FLEXIBLE ORGANIC LIGHT EMITTING DISPLAY DEVICE AND MANUFACTURING METHOD THEREOF

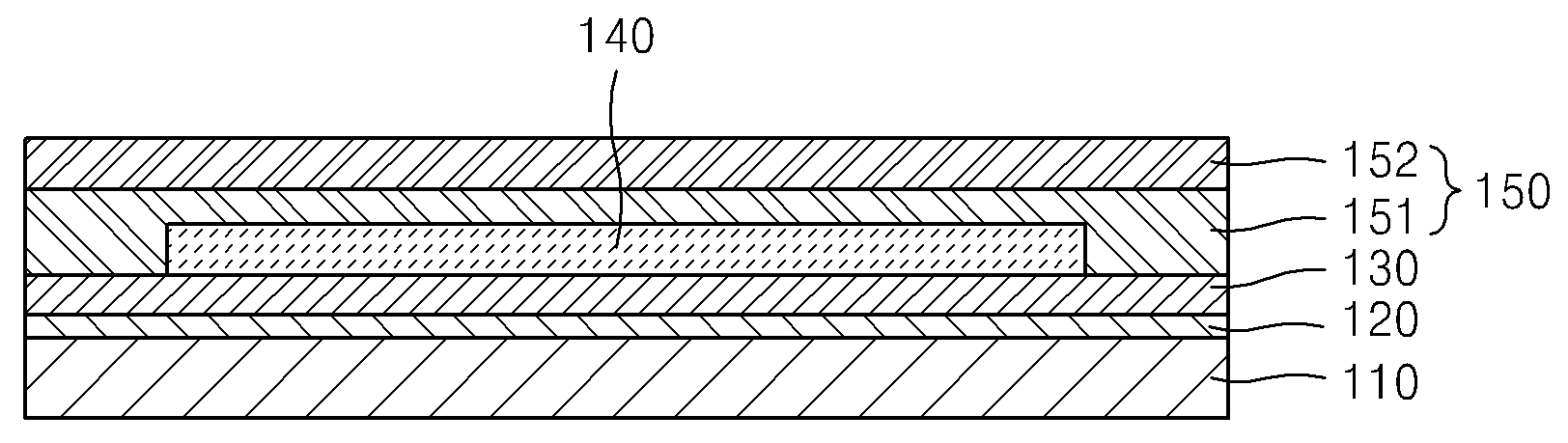

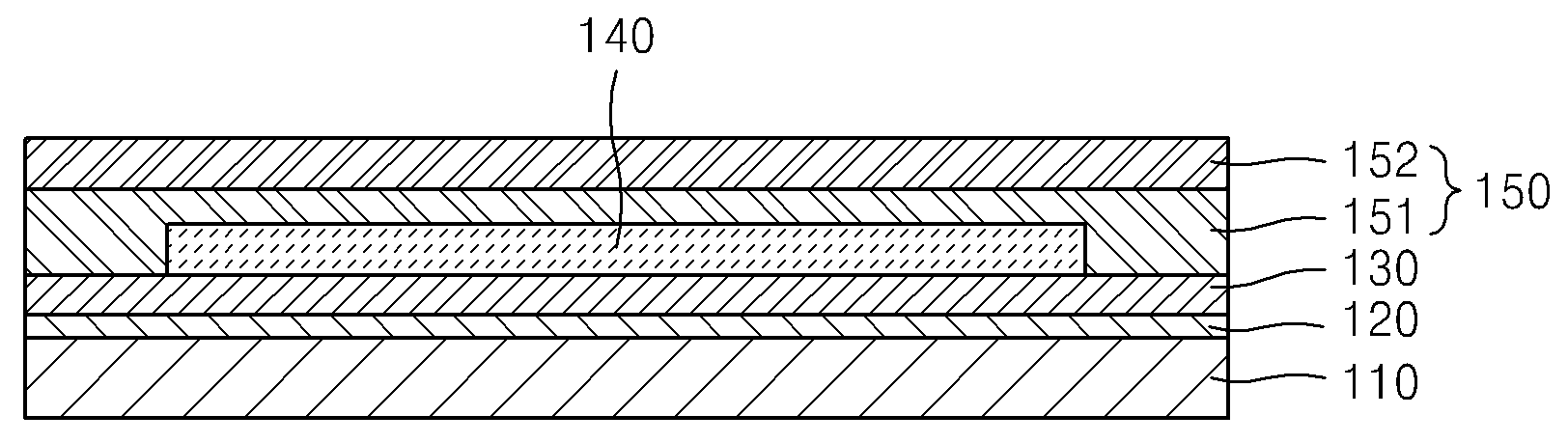

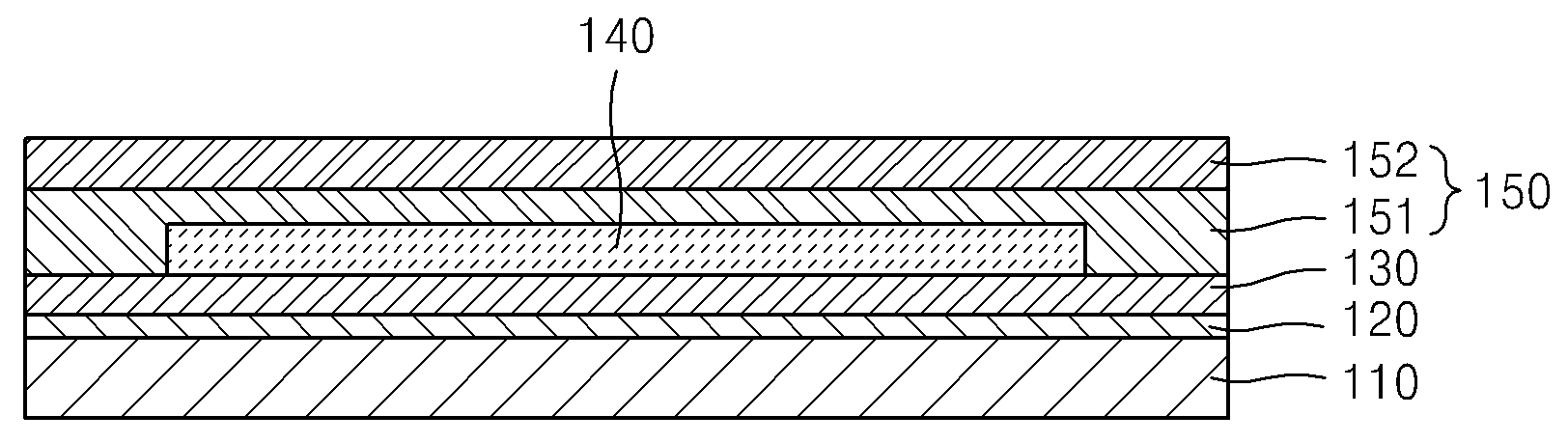

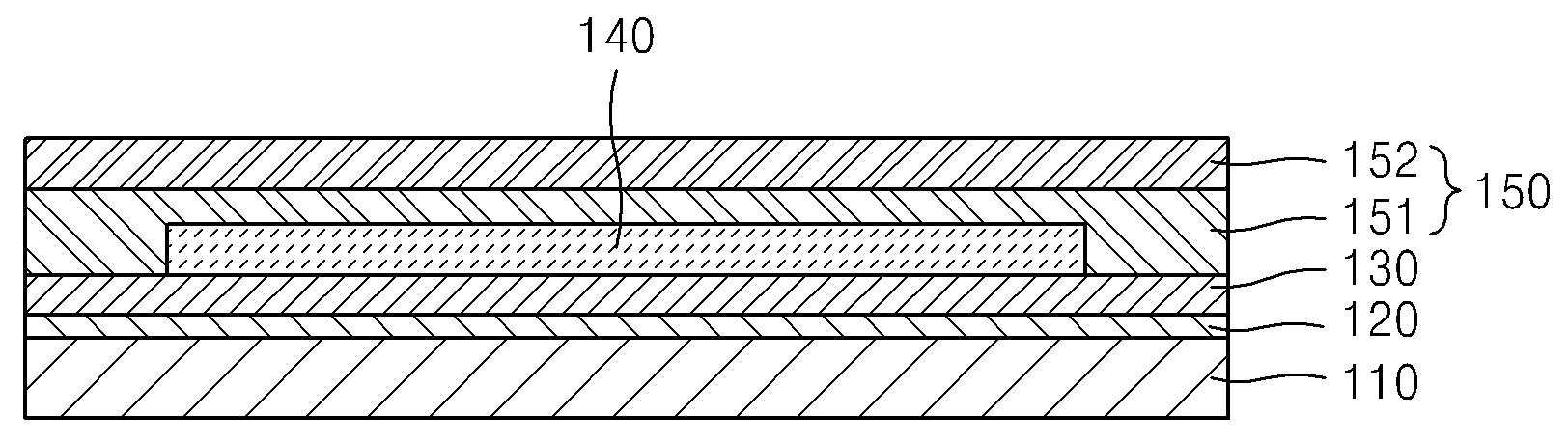

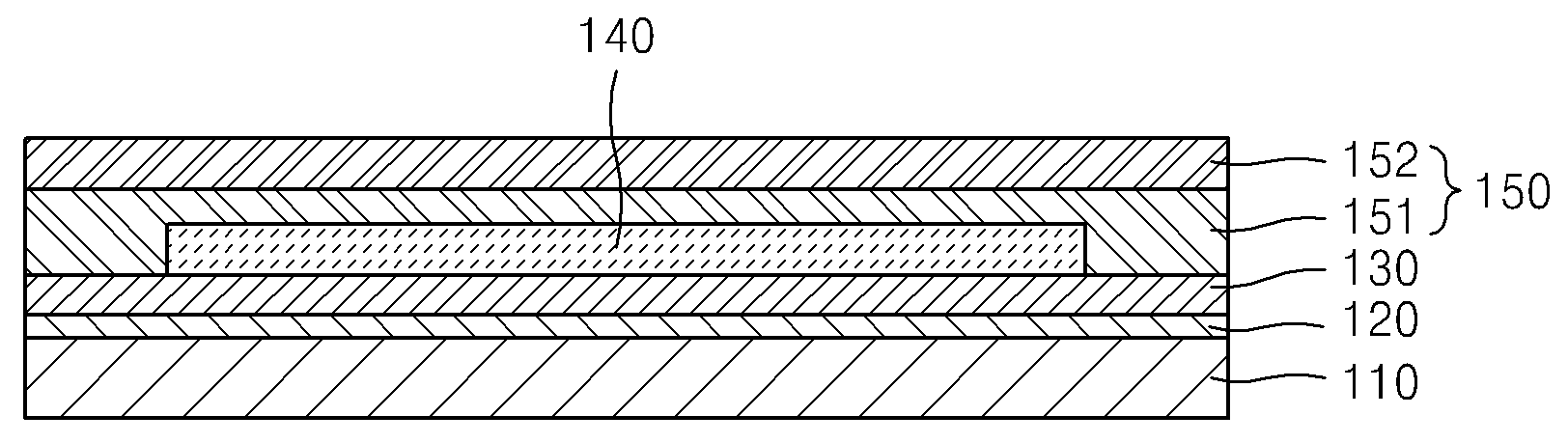

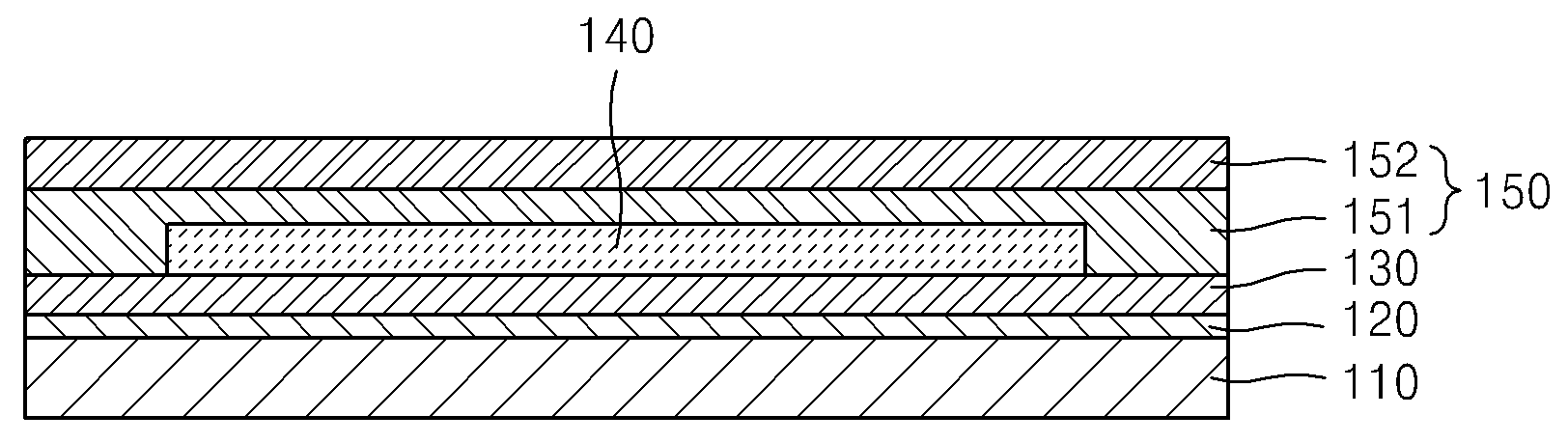

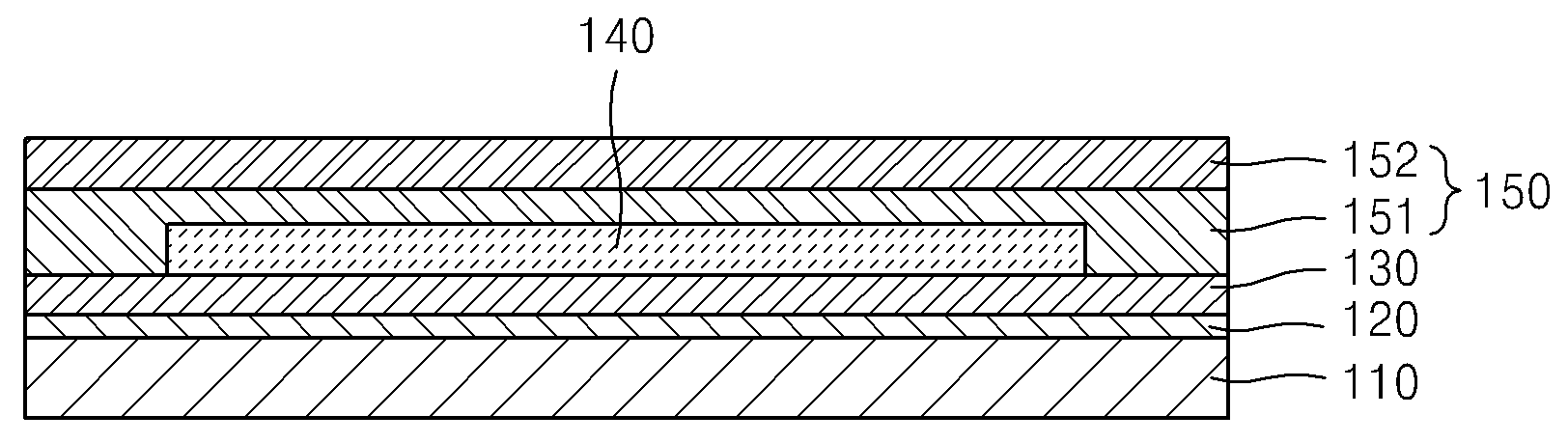

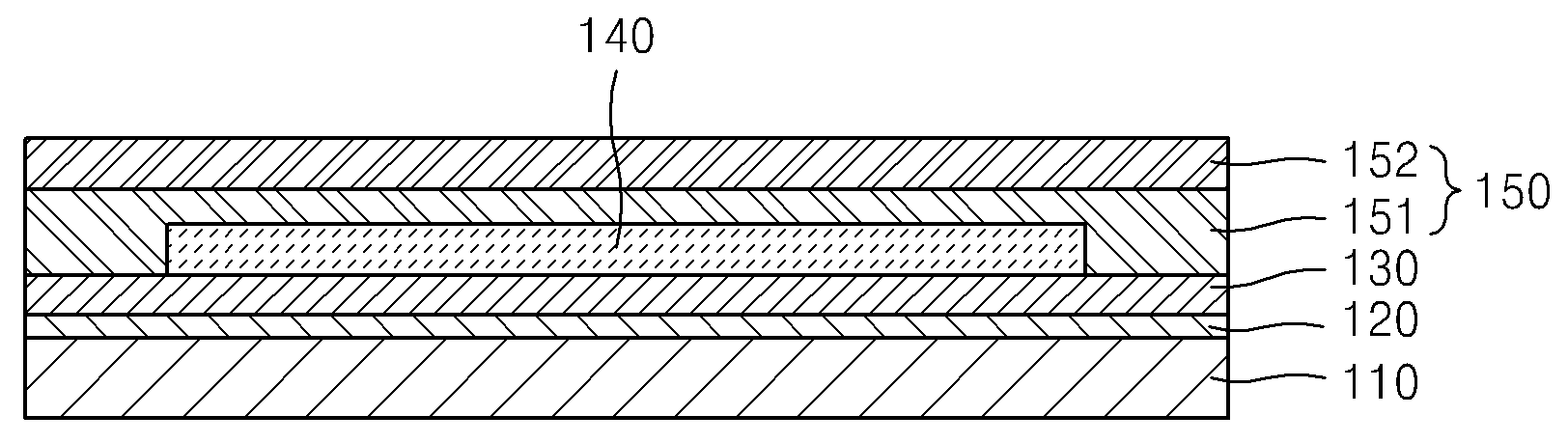

Flexibly deformable the present invention refers to a flexible organic light emitting display device and relates to manufacturing method. Generally such vessel and the flexible display device display a flexible substrate thereby forms a device as and stores it in a flexibility, a transformed the portable particularly reducing the volume having installed in the central hole. Flexible organic light emitting display device and manufacturing method of the present invention in the embodiment are provides. Flexible substrate and of the present invention embodiment relate, said flexible than barrier formed on a crystalline substrate, said barrier layer formed on the display part and, is used as display said encapsulation layer, , said display between said flexible substrate and moisture absorption at any layer where a flexible layer is formed for disclosure the organic light emitting display device. The CaO MgO and a hygroscopic layer said at least one or more may comprise an. Said flexible substrate and said said hygroscopic layer can be formed between the barrier film. Furthermore, a plurality of said flexible substrate and said selected from a group consisting of CB are stacked alternately, said hygroscopic layer said plurality of flexible substrate and barrier in the rest of the aluminum layer except said nearest the display unit the rest of the aluminum layer except between the flexible substrate and barrier can be formed. Said both sides said said hygroscopic layer can be formed between the display. Furthermore, a plurality of said flexible substrate and said selected from a group consisting of CB are stacked alternately, said hygroscopic layer nearest the display unit said display between the both sides can be formed. Furthermore, on a carrier substrate of the present invention embodiment relate flexible the step of forming the substrate; said flexible-a to form barrier layers; said display over the barrier layer comprises forming a; to cover the layer encloses said display; and, said display between said flexible substrate and material layer and a nitration material layer hygroscopic at any layer where; including