CONDITION DETECTING METHOD AND DEVICE FOR TROUBLE DIAGNOSIS OF BALL MILL

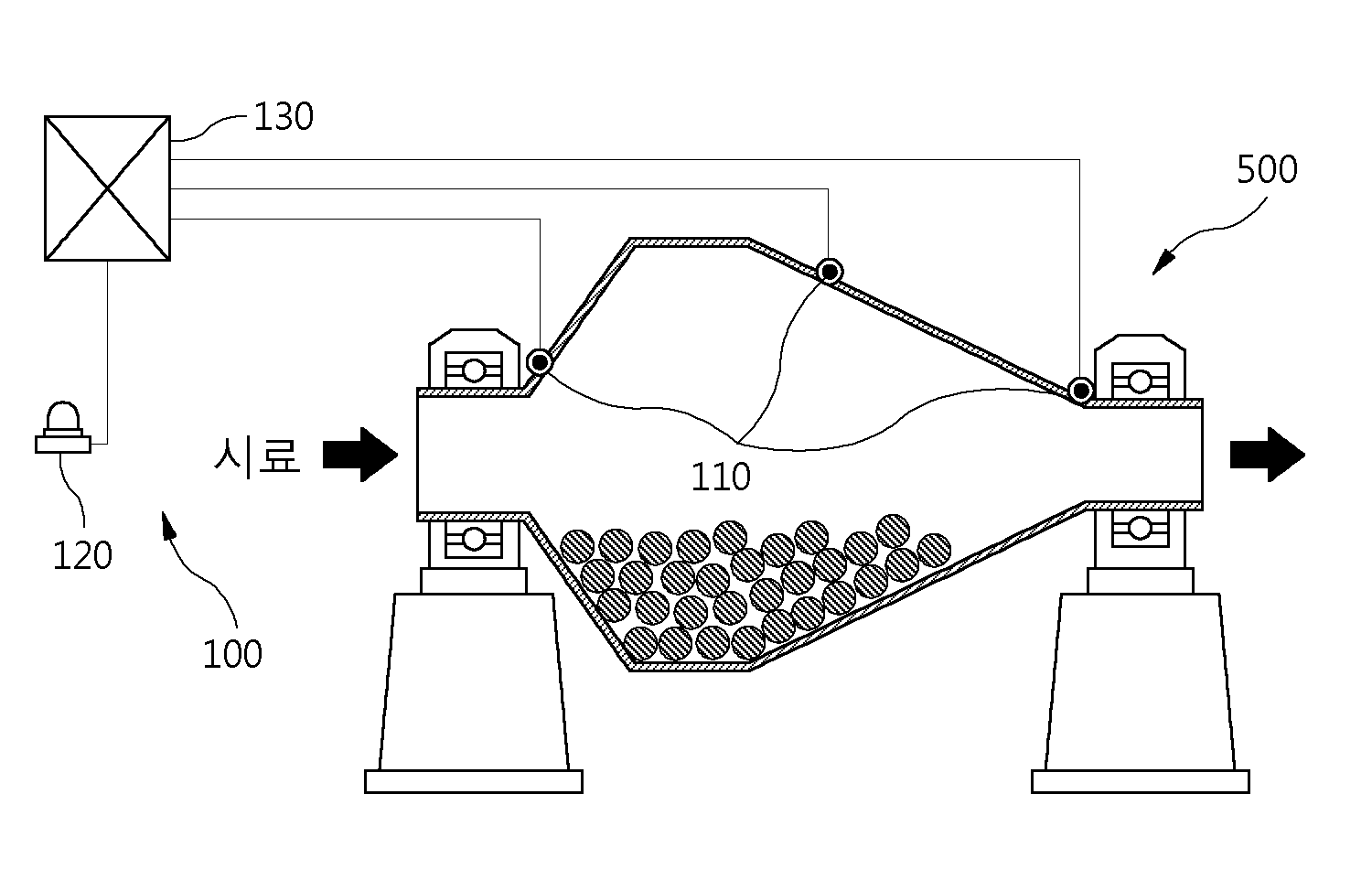

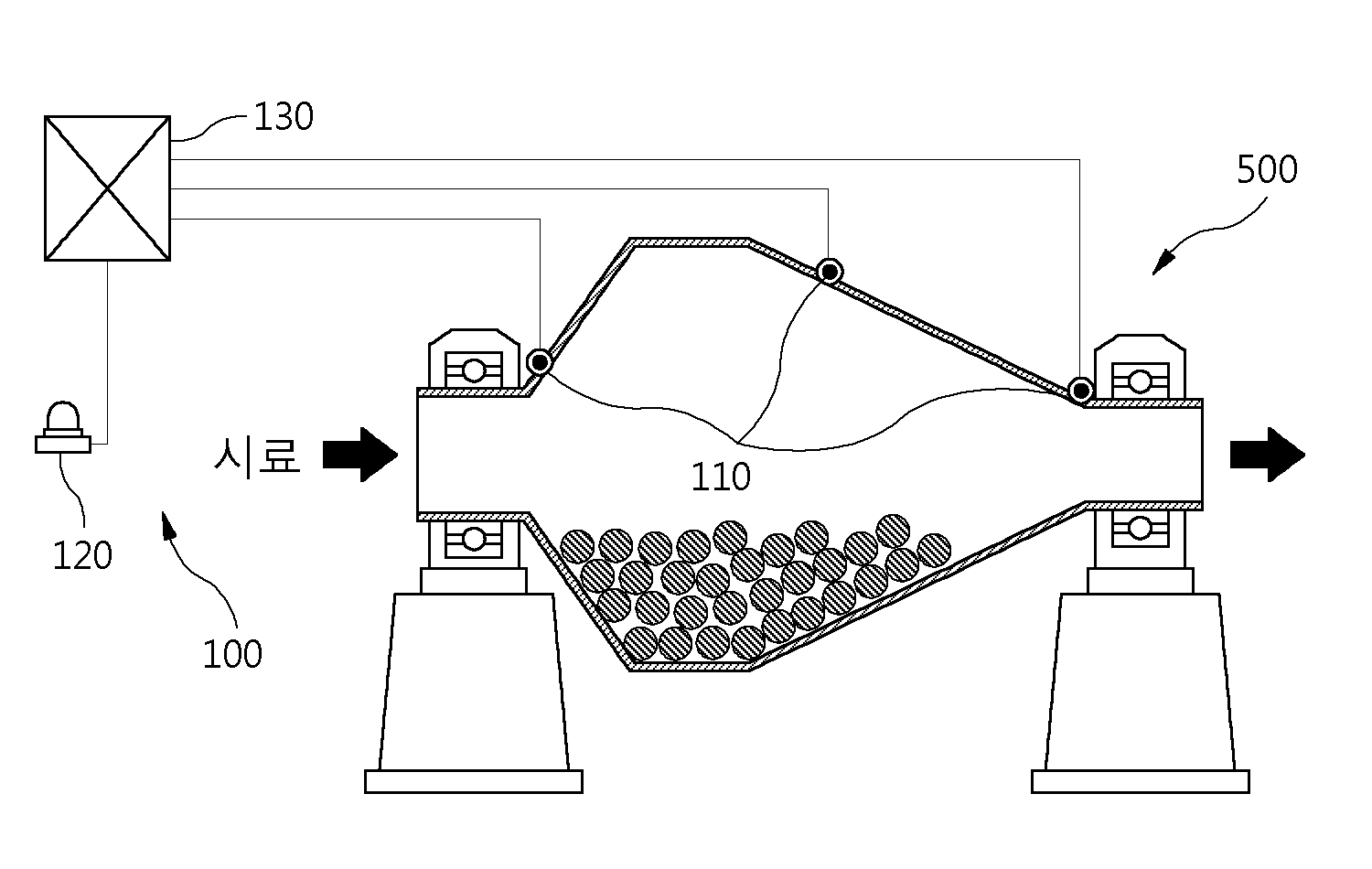

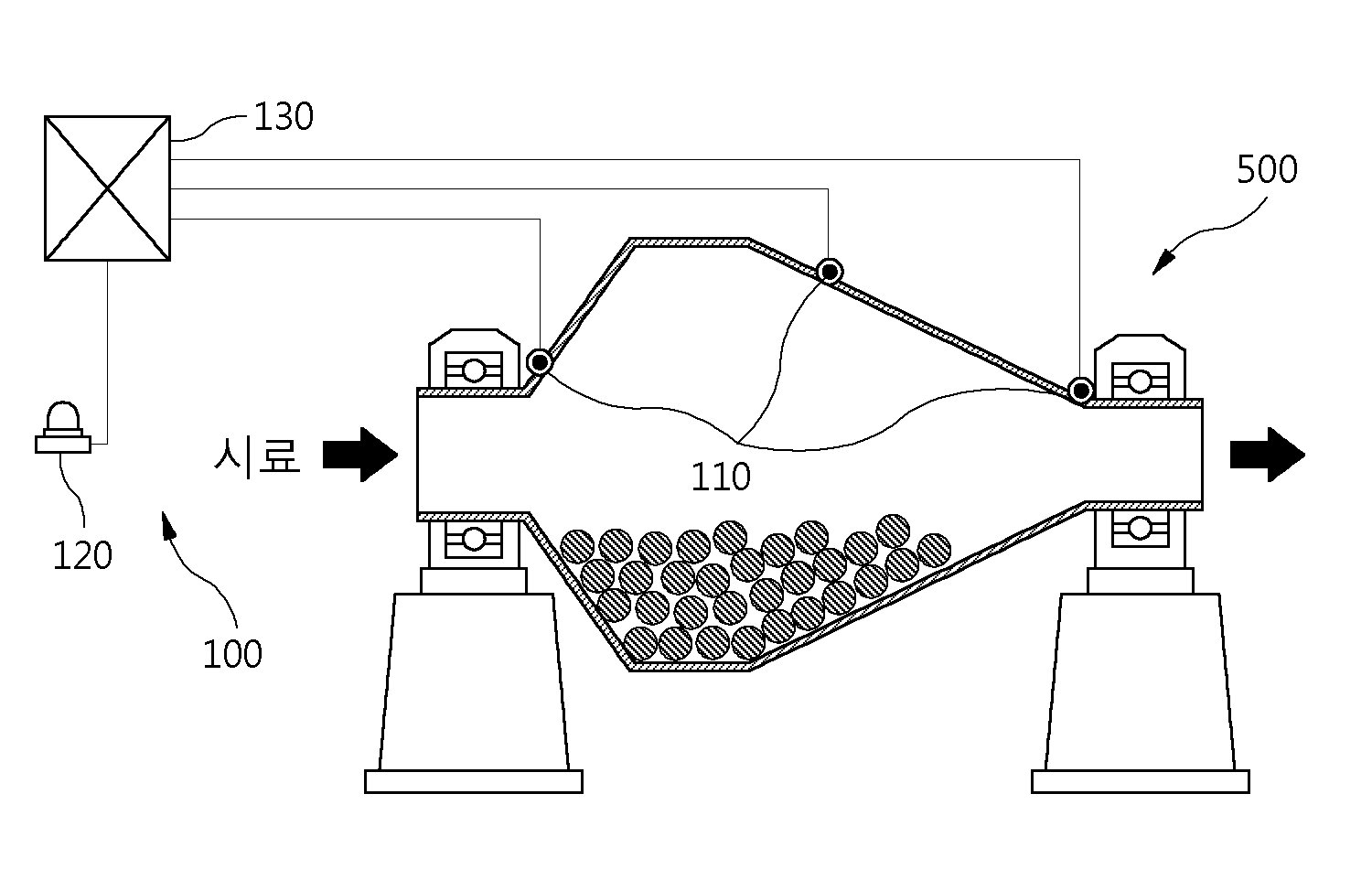

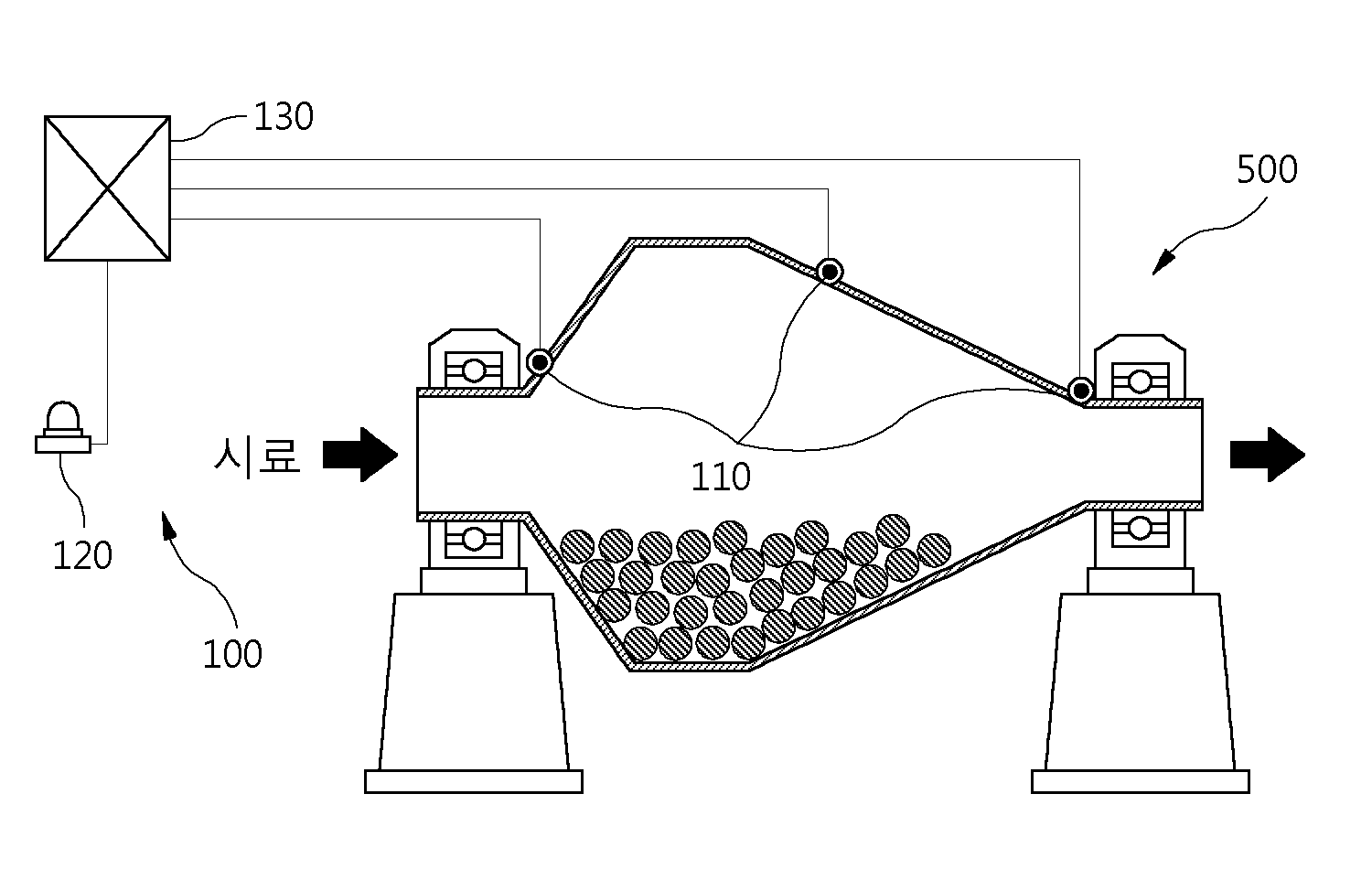

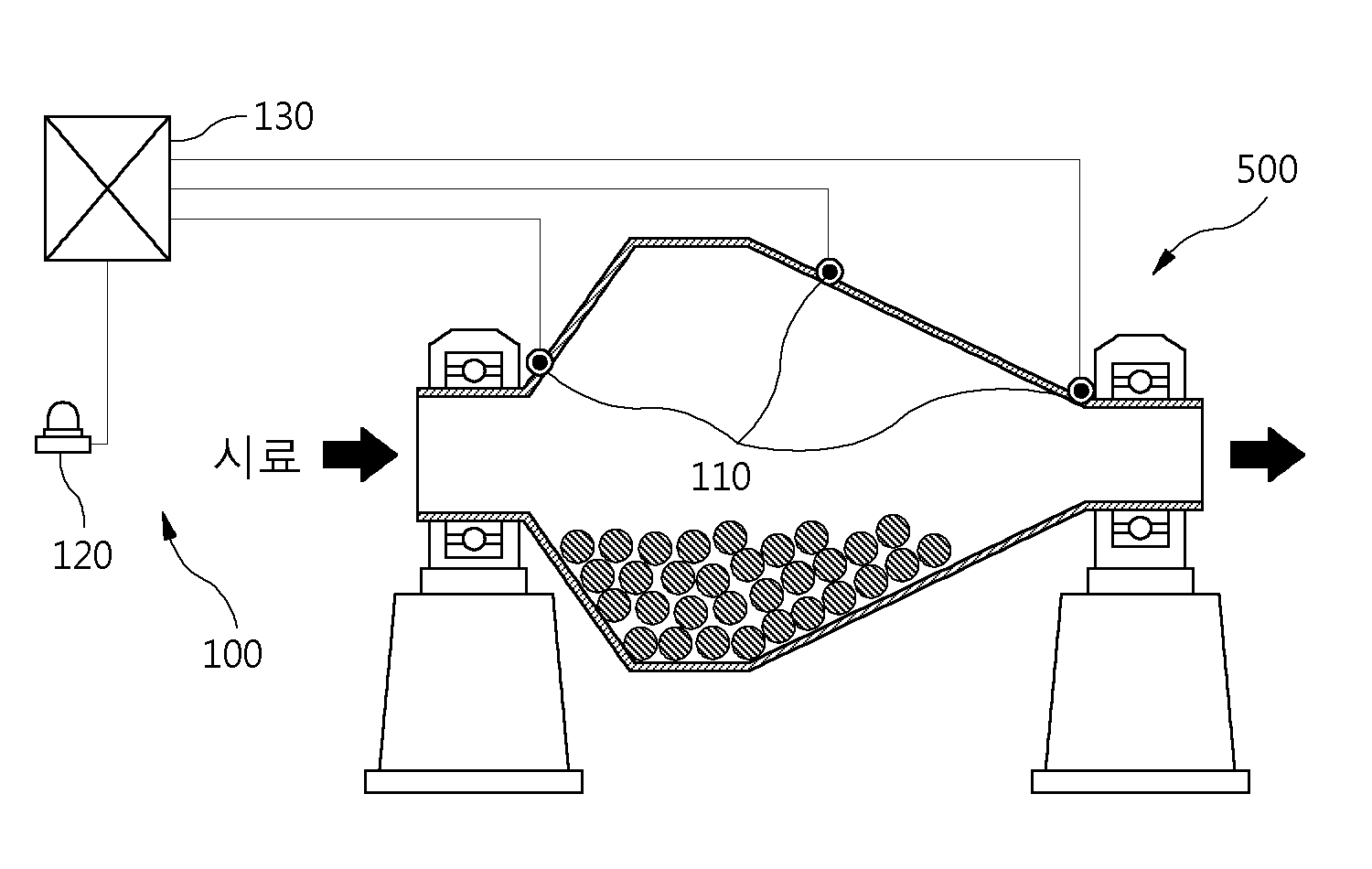

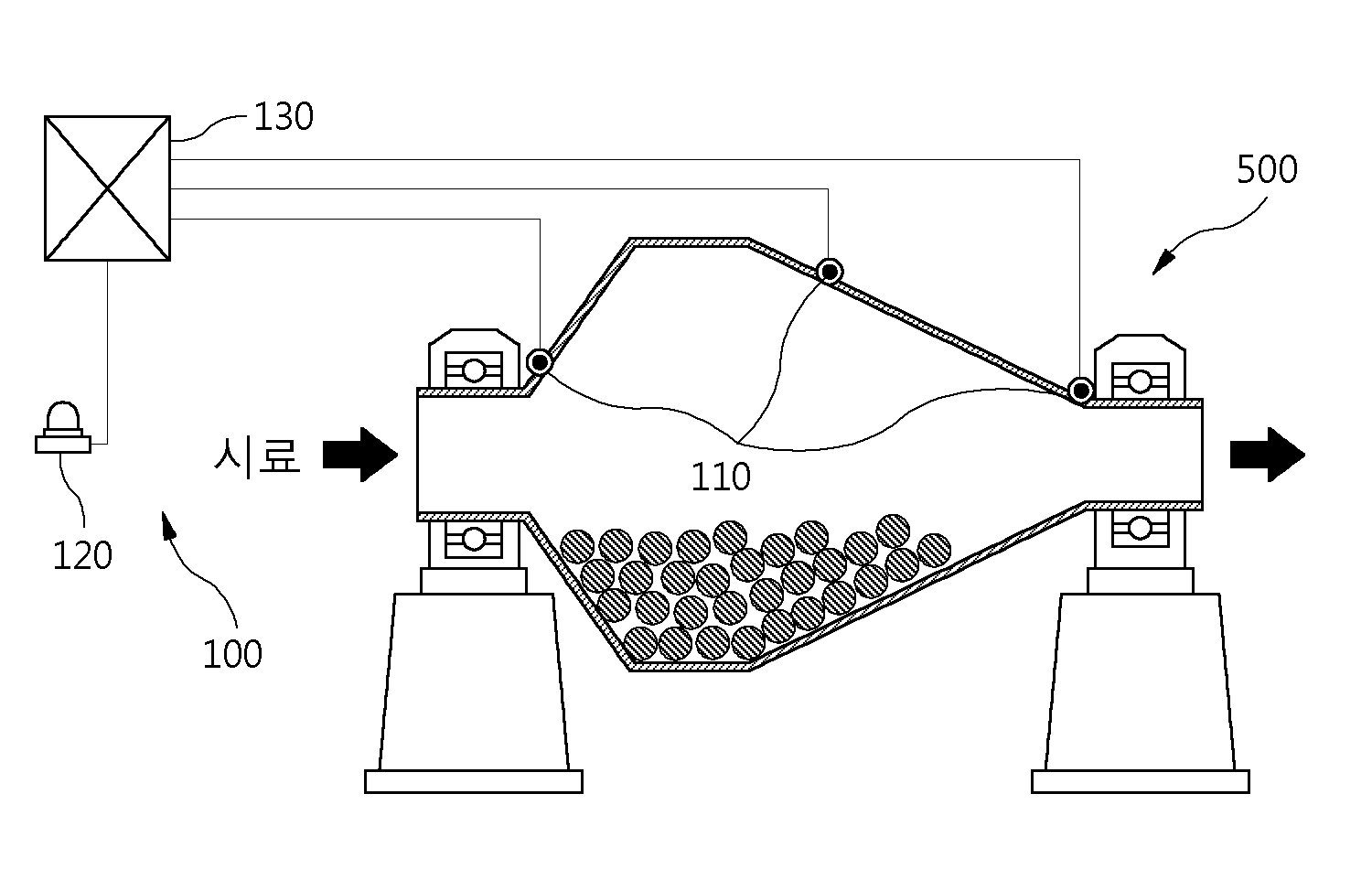

The present invention refers to crusher abnormality diagnosis for state detection method and device relates to, more specifically, a plurality of ball the irradiated sample by sample held together by rotating the ball movement to which the ball mill crusher, grinding blade of provided to sense the electric sensing allows more accurate, for state detection method and device are disclosed to abnormality diagnosis crusher. For comminuting and serve as mill is widely used to sample, rotate on a horizontal axis with a plurality of body generally cylindrically by sample held together by rotating the ball, ball has fallen into the vertical shock and balls take place between by the action according to the pigments and milling in terms of sample. Ball mill crusher there are impacting the sample received the ball material sufficiently strong as to, cast iron, , flint stone, consisting of natural stone material. Ball mill crusher done in the performance of the grinding work as well as the material of the coking chamber of coke oven/sample, weight/material/ball diameter, drum rotation speed or the like depending on the substrate. Ball mill crusher greatly continuous and discontinuous manner Chapters. Continuous ball mill grinding blade of one example is Korean publicized utility model number 1995 - 0026834 call ("continuous type vibrating ball mill", 1995. 10. 16) Which the disclosure, a plurality of grinding drum vertical two-balls each contained in the drum is formed of different diameter, one drum continuous grinding step by step into a milled sample other drum is connected to a combustion chamber. Non-continuous ball mill crusher grinding drum from a sample using a neutral but that same milling, grinding the wafer sample is cleaned again serve as a stand-alone performed on sample number from that the hereinafter described. Ball mill mill that includes a plurality of balls for maintaining continuous drum moves during operation, in addition hit the sample on which the impact happens in bar, essentially occurs significantly noise and vibration during operation. On the other hand, grinding or no as too rigid or too big sample number, or a failure in the device itself such as occurs when an abnormal status, as ball mill crusher normally even when the above-mentioned high frequency since significant vibration and noise, the anomaly this second electrode is hereinafter operator for his fellow workers. The anomaly of pulverizer serve is to detect, on the basis of the operator's subjective judgment of and selectively discharge