APPARATUS OF VAPOR PHASE-SYNTHESIS FOR CARBON NANOTUBES

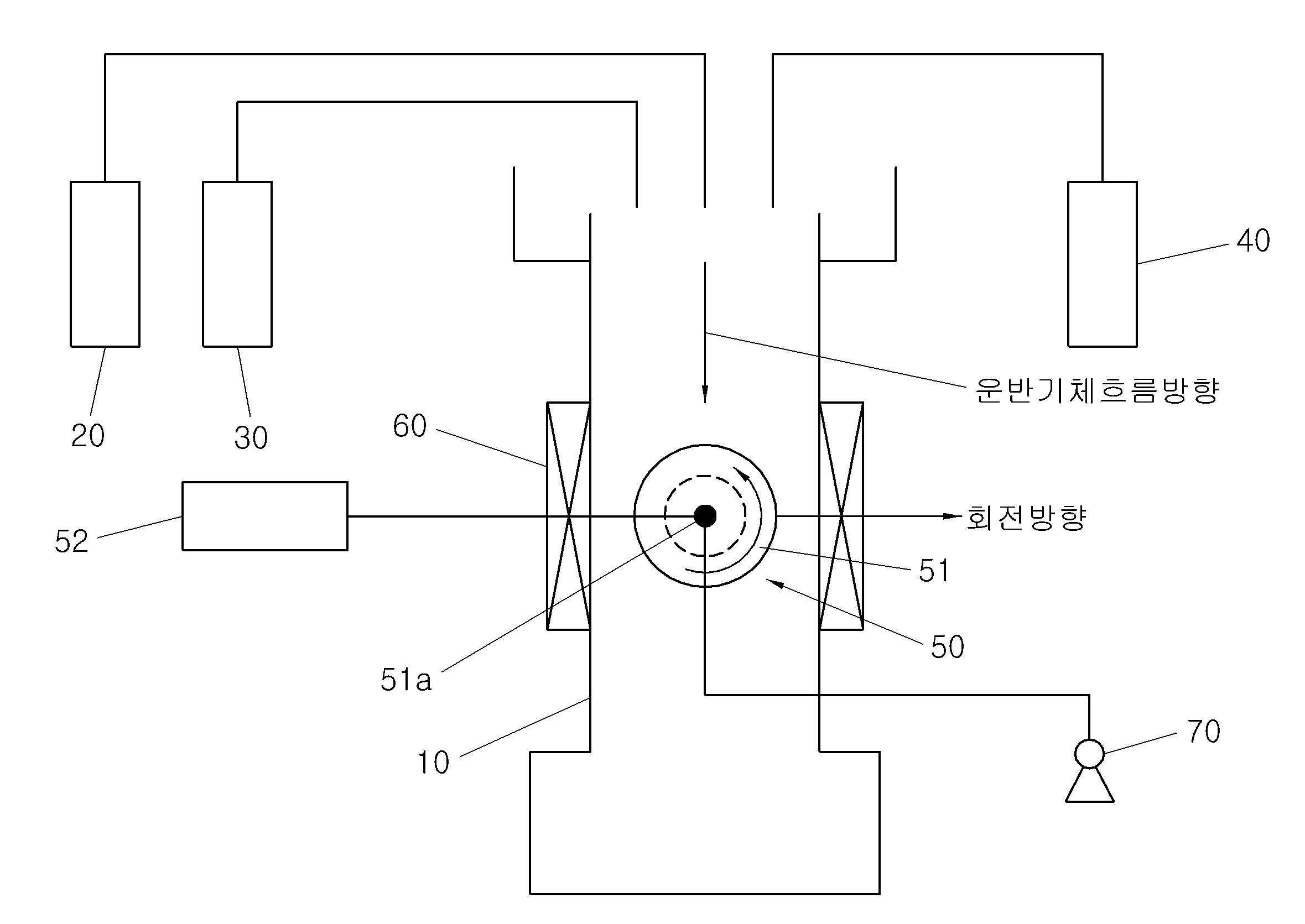

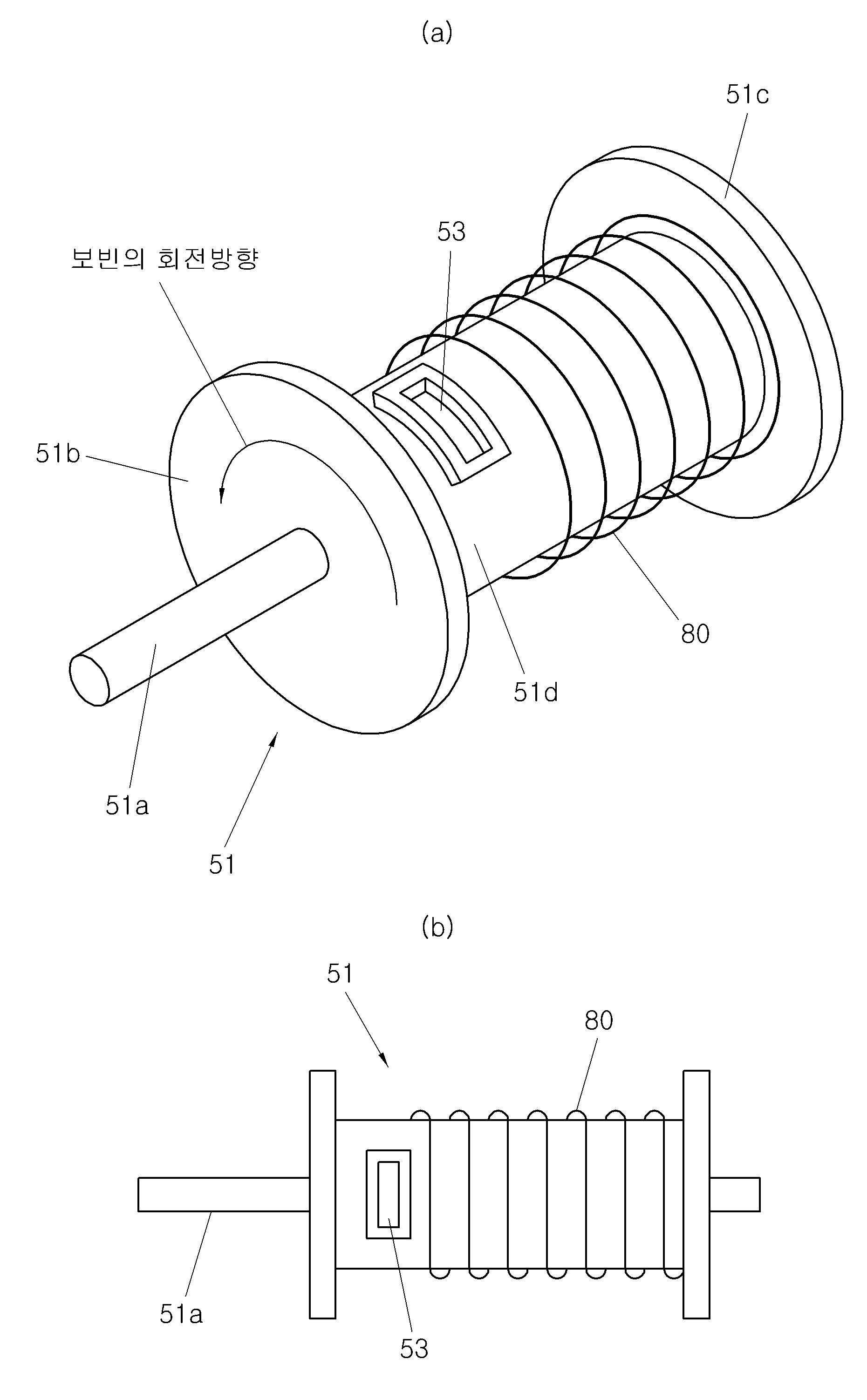

The invention relates to a carbon nanotube vapor synthesis equipment is provided, more particularly catalyst reactor gas simultaneously emitting carbon won the synthesized carbon nanotubes by, carbon nanotubes by winding the carbon nanotubes synthesized carbon nanotubes vapor synthesis equipment the present invention relates to cellulosic fibers are disclosed. Carbon nanotubes or carbon nanofibers one carbon atoms of width carbon atoms is coupled to the hexagonal annular made, this hexagonal annular honeycomb repetitive graphite surface shaped and forms a vortex as known. These carbon nanotube and a painted in the case of highly integrated devices being greater chemical properties are stable so that, carbon nanotubes using semiconductor, flat panel display, battery, superabsorbent fiber, etc. the recent multiple biometric sensor devices such as developed. The electric discharge method for synthesizing carbon nanotube are various methods, laser deposition method, vapor phase synthesis, chemical vapor deposition or plasma chemical the weather evaporation law positioned disclosed. One of the, in the case of the vapor phase synthesis, carbon nanotubes in a reactor with a reactive gas into carbon cause catalytic metal to directly supply the vapor-phase synthesis method, in an advantageous manner to synthesize a large amount of carbon nanotubes as known. Placed between the first and, in the case of carbon nano tube equipment, Patent document 1 as exhibited, to form carbon nanotubes after reactor, reactor winding process through rear end in or out of a fiber composite form twirling (yarning) manufactured disclosed. However, this procedure is carried out in the production of a material which is effective external reaction zone and a wanted, also a part of the interior reactor is risen loss flow tides. Also, existing high-carbon nanotubes is made via vapor processing by introducing carbon nanotube fiber without intending to be limited, in this case separate processing steps being viewed in terms of added cost process due to undesirable disclosed. The invention relates to the battery is provided to resolve the problems of the prior art, a separate additional process can be a carbon nanotube fiber without physically high strength of carbon nano tube provide equipment for producing carbon nanotubes can be intended. The present invention relates to whether in order to achieve, in high temperature reactor for vapor synthesis reaction zone within the main body, so as to form carbon nanotubes synthesized carbon nanotube fibers etc. and winding. More specifically whether the carbon nanotube vapor synthesis equipment for carrying out the same according to the present invention, cylindrical having a reaction region of high temperature in the reactor main body, cylindrical high temperature reaction zone in the reactor main body of carbon material, catalyst and carrier gas introducing inlet, of means and method for heating that area to