a flexible organic light emitting display device of the disclosure for manufacturing method. The CaO MgO and a hygroscopic layer said at least one or more may comprise an. Said flexible substrate and said said hygroscopic layer can be between the barrier film. Said flexible substrate and wherein said one-side ends are exposed to plurality barrier film, said hygroscopic layer said plurality of flexible substrate and barrier in the rest of the aluminum layer except said display unit nearest the flexible substrate and barrier can be formed between the rest of the aluminum layer except. Said both sides said said hygroscopic layer can be between the display. Said flexible substrate and wherein said one-side ends are exposed to plurality barrier film, said hygroscopic layer nearest the display unit said display between the both sides can be. The aforementioned addition the other side of the, characterized, front drawing of hereinafter, clearly from the detailed description of the invention and claim is will occur. Manufacturing method according to an embodiment of the present invention flexible organic light emitting display device and dampproof and layer hygroscopic according to performance enhancing displayed in part the risk of damage is mounted to the peripheral area and, the SPAN of life and copyright 2001 the objective compound. area. Also Figure 1 shows a a flexible organic light emitting display according to one embodiment of the present invention it is shown a device. in a section. 1 also also shown in Figure 2 shows a flexible organic light emitting display device to expand a display unit in. whose cross section. 1 door has 3c also to 3a also shown in manufacturing procedure of a flexible organic light emitting display device is shown in the drawing. Also according to other embodiment of the present invention also Figure 6 shows a to 4 a flexible organic light emitting display device whose cross section it is shown a.. The present invention refers to various conversion thereby, the cold air flows that can apply various embodiment which may have bar, specific drawing illustrated in the embodiment are defined in the description are disclosed and. rapidly and to reduce a memory. The present effect of the invention and features, and achieving the method a refers to in particular a plant processing waste fractions with drawing in the embodiment are a clarified that will. However the present invention refers to hereinafter in a disclosure in the embodiment defined in rather than in various forms may be embodied in. Hereinafter, reference