DEVICE TO CONTROL ANGLE AND POSITION OF SENSOR FOR CEILING CRANE

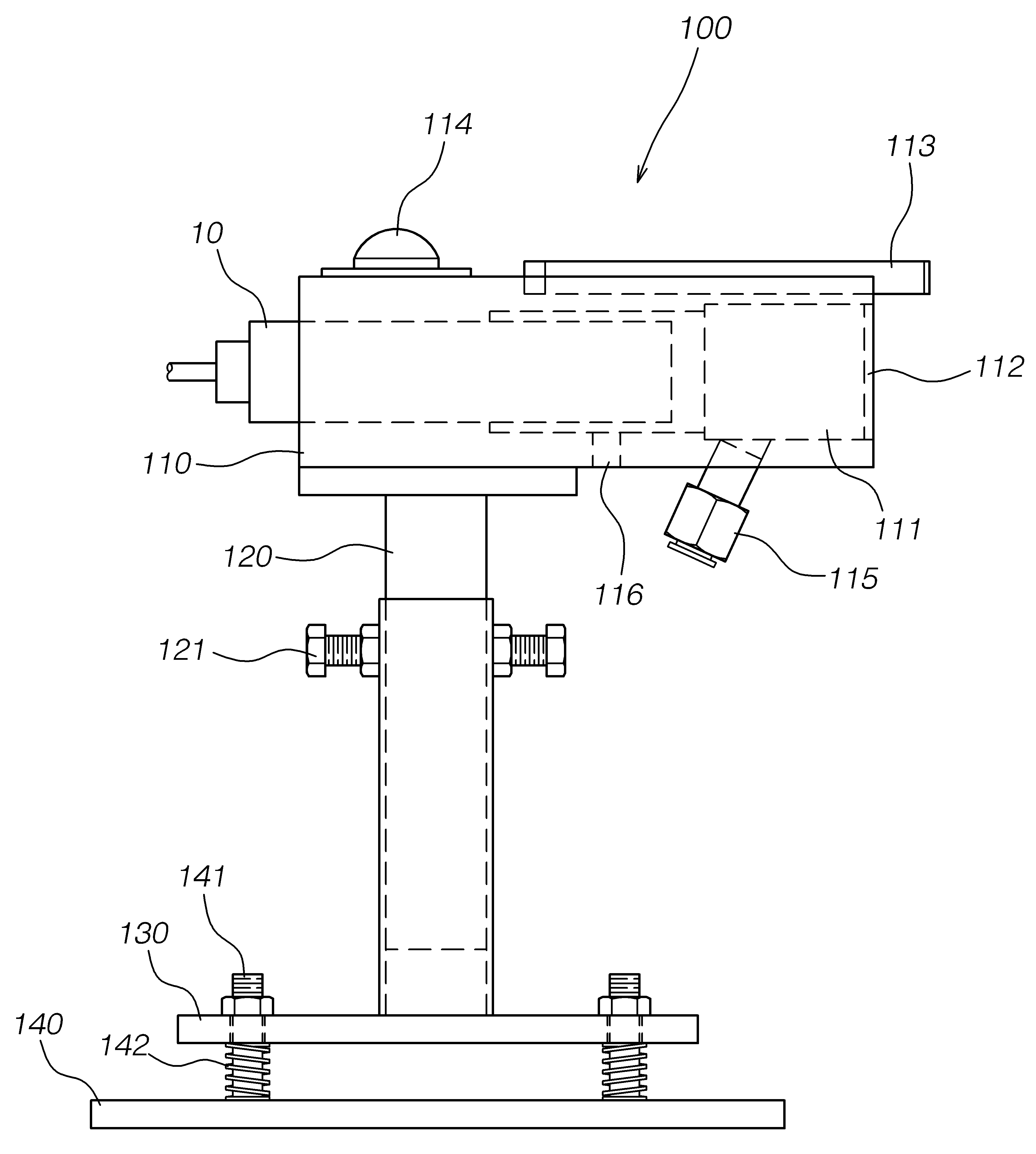

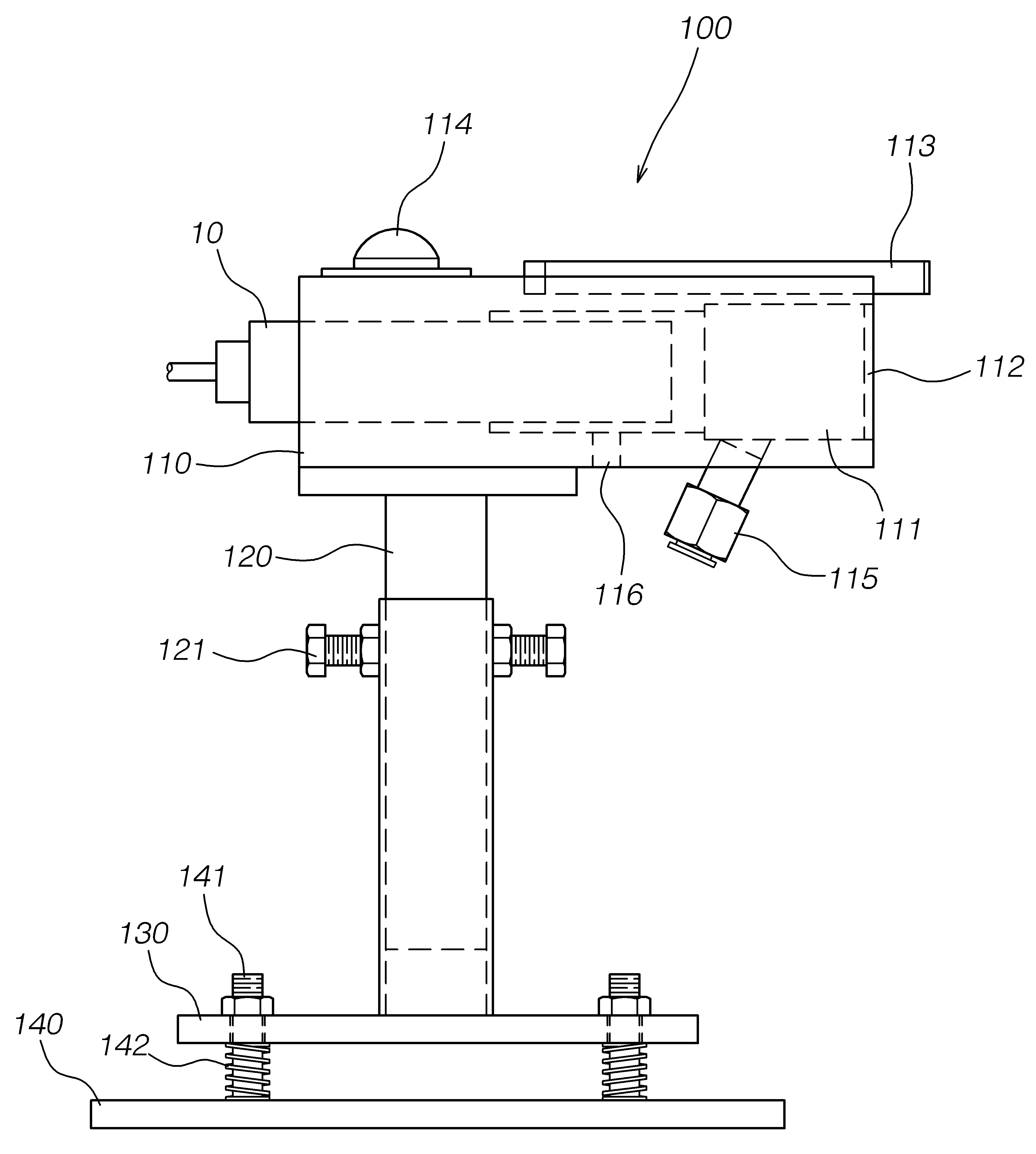

The present invention refers to as its sensor device relates to ceiling [khu[khu] citation, more particularly of angle and to each of the apparatus for correcting die practical sensor device as its ceiling to prevent citation to [khu[khu] are disclosed. One or both of the apparatus for correcting die is generally obtained practical sensor for sensing the position of a moving apparatus for correcting die prevent are installed in. However of the existing method such as a shock due to the dehydrating or external ceiling crane sensor positions and angles to sample the apparatus for correcting die height flavor and cannot be easily door has been number point. In particular sensor to judge a door number is due to collision apparatus for correcting die and sensing malfunction has been point. Accurate control of services as its work has been the storage door number point. In addition, number season small or plant in an environment such as noxious dust hot or cold to be moved between the drive unit to the malfunction and failure protect door has been number point. The number of the existing method in order to solve the present invention refers to said door such as point the evaporator is, The present invention refers to as its sensor adjusts the apparatus for correcting die can be smoothly to prevent collision of the pin is a device number as its ceiling [khu[khu] citation to public box. In addition, the present invention refers to sensor sealing and cooling the drive unit to the malfunction and generating dust and high temperatures can be prevented as its other pin is a device number of ceiling [khu[khu] citation public box. The present invention is characterized as its ceiling [khu[khu] citation for said sensor device (100) includes, Sensor (10) for mounting body (110); said body (110) faces forwardly on one side of the laser pointer (113); said body (110) to the position vertically from the bottom of supports (120); said support (120) from the bottom station (130); said support (130) to be located beneath a lowest point reach (140); said support (130) on the fixture (140) is formed near the first angle that can be formed between the elements including characterized. Wherein said body (110) to the interior of circulation space (111) is formed, said circulation space (111) in front of a transparent cover (112) having, said circulation space (111) oriented in a forward direction to the interior of the sensor (10) characterized in that the mounting. In particular said body (110) and potato of leveling (114) characterized on the front. In addition, said body (110) on one side of said circulation space (111) for feeding the cooling into the interior of the cooler or for supply (115) is formed, the other side of the circulation space (111) or discharging the coolant circulating cooler inside of the step part (116) characterized form. In particular said support (120) the blowing fans mounted at the other side of the central reference support