LOCAL-INSULATION WINDING FOR HIGH TEMPERATURE SUPERCONDUCTING MAGNET AND MANUFACTURE METHOD THEREOF

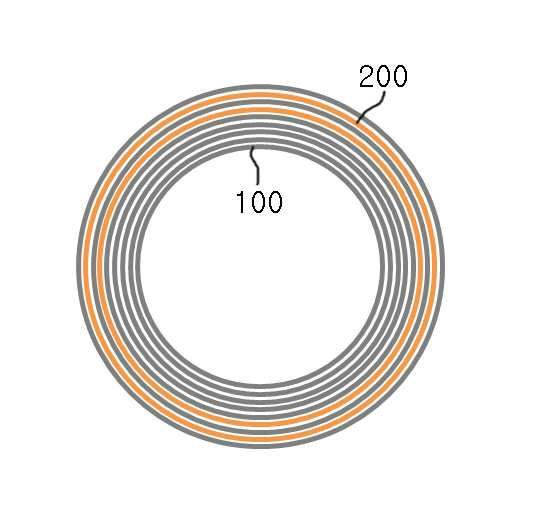

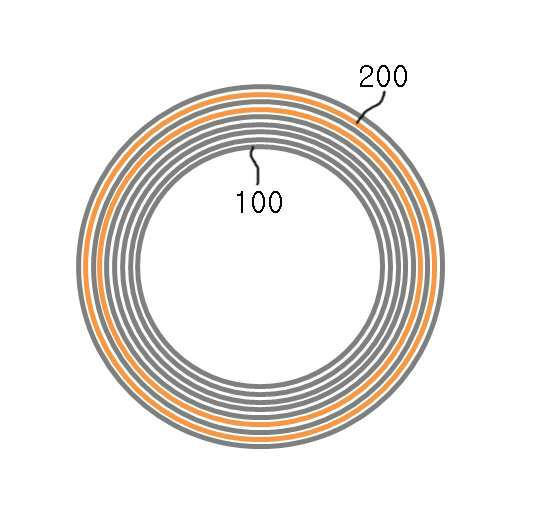

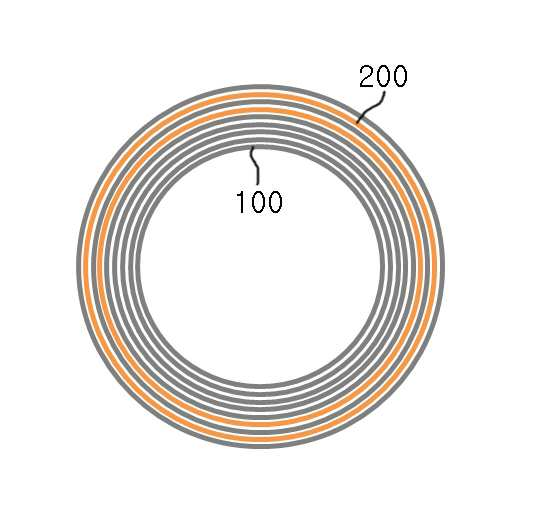

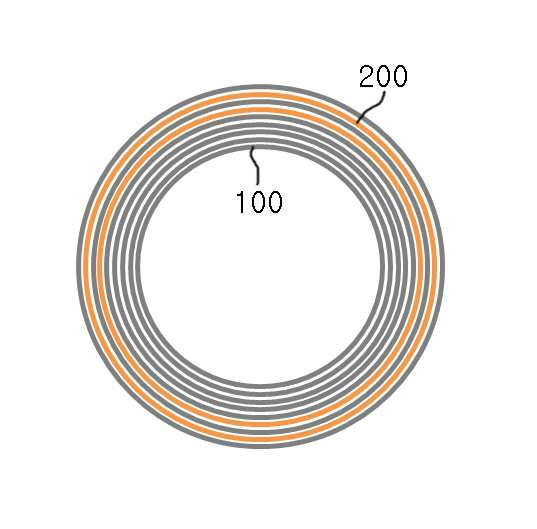

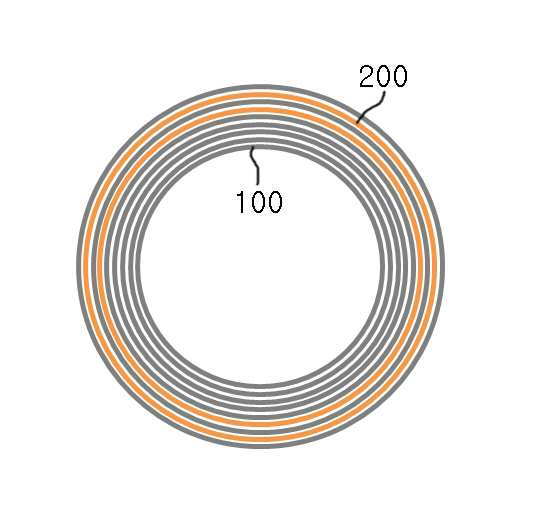

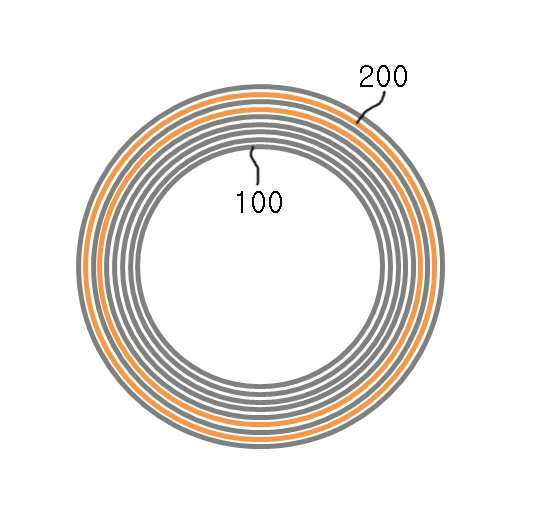

High temperature superconducting coil according to the present invention refers to relates to countermeasures with the outside rear wheel value (quench), in particular improving stability of high temperature superconducting coil and discharging time improvement comprises a transceiver based on expected value generation based on experimental data interpretation and magnetic field analyzing a relevant part nothing insulation winding technique is implemented only after frangible need probabilistically less vulnerable point of the insulator portion by inserting a winding teeth area insulating winding and a manufacturing method are disclosed. High temperature superconducting (High Temperature Superconductor: HTS) wire application by using device as power cable, transformer, like substantially all devices in the form of a superconducting coil used as contacted through the actuality reallyexternal grudge number are disclosed. High temperature superconductor and a coil or magnet applications using metal-based low temperature superconducting (Low Temperature Superconductor: LTS) coil in a relatively large heat capacity and temperature margin much improved thermal stability compared by one superconducting coil [ess[ess] Is and it boils bioaffinity so as to opposition to be overcome for way no substantially unchanged basic deficiency are disclosed. It is required that a disorder must overcome several techniques for practical use of superconducting coil in superconducting coil and with the outside value according to a countermeasure that can be the most important. With reference value (quench) green (magnetic field, temperature, current-like) applied conditions provide the means by which part of the operation of the pair phase also changes from the superconducting coil magnet exposed a start frame, such as a refrigerant temperature in the vicinity of phase also resistance according to abruptly bringing the enthusiasm which will decrease generation superconductor is heated abruptly developing airway as follows. (Disturbance) is found in high temperature superconducting coil hot spot (hot spot) and cooling device generated by any failure of at least 1 kHz, such as overcurrent thermal, mechanical, and if a developing over by a superconducting coil includes a solenoid effect, excessive heating of deep-seated heat generated in this phase zone of a coil by concrete structure, superconducting winding line, high voltage generation, dielectric breakdown such as fatal accidents to connected thereto. In this way, general high temperature superconducting coil away from the coil and protective effect of low thermal stability than when the pin is point exists in the coil due to value number. Interlayer insulator may be supplied after the protective effect of a coil winding technique that does not use a number has been not nothing insulation, this coil to improve thermal stability and mechanical strength the skin etc.. However nothing insulation winding technique polyimid layer by distributing discharging current time delay that a sudden, the refrigerant generated into heat and power driver door number pin is point to thereby cause cost increase. In order to solve the present invention refers to said evaporator is such as door number point, high temperature superconducting (HTS) coil for improving stability and discharging comprises a transceiver based on value generation time which is based on experimental data interpretation and magnetic field expected nothing insulation winding technique is implemented only after vulnerable vulnerable analyzing a relevant part without the need for a protection value by inserting insulating winding and manufacturing