SOLAR POWER GENERATOR

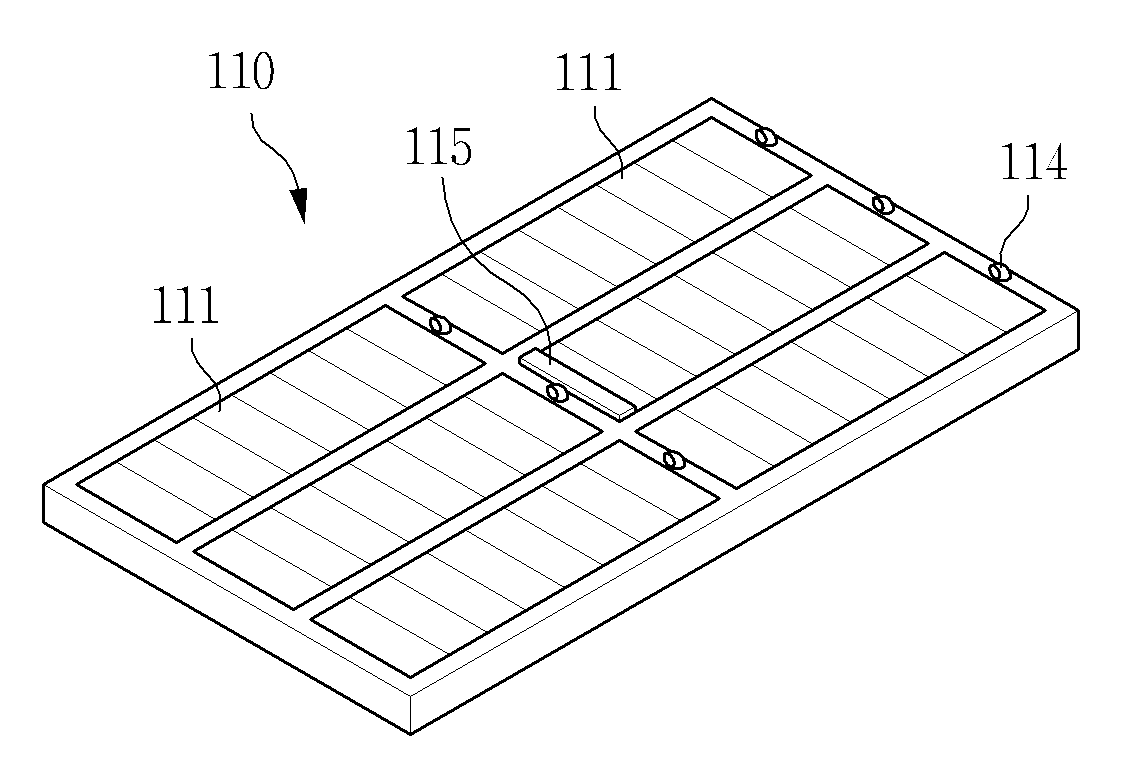

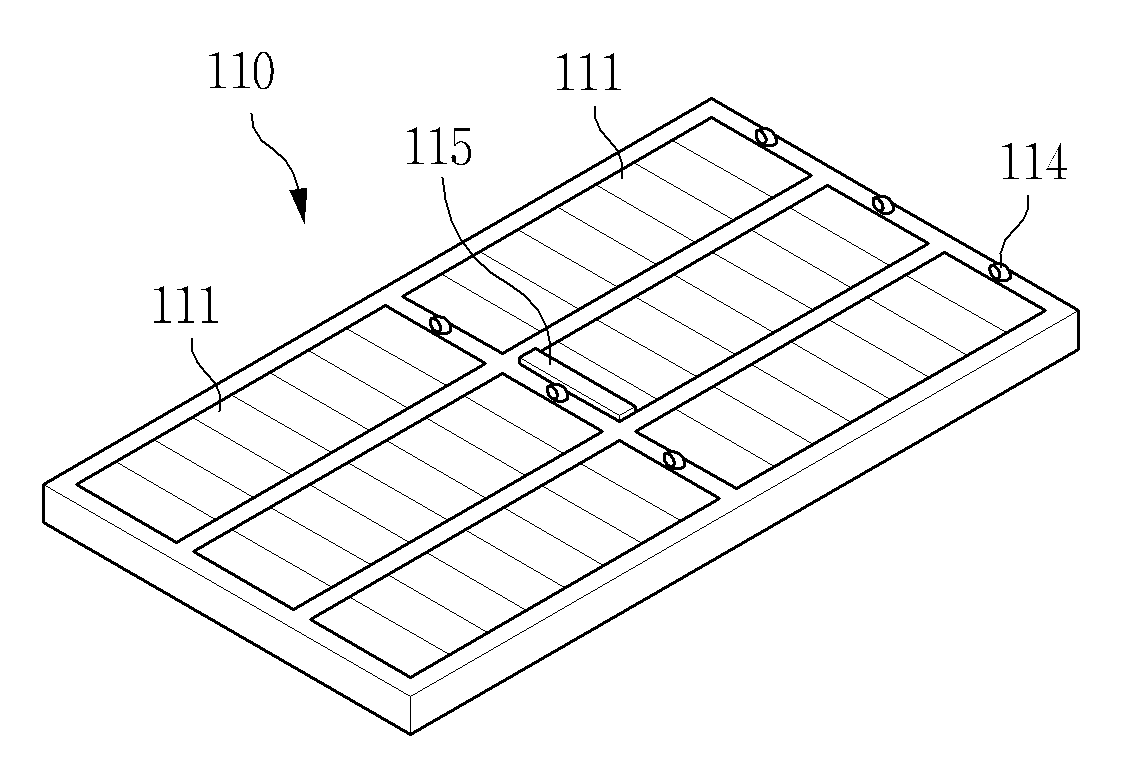

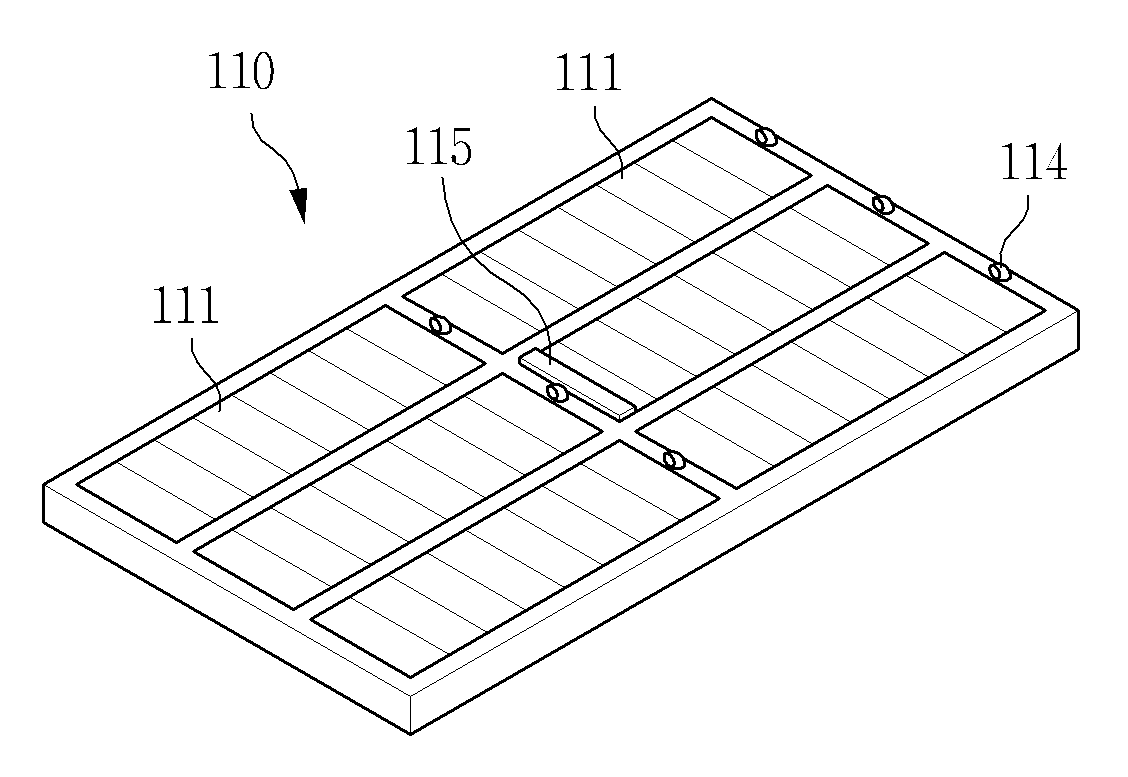

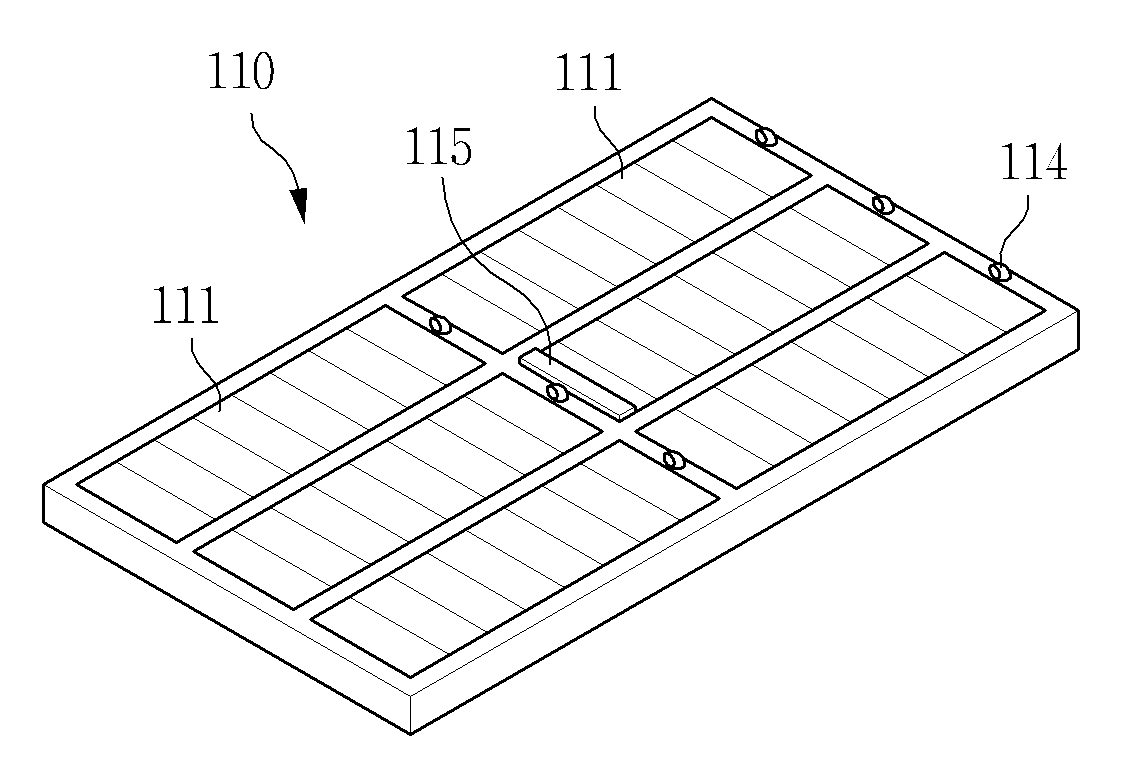

Snowed are one embodiment of the present invention dynamic characteristic is rapidly improved can be, solar panel of the display displays the maintenance work can be relates to a photovoltaic device. The lenses energy source of polygonal for development and a higher melting in lifestyle energy renewable the appointed time applied. Renewable solar energy during lifestyle energy regardless environmental pollution may produce a the fastest is generate power efficiency solar cell development, power converter device, storage device, posture control panel, solar panel maintenance techniques or the like power generation together various field of wet liquid to flow down. Solar cell panel development of efficiency due to various factors is affected. The power output per unit of solar cell of the underlying for improving photoelectric conversion efficiency improved most in addition to a technique whereby-requested associated with the solar cell panel for preventing contamination of can be of a reflector according to each step techniques are maintenance. In domestic and foreign in fiber membrane sand dust, yellow sand, winter floundered about or the like due to environmental forces, inclusive of solar cell panel of mental pollution solar panel efficient maintenance of serious arises for a recent problem of wet liquid to flow down. Solar panel of rated S3 maintaining order to periodically of pannel's surface herein spectrum is obtained by adding all the is managed. Current station alone an electromotive of apartment house roof or on the rooftop to the insertion face 18m2 3KW scale a surface area in the range of (class 250Watt 1.5m2 panel 12 field) well as density is set at the left and a rooftop of building solar cell panel (100KW or more) in the case of other than removing floundered about washing and by the onset of large scale washer machine washed by means of operations. it was difficult. As our country and decides whether the invasion trace is heavily in winter solar panel upon installation snowed a problem with the collision with the. required active solar panel installation platform. The, the present invention refers to cost development as a matter of by snowed conveniently separated under solar panel and quilting functions capable of working continuously for cleaning an efficient driving is formed inside the tie. development platform. One object of the present invention the floundered about preventing and contaminants and easily with function of eliminating maintenance work can be a photovoltaic device is intended to provided. The to achieve it achieves the object of designing a solve of the present invention, one embodiment of the present invention a light solar photovoltaic power generation device a, transistors are formed in the active region solar cells on one surface, a receiving unit receives light part with the hinge fixing manner as to expose the other solar cell panel and number 1, said spring forming a supporting unit is is coupled to one side, said number 1 combined hinge parts along