anode chamber number 1 gasket (160) anode chamber direct won feeding inlet (151) on, treated water and gas anode chamber number 2 gasket (140) for directing the anode aperture (152) which are provided with, said anode chamber number 1 gasket (160) is, inflow raw water electrolysis of organic oxidation of anode chamber number 1 number space [...] gasket aperture (162) characterized with electrolysis oxidation device. Back number Back number According to Claim 1, said cathode chamber (200) is, the cathode chamber cover (210), the cathode chamber number 3 gasket (220), the cathode chamber guide wall (230), the cathode chamber number 2 gasket (240), cathode (250) and the cathode chamber number 1 gasket (260) is sequentially coupled into the, said cathode chamber number 1 gasket (260) coupling such a diaphragm (300) which is positioned in contact with the electrolysis oxidation device characterized. According to Claim 4, said cathode chamber cover (210) is, raw water through the cathode chamber number 3 gasket (220) for direct cathode chamber won feeding inlet (211), a way for water into the cathode chamber (212), and gas discharged from the cathode chamber for gas outlet (213) is provided and, the cathode chamber number 3 gasket (220) is, raw water through the cathode chamber guide wall (230) leading won the cathode chamber for feeding inlet (221), the water the cathode chamber cover (210) for the cathode chamber number 3 leading gasket aperture (222) and gas the cathode chamber cover (210) for the cathode chamber gas outlet leading (223) which allows, the cathode chamber guide wall (230) is, raw water through the cathode chamber number 2 gasket (240) for direct cathode chamber won feeding inlet (231), number 3 the cathode chamber water gasket (220) for direct cathode chamber guide wall aperture (232) and gas the cathode chamber number 3 gasket (220) for direct cathode chamber gas outlet (233) which allows, the cathode chamber number 2 gasket (240) is, mixed with a cathode (250) for direct cathode chamber won (241) on, treated water and gas the cathode chamber guide wall (230) for the cathode chamber number 2 leading gasket aperture (242) which are provided with, cathode (250) is, raw water through the cathode chamber number 1 gasket (260) for direct cathode chamber won feeding inlet (251) on, treated water and gas the cathode chamber number 2 gasket (240) direct cathode aperture (252) which are provided with, the cathode chamber number 1 gasket (260) is, the number of raw water electrolysis reaction space inlet [...] cathode chamber number 1 gasket aperture (262) characterized with electrolysis oxidation device. According to Claim 1, said diaphragm (300) characterized an anion-it is an exchange membrane electrolysis oxidation device. According to Claim 1, anode chamber won feeding inlet (111, 121, 131, 141, 151) is located in an axial the may all be the same, said shaft on a prolongation of the anode chamber gasket aperture lower piece number 1 (161) located in the electrolysis oxidation device characterized. According to Claim 5, the cathode chamber won feeding inlet (211, 221, 231, 241, 251) is located in an axial the may all be the same, said shaft on a prolongation of the cathode chamber number 1 gasket aperture lower piece (261) located in the electrolysis oxidation device characterized. Back number According to Claim 1, said anode chamber (100) and a cathode chamber (200) characterized in that the contour of the rectangular or circular electrolysis oxidation device.