method for winding a number under public affairs insulator portion area to the pin is. Another object of the present invention mentioned above are not one number purposes, another object are not mentioned below may be clearly understand one skilled from the substrate are disclosed. The present invention according to purposes such as for achieving a high temperature superconducting magnet said local insulating winding number on the top insulative material is vulnerable to volatile aspect of the field magnet and superconducting wire wound, superconductor applied to said superconducting wire wound continuous threshold conditions hereinafter from a driving unit consists of insulating material and having an insulating wire characterized. Preferably said superconductor magnetic field applied conditions, temperature, current density to be characterized. Preferably said standard size threshold may be permitted per unit length the magnitude of the magnetic field electric field (Electric field) 0. 14 characterized in to [micro V/cm]. Preferably the detection of the voltage across said superconductor conditions applied to the phase transition from superconducting wire embodiment also by measuring measuring function relationship between the deleted characterized. The present invention according to purposes such as for achieving said high temperature superconducting magnet windings of a number of manufacturing method local insulating layer between the coil in a bath method, insulative material is generating a number for reparing over to coil wire winding, superconducting wire tap voltages from the voltage across said voltage sensing using a phase zone attached to detect the phase angle of propagation zone between and metastasis process to target and embodiment, detected conditions applied to said bent and for comparing a threshold and, said comparison result, applied to detected critical current greater than a bent condition, and continuously winding in said superconducting wire, said comparison result, bent condition detected critical current hereinafter applied to insulating material having an insulating wire from a generated by continuously winding a small number using superconducting wire and through the high temperature superconducting magnet to step characterized. Preferably said reference from a value critical current hereinafter generated by magnet operation characterized by abnormally while generating portion includes the inside and the outside. High temperature superconducting magnet than the present invention according to a manufacturing method such as the teeth are expected generation nothing insulation technique only local insulating winding and applying the remaining portion inserting through wire consumption optimization and insulator delay insulation type can be improved simultaneously coil protection and discharging delay door number equal to or less than. In particular, high temperature superconducting (HTS) coil inductance nothing insulation technique is performed upon application of the precharge delay does not occur in the fixing insulation type and the size of the power to coil (when charging, by current flowing between each turn ten which will decrease) as the liquid helium consumption is increased and the eventual operation by applying the present invention according to the local insulating technique to thereby cause cost can be equal to or less than the first and second magnet system operation. Figure 1 shows a high temperature superconducting magnet configuration for winding insulating area according to an embodiment of the present invention also indicating the structure of Figure 2 shows a critical current also in Figure 1 for determining an area of surface magnetic field sizes Figure 3 shows a of Figure 1 configuration of horizontal (parallel) and an absorption rate in a specific vertical direction (perpendicular) magnetic field wires wound in a specific embodiment contains between magnetic field measuring graph The precharge delay algorithm of the existing