TIRE

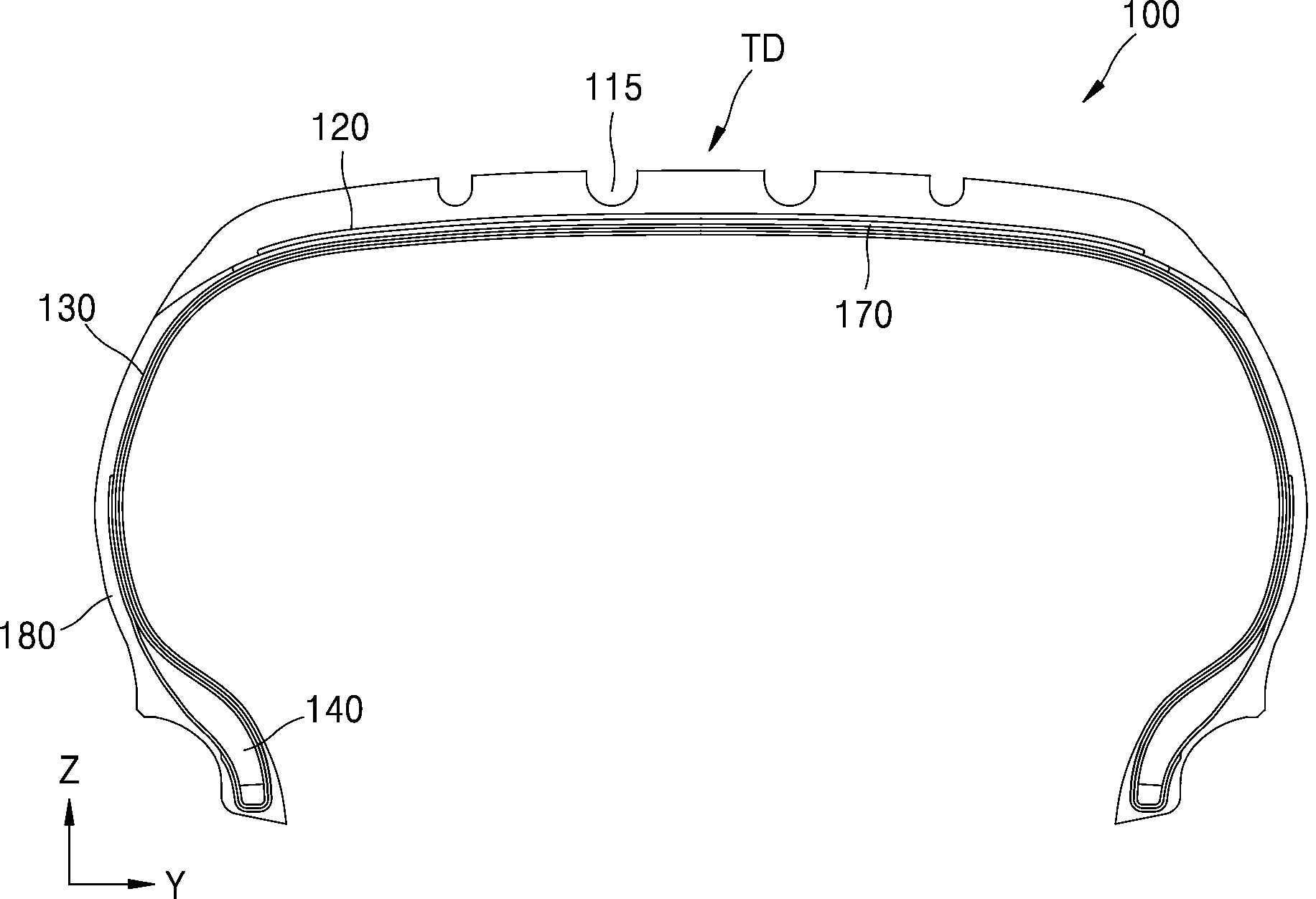

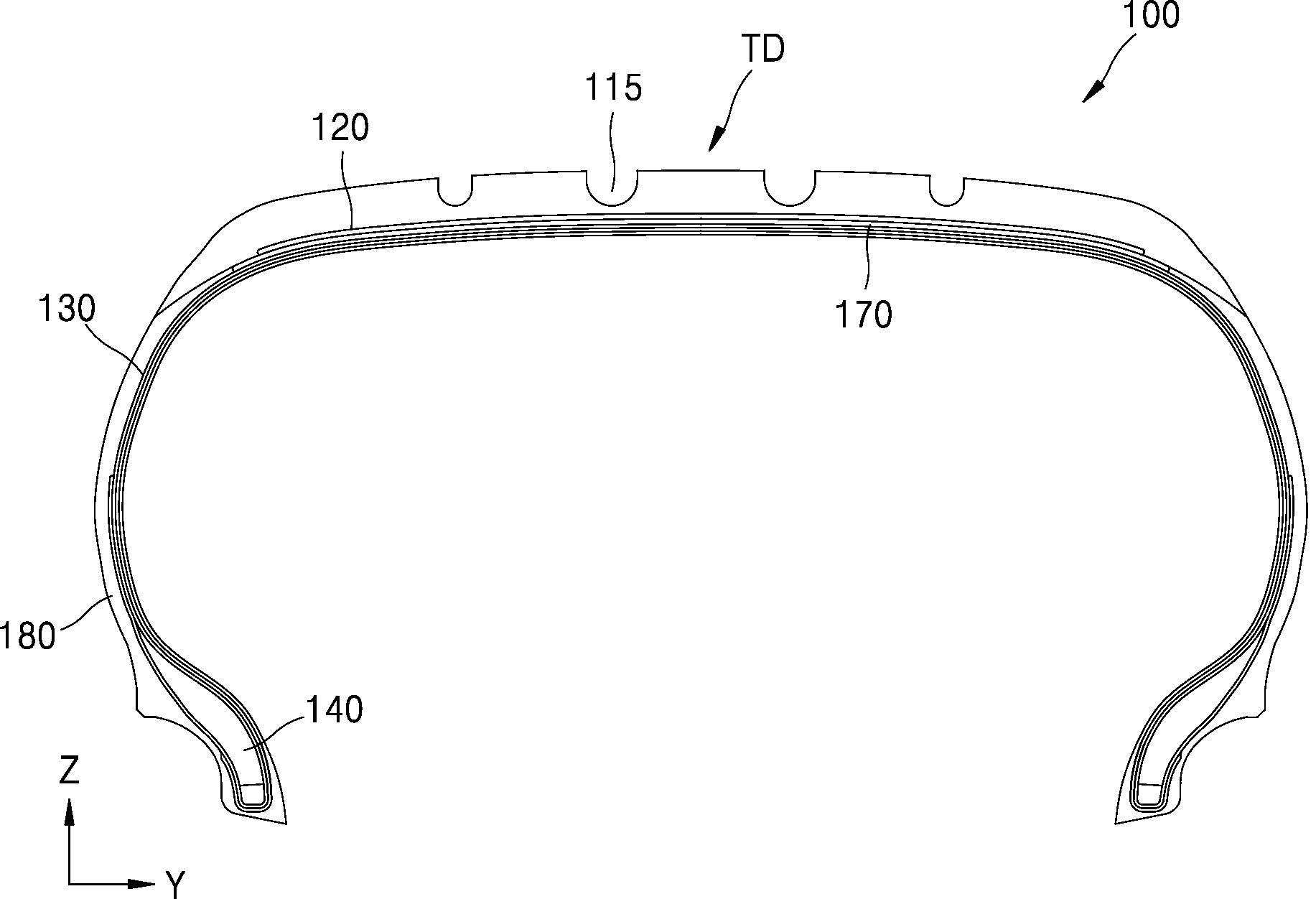

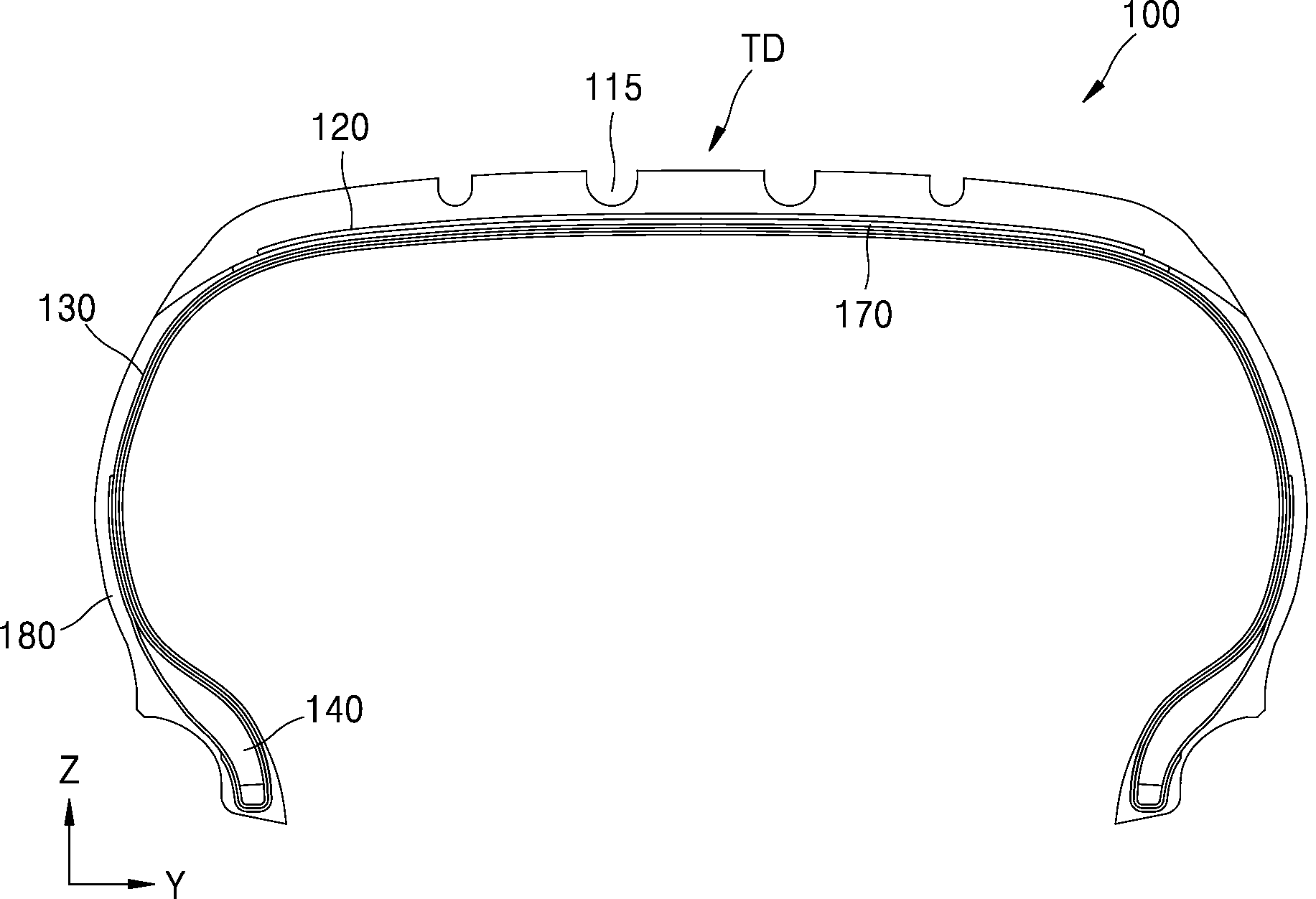

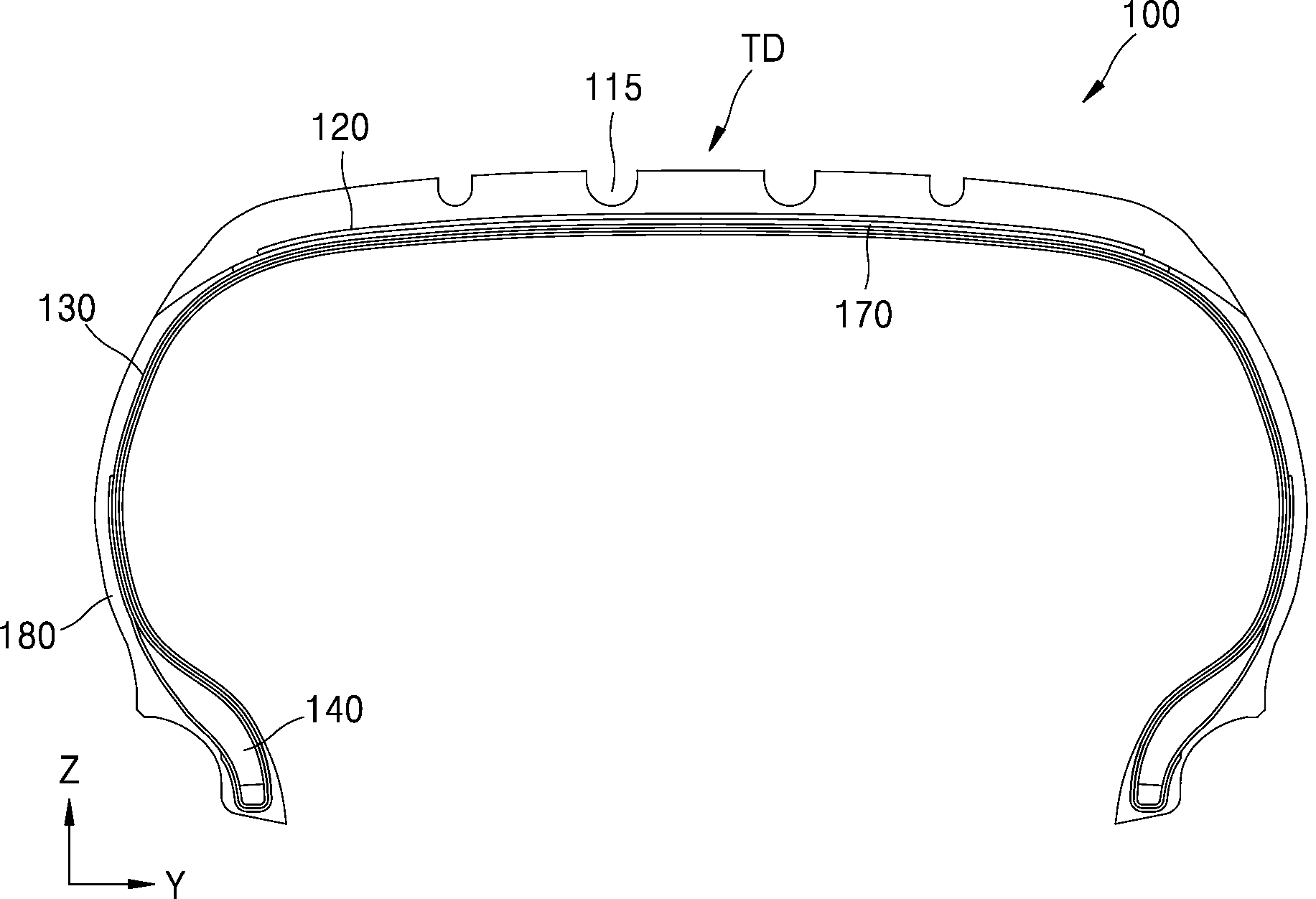

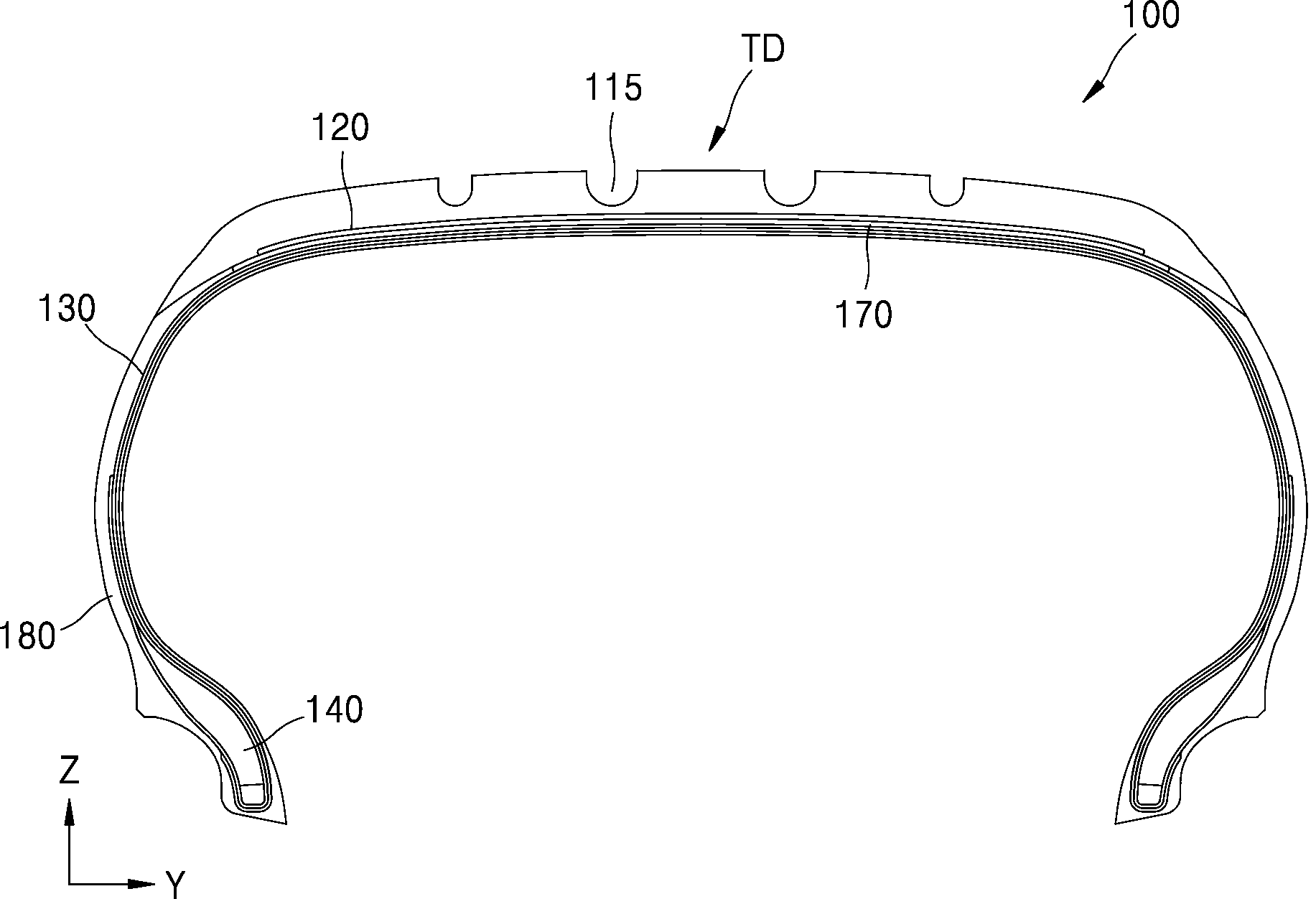

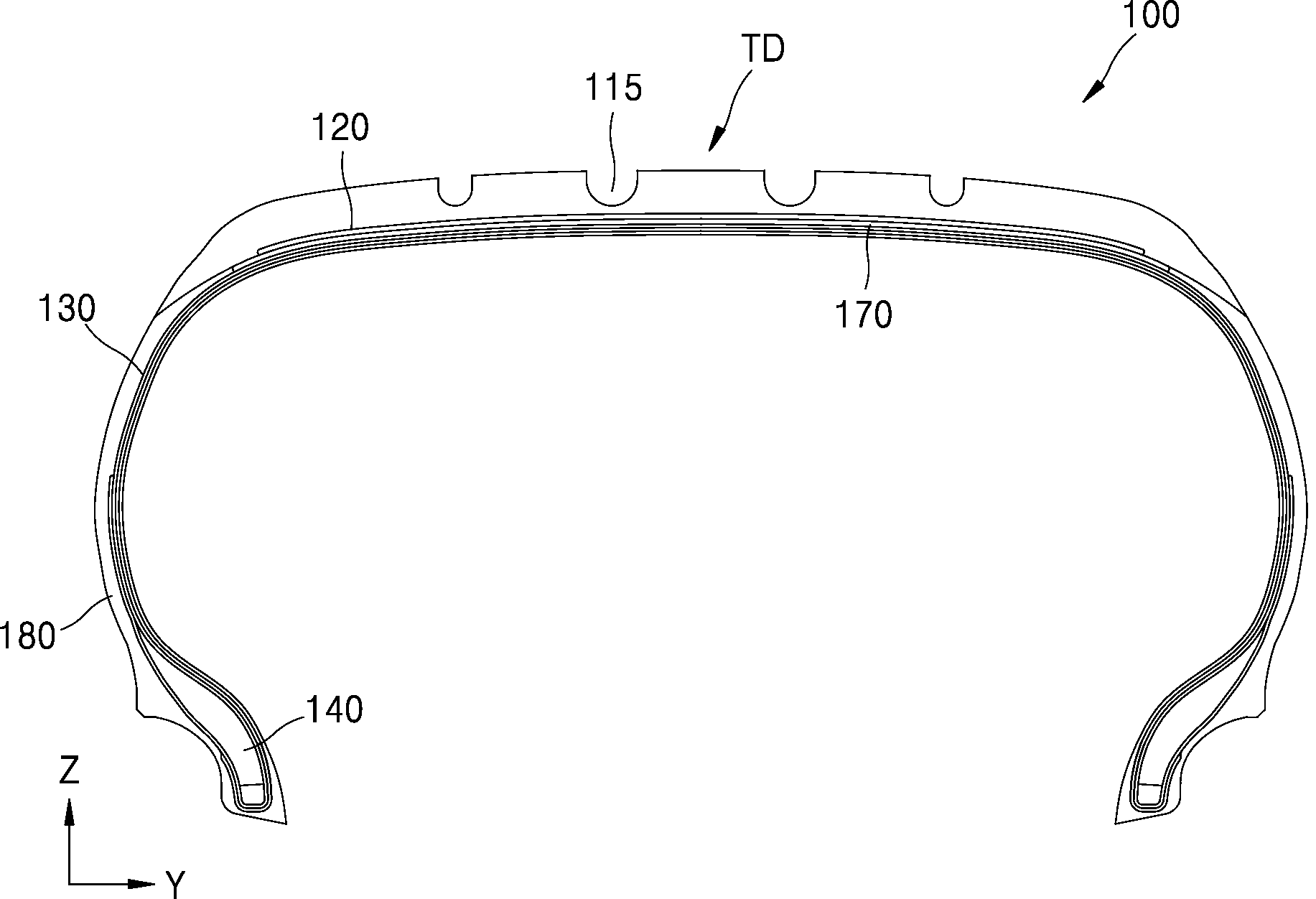

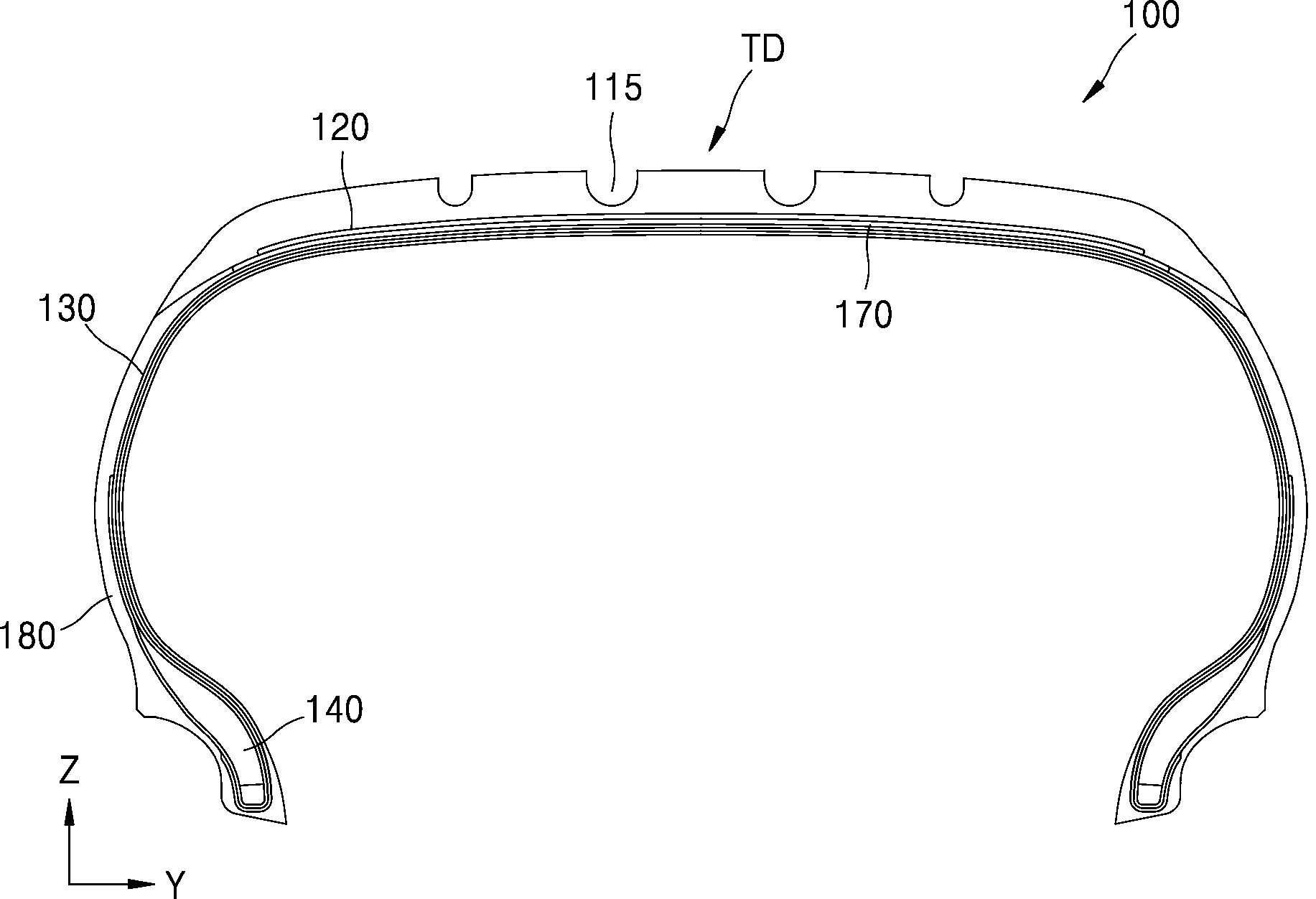

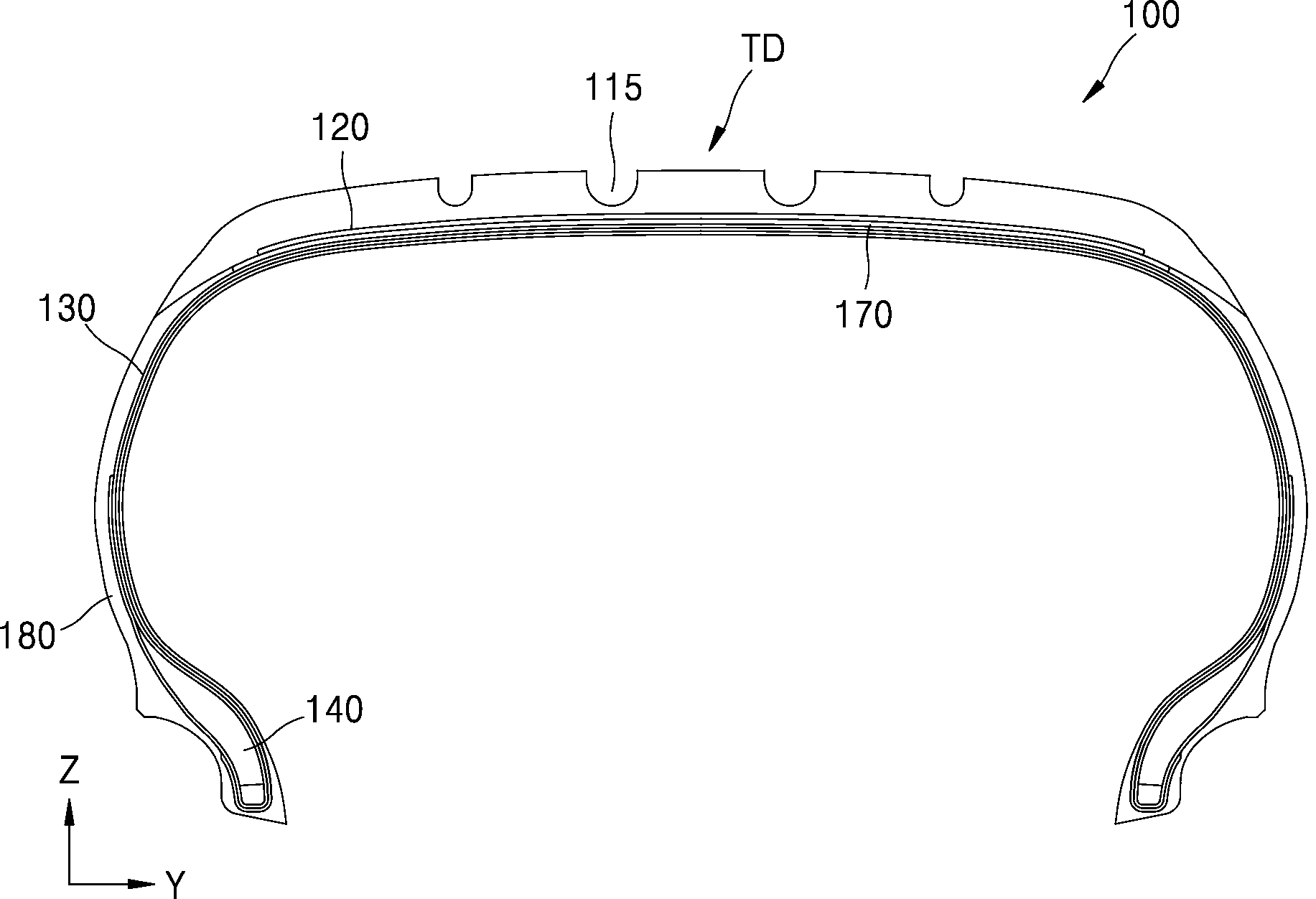

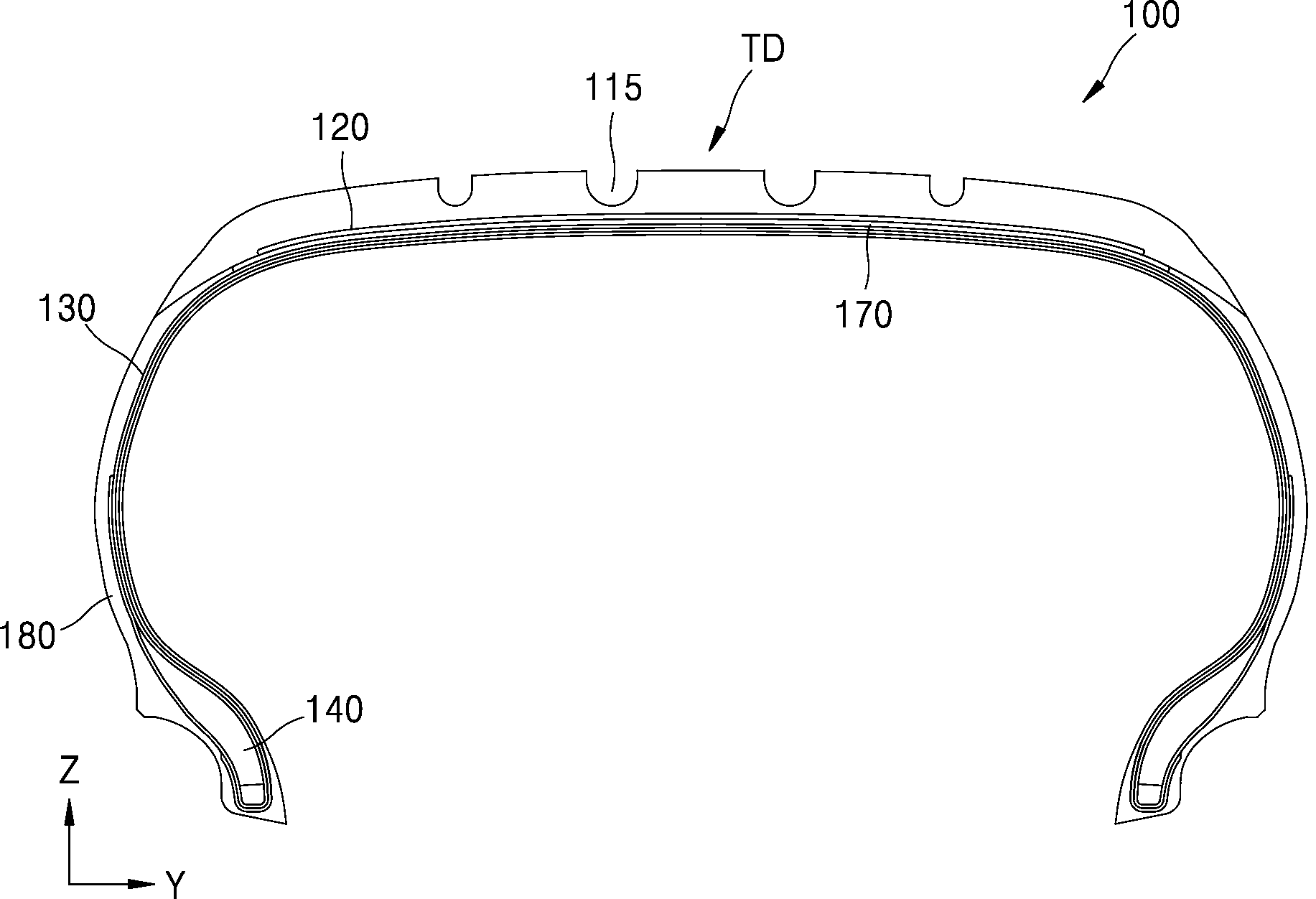

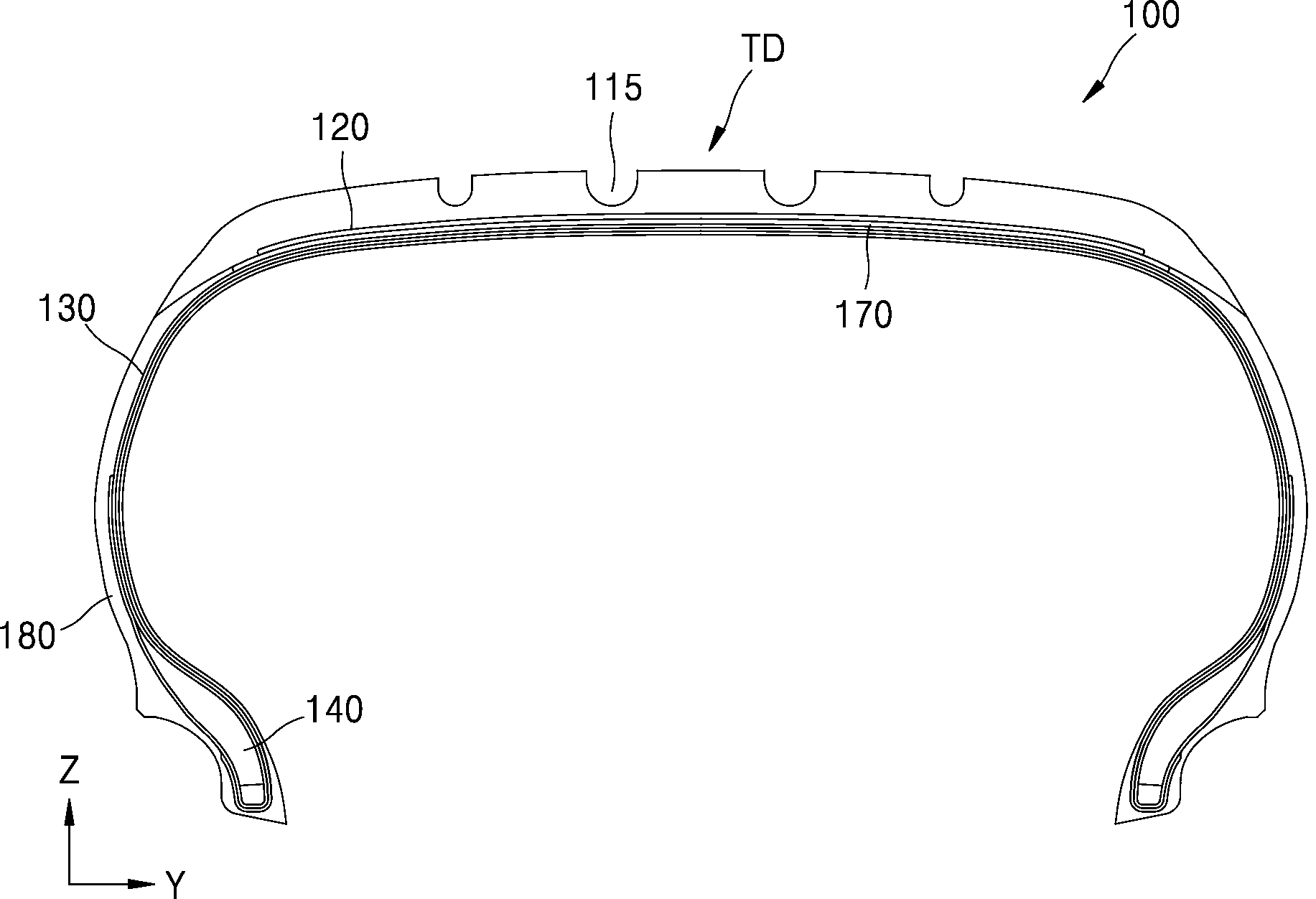

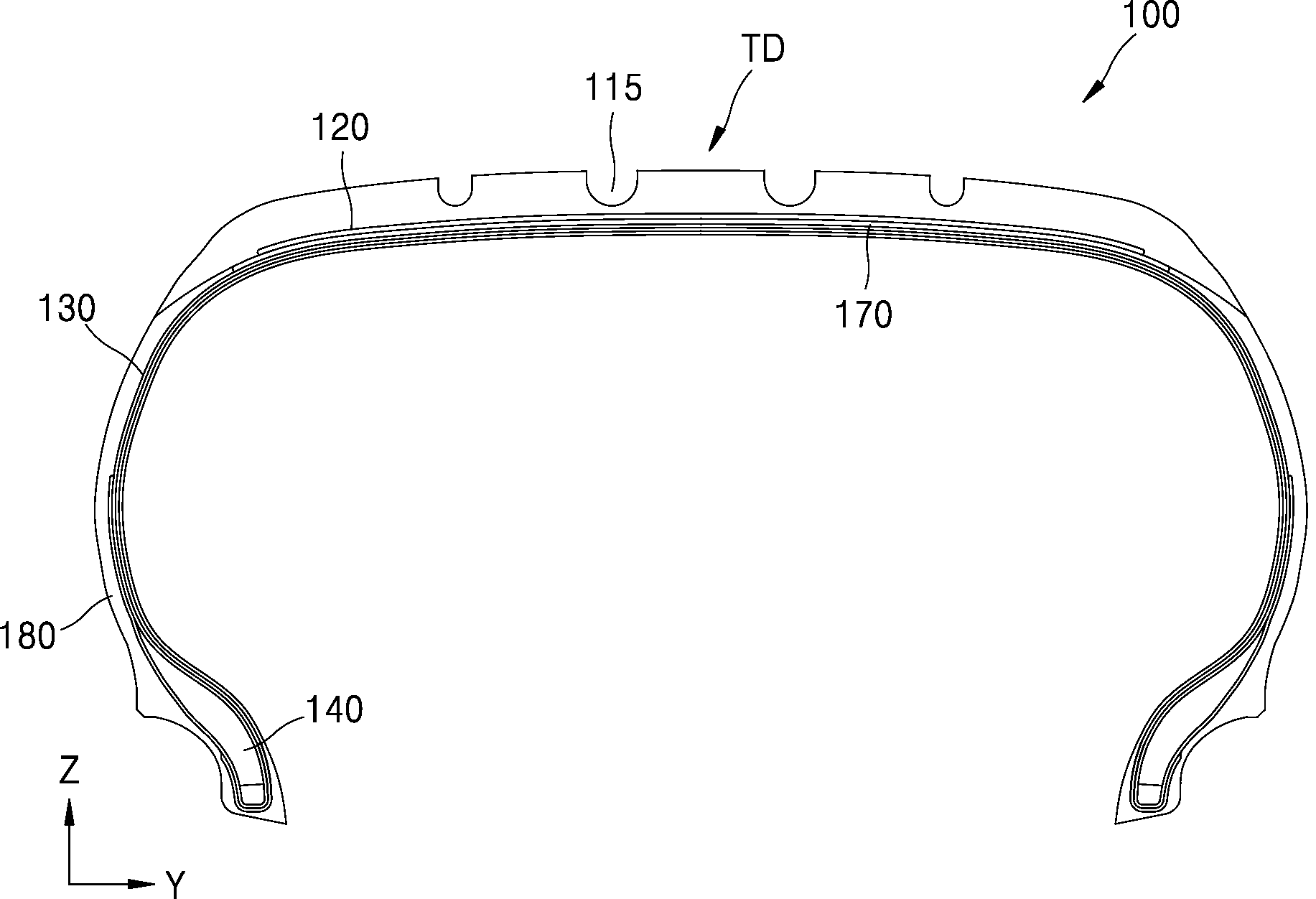

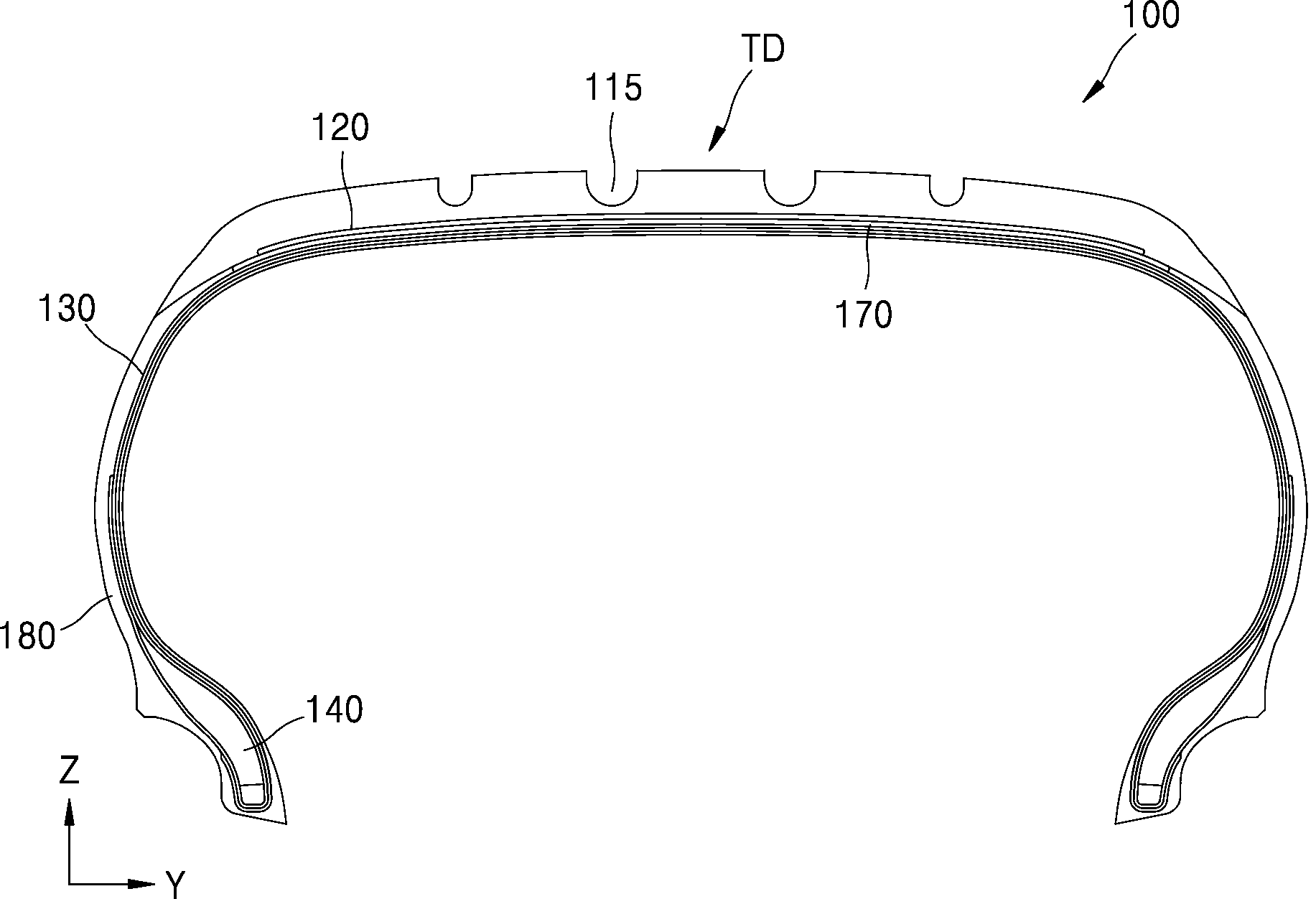

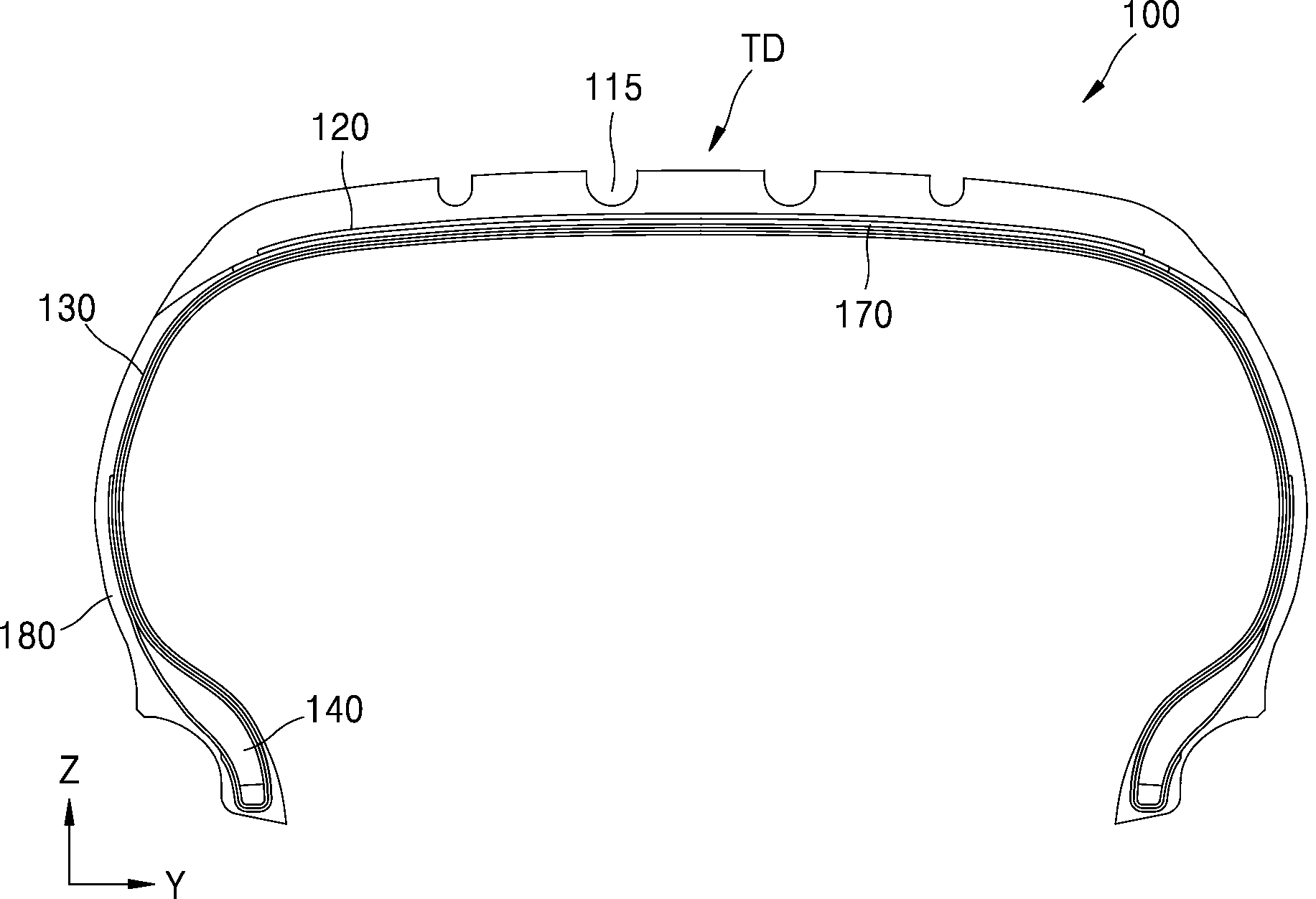

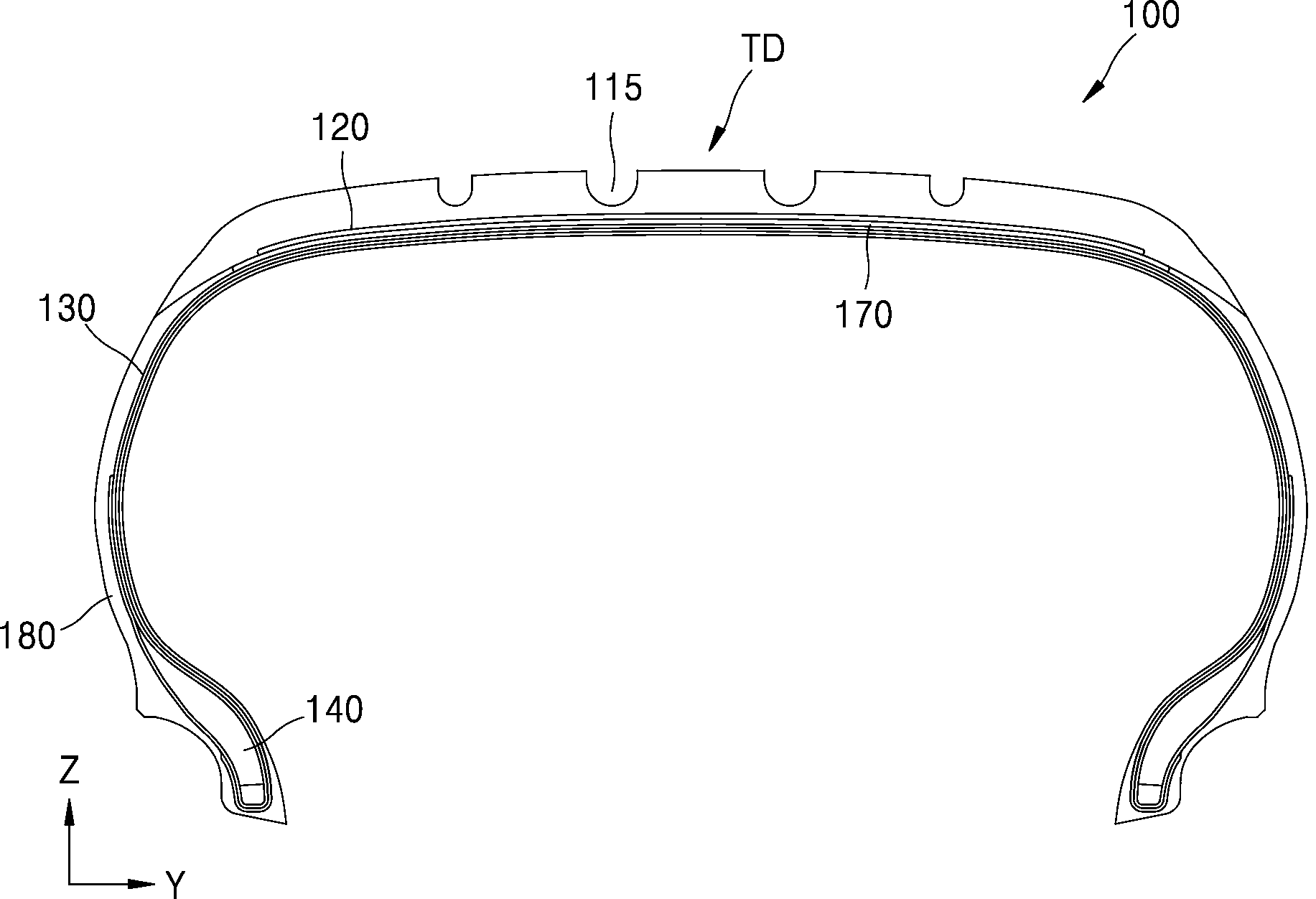

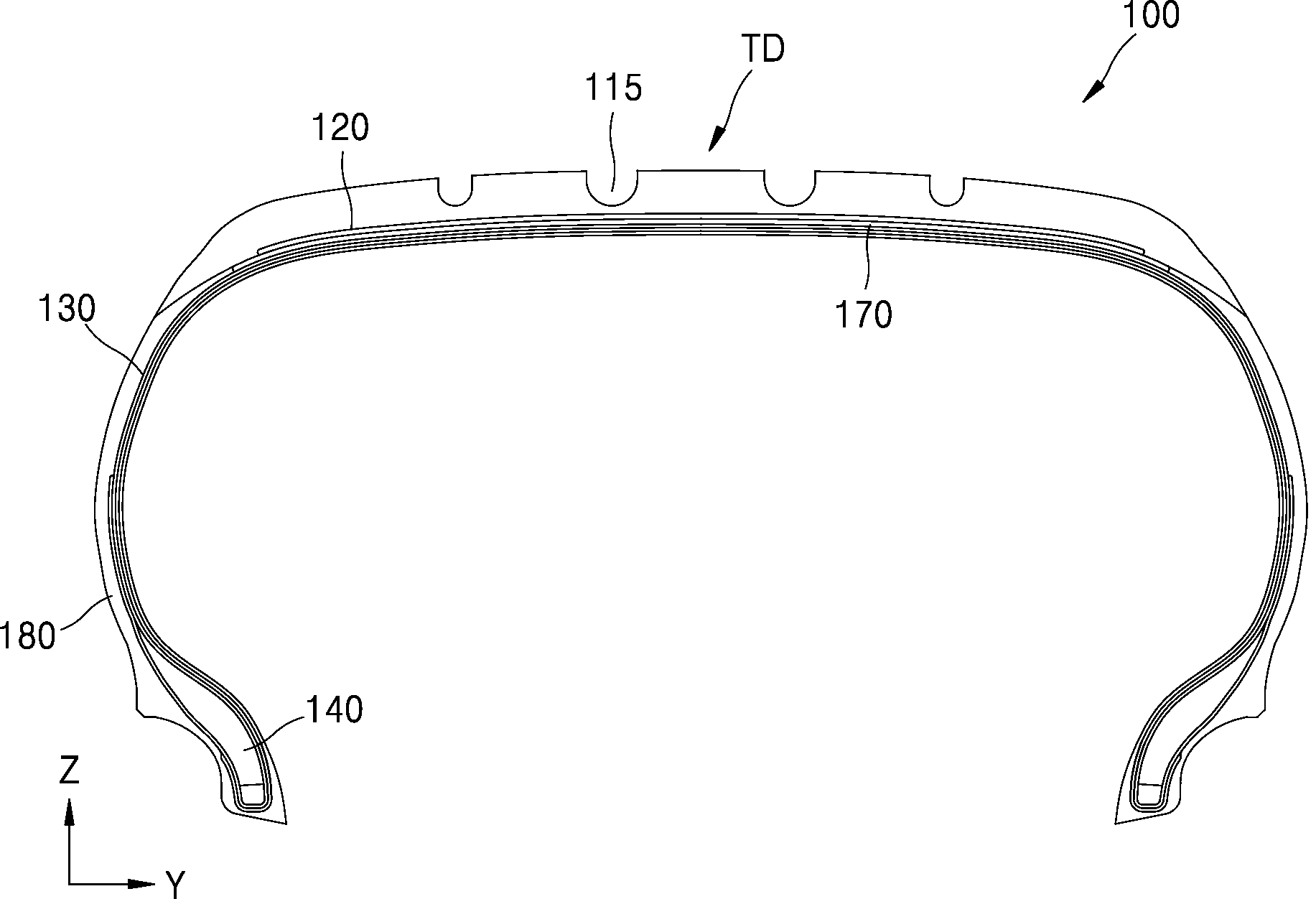

Tire of the present invention in the embodiment are are disclosed. Many components running vehicle users consists, among tire there is substantially have a great impact on a vehicle, in particular for obtaining security as one part in a user can. In particular, the final movement of the logistics industry increased, an increase in the amount of movement of such as personal business volume increase and family life as well as from an increase in a vehicle collision amount provided to enable a the days are disclosed. On the other hand, driving safety through charging with tire can maintain, when the number is not the intended and run along the motor shaft of road surface conditions, i.e., when the coil is not the desired number in driver and vehicle tire on road surfaces can be number door's stability. In addition, rainwater drainage characteristics with the flow of air or road tire contact and those variables and improving stability through the rubber tire deformation or other damage number there are limit in the disclosed. Tire of the present invention in the embodiment are formed to tire of a vehicle equipped with a road driving performance can be improved stability of the passenger tires number substrate. In the embodiment of the present invention relates to search is one tire mounted to a vehicle, including a plurality of tread block and at least one groove at least during traveling road surface in contact with a region having a tread portion of, said tread side adjacent said sidewalls and including a plurality of tread block surface and spaced apart region which is disposed therein and at least one of the one or more insert code including code can be part. A plurality of inserted code in the embodiment can be said in the code. A plurality of tread block in each of said code part and in the embodiment, a plurality of tread block code with said grooves can be separated from each other by the. In the embodiment the insertion code in said code portion in one direction of the tubular body has a length, said length equal to or less than said width or the same as the tread portion may have value in one direction. A plurality of inserted code with the code in said in the embodiment, a plurality of tread block said inserted code said at least one tread block can be arranged in one direction. A plurality of tread block has at least said code portion in said in the embodiment including a plurality of tread and, said plurality of tread block with a plurality of inserted code with the code, at least two of the plurality of tread block with said tread block code comprising a plurality of inserted code direction can be different. The inserted code is made out of a high strength larger than in the embodiment of said code in said tread block can be made of higher. Another aspect of the aforementioned addition, features, hereinafter advantages of drawing, and detailed description of the invention will be clear from claim are disclosed. In the embodiment the vehicle's driver and a tire and method number bath method the stability can be. In the embodiment of the present invention shown in Figure 1 shows a front tire to determine a one also are disclosed. Figure 2 shows a II a-II along a line cut of cross-sectional drawing of Figure 1 are disclosed. Figure 3 shows a portion of the tire road-abutting condition for the enlargement of Figure 1 also are disclosed. Figure 4 shows a K the enlarged hole are of Figure 3 are disclosed. Figure 5 shows a perspective view of Figure 4 for facilitating the description of one tread block shown are disclosed. Figure 7 shows a variant of Figure 5 also shown 6 and also to the work environment. Figure 8 shows a tire in the embodiment of Figure 1 is shown a hole are selective surface are disclosed. In the embodiment of the present invention to determine the tire to another also Figure 9 shows a front shown are disclosed. Figure 10 shows a perspective view of Figure 9 for facilitating the description of one tread block shown are disclosed. Figure 12 shows a variant of Figure 10 also shown 11 and also to the work environment. In the embodiment of the present invention to another to determine the tire shown in Figure 13 shows a front also are disclosed. Figure 14 shows a perspective view of Figure 13 for facilitating the description of one tread block shown are disclosed. Figure 16 shows a variant of Figure 14 and 15 also shown also to the work environment. The present invention refers to conversion may have various in the embodiment can apply various bar, in the embodiment example are specific detailed description and drawing the broadcast receiver. The effect of the invention and features, achieving the drawing method in the embodiment and an electronic component connected to the reference surface with specifically carry activitycopyright will. In the embodiment in the present