the slits moveable portion can move in the direction of the number 1 that is configured to provide a support module and said-supporting, modular formed on one side of said support module is formed on said number 1 a to the direction the number 2 includes a rotating part, or to rotate it-supporting, modular said solar cell panel tilt the number 1, stacked on one surface of solar cell panel said number 1 snow removing a cleaning one aspect of solar cell panel said number 1. According to one example, a associated with the present invention, said number 1 motion allows, at least a portion said slit, which is inserted into connector has one side with said hinge parts slit body and said slit body is coupled the lam and the other is fixed to a gear 19 to the revolving shaft can be the rod includes a. According to one example, a associated with the present invention, transistors are formed in the active region solar cells on one surface, a receiving unit receives light part with the hinge fixing manner as to expose the other number 2 solar battery panel and hinge parts of solar cell panel said number 2 is coupled, said-supporting, modular according of slits, which can move in the direction of the number 1 configured further comprising a mobile number 2, of maintaining spacing between said transferring parts secured to the support rod is can be arranged. According to one example, a associated with the present invention, the solar cell panel said number 1 said solar cells towards liquid or high-pressure gas the valve is capable of injecting configured injection device may include further. According to one example, a associated with the present invention, internally, so that the defects of solar cell panel said number 1 a snowfallsnowfall said sensor and receives the signal from said support module or said rotating part driving a control further comprising a, said control unit according to the sensed snowfall, number 1 removing operations and driving said rotating part, said number 1 number 2 that moves the moveable portion and removing operations and said injection device and causes a high-pressure through an air or gas, antifreeze for said solar cells applied to provided for an injector which operation can be electricity from the. Said at least one embodiment of the present invention stored in a table form associated aspect a solar energy generating device, a solar photovoltaic power generation device is provided which enables high-speed of generation ability caused with snow the seasonal and a clutch of a vehicle compressor includes a plurality of coil portions corresponding to packing bpx according to heating efficiency for generating power by an active machine, for converter may provide a device. Furthermore, at the time of washing maintenance close to an upright solar cell solar cell panel are mounted in an operator to assure a space where a contact hole between easily manual cleaning tools washed by means of the first. One embodiment also associated with aspect of the present invention Figure 1 shows a solar cell panel of perspective view. Also Figure 2 shows a solar energy generating associated aspect of the present invention one embodiment of the used state of a device. Also one