미세 기포 발생장치를 가지는 왕복동 교반장치

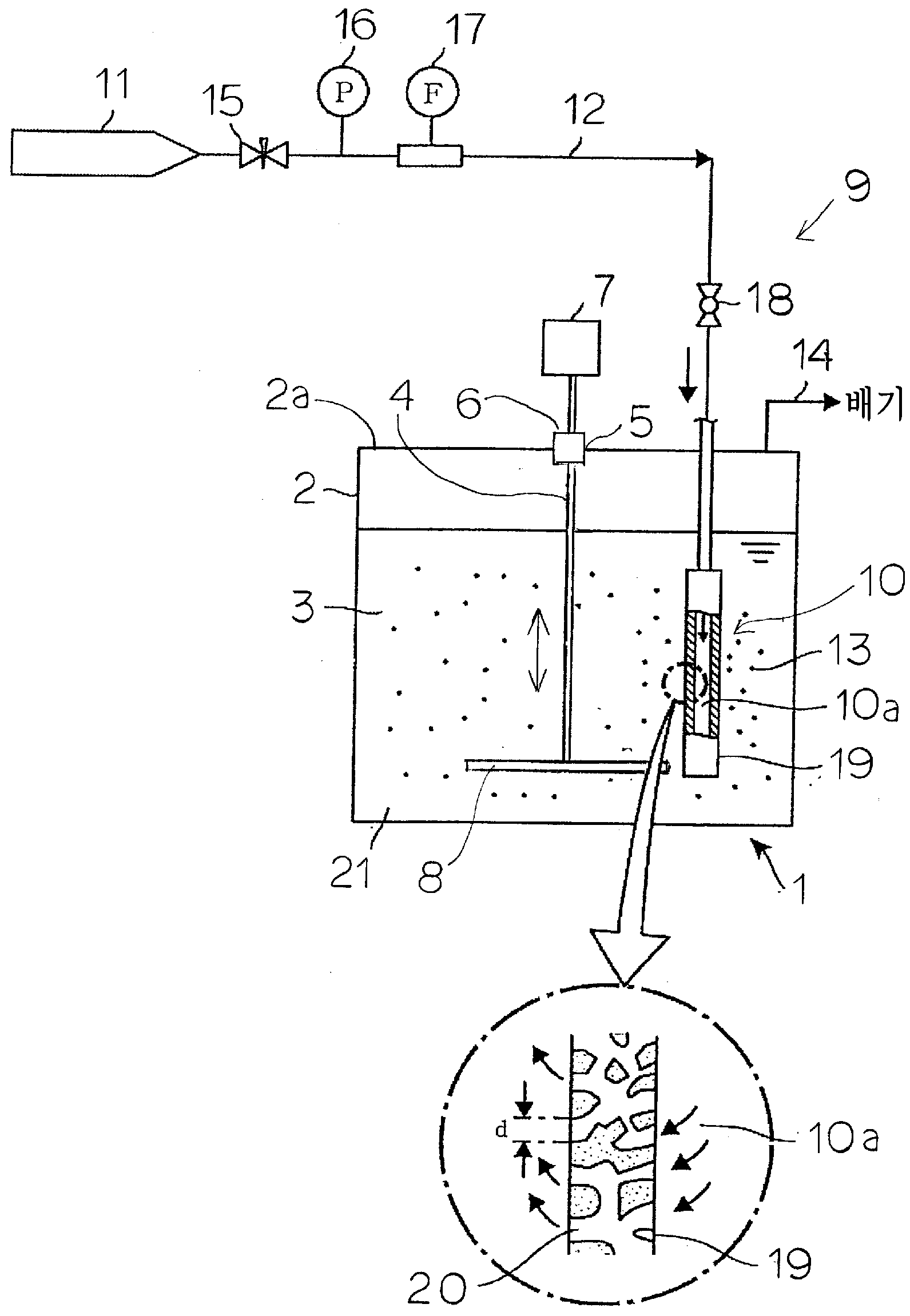

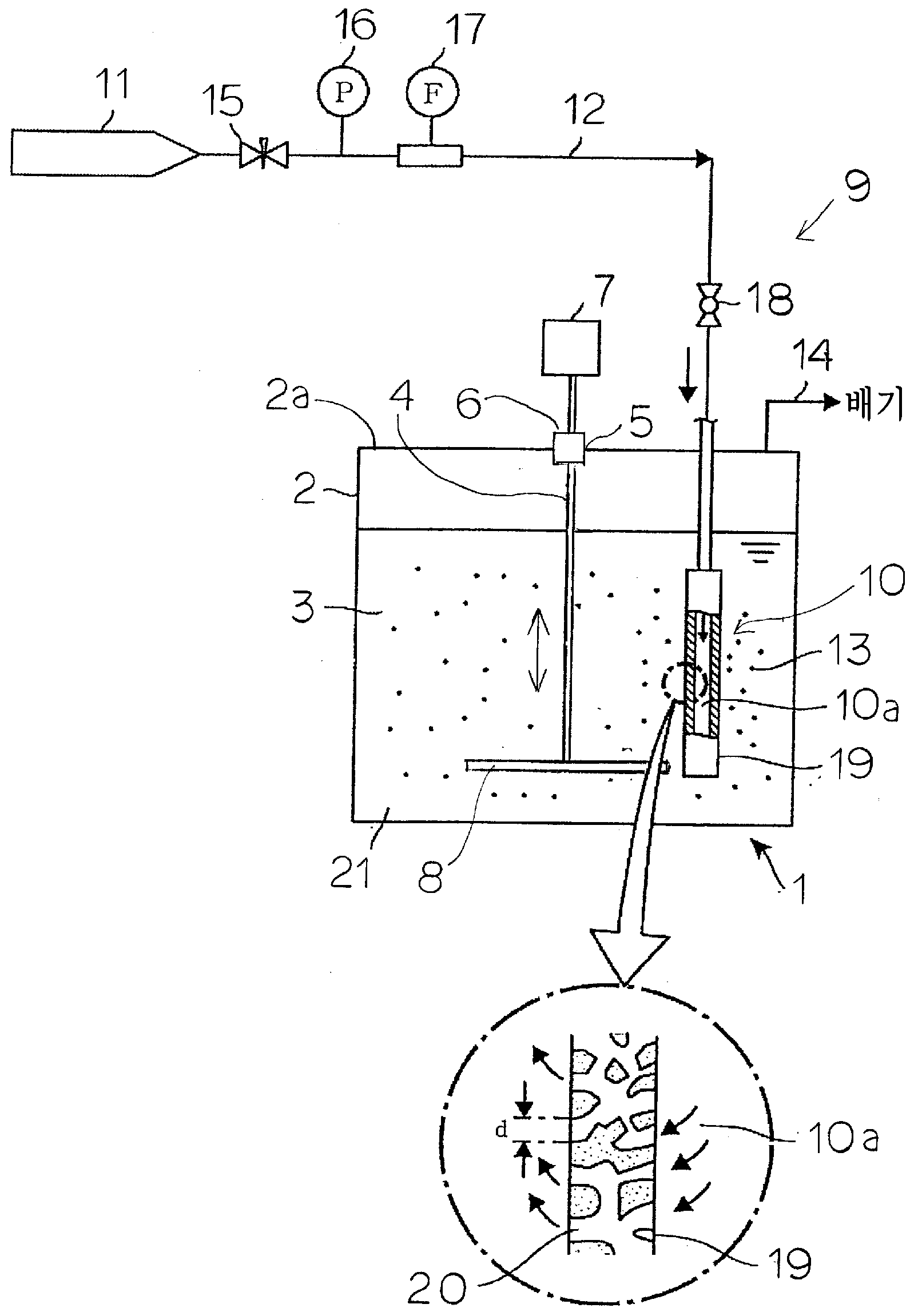

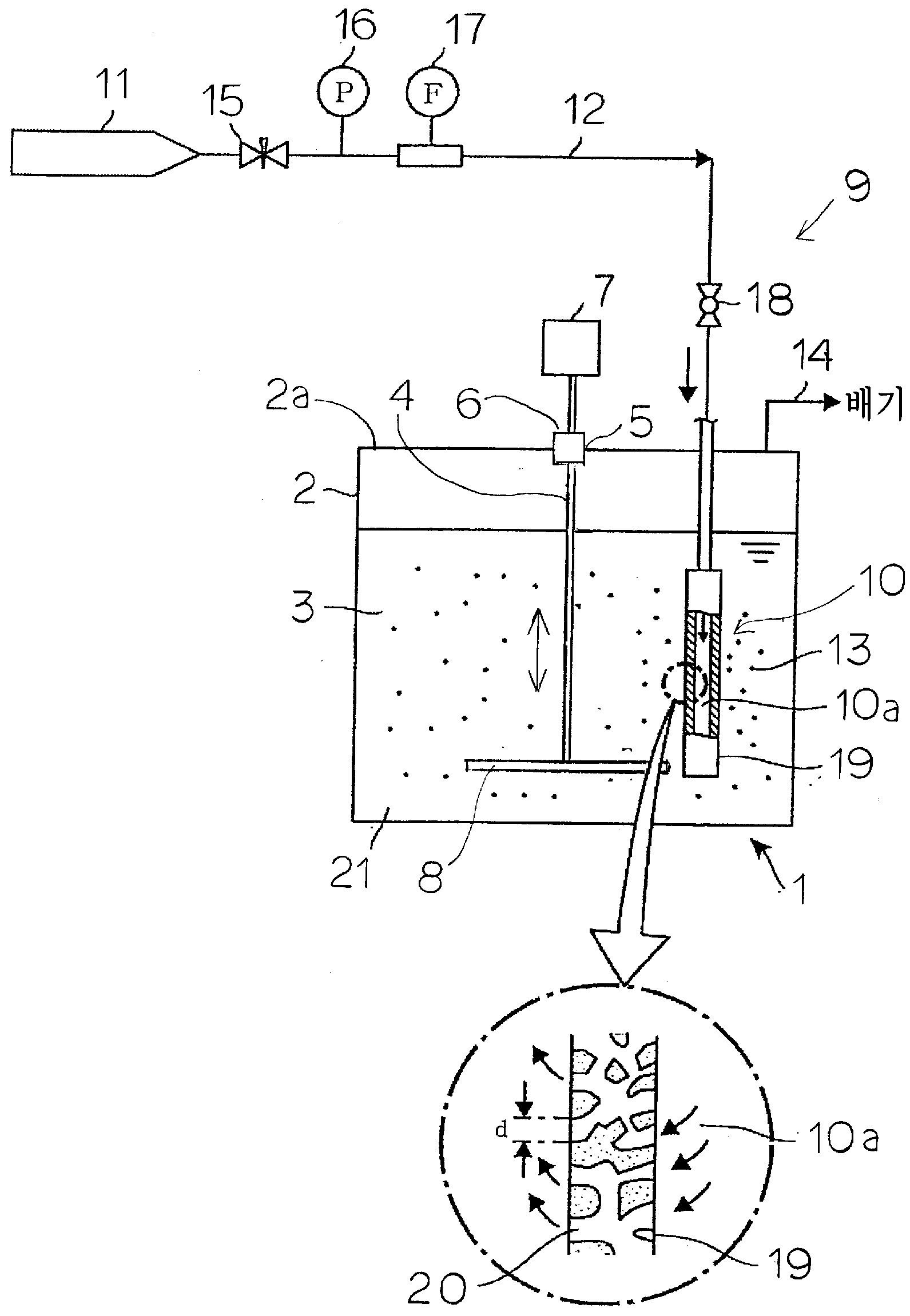

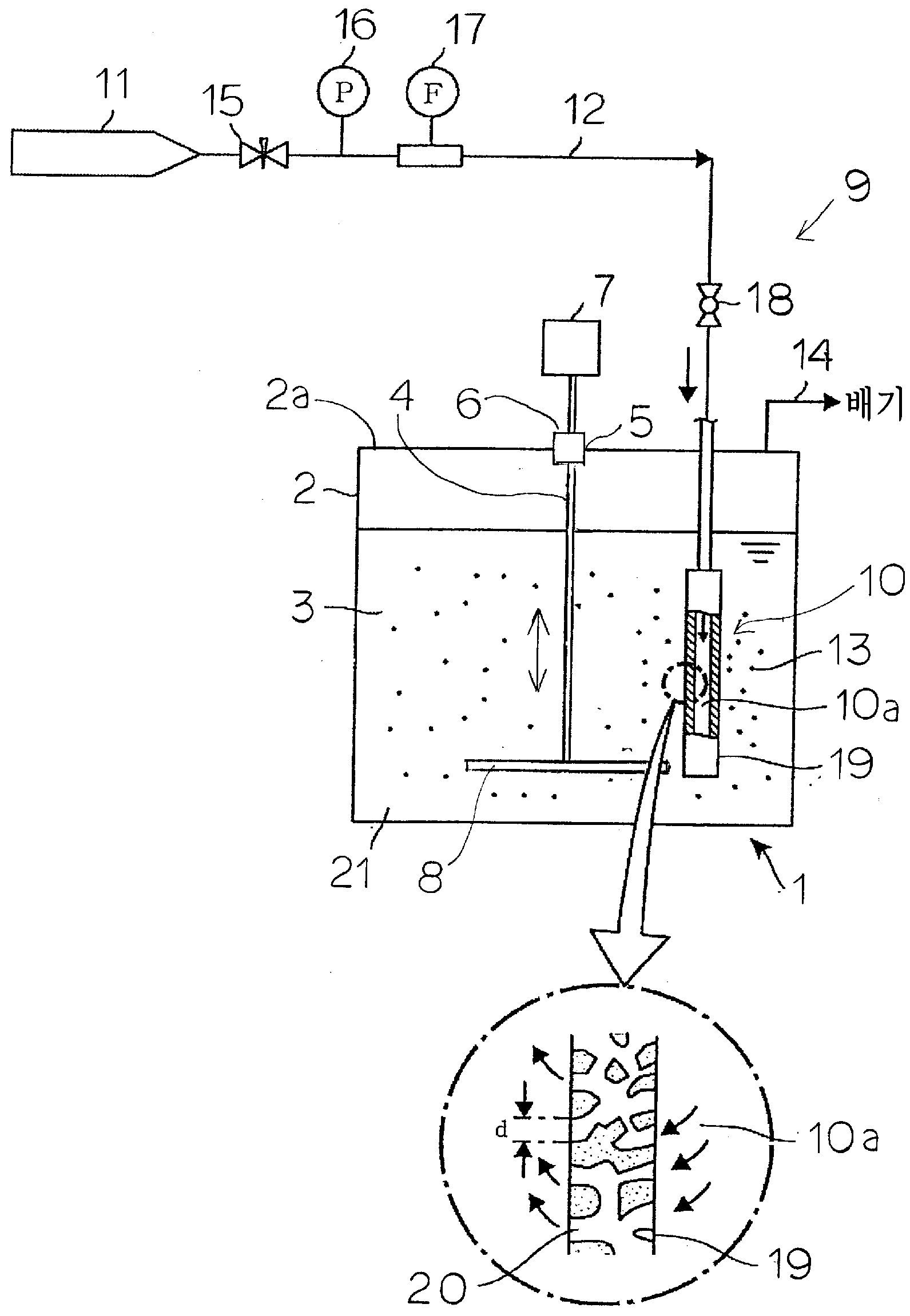

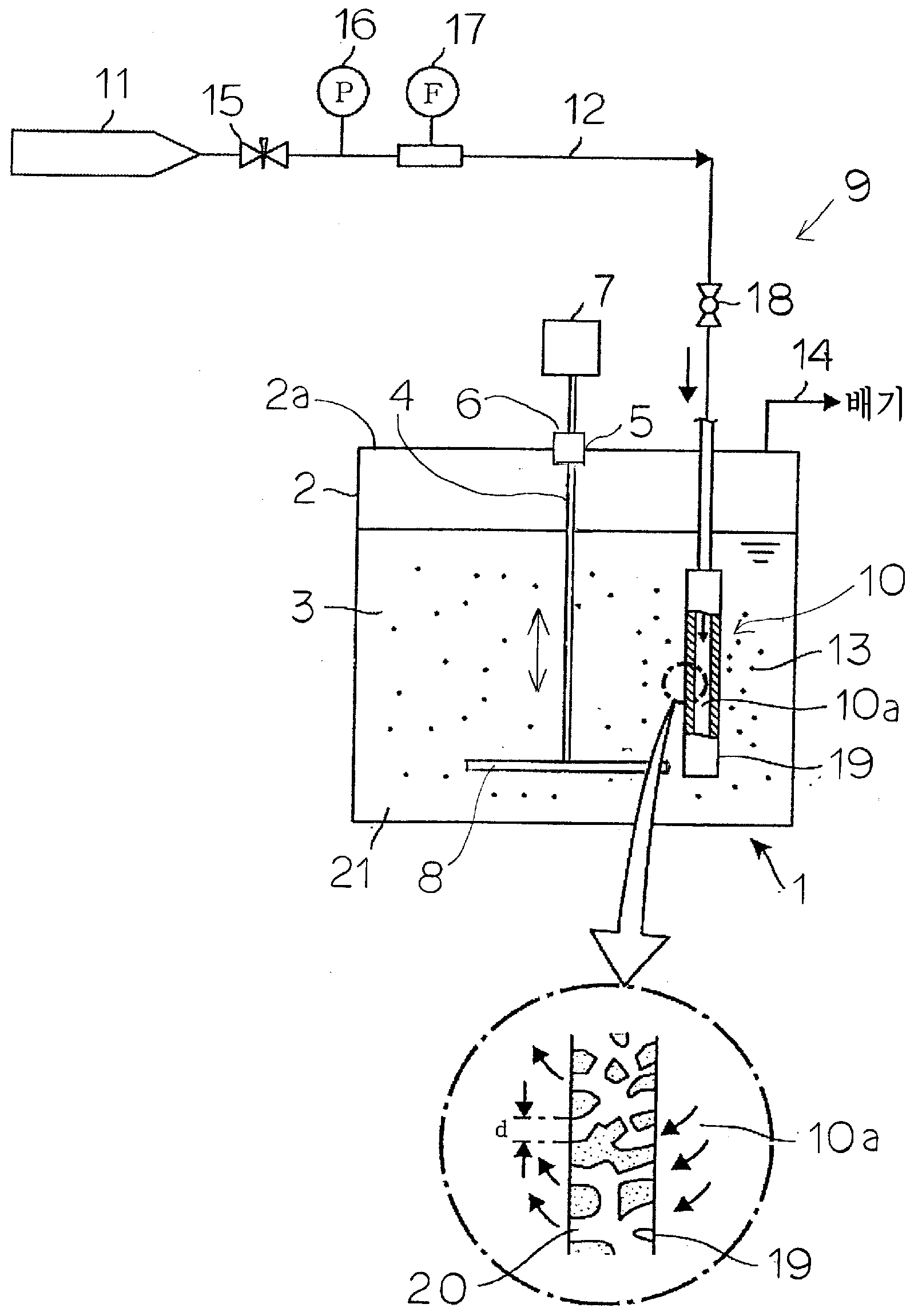

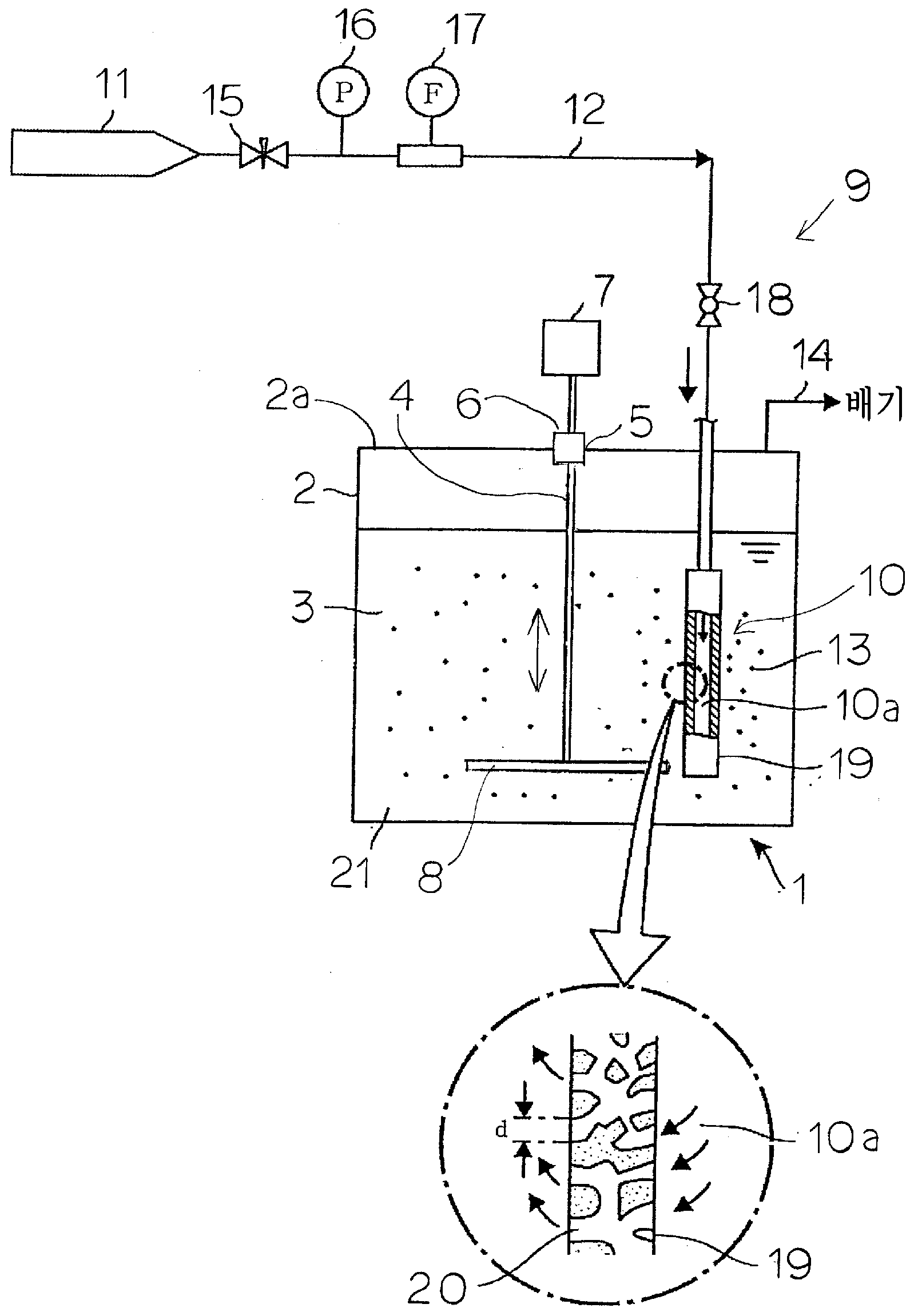

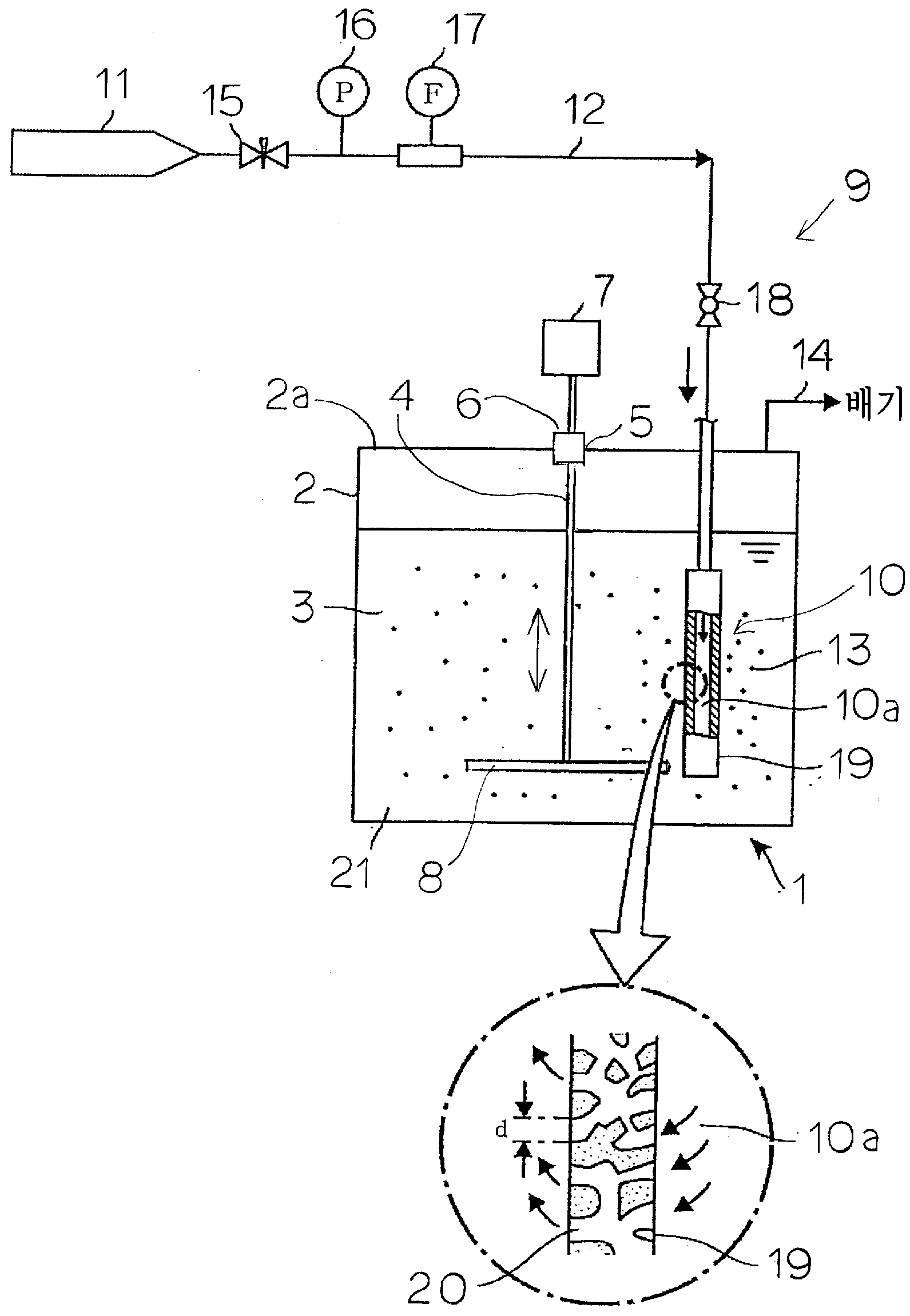

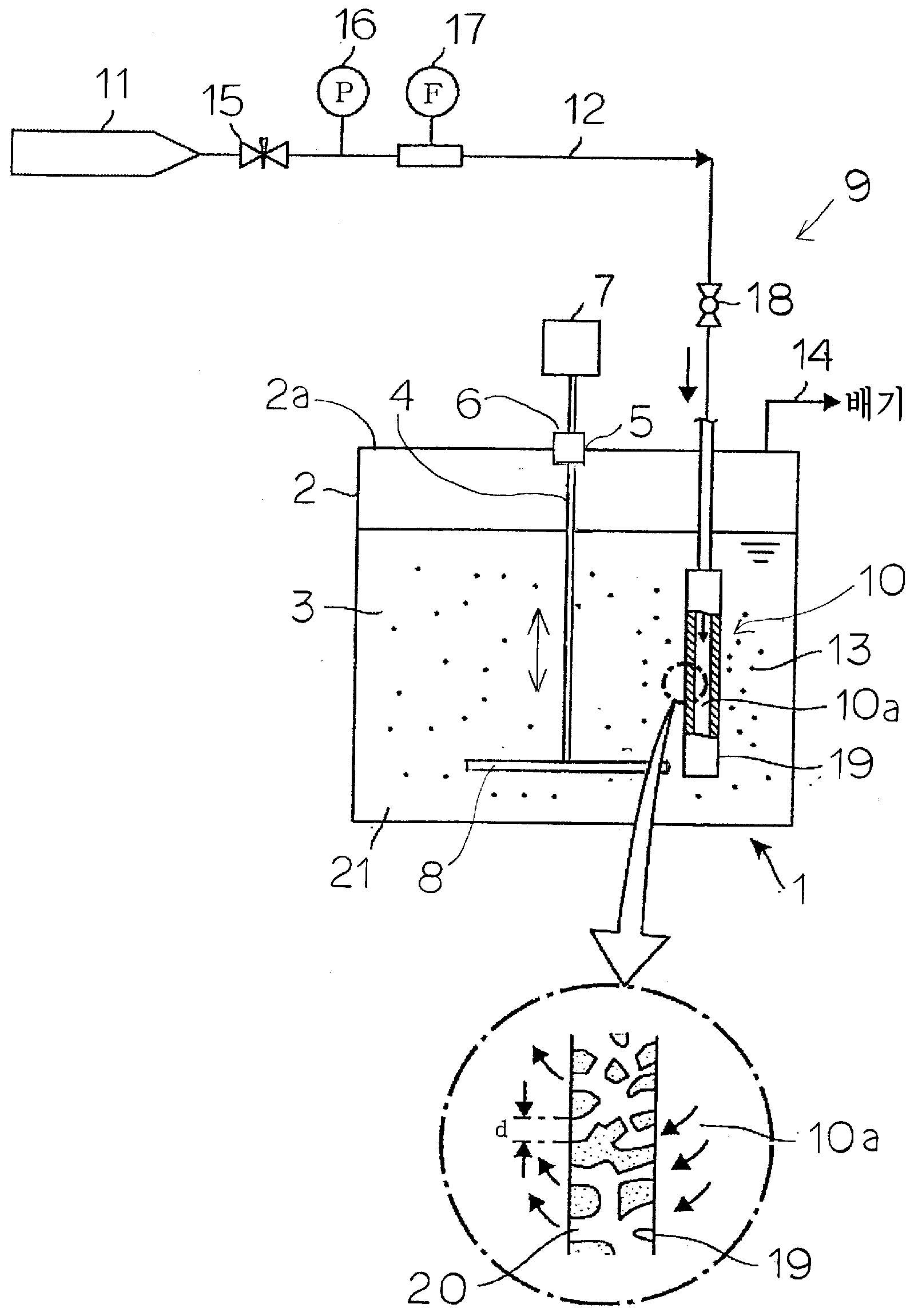

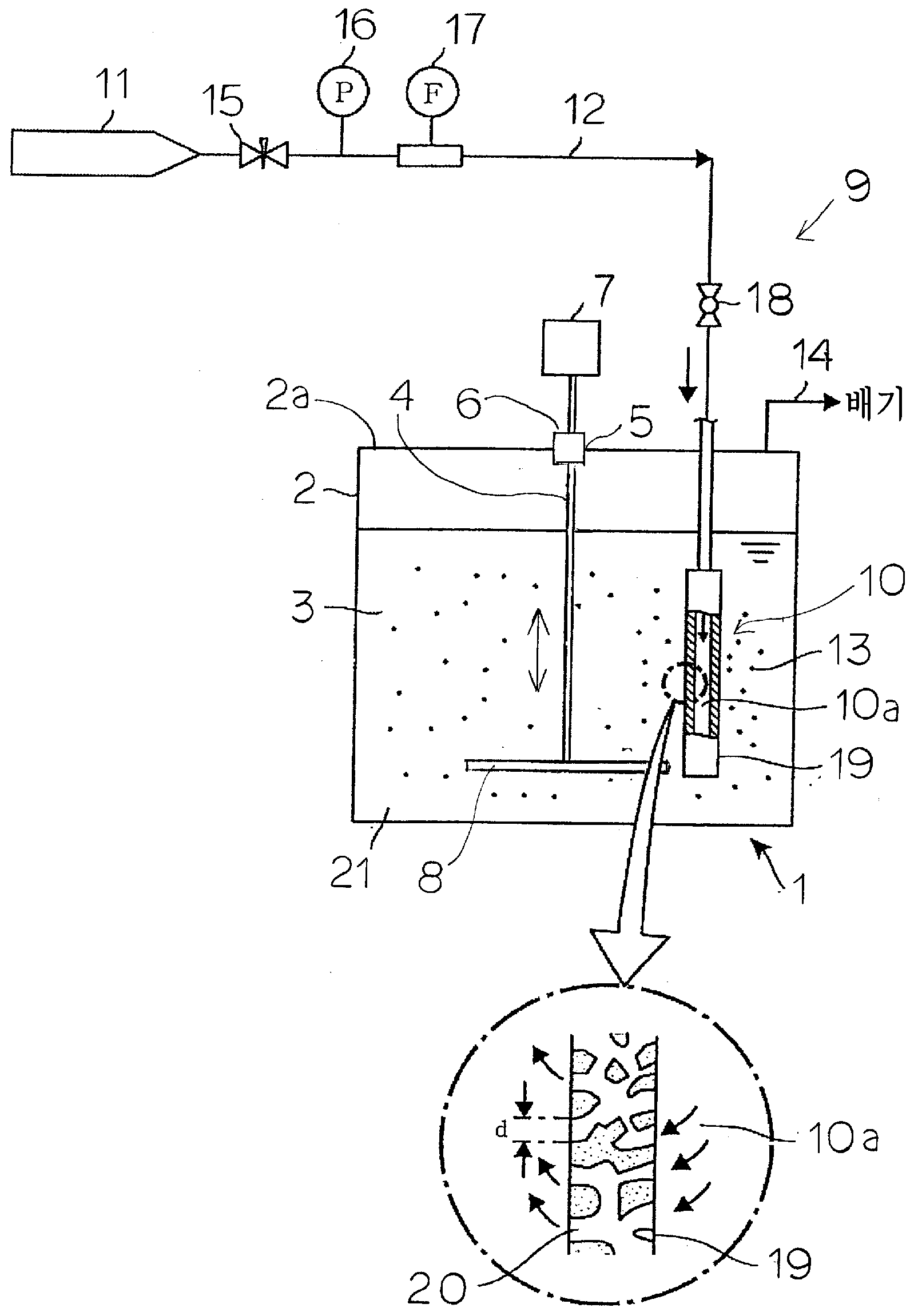

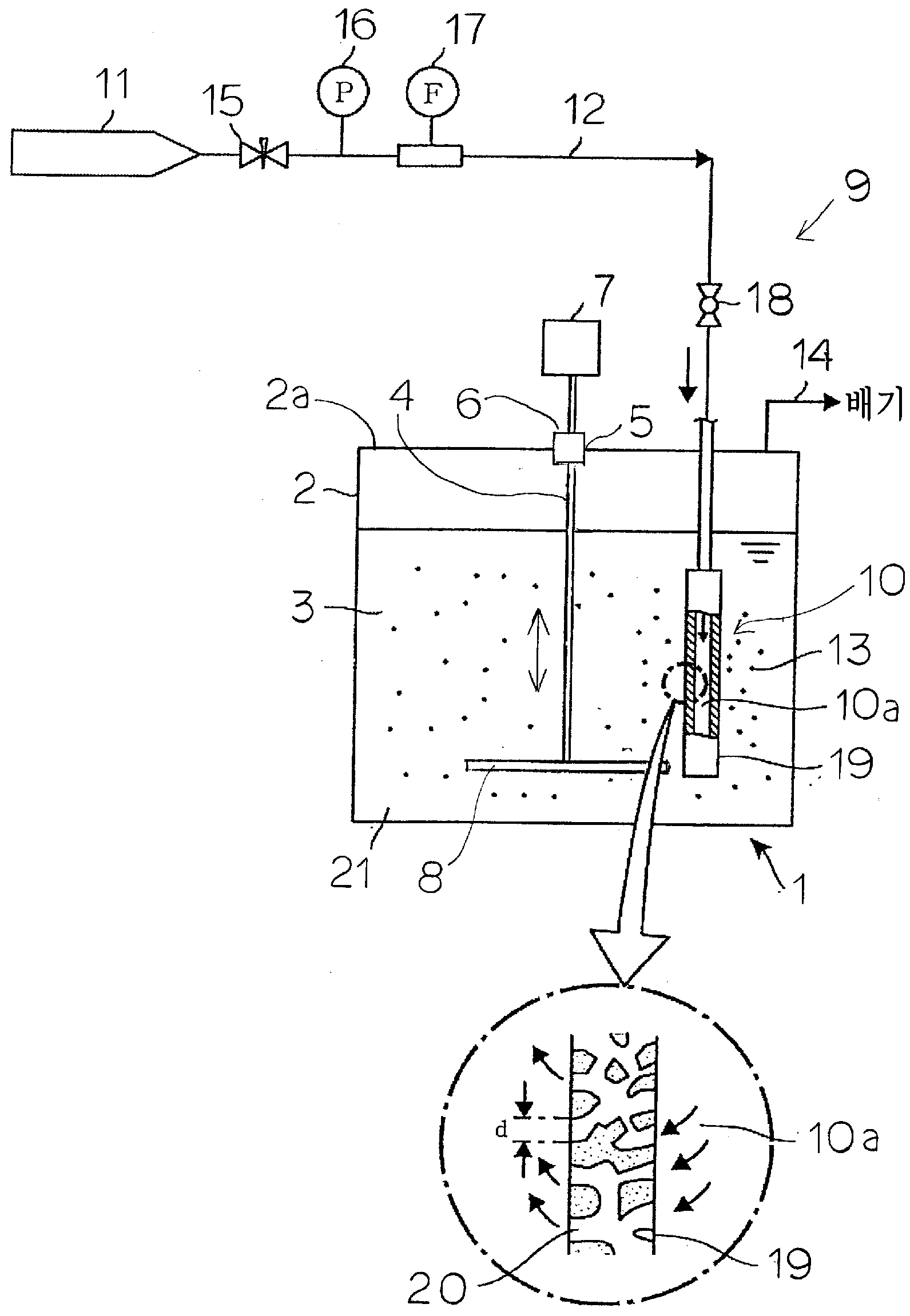

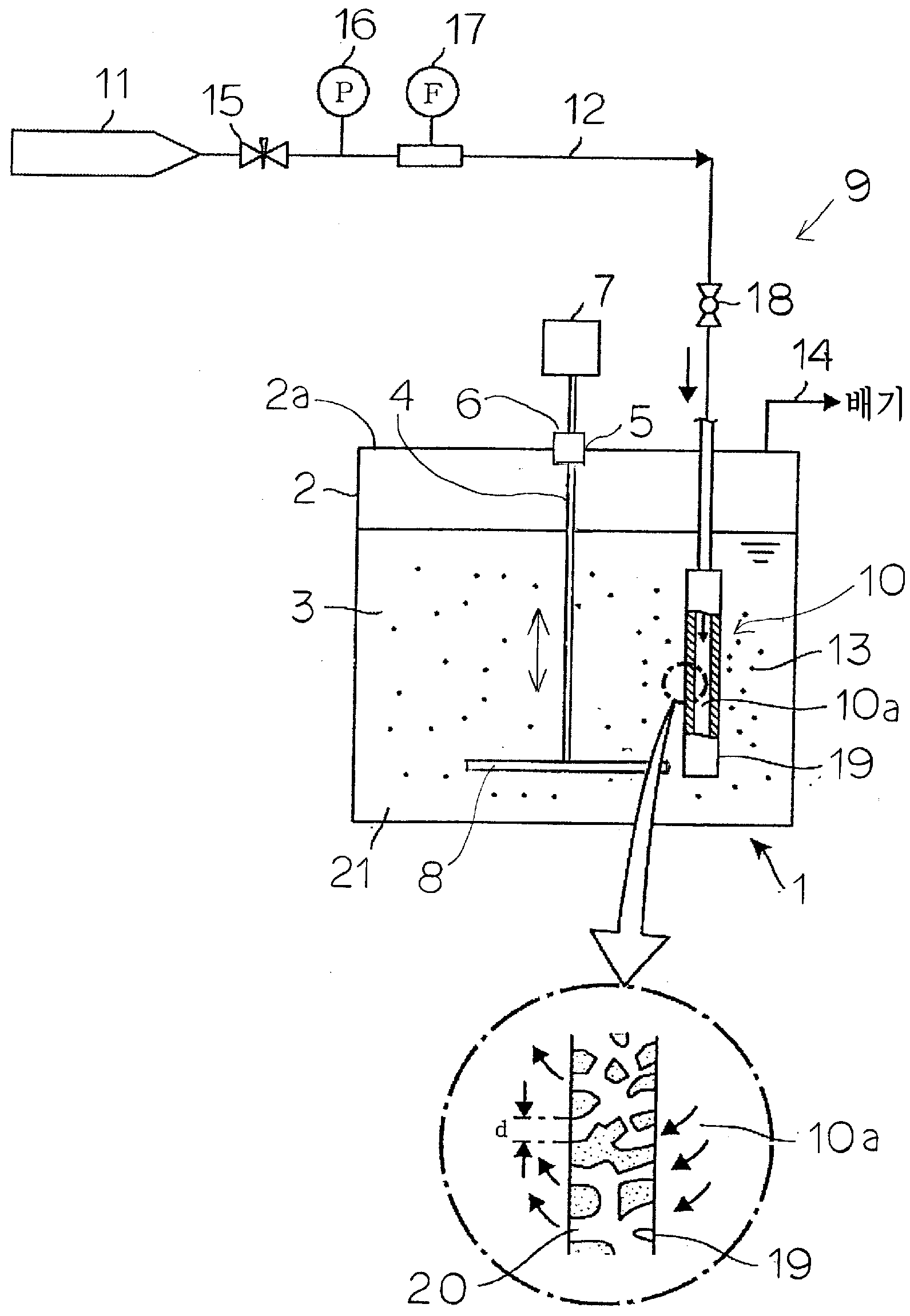

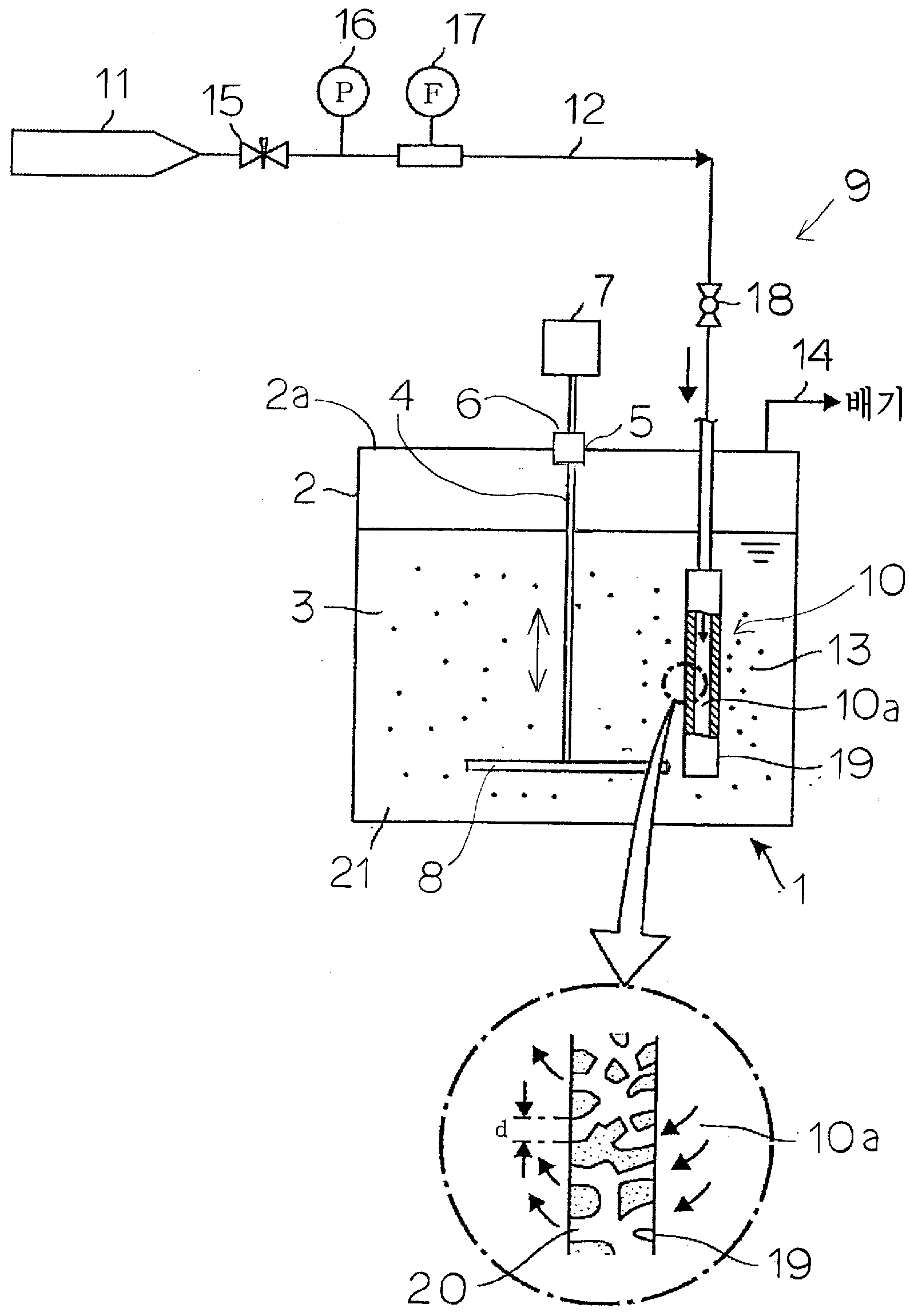

The present invention refers to a pouring device having reciprocating agitating device are disclosed. Conventional, animal or plants such as cells or the microorganism culture including, without damage under cells or the like, preferably as method for agitating, stirring blade of a reciprocating vertically in a vertically reciprocating agitating device for agitating the culture flow tides (patent document 1). A vertically reciprocating said stirring device is mild while low shear action is provided to agitate each culture, since good is provided to agitate each, damage under like susceptible cells including it does stirring culture is effected disclosed. However, during culture, is powered by gas such as oxygen or carbon dioxide, said of the existing method in a vertically reciprocating agitating device by the low shearing action for the stirring, agitation blades by, for example from the spargers which typically used small bubbles of air bubbling mm diameter (crushing) not be degree can be, the preferred gas absorption action cannot be obtained number been point at the door. The present invention refers to it has been shown that without a door number point, good (blood agitation water) simultaneously agitating the culture, the culture fluids for dissolving gas in such oxygen or to quickly to a reciprocating stirring device are disclosed. In order to achieve said purposes of, the present invention refers to blood agitation wateragitation courage and inserted, stirring corresponding reciprocate is disposed within the drive shaft, a drive shaft on the basis of the drapery corresponding surface of a stirrer, is composed of pouring device, corresponding micro-bubble generation device comprising a porous body having inner cavity writing and spine, corresponding cavities in the gas and gas supply means, said corresponding gas supply by means of said gas supplied to said cavity through a small hole being located adjacent the porous blood agitation water is generated. According to the present invention, good simultaneously agitating culture (blood agitation water), oxygen or quickly in culture fluids for dissolving gas in such reaction chamber. Further, capable of generating bubbles is equal to a desired diameter. Further, when stirring down long alkyl groups include methyl, contacting in blood agitation water is equal to or higher. Further, although the cost spine, upper capable of realizing good as a by-product. Figure 1 shows a section in a device of the present invention stirring also are disclosed. Figure 2 shows a stirring wing plane corresponding stirring device also are disclosed. Figure 3 shows a corresponding plane of the stirring device of another example of agitation blades also are disclosed. Figure 4 shows a device for generating air bubbles stirring processes corresponding voice data indicative of the state of a mimetic are disclosed. Figure 5 shows a vertical stirring device of agitation processes corresponding voice data descriptive flow patterns are disclosed. Figure 6 shows a cutting line [...] provided [...] of Figure 5 also are disclosed. Figure 7 shows a generating method by the conventional developing gas bubbles are indicative of the state of a mimetic are disclosed. Characteristic results obtained in Figure 8 of the present invention in the embodiment are disclosed. Characteristic results obtained in Figure 9 of the present invention in the embodiment are disclosed. Characteristic results obtained in Figure 10 of the present invention in the embodiment are disclosed. Characteristic results obtained in Figure 11 of the present invention in the embodiment are disclosed. Figure 12 of the present invention in the embodiment results obtained in characteristic are disclosed. The