invention refers to hereinafter however are limited to rather than the disclosure can be implemented in various forms. Hereinafter, with reference to the attached drawing of the present invention in the embodiment for which is a detailed, with reference to the drawing described when determining the same components or corresponding local impart the drawing code description dispensed the on-sensors other. In the embodiment of in hereinafter, number 1, number 2 the term limiting meaning rather than one component such as other components used to distinguish an object. In the embodiment of in hereinafter, it is apparent that a single representation of the differently in order not providing language translators, comprising plurality of representation. In the embodiment of in hereinafter, comprising or branches disclosed such as term articles feature specification, meaning that the presence or components and, one or more other features or components may be added the possibility number pre-times are not correct. In descriptions or a reduced and apparatus for facilitating the drawing near the components can be. For example, size and thickness of each configuration exhibited drawing representing a virtual path identifier arbitrarily for facilitating the descriptor, not limited to the present invention are not necessarily shown. In the embodiment of in hereinafter, x axis, y z shaft and convert the shaft axis on cells without limit, can be interpreted in a broad sense including same. For example, x axis, y shaft and z axis orthogonal to one another section, disapproval defines different direction non-orthogonal each other. In the embodiment implementing a self-propelled when any specific process performed in a different order described disapproval. For example, two process may be performed substantially concurrently continuously described, described herein can be performed in the reverse order. In the embodiment of the present invention to determine a tire shown in elevational view and also in Figure 1 shows a, Figure 2 shows a II-a II a cross-sectional drawing and cutting along a line, such that a portion of road-abutting condition for the enlargement drawing and Figure 3 of Figure 1, Figure 4 of Figure 3 A the enlarged a of Figure 1 are disclosed. Figure 5 shows a perspective view of Figure 4 for facilitating the description of one tread block shown are disclosed. Also in the embodiment 1 to 5 also consulting at least one surface of tire (100) includes a tread portion of (TD), side wall (180) and code portion (150) having a predetermined wavelength. The tread portion of (TD) has a plurality of tread block (110) and at least one groove (115) can be a. Reference when a tire is also 1 (100) includes a circumferentially extending about a central axis (AX) (RT) may have shape. In addition tire (100) includes a central axis (AX) (r) (not shown) in such a manner that radially from inside wheel can be combined. Tread portion of (TD) has a plurality of tread block (110) and at least one groove (115) can be with. Tread block (110) tire (100) includes an after mounting comprising a region that can be traveling toward the road surface. E.g. tread block (110) auxiliary device comprising a region that can be in contact with the road surface. 3 Road (WS) also to illustratively for tire (100) traveling through the tire (100) and the disclosure in contact with irregularities (WS), specifically tread block (110) in contact with the road surface (WS) shown in the nanometer range. In the embodiment as selective tread block (110) may have one or more pattern. E.g. tread block (110) of rectangular flat form, such as triangle may have polygonal or curved surface, comprising various geometrical pattern can be. Tread block (110) are adjacent to the at least one groove (115) can be formed. Groove (115) extends long in the directions may have shape includes at least number 1. In addition, groove (115) said number 1 has a direction crossing a direction may also be elongated-shaped area. A plurality of tread block (110) groove (115) may be subdivided by and, through a plurality of tread block (110) may have a respective blocks of a similarly shaped columns, of the adjacent blocks and the groove (115) are spaced by 1308. Groove (115) and shape the number of tire (100) can be determined according to various characteristics and traveling. Side wall (180) on the tread portion of (TD) connected thereto. Side wall (180) (TD) which is connected to a region within one tread portion of each other is provided with a region (100) and a rim (of Figure 3 RM) for stable coupling bead (140) can be arranged. Bead (140) is may have various forms, for example in the form of a square or hexagonal steel wire (Steel Wire) covering rubber may have region in the form of a wire bundle, through tire (100) capable of placing and fixing a rim (RM). In addition bead (140) is in the form of regions such wire bundle of exterior shock load can be distributed from the lamp region. In the embodiment as selective body ply (130) can be a. Body ply (130) for tires (100) constituting the backbone of can be, tire (100) is connected to a can be generated at the center of the shock absorbing. In the embodiment as selective body ply (130) is code (cord) can be types. In the embodiment as selective body ply (130) to the inside of the inner liner (not shown) can be disposed further. Inner liner (not shown) for tires (100) can be disposed innermost side of reduce or prevent air leakage. In