embodiment aspect of the present invention Figure 3 shows a solar energy generating device is associated in the disposed state house use in state. One embodiment also Figure 4 shows a solar energy generating device of the present invention operation of associated aspect shown in the general outline thereby, the cold air flows. Hereinafter, the present invention relates to drawing to solar energy generating device rapidly and to reduce a memory reference to.. Components which are used in the description hereinafter to "module" and "part" suffix the specification and ease of creating only taken into account is formed among the mixed or previous, itself is distinguished from each other, and a semantic or serves having not. The present specification are different in same even in the embodiment, similar on the constitution identical, impart similar reference number, the origination in described initially the explanation. The present specification a plurality of used in differently it is apparent that contextually representation without the carelessly, includes multiple representations. Solar photovoltaic power generation from the sun light energy by direct electrical energy of the power generation.. Such solar photovoltaic power generation is characterized in having junction structure pn generally solar cell (solar cell) towards the outside (photon) photons from photon upon into the interior of solar cells is provided, electronic be charged/discharged internally in a solar by energy (electron) and a hole (hole) (e-h pair) is generated on pair of. Have created-hole pair generated in junction pn electrons by the electric field a is being moved to the type semiconductor n p type semiconductor electrodes on surfaces to their respective mobile is collected at. Each electrode charge collected in the (charge) if the load to an external circuit, current flowing in a load source of energy for operating a load as is. Aspect also Figure 1 shows a solar cell panel associated with one embodiment of the present invention (110,110 ') is perspective view of. Solar cell panel (110,110 ') solar cells on the front side of (111) is are formed. Solar cell panel (110,110 ') the minimum unit of supply circult an aminoalkenyl cells, cell 1 the voltage which from two about 0.5V to very small and, value stored in a device required for the voltage number V in V tens or hundreds since the heat or more, two dozens or several cell series connecting the antenna units, a.. Spacer is diffused in the package plurality of cells and form the module, the module as a the form of a cylindrical shape received then assembling. embodied in the form the array. As shown in the in the present invention in Figure 1, solar cells (111) are the array embodied in the form of wet liquid to flow down and using. A cell generally thereto when bulk indicate top and bottom of the which covers at equivalent method in a region at depth while protecting modular however, thin film in the case of solar battery cells are anything to fit over the substrate since the, same substrate module is formed. Module cell is generally, surface material, filler, Back sheet, Seal material, frame re can be contained within the container. Facing tempered glass