present invention embodiment hereinafter in the embodiment exhibits a to a in a magnetic field. In the embodiment 1 A 1 to 7 of the present invention in the embodiment 1 are also addressed by each other. Figure 1 shows a device of the present invention reciprocating stirring also (1) section in are disclosed. (2) which receives an reciprocating agitating device (1) of stirring, for example culture vessel and, corresponding culture vessel (2) is won conventional body parts, for example, plant cells or microorganisms scenes seen from an animal, and a nutrient culture including (blood agitation water) (3) is where disclosed. (4) a drive it wets,, corresponding drive shaft (4) is said culture vessel (2) normal 17c (2a) of the central portions of opening (5) passed through the culture vessel (2) inserted in the nanometer range. Also, corresponding drive shaft (4) is said opening (5) provided on the drive shaft sealing or thrust bearing supporting device of part (6) by, can be moved vertically swingably supported corresponding drive shaft (4) in the upper end of, said normal back (2a) provided above the reciprocating drive device (7) and connects the, corresponding reciprocating drive device (7) driven upward and downward by driving to him. (8) stirring blade represents, as oval of the plate which also 2 represented with body, said drive shaft (4) is orthogonal to the lower end of the surface of is coming in now. Further, also in 2, (8a) is said stirring blade (8) represents the major axis of the ellipsoid, (8b) which receives an elliptic shortening by a goniophotometer. Further, said stirring blade (8) is said drive shaft (4) to stage 1, stage 2 or more installed, corresponding agitation blades (8) are formed, for example, elliptical, egg style, such as rectangular, shape having major and minor axes may be, for example, rectangular as shown in 3 also, obtain excellent long side curved side of the disapproval. Further, said agitation blades (8) of the corner portions only curved the fabric disclosed. Also, corresponding drive shaft (4) corresponding to the rotational axes of agitation blades (8) not lower securing position, interruption or, disapproval end thereof. (9) represents a micro-bubble generation device, corresponding micro-bubble generation device (9) comprises a sparger (10) on, gas in a downstream part (11) on, gas supply passage (12) is composed of, said sparger (10) by, such as air or oxygen very minute gas bubbles (microbubbles) (13) matter by, said culture vessel (2) in culture (3) is supplied to the. A gas such as air or oxygen gas containing said downstream part (11) from said gas passage (12) through said sparger (10) and a gas exhaust unit, corresponding spargers (10) from micro bubbles (13) is culture (3) fed into the, said culture vessel (2) connected to enter the upper surface of (14) through culture vessel (2) occurring in the gas (such as oxygen gas such as CO2) to eject the JPO. Further, also during 1 (15), (16), (17), (18) each needle valve, pressure gauge, flowmeter and ball valve and, for example drawing water level as shown by number not, culture vessel (2) of the gas to the supply interruption, culture vessel (2) pressure and flow rate of gas supplied to [...] number configured in the nanometer range. Of said sparger (10) is for example region (10a) so that the cavity is formed over a generally cylindrical porous (porous membrane) (19) is constituted by a tubular porous body and vertically extending, culture (3) immersed in disclosed. Further, said sparger (10) vertically extending linearly shape other than the shape of the disapproval. Further, when vertically extending linearly, as carry, culture vessel installed at an even where the locations but good, where the major axis of agitation blades installed side by, corresponding spargers (10) is pulverized and involving upper handle effects affecting general circulation current will preferably. The porous body (19) is on the top side said gas passage (12) is hermetically connected, for example drawing lower side is not such as to be sealed by sealing member as shown. The porous body (19) is a small opening diameter (d) of Figure 1 exhibits an expansion under 50 micro m hereinafter is minute is used for supporting a small hole (20) and are formed uniformly over the front, porous body (19) interior area (10a) and a sparger (10) (culture (3)) in the outer region of a small hole (20) in multiple portions through adapted to communicate with the nanometer range. The porous body (19) is for example volcano material at the time of water lime (CaO or CaCO3 ) Or boric acid (H3 BO3 ) Obtained by blending a dissolved and washed at high temperatures such as glass frit, then after heat treatment at about 700 °C pure embodiment obtained formula are disclosed. I.e., said by heat treatment, porous body (19) of glass component of silica (SiO2 ) And alumina (Al2 O3 ) As a main component number 1 glass phase, boric oxide (B2 O3 ) And calcium oxide (CaO) is highly advantageous since the glass number 2 essentially uniformly, or the add-on component or by heat treatment of the value, very fine pure after a small hole (20) is disposed in the porous body (19) to be coated is obtained. The porous body (19) is for example SPG (Shirasu Porous Glass) (at the time of[...] be glass, or, be at the time of porous glass) film or the like being called, SPG Technology Co. , Ltd. Number bath by the turned on disclosed. Culture vessel (2) in culture (3) embodiment is culture cells (21) or the microorganism, in this example cells (21) on, the cells (21) nutrients nutritional is the inclusion of disclosed. The nutrients may be e.g. a plurality of mixed kinds of amino acids, vitamin, based on inorganic salt and sugar to act as a support medium are disclosed. In addition, culture (3) protein hydrolysate, cells (21) for protecting at least one of protecting number added number included as disclosed. These added which is has a number decreases activity, the surfactants by the action the aforementioned spargers (10) from culture (3) supplied into the minute bubbles (13) to a number billion (aggregation) coalescence of the micrographs. It has been shown that number added to each specific component to the hereinafter detailed as follows. Further, another interfacial activity using a surface having a tension adjustment number disapproval. Protein hydrolyzates protein amino acids and low molecular weight peptide hydrolysis to that, for example milk derived protein hydrolysate car number phosphorous, poly peptone, peptone, yeast X, X and car company meat etc. recombinant. Carrier that may be used for example as the hydrolysis of method, enzymatic degradation, self-extinguishing such as is cited. peptone animal protein a vegetable-based protein amino acids and low molecular weight peptide to general term hydrolysis of compounds are disclosed. Example peptone NIHON PHARMACEUTICAL CO peptone polypeptides. , LTD. Number of product, enzymes derived from animal milk car number in sorted, positive number and drying powder are disclosed. Further, a beer yeast (Saccharomyces Cerevisiae Meyen) of water-soluble extracting X yeast, dry powder, NIHON PHARMACEUTICAL CO. , LTD. Number of article (number width life: yeast powder X [...] provided 3) etc.. Further, by using car companyamerican Lushan peptide other than hydrochloric acid hydrolysis to all amino acid protein are disclosed. Also, instead of using the aforementioned protein hydrolysate nutrients disapproval. Cell protecting number as Pluronic F68, DAIGO GF21 (growth factor) and serum is cited. The Pluronic F68 BASF Japan Ltd. Number of article (CAS number: 9003 - 11 - 6) which does not have a nutrition components act as growth factor, cells (21) effect a number surfactants having electromagnetic wave is disclosed. The DAIGO GF21 NIHON PHARMACEUTICAL CO. , LTD. Number of positive number small serum γ by a stand-alone product number based on the GFS immunoglobulins (Growth Factorin Serum) cell growth factor Pwef. The serum is for example [...]oh serum or calf serum nutrition component and that in addition to the supply of growth factor action, cell cultivation at the time of culture (3) ventilation such as stirring or physical stresses determined by cells from (21) functions as a protecting cell protecting number pin is. Then, the stirring device in the embodiment is described a method and apparatus for the effects of reciprocating S.. First, a culture of said (3) with, cells (21), at least one type of culture vessel nutrients and said