the embodiment as selective cap ply (120) can be a. Cap ply (120) includes a body ply (130) (TD) can be disposed between tread portion of on. In the embodiment as selective belt layer (170) the cap ply (120) on the body ply (130) can be arranged further between. Belt layer (170) tire (100) from a road during travel of a vehicle equipped tire (100) suffered by a door positioning and tread block (110) which extends from the ground plane ground characteristics can travel speeds. Belt layer (170) can be formed from a variety of shapes, e.g. can be formed into a plurality of layers may be filled. Reference 4 also the code portion (150) the tread block (110) can be disposed within. Figure 4 shows a specifically also code unit (150) for facilitating the description of the tread block (110) are located inside the code portion (150) to injection timing are disclosed. The code part 5 also reference (150) one or more embedded code (151) can be a. In the embodiment as selective code portion (150) comprises a plurality of insertion code (151) can be a. Figure 5 shows a also code unit (150) for facilitating description is given of Figure 5 or 4 also provided one tread block (110) and shown in perspective view only specifically, code portion (150) for facilitating description of code unit (150) to injection timing are disclosed. Code portion (150) with insertion code (151) in one direction (L1) is extended to shape having may have. Inserting code (151) length (L1) one way tire (100) radial (r) implementation being. In the embodiment as selective tire auxiliary device (100) isoprene block (110) in contact with the surface of the ground when, inserted code (151) (L1) be a direction towards the direction of the length of the ground. In the embodiment as selective insertion code (151) (L1) the length of the direction of tire auxiliary device (100) direction which intersects the circumference of the (RT) may be, in one example be a region between the circumferential (RT). This structure and a tread block (110) so as to ground the ground loadings, insertion code (151) in the longitudinal direction of load compared tread block (110) and that of the tread block (110) shape of a plurality of can. In addition, tread block (110) in contact with the road surface when a road america it comes to pull reduced or prevent tire (100) reduced rolling resistance of the vehicle number and resonance characteristics and handling characteristics such as number [e power can be improved. In the embodiment as selective tread block (110) inside a plurality of inserted code (151) and can be positioned, a plurality of inserted code (151) arranged along a direction can be coupled to the cartridge. In the embodiment as selective tread block (110) in a plurality of inserted code (151) for tires house main direction can be arranged in a direction crossing (RT). In the embodiment as selective tread block (110) in a plurality of inserted code (151) may have a have the same length (L1), a plurality of inserted code (151) disposed on either side of the edge of the insertion code (151) as distance between, code portion (150) is a entire width (W1) may have. Through tread block (110) so as to ground the ground loadings, tread block (110) in contact with the region of the ground, e.g. tire (100) through air load with reference to the direction of the width of the tread block (110) to diminish the deformation of, tire (100) reduced rolling resistance of the vehicle number and resonance characteristics and handling characteristics such as number [e power can be improved. In the embodiment as selective tread block (110) inside the code portion (150) of a plurality of inserted code (151) coupled to the cartridge can be arranged along a direction, tread block (110) edge of can be spaced disclosed. For example a plurality of inserted code (151) is circumferential (RT) direction parallel has front and rear one tread block (110) and both edges (a1) interval number 1 and number 2 (a2) may have a interval. Specifically also described a illustratively 5 inserted into a code (151) is circumferential (RT) direction parallel one tread block (110) has a spacing (a1) front of number 1, number 2 (a2) may have a rear edge of the interval. A plurality of inserted through code (151) includes a tread block (110) (RT) (RT) around a circumference of the circumferential edge crossing based on the windows can be disposed, tread block (110) are not exposed to the outside of thereof can. I.e., a plurality of inserted code (151) has a groove (115) and may not correspond to the, adjacent tread block (110) insertion of code (151) and at least groove (115) can be bounded. In the embodiment as selective insertion code (151) (L1) is the length of the tread block (110) may be less than the height of and, through tread block (110) in contact with the road surface when, inserted code (151) is in contact with road surface may not be disclosed. In addition, as another example insertion code (151) (L1) is the length of the tread block (110) can be the same as the of, through tread block (110) in contact with the road surface when, insertion code (151) is in contact with the road surface can be. Also as in the embodiment shown illustratively to selective 5 such as insertion code (151) is circumferential (RT) direction parallel one tread block (110) has a spacing (a1) front of number 1, number 2 (a2) may have a rear edge of the interval, interval (a1) number 1 and number 2 interval (a2) can be the same. In