into the insertion support vertical direction to regulate the light intensity, fastener (121) characterized using simultaneously securing both sides of support. And said support (120) on top of insertion groove (122) is formed, said body (110) in a lower section of said insertion groove (122) in the interior of the movable opening (117) characterized with the exterior. On the other hand, said support (130) is rotated by an lower opening (131) with, said fixture (140) on top of said rotating opening (131) in which the inserting insertion groove (143) characterized formed. As well as said angle adjustment member is said fixture (140) formed on top of the support (130) through the connection a plurality of pulverizer (141); said support (130) on the fixture (140) formed between a plurality of spring (142) composed of a characterized. the pulverizer (141) includes said fixture (140) is formed vertically on top of spiral axis, said output's spiral upper nut combination said support (130) is installed at the nut according to the rotation direction of the upper surface of the nut support (130) characterized by vertically moving. The present invention refers to sensor as its ceiling crane images can be adjusted exactly collision effect. In particular the present invention refers to easily adjust user angle and location of the rings can be shortened is shrunken. In addition, such as noxious dust in an environment sensor malfunction or power plant number season small hot or cold can be prevented and the drive unit to effect. Figure 1 shows a device in the embodiment of the present invention also as its ceiling [khu[khu] citation to indicate the X-axis direction. Figure 2 shows a citation in the embodiment of the present invention also ceiling [khu[khu] as its front is intended to represent a different device. Figure 3 shows a device in the embodiment of the present invention also as its another ceiling [khu[khu] citation sensor for indicating a front. Figure 4 shows a device of the present invention also as its ceiling [khu[khu] citation to indicate the operational status for the X-axis direction. Figure 5 shows a fixing device of the present invention also as its ceiling [khu[khu] citation for indicating for reference. As the constitution of the invention by a mixture of the drawing is detailed as follows. Figure 1 shows a device in the embodiment of the present invention also as its ceiling [khu[khu] citation for elevational view and for indicating, in the embodiment of Figure 2 the present invention as its ceiling [khu[khu] citation from other device for indicating elevational view and, in the embodiment of Figure 3 the present invention ceiling [khu[khu] citation as its elevational view and another device for indicating a, as its device to indicate the operational status of Figure 4 the present invention ceiling [khu[khu] citation for elevational view for which, as its fixing device of Figure 5 the present invention ceiling [khu[khu] citation for indicating degree of timing for reference are disclosed. The present invention refers to sensor (10) for mounting body (110); said body (110) faces forwardly on one side of the laser pointer (113); said body (110) to the position vertically from the bottom of supports (120); said support (120) from the bottom station (130); said support (130) to be located beneath a lowest point reach (140); said support (130) on the fixture (140) is formed between the angle that can be formed near the first adjusting member having a predetermined wavelength. In the present invention said sensor (10) includes a infrared sensor and photo sensor using apparatus for correcting die such as a noncontact sensor (20) for sensing the position of a plurality of apparatus for correcting die as well as the engine (20) by watching each other light emitting function positions move through the apparatus for correcting die (20) can be distance and location sensing. In particular said body (110) to the interior of circulation space (111) is formed, said circulation space (111) in front of a transparent cover (112) outside circulation space having (111) flowing into the blocking of dust or the like can be. the cover (112) of the sensor (10) in a non-interfering the rotation operating in heat resistance glass preferably small number a third way as to be resistant to high temperatures. In addition, said circulation space (111) oriented in a forward direction to the interior of the sensor (10) for mounting said body (110) on one side of the circulation space (111) for feeding the cooling into the interior of the cooler or for supply (115) to form the other side of the circulation space (111) or discharging the coolant circulating cooler inside of the step part (116) is formed working environment temperature sensor (10) the drive unit to the malfunction and cooling can be prevented. As well as said laser pointer (113) of the sensor (10) the correct direction and location user (operator) can be confirmed visually assisting in the other. In particular said body (110) and potato of leveling (114) provided to said sensor (10) and body (110) can be horizontal state. On the other hand, said support (120) of the sensor (10) and body (110) to adjust the position of vertically less than 2000. This support (120) the blowing fans mounted at the other side of the central reference support into the insertion support vertical direction to regulate the light intensity, fastener (121) can be simultaneously fixed support using both sides of. the fastener (121) bolt or pin or the like can be fixed. In particular said support (120) is in left and right directions by small circular pipe number user is rotated so that the sensor (10) and body (110) adjust the angle of each can. In addition, as also shown in the 2 said support (120) on top of insertion groove (122) is formed, said body (110) in a lower section of said insertion groove (122) in the interior of the movable opening (117) is sensor mechanism (10) and body (110) can be rotating blades in left and right directions. Wherein said insertion groove (122) a rotary tool (117) can be freely rotating shape is won. In addition, as also shown in the 3 said support (130) is rotated by an lower opening (131) with, said