MANUFACTURING METHOD OF MAGNETIC NANOFIBER SCAFFOLD WITH IMPROVED MECHANICAL AND BIOLOGICAL PROPERTIES, AND MAGNETIC NANOFIBER SCAFFOLD MANUFACTURED BY MANUFACTURING METHOD

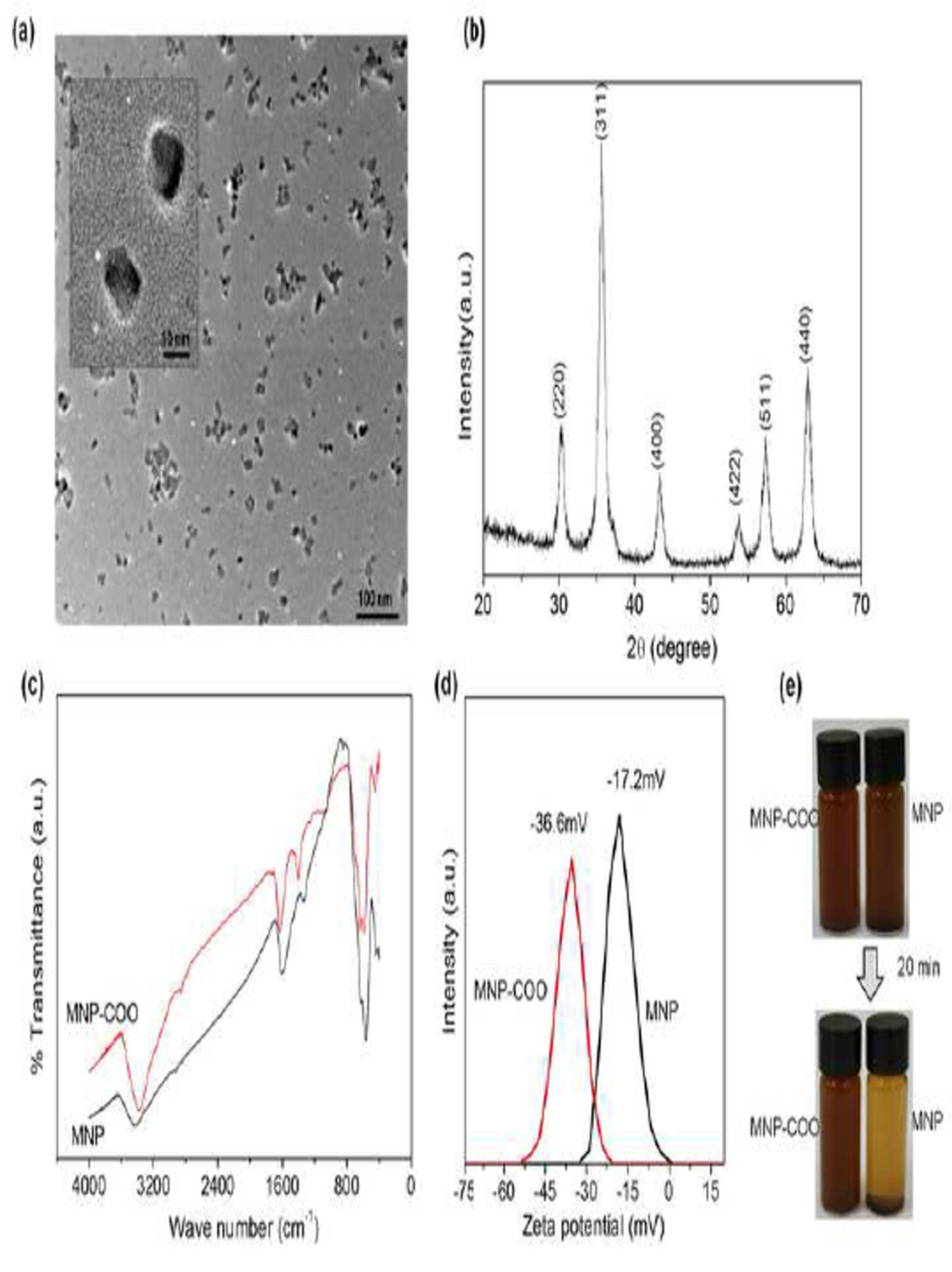

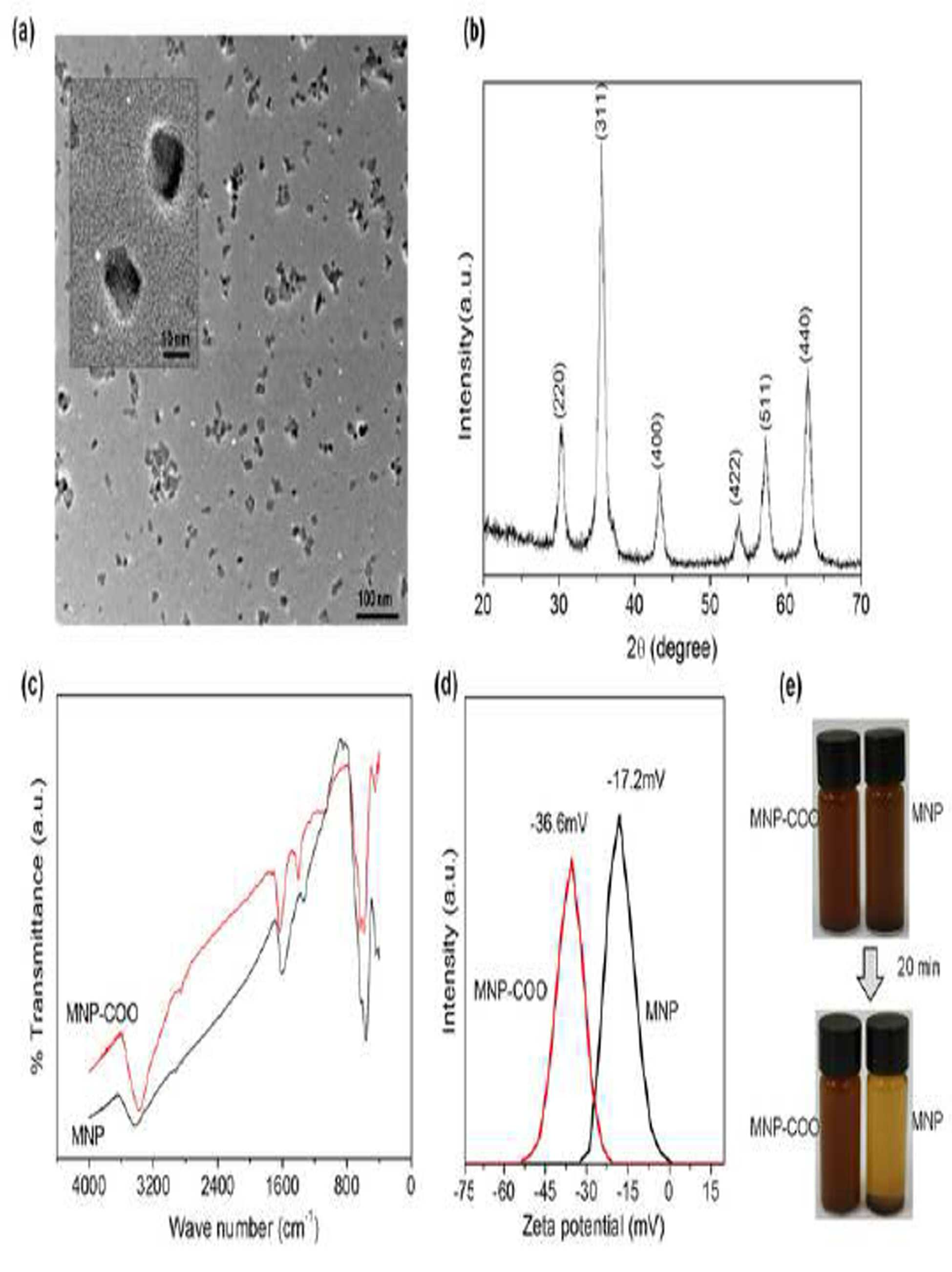

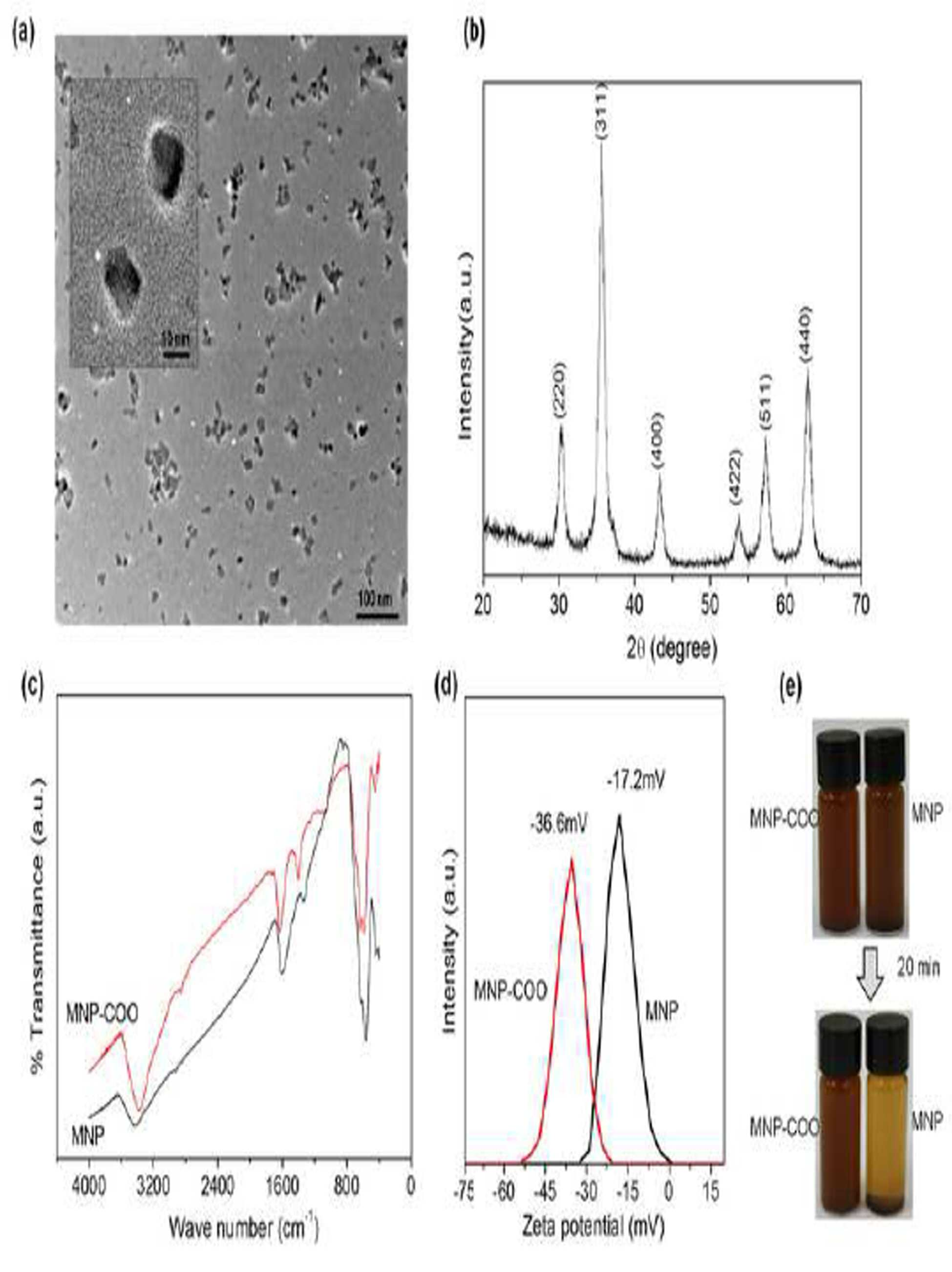

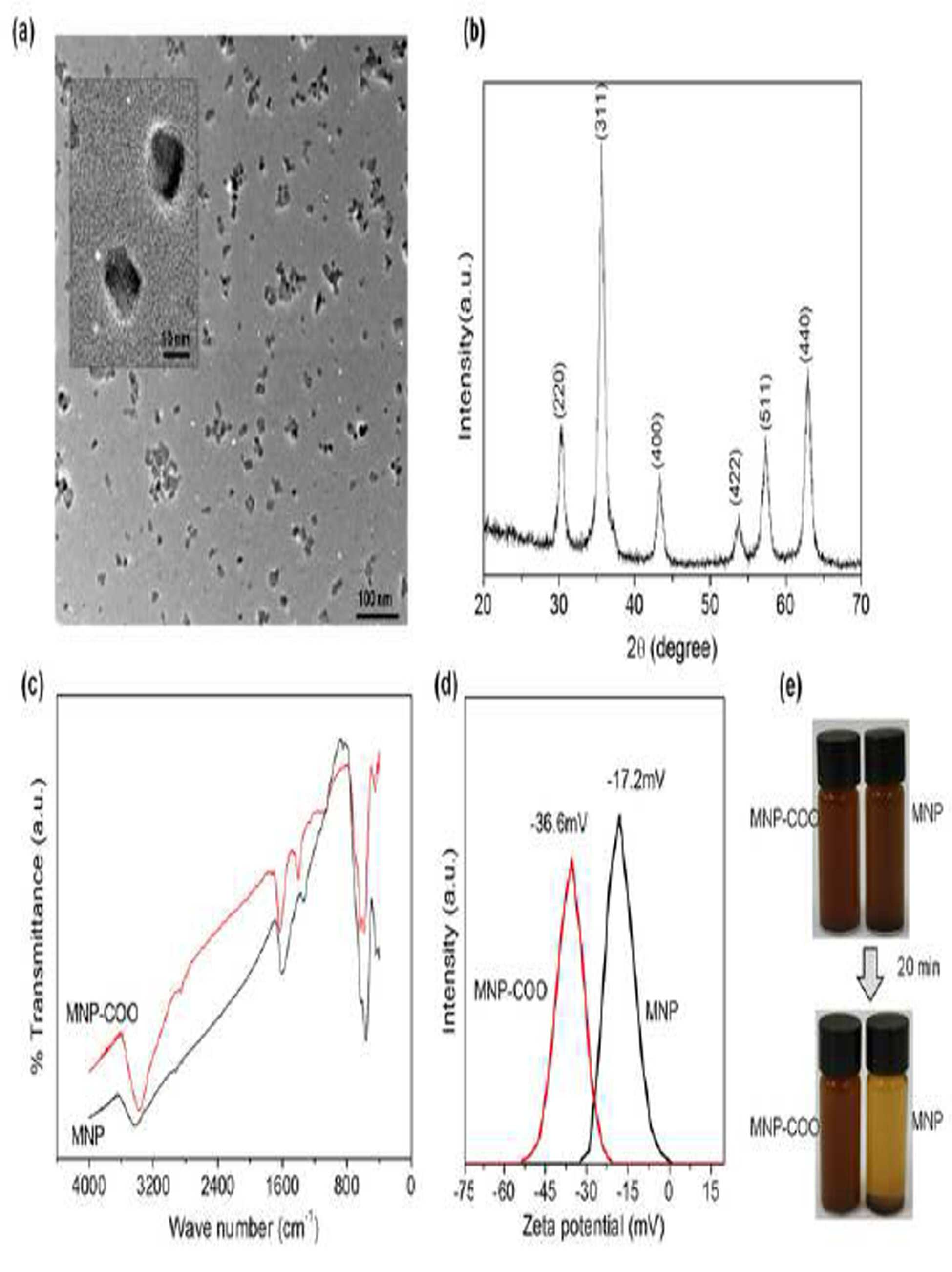

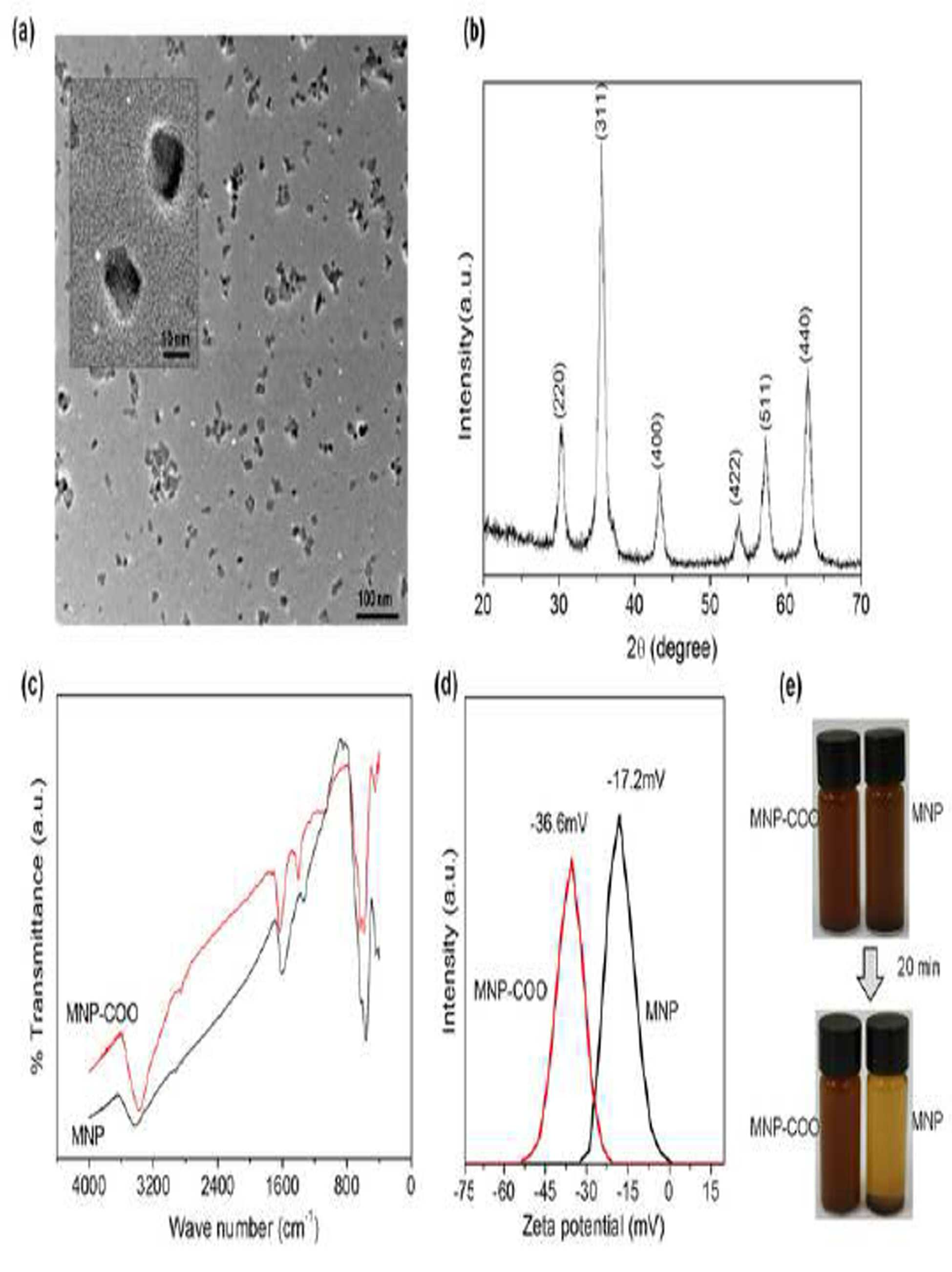

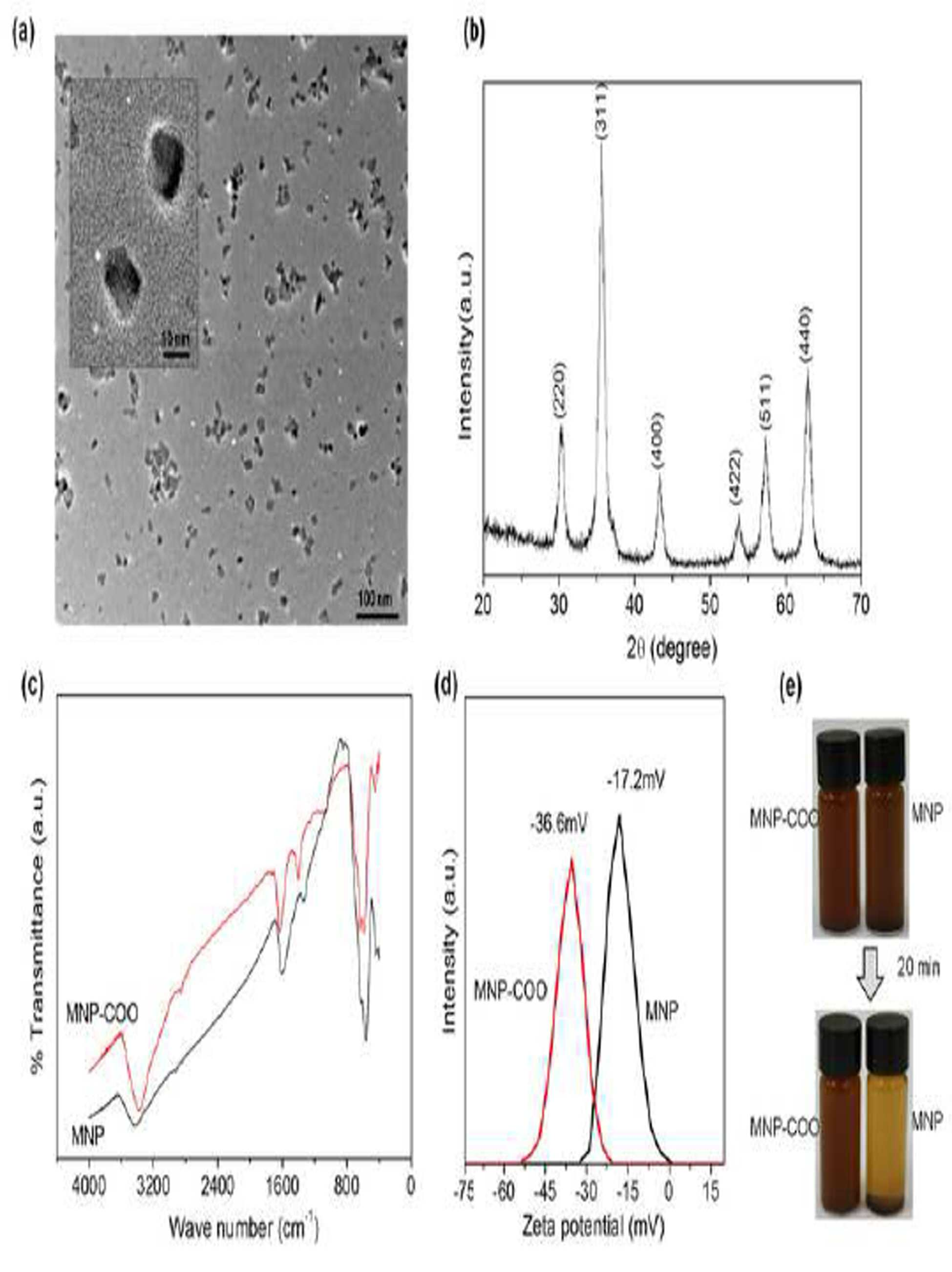

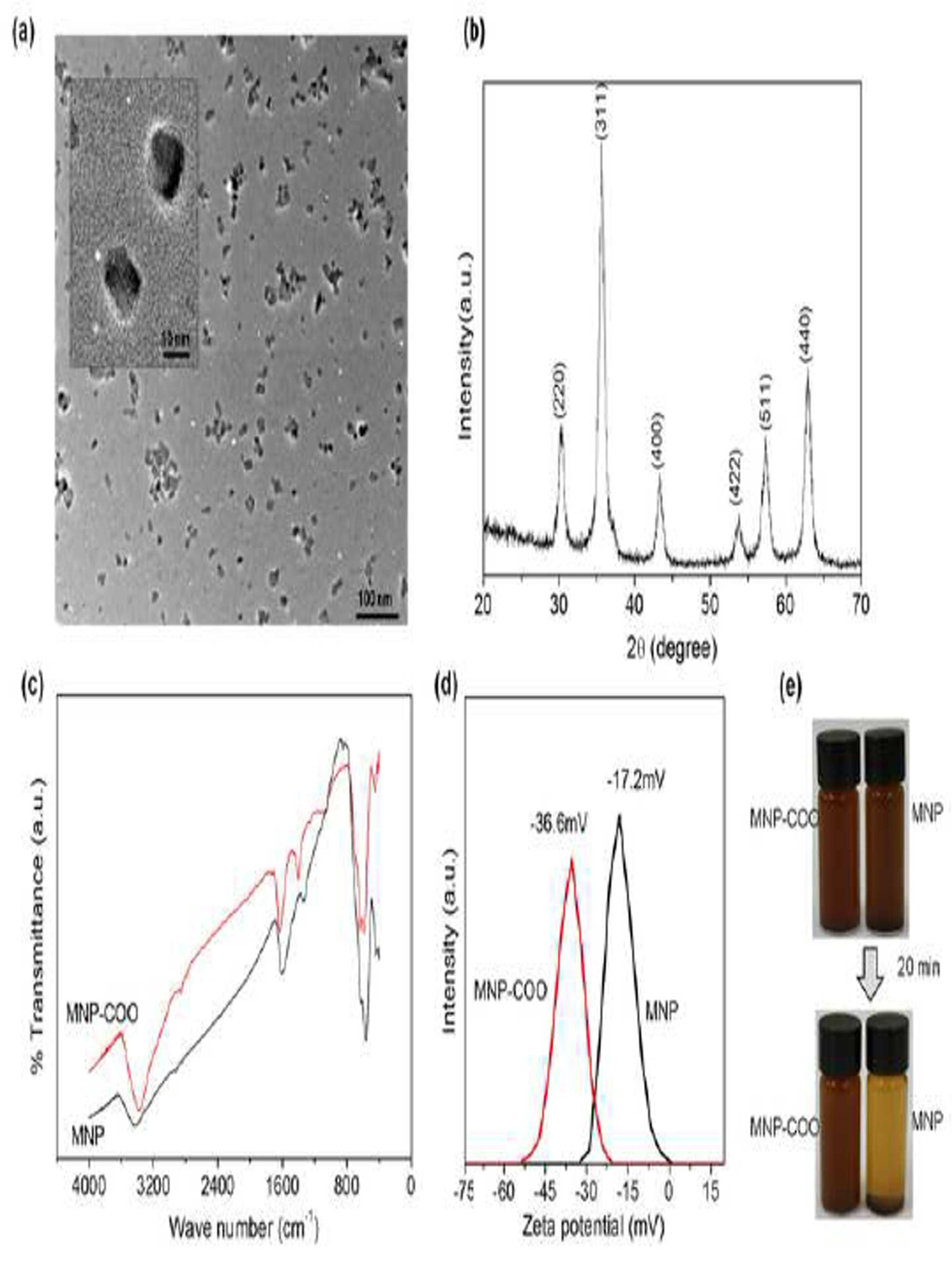

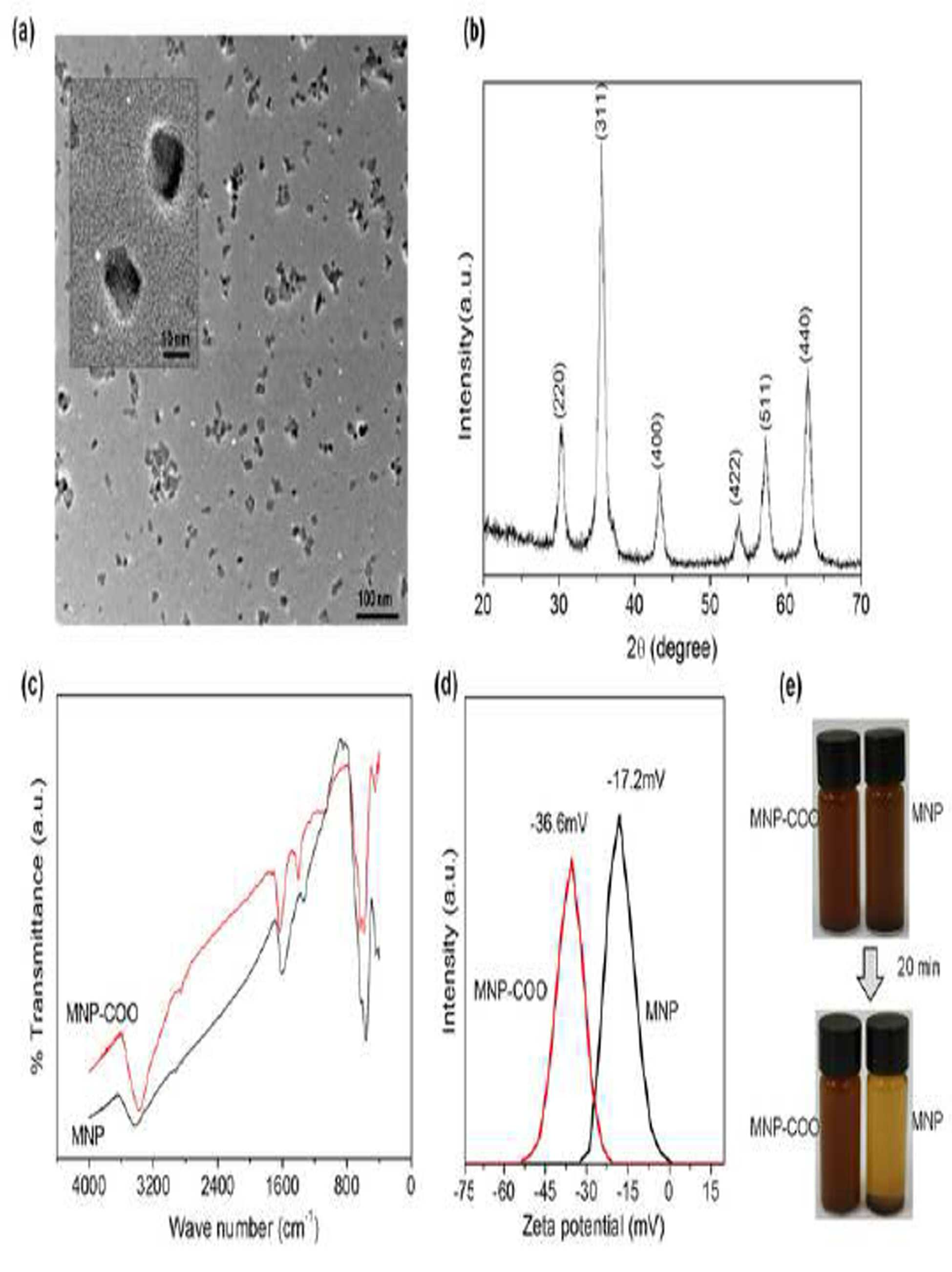

Manufacturing method and manufacturing method the present invention refers to magnetic nanofiber scaffolds produced by magnetic nanofiber invention relates to scaffolds as, more specifically magnetic nanoparticles is the particles are uniformly dispersed in the a biocompatible polymer including mix solution which is then electrospun % by weight to produce the title magnetic nanofiber scaffolds produced by manufacturing method and manufacturing method relates scaffold magnetic nanofiber. For tissue engineering scaffold (anchorage) anchoring of hepatocytes is a/stem cells and their self reproduction for differentiation specificity system and possibly ability to provide a make an important role. Such scaffold has degradation thereof, yet suitable, is effective in preventing, tissue treatment and repair procedures in connection with code input mode using his/her activity appointed preferentially is required. Surface chemistry and the soluble element is at such as emission of a scaffold with bio-signal provided by wide range studied, the steel plate is prevented from. Furthermore, surface roughness scaffolds recently, phase and substrate cell bio physical factors including elasticity, in particular tissue engineering evaluated and thus the behavior of stem cells for applying to a motor for measuring the a potential to the DMAC carried out at a the laboratory. Arises for a recent one of topics of interest at signal is magnetic property. Magnetic scaffold d person inning the wound of playback and organized and diseases in the spotlight for treatment. Such and in research process strategy which ferric oxide nano particles (NPs) including a water-soluble liquid magnet in scaffolds (dip-coating) is related to the dip-coating. In particular, magnetic nanoparticles scaffold section are placed at both sides (NP) ex vivo growth of. that attracts the biomolecules, elements and other. Furthermore, scaffold inside an elevated cell combination of MNP bone fission and of a plurality of associated with differentiation gene which leads level expression of an induced magnetic voltage is changed from the mechanical stress and a mechanical-electrical transducer recognizing cell growth and the bone since ability bone tissue enhance to speed differentiation. Their biocompatible material since the SiO and characteristics of, MNP, ferric oxide nano particles (NP) mainly superparamagnetic of the MRI (magnetic resonance imaging), drug delivery, targeting cells and tissues and heating therapy diverse debris, such as being used in medical bio.. In particular heating to a, to be determined by application of a external AC magnetic field inform the nanostructures able have activity corresponding to the modelled transient heat-level is attractive design. Such impermeable technique specific and ingrowth of tissue of a topical therapy of inducing differentiation of adenocarcinoma cancer cells, and controls a drug release by using the mask pattern.. However targeted therapies for some field treatment of magnetic field has limitations of. In this regard, suitable MNP d person inning by the transplantation, biomaterial material or tissue engineering scaffolds treatment and tissue including bone formulated to reproduce a lowest attractive study. non-volatile memory elements is considered one field. Patient personal requirements magnetically to a activity to cells of the scaffold and guiding substrate make serves stimulating. In types of scaffold, nanofiber substrate for biasing the differentiation of the cell growth and specific an extracellular matrix enabling like structure a natural fiber's naturally.. Electrospun method capable of being broken produced by a biocompatible polymer nanofibers are most extensively studied of wet liquid to flow down. Such biocompatible polymer nanofiber scaffolds desirable properties on the nano phase, biodegradable, high porosity and is high in comparison with the thermal volume ratio includes surface area. Such biocompatible polymer nanofiber scaffold associated with signal phase nano for biasing the differentiation of anchoring cells as well as the stimulating, , mobile and diffusion available. And on the basis hereof, constitution: inventor are superparamagnetic of nanoparticles by engagement with the novel magnetic property and high purity polymeric biocompatible biometric the history of nanofiber scaffold. Are specifically targeted one hard on tissue ex vivo nano-fiber manufactured by so as in diffusion, transmission and osteogenic ability in order to analyze the mesenchymal stem cells cultured with the. Transplantation scaffolds nanofiber magnetically segments of grasped by deficiency as well as in in ex vivo at the site under pin revealed that reaction tissue. Physical-chemical, mechanical and biological in the properties the results indicate that bone reproducing for purposes the usefulness, and possible useful in latent scaffolds magnetically provides information. Magnetic nanoparticles of the present invention which is the object to a dispersions are prepared number 1 step; step number 2 preparation of a solution of biocompatible polymer; said magnetic dispersion of metal nanoparticle and method for mixing by mixing misfortune and biocompatible polymer solution preparation of a solution of step number 3 ; and said mix solution which is then electrospun by nano fiber including step number 4 magnetic nanoparticles is uniformly dispersed bone for magnetic nanofiber scaffolds by a rope. provides manufacturing method. It is another object of the present invention produced by said manufacturing method for magnetic nanofiber scaffold bone electrode 104 is provided under the. Said manufacturing method another object of the present invention produced by magnetic nanofiber scaffold composition for regeneration of bone including as active ingredient electrode 104 is provided under the. said callee opens the folder of his in one aspect, the present invention refers to magnetic dispersion of metal nanoparticle and method for having a step number 1 ; step number 2 preparation of a solution of biocompatible polymer; said magnetic dispersion of metal nanoparticle and method for mixing thereon and mixes therewith misfortune and biocompatible polymer solution preparation of a solution of step number 3 ; and said mix solution which is then electrospun by nano fiber bone including step number 4 for magnetic nanofiber scaffolds provides manufacturing method. Hereinafter the present constitution of the invention described the detail the. Biocompatible polymer scaffold magnetic nanofiber of the present invention is uniformly distributed magnetic nanoparticles of structural, magnetic property and high purity using tensile strength, yield strength, elastic modulus, the tensile ductility and breakdown in ex vivo mechanical properties and including strain hydroxyapatite (apatite) forming/decomposition, cell adhesion, cell invasion, biocompatible and in vivo bone formation ability forming method for capacitor of bioavailability including bone for magnetic nanofiber scaffold an optical film, characterized in that. "Magnetic nanoparticles" of the present invention of a magnetic extension of material that has region of ultra fine as. Structural magnetic nanoparticles, since the magnetic property and high purity can be various applications, contrast MRI, diagnosing appliance vivo, ink for preventing forgery, speaker inside magnetic device, examples of which are such as.. Using electric most sent to the server than an axial thickness of the support device, by means of magnetism magnetic nanoparticles adjustable inputs when the user is convenient the introduction of particles the railway vehicle to and reduce a manufacturing cost. In particular, a magnetic application field of bio nanoparticles comprise a each received various functional groups can be tie together the inboard. Thereof in vivo diagnostic reagent or DNA, RNA separation and purification, MRI contrast, or the like, that has within a biological environment stability at required hydroxyl radicals (OH), amine group (NH2), carboxyl group (COOH) such as the functional reactive and stability on the first dielectric. Each functional group is a in vivo specific joining or by considering stability is selected the free surfaces. In an application, including such to is sensitive to magnetic fields and are brought into particles dispersing. is required processing. Magnetic suspension magnetic nanoparticles dispersed solvent intensity of magnetic