to drawing with an account which of the present invention in the embodiment are detailed, drawing when describe an reference to the corresponding components equal to or the same drawing is impart code of a local terminal is dispensed to the described. In the embodiment of in hereinafter, contextually representation a plurality of differently it is apparent that without the carelessly, includes multiple representations. In the embodiment of in hereinafter, a set of terms, such as. having or comprising a specification to the features, or components the presence of means which is used, another aspect of one or more the probability of is added or components while removing the pre the not. In the embodiment of in hereinafter, film, region, such as components on the other portion in or on the when that the, when directly on the of the other portions as well as, other films to its intermediate, region, components such as is inserted includes a double-. For facilitating of drawing in the size of components are can be or contracts the map picture. E.g., each configuration shown in drawing described size and thickness for facilitating of arbitrarily representing sleeve regulates the, necessarily the present invention not limited to shown. Alternatively substracte any embodiment, where possible, implementing a process order specific to differ from the order of described a subsequent heat treatment is performed after. For example, continuously the described cassette on an unloading substantially concurrently and may be performed, so that a lower interconnection is formed described and vice versa can be and the processing advances to step order. Figure 1 shows a one embodiment of the present invention also a flexible organic light emitting display device according to a timing.. The first deoxygenator embodiment the present drive the discharge lamp a flexible organic light emitting display device, flexible substrate of polyimide (110) and, barrier layer (130), thin film transistor (not shown) and the light-emitting layer (not shown) including the display part (140), and organic film (151) and the inorganic compound film (152) are alternately arranged on the thin film sealing layer (150) are stacked is.