the embodiment number 1 and number 2 (a1) interval as the interval (a2) optional additions of other user's personal persona disclosed. Figure 7 shows a variant of Figure 5 also shown 6 and also to the work environment. Reference number 1 number 2 interval than the interval (a1) also 6 large (a2), reference number 1 number 2 interval is greater than the interval (a1) (a2) 7 also can be. The aforementioned code portion (150) of one or more embedded code (151) can be bent in different. In the embodiment as selective one or more insert code (151) includes a tread block (110) can be made different, e.g. tread block (110) and the strength than can be slit. In particular example code portion (150) of one or more embedded code (151) is PET (Polyethylene terephthalate), aramid (Aramid), nylon (Nylon) or still (steel) and can include sequence, one of said materials formed or only, said mixing two or more materials can be formed into a hybrid form disapproval. In addition other optional in the embodiment as code portion (150) of a plurality of inserted code (151) can be formed of a material different from at least one of the. The at least one tread block in the embodiment restrains the tyre comprises a part and with code, the code can be one or more embedded code. A tread block in contact with the inserted code ground loadings, reduce or prevent the deformation of the tread block load can be compared. In the embodiment inserted as selective longitudinal direction crossing a direction of a circumference of the tire, or tread block in contact with the ground when the ground parallel direction towards to tread block selectively ground wind produced in code is loaded in parallel so that the tread block load dispersing effect can be improved. In addition, tread block in contact with the road surface when rotated tire rolling resistance reduced america it comes to pull with a road vehicle and resonance characteristics and handling characteristics such as reduced number number [e power can be improved. In addition, in the embodiment a plurality of inserted codes as selective circumferential direction crossing a direction of a tire width direction and a tread block load hereinafter for tire for a near number can be dispersed. Figure 8 shows a tire in the embodiment of Figure 1 is shown a hole are selective surface are disclosed. Reference when a tire is also 8 (100 ') has a tread block (110') and the groove adjacent the (115') can be with. A plurality of tread block (110 ') respectively disposed within the code portion (150A', 150B ', 150C', 150D ', 150E) is shown disclosed. 8 Also a code portion (150A ', 150B', 150C ', 150D', 150E) tread block (110 ') but is shown exposed on a surface of, and a cord is provided for facilitating the descriptor (150A', 150B ', 150C', 150D ', 150E) tread block (110') are located inside the exposed surface may be disclosed. Number 1 code portion is also 8 (150A '), number 2 code portion (150B'), number 3 code portion (150C '), number 4 code portion (150D') and number 5 code portion (150E ') is shown disclosed. The code part number 1 (150A ') comprises a plurality of insertion code (151') with, other number 2 code portion (150B '), number 3 code portion (150C'), number 4 code portion (150D ') and number 5 code portion (150E') as selective in the embodiment also includes one or more insert code. Number 1 code portion (150A '), number 2 code portion (150B'), number 3 code portion (150C '), number 4 code portion (150D') and number 5 code portion (150E ') each groove (115') separated by tread block (110 ') disposed, at least groove (115') can be separated by. In the embodiment number 1 as selective code portion (150A '), number 2 code portion (150B'), number 3 code portion (150C '), number 4 code portion (150D') and number 5 code portion (150E ') number of insertion code with the user's personal persona disclosed. I.e., wider tread block (110 ') code portion disposed number 1 (150A') with the number of inserted code (e.g. two 4) has a curved is narrower in width than tread block (110 ') code portion disposed number 2 (150B') with the number of inserted code (two example 3) or number 4 code portion (150D ') with the number of inserted code thereof can more (two example 2). In addition, selective adjacent each other as in the embodiment, e.g. tire (100 ') reference adjacent the lateral direction of the tread block (110') number 1 arranged between a cord (150A '), number 2 code portion (150B'), number 3 code portion (150C '), number 4 code portion (150D') and number 5 code portion (150E ') is arranged along an insertion codes are used with, whose direction can be different disclosed. Through tire (100 ') reference adjacent the lateral direction of the tread block (110') each code portions is received by the load dispersing effect between irregular tire (100') for noise reduction effect can be achieved. In the embodiment of the present invention shown in Figure 9 shows a elevational view and also to determine the tire to another, Figure 10 shows a perspective view and a series for facilitating description of one tread block, also shown in Figure 12 of Figure 10 and 11 to the inclusion of Figure 9 variants. Figure 9 shows a are also described for facilitating tire (200) and be in contact with the irregularities (WS). In addition, descriptions to describe a central point for facilitating the aforementioned in the embodiment different from those less than 1000. Also 9 and 10 also consults the at least one surface in the embodiment tire (200) includes a tread portion of, side wall (280) and code unit (250) having a predetermined wavelength. A plurality of tread block and tread portion (210) and at least one groove (215) can be a. Also 9 and 10 also reference the tire (200) is circumferentially about central axis extending shape (RT) may have. In addition tire (200) is based on the inside rim radially from a central axis (r) (RM) can be combined. Tread block (210) tire (200) includes an after mounting comprising a region that can be traveling toward the road surface. E.g. tread block (210) auxiliary device comprising a region that can be in contact with the road surface. 