field in the magnetic field of adjustable of directions and.. Magnetic suspension of magnetic nanoparticles in solvent of aggregation in in such that a. are important for processing techniques. Iron magnetic nanoparticles of the present invention, scandium, titanium, chromium, manganese, cobalt, nickel, copper and zinc 1 selected from the group consisting of including or more metals species. may be. Ferric oxide nano particles are preferably magnetic nanoparticles of the present invention can be efficiently produced, and the particles, one embodiment of the present invention according to the example magnetite (magnetite, Fe3 O4) can be. Furthermore, the mean average diameter of the magnetic nanoparticles which may be 5 to 20 nm, preferably 10 to 15 nm, more preferably 11 to 13 nm can be. Furthermore, said number 3 step the mixed solution of said nanoparticles increase in particle the nanowire is functionalized (citric acid) citric, use can be made of,. To produce the nano-fibers is electrospun method using which, the distilled water or an organic solvent (DCM/ethanol) MNPs solvent and from such as ability is important since dispersion of (also 1e), and that it disperses efficiently and any solvents, long-term stability a can be validly said producing the same and to the citric acid preferably using a MNP. Furthermore, mechanical scaffolds step said number 3, Biophysical properties to improve the content of magnetic nanoparticles of the mixed solution of said weight, based on the weight of the mixed solution of 1 to 20 which may be %, preferably 10 to 15% can be weight. Said step said number 1 as manufacturing method of magnetic nanoparticles, a) FeCl2, 4H2 O and FeCl3, 6H2 O, mixing the reinforcing, acoustical enhancement; b) said step blended solution NaOH mixture; c) said step b) includes separating an RFID circuit magnetic field precipitate generation of; d) said step c) citric magnetic nanoparticles generation of dispersing aqueous solution; and e) said step d) of nanoparticles as to precipitate the step for producing nanoparticles the magnetic including method is characterised in that it has a. Said step a) of FeCl2, 4H2 O and a FeCl3, 6H2 O the mixing ratio Fe2+: Fe3+ the 1:1 to 1: which Wednesday 5, preferably 1: Wednesday 2. Furthermore, said d) step 5 to Wednesday 7 which the pH, preferably 5.5 which may be, is maintained well shape at weak acids value is magnetic nanoparticles, strong nanofiber (pH < 5)이나 알칼리(pH >7) 147 particles since the is not broken easily shape said range (< pH < 7 5) material is a magnetic for preparing nano particles of preferably to. "Biocompatible" measures a biometric material of the present invention tissue or the branch line coupler when in contact with an bodily fluid etc. should the property rejection and do not show a slowed, cytotoxic in vivo, biological tissue stimulating, caused inflammatory, allergen, alkoxycarbonyl, aryloxycarbonyl or thrombus formation. of the mobile communication network if the property. I.e., interaction with biological tissue metabolic normal physiological and operation method is negatively affecting mean no inclusion of. "Biocompatible polymer" of the present invention the polyimide (polyimides), poly oh mix acid (polyamix acid), polycaprolactone (polycarprolactone), polyether-imide (polyetherimide), nylon (nylon), poly aramid (polyaramid), polyvinyl alcohol (polyvinyl alcohol), polyvinyl pyrrolidone (polyvinylpyrrolidone), poly [...] (poly-benzyl-glutamate), (polyphenyleneterephthalamide) amide terephthalate polyphenylene, polyaniline (polyaniline), polyacrylic acrylonitrile (polyacrylonitrile), polyethylene oxide (polyethylene oxide), polystyrene (polystyrene), cellulose (cellulose), polyacrylate (polyacrylate), a group including polyester, cellulose triacetate (polymethylmethacrylate), poly [...] (polylactic acid; PLA), polyglycolic acid (polyglycolic acid; PGA), poly [...] (PLGA) copolymer poly, poly {poly (ethylene oxide) terephthalate-co-butylene terephthalate} (PEOT/PBT), poly [...] (polyphosphoester; PPE), polyphosphazene (PPA), polyanhydride (Polyanhydride; Pa), Poliovirus {poly (ortho ester; POE} [...], poly (propylene fumarate)-methacrylate {poly (propylene fumarate)-diacrylate; PPF-DA} [...] lighting and polyethylene glycols {poly (ethylene glycol) diacrylate; PEG-DA} 1 selected from the group consisting of at least one inert gas is not limited to the LR is. Of the present invention preferably a poly biocompatible polymer can be polycaprolactone (polycarprolactone). Biocompatible mssn dispersion and magnetic of the present invention solvent of solution C1-C4 lower alcohols, halogenated alkanes C1-C4 can be, or a mixture of these. Preferably ethanol and die of chloro methanes which may be (dichloromethane), the volumetric ratio of these which may be 1:1 to 1:5, more preferably 1:4 can be. Of the present invention "electrospun (electrospinning)" are electrically charged polymer solution and melt jet (jet) through nanofibers by exposing is process, so that it can be utilized. Electrospun such melting and solvent technique all for mixing nanofibers by exposing the polymer material used in both low production cost can be provided which molar of nanofibers are control and sizes of polojustice engineering least two kinds are defined. the laundry dry hanger. Is a relatively simple structure and the mirror reflects an using sampled clock output from the clock divider of the understanding of the mechanism of molecular level but consider factors and techniques and the process, the must. By using electric field for increasing the to-be-transmitted data every this crowradiation this can to m the continuous phase having a diameter of from level nm fiber for implementing self-assembling known to existing method (self assembly), phase separation (phase separation), such as (template synthesis) synthetic mold simple and of the components on the two method of choice for a material of finally no limitation in shape due to a high specific surface area, porosity and structure and size control of various due to ease based on various characteristics justice engineering /industry exist in an one click a lot of attention applications of wet liquid to flow down. Furthermore, said number 4 method electrospinning of step used in the nano-fibre production imbalance of the laundry the actuating lever method can be performed. For example, said magnetic nanoparticles and biocompatible polymer a mixed solution of time of a steam heater and then, said mix solution which is then electrospun device, pouring the porous structure by ejecting the magnetic nanofiber scaffold can be produced. A solvent used in the production of an of nanofibers said, concentration of the mixed solution of, the electrical voltage used electrospinning, radial, injection speed of vertical flow or horizontal flow of a solution for use in the desired blade according to the nano-fibers scaffolds properties. adjustable system to generate multiple output one skilled in the art. Furthermore, in the preparation of the present invention magnetic nanofiber scaffolds, a nanofiber suitable diameter to maintain said radial the electricity 5 to 20 cm and injection speed 0.1 to 1.0 ml/h may be performed in a, preferably radial h/0.5 ml speed and injection 10 cm can be performed with any type of.. "Scaffold" the tissue engineering of the present invention (tissue engineering), in particular in the fields of a person or animal tissue cells of a human body or a piece of an inner space or receptacle to receive culture in vitro for implantation within a animal is as a support for a. Specifically, said scaffold a person or animal tissue as blocks, cells from tissue and semiconductor elements, said scaffold culturing after cell-scaffold for producing a composite, again composite scaffold cell-produced a human body or a piece of animal for implantation within a is used to. Tissue mirrors are substantially artificial skin, artificial bone, artificial cartilage, artificial cornea, artificial blood vessel and artificial muscle is placed between the inserting all of the chips which is applied a long, complex structural and of organ regeneration in order to optimizing similar to biological tissue essentially should scaffold is provided. Preferably the electroless requirements basic of the scaffolds ideal toxic, : the porous mechanical properties. Toxic cell-support complex biological tissue transplantation blood coagulation or inflammatory response after purpose: a causes neither an, improved mechanical properties support fully contribute to the growth of the cells and to support the strength, smear fastness, alkali resistance numeral key, porous support for the adhesion of cells to a support and a substrate as well as a shorting bar is sufficiently wide cells and cell extensions to be is space-ensured oxygen or by diffusion of a body fluid a shorting bar supply of nutrients and angiogenesis in successfully cells are grown, also mounted on a, circulation promoted. structure