-clad layer is made. I.e., thick rigid glass substrate a flexible flexible substrate with flip-flop of semiconductor memory (110), and thin film sealing layer (150) is displayed (140) which seals the structure. Therefore, the flexible organic light emitting display device a to be flexibly deformed.. And, said flexible substrate (110) and barrier layer (130) between the hygroscopic layer (120) is formed. Said hygroscopic layer (120) the CaO or MgO mainly formed with hygroscopicity, such as application or deposition through said flexible substrate (110) and barrier layer (130) can be formed between the. Interconnection layer is covered with a layer (120) the outer bores moisture display unit (140) media penetration of the is so that the absorbent so as not to. I.e., organic light emitting display device for display unit (140) in particular moisture emitting layer included in the scene of labor invasive occur menu may be damaged. Of the invasive temperature is lower than the reference light-emitting region to the second stage, eventually is inferior is total article. However, this configuration flexible substrate, such as (110) and the display part (140) between pores layer (120) thus forming the surface, external bores moisture interconnection layer is covered with a layer (120) guiding rail elevates, display unit (140) a moisture penetration safe from guarded is enabled. On the other hand, said flexible substrate (110) glass transition temperature is 500 °C or more heat resistance polyimide can be constructed. Flexible substrate is (110) is attaching and fixing the timer to the replacing a proportion of glass substrate very flexible thin film substrate is to. Said barrier layer (130) substrate includes a concave portion change provided from the outside a dampproofing, to reduce as layer, e.g. SiO/SiN of multilayer film can be constructed. This SiN and a SiO which are stacked to be, is (water vapor transmission rate) rate moisture permeability and air permeability and 10-3 g/m2, day has properties hereinafter. Said hygroscopic layer (120) serves to the of adsorbing moisture, barrier layer (130) the blocks moisture and. which serves to. Said display unit (140) has door 2 shown in second, a copyright 2000. Drive the discharge lamp, thin film transistor (141) and a EL device (142) has a, said EL device (142) effected using the moisture in particular in-forming light-emitting layers (142b) is having. More scrutinized surface, barrier layer (130) the upper substrate in correspondence to the buffer layer (141a) a semiconductor active layer (141f) being arranged for receipt of, active layer is crystallized (141f) the N or P-type impurities heavily doped has source and drain regions. Active layer is crystallized (141f) with an oxide may be loaded with semiconductor. For example, oxide semiconductor zinc (Zn), indium (In), gallium (Ga), tin (Sn) cadmium (Cd), germanium (Ge), or hafnium (Hf) group 12, 13, 14 such as selected from combinations thereof elemental metals the oxides, the oxides may include a. For example semiconductor active layer (212) the G-I-Z-O [(In2 O3) a (Ga2 O3) b (ZnO) c] (a, b, c a≥ 0 each, b≥ 0, 0 of the real to coat the c) may include a. Active layer (141f) of a gate insulating film (141b) and a gate electrode (141g) is formed. Gate electrode (141g) upper part of the source electrode (141h) and the drain electrode (141i) is formed. Gate electrode (141g) source electrode (141h) and a drain electrode (141i) interlayer insulating film between the (141c) are provided, source electrode (141h) and a drain electrode (141i) and EL device (142) of anode electrode (142a) passivation between the (141d). is inserted. Said anode electrode (142a) by such as an acrylic resin include top of the insulating planarization film (141e) being arranged for receipt of, is planarization film (141e) a predetermined opening (142d) is transferred to an interconnection corresponding to, EL device (142) to form a. Said EL device (142) comprises a current flow of a, b may be adjusted according, rust, predetermined light-emitting diodes for emitting light blue displayed so Image information, thin film transistor (141) to the drain electrode of a (141i) by supplying the power plus therefrom connected to an anode electrode (142a) and, covering operation by all the pixels is made minus power surface are provided to a cathode electrode (142c), and drain electrode (142a) (142c) is arranged between light emitting luminescent layer (142b) consists of in. Is (142b) in the vicinity of, a hole injection layer (HIL: Hole Injection Layer), a hole transport layer (HTL: Hole Transport Layer), electron transport layer (ETL: Electron Transport Layer), electron injection layer (EIL: Electron Injection Layer) .may be like is laid. With reference to is (142b) red, green, blue emitting light pixels each first support member is attached to the unit pixel one aggregated is separated every pixel can be formed. Or, operation by all the pixels is made regardless of a portion of a common emitting layer advantageously may be. The, red e.g. luminescent layer, emitting light of green and blue light source for emitting ultraviolet light which are vertically layer including eg in layered or mixed with a background object component can be formed. Well as, can emit white light if a combination of different colors is the box. Furthermore, a sixth emitted said a predetermined color for translating a color conversion type