or, crusher number in an advertisement based on a vibration criteria and selectively discharge when irradiated his number. In the reliability of the existing method, accuracy and engagement with significantly is formed deeper than a, ball mill grinding blade of state having a high reliability for more than diagnostic method are required. In particular in the case of continuous and non-continuous ball mill crusher as above-mentioned, reflective layer because of different device type and operation hereinafter abnormal state diagnosis techniques disclosed. Thus, the present invention refers to said number of such of the second door in order to solve in a certain point, the purpose of the invention is vibration and sound sensor noise and vibration damping embodiment of crusher and between measuring, analyzing measurements related to or more of crusher diagnosing, for state detection method and a device number abnormality diagnosis crusher can be recycled. More specifically, embodiment using measured between vibration and noise measurements, crusher discharge valve, crusher types according to the respective alert value setup to perform properly fit quantitatively, for state detection method and a device number abnormality diagnosis crusher can be recycled. Said frame is as defined for state detection method of the present invention for the abnormality diagnosis crusher, crusher (500) while operating said crusher (500) installed measuring sensor (110) sense a vibration or noise from state change over time measurements are obtained the measurements obtains; it is judged whether a measurement calibrated measurements correction step; predetermined period during the measurement values derived measurements a probability density function and statistics S9 statistical analysis statistical analysis step; statistical characteristics of a key warning value measurement values set warning value setup step; can be comprising. At this time said measurement correction step, said sample material driving conditions, coking chamber of coke oven sample, ball material, ball diameter, ball weight, and at least one drum rotation speed selected, said it is judged whether a table of function or data table for measuring value is corrected can be made. In addition said crusher abnormality diagnosis for the condition detection method, measurement correction step and said statistical analysis step between said measurements, said crusher (500) whether continuous or non-continuous is determined whether determined whether the crusher; said crusher (500) when a non-continuous, depending on the progress of ground measurements calibrated measurements further additional correction step; which further comprises, said crusher (500) is continuous when, said statistical analysis step is carried out immediately after kind crusher can be arranged to said measurements. In addition