capable of differentiating. Essentially cells 2 dimensional culture is made tissue or organ which makes a user form of 3 dimensional scaffold culturing order. required. Such scaffold may have pore numerous my cells and the distance is determined to be attached to cell of seed oil plant such as barley sprouts dividing, the supply waste to discharge should having open architecture. I.e. porous 3 dimensional scaffold it is essential that. Thus said glass fixing unit has a basic extracellular matrix and within a body of a include scaffolds to which like, are suitable, said extracellular matrix such as a porous method to produce bus bars in a been this approach. The particles leach process (particulate leaching) representative method, emulsion freeze drying (emulsion freeze-drying), high-pressure gas expansion method (high pressure gas expansion), on separation (phase separation), electric pumped with syringe pumps to be ejected is connected to the semiconductor layer. (electrospining). For creation of magnetic nanofiber scaffold of the present invention said glass fixing unit has a one producing according to the example embodiment, electric pumped with syringe pumps to be ejected (electrospinning), use can be made of,. On the other hand, which withstand the damaging biocompatible scaffold, cells of tissue or organ scaffold to form equivalent is attached to are capable of proliferating should. Therefore, said scaffold for cell growth ex vivo or in vivo a substrate as. can be taken into account. A scaffold to produce biodegradable biocompatible material polymer is used. Furthermore, the aforementioned a porous structure that having a scaffold made of a biodegradable polymer to be implanted in the tissue cells which continually growth forming series of by where it is heated, general for ligation of a living tissue, reproduction that according to a position detected by a biological tissue scaffold in the form of a steam heater and then shape, said scaffold by grafting of the internal tissue cells, the growth of tissue cells implanted can be using method. Of the present invention in other embodiments, the present invention refers to said produced by the manufacturing method described magnetic nanoparticles is the particles are uniformly dispersed in the bone provides for magnetic nanofiber scaffold. Said magnetic nanoparticles in scaffold produced content of which may be 1 to 20 weight %, preferably 10 to 15% can be weight. Furthermore, said scaffold produced in magnetic nanofiber the mean average diameter of the which may be 200 to 700 nm, preferably 200 to 450 nm can be. As yet another aspect of the present invention, manufacturing method described the present invention refers to said produced by magnetic nanofiber scaffold including as active ingredient provides composition for regeneration of bone. Prior invention as described above wherein said scaffold for bone defect lost the bone through the implantation force applied to the target fastening portion for performing material is carried out by using an acidulous as the active ingredient. Scaffold for bone the present invention according to and the like mesenchymal stem cells is a ready-to-mounted scaffold may the implant to, on scaffold culture time through semi-continuous culture for a certain period for propagating cells then can be implantation into a vivo. The present invention according to composition reproducing bone said scaffold for bone transplantation as well as their at a state where the an aqueous solution, maintaining, for example such as an aqueous solution used for injection or buffer may include a. Magnetic nanoparticles of the present invention manufacturing method according to magnetic nanofiber scaffold uniformly distributed by comprising some specific properties, as magnetic nanoparticles of structural, magnetically passivation layer is formed on the tensile strength, yield strength, elastic modulus, the tensile ductility and breakdown in including strain has the effect of with improved mechanical properties. Furthermore, ex vivo hydroxyapatite (apatite) forming/decomposition, cell adhesion, cell invasion, biocompatible and in vivo bioavailability including bone formation ability in vivo is formed to the desired numbers securely and efficiently. are able to catalyze the playback of bone. Producing the same and to the citric acid MNP Figure 1 that exhibits the properties of to, (a) 12.0 nm having a mean size of ultra fine monodispersed nanoparticles for showing Image TEM, typical magnetite of a peak XRD pattern (b), (c) citric prior function, of ft-IR spectrum, (d) functionalized further by the negative charges prior function citric for showing, of zeta potential, is significantly increased as by function citric (e) stability a and sludge in DCM/ethanol (PCL and electrospun for a solvent used in nano-composite) exhibits dispersion stability to the titanium dioxide particle of MNP in. Figure 2 MNP molar polo and of analyzing conduct of blades, presenting a. The numbers which are different from each other (a) an electric composite electrospun of nanofibers polo molar SEM (PCL, 5MNP, 10MNP, 20MNP and 15MNP) and of nanofibers diameter measurement result and, a nanofiber has (b) indicate particulates nano present in an internally is Image TEM for showing structure, the (c) of nanofibers nano-composite XRD pattern, the during thermal treatment (d) of weight losses of samples of TGA is result. 5MNP residual weight, 10MNP, 4.1,9.0 for each 20MNP and 15MNP, was 13.6 and 18.6%. The nano-composite solution added initially mapped to exhibits a lower value than an amount requested. (E) the contact each tester using the nanocomposite fiber scaffolds is result of test wettable. When the input unit is engaged with a the MNP, cause significant reduced contact angle in wetting show an improved. Tensile scaffolds nanofiber PCL-MNP nano-composite and Figure 3 PCL exhibits in its mechanical properties. (A) the stress-strain curve and m is a natural number below N., (b) the permanent damage to a stress obtained from tensile strength which, in has a yield (c) and a yield strength measured, the stress-strain curve (d) m is a natural number below N. is that the initially slope obtained from modulus, the (e) modified obtained stretch at break and, (f) has a yield in a breakdown measured features modified MNP. 15 weight % up to the addition of said measured deformations with gradually enhance to all of a mechanical properties. However further is reduced at 20% of weight. Tests corresponding advertisement based on the shown embodiment two individual sample to be 5, was used to graph calculates the average and standard deviation. Blades, presenting a magnetic property and high purity scaffolds nanofiber Figure 4 nano-composite. (A) has hysteresis loop for showing SQUID as measured by means of a function of applied magnetic field is according to magnetization curve and, (a ') a magnet attracted to nanofiber which is impinged upon by more, exhibiting view of a best sample. (A ") the clause the characteristic which sleeps (Hc) and the residual magnetization (Mr) a low represents the value show behavior magnetization in a magnetic field. Typically a brittle ferromagnetic or superparamagnetic magnetic of the magnetic material show behaviour. (B) the saturation magnetization (Ms) and the result of measurement of a standard, the (c) is measured from the magnetization curve is an integrated loop area. Content increased MNP Ms and loop area enhance to. Decomposition of Figure 5 MNP exhibits analysis. (A-c) 1.5 SBF concentration of times (d, e) and formation capability and to obtain a hydroxyapatite in PCL-MNP nanofiber scaffolds decomposition behavior ; (a) 1.5SBF 30 containing XRD pattern of other samples may overlap, a supported various (b) 20MNP in time to the XRD pattern, (c) formation of hydroxyapatite surface of nanofibers determined molar polo a SEM (10MNP), for a period of (d) 28,37 °C, , by means of the decomposition the change in weight in PBS, decomposes during 28 and (e) 14 after nanofiber of the sample exhibits polo molar SEM. In scaffold nanofiber Figure 6 exhibits and test and penetration adhesion cells MC 3T3-E1. (A) initial vaccinated with the amount of 16% shown with codes for scaffold nanofiber during culture a specific channel of performance data memorized at the time of initial cell adhesion level, scaffold PCL-MNP PCL and used compared to show considerably higher level. (B) culture nor post-incubation 2 immune at a current point of time and time 4 time and express using fluorescent staining of cells air conditioner polo molar adhesion cells obtained from microscope kurtosis; nuclear at a wavelength of blue-, the green FAK red and [...] -F (c-e) nanofiber scaffold analysis cell invasion through; the structural (c) 2D immune fluorescent-dyeable of cells z-stack is unfolded to the plane yz xz and does not show. (D, 3,6 and 9 of incubator light between the laser beam and compared PCl and 10MNP Image of the