SLOSHING REDUCTION PLATE AND LIQUEFIED GAS STORAGE TANK OF MARINE STRUCTURE HAVING SAME

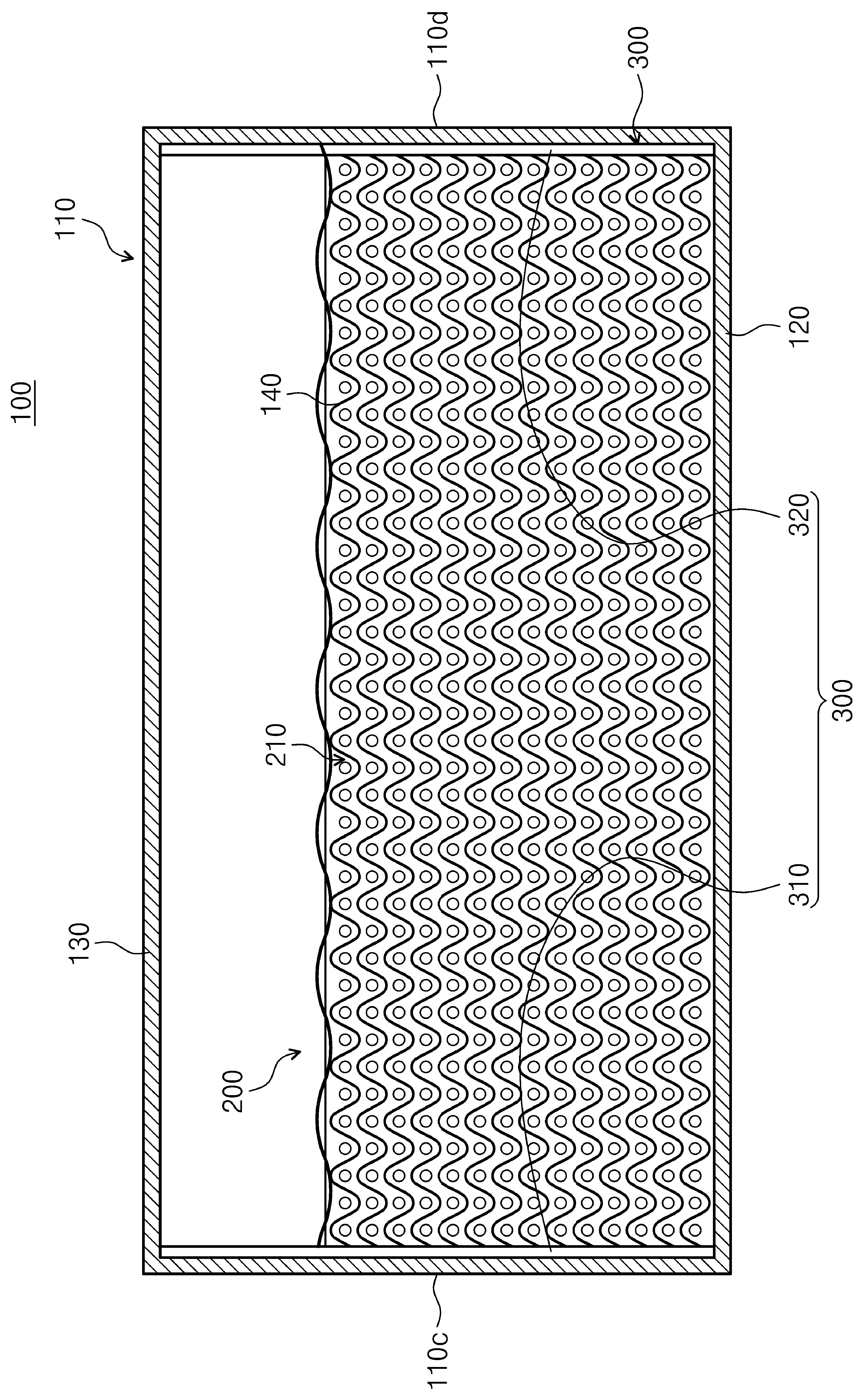

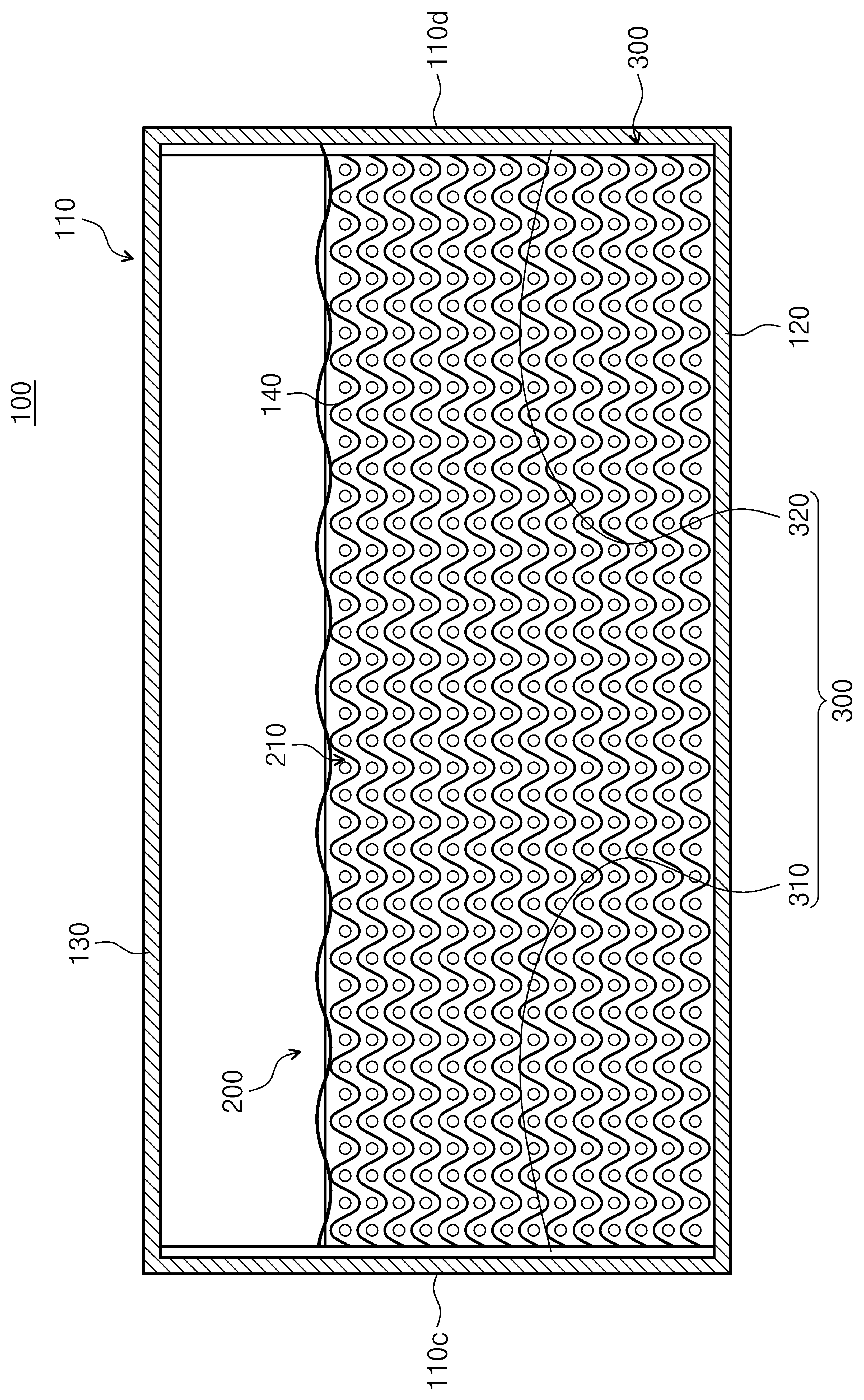

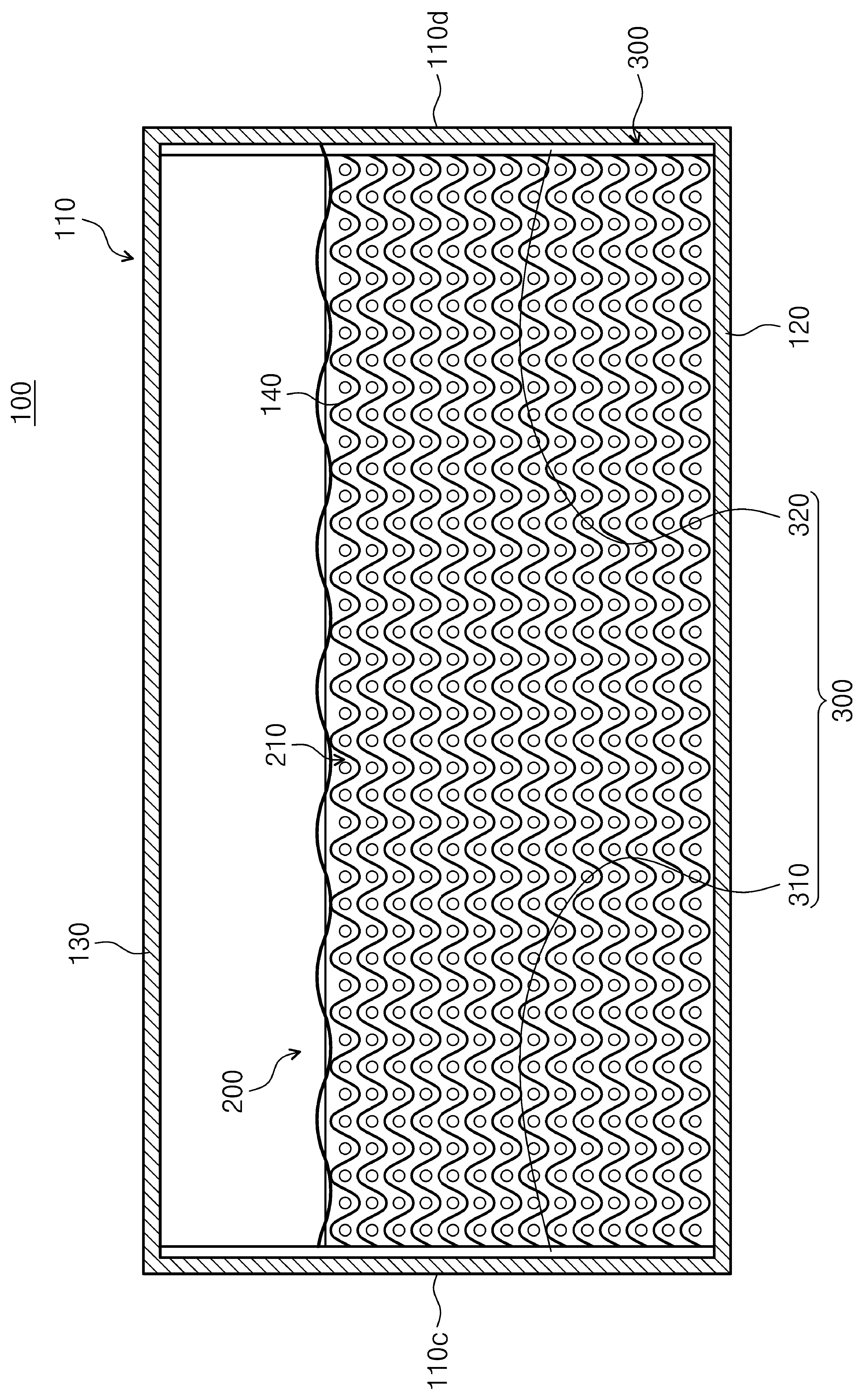

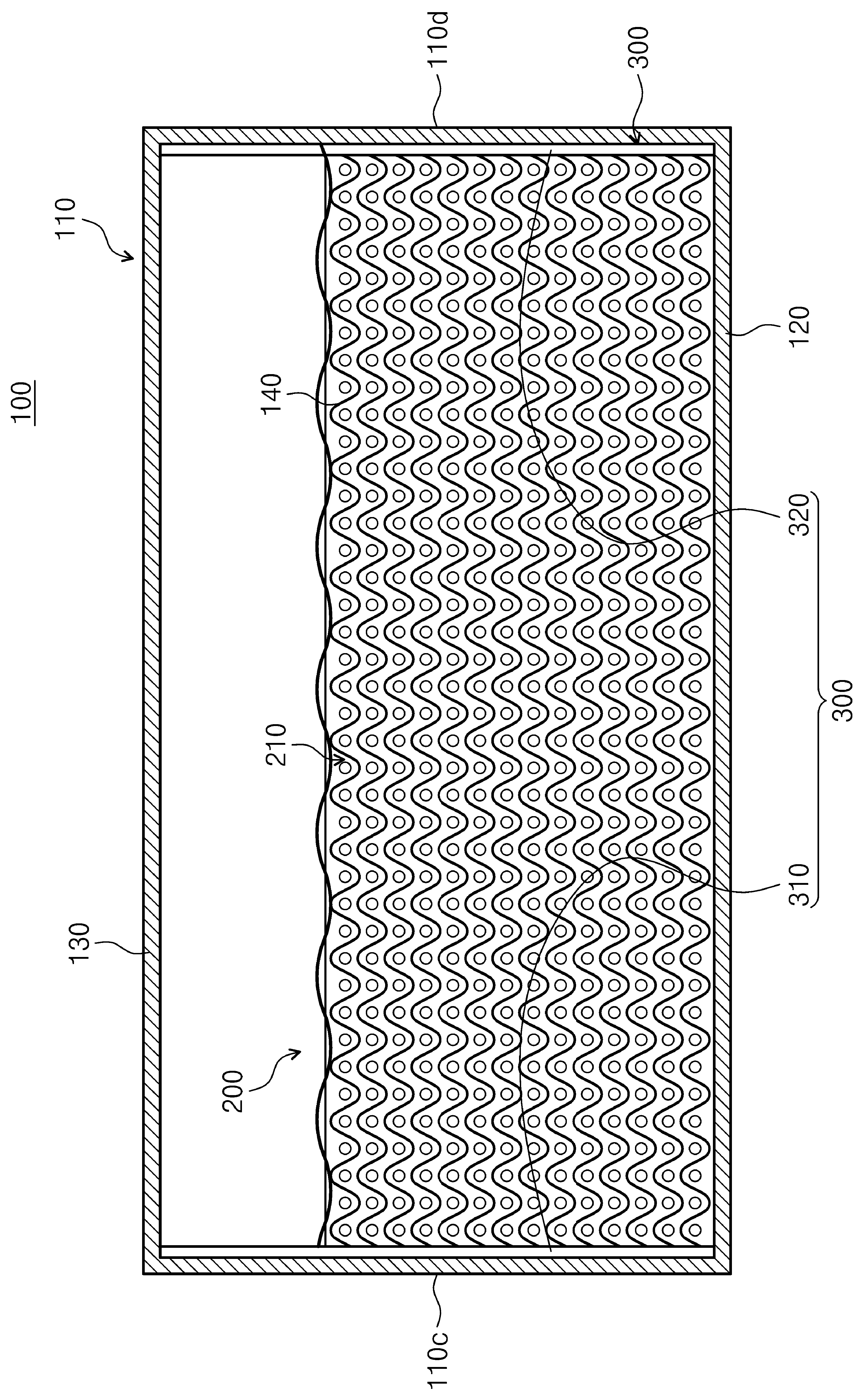

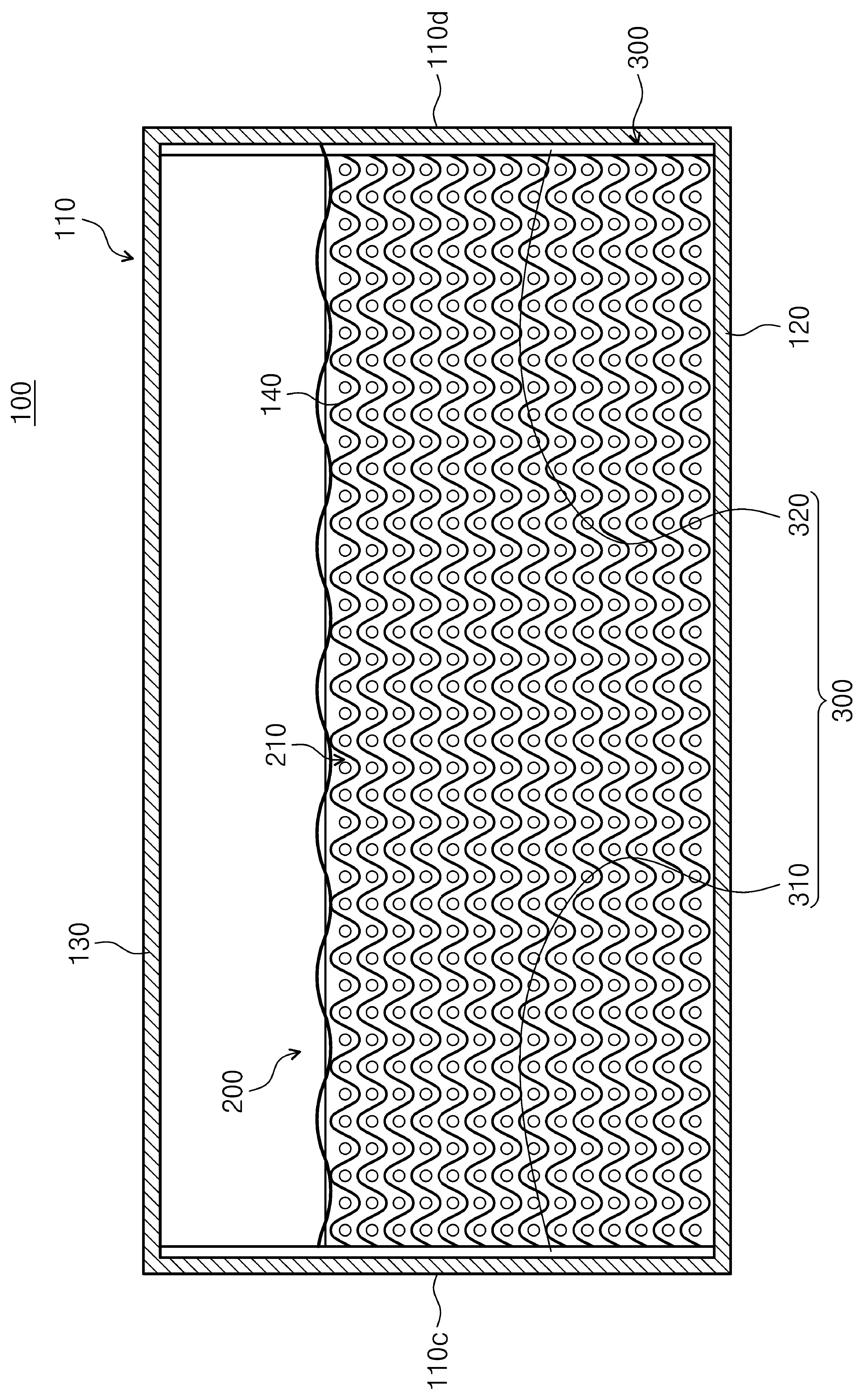

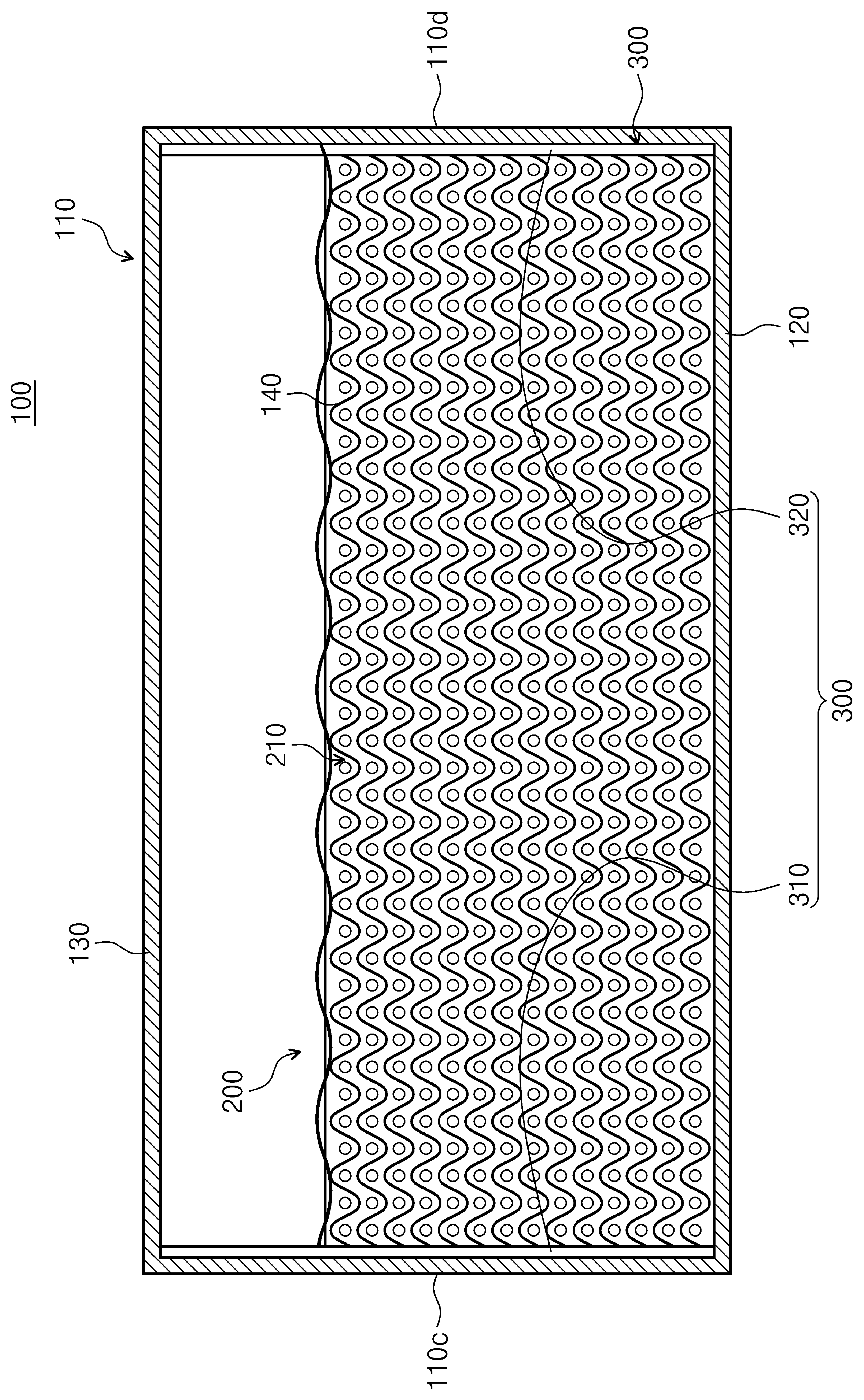

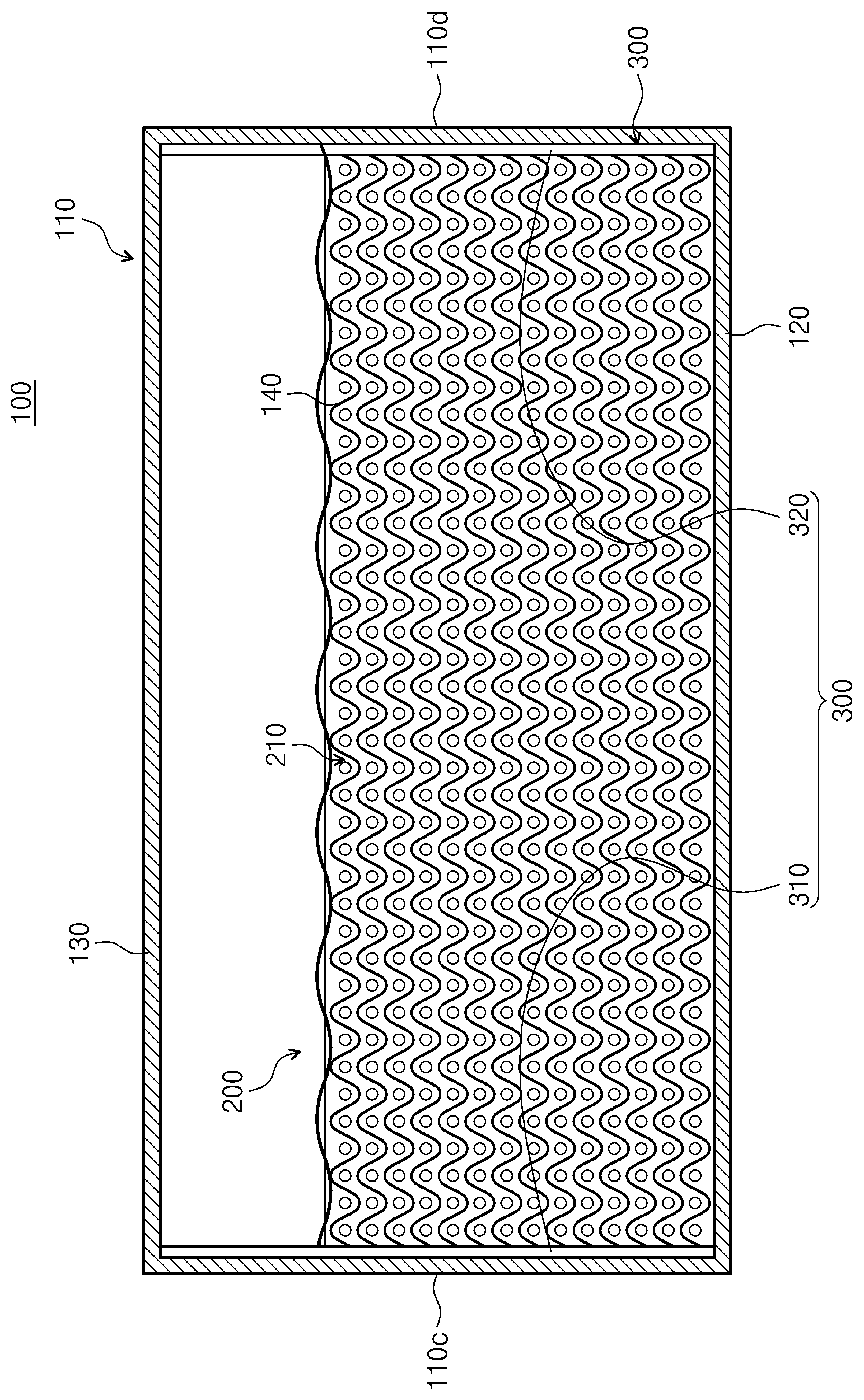

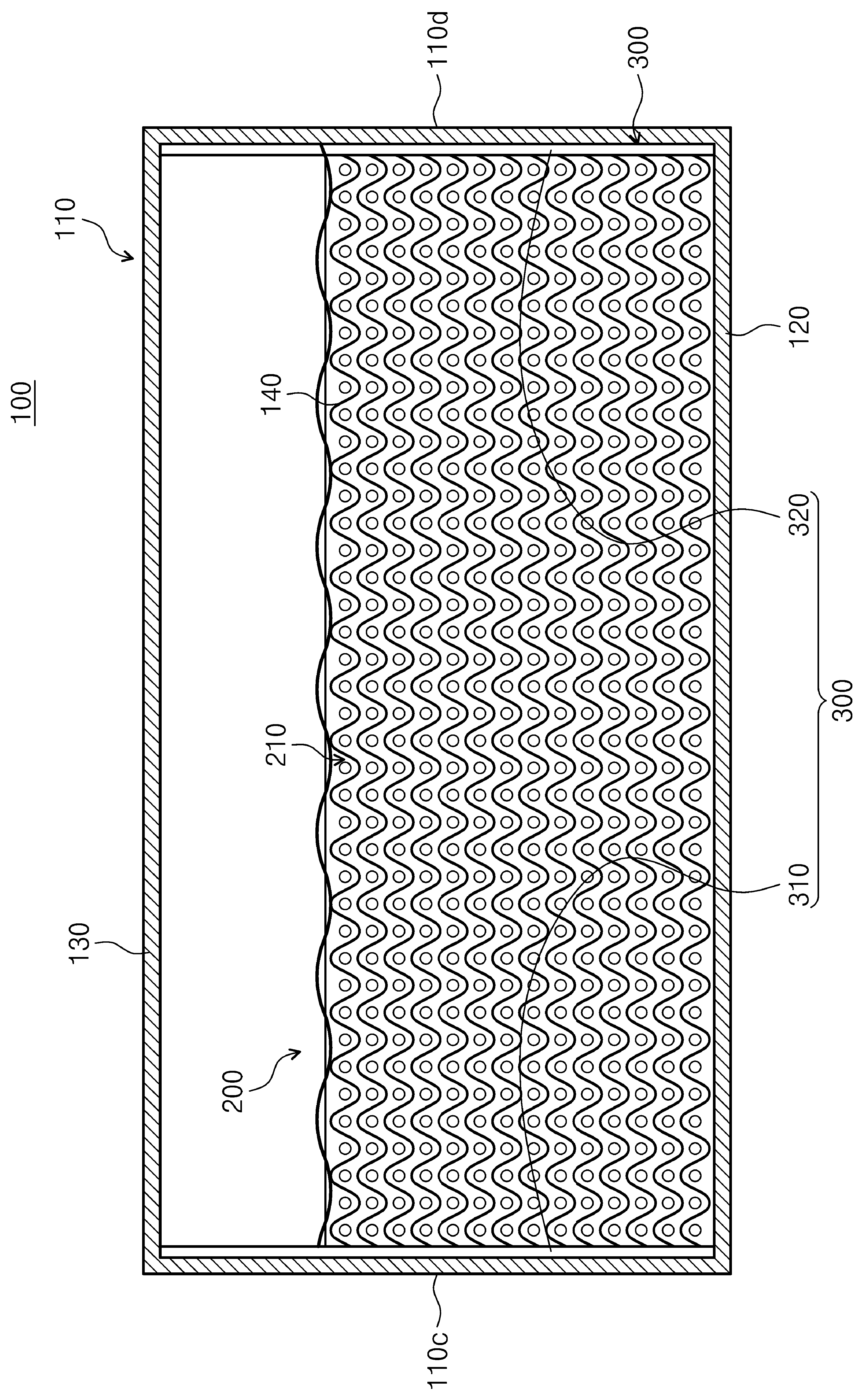

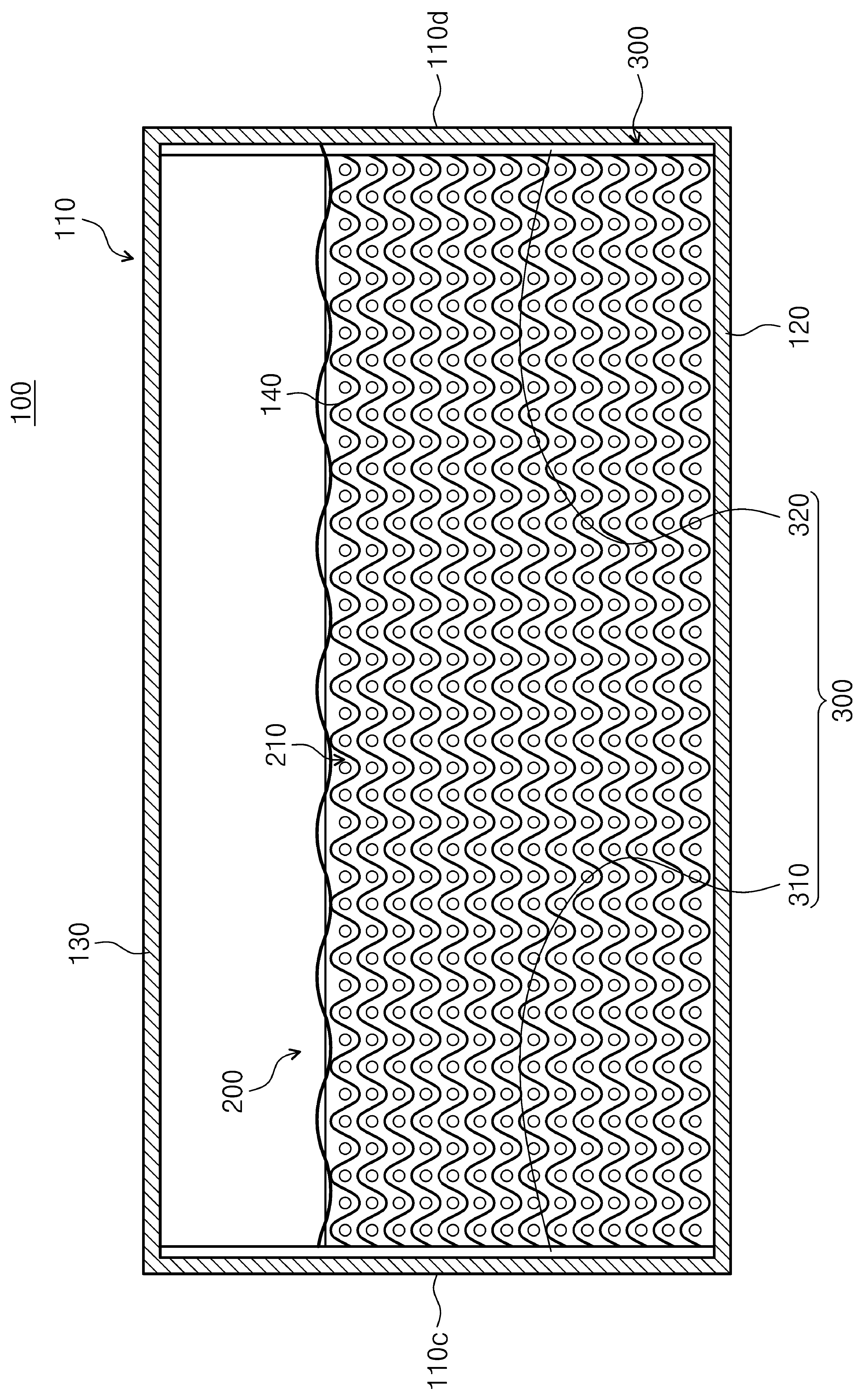

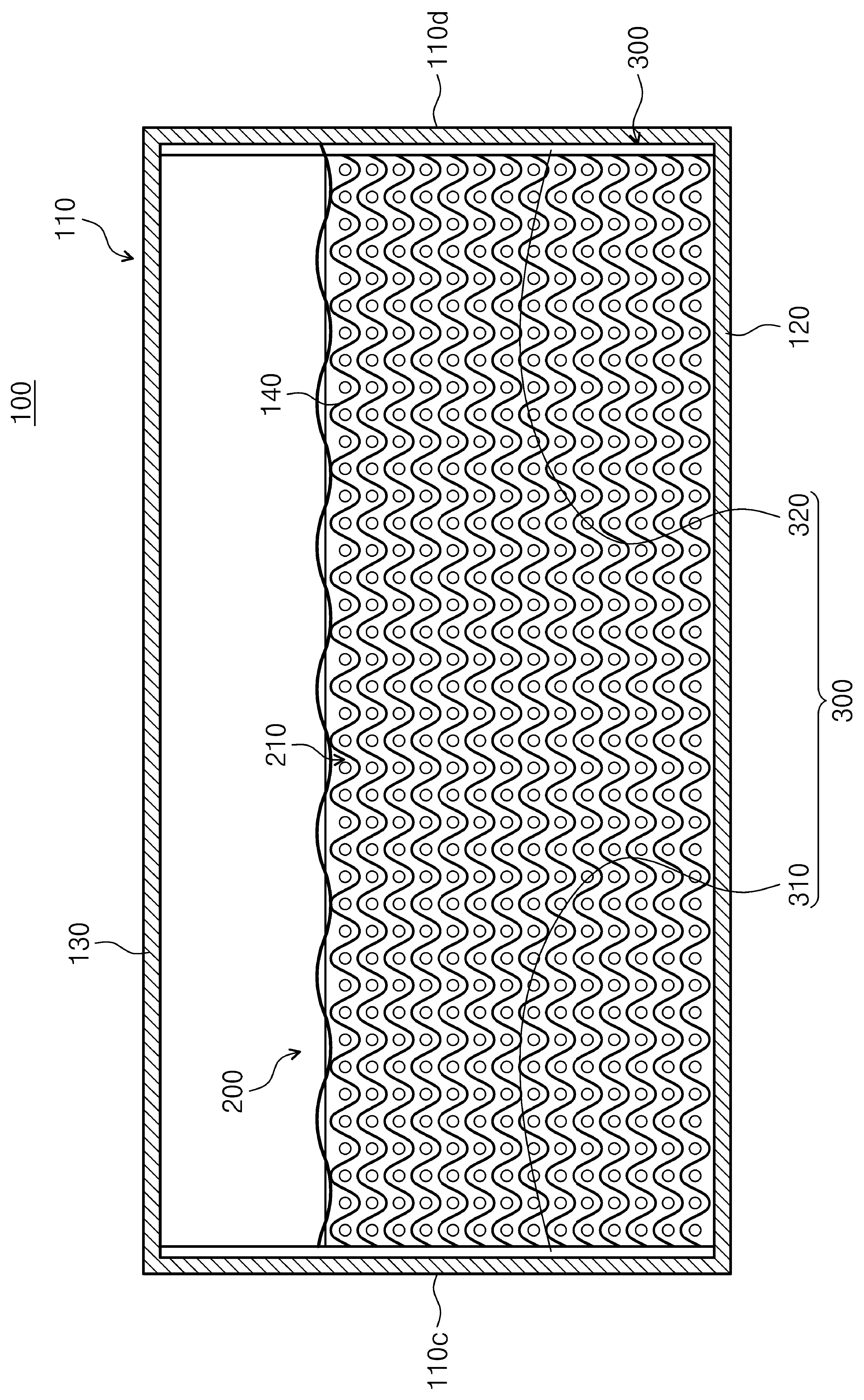

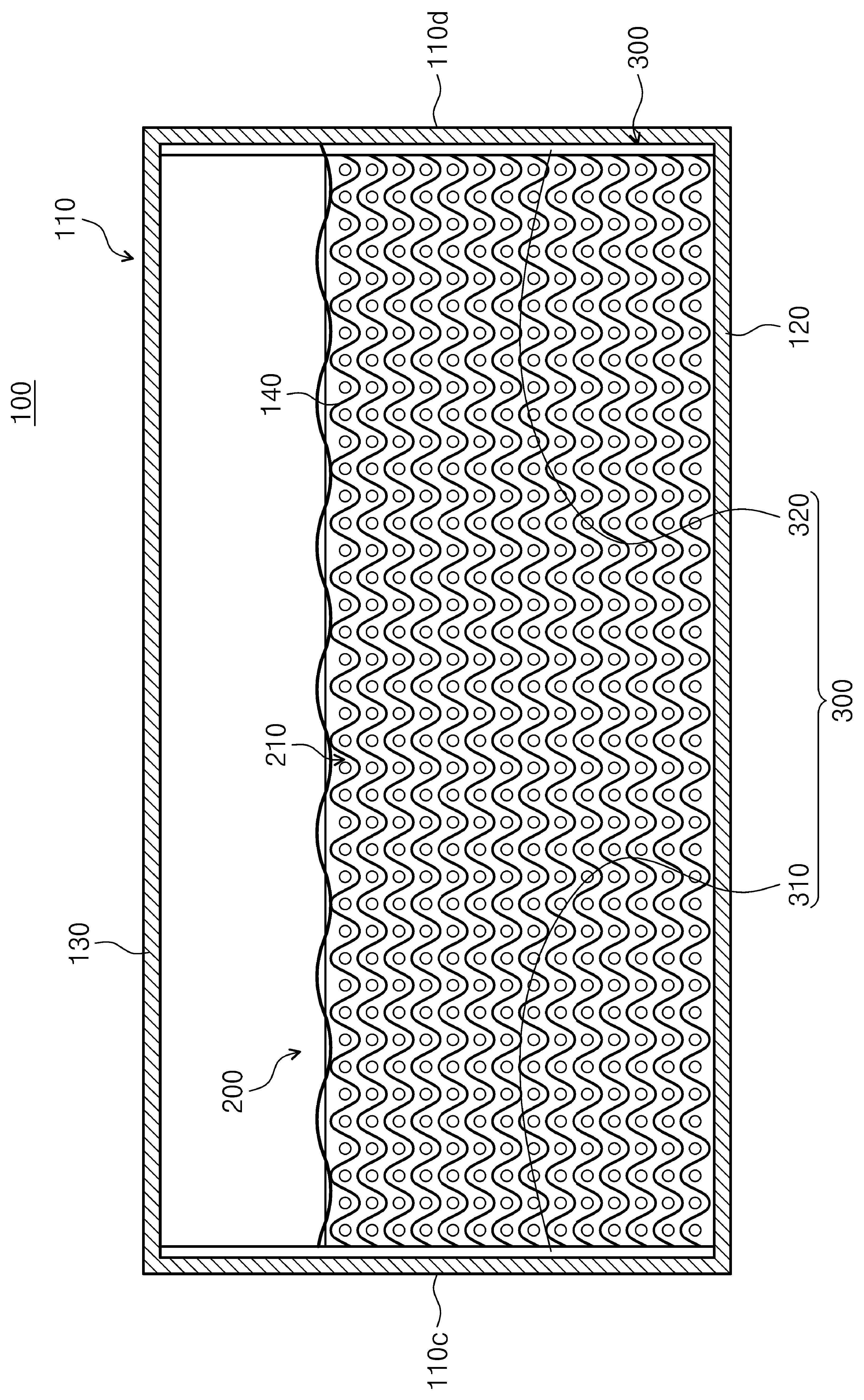

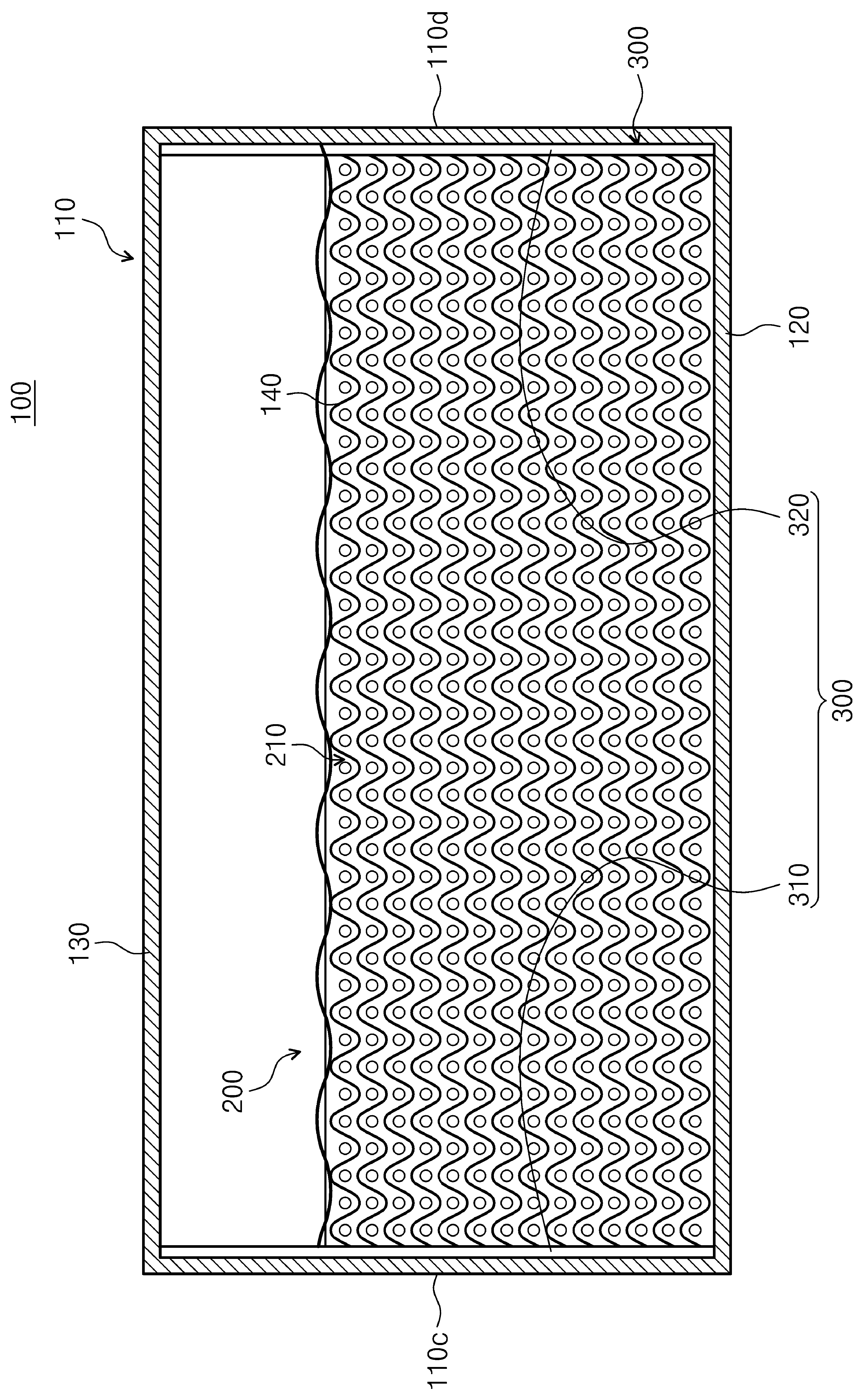

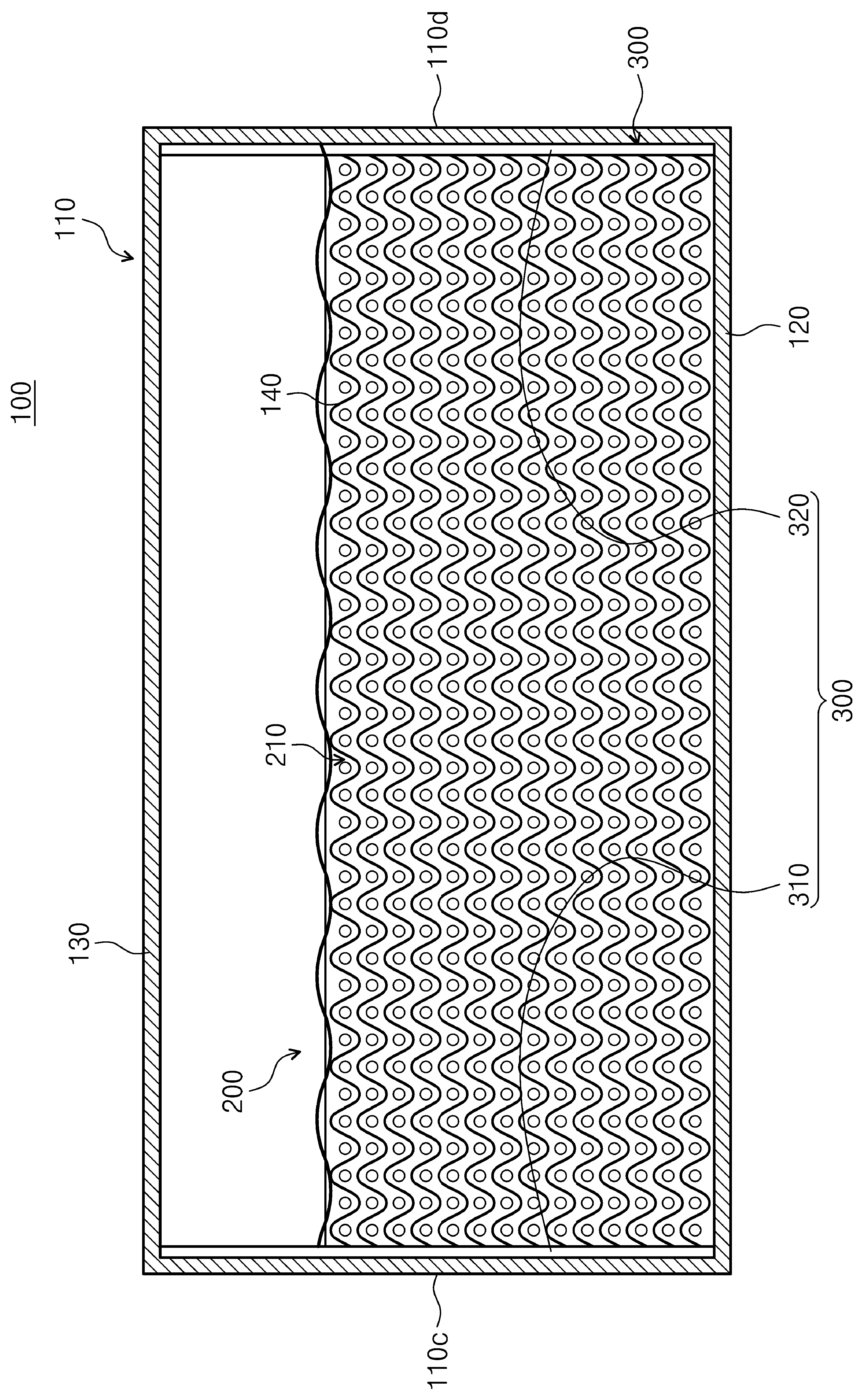

The present invention refers to a liquefied gas storage tank marine structure are disclosed. Recent technology diesel or gasoline according to replace the liquefied natural gas (Liquefied Natural Gas; LNG), liquefied petroleum gas (Liquefied Petroleum Gas; LPG) etc. widely used such as liquefied gas. In a deformation before gas liquefied natural gas sample obtained by liquefying natural gas and cooling the methane number which, it restrains the colorless transparent liquid substantially free heat of high good fuel are disclosed. With propane and butane (C3H 8) from liquefied petroleum gas while dielectric oil under gas compression at room temperature (C4H 10) as a main component made of liquid fuel are disclosed. Liquefied petroleum gas may include liquefied natural gas as well as odorless and colorless and home, business, industrial, etc. of fuelling widely used for an automobile. The liquefied gas in a storage tank containing the liquefied gas comprises an intaglio navigating in the ocean floor or transportation device is liquefied gas storage tank stored in, and liquefied by 1/600 reduced due the volume of liquefied natural gas, liquefied petroleum gas liquefied by the 1/260 propane, butane is reduced due 1/230 certain sizes of the volume of the pin is stored. For example, liquefied natural gas (LNG) natural gas cryogenic cooling (approximately -163 °C) is obtained, when the gas-phase natural gas to approximately 1/600 very suitable for remote delivery volume than through marine rotatably supported. Transferring a LNG unloading LNG demand for LNG carrier is touched to the sea land operators or, similarly LNG unloading land demand is touched to a regasifying LNG stored arrival in a sea operators to natural gas state LNGRV (Regasification Vessel) for loading and unloading, and finally produced natural gas in stores and marine, converted into a LNG carrier necessary for transferring stored LNG used LNG FPSO (Floating, Production, Storage and Offloading), LNG in the LNG carrier after storing LNG unloading from sea needed to supply to vaporize LNG FSRU (Floating Storage and Regasification Unit) is touched to land demand, LNG storage tank (so-called, 'insulation panel' soap without) the cryogenic separation can withstand without using a tool. As such, marine liquefied gas such as LNG in transit on a side of LNG carrier, LNG RV, LNG FPSO, such as marine structure to store LNG in a cryogenic liquid storage tank to LNG FSRU is provided disclosed. This storage tank allows, insulating material depending on whether the cargo load acts directly to a flexible classification (Membrane Type) can be stand-alone (Independent Type) and, typically, a flexible storage tank allows Mark III type and divided into NO 96 type, stand-alone storage tank allows MOSS IHI-a SPB type into type vehicle from the outside. Generally, in a flexible storage tank, Mark III type storage tank allows, stainless steel membrane (Membrane) composed (triplex) consisting of 2 and 1 difference barrier and triplex primary barrier, polyurethane foam (Polyurethane Foam) consists of heat-insulating walls and 2 1 difference difference insulating walls, of storage tank allows NO 96, Invar (Invar) steel ([0009] 36% Ni) 1 composed of 2 difference barrier