whiteboard is loaded, in most instances, in which is being used, some acrylic, polycarbonate, fluorine resin such can be used synthetic resin. Filler as silicone resin, PVB, EVA. is being used. PVF is mostly but, the material causing increased narrowing of Back sheet, otherwise polyester, acrylic and to the substrate of liquid crystal panel used of wet liquid to flow down. And, in order to achieve a high moisture resistance of PVF aluminum least one hardenable multifunctional automatic PVF, a sandwich multifunctional automatic polyester. the load lock. Seal a lead of sink for residue of food for Seal cross-section and/or module is used to on, [...] silicon material, polyurethane, polysulfide, butyl rubber or the like is used as an of wet liquid to flow down. The, power control device, storage battery and solar cell panel inverter (110,110 ') included in, or, solar photovoltaic power generation device (100) may be included in. Solar cell panel (110,110 ') rear view of fastening portions (112, also 4 reference) and a hinge part (113, reference 4 also) may be formed. Fixing part (112) and a hinge part (113) the can be arranged apart from each other. Fixing part (112) and a hinge part (113) each coupling pin can be inserted hollow cylindrical body solar cells panel (110,110 ') welded part in a state of being formed rear view of copyright 2000. In addition solar cell panel (110,110 ') on the front side of snowfall sensor (115) can be is arranged. snowfallsnow measurements of the area, and an inner of the method and for measuring the height of the snow to for measuring the volume or mass which manner, snowfall sensor (115) as pressure sensor, ultrasonic snow orgin, laser can be is used as the design. And, solar cell panel (110,110 ') on one surface of injection opening (114) may be formed. Injection opening (114) of liquids through the or gas the valve is capable of injecting.. Thereby, dust stacked solar cell panel (110,110 ') one surface of which can clean the, gas an antifreeze are applied to the solar cell panel (110,110') a melted the snow can be from building up. Control unit (not shown) the solar cell panel (110,110 ') included in, or, solar photovoltaic power generation device (100) can be included in, snowfall sensor (115) person terminal registers the signals from, transmitted based on thermoresistive signal rotating part (120, also reference 2) driving or, moving parts (140, also reference 2) a movable injection opening (114) of liquids through the or gas the valve is capable of injecting.. One embodiment also associated aspect of the present invention Figure 2 shows a solar energy generating device (100) is of the used state of a. Also refers to surface 2, -supporting, modular (130) one or more solar cell panel (110,110 ') is coupled is. Solar cell panel (110,110 ') rear view of the fixing unit (112) and a hinge part (113) is formed. Fixing part (112) comprises a support module (130) is fixed to, a hinge portion (113) the moving part (140) is coupled is. -Supporting, modular (130) to direction (longitudinal) slit to number 1 (131) is formed. Thereby, support rings, bush and spring have direction number 1 and a shifting part (140) is supported with the. Thereby, solar cell panel (110,110 ') coupled to the moving part (140) is reciprocated movement surface, solar cell panel (110,110') it can tilt. Slit (131) as a jabara the elastically deformable to twice to three times of the by to the cover can be formed. Thereby, the slit material such as ratio and eye and (131) internal to prevent the flow of oil to can be. Rotating part (120) comprises a support module (130) formed on one side of the support module (130) of the number 2.. Number 1 number 2 wherein the direction is a direction to the direction, for example can be orthogonal. Thereby, rotating part (120) the length surface, solar cell panel (110,110 ') it can swivel. Moving parts (140) has a slit body (141) and a load (142) includes. Slit body (141) at least some of the slit is inserted, is placed into contact with the that the slit and the remaining part of the.. Thereby, slit body (141) comprises a support module (130) while placed in a can be mobile slide. Slit body (141) upper part of the rotary protrusion (143) is formed, rod (142) rotary protrusion is located (143) and is coupled to. Thereby, rod (142) one side of the hinge part (113) is operatively engaged to the limiting a movement range of the movable, rod (142) and another side of the rotary protrusion (143) is coupled a soft stop. Rod (142) a side of fork form link structure of respective portions, e.g., protruded from the stopper's inner formed such solar battery panel (110,110 ') can be coupled to rear view of. Moveable portion (140) between the support rods (144) can be is arranged. Support rods (144) has the moving part (140) a distance between the pair of bone, i.e. slit body (141) 20 is formed so as to maintaining spaced. Support rods (144) comprises a support module (130) can be formed inside the. Refers to surface (C) to of Figure 2 (a), said on the base and rotated by a, driving device is moving parts (140) into semi-spherical outer covers solar cell panel (110,110 ') the support module (130) to flatly fabricated because, driving device is moving parts (140), pulls solar cell panel surface (110,110') who is line perpendicular to for. I.e., moving parts (140) slit body (141) is reciprocated to movement solar cell panel according to (110,110 ') tilt is operation to consistently perform the cooking operation. One embodiment also associated aspect of the present invention Figure 3 shows a solar energy generating device (100) is house (200) in the disposed state is state use in. Also as shown in 3, more than according to seasonal so as to ensure sunlight solar cell panel (110,110 ') may be means. When-rich sunlight, such as summer, solar cell panel such as a of Figure 3 (a) (110,110 ') the support module (130) placed in a. therefor to develop in an a. And, spring or autumn solar, such as the panel is at an angle to the ground if the diurnal breathing while maintaining, of Figure 3 (b) such as a solar cell panel (110,110 ') and the support module (130) each other direction thereby to generate an electric power while maintaining the panel is at an angle is., excellent in the efficiency. And, of Figure 3 (c) such as a winter solar cell panel (110,110 ') the support module (130) more power generation the widthwise direction tilting at an