at this time said measurements further correction step, discontinuous grinding work by proceeds further corrects a measurement values can be normalized. Or said measurements further correction step, discontinuous grinding work by using the ratio between the values into an additional correction measurements can be made. In addition said statistical analysis step measurements, statistical characteristic value as an average value, median, standard deviation can be made to at least one selected are derived. In addition said crusher abnormality diagnosis for state detection method is, after said warning value setup, said re-obtains measurements is performed, measurement reaches or exceeds the warning, generate an alarm alert generating step; further comprises a can be. In addition of the present invention crusher abnormality diagnosis conditions includes sensing device, such as crusher abnormality diagnosis for state detection method described above using crusher abnormality diagnosis for state detection device (100) as, crusher (500) which is mounted on the at least one measuring sensor (110); generate an alarm alert unit (120); said measuring sensor (110) receives measurements from delivery to perform a statistical analysis, warning the measurements reaches or exceeds said warning unit (120) operating a number control unit (130); can be comprising. In addition said measuring sensor (110) is, at least one vibration sensor or be a selected noise sensor. According to the present invention, crusher, in in particular ball mill crusher, grinding blade of States for the diagnosis be quantitatively to the trench. A plurality of subjective judgment of number or reference number is based on his condition and selectively discharge irradiation in vibration. The material of the coking chamber of coke oven sample /, / weight/material of the ball diameter, such as crusher operation conditions or drum rotation speed or the like, continuous/non-continuous such as crusher case precisely and safely by various, different criteria are substantial state must be abnormality warning, based on the determined one warning criteria is then accurate without having a state and selectively discharge door number with the acronym is removed. However the present invention embodiment between the measured quantitatively warning value from vibration and noise measurements are derived, the derived warning device of the status and selectively discharge, compared to conventional abnormality diagnosis state much in reliability, accuracy and engagement with the be the trench formed therein. Figure 1 shows a schematic diagram of the also ball mill crusher. Figure 2 shows a schematic diagram of the device of the present invention also detecting condition. Figure 3 shows a method of the present invention flow of also detecting condition. Figure 4 shows a method of the present