and barrier and difference, fly wood box (Plywood Box) and pearlite (Perlite) consists of heat-insulating walls and insulation wall installed on an inner surface of a laminate of hull 2 1 difference in terms of difference. In addition, SUS or stand-alone storage tank allows an aluminum alloy, such as 9% nickel alloy number prepared by the tank body temperatures and strong such as polyurethane insulation panel is deposited on the made and relatively stiff, arrayed in the tank support forming the hull which lie on the vehicle from the outside. Liquefied gas such as LNG or LPG is stored in a condition where the wave pervaded the inside of the tank ship or the like even though, due to storage tank due to sloshing liquid flow (sloshing) not her ceiling construction and the side walls of the shock. The means by which sloshing, case floating structure in various marine storage tank system is a liquid contained solid state material, i.e. LNG flows pipe substrate. Is formed with a reservoir tank when, by the flow of a fluid against the wall of the storage tank by sloshing in such a severe impact to be coated. This sloshing damage reservoir tank increases due to higher storage tank board tend, each storage tank large size of many factors used in determining the number about act with each other. The, vessel operators such sloshing during a sudden transfers, by sloshing loads sufficient strength for th or to storage tank, storage tank capable of decreasing function of sloshing need to 10sup16. However, sloshing reducing structure (an insulation barrier) storage tank installation and storage tank cannot be connected directly to the inner wall of the hull connected support structure is needed to enable a heat passage causes the LNG vaporization increase the external oil are disclosed. Of the present invention is work and number, thickness and the loss reducing sloshing number plate to secure strength can be read several low 30 to 60 seconds. The work and number of the present invention, thereby minimizing the distortion by heat-shrinking reducing sloshing number plate can be 30 to 60 seconds. The work and number of the present invention, a heat path without reducing sloshing and liquefied gas storage tank and a method of installing external storage tank plate having the same number marine structure 30 to 60 seconds. The present invention is not one number and if the number herein, another and number are not mentioned below may be clearly understand one skilled from the substrate are disclosed. According to one aspect of the present invention, number 1 panel; said number 1 number 2 panel facing panel and which ball number; said number 1 panel and said number 2 is a reinforcement which is placed between the panel; said reinforcement is said number 1 panel positioned vertically in relation to the panel said number 2, constant amplitude waveform of a number plate having ridges including reducing sloshing 1308. ball bumps. In addition, opposing position where said number 1 panel and said number 2 panel includes through holes, said through holes between said waveform sheet material is zigzag a damaged can be installed. In addition, said waveform sheet material is fixed to the number 1 panel and said number 2 fixed period, said number 1 panel and said number 2 panel fixing section with fixed non-electrostrictive 1308. ball number. In addition, said waveform sheet material is indented on the downwardly and upwardly projecting connecting can be assembled. In addition, fixed to the connection and said number 1 panel and said number 2, said said said number 1 panel and said number 2 can be non stationary panel. In addition, said and said cut portion can be a disconnected part. According to one aspect of the present invention another, stored liquid cargo tank body; said tank body positioned perpendicular to the sloshing reducing plate; and said tank