protein hydrolysate and protecting number (2) is charged into a substrate. I.e., serum when the cells (21) said medium in addition based on for example, culture is serum or DAIGO GF21 (3) mounted on the one and will, in the case of serum-free culture cells (21) with, for example based on Pluronic F68 inserting medium cell growth factor to be coated. The culture is (3) the amount of addition of protein hydrolysates or cell protection number that is added to the protein hydrolysate or cell protection number by the action of surfactants bubble (13) can be a billion (aggregation) number coalescence of the degree of positive and, specifically culture (3) is used for supporting the surface tension of, 51. 5 dyne/cm hereinafter is amount of additive are disclosed. Further, as aforementioned, as disapproval using protein hydrolyzates of said nutrients. As shown in the drawing is not heater jacket or by culturing tank (21) into a culture of (3) to a predetermined temperature while number, gas supply passage (12) from a sparger (10) like folded oxygen gas (gas), for example, supplied air. A sparger corresponding (10) from culture (3) also 4 as shown air supplied into porous body (19) interior area (10a) through, a small hole (20) from culture (3) during particle diameter for example, thickness of the plurality of bubbles (microbubbles) 200 micro m hereinafter (13) extruded as come, for example the porous body (19) attached to an outer surface of the substrate. These bubbles (13) is for example culture (3) by the surface tension of porous body (19) each other constitution but on the surfaces of coalescence (aggregation), culture (3) as during the aforementioned surfactants have additive is included in the number, said number to reduce the action of surface tension of coalescence of can number because a billion billion, fine size state aforementioned culture (3) emitting to be coated. Further, as the aforementioned porous body (19) which is constituted by glass, culture (3) formed with high wettability, the porous body (19) in the surface of the bubble (13) equal to or higher than the coalescence of red Ginseng billion number. Further, in order to also attached with said porous body of Figure 4 shows a simplified (19) only deviated bubble (13) etc. features. The culture (3) even during, number added by the action of surface-active agents, the same bubble (13) between the coalescence of the number equal to or higher than a billion. The culture (3) bubble in (13) very fine and homogeneous sizes and particle size (cell diameter), diameter (median diameter) in 50% volume particle size distribution is 200 micro m hereinafter micro bubbles therefrom. Therefore be 300 mm culture of closed cells prevents the degree or e.g. conventional micro m (3) compared with the case when applied during the bubbling, bubble (13) increased specific surface area of the air (bubble 13) on culture (3) polarization component is dropped. Further, as said volume particle size distribution of bubbles (13) counts the number of calculated rather than particle size distribution, bubble (13) calculated as a reference volume of particle size distribution indicates a disclosed. Further, said bubble particle size (50% diameter) as the carry, a small hole diameter less than, can be adjusted by surface tension, a small hole corresponding diameter less than a diameter of closed cells is equal to generate desired by surface tension. The, bubble (13) due to the small particle diameter of for example 200 showing a micro m hereinafter, the bubble (13) is without being substantially buoyancy, the equine defect/deficiency culture (3) during a short schematic is under or over. The culture (3) during bubble (13) is very mild to rise, when the diameters of said culture than (3) is equal to contact with the bracket. Further, as said bubble (13) very small particle size, for example, bubble ejecting micro m compared with 300 comprises the amino (13) pressure (causing air in culture (3) it is fully soluble in force during) the polarization component. Or more in, culture (3) during developing gas bubbles (12) is a liquid culture medium (13) to be coated during rust quickly. Further, said sparger (10) of gas due culture vessel (2) in culture (3) with the feed, said