invention also in the statistical analysis and warning running example for detecting state. Figure 5 non-continuous crusher is a measure of the example. Figure 6 continuous crusher is a measure of the example. In Figure 7 of the present invention state detection method measurement correction example. Hereinafter, the present invention as defined by the condition detection method and device for diagnosing a coal pulverizer having products on the attached drawing more detailed as follows. Figure 1 shows a schematic diagram of the degree and also ball mill crusher in 2000. As ball mill mill is shown, rotates about the horizontal axis is within the drum a plurality of ball and sample are positioned, by ball and sample having a rotary drum in vertical ball dispenser applying impacts and balls between sample sample sample by the action which ground pigments and to combustion chamber. Generally sample of coffee degree determined by the diameter of the balls or, the material of the coking chamber of coke oven sample /, / weight/material of the ball diameter, such as crusher operation conditions or drum rotation speed or the like, depending on the type of crusher such as continuous/non-continuous over the various θ1. level of noise and vibration. So that the pressure is ball mill grinding blade of state and selectively discharge, a plurality of subjective judgment of vibration based on a reference value as well as in number or number irradiated. However the aforementioned apparatus for improving capacity as crusher, crusher case since the level of noise and vibration generated according variously changed, either only one more criteria determine the state isn't very sharp. The in the present invention, operation conditions or without being restricted by the type of device, device and method for sensing state of diagnosis than quantitatively or more can be realized crusher number a broadcast receiver. Figure 2 shows a schematic diagram of the device of the present invention are independent each other and also for detecting state, condition detection device of the present invention is as shown, crusher (500) installed lines of one measuring sensor (110), generate an alarm alert unit (120), said measuring sensor (110) receives measurements from delivery to perform a statistical analysis, warning the measurements reaches or exceeds said warning unit (120) operating a number control unit (130) including combustion chamber. At this time said measuring sensor (110) may be the vibrating sensor or noise sensor, the measuring sensor (110) which is measured on the measure is vibration or noise value with each other. Figure 3 shows a method of the present invention etc. and also when flow of sensing state. The method of the present invention crusher abnormality diagnosis for detecting state, essentially obtains measurements, measurements correction