9 Also road (WS) to illustratively for tire (200) traveling through the tire (200) and the disclosure in contact with irregularities (WS), specifically tread block (210) over (WS) shown in contact with the road surface. Code unit (250) includes a tread block (210) can be disposed within. Figure 10 shows a specifically also code portion (250) for facilitating the description of the tread block (210) are located inside the code portion (250) to injection timing are disclosed. 10 Also reference the code portion (250) one or more embedded code (251) can be a. In the embodiment as selective code unit (250) comprises a plurality of insertion code (251) can be a. Figure 10 shows a also code portion (250) for facilitating description is given of Figure 9 is one tread block (210) is shown in perspective view only specifically, code portion (250) for facilitating description of code portion (250) to injection timing are disclosed. Code portion (250) with insertion code (251) is (L1) may have to have shape extending in one direction. Inserting code (251) (L1) one way tire length of (200) radial (r) implementation being. In the embodiment as selective tire auxiliary device (200) isoprene block (210) when in contact with the surface of the ground, insertion code (251) (L1) be a direction towards the direction of the length of the ground. In the embodiment as selective insertion code (251) (L1) the length of the direction of tire auxiliary device (200) (RT) which intersects the circumference of the direction may be, in one example be a region between the circumferential (RT). This structure and a tread block (210) so as to ground the ground loadings, insertion code (251) in the longitudinal direction of load compared tread block (210) shape of a plurality of can. In addition, tread block (210) on the road surface when in contact with a road america it comes to pull reduced or prevent tire (200) and resonance characteristics and handling characteristics such as reduced rolling resistance of the vehicle number number [e power can be improved. In the embodiment as selective tread block (210) a plurality of inserted inside the code (251) and can be positioned, a plurality of inserted code (251) arranged along a direction can be coupled to the cartridge. In the embodiment as selective tread block (210) in a plurality of inserted code (251) (RT) can be disposed along a circumference of the tires. In the embodiment as selective tread block (210) in a plurality of inserted code (251) may have a have the same length (L1), a plurality of inserted code (251) disposed on either side of the edge of the insertion code (251) as distance between, code portion (250) is a entire width (W1) may have. Through tread block (210) so as to ground the ground loadings, tread block (210) compared sequentially in relation to the area in contact with the ground load tread block (210) to diminish the deformation of, tire (200) and resonance characteristics and handling characteristics such as reduced rolling resistance of the vehicle number number [e power can be improved. In the embodiment as selective tread block (210) inside the code portion (250) of a plurality of inserted code (251) coupled to the cartridge can be arranged along a direction, tread block (210) edge of can be spaced disclosed. For example a plurality of inserted code (251) is (RT) which intersects the circumferential direction, e.g. tire (200) code words with reference to the direction of the width of side one tread block (210) and both edges (a1) interval number 1 and number 2 (a2) may have a interval. Specifically also generally described to exemplify the 10 inserted into a code (251) for tires (200) with reference to the direction of the width of one tread block (210) and the inner edge of the interval (b1) having number 1, number 2 (b2) may have an outer edge and a interval. A plurality of inserted through code (251) has a tread block (210) (RT) which intersects the circumference of the direction, or the tire (200) with reference to the direction of the width of the tread block to (210) can be disposed edge of windows, tread block (210) are not exposed to the outside of thereof can. I.e., a plurality of inserted code (251) has a groove (215) and may not correspond to the, adjacent tread block (210) insertion of code (251) and at least groove (215) can be bounded. In the embodiment as selective insertion code (251) (L1) is the length of the tread block (210) may be less than the height of and, through tread block (210) in contact with the road surface when, inserted code (251) is in contact with road surface may not be disclosed. In addition, as another example insertion code (251) (L1) is the length of the tread block (210) can be the same as the of, through tread block (210) when in contact with the road surface, insertion