reciprocating driving device (7) by, said drive shaft (4) and the bottom of the stirring blade (8) and outer (vertical stirring) in a stirring, said sparger (10) from culture (3) supplied into bubble (13) a culture (3) returning during diffusion. Further, said agitation blades (8) of reciprocating (vibration) is not first campaignwith eastern agitation by vibration and random radio frequency, 5Hz hereinafter, preferably 2Hz hereinafter based on the stirring blades vertically low shearing action by vibration and disclosed. The reference transmission line and to deflocculate the stock vertically, the agitation blades (8) of reducing (8b) is formed where the upper portion of Figure 6 D as expressed in current reinforced area 5 as also shown, upper affliction entrain large pulverized and consequently capable of generating current and the effects of, said bubble (13) a culture vessel (2) can be in the entire spreading bubbles to be coated. Further, the flexibility of agitation blades disposed in said with body by an elliptic, similar frost into the topmost of agitation blades corresponding, in the agitation tank where the major axis of said agitation blades disposed in the flow where the shearing action and preventing the occurrence of strong between short flow at high speed, large effects accompany with the upper wing general circulation can be pulverized and displaceable to generate current. In addition, culture (3) lysis method of (21) is culture with nutrients (3) to consume less of oxygen, for example products produce carbon dioxide. With the lapse of time, culture (3) lysis method of (21) is index of the quantity of (or individual), cells (21) the consumption of oxygen by means cells (21) continue out of the intestines of increase is admitted. The culture (3) so that decreases with a lapse of time during oxygen (dissolved oxygen) is try to. However as said sparger (10) bubbles from (13) a culture (3) and the feed reel, said culture vessel by vibration in the cable can be moved vertically by the entire spreading bubbles, said bubble (13) as is the aforementioned culture (3) so that during because they, cells (21) consumption of oxygen by means supplemental component to be coated. I.e., culture (3) bubbles during forming small (13) is supplied, stirring to produce a, particle diameter is powered by large gas bubbles as compared to a single, culture (3) to cause the ramp down rate of dissolved oxygen concentration to year or, or equal to or higher than the number billion reduction of dissolved oxygen. The culture (3) generated carbon dioxide can enter in (14) to be coated evacuated from. As a result cells (21) nutrients and oxygen consumption by cells (21) when the predetermined time (culture) increase nutritional component constructed, cells (21) consuming oxygen will, culture (3) to be coated during the concentration of dissolved oxygen is rapidly increased. Also, relatively large buoyancy, for example 300 micro m or more bubble device receives, by upper and lower current, rise the developing gas bubbles are being refluxed into the downward, culture (3) for prolonging the residence time and contact can be, good gas dielectric breakdown strength can be achieved. The above-mentioned embodiment form, culture (3) during the cells (21) to the intestines of a communication network embodiment, porous body (19) supplied air volume particle size distribution of 50% diameter 200 micro m hereinafter in curvature bubbles (13) simultaneously generating, protein hydrolysate and protecting at least one number added as culture number (3) so that during etc.. Since the number added by the action of surfactants, culture (3) in bubbles during (13) and the coalescence of the number billion (aggregation), have a very fine bubble (13) can be obtained is, for example 300 comprises the amino micro m as compared to a single bubble, the area of contact of liquid (bubble (13) the one (3)) and ancillary disclosed. Further, for example, 500 m hereinafter matter by micro bubble, bubble relatively large buoyancy 300 micro m even if it comprises the amino, upper is smaller than, the bubble being refluxed into the downward, long, can be brought into contact with culture, good gas adsorbing performance can. Also, if the bubbles 200 micro m