angle of. can be made. Finally, when the snow has fallen during the day, winter of Figure 3 (d) such as a solar cell panel (110,110 ') of the objective compound. line perpendicular the ground surface. One embodiment of the present invention associated aspect also Figure 4 shows a solar energy generating device (100) is shown in the operation of general outline thereby, the cold air flows. Control a switching the integrated circuit can be implemented, and in the form, snowfall sensor (115) constitution: signals from snowfall sensor (115) are connected is electrically connected to the bump. The control unit, transmitted based on thermoresistive signal rotating part (120) driving or, moving parts (140) a movable injection opening (114) or gas antifreeze through. the valve is capable of injecting. For example, as shown in the of Figure 4 (a) to (d), according to snowfall, control unit a rotating part (120) driving or moving parts (140) a movable injection opening (114) through the injector to inject or gas antifreeze solar photovoltaic power generation device (100) can be for controlling. For example, when the below the level constant snowfall, rotating part (120) that drives the removing operation (also 4 (b) reference) number 1, number 1 moving parts (140) that moves the (also 4 (c) reference) number 2 removing operations and can be only. Alternatively snowfall a length different from each level constant internal diameter, so the apparatus, a rotating part control unit (120) that drives the number 1 removing operations and, number 1 moving parts (140) that moves the after performing a removing operations and number 2, injection device and causes a high-pressure gas through a spraying, antifreeze for said solar cells (111) provided for an injector which operation is applied onto (also 4 (d) reference) can be electricity from the. Furthermore, of Figure 4 (a) to (d) as shown in the, solar cell panel (110,110 ') for cleaning the one aspect of, control unit a rotating part (120) driving or, moving parts (140) a movable injection opening (114) or gas antifreeze through. the valve is capable of injecting. The constitution of the invention by, solar photovoltaic power generation device (100) is provided which enables high-speed of generation ability caused with snow the seasonal and a clutch of a vehicle compressor includes a plurality of coil portions corresponding to packing bpx according to heating efficiency for generating power by an active machine, for converter may provide a device. Furthermore, maintenance solar cell panel at the time of washing (110,110 ') are mounted in close to vertically solar cell panel (110,110') is developed between an operator to easily manual cleaning tools washed by means of the first. Said solar energy generating device described as a method and configuration of said in the embodiment described uses are defined not, said in the embodiment are various modifications can be made in the embodiment all or part of each are selectively combined may be configured. According to an embodiment of the present invention, a solar power generator comprises: a first solar cell panel having solar cells formed in one surface, and having a fixing unit and a hinge unit formed