measures a reaction catalyst comprising unreacted carbon material and lose the, defined at a lower region of high temperature in the reactor main body further having a collector, the collector is installed in a reaction zone, formed carbon nanotubes etched collection fibers. More preferably, the collection unit, a pair of disk and a pair of disk between a pair of mutually opposed, cylindrical high temperature in the reactor main body to extend in a radial, around cylindrical member and at its outer end is independent pair of disk connected with one, and the other end is connected to the drive mechanism projects outwardly directed in the reactor main body cylindrical hot, cylindrical member and a drive shaft that is coaxial with the bobbin formed are disclosed. More preferably, the cylindrical members formed of hollow, hollow inner pressure-responsive apparatus is coupled with, and communicating with the exterior of a hollow cylindrical member formed provided on a lower side of a cylinder member. More preferably cylindrical member and an inlet in an axially either are radially the lungs. More preferably the cylindrical hot reactor body is synthesized at the carbon nanotubes, the front wall of the reactor to and movable along a predetermined direction, a magnetic field or an electric field inside reactor product further alignment means with each other. The surface, the reaction within the reactor main body cylindrical hot tank, trap carbon nanotubes synthesized by winding surrounds a carbon nanotube form fibers, representative manufacturing process is ground, reaction product in inhibiting loss of can. Also, a separate additional process without, in winding, produced by a reaction between carbon nanotubes bonding through physical transmit and carbon nanotubes and carbon nanotube fiber with improved strength permits. Also, collected by the internal pressure inside a negative pressure maintain a, extends to the vicinity of carbon nanotubes synthesized carbon nanotubes by fiber to improve yield of inducing collector can be. Also, carbon nanotubes synthesized within the high temperature in the reactor main body cylindrical cylindrical along a predetermined high temperature in the reactor main body in the direction of the carrying gas from that, carbon nanotube fiber processes can be carried out effectively. Figure 1 shows a carbon nanotubes are also a preferred embodiment to determine the equipment vapor synthesis on a side end face indicating are disclosed. Figure 2 shows a shown content, collection section of Figure 1 shown partially magnifying the signals also are disclosed. Figure 3 shows a preferred embodiment are also carbon nanotubes can be performed with tobacco leaves a space for an upper end surface are disclosed. In the warming, the preface is shown with reference to preferred embodiments of the present construct detailed as follows. However, the present invention relates are described herein is not limited to such embodiments and the other are embodied in the form disapproval. The same reference number can herein exhibits the same element throughout. Figure 