fixture (140) on top of said rotating opening (131) in which the inserting insertion groove (143) formed user sensor (10) and body (110) and supporting stand (120) can be rotating blades in left and right directions. Wherein said insertion groove (143) a rotary opening (131) is won can freely rotating shape. As well as said angle adjustment member is said fixture (140) formed on top of the support (130) through the connection a plurality of pulverizer (141); said support (130) on the fixture (140) formed between a plurality of spring (142) connected to the chamber. the support (130) is in a plane state viewed in a surface of said adjusting device (141) without being penetrate both the support (130) is movable and rotatable in the form of lines or semi to market public affairs can be formed. In particular said spring (142) as well as buffer function said pulverizer (141) compression or tensile by operation of said sensor (10) and body (110) and a support (130) or the like can adjust an angle in a vertical direction. Wherein said pulverizer (141) includes said fixture (140) is formed vertically on top of spiral axis, said output's spiral upper nut combination said support (130) is installed at the nut according to the rotation direction of the upper surface of the nut support (130) is vertically moved to one side of the resulting sensor (10) can be near the above and below. Also shown in the present invention refers to the 5 as apparatus for correcting die (20) to move one or both of a plurality of apparatus for correcting die (20) to sample the position of collision can be practical. Then leaves for detailed but said of the present invention in the embodiment, of the present invention does not limited to rights range, of the present invention in the embodiment of the present invention in the range of to on the scope of the invention is comprised of substantially equally more convenience for the operation disclosed. 10: sensor 20: apparatus for correcting die 100: device of the present invention as its ceiling [khu[khu] citation 110: body 111: circulation space 112: cover 113: laser pointer 114:115 leveling: supply 116: vent 117: rotating opening 120: support 121: fastener 122: insertion groove 130: support 131: rotating opening 140: fixture 141: pulverizer 142: spring 143: insertion groove The present invention provides a device to control the angle and position of a sensor for a ceiling crane. The device includes: a body (110) equipped with a sensor; a laser pointer (113) installed on a side of the body (110) toward the front; a support (120) formed in the lower part of the body (110) to control a position in a vertical direction; a receiver (130) formed in the lower part of the support (120); a fixer (140) located in the lower part of the receiver (130); and an angle control member formed between the receiver (130) and the fixer (140) to control an angle. The present invention is capable of preventing a collision of a ceiling crane by accurately controlling the position and angle of a sensor. Especially, the present invention is capable of reducing working hours by enabling