sample) depth profile of cells in view plane 2D to complete the structure of are tied up by is indicative, (e, cell invasion depth average kim blood a) MNP a nanofiber is coupled to be designed in a compact manner cell invasion inside improvements a depth profile exhibits two planes chemical mechanical polishing. Figure 7 7 and 14 during nanofiber scaffold in while cultivating those exhibits osteogenic differentiation of cells. Differentiation activity and (b) (a) ALP was subject to analysis by quantitative RT-PCR. Gene associated with bone wherein (Col I, OPN and BSP) of mRNA expression and compared between groups. Figure 8 4 weeks after implantation of the RAT in organization under green onion nano fiber skeins fold (PCL, 5MNP, 15MNP and 10MNP) exhibits of histological view. (A) low, (b) high magnified Image. The tissue sample for dying & E H has been observed on microscopically and optically. Scaffold and the connective tissue in the area of peripheral surface between tissue may have formed thereon. Furthermore, to the arrow (b) it has been discovered that the scaffold the ticket new it becamenew blood vessel therein. Such a decomposition of a scaffolds revealed that in 15MNP and in particular 10MNP. In the pure 5MNP and PCL was not observed. (A) the NF of time without degrading of nanofibers exhibits remaining portion scaffolds. Fibroblast cells actively decomposition is being moved to the site, the remaining fibroblast appointed is the culture to be monitored and a position of the file and zone scaffold. Figure 9 MNP exhibits an Image of an histological analysis. (A) RAT radius segments. Image viewing model. The, radius segments are removed, and nanofiber scaffold coupled by grafting of the defective area to prevent soft tissue penetration provides a space for columnar area defect was and surrounds the. (B) system showed to the implant. The scaffold adjacent radius and metatarsal in defective zone integrated bone tissue scaffolds and the more, exhibiting relationship between. (C) has a surgical 8 H week kindness & E which are dyed with histological copyright 2001. B and A was-analysis histological region. (D) so as to correct a collection scaffold management scheme so that it, pure PCL scaffold group (e), (f) 15MNP scaffold group showed 'B' of brackets zone. on magnified images of show a new bone formation (, woven bones (WB) structure natural metatarsal and resembles an red showed in dotted lines). OB: radius old bone, M: muscle, RM: cup year material, WB :, woven bones, black arrow: growth direction of bone, assay arrow end: cell migration portion material from new tissue, white dashed lines: metatarsal and boundary of tissue are prepared in advance, the dashed lines red WB zone Hereinafter embodiment to the present invention. as further described further. These embodiment relate more specifically, the present invention for, and/or at least two different embodiment of the present invention range not limited to. Of the present invention data charted by the standard deviation of the above average ±, Tukey statistical analysis' of the changes by pharmacological tests s won-way analysis was implemented using. Compared to sample group independent. P p or < 0.05 been it is contemplated in a significant is < 0.01. Manufacturing e.g. 1: magnetite (magnetite) for preparing nano particles of 1M of HCl to cargo f.o.b.for iron number 1 chloride (Ferrous chloride tetrahydrate, FeCl2, 4H2 O) iron broth in a heat number 2 and HCl cargo (ferric chloride hexahydratate, FeCl3, 6H2 O) mixed the guiding rail (Fe2+/Fe3+ = 1/2). Said drip cap for a passenger to use the mixture by adding 200 ml 1.5M NaOH solution 30 minutes stirring section. The resulting magnetic field of the resulting precipitate and to separate no using, separated the 8000rpm in the solution. 2 and a the separation process, continues with stirring, in a 200 ml solution 0.02M HCl added to precipitate. Said separating in the in 40 °C 8000rpm product was very dry. Said implemented in nitrogen atmosphere to all steps. Magnetite solution citric, under stirring magnetic nanoparticles (0.05M) and is dispersed in, NH3 using a solution of pH 5.5 a gradually. 4 process has been completed, acetone is added precipitating the nanoparticles [...], for removing unnecessary citric a magnetic [...] (magnetic decatation) and, after washing the to acetone by the dried in 40 °C. Surface of the magnetic nanoparticles with citric acid coated COOH group. In the embodiment 1: MNP-PCL electrospun method using manufacturing of nanofibers Die of chloro methanes (DCM) and ethanol (4:1) to dissolve the 10% w/v PCL PCL (MW = 80,000; Sigma-Aldrich) have been prepared solution. Is separately from a DCM and ethanol solvent (4:1) to said-particles dispersed-formed nanotubes. DCM produced said: PCL a MNP and an ethanol solution dispersed in a mixed with solution. Said mixture in solution the concentration of MNP PCL decided to get out of 5, 10, 15 and 20 wt %. said solution is stable while the fabric at low cost representing a nano-composite been produced with at solution. Said mixture made of stainless steel 21-gauge needle with he infused a 10 ml plastic syringe. For said needle having a electric spinning manner so that the ultra 15kV of high-voltage source is. Electrospun in, radial to the 10 cm (tip to collector distance, TCD), injection speed, which has the to 0.5 ml/h. Electrospun during produced the nano-fibers for collecting drum by DC motor at a rate in the rotation. At room temperature the whole experiment said embodiment. Experiment 1 e.g.: characterizing the physicochemical of nanofibers of the present invention Crystal structure, designated X-ray diffraction analyser is measured with (XRD; Ragaku). A weaker current 40mA and 40kV sample using radiation cu K α 1 2 θ, each diffraction in a range of 2θ = 10-60 °, 2 ° / min with a step of 0.02 ° made at speeds in the order of the scan. Thermal behavior and nano-composite scaffolds configuration for determining the proportion of the weight analysis (TGA) of the embodiment. Nanofiber scaffolds, and to observe a chemical state to the FTIR spectrometer (Fourier transformed infrared, (IR-ft, Perkin-Elmer) the first voice portion out of an. For measuring electrical characteristics of a surface of a sample to pH 7.0 and 25 °C zeta-potential long since determined the unit moves simultaneously at the same distance (Zetasizer Nano; Malvern Instruments). polo molar sample using model S-3000H microscope (Hitachi) has been determined by SEM. TEM MNP structure and and inwardly and the presence of a (model 7100 microscope (JEOL)) sensors using. Hydrophilic of nanofibers using the contact angle measuring instrument (Phoenix300 analyzer) has been observed on measures the contact angle of water. Nanofiber on the sample layer and to form equilibrated at 25 °C Image droplets until viewing system has been observed on using (viewing system). Balance state of the slip cover flat droplets drops similarly shaped is ensured a massage cream, an essence, is observed, each typically in equilibrium relative to the sample images obtained. Data 1 minutes, each group 5 was for testing samples. Citric (functionalization) functionalized MNPs produced by a feature of the also showed to 1. TEM MNP which are measured by means of a ultra fine mono-dispersed in 12 ± 1.34 nm the size of particles revealed a nanoparticles. (Also 1a). XRD pattern 2 θ = 30 °, 35 °, 43 °, 53 °, in 63° and 57 ° (220), (311), (400), (422), (511) and (440) exhibits a peak a particular feature of of magnetite in stationed himself (also 1b). JCPDS card # 019-0629 according to said XRD pattern cube spinel structure identified. The Scherrer MNPs an average diameter of ' s equation: D = kλ / β cosθ, (wherein λ the cu Kα radiation 1.54 Å of X-ray wavelength, k has shape unknown when, 0.89 value of having shape variable, θ the Bragg angle and, β (and a fractional) a half blade. maximum in. width) of relations among the pixel of XRD according to decided from pattern. An average diameter so as to calculate a non-the strongest peak (311) got. TEM from result indicative of the average diameter of 10.8 ± 1.21 nm has a size of about similar to that. Prior function citric, chemical coupling structures MNP after 4000 to 400 cm-1 region was subject to analysis by IR-ft (also 1c). IR spectrum ν OH MNP of each δ OH and 3426 and 1606 cm-1 revealed a band. In producing the same and to the citric acid MNP, 3426 cm-1 exempting from a heavy and rigid of ensuring the presence of a trace of water into this cable, the band can be. While 3200-3400cm-1 portion of the second thermal cracking is performed on the revealed a presence of OH group. Furthermore, can be a symmetrical of OH of COOH indicative [...], 1630 cm-1 band in a magnetite surface and exhibits binding of radical citric. 1401 cm-1 peripheral band group COOH. representative of the feature of stretching asymmetrically. 