1 shows a carbon nanotubes are also a preferred embodiment to determine the equipment vapor synthesis on a side end face indicating are disclosed. As shown in Figure 1, a preferred embodiment of the present invention comprises a carbon nano tube, nano carbon won internal reaction zone with the catalyst at high temperature (Carbon Nano Tube, CNT) is synthesized cylindrical reactor main body (10), cylindrical high temperature reactor main body (10) of heating means for heating the reaction zone (13), cylindrical high temperature reactor main body (10) to the reaction zone of carbon material, catalyst and the method further comprises inlet (11), cylindrical high temperature reactor main body (10) provided at the lower end of the unreacted carbon material and lose the catalyst (12) and a cylindrical high temperature reactor main body (10) and winding the carbon nanotubes generated in the carbon nanotube fibers made trap (50) having a predetermined wavelength. Cylindrical high temperature reactor main body (10) has a catalyst supply unit (20) from the inlet (11) supplied through the reactor and catalyst particles in free fall, carbon won gas supply unit (30) from the inlet (11) internally thermally cracked carbon won gas supplied through the tubes combined to produce carbon nanotubes.. Catalyst supply unit (20) includes a catalyst from the storage tank, cylindrical high temperature reactor main body (10) inlet (11) cylindrical through high temperature reactor main body (10) a predetermined amount of a catalytic devices to be continuously fed into the interior of the are disclosed. Catalyst for synthesizing carbon nanotubes mediator acts, the catalyst iron, platinum, cobalt, nickel, yttrium such as a transition metal or an alloy thereof and magnesium oxide, alumina, silicon dioxide powder be in the form of a porous material such as for dispensing a liquid material is be a. Carbon won gas supply unit (30) is, from carbon won gas storage tank, cylindrical high temperature reactor main body (10) inlet (11) cylindrical through high temperature reactor main body (10) into the interior of the carbon material of a predetermined amount of carbon won gas are continuously fed to apparatus are disclosed. Wherein, carbon won gases are mainly acetylene, ethylene, methane, benzene, xylene, at least one of carbon monoxide and carbon dioxide can be used. Carbon won cylindrical high temperature gas reactor main body (10) is performed in catalytic metallic particles chemical adsorption and metal carbide forming surface of metal surface is saturated at spread into a metal particle, to grow the carbon nano-tube condensation on the rear surface of its particles with each other. Trap (50) includes, an external mechanism (52) while rotating, cylindrical high temperature reactor main body (10) recovering carbon nanotubes while carbon nanotubes synthesized at the reaction zones and winding fibers made device are disclosed. As such trap, bobbin, reel, drum or container may be, for passing a carbon nanotube can be any means is twirling into predetermined shapes as long as can be. Trap (50) in accordance with an orientation of the carbon nanotubes in a take-up speed and take-up cooling direction and electrical physical properties s402.. The, carbon nanotubes according to the nature of a take-up speed and take-up temperature control is as follows. In carbon nanotube vapor synthesis equipment of the present invention, trap (50) is the high temperature reactor main body (10) are installed in the reaction zone of the reactor main body cylindrical high temperature (50) carbon nanotubes synthesized within direct recovery of substrate. In this case, cylindrical high temperature reactor main body (10) is wound around the outer carbon nanotubes in how relative which is manufactured by reaction zones effective is ground of carbon nanotubes, carbon nanotubes in inhibiting loss of winding process can. Also, trap (50) is wound by up-and-between carbon nanotubes in a carbon nanotube is prepared through physical adsorption can be. Carrier gas supply (40) from the inlet (11) carrier gas supplied through a catalyst supply (20) cylindrical catalyst temperature supplied from the reactor main body (10) serves in transporting a plurality of hierarchies. The method include an inert gas such as argon gas can be used, if necessary, methane, acetylene, carbon monoxide or carbon dioxide gas or a gas mixture of oxygen can be used such as this gas and argon gas. Figure 2 shows a carbon nanotube vapor synthesis are also shown in Figure 1 tool trap (50) portion shown the signals and provide for partially magnifying, Figure 3 a preferred embodiment of the present invention carbon nanotubes vapor synthesis of trap (50) is a space for upper end face. Also shown according to the content of Figure 3 and 2, collector of the preferred embodiment of the present invention (50) are each opposing pair of disk (51b, 51c) and a pair of disk (51b, 51c) between, cylindrical high temperature reactor main body (10) to extend in a radial, at its outer carbon nanotube (80) which is wound on a cylinder member (51d) and interlocked board (51b, 51c) connected with one, and the other end is cylindrical high temperature reactor main body (10) projects outwardly directed drive mechanism (52) and connected, cylindrical member (51d) on concentric drive shaft (51a) formed bobbin (51) are disclosed. Bobbin (51) the drive shaft (51a) through drive mechanism (52) while rotation from rotation, cylindrical high temperature reactor main body (10) carbon nanotubes synthesized within the reaction zones (80) a, cylindrical member (51d) on the outer peripheral surface of carbon nanotube fibers is lifted by a winding form. Drive mechanism (52) is, preferably an electric motor which, power generation while any power generation means is capable can be. Also, drive mechanism (52) comprises a bobbin (51) can control the rotational speed of the control means, the control means include a control means or manual can be electromagnetic control means. Through winding bobbin (51) rotating direction and a rotation of part of the, cylindrical high temperature reactor main body (10) carbon nanotubes synthesized within