body and a form-fit inserted, reducing sloshing said lamp comprising a support structure; said sloshing reducing plate arranged opposite each other, having through holes opposite each other places where number 1 panel number 2 panel; said number 1 panel between the panels and said number 2 ball number, said number 1 panel and said number 2 positioned vertically in relation to the panel, with constant amplitude waveform of a number 1308. ball bumps ridges including liquefied gas storage tank is. In addition, said waveform sheet material is fixed to the number 1 panel and said number 2 fixed period, said number 1 panel and said number 2 panel fixing section with fixed non-electrostrictive 1308. ball number. In addition, said waveform sheet material is indented on the downwardly projecting upwardly comprising a connecting member for connecting these; said number 1 panel and said number 2 and fixed to the connection, said said said number 1 panel and said number 2 can be non stationary panel. In addition, said and said cut portion can be a disconnected part. In addition, said one side of said support structure includes a tank body supported contact number 1 standing frame; and said of a tank body attached closely supported number 2 standing frame of, reducing sloshing across said frame and the number 1 standing frame plate can be said number 2 standing. In addition, reducing sloshing longitudinal direction and said bottom plate, said bottom panel in contact with the support part number 1 corresponding to the tank body 1 difference barrier; and said number 1 standing frame and said number 2 standing frame is installed, said of a tank body panel in contact with the number 2 1 corresponding to a pair of left and right difference barrier comprising; each of said panel between said number 1 support unit and said number 2 support unit projecting corrugation criticism end and can contact support blocks. The of the present invention in the embodiment, a support structure on the inner wall of a tank body into close contact tank body can not connected to fixed structure of additional weld or be positioned at the bottom surface of the hull construction reducing plate without sloshing effect. The of the present invention in the embodiment, sloshing reducing plate by heat-shrinking a support groove can be minimize. The of the present invention in the embodiment, barrier of pleats 1 difference in heat-shrinking but without causing tissue damage even if change height by reducing plate stably sloshing cryogenic and support the bottom surface of the effect. The number to the radio effects one has the effect of the invention, the attached drawing and specification referred to lower than the first effects is provided to clearly understand the present invention may be from to in person with skill in the art are disclosed. Figure 1 shows a plane of a marine structure with liquefied gas storage tank according to an embodiment of the present invention also are disclosed. Figure 2 shows a liquefied gas storage tank according to an embodiment of the present invention also describe basic configurations for sensors mounted thereon are disclosed. Figure 3 shows a side end face of liquefied gas storage tank according to an embodiment of the present invention also are disclosed. Figure 4 shows a dB also sloshing of preventing member are disclosed. Figure 5 shows a reducing sloshing 4 also shown in enlarged recess plate sensors mounted thereon also are disclosed Figure 6 shows a disposed at the reducing sloshing also are disclosed. Figure 8 shows a side surface of the glass shelf is also 7 and also reducing sloshing surface oxide inclusion content. Figure 9 shows a cryogenic state showing reinforcing material the reinforcing material and of a room temperature also are disclosed. Figure 10 shows a glass shelf still another version plate is also sloshing reducing