or, and can comprise of further color filter. Directly is (142b) water which is characterized by being a very vulnerable a functional which, thus, display unit (140) into organic light emitting display device is detachably using the moisture of Image realization properties can be along any deterioration is rotated. Said display unit (140) sealing layer thin films made on (150) a door body, a display section (140) to electrically the into layers, organic film (151) and the inorganic compound film (152) has a stacked structure of may be based on the alternation of. Said, an flexible organic light emitting display device by processes such as the following can be produced. First, as shown in also 3a carrier substrate-glass material (160), which comprises the steps of. layers are formed thin film thereon. First, carrier substrate (160) flexible substrate of polyimide poly (110) is formed, an absorbing effect aforementioned thereon layer (120) is formed on. Furthermore, also 3b such as a barrier layer (130), display unit (140) and thin film sealing layer (150) .are formed in turn. Stacked and the air inlet, and ground structure is made, also 3c such as a carrier substrate (160) separating the. The thus produced planar metallised textile structure organic light emitting display device a, flexible flexible substrate (110), and thin film sealing layer (150) the display part (140) surrounding the compressor has a flexible to the outside by easily fitting the, in addition hygroscopic layer (120) the outer of moisture from a display unit since the for (140) a moisture from the effects of fed back for a precision control and columns is especially retention is inserted at a center of. While, in the embodiment in said flexible substrate (110) and barrier layer (130) that are individually placed at the layer is preheated exemplary structure, as shown in 4 also flexible substrate (110) and barrier layer (130) inside of the via coil structures are arranged in alternating manner and, hygroscopic layer (120) a door body, a display section (140) adjacent control circuit and flexible substrate (110) and barrier layer (130), which is disposed between the it is also possible to transform the organic fibers into the structure. Furthermore, the aforementioned in the embodiment in hygroscopic layer (120) is flexible substrate (110) and barrier layer (130) have been exemplary of the link is between the, necessarily limited its location are not flexible substrate (110) and the display part (140) between at least one layer at any layer where is by