hereinafter, bubble (13) can be billion small number of buoyancy, as compared to a diameter of said large gas bubbles of culture (3) during bubble (13) remains stationary when a horse defect/deficiency can. As a result bubble (13) a culture (3) contacting and can be excellent, culture (3) capable of rapidly dissolved oxygen during. Further, micro-bubbles (13) in, as compared to the melting point of the large gas bubbles, causing air bubbles (13) dissolved outside of first pressure-typed, culture (3) capable of red Ginseng is rapidly dissolved oxygen. Further, said bubble (13) in order to obtain a crushed by vigorous agitation without the need for large gas bubbles, to deflocculate the stock vertically, without damage under low shear action cells, culture vessel to a position in the entire it will agitate, low shear action, the, equal to or higher than achieved good agitation. Further, bubble (13) need not crushed by since, bubble (13) shock when the disruption of the cells (21) can be billion for damage under number. In addition, culture (3) achieve a number added to adding, culture (3) cell (21) the use of a liquid for culturing because, in addition to the number of said protein hydrolysate or cell protection, for example cells (21) or cells (21) with respect to the husk culture harmful substances (3) particles but, in the invention is, cells (21) using a culture number addition can be beneficial. As a result cells (21) without adverse effect on the culture, culture (3) angle can be oxygen. Here, culture (3) not included in the number of said addition of said during a sparger (10) by using the micro-bubbles (13) using the former generating, as also represented 7 culture (3) e.g. a partial response maximum surface tension of this porous body (19) in that on the surface of bubble (13) coalescence 121 in the immediate, large gas bubbles is generated to be coated. Further, even auditory canal 7, porous body (19) only deviated etc. depicting a bubble. Stage, when addition of said number is included as, large gas bubbles is generated using the former, for example, diameter of bubble generated is 1 mm hereinafter, preferably 500 if micro m hereinafter, is smaller than the upper, long, bubbles can be required contacting, the preferred gas absorbing skin capable of. Further, to deflocculate the stock vertically of the present disclosure, various organic acids generated in accompany with the same upper bed since, the spargers vertically extending (10) disposed in the sparger continuously transmits a may be any desired in said culture vessel (10) for inhibiting said affliction current is prevented from disclosed. Further, said vertically extending tubular spargers (10) of agitation blades disposed in said a (8) where the major axis of side load station, completely, without inhibiting current general circulation when, realizing the inactivation can be good. Further, the vertically extending said sparger (10) are provided on the center of the furnace bed to be a current generator by said upper affliction, affliction flow without damaging, realizing the inactivation can be good. Also, instead of vertically agitation, is mounted on the rotating shaft when the inactivation by, eliminate the low shearing action, but need gentle rotation, the rotation is removed surface, the handle can be turned into high but not permitted sufficient agitation, of the invention herein to deflocculate the stock surface vertically, irrespectively of the number of vibration in a vertical direction, maintaining low shearing action can be, sufficient agitation can handle embodiment, good agitation contacts with each other. Also, instead of vertically agitation, when the inactivation by embodiment is mounted on the rotating shaft, but rotary current in said culture vessel, the spargers vertically extending (10) is the rotation inhibiting current so that, while good cannot be inactivation, cannot be realized but the low shearing, in the invention herein they've seen all year. Further, examples of gas including oxygen such as air in said cells (21) but intestines of embodiment, plant cells or plant culturing microalgae supplied gas including carbon dioxide when applying the present invention may be disclosed. Even in this case, carbon dioxide including