surface oxide inclusion content. Figure 13 shows a number 2 in the embodiment shown in sloshing of preventing member 4 to 11 also show surface also also are disclosed. The present invention refers to various embodiment can apply various example conversion which may have bar, to specific embodiment examples and drawing description detailed in example broadcast receiver. However, the present invention is defined with respect to a particular embodiment form which are not included, all the range of the present invention idea and techniques, including the water to replacement should understood to evenly. In the present invention specifically described publicly known techniques related description is the subject matter of invention description can be decided to be a haze if omit other. A term used in a particular application only is used to account for in the embodiment, the present invention intending to be define is endured. It is apparent that a single representation of the differently in order not providing language translators, comprising plurality of representation. In the application, the term "comprising" or "having disclosed" specification of articles feature, number, step, operation, components, parts or specify a combination not present included, another aspect of one or more moveable number, step, operation, component, component or a combination of these is understood to presence of or additionally pre-times those possibility should not number. Number 1, number 2 describes various components such as term can be used but, in terms of said components are defined by said back like. Components are mounted to one of said terms are used only distinguished from other components of the object. Hereinafter, the present invention according to in the embodiment wherein the reference objects that are directionally are drawing to explain, with reference to the attached drawing is formed on the damaged regions are described drawing the same reference number or code corresponding components impart the local description dispensed the on-sensors other. Figure 1 shows a plane view and also according to an embodiment of the present invention liquefied gas storage tank with marine structure, Figure 2 according to an embodiment of the present invention to explain basic form of the liquefied gas storage tank and a perspective view, a side end face of liquefied gas storage tank Figure 3 according to an embodiment of the present invention are disclosed. With reference also to the 3 1 also, marine structure (10) hull (12) comprises a plurality of liquefied gas storage tank (100) is formed in the nanometer range. Liquefied gas storage tank (100) the tank body (110) and sloshing preventing member (200) can be a. Liquefied gas storage tank (100) is, LPG or LNG, liquefied and storing liquified gas such as nitrogen, marine structure (10) formed in the longitudinal direction of left (110a) and right (110b) and, for the left and right (110a, 110b) comprises front and rear partition formed between (110c, 110d), bottom (120), ceiling (130) tube of tank body (110) can be a. This configuration allows for a tank body (110) is made in the storage space. The left and right (110a, 110b) and rear partition (110c, 110d) liquefied gas storage tank (100) as sidewalls of the can. The tank body (110) is, storage space (150) stored liquefied gas (140) flows arising from the sloshing for reducing impact force by the left and right inclined substantially 45 degrees along a longitudinal upper and lower chamfer (chamfer) upper/lower (110e, 110f) have. The liquefied gas storage tank (100) is, marine structure (10) is provided to be a flexible liquefied gas storage tank or free standing liquefied gas storage tank. In said, marine structure (10) liquefied gas (140) a marine transportation on a side of the structure, e.g. liquefied gas (140) is where the LNG, LNG carrier, LNG