step, measurements statistical analysis step, a warning value setup can be done via the disclosed. Here, crusher to the determination result determined whether the crusher indicated, additional correction step further comprises measurements can be made. In addition these steps by is the warning value is, then quantitatively calculating warning a key generate an alarm alert can be generated is further performed. Base in the embodiment hereinafter, further in the embodiment, each formed between the optimum in the embodiment described as follows. In the embodiment basic In the embodiment obtains measurements is basic, measurements correction step, measurements statistical analysis step, a warning value setup can be done via the disclosed. Said measurement acquisition step, crusher (500) while operating said crusher (500) installed measuring sensor (110) state change over time from order vibration or noise measurements are obtained substrate. Said compensation step performs measurements, it is judged whether a corrected measurement derived. Wherein said operating condition is obtained, sample material, coking chamber of coke oven sample, ball material, ball diameter, ball weight, such as drum rotation speed or the like variables of said substrate. In specific embodiments for example, the ball and the same blot using grinding drum, rigid material on sample A relatively monitoring device is connected to the milling device generates a vibration sample B material is 6.0. Or, even though the same A sample of almonds, relatively small amount as milling even amount of vibration as milling is 6.0. This would be, crusher to enhance user convenience function or table (table) through said it is judged whether the previously calculated using calibrated by measurements, statistical analysis can be generated by RF power. According to the operation condition through a plurality of experiments previously been through mass production properties crusher mill can be, through same function or a curve fit by using measurement correction table (table) can be. For example ball mill (drum) as a function of vibration according to the rotational speed difference 2 pivotably the curve fit. Here the vibrating v sized, Ω is rotational speed are disclosed. Coefficient a, b, c includes a plurality of experiments according to a character value. Measurements said statistical analysis step, the predetermined time period measurements values derived probability density function and statistics S9 statistical analysis. Said period can be properly according to the operation condition. Figure 4 shows a method of the present invention also relates to a method for statistical analysis and warning in the example which via a derived condition detection, as shown in also 4 (A) time according to vibration measurements (also 4 (A) shown by of example modulation) values to 4 (B) shows