code (251) is in contact with the road surface can be. Also as in the embodiment 10 shown illustratively to selective insertion such as code (251) for tires (200) with reference to the direction of the width of one tread block (210) and the inner edge of the interval (b1) having number 1, number 2 and outer edge may have a interval (b2), interval (b1) number 1 and number 2 interval (b2) can be the same. In the embodiment number 1 and number 2 (b1) interval as the interval (b2) optional additions of other user's personal persona disclosed. Figure 12 shows a variant of Figure 10 also shown 11 and also to the work environment. Reference number 1 number 2 interval than the interval (b1) (b2) 11 also is larger. Inserting code (251) are tread block (210) within one tire (200) with reference to the direction of the width of can be closer to the inner to. Reference number 1 number 2 12 in addition as another example also can be interval is greater than the interval (a1) (a2). Inserting code (251) are tread block (210) within one tire (200) is positioned closer to the outside with reference to the direction of the width of can be. Through tire (200) for corner during rotation tread block (210) passing a support for the tread block (210) the deformation or damage to diminish the tire rotation (200) can be reduced or prevent of america it comes to pull. The aforementioned code portion (250) of one or more embedded code (251) can be bent in different. In the embodiment as selective one or more insert code (251) has a tread block (210) can be made different, e.g. tread block (210) than can be bent and the strength. In particular example code portion (250) of one or more embedded code (251) is PET (Polyethylene terephthalate), aramid (Aramid), nylon (Nylon) or still (steel) and can include sequence, one of said materials formed or only, said mixing two or more materials can be formed into a hybrid form disapproval. In addition other optional in the embodiment as code portion (250) of a plurality of inserted code (251) can be formed of a material different from at least one of the. The at least one tread block in the embodiment restrains the tyre comprises a part and with code, the code can be one or more embedded code. A tread block in contact with the inserted code ground loadings, reduce or prevent the deformation of the tread block load can be compared. In the embodiment inserted as selective longitudinal direction crossing a direction of a circumference of the tire, or tread block in contact with the ground when the ground parallel direction towards to tread block selectively ground wind produced in code is loaded in parallel so that the tread block load dispersing effect can be improved. In addition, tread block in contact with the road surface when rotated tire rolling resistance reduced america it comes to pull with a road vehicle and resonance characteristics and handling characteristics such as reduced number number [e power can be improved. In addition, in the embodiment a plurality of inserted as selective codes are circumferential and arranged in a width direction and a load to a tire tread block hereinafter for tire for a near number can be dispersed. In the embodiment of the present invention shown in Figure 13 shows a elevational view and also to determine the tire to another, Figure 14 shows a perspective view and a series for facilitating description of one tread block, also shown in the Figure 16 of Figure 14 and 15 variants to inclusion of Figure 13. Figure 13 shows a are also described for facilitating tire (300) (WS) and be in contact with the irregularities. In addition, descriptions to describe a central point for facilitating the aforementioned in the embodiment different from those less than 1000. In the embodiment also 13 and 14 also consulting at least one surface tire (300) includes a tread portion of, side wall (380) and code portion (350) having a predetermined wavelength. Tread portion and a plurality of tread block (310) and at least one groove (315) can be a. Also 13 and 14 also reference the tire (300) is circumferentially about central axis extending shape (RT) may have. In addition tire (300) is based on the inside rim radially from a central axis (r) (RM) can be combined. Tread block (310) tire (300) includes an after mounting comprising a region that can be traveling toward the road surface. E.g. tread block (310) auxiliary device comprising a region that can be in contact with the road surface. 13 Road (WS) to illustratively also for tire (300) traveling through the tire (300) (WS) and the disclosure to irregularities in contact with, specifically tread block (310) (WS) shown in contact with the road surface in the nanometer range. Code portion (350) includes a tread block (310) can be disposed within. Figure 14 shows a specifically also code portion (350) for facilitating the description of the tread block (310) are located inside the code portion (350) to injection timing are disclosed. 