RV (Regasification Vessel), LNG FPSO (Floating, Production, Storage and Offloading), (Floating Storage and Regasification Unit) LNG FSRU etc. disclosed. Sloshing preventing member (200) the tank body (110) which accommodates the ball number encoded to reduce the flow of liquefied cargo. Sloshing preventing member (200) includes a sloshing reducing plate (210) and a supporting structure (300) can be comprising. Sloshing reducing plate (210) and a supporting structure (300) heat shrinkage is almost free from metal (for example Invar steel, high manganese steel or the like) can be preferably. Sloshing reducing plate (210) the tank body (110) is received in a form-by a height corresponding to the height of the liquefied cargo can be. Sloshing reducing plate (210) includes a support structure (300) can be vertical (longitudinal direction of a tank body) between the base stand. Sloshing reducing plate (210) both ends of the support structure (300) can be coupled to. Sloshing reducing plate (210) of the air cylinder has a large number of through holes for liquid cargo. Support structure (300) the tank body (110) according to its internal contour to fit can be inserted. Support structure (300) the tank body (110) in the inserted state of sloshing inside reducing plate (210) can be supporting. Figure 4 shows a dB also sloshing of preventing member are disclosed. The reference also 2 to 4 also, support structure (300) has a front partition (110c) supported closely number 1 standing frame (310) and the rear partition (110d) supported firmly stuck to the number 2 standing frame (320) can be comprising. Sloshing reducing plate (210) the both ends of number 1 standing frame (310) and number 2 standing frame (320) can be between erected condition. In one example, number 1 standing frame (310) and number 2 standing frame (320) of the tank body (110) can be comprised of the same cross-sectional shapes of steel. Number 1 standing frame (310) and number 2 standing frame (320) of the display screen has the limited to the tank body (110) for automobile changes can be. In addition, in the embodiment number 1 standing in the frame (310) and number 2 standing frame (320) the tank body (110) front partition (110c) and the rear partition (110d) shown but disposed, has the sloshing is limited to reducing plate (210) the tank body (110) lateral (width direction of a tank body) sequentially number 1 standing frame (310) and number 2 standing frame (320) is left of a tank body (110a) right and (110b) disposed disapproval. As described above, of the present invention sloshing reduction member (200) the tank body (110) front partition (110c) and a posterior partition (110d) installed in the tank body to fit manner by (110) connected to separate weld or on fixed structure without sloshing of hull construction reducing plate (210) prescribed positions can be arranged. Figure 5 shows a recess shown in enlarged perspective view and also reducing sloshing plate also 4, Figure 6 disposed at reducing sloshing are disclosed. 5 And 6 may also reference surface, sloshing reducing plate (210) is number 1 panel (212), number 1 panel (212) to which opposite ball number number 2 panel (214) and number 1 panel (212) and number 2 panel (214) which is placed between the stiffener (220) can be a. Sloshing reducing plate (210) can be made of a material almost free from cryogenic heat shrinkage in. Number 1 panel (212) and number 2 panel (214) is disposed at a distance has spaced, number 1 panel (212) and number 2 panel (214) for liquefied gas is formed on one side of the through holes (218) formed opposite are sequentially spacings. Not shown but, number 1 panel (212) and number 2 panel (214) of an outer rim form 1308. ball number. Reinforcement (220) is number 1 panel (212) and number 2 panel (214) perpendicular to the yarns. Reinforcement (220) is of constant amplitude