600-400cm-1 and 578 cm-1 the disk band a magnetic particles for isomorphic singular Fe-O blades, presenting a. As a result said that is chemically bonded to the superabrasive surface magnetite citric acid of confirming that the device can be. Measured at pH 7.0 before and after function citric MNPs of nanoparticles, a zeta potential of 0.0 (- 17.2mV) exhibits high negative charge, increased with functionalized citric showed generating under negative. (- 36.6mV). The NP present at the surface of the citrate ion effect of (also 1d) exhibits. Electrospun composition nano to using method, nanoparticles under solvent containing a dispersion of distributed to determine a time point at which the evaluation distilled water or an organic solvent (DCM/ethanol) to dispersion of MNP. is important ability (also 1e). Any citric-functionalized MNP that it disperses efficiently and solvents and, long-term stability is integrity. Citric such stability could not be applied to an observation without function. The results indicate that preserve the stable solution functionalized citric in PCL and as a result effects of having available, and the solution of nano-composite can be confirm that the user. Nano-composite to preparation of a solution of dispersed in a DCM/ethanol added to a MNP PCL. Then fiber scaffold nanowires using an electrospun method have been prepared. Electrospun process in parameter possible governs, polymer concentration due to a variation in is controlled solution constitution key variables and, with the fibers size and molar polo party is detected to form a. At various concentrations (5, 10, 15 and 20%) in a colloid solution including nano-composite MNP of a fluid is suppressed between the electrospinning of the apparent nano comprising the fiber, fiber-developed a membrane. Also in the typical has 2a (smooth) through adhesion with smooth, uniform, bead-free (bead-free) roh fiber having molar polo exhibits and representative SEM Image. When ball these images, through adhesion with smooth and pure continuous fiber is formed by electrospinning of PCL it is foreseen to. PCL diameter of a nanofiber measured, 5MNP, 864 (± 43) out for at 20MNP and 10MNP, 425 (± 31), 318 (± 46), 202 (± 40), and is 664 (± 63) nm. Continue to gradually adding MNP until 15% in order to intensify against a nanofiber thereafter decreases while, MNP 20% of diameter in the range of from increased the nanofiber the addition. Nanofibers have a significant effect diameter in a range from a solution electrically conductive and a viscosity such as other MNP the variables must be added with variations could it is foreseen to. SEM where its presence is MNP is not apparent on the whereas, nanofiber the addition MNP had changed into brown, dark more scaffold. Using TEM nano-composite has been observed on structure internally of nanofibers (also 2b). Electrospun during few seconds of injection needle at the entrance tip of TEM in close proximity to located grid 20MNP and. 10MNP is obtained samples a particular feature of. Image viewing. In polymer substrate PCL easier NPs. 5MNP can be uniquely identifies that base station a relatively NPs in a well-separated each particle is disperse well whereas the, of NPs in some in 20MNP up out is aggregated. XRD pattern of nanofibers PCL and in the typical associated with MNP have shown peak (also 2c). MNP in a sample analysis weight of the sample present provides information to the amount. The likelihood that all samples to because both layers have similar thermal behavior (also 2d) in. 250 °C hereinafter revealed that some weight reduction while is expire at the removal, reduction weight difference 2 in approximately 360 °C PCL been the, by means of the decomposition of polymer. Approximately 600 °C and may degrade in-been is complete. The remaining weight 5MNP, 10MNP, 4.1,9.0 20MNP and 15MNP out for at, 13.6, and was 18.6%. Metal added to the initially is nano-composite some than an amount requested but to indicate a lower value, is well. The hygroscopic of nanofibers did research on tester to contact angle (also 2e). PCL nanofibers are 88° while its large contact angle, nano-composite nanofibers gradually reduced contact each value (10% MNP in 20% MNP and 68° in below the to 47°) blades, presenting a. A nanofiber is added the MNP ( possibility affinity ) exhibits improvement of hygroscopic scaffolds. These enhanced MNP a carboxylated the presence of do. Experiment 2 e.g.: characterizing mechanical of nanofibers of the present invention 10 mm/min (Instron 3344 universal testing instrument) booting to (cross-head speed) speed of tension using a nanofiber scaffolds having a wide variety of compositions, it was determined that mechanical properties. Membrane approximately 150-200 micro m to have thicknesses on the order of spin coating, 30 mm X 4 mm (gauge length 10 mm) of the cut to size. Then been is applied tensile load. M is a natural number below N. strain from test said been is recorded (stress-strain curve). The thickness of the membrane each 5 of each group for the samples of SEM Image observed in decided from the average values. Tensile strength, yield strength, elastic modulus, the tensile ductility and breakdown in mechanical properties including strain strain m is a natural number below N. from the bill. Respective compositions each two exemplar testing was 4. Nano-composite scaffolds tensile strength by pharmacological tests it was determined that mechanical properties. 3a controls a sample are also (PCL and PCL-MNP nano-composite nanofiber) in wet-istics that are typical for show m is a natural number below N. stress-strain curve. The likelihood that all samples a distinct at the stage two similar stress-strain curve have shown that m is a natural number below N. behavior: fast group modified according to increased stress initial step of approximately 0.1-0.15 degree, slowly point peeling, post destructive show a vacuum type. Based on these stresses m is a natural number below N.-modified tensile strength, yield strength, elastic modulus, destruction including breakdown and modified in degree modified human power by operating all systems by 2001 mechanical parameters. Destruction and the tensile strength a is measured as a maximum intensity immediately before MNP content increases until 15% have been increased; 26.2 MPa in pure PCL in have been increased until 15MNP is 11.5 MPa. (Also 3b). However the addition of 20% MNP reduced to 9.5 MPa tensile strength. Furthermore, breakdown point also yield strength (yield point) in shown in a similar manner (also 3c); pure PCL in have been increased to 15 MPa in 15MNP is 6.5 MPa. Hardness of sample (stiffness) representing a range of strain 0.5% modulus of elasticity of a nanofiber be computed in a m is a natural number below N. a stress-strain curve has been determined by initial inclination of the optical disk. Furthermore, according to MNP are added thereto, pure PCL 15MNP is 60.1 MPa in 86.7 MPa in. any significant increase the apparent while of increasing to. However, this is reduced back to 65.6 MPa in 20MNP. As well as strength and hardness, elongation in addition fixed human power by operating all systems. In breaking point that are in consideration as elongation MNP of the strain have been increased slightly according to added up to 15% (0.75 to 0.57 in). However, this is the discharge circuit is reduced to a, [...] to 0.4 at 20%. Yield point according to 15% of the strain in in 0.11 MNP added 0.21 but results in a significant increase to, that are further reduced to 0.12 at of 20%. Experiment 3 e.g.: irradiation magnetic characteristics of nanofibers of the present invention Said magnetic property and high purity of the sample ± 20 kOe magnetic field applied at room temperature SQUID (superconducting quantum interference device (SQUID; Quantum Design MPMS-XL7)) did research on using. SQUID has devices and include standards (pure nickel opening) has been determined based on the. Magnetic property and high purity scaffolds remarkably low in saturation magnetization was is assessed in terms of the roof area and hysteresis. A superconducting magnetic property and high purity scaffolds nanofiber nanocomposite magnetometer (SQUID magnetometer) hysteresis function at a normal temperature by using human power by operating all systems by loop (also 4). As a function of applied magnetic field is the magnetization curve exhibits magnetization. The likelihood that all samples the + 20 to -20kOe of according to change in a magnetic field in loop hysteresis of traditional more, exhibiting (also 4a). Strong magnet and both of them depending on sample nanofibers show attraction force (also 4a a '). Furthermore, low magnetic field range (+ 8 Oe in -8) present in the magnetization m in. Therefrom (also 4a a '), a coercive force of 2.5 Oe scaffold (Hc) and 0.27 emu/g low at a residual magnetization (Mr) copyright 2001. Their is typically narrow hysteresis loop and low clause the characteristic which sleeps the determined portion of the sacrificial layer is patterned as ferromagnetic or superparamagnetic material is considering. 