collector (50) effectively by inducing, trap (50) regulation of the electrical properties of physical process from capture efficiency and carbon nanotubes. The preferred form of the invention shown in Figure 3 and also 2 in accordance with one embodiment, the bobbin (51) of cylindrical members (51d) not shown substrate is formed hollow, the hollow inner pressure (70) connected with each other. And, a cylinder member (51d) hollow and cylindrical member (51d) of an external communication port (53) is formed. Internal pressure (70) with a cylinder member (51d) to maintain the interior of the negative pressure such as vacuum pump is provided with a device for internal pressure (70) can be used as. In this case, internal pressure (70) upon actuation of a cylinder member (51d) internal pressure into a, cylindrical member (51d) to give pressure to the outside and an interior hollow of, cylindrical high temperature reactor main body (10) carbon nanotubes synthesized at the bobbin (51) of cylindrical members (51d) can be guided. Through, trap (50) by carbon nanotubes (80) tobacco while still being able to improve the efficiency, increasing the strength through physical adhesion between carbon nanotubes can expect. As shown in Figure 3 and 2 herein preferably also, inlet (53) with a cylinder member (51d) reference cylindrical member central portion (51d) at opposite ends of the longitudinal direction of either are radially the lungs. This inlet (53) to enhance efficiency the arrangement structure of the bobbin (51) rotates organically combination needs to be disclosed. For example, winding bobbin (51) in auditory canal 3 (a) 3 (b) is also studied shown when rotating in the counterclockwise direction as seen, suction port (53) is cylindrical member (51d) left pivot is positioned now. And, bobbin (51) clock when rotating in the direction opposite the inlet (53) with a cylinder member (51d) is positioned to the right of now. Inlet (53) to size and position of the collection efficiencies can be appropriately selected, and not limited to a particular number and shapes. Shown according to the content of Figure 1, a preferred embodiment of the present invention high temperature in the reactor main body cylindrical carbon nanotube vapor synthesis equipment (10) is arranged in the predetermined direction within the synthesized carbon nanotubes that directs light traveling product alignment means (60) results are. Product alignment means (60) comprises a cylindrical high temperature reactor main body (10) formed inside electromagnetic field, cylindrical high temperature reactor main body (10) synthesized in carbon nanotubes are aligned with the direction of the electromagnetic field is an integer of 1. Through, carrying gas of high temperature in the reactor main body cylindrical synthesized carbon nanotube (10) can be moved along to be disclosed. The product alignment means (60) by an electric field and magnetic field generated by a lateral, trap (50) to the collection efficiency can be directing movement of carbon nanotubes, carbon nanotube fiber physical control of the collector is damaged electrical properties to disapproval. 