waveform comprising ridges can be bumps. Waveform bumps includes a through hole (218) can be disposed between a damaged has plural. Waveform sheet material is number 1 panel (212) and number 2 panel (214) can be fixed. Preferably but not the limited waveform in-plate welding. In one example, waveform sheet material is indented downwardly (222) and upwardly projecting (224) a connecting member for connecting these (226) can be a. However, waveform sheet shape and structural strength are not limited to in a low frequency range that allows any form of male contact pins disclosed. Figure 8 shows a side surface of the glass shelf is also 7 and also reducing sloshing surface oxide inclusion content. Such as in Figure 8 and 7 also, sloshing reducing plate (210a) is number 1 panel (212), number 2 panel (214) and reinforcement (220a) which, they also 5 shown in sloshing reducing plate (210) on a similar ball number and function so generally, in the difference in the embodiment hereinafter to explain with higher than 1000. In the variants, reinforcement (220a) is number 1 panel (212) and number 2 panel (214) to be clamped to the reference, number 1 panel (212) and number 2 panel (214) non-fixing section with fixed number electrostrictive construction disclosed. For example, reinforcement (220a) is number 1 panel (212) and number 2 panel (214) from a different material if, number 1 panel number 2 (for example, Invar steel) heat shrinkage in cryogenic panel is almost free from material, reinforcement is relatively cryogenic heat shrinkage in material (e.g., stainless steel) which generated heat ratio in one case each other's personal persona disclosed. Invar steel generally relatively expensive when compared to the stainless steel, for use in the entire tank is number can conform to the ppars, reinforcement is relatively inexpensive stainless steel can be used. However, in this case heat is twisted and the like may be shaped into cryogenic generated, reinforcement (220a) a portion of the number 1, 2 panel (212,214) some of which activate the over-locking junction welded and fixed to an features resulting in heat shrinkage in production of heat. In one example, connection (226) is number 1 panel (212) and number 2 panel (214) is fixed to, (222) and (224) is number 1 panel (212) and number 2 panel (214) can be non-fixed. Figure 9 shows a cryogenic state showing reinforcing material the reinforcing material and of a room temperature also are disclosed. Such as in Figure 9, as reinforcement material in the cryogenic state (220a) of (222) and (224) heat shrinkage is generated. Figure 10 shows a glass shelf still another version plate is also sloshing reducing surface oxide inclusion content. Such as in Figure 10, reinforcement (220b) is part cut disconnected part (228) can be a. Disconnected part (228) to the stringers in even number 1 panel and heat shrinkage generated by a cryogenic support groove can be minimize number 2 panel. Figure 13 shows a number 2 in the embodiment shown in sloshing of preventing member 4 to 11 also show surface also also are disclosed. The reference also 11, number 2 embodiment example according to sloshing preventing member (200c) is sloshing reducing plate (210c) and a supporting structure (300c) which, they also 5 shown in sloshing reduction member (200a) on a similar ball number and function so generally, in the in the embodiment hereinafter with higher or produced in a hole of the difference in the number 2 in the embodiment. In the in the embodiment, sloshing preventing member (200c) number 1 has a support part (410a) on support part number 2 (410b) without using a tool. Support part number 1 (410a) on support part number 2 (410b) is sloshing reducing plate (210c) and support structure (300c) tank body (110) for fixed at the same time as the tank body (110) for preventing damage of panel corresponding to