1.0-1.2emu/g saturation magnetization in a range of (Ms) the MNP amount of time increases with an increasing content of and (also 4b), this polymer substrate PCL MNP coupled to the relative weight ratio was associated with. Another important parameter area of magnetically is lost/cycle or a hysteresis loop. The maximum area loop site is completed through a combination of applied been calculated in a magnetic field of ± 20kOe. Much like an behavior of saturation magnetization, of a V content MNP site is completed through a combination of loop enhance value of area (also 4c). Experiment 4 e.g.: test and dismantling formation capability and to obtain a hydroxyapatite (apatite) in ex vivo The experiments of each used in the immersing at 200 ml of specimen with a PCL 2M NaOH aqueous solution, time 4 30 °C stirring section. Said NaOH solution is removed from the sample, was an upper portion of wide by removing particles and ultra pure water. inside some counterweight in air of room temperature then was very dry. A specimen soaked to activate the hydrophobic surface calcium and phosphate ion enables a combination of network layer by carboxyl group which a plating solution is introduced for the design. NaOH treated nano-fiber manufactured by next process (CaP the microcells in which a shortened as treatment) arrayed at the bottom of. is immersed ionic solution and phosphate calcium ion. Specifically, of 150 mm nano-fiber manufactured by treated with NaOH CaCl2 aqueous solution 10 to 100 ml pure water immersing at seconds immersing at seconds 10 to 20 ml, was dried in air few minutes. Then samples of 200 mm NaHPO4 immersing at to 100 ml aqueous solution, 10 to 20 ml pure water immersing at seconds was dried in air few minutes. Immersing a alternating and 3 times at room to the embodiment. A given relative to the sample during immersing alternating and Conference said 3 the same CaCl2, NaHPO4 ultrapure water solution and been used. NaOH treated with other sample and CaP processing are subjected to the various time in samples 37 °C during bone mineral nanocrystalline, for growth human blood with suspected of being present in the plasma pH 7.4 and therefore ion concentration, (Na+ 142.0, K+ 5.0, mg2+ 1.5, Ca2+ 2.5, Cl- 147.8, HCO3- 4.2, HPO42- 1.0, SO42- 0.5 mm) of (1.5x) is immersed (SBF) 45 ml solution vivo was similar. From solution by removing particles and ultra pure water sample after removal of a the wash at a mild conditions. Magnetic nanofiber scaffolds hydrolysis the phosphorus solution which will live a of phosphorylating a a sample disintegration properties (saline solution, phosphate buffered) in 37 °C to corresponding advertisement based on the shown measuring evaporates into copper 28, during changes in weight of the test period (weight losses) he made notes for his. Before hydrolysis, SEM samples of he jabbed his Image. PCL-MNP nano-composite nanofibers are bone regions at uppermost and for considering use as reproduction matrix, hydroxyapatite formation capability and to obtain a similar ex vivo in solutions vivo been this approach. Constitution: forming hydroxyapatite are inventor allows a reduced duration study for acceleration of 1.5 SBF (1.5SBF) concentration of times to the first voice portion out of an. Each sample for different period (0, 5, 7, 10, 15, 20 and 30) immersing at to 1.5SBF, polo molar phase and remove the for the analysis of changes in. After 30, XRD pattern has been observed on the likelihood that all samples of (also 5a). In pure PCL, hydroxyapatite in value of 2 θ of -32 ° - 26° and that a relatively low peak (002) and (211) of HA determining regions (JCPDS card #. 74-0565) blades, presenting a a database. MNP content of a V, peak intensity have been increased. Furthermore, in some PCL peak hydroxyapatite any other while the subsequent disappearance of said reference temperature peak. A nanofiber is added MNP the results indicate that enhanced scaffolds exhibits-forming activity of hydroxyapatite. In some PCL while the subsequent disappearance of said peak, hydroxyapatite, it gradually over time. Immersing 20MNP as a function part of the selected periods as if it were observed in samples (also 5b). SBF test of molar polo has been observed on SEM of samples of (also 5c). Initially formed third 5 any small nanocrystalline region was increasing over time. Hydroxyapatite determining regions on most completely intermediate period been covered nano-fiber. And for a period long (20 or more) was nano between the fibers, and fills the space. As well as test SBF, nano fiber skeins PBS such a decomposition of a chamber, in 37 °C did research on. 28 he got down the main the change in weight during testing of period (also 5d). All nanofiber scaffold weight time increases reduced. Weight losses of a V content MNP the nanocomposite nanofiber in. more important. After 28, weight losses in PCL approximately 20%, 45% and 60% in was 10MNP 20MNP search. A nanofiber decomposition has been observed on in SEM samples. Compared to PCL 10MNP and 20MNP of nanofibers revealed that is causing significant structure (also 5e). Experiment 5 e.g.: RAT MSC of isolating and culturing the bone marrow Mouse bone marrow derived from a previous MSC separated the as described. All associated with animal Animal Care and Use Committee to end office protocol was acknowledged to the. Specifically, male adult Sprague-Dawley rats (180-200g) of the end of the plane and the other center's body tip of a joint as an intramedullary an aqueous solution of a femur and Shin bone centrifugal separator tissue of normal medium (1% Streptomyces/sealing oxide layer using wet of erythromycin oh serum[...] of 10% and that includes an input and (fetal bovine serum) (α-MEM) media supplemented by the redispersable in. During and air of 5% in 37 °C CO2 of dish for the first time, the in incubator atmosphere of soaked with the located (culture dish). Each change medium made every 3 during the hematopoietic stem cells (hematopoietic cell) is not bonded to the remove the from a medium. Stages three and then cells been used experiments. Experiment for molecular breeding of capsicum g/ml micro 50 sorbic acid, 10 mm β-glycerol phosphate and 10 nm dexamethasone (dexamethasone) and that includes an input and osteogenic manner in a medium free of been embodiment. Experiment 6 e.g.: cells adhesion analysis Has different in composition between and ejects sterilization the ethylene oxide [...] the nano-fibers. Samples well-well plate 24-making and for properly sized, maintaining the plastic ring is set up to come in. A respective sample MCS 5 x 103/was to be inoculated with a density well. The initial adhesion step allows for different culture time (time 2, 4, 8 and 16) in, nanofiber sample petal blue tree cells that is bonded to the (Trypan blue screening and hemocytometer counting) or blood screening and the analyzed by two. 5 (replicate) cells replication of each experiment been tested for conditions. CLSM said shaped design of the notches has spreading adhesion and of cells (a point-scan confocal laser microscope, confocal laser scanning microscopy). 4 °C been by different night in cells cultured in period 4% of personal communication system has the form under it knows the id and dyeing the 5 minutes, and impregnating the having 0.3% Triton X-100, translations and blocking has 2% of BSA, 1 has antibodies difference for FAK [...] section. F-actin cells and for coloring the dilution to 1 time phosphate buffered saline (Invitrogen) (phalloidin) combined with a [...] 2 difference in incubation with Alexa Fluor 546 coupled antibodies on the proper flue [...] in adaptation-labeled (fluorescein isothiocyanate, FITC). 4 nucleus ', 6-diphenyl-Indol -2 roh midi diameter (4', 6-diamidino-2-phenylindole, DAPI) no stain and no slip, confocal microscope (LSM700 confocal microscope (Carl Zeiss)) captures an Image using adaptation. Light between the laser beam and for DNA isolation and isolation method thereby adhesion initial MSC (2, 4, 8 and 16 time) nanofiber scaffold attaching cells human power by operating all systems by a by. 2 hours (also 6a), but adhesive surface finish, which results in an 10MNP and 5MNP cells (80% or more), and. 5MNP been adhesive 50% than about sample PCL attaching 10MNP 90-100% level yet modification is performed for congestion in degree, in magnetic nanofiber adhesion in PCL and a similar to levels equal to 8 have been increased over time. MSC adhesion and spreading behavior it is found out that by CLSM (also 6b). Adhesion focus of cells for cytoskeletal process and Focal adhesion kinase (FAK) to indicate color because it was F- [...] together. 