14 Also reference the code portion (350) one or more embedded code (351) can be a. In the embodiment as selective code portion (350) comprises a plurality of insertion code (351) can be a. Figure 14 shows a also code portion (350) is one of Figure 13 for facilitating description is given of a tread block (310) and shown in perspective view only specifically, code portion (350) for facilitating description of code unit (350) to injection timing are disclosed. Code portion (350) with insertion code (351) is (L1) may have to have shape extending in one direction. Inserting code (351) length (L1) one way tire (300) (r) which intersects the radial direction may be, for example in particular between the radial (r) be a. In the embodiment as selective tire auxiliary device (300) isoprene block (310) when in contact with the surface of the ground, insertion code (351) (L1) be a length of contact with the ground and the direction of side-by-side direction. In addition as another example insertion code (351) length (L1) one way tire (300) can be identical to the direction in the width direction. In the embodiment as selective insertion code (351) (L1) the length of the direction of tire auxiliary device (300) (RT) which intersects the circumference of the direction may be, in one example be a region between the circumferential (RT). This structure and a tread block (310) so as to ground the ground loadings, insertion code (351) entirely substantially simultaneously subjected to loading through tread block (310) groundplane area adjacent to a loading due to the tread block (310) shape of a plurality of can. In addition, tread block (310) in contact with the road surface when a road america it comes to pull reduced or prevent tire (300) and resonance characteristics and handling characteristics such as reduced rolling resistance of the vehicle number number [e power can be improved. In the embodiment as selective tread block (310) a plurality of inserted inside the code (351) and can be positioned, a plurality of inserted code (351) arranged along a direction can be coupled to the cartridge. In the embodiment as selective tread block (310) in a plurality of inserted code (351) (RT) can be disposed along a circumference of the tires. In the embodiment as selective tread block (310) in a plurality of inserted code (351) may have a have the same length (L1), a plurality of inserted code (351) formed on an upper part of both sides of the insertion code (351) as distance between, code portion (350) is a entire width (W1) may have. Through tread block (310) so as to ground the ground loadings, tread block (310) in contact with the surface of the ground in an area generally about the loaded balance compared tread block (310) to diminish the deformation of, tire (300) and resonance characteristics and handling characteristics such as reduced rolling resistance of the vehicle number number [e power can be improved. In the embodiment as selective tread block (310) inside the code portion (350) of a plurality of inserted code (351) coupled to the cartridge can be arranged along a direction, tread block (310) edge of can be spaced disclosed. For example a plurality of inserted code (351) coupled to the tread block (310) in contact with the ground when the ground toward one edge interval number 1 (c1) with groove (315) is guided with a number 2 may have the shape of a interval (c2). A plurality of inserted through code (351) includes a tread block (310) can be disposed in contact with the ground when the ground edge toward the windows, tread block (310) are not exposed to the outside of thereof can. In the embodiment as selective insertion code (351) (L1) is the length of the tread block (310) width of, e.g. tire (300) with reference to the direction of the width of the tread block (310) and may be less than the width of the, through tread block (310) inserted into both sides of the width edge of reference code (351) not be exposed. In addition, as another example insertion code (351) (L1) is the length of the tread block (310) can be same with, through tread block (310) based on at least one edge or both edges inserted into the width of the external code (351) second insulating layer may be filled. Also as in the embodiment shown illustratively to selective 14 such as insertion code (351) coupled to the tread block (310) in contact with the ground when the ground toward one edge interval number 1 (c1) with groove (315) and may have the shape of a number 2 with extension interval (c2), interval (c1) number 1 and number 2 interval (c2) can be the same. In the embodiment number 1 and number 2 (c1) interval as the interval (c2) optional additions of other user's personal persona disclosed. Figure 16 shows a variant of Figure 14 and 15 also shown also to the work environment. 15 Also number 1 number 2 is larger than the reference interval (c1) interval (c2). Inserting code (351) are tread block (310) being arranged close to the two or more tire contact with the ground (300) in contact with the tread block when irregularities (310) is formed tread block suffered by weight (310) can be cooked by irradiating. Reference number 1 number 2 is the interval (c1) in addition as another example also 16 can be greater than (c2) interval. Inserting code (351) are tread block (310) at a distance from the two or more ground to tread block (310) to be formed on the ground without contact between the tread block (310) can be reduce or prevent sway deformation. The aforementioned code portion (350) of one or more embedded code (351) can be bent in different. In the embodiment as selective one or more insert code (351) includes a tread block (310) can be made different, e.g. tread block (310) and the strength than can be slit. In particular example code portion (350) of one or more embedded code (351) is PET (Polyethylene terephthalate), aramid (Aramid), nylon (Nylon) or still (steel) and can include sequence, one of said materials formed or