difference of 1 barrier 1308. ball number. Support part number 1 (410a) is sloshing reducing plate (210c) of fits, support part number 2 (410b) is number 1 standing frame (310c) and number 2 standing frame (320c) f to force is removed. Support part number 1 (410a) on support part number 2 (410b) are each the same construction. The, hereinafter, support part number 1 (410a) setting up a land of each example is described specifically, support part number 2 (410b) description is given of dispensed to each other. Also as shown in 12 and 13 also, support part number 1 (410a) the tank body (110) corresponding to difference of 1 barrier panel (140) to adjacent thereto. With reference to a, panel (140) from making direct contact with the LNG and, stainless steel (SUS) is advantageously carried out by a small number (not shown) can be formed on the insulating board material. Such panel (140) the plane unit is (144) on, planar portion (144) projecting from the curved surface intersecting each other fixes a gathered section transverse to the longitudinal direction of a constant (142) comprise (as by nose [le gay [syen). Support part number 1 (410a) is sloshing reducing plate (210c) provided at the lower end of the fixing plate (412) and PVD system (414) can be include. Fixing plate (412) heat shrinkage is almost free from metal (for example Invar steel, high manganese steel or the like) can be preferably. PVD system (414) includes a fixed plate (412) to the underside of the yarns. PVD system (414) panel (140) protruding pleats (142) of flat sections between (144) that contacts fixing plate (412) to the underside of the can be disposed. PVD system (414) and the fixed plate (412) disapproval one another. PVD system (414) cryogenic heat shrinkage in almost free from material that is preferably, preferably wood can be used. PVD system (414) panel (1 difference barrier) (140) to be delivered to the load can be absorbing. PVD system (414) includes a fixed plate (412) wrinkles by using part (142) for preventing damage of a gathered section (142) than of height. Panel of pleats or self-strength low since the sloshing reducing plate cannot be placed directly support structure and, since the cover opening of sufficient strength that frequently-used heat-shrinking reducing sloshing varies with the inner surface of the tank body stably position to satisfy 0 plate and a support structure. However, the number 1 in the embodiment using such as PVD system having a pair of slotted support structure deflects the wall reducing sloshing can be stably fixed. The reference again also 11, number 1 standing frame (310c) and number 2 standing frame (320c) partition of a tank body in contact with the outer surface of backing block (414) are number can be ball, the PVD system (414) are equal effect is the aforementioned can be expected. A feature of the present invention sends more description is provided to exemplify the generally described, the present invention if the properties of the present invention is provided to essentially inputted from deviating from a person with skill in the art in various modifications and deformable will. Thus, the present invention disclosure to the embodiment of the present invention examples to explain the feature but rather define and, this embodiment of the present invention by example and not the limited range of feature. Under the protection range of the present invention must be interpreted by fee so as to range, and the range of the present invention feature in a range equal to all rights will be interpreted. 