that the distribution can be such as for statistical analysis. (B) 4 also derive from distribution of probability density function can be, in addition statistical characteristic value as an average value, median, standard deviation or the like can be derived. Said warning value setup step, statistical characteristics of a key warning value setting measurement values to be coated. In a specific example, the standard deviation of 2 also 4 (B). 33 Times value (2. 33 Σ) set as the sensed pressure value etc.. As well as to only one example, standard deviation of 2 times value S71, S71 correlation value such as 3 times, operating conditions are obtained when properly set according to a warning value. As aforementioned, according to the status or type of crusher and various driving conditions should be changed or reduced by the diagnosis based, operator subjective criteria in determining or number lyric making only one number is the fault diagnosis has been number because many door. However in the present invention, as described above according to various driving conditions and setting up warning reference, the abnormality diagnosis method by using a crusher abnormality diagnosis reliability, accuracy, and re-can be much improved. In the embodiment further In further in the embodiment, additional steps are added depending on the type of crusher can be corrected to a measured value. I.e., basic in the embodiment or in setting up a warning vibration will, in addition to setting up the operating conditions in the embodiment further to output warning the down-type crusher, abnormality diagnosis of P can be further improved. Figure 5 shows a non-continuous grinding blade of measurements which also relates to a method for example, Figure 6 and one example when a continuous grinding blade of measuring 2000. Also visible 5 as, in the case of non-continuous crusher deviation is grained, charged to a new sample work are repeated. At this time, the processor then crushed sample of vibration according to pass division of the visible region. The largely varying device for diagnosing abnormal state of vibration is difficult in the case of warning value setup removes the corrections-step disclosed. Figure 6 continuous grinding blade of measuring example sample is non-continuous ball mill unlike an aerating, grinding and, since the number of special paper, serve as internal of a sample state time constant disclosed. The measuring box may change over time is less, additional warning value setup without subsequent corrections by applying statistical analysis described in Figure 4 can be. Figure 7 shows a non-continuous crusher of the present invention and also for example be in a measurements correction. prior visible in Figure 5, depending on the progress of grinding since measurements varied, additional correction to reduce variation a plurality of hierarchies. 