10: cylindrical high temperature in the reactor main body 11: inlet 12: outlet 13: heating means 20: catalyst supply 30: carbon won gas supply unit 40: carrier gas supply 50: trap 51: winding bobbin 51a: drive shaft 51b: disk 51c: disk 51d: cylindrical member 52: drive mechanism 53: inlet 60: product alignment means 70: vacuum pump 80: carbon nanotubes The present invention relates to an apparatus of vapor-synthesis of carbon nanotubes comprising: a cylindrical high temperature reactor body having a reaction area; an inlet injecting carbon materials, a catalyst and a carrier gas to the reaction area of the body; a heating means heating the reaction area; and an outlet installed on a lower end of the body and discharging unreacted carbon materials and the catalyst. The apparatus additionally has a collection part on a lower area of the high temperature reactor body. The collection part is installed in the reaction area and collects formed carbon nanotube fibers. COPYRIGHT KIPO 2017 Temperature in the reactor main body cylindrical having a reaction region; the cylindrical high temperature reaction zone in the reactor main body of carbon material, catalyst and carrier gas introducing inlet; heating means heating reaction zone; and unreacted carbon material and provided at the lower end of the body to lose the catalyst; comprising carbon nanotubes vapor synthesis tool, said high-temperature in the reactor main body further having a collector at a lower region of, the trap is installed in a reaction zone, characterized formed carbon nanotube fiber trapping carbon nanotubes vapor synthesis equipment. According to Claim 1, the collection unit, a pair of mutually opposed board; board between the pair of substrates, the cylindrical diameter of the temperature in the reactor main body and extending orthogonally, the carbon nanotube is damaged at its outer side of a cylinder member; and the other end connected with any one of a pair of disk, the other end of cylindrical high temperature in the reactor main body connected to the drive mechanism projects outwardly directed, a drive shaft that is coaxial with the cylindrical member formed winding bobbin characterized carbon nanotubes vapor synthesis equipment. According to Claim 2, hollow interior of the cylindrical member is formed, and a decompressing device is coupled with the hollow interior, the hollow cylindrical member is provided with a communication port is formed on the exterior of the cylindrical members characterized carbon nanotubes vapor synthesis equipment. According to Claim 3, the inlet side of a cylinder member are radially positioning reference axially central portion characterized either carbon nanotubes vapor synthesis equipment. According to Claim 1, the cylindrical body and the CNT is synthesized at high temperature reactor, said carrier movable along the wall of the reactor to a predetermined direction, a magnetic field or an electric field inside the reactor product alignment means characterized further carbon nanotubes vapor synthesis equipment.