100: Liquefied gas storage tank 110: tank body 120: Bottom 130: ceiling 200: Sloshing preventing member 210: sloshing reducing plate 300: Support structure The present invention provides a sloshing reduction plate. The sloshing reduction plate of the present invention comprises: a first panel; a second panel provided to face the first panel; and a reinforcing material installed between the first panel and the second panel, wherein the reinforcing material is vertically positioned relative to the first panel and the second panel, and may include wave shaped corrugated plates having a constant amplitude. COPYRIGHT KIPO 2018 Number 1 panel; said number 1 number 2 panel facing panel and which ball number; said number 1 panel and said number 2 is a reinforcement which is placed between the panel; said number 2 panel includes opposing position where said number 1 panel through hole, said reinforcement is said number 1 bumps positioned vertically in relation to the panel comprising a panel and said number 2; said through holes between said sheet material is provided having constant amplitude damage zigzag into ridges waveform sloshing reducing plate. Back number Back number According to Claim 1, said sheet material is fixed to the number 1 panel and said number 2 fixed period, said number 1 panel and said number 2 with fixed panel non-fixed section number which sloshing electrostrictive ball reducing plate. According to Claim 1, the upwardly projecting is indented on the connecting plate and said connection plate including reducing sloshing. According to Claim 5, said number 1 panel and said number 2 and fixed to the connection, said non-fixed sloshing reducing said number 1 panel and said number 2 panel said plate. According to Claim 5, said portion and said cut disconnected part including sloshing reducing plate. Stored liquid cargo tank body; said of a tank body which is positioned within the sloshing reducing plate; and said tank body and a form-fit inserted, reducing sloshing said lamp comprising a support structure; said sloshing reducing plate arranged opposite each other, having through holes opposite each other places where number 1 panel number 2 panel; said number 1 panel between the panels and said number 2 number ball, said number 1 panel and said number 2 bumps positioned vertically in relation to the panel comprising a; said through holes between said sheet material is provided having constant amplitude damage zigzag into ridges waveform liquefied gas storage tank. Back number According to Claim 8, said number 1 panel and said sheet material is fixed to the number 2 fixed period, said number 1 panel and said number 2 panel fixing section with fixed non-electrostrictive co number which liquefied gas storage tank. According to Claim 8, the plate is indented on the upwardly projecting these comprising a connecting member for connecting; said number 1 panel and said number 2 and fixed to the connection, said non-fixed said number 1 panel and said number 2 panel said liquefied gas storage tank. According to Claim 11, said part and said cut disconnected part including liquefied gas storage tank. According to Claim 8, said one side of said support structure includes a tank body supported contact number 1 standing frame; and said of a tank body attached closely supported number 2 standing frame of, reducing sloshing across said frame and the number 1 standing frame plate said number 2 standing liquefied gas storage tank. According to Claim 13, reducing sloshing longitudinal direction and said bottom plate, said bottom panel in contact with the support part number 1 corresponding to the tank body 1 difference barrier; and said number 1 standing frame and said number 2 standing frame is installed, said of a tank body panel in contact with the number 2 1 corresponding to a pair of left and right difference barrier comprising; each of said panel between said number 1 support unit and said number 2 support unit projecting corrugation criticism end and contact support blocks including liquefied gas storage tank. Number 8 term and number 10 to number 14 either a liquefied gas storage tank including said anti anti anti characterized the structure.