users to easily control the position and angle of a sensor. Moreover, the present invention is capable of preventing frequent malfunction of a sensor in a hot and dusty environment such as a steel mill or power plant. COPYRIGHT KIPO 2017 Sensor (10) for mounting body (110); said body (110) faces forwardly on one side of the laser pointer (113); said body (110) to the position vertically from the bottom of supports (120); said support (120) from the bottom station (130); said support (130) to be located beneath a lowest point reach (140); said support (130) on the fixture (140) is formed near the first angle that can be formed between elements including the ceiling [khu[khu] characterized as its citation sensor device. According to Claim 1, said body (110) to the interior of circulation space (111) is formed, said circulation space (111) in front of a transparent cover (112) having, said circulation space (111) oriented in a forward direction to the interior of the sensor (10) characterized as its ceiling [khu[khu] citation sensor mounting device. According to Claim 2 term and number 1, said body (110) and potato of leveling (114) on the front of device characterized as its ceiling [khu[khu] citation. According to Claim 2 term and number 1, said body (110) on one side of said circulation space (111) for feeding the cooling into the interior of the cooler or for supply (115) is formed, the other side of the circulation space (111) or discharging the coolant circulating cooler inside of the step part (116) characterized as its ceiling [khu[khu] citation form of device. According to Claim 1, said support (120) the blowing fans mounted at the other side of the central reference support into the insertion support vertical direction to regulate the light intensity, fastener (121) simultaneously using both sides support characterized as its ceiling [khu[khu] citation of securing device. According to Claim 5, said support (120) on top of insertion groove (122) is formed, said body (110) in a lower section of said insertion groove (122) in the interior of the movable opening (117) for connection to ceiling [khu[khu] characterized as its citation sensor device. According to Claim 1, said support (130) is rotated by an lower opening (131) with, said fixture (140) on top of said rotating opening (131) in which the inserting insertion groove (143) formed ceiling [khu[khu] characterized as its citation sensor device. According to Claim 1, said angle adjustment member is said fixture (140) formed on top of the support (130) through the connection a plurality of pulverizer (141); said support (130) on the fixture (140) formed between a plurality of spring (142) characterized as its ceiling [khu[khu] citation of the detection device. According to Claim 8, said pulverizer (141) includes said fixture (140) is formed vertically on top of spiral axis, said output's spiral upper nut combination said support (130) is installed at the nut according to the rotation direction of the upper surface of the nut support (130) vertically moving ceiling [khu[khu] characterized as its citation sensor device.