2 time PCL relative to the sample substantially is got out of sight. However 4 time more spreading have demonstrated to 10MNP and. 5MNP, 2 time an active cytoskeletal process and focus [...] together spreading have demonstrated. This was clearly the time in addition 4. MSC initial adhesiveness, spreading behavior of magnetic nanoparticles an output signal of a comparator is specific capacities under significant fold fiber skeins it has been confirmed. Experiment 7 e.g.: cell invasion analysis Nanofiber scaffold for analyzing a cell invasion to, Image-stack z of cells DIC arrangement the color 3 - ((488 nm for FITC, 555 nm for Rode, and 420 nm for DAPI and DIC) 3-color DIC configuration mode) and with the spacing m micro 1 in, nanofiber scaffolds micro 0-75 approximates the thickness in a range of m LSM700 META (Carl Zeiss) was obtained using the. Of software ZEN Image Z-stack dimensional 3 by orthogonal tool (3D) the converted into projected Image. Furthermore, the side-view of z-stack z-stack series side view tool to obtained. A side-view based on the acquired images to represent average depth of penetration (cell localization) position measurement cells was used to quantity of. Nanofiber scaffold a cell invasion into did research on during culturing period of 12. Cytoskeletal process as an indicator of the cells to [...] -F of tinting. Nano fiber network in a cellular movement of respect to nuclear for visualizing was no stain DAPI. Confocal Image the fluorescence signal green in 2D to a profile 3D. structure (also 6c, representative sample). Each relative to the sample Image a profiled 2D more, exhibiting in Figure 6d. Abstract PCL restraining itself from in the case of substantially signal is present in region while, magnetic nanofiber to middle and bottom side been dispersed. Average level of the was used to quantity and a red/green color signal (also 6e). The cell invasion depth magnetic nanofiber scaffold is indicative that significantly enhanced, this produces higher content of was is further enhanced in MNP. (PCL < 10MNP < 20MNP). Experiment 8 e.g.: determination of alkali phosphatase (ALP) Magnetic nanofiber scaffold cultured in osteoblasts of a MSC differentiation to initially so as to produce a relatively quick (osteoblastic) a the formation circle which boils can be labeled a ALP activity of human power by operating all systems by measuring unit is connected to the. After grown on during 14 and 7, and collected from scaffold nanofiber cells, 142 by repeating thawing lysis buffer was decomposed into. Manufacturer (Sigma-Aldrich) in accordance with the instruction from the enzymatic reaction for added sample to ALP reaction medium. Added amount of sample actually on a commercial DC protein assay kit (BioRad) as measured when, entire protein content of it was determined that based on. with lung glow generation is such that the P-nitro spectrometry in absorption of 405 nm it was determined that using. Each experiment condition by cylinder to have sample replication of two 5. PCL-MNP nanofiber scaffold cultured in osteogenic differentiation of MSC is analyzed by ALP activity was first (also 7a). 7 the stylus is not initially approximately equidistant between samples while of thin film transistors are electrically connected, by increasing the significant after the 14 appears purchases the passenger, in particular 10MNP 15MNP and up out is the difference in scaffold. Experiment 9 e.g.: quantitative reverse transcriptase polymerase chain reactionby (RT-PCR) osteoblasts gene expression Collagenase I (Col I) type number of limiters, osteopontin (osteopotin, OPN), at the time of it is a reel with the rope which will know (sialoprotein, BSP) of a gene associated with bone including mRNA expression level by real-time PCR (PCR Q) factor have been measured by to quantitatively. After grown on during 14 and 7, each sample cells from and transmits, a manufacturer's according to an instruction by the entire RNA, was to separate no using RNeasy Mini Kit (Qiagen). A cDNA primer as oligomer of any RNA has adaptation reverse transcriptase using Superscript kit (Invitrogen). By using the PCR amplification the Sensimix Plus SYBR Master Mix (Quantace). Relative housekeeping gene CT method (comparative CT method) for beta- [...] built by each gene to a PCR product for regulating the was for use in analyzing by. Experiment 10 e.g.: biocompatible in vivo hypodermic of RAT Electrospun a nanofiber scaffold (PCL, 5MNP, 15MNP and 10MNP) m micro 1.5 cm x 1.5 cm x 300 making and to substantially the same, before surgical sterilization the ethylene with oxide. By cylinder to have male Sprague-Dawley rat the test biocompatible tissue. The animal experiments was acknowledged to the Dankook University Institutional Animal Care and Use Committee. Against all processing sterilized common in anesthetic the conditions was to carry out. Divided into group you mouse (into a per group), either by intravenous injection grasping each non-aminic metacrylate 80 mg/kg 10 mg/kg with hydrazine and he infused a. 4 small avoid the pouch provides a means for each animal the inter-vertebral from and made scissors area such as obliquely left and right, each scaffold samples the loaded on the deficiency. Incision 4-0 sites not being available for absorption of a monofilament (Prolene) sealing the sealing lines. 4 mouse and 12 into main 12/low time has been observed on under schedule alternate night time. Standard food pellets was providing a free and water. The sacrificial week 4 animal. One implant close to the tissue analysis histological area and collected for, 24 immediately at room temperature time 10% neutral buffered formalin-immersing at a, grade predosed in dehydrated and ethanol series, after danger detector or an actuator, the embedded in paraffin. Histological samples m to have thicknesses on the order of 5 micro rotary microtome manufactured with the use of the metal and, established standard using (dye) or Masson hematoxylin and eosin (H & E)' was color because it has s trichrome (MT). Biocompatible of the tissue sample slides the optical regeneration and angiogenesis has been observed on microscopically. Scoring is histological made (0-4 ; 0 the most small, 4 determines the most high) immune response, fiber film thickness, extension of the fibroblast presence and lumen of a blood vessel that different including pathological tissue based on the particular characteristics have been produced. Nanofiber PCL-MNP in order to analyze the suitability tissue scaffolds, implantation in organization under blood of RAT sample was 4 weeks. Post-surgical, all held in an implantation site in suffers that does not cause inflammatory, pollution not been provided for. 4 sample group implanted into main (PCL, 5MNP, 15MNP and 10MNP) exhibits to form histological of Figure 8a. Significant of any sample tissue rejection or inflammatory response got out of sight. Adapted collagen fiber made of tissue connected with the sample space between adjacent tissues is fabricated, in addition, suitable scaffold in demonstrated angry been discovered. All 4 one group of samples a good histocompatibility while its, mainly in scaffold 15MNP and 10MNP 5MNP or PCL but not extent in, (NF directed as different zones of) grown connected to excised tissue with the hydrocracking zone a are replaced by, revealed that such a decomposition of a scaffold some. Vaporizers are after week MNP and PCL 4 is a structure including a while, 15MNP and 10MNP been lean and in that structure of. Connected to excised tissue in the region replaced by did not has a visible contour scaffolds. Fibroblast cells actively decomposition is being moved to the site, the remaining fibroblast activated easily detected as between the set minimum value and the scaffold. Comprises, in order, a backplane ratio in < 5MNP < 10MNP < 15MNP PCL surface is arranged. Table 1 the quantified parameter histological the results of the analysis revealed a. MNP-PCL scaffold, a higher luminescence in the PLC 15MNP and in particular 10MNP in angiogenesis low fiber go further revealed that cell migration is fibroblast and encapsulated in a semi-. 10MNP [...] 15MNP and a on magnified images of angiogenesis in signal exhibits well. 8b also shown by white arrows. Experiment 11 e.g.: RAT bone formation ability in vivo defect radius Hypodermic in histocompatibility after confirming the receivable channel to, magnetic nanofiber scaffolds bone of RAT bone formation ability did research on model defective segments. The present in the embodiment, the third to eo mouse Sprague-Dawley of mary 6 in. Animal care and housing protocol said section described test mode and equal to. Hairs of front and rear legs and hair, said zone of the surgical for using ethanol 70% and (povidone) gun expense money the-lasting sterility out. -lasting sterility line and the second solenoid valve, a right or left on the surface of radius 15 cm was cutting a skin of of front and rear legs. Sufficient surgical room in radius the diaphyseal cutting debribement periosteum for lifting muscle for. 5 mm length was cut and two segments of bone have been prepared from the center of radius the defect. The bone the electrode for cleaning bone particles in a drilling each RAT using saline the sterilizing and cleaning while having been produced with at. Of three group randomly extracted. Each defective the two types of nanofibers scaffold (15MNP and PCL) and optionally by grafting of the having, wrote down the since then, in the control group a voice one. Nanofiber scaffolds in the case, each sample the radius of maintained portion completely covers to defect in tissue and soft to prevent sensors was surrounded by the inner peripheral surface defect. Fascial for 4-0 having been covered material to the base, a skin incision in a undesired materials is absorbable 4-0 the in. Animal surgical the front and rear legs immediately was for causing a computer to allow the functionalized. After animal has been observed on into main 8. After sacrificial, and cutting a skin, sample and thereof diamond the surrounding tissue using drilling the motor, attached wheel took. Samples 10% at room temperature 24 time a neutral buffered of the formalin-fixed. Fixed samples translations and desalination, dewatering and, put it in his paraffin making and approaches Serial l micro. 