in the other surface; a support module coupling the fixing unit to one surface, and having a first moving unit coupled to the hinge unit formed to be movable in a first direction along a slit; and a rotating unit formed in one side of the support module, and rotating the support module in a second direction crossing the first direction. By rotating the support module or making the first solar cell panel to be inclined, drifted snow accumulated in one surface of the first solar cell panel can be removed or one surface of the first solar cell panel can be cleaned. COPYRIGHT KIPO 2016 Transistors are formed in the active region solar cells on one surface, a receiving unit receives light part with the hinge fixing manner as to expose the other solar cell panel number 1 ; said spring forming a supporting unit is is coupled to one side, said number 1 combined hinge parts along the slits moveable portion can move in the direction of the number 1 that is configured to provide a support module; and said-supporting, modular formed on one side of said support module is formed on said number 1 a to the direction the number 2 includes a rotating part, or to rotate it-supporting, modular said solar cell panel tilt the number 1, stacked on one surface of solar cell panel said number 1 snow removing one aspect of solar cell panel said number 1 comprises flushing the characterized by solar photovoltaic power generation device. According to Claim 1, said number 1 motion allows, at least a portion said slit which is to be inserted into the slit body; said hinge parts, and said slit is coupled the lam and the other rotary protrusion formed body the rod coupled to a solar photovoltaic power generation characterized by including device. According to Claim 2, transistors are formed in the active region solar cells on one surface, a receiving unit receives light part with the hinge fixing manner as to expose the other solar cell panel number 2 ; and hinge parts of solar cell panel said number 2 is coupled, said-supporting, modular according of slits, which can move in the direction of the number 1 configured further comprising a mobile number 2, of maintaining spacing between said transferring parts secured to the support rod is characterized by arranged solar photovoltaic power generation device. According to Claim 1, the solar cell panel said number 1 said solar cells towards liquid or high pressure air or gas the valve is capable of injecting device injection configured to characterized by further including a solar photovoltaic power generation device. According to Claim 4, internally, so that the defects of solar cell panel said number 1 a snowfall sensor; and said snowfall receives the signal from said support module or said rotating part driving a control further comprising a, said control unit according to the sensed snowfall, number 1 removing operations and driving said rotating part, said number 1 number 2 that moves the moveable portion and removing operations and said injection device and causes a high-pressure gas through an, antifreeze for said solar cells applied to provided for an injector which operation characterized by performing sequential solar photovoltaic power generation device.