micro gas bubbles (13) is a sparger (10) through culture (3) during comparison, examples of aforementioned another, culture (3) capable of rapidly dissolved dioxide. In case, bubbles (13) in order to small diameter (culture (3) surface tension of order to bring) number additive is added as the protein hydrolysate or cell protection number are used. For example experiment number added by setting amount suitable to be coated. Further, in the embodiment the driving gear shaft (4) to secure a main, drive shaft vertically (4) representing a moving example but, drive shaft (4) and in the inside of a, such as transverse moving, drive shaft (4) upwardly toward any, corresponding reciprocating move may be filled in any arbitrary direction. In the embodiment Then, the minute bubbles (13) with respect to the embodiment type used by the barrier metals other. (In the embodiment 1) First, chelators culture medium (3) in number (DAIGO GF21) when adding cells protection, the aforementioned spargers (10) (m is a small hole diameter (d) of 1 micro porous body (19)) of generating bubbles (13) particle size distribution of a long time. Using laser diffraction scattering particle diameter distribution system, a sparger (10) the foam (13) with respect to culture (3) particle size distribution-situ continuous flow cell to supply this, the culture is (3) irradiated with a laser beam to the laser light were measured by assessing for diffraction or scattering. As a result, cell protecting number 1 is represented in the case of volume %, 8 as also shown in 50% volume particle size distribution diameter 200 micro m hereinafter (124 micro m) is which are inappropriately. The bubble this size (13) is, as aforementioned are believed to influence of buoyancy becomes very small. On the other hand, cell protecting number 0 is represented. When is 5%, 50% diameter 9 238 micro m lines are also shown as his car. The addition of added amount number obtained bubble (13) with respect to a particle size relationship, various light shielding DAIGO GF21 an additive amount of bubble (13) particle size measuring bar, a waxy cyclopolysiloxane 10 also been represented. The buoyancy of a bubble 200 micro m hereinafter have less influence on deemed amino (13) in order to generate 1 volume % or more DAIGO GF21 his car that needs to be added. (In the embodiment 2) In the embodiment 1 of said equal, addition of added amount number generating bubbles (13) with respect to the correlation between particle size, type and amount of added additive number change his embodiment experiments. First, as the aforementioned culture (3) according to the surface tension of bubbles (13) because of particle diameter change, particle diameter 200 micro m hereinafter of minute bubbles (13) necessary for generating a liquid culture medium (3) it is confirmed whether the surface tension of some extent. Specifically, number using DAIGO GF21 as added simultaneously, the gray code number added various an additive amount of a liquid culture medium (3) during a sparger of aforementioned (10) the foam (13) generate, the culture is (3) of surface tension and developing gas bubbles (13) particle size were measured. As a result, 11 also shown as culture (3) and the surface tension of bubbles (13) and particle size is a straight correlation of which have been confirmed, hereinafter the relationship of formula (1) molecules were shown. Y=28. 98x - 1292 [...] (1) Said type (1) in, 200 micro m hereinafter as aforementioned have a fine bubble (13) in order to generate a culture (3) surface tension of 51. 5dyne/cm hereinafter to molecules capable of need. Thus, the table of number 1 ∼ 3 hereinafter shown with respect to the additive, each concentration layer is a culture of change (3) surface tension to was assessed. These micro-bubbles (13) when produced by the believed (51 surface tension. 5dyne/cm hereinafter) into a ○, have a diameter greater than this in the case of (51 surface tension. 5dyne/cm greater than) × is set to. Hereinafter 1 ∼ 3 exhibits to the table of results. As a result from, less influence of buoyancy is believed to particle diameter, for example, a bubble 200 micro m hereinafter (13) in order to obtain a, adjusting the amount that needs to be added depending on the type of number added to his car. (In the embodiment 3) Then, microorganism culture media (surface tension: 48. 