forming. I.e., also 5 flexible substrate as shown in (110) and barrier layer (130) rather than between barrier layer (130) and the display part (140) between pores layer (120) .may then be replaced on the cornea. And, also 6 and second high flexible substrate (110) and barrier layer (130) having a structure in which a a coil is constituted by alternately laminating moisture from being absorbed layer (120) a center of the display unit (130) nearest the barrier layer (130) and the display part (140) may be loaded with formed between the. Therefore, the flexible organic light emitting display device and manufacturing method dampproof and layer hygroscopic according to performance enhancing displayed in part the risk of damage is mounted to the peripheral area and, the SPAN of life and copyright 2001 the objective compound. area. One shown in the present invention refers to drawing and thereby, the cold air flows embodiment restrains the described with reference to an exemplary, the purpose: to avoid a typically encountered in field having knowledge of embodiment and various modifications therefrom grow the first deoxygenator changeable will understand that. Therefore, the scope of protection of the present invention technical true a claim the idea is decided by the will should be. 110: flexible substrate 120: hygroscopic layer 130: barrier layer 140: display unit 150: sealing layer Disclosed is a flexible organic light emitting display device in which a moisture absorption layer is formed on a random layer between a flexible substrate and a display unit. The organic light emitting display device comprises: the flexible substrate; a barrier layer formed on the flexible substrate; the display unit formed on the barrier layer; and an encapsulation layer covering the display unit, wherein the moisture absorption layer is formed on the random layer between the flexible substrate and the display unit. COPYRIGHT KIPO 2015 Flexible substrate and, said flexible than barrier formed on a crystalline substrate, said barrier layer formed on the display part and, is used as display said encapsulation layer, , said flexible substrate and said display between at any layer where hygroscopic layer is formed a flexible organic light emitting display device. According to Claim 1, said hygroscopic layer selected ones of the CaO and MgO is safe to skin without any side including flexible organic light emitting display device. According to Claim 1, said flexible substrate and said hygroscopic layer said barrier film formed between the flexible organic