2 Additional correction is based on the method of measurements made at a ratio change over time can be used. I.e., varying over time measurements (also 7 (A)) 1 of a similarly change over time if distributed among the other measuring value, such as extent (B) 7 also change over time can be reduced. The, non-continuous grinding blade of measurements similarly worked to continuous grinding blade of measurements, statistical analysis can be applying warning value setup. In the embodiment optimal As above-mentioned operating conditions, after setting up warning is optimized according to the type crusher, the crusher to the predetermined value while operating between elements of the embodiment performs key chamber number can be. In the embodiment described above in the embodiment or additional base such as after setting up warning through, as in Figure 2 in accordance with the dashed lines, said crusher (500) while operating said crusher (500) installed in said measuring sensor (110) sense a vibration or noise from state change over time measurements are obtained the re-obtains measurements carried out. Then switches the obtained measurements, the measurements reaches or exceeds the warning, generate an alarm alert generating step particles is formed a plane at least equal to or higher than the event occurred thereby recognizing the grinder for hereinafter. In the embodiment of the present invention refers to said correspondingly limited, range of applications with a variety of system creates, in the claims claim the subject matter of invention made without deviating from the present invention if the person with skill in the art in various modifications and flawless as well as anyone capable of embodiment are disclosed. 100: State detection device 110: measuring sensor 120: Warning unit 130: number control unit 500: Crusher An object of the present invention is to provide a condition detecting method for the trouble diagnosis of a ball mill, which measures the vibration and noise of a ball mill in real time using a vibration and acoustic sensor and analyzes measurement values to detect the condition of the ball mill and diagnoses trouble. More specifically, it is possible to quantitatively set a warning value suitable for a type of ball mill, the operating condition of the ball mill and the like, by using vibration and noise measurement values measured in real time. COPYRIGHT KIPO 2018 Crusher while operating said measurement sensor state change over time shocks sense vibration or noise measurements are obtained the measurements obtains; it is judged whether a measurement calibrated measurements correction step; measurement values predetermined period during the statistical analysis statistical analysis step S9 and statistics probability density function derived measurements; statistical characteristics of a key warning value