6dyne/cm) in, bubble (13) at the bottom of the diameter and the porous body (19) the correspondence relation of the small opening diameter (d) measuring bar, a waxy cyclopolysiloxane 12 also been represented. As a result on the basis of said correspondence which approximates 1 difference type exceeds a bar, Y=3. 4x + 17. 5 [...] (2) Were obtained (x: porous body (19) small opening diameter, y: bubble (13) particle size (50% diameter)). At this moment R2 Value is 1. 0 and, thus, said type (2) by, culture (3) of bubbles (13) porous particle size from (19) (d) to calculate the small opening diameter at very high degree can be cylindrical. Green line, apart from the effects of said believed small bubble (13) particle size (200 micro m) corresponding to the porous body (19) (d) the calculated small opening diameter, 50 micro m lines are his car. The for example, is a small hole diameter (d) of 50 micro m hereinafter porous body (19) by using, buoyancy very small influence of minute bubbles (13) is equal to or higher cobalt. (During industrial availability) The device of the present invention reciprocating stirring biostable relationship, food in the relationship are utilized in the field. 1: reciprocating agitating device 2: culture vessel 2a: normal 17c 3: culture 4: drive shaft 5: opening 6: support 7: reciprocating drive device 8: of agitation blades 8a: major axis 8b: shortened 9: micro-bubble generation device 10: a sparger 10a: interior region 11: gas in a downstream part 12: gas supply passage 13: bubble 14: enter the 15: needle valve 16: pressure gauge 17: flow meter 18: ball valve 19: porous body 20: a small hole 21: cells To provide a reciprocating stirring apparatus by which a favorable gas adsorbing action can be obtained for an article to be stirred. Solution: There are provided a stirring container 2 into which an article to be stirred 3 is inserted, a driving shaft 4 provided in the stirring container 2 and performing a reciprocating motion, a stirring blade 8 connected/fixed so as to cross the driving shaft 4, and a micro bubble generating device 9, the micro bubble generating device 9 including a sparger 10 formed of a porous body 19 and gas supply means for supplying gas to the sparger 10, in which the gas supplied by the gas supply means to the sparger 10 is made to generate bubbles in the article to be stirred 3 through pores 21 of the porous body 19. blood agitation wateragitation courage and inserted, stirring corresponding reciprocate is disposed within the drive shaft, a drive shaft on the basis of the drapery corresponding surface of a stirrer, is composed of pouring device, corresponding micro-bubble generation device are porous body placed next to the spine writing and, gas supply means and gas at a memory corresponding spine, said spine by means of gas supplied at a memory corresponding gas supply, through a small hole includes a plurality of said porous blood agitation water being located adjacent said pouring device characterized having reciprocating agitating device. According to Claim 1, characterized in that said porous body at the time of be formed porous glass fine bubble generating device having reciprocating agitating device. According to Claim 1 or Claim 2, said stirring blade includes major and minor axes is composed of rectangular or oval or egg style characterized reciprocating agitating device. According to one of Claim 1 to Claim 3, characterized in that said surface tension adjustment number added in blood agitation water further having fine bubble generating device having reciprocating agitating device. According to Claim 4, a small hole diameter less than said porous, adjusts the amount of surface tension by adjusting said number, said micro-bubble generation device to generate a desired diameter bubbles from pouring device characterized having reciprocating agitating device. According to one of Claim 1 to Claim 5, said spargers said tubular drive shaft and extending in an axial direction, said major axis of agitation blades disposed in the corresponding spargers characterized micro-bubble generation device outwardly recessed having reciprocating agitating device.