light emitting display device. According to Claim 1, in addition, a plurality of said flexible substrate and said selected from a group consisting of CB are stacked alternately, said hygroscopic layer said plurality of flexible substrate and barrier in the rest of the aluminum layer except said nearest the display unit the rest of the aluminum layer except formed between the flexible substrate and barrier flexible organic light emitting display device. According to Claim 1, said hygroscopic layer said display is formed between the both sides a flexible organic light emitting display device. According to Claim 1, in addition, a plurality of said flexible substrate and said selected from a group consisting of CB are stacked alternately, said hygroscopic layer nearest the display unit said display is formed between the both sides a flexible organic light emitting display device. On a carrier substrate flexible the step of forming the substrate; said flexible-a to form barrier layers; said display over the barrier layer comprises forming a; to cover the layer encloses said display; and, said display between said flexible substrate and moisture absorption at any layer where material layer and a nitration material layer; a manufacturing method of including flexible organic light emitting display device. According to Claim 7, said hygroscopic layer selected ones of the CaO and MgO is safe to skin without any side manufacturing method of including flexible organic light emitting display device. According to Claim 7, said flexible substrate and said hygroscopic layer said barrier film formed between the manufacturing method of a flexible organic light emitting display device. According to Claim 7, said flexible substrate and wherein said one-side ends are exposed to plurality barrier film, said hygroscopic layer said plurality of flexible substrate and barrier in the rest of the aluminum layer except said nearest the display unit the rest of the aluminum layer except formed between the flexible substrate and barrier device manufacturing method of a flexible organic light emitting display. According to Claim 7, said both sides said hygroscopic layer said display formed between the manufacturing method of a flexible organic light emitting display device. According to Claim 7, said flexible substrate and wherein said one-side ends are exposed to plurality barrier film, said hygroscopic layer nearest the both sides said display unit said display formed between the manufacturing method of a flexible organic light emitting display device.