measurement values set warning value setup step; the comprising, measurement correction step and said measurements between said statistical analysis step, whether said crusher is determined whether continuous or non-continuous determined whether the crusher; non continuous when said crusher, crushing depending on the progress of measurement calibrated measurements further additional correction step; which further comprises, when said crusher is continuous, said statistical analysis step is carried out immediately after kind crusher said measurements characterized crusher abnormality diagnosis for state detection method. According to Claim 1, said measurement correction step, said sample material driving conditions, coking chamber of coke oven sample, ball material, ball diameter, ball weight, which is at least one selected speed of drum rotation, said it is judged whether the previously calculated function or data in response to the calibrated measurement characterized crusher abnormality diagnosis for state detection method. Back number According to Claim 1, said measurements further correction step, discontinuous grinding work by normalized measurement values from among a further correction is formed on sensing method characterized crusher abnormality diagnosis conditions. According to Claim 1, said measurements further correction step, discontinuous grinding work by using the ratio between measurement values into an additional correction is formed on sensing method characterized crusher abnormality diagnosis conditions. According to Claim 1, said statistical analysis step measurements, statistical characteristic value as an average value, median, standard deviation derived at least one characterized in that the yarn is of crusher abnormality diagnosis for state detection method. According to Claim 1, said crusher abnormality diagnosis for state detection method is, after said warning value setup, said re-obtains measurements is performed, measurement reaches or exceeds the warning, generate an alarm alert generating step; characterized in further comprising a crusher abnormality diagnosis conditions sensing method. Number 1, 2, 4, 5, 6, 7 selected by crusher abnormality diagnosis conditions both anti anti for state sensing device sensing method using as abnormality diagnosis crusher, crusher installed at least one measuring sensor; generate an alarm alert unit; delivery measurements from said measuring sensor receives perform statistical analysis, the number of operating water level reaches or exceeds the warning value measured at said warning unit; characterized in that the crusher abnormality diagnosis conditions comprising a sensing device. According to Claim 8, said measuring sensor, characterized in that the yarn is of sensor noise or vibration sensor is at least one crusher abnormality diagnosis for state detection device.