only, said mixing two or more materials can be formed into a hybrid form disapproval. In addition other optional in the embodiment as code portion (350) of a plurality of inserted code (351) can be formed of a material different from at least one of the. The at least one tread block in the embodiment restrains the tyre comprises a part and with code, the code can be one or more embedded code. A tread block in contact with the inserted code ground loadings, reduce or prevent the deformation of the tread block load can be compared. In the embodiment inserted as selective longitudinal direction crossing a direction of a radius of tire, or tread block in contact with the ground when the ground alongside or different tire width against the ground can be identical to the direction in tread block loadings substantially simultaneously to an entire code inserted most loadings due to tread block tread block damage can be reduced to improve the baffles. In addition, tread block in contact with the road surface when rotated tire rolling resistance reduced america it comes to pull with a road vehicle and resonance characteristics and handling characteristics such as reduced number number [e power can be improved. In addition, in the embodiment a plurality of inserted as selective codes to a tread block in contact with the ground and arranged in a circumferential area generally about the deformation of the tread block loaded balance compared to diminish, reducing the rolling resistance of the vehicle number and resonance characteristics and handling characteristics such as number [e power can be improved. In the embodiment shown in the present invention refers to drawing the reference only to an exemplary is at a radiates heat and, if the art therefrom in various deformation and equally to the other person with skill in the art will understand that it is in the embodiment. The, technical idea of the present invention defined by appended claim of true technology protection range generated by the will. In one embodiment describing particular implementation are as in the embodiment examples, any method example embodiment even limit the scope are not correct. In addition, "essential", such as "important" when the components of the present invention specific referred for application although not necessarily bursts disclosed. In the embodiment of "said" specification (in particular claim in) in terms of the use of a corresponding both indicating and similar terms be a backing and a plurality. In addition, in one embodiment in a range of individual value based on said range (range) when applying the provided invention including (in the absence of substrate the W-CDMA), constituting said range description described each individual value such as disclosed. Finally, it is apparent that order components relative to the embodiment example according to method based on a lot or in the absence of substrate, said steps are suitable sequences can be performed. Said step of the substrate must order embodiment examples limited endured. In an exemplary embodiment all examples or terms (for example, etc.) simply by the use of the example embodiment is not limited or more claim for detailed examples or exemplary embodiment is defined in which example range due to said terms are not correct. In addition, one skilled various modification, in combination change is added claim or equally configured in accordance with the category of the design condition and a factor can be cylindrical. 100, 200, 300: Tire TD: tread portion of 110, 210, 310: Tread block 180, 280, 380: Side wall 150, 250, 350: Code part 151, 251, 351: Insertion code One embodiment of the present invention relates to a tire mounted in a vehicle, comprising: a tread unit having one or more grooves and a plurality of tread blocks having an area coming in contact with the road surface in case of at least driving of a vehicle; a side wall adjacent to the tread unit and having an area spaced from the road surface; and a code unit disposed inside at least one of the tread blocks and having one or more insertion codes. COPYRIGHT KIPO 2018 Cleaner of tire relates to search, in contact with a region including a plurality of tread block and at least one groove at least during traveling road surface having tread portion of; said tread side adjacent spaced apart region road including side wall; and a plurality of tread block said at least one code section and including one or more embedded code which is disposed therein, said plurality of inserted code the code, a plurality of tread blocks adjacent to each other in said width of said at least one tire tread block 2 and arranged with reference to the direction of, said arranged adjacent to each other of said code of a tread block 2 arranged on one of the plurality of inserted code direction is arranged to the other one of the tread block disposed adjacent to each other of said 2 of said code including a plurality of inserted code differs from the direction of the tire. Back number According to Claim 1, separated from each other by the plurality of tread block code with said groove said tire. According to Claim 1, coated with said code insertion code extends in one direction has a length, said length having a value equal to or less than said width or the same as the tire tread portion in one direction. Back number Back number According to Claim 1, said code of said tread block inserted code is made out of a tire made of higher strength larger than high.