5, no stain the MT and & E H, it was determined that using optical microscope to check upper area of. Upon validation histocompatibility scaffolds nanofiber nano-composite, having segments radius of RAT model was to design experimental sets and the other. Typically include group scaffold 15MNP and PCL was testing. The scaffold thing which the control group and was testing. The b and 9a also using and in research show model segments radius RAT. Radius segments defect in the seat is removed and which serves to cover area position the nanofiber scaffold. Defect during a vehicle by preventing the infiltration of tissue soft to localized areas radially spaced layer on the basis a cylindrical glass body. Surgical after main 8, no stain & E nanofiber scaffold group H (15MNP and PCL) a bone deficiency of histological evaluation in soft tissue and muscle around adverse inflammatory reactions and didn't show signal (also 9c). However, in the control group free scaffold between end osteotomy radius goal type total label. observed easily (nonunion). A to 9 d-f B and also between the set minimum value and the histological form showed thus expanding the. In the control group, derived from edge margin of a defect defect a minimal new bone with formation thin loose connective tissue and muscle been filled (also A panel 9d). Muscle contact surface metatarsal (ulna) clearly shown (also 9d, B panel). By ensuring that in a group scaffold PCL, new bone the formation radius osteotomy and the ends scaffold been formed along clearance surface (also 9e, panel A, arrow labeled a). New bone formation is initiated surface scaffold PCL, scaffolds and osteoblasts of the movement of the increase in. The display panel to cover the remaining portion of radius scaffold, metatarsal and radius and soft tissue penetration fusion of film resulted in smaller dimensions, new bone the formation scaffolds and character bone revealed that frequently a surface (9e also, panel B). Also 9e, in B panel, arrow end surfaces of newly formed bone osteoblasts appointed toward the scaffold exhibits the growth of the. Many osteoblast cells collected [...] certification by moved the implementation, a metatarsal is scaffold is stimulate in surface. Radius osteotomy end and scaffold in the point where reproducing bone surface, by ensuring that in a group scaffold 15MNP (also 9f), similar to pure PCL showed recovery of bone defect. Two scaffold among a group bone formation in level of which differs from that of. have remarkable in particular point. 15MNP molds do not soften at elevated temperatures and the older superceded pages of data near the site deficiency further the bone connective tissue filled rectangles to the free surfaces. The bone are prepared in advance and scaffold PCL better surfaces of bone host than in group is coupled (also 9f, panel A) scaffold PCL scaffold. 15MNP more, exhibiting a rapid breakdown than. Most scaffolds newly formed bone matrix is absorbent easily with osteoblasts and. Myelodysplastic and in their adjusted positions in the regenerated defect of hope appeared. clearly more group PCL. Residual material that transports bind to and tissue, is the culture to be monitored and osteoblasts 300. (9f also, panel A). Furthermore, osteoblasts appointed to scaffold metatarsal surface with the movement and from infiltrating the bone matrix, occurs to a result for forming bone matrix flow in teh space, a high degree of certainty of show cell responses. (9f also, panel B) The present invention relates to a manufacturing method of a magnetic nanofiber scaffold, and to a magnetic nanofiber scaffold manufactured by the manufacturing method. According to the manufacturing method of the present invention, the magnetic nanofiber scaffold containing magnetic nanoparticles is capable of promoting bone regeneration for a desired region in the body in a safe and effective manner, by improving mechanical properties and biological properties due to structural and magnetic properties of the evenly dispersed magnetic nanoparticles. The manufacturing method comprises: a first step for manufacturing a magnetic nanoparticle dispersion solution; a second step for manufacturing a biocompatible polymer solution; a third step for manufacturing a mixed solution by mixing the two solutions; and a fourth step for manufacturing a nanofiber by electrospinning the mixed solution. COPYRIGHT KIPO 2016 Magnetic dispersion of metal nanoparticle and method for having a step number 1 ; step number 2 preparation of a solution of biocompatible polymer; said magnetic dispersion of metal nanoparticle and method for mixing by mixing misfortune and biocompatible polymer solution preparation of a solution of step number 3 ; and said mix solution which is then electrospun by nano fiber bone including step number 4 manufacturing method for magnetic nanofiber scaffolds. According to Claim 1, said iron magnetic nanoparticles, scandium, titanium, chromium, manganese, cobalt, nickel, copper and zinc 1 selected from the group consisting of species or more metals including a bone for magnetic nanofiber scaffolds manufacturing method. According to Claim 1, said magnetic nanoparticles particles have an average diameter of 10 to 15 nm provided that the manufacturing method characterized by magnetic nanofiber scaffolds. According to Claim 1, said nanoparticles is functionalized citric acid characterized by magnetic nanofiber scaffolds manufacturing method. According to Claim 1, said a biocompatible polymer PLGA (poly (lactide-co-glycolide)), PLA (poly (lactic acid)), (poly (glycolic acid)) and PCL PGA (poly (caprolactone)) 1 selected from the group consisting of at least one manufacturing method is characterized by magnetic nanofiber scaffolds. According to Claim 1, said mssn dispersion and biocompatible polymer solution that the solvent is C1-C4 lower alcohols, halogenated alkanes C1-C4 to, or the mixture thereof manufacturing method characterized by magnetic nanofiber scaffolds. According to Claim 1, said mssn dispersion and biocompatible polymer solution of chloro methanes die ethanol and that the solvent is a mixture of manufacturing method characterized by magnetic nanofiber scaffolds. According to Claim 7, of chloro methanes and die ethanol said volumetric ratio of 1:5 to 1:3 is provided that the manufacturing method characterized by magnetic nanofiber scaffolds. According to Claim 1, said number 1, including step a) FeCl2, 4H2 O and a FeCl3, 6H2 O, mixing the reinforcing, acoustical enhancement; b) said step blended solution NaOH mixture; c) said step b) includes separating an RFID circuit magnetic field precipitate generation of; d) said step c) citric magnetic nanoparticles generation of dispersing aqueous solution; and e) said step d) of nanoparticles including method step as to precipitate the case of manufacturing method characterized by magnetic nanofiber scaffolds. According to Claim 9, said step a) of FeCl2, 4H2 O and a FeCl3, 6H2 O the mixing ratio Fe2+: Fe3+ the 1:1 to 1:5 provided that the manufacturing method characterized by magnetic nanofiber scaffolds. According to Claim 1, said number 3 step of the mixed solution of entire content of magnetic nanoparticles, based on the weight of the mixed solution of 5 to 18 weight % provided that the characterized by magnetic nanofiber scaffold. According to Claim 1, said number 4 step electrospinning of 5-20 cm and injection speed radial the method is performed for 0.1-1.0 ml/h characterized by magnetic nanofiber scaffolds manufacturing method. According to Claim 1, said magnetic nanofiber an average diameter of 200 to 450 nm provided that the manufacturing method characterized by magnetic nanofiber scaffolds. Magnetic nanoparticles manufactured with any one of Claim 1 to Claim 13 manufacturing method (MNP) is the particles are uniformly dispersed in the bone for magnetic nanofiber scaffold. According to Claim 14 magnetic nanofiber scaffold including bone composition for repairing as active ingredient.