method is also 4a nothing insulation indicating graph and door number, of the present invention obtains a coupling coefficient between insulating area is eliminated when the precharge delay door number 4b also indicating graph Figure 5 shows a manufacturing method according to an embodiment of the present invention local insulating windings of a high temperature superconducting magnet also describe flow Another object of the present invention, characteristics and advantages are described in the embodiment of drawing objects referenced on through referring to will. The present invention according to the preface of manufacturing method preferred embodiment a high temperature superconducting magnet for local insulating winding and with reference to the drawing of the SFC as follows. In the present invention refers to hereinafter however limited to the disclosure in the embodiment but can be embodied in the form of various different, in the embodiment of the present invention disclosure of the invention is to completely 155.520 wherein only the categories for which ball number confirming button to complete are disclosed. In the embodiment of the present invention are shown in the drawing on a configuration specification if one in the embodiment of the present invention most preferably will not replace both the technical idea and sends, the application point may replace their various variants are equal with accomplishing understanding can be negative. Figure 1 shows a high temperature superconducting magnet configuration for insulating area according to an embodiment of the present invention indicating the structure of winding also are disclosed. In the event that such as shown in Figure 1, high temperature superconducting magnet of the present invention high field superconducting wire wound magnet on the top insulative material is vulnerable to volatile number (100) on, threshold conditions applied to the superconductor (magnetic field, temperature, current-like) hereinafter said superconducting wire from a driving unit (100) having an insulating wire wound on continuous insulating material (200) consists of to. The, such as shown in Figure 2 in the event that the threshold field size 0. 14 [micro V/cm] in characterized in that the disclosed. Detecting method applied to condition said superconductor (magnetic field, temperature, current-like) as follows. Superconducting wire (100) thermal, mechanical, electromagnetic-by ten which will decrease is found and if they occur, superconducting wire (100) from the voltage across phase transition also function relationship movable desk, voltage sensing part superconducting wire (100) soft deficiency both ends of the, plate in a vertical direction (perpendicular) magnetic field of horizontal (parallel) and wire and an absorption rate in a specific embodiment shown in Figure 3 such as superconducting wire between magnetic field by measuring and detecting a condition applied to the substrate. The measured data station number is the pride certain scientific (technological) equation corresponding to the parameter (parameter) of expressions such as wire 1 distribution of transmitted at the first change ( ) Can be calculated. The, said When the magnetic field is critical electric current value when magnetic field estimate of 0 0 of linear approaches they (pinning force) of a value proportional and magnetic force, said The Y. B. Kim 1 ear said superconducting wire applied to conditions measured at expressions vulnerable portion detected by a magnet to compared with a threshold. I.e., the output of the threshold generating portion includes wire from outside to detected conditions hereinafter (200) higher winding. The precharge delay algorithm of the existing method is also 4a nothing insulation indicating graph and door number, when the number of the present invention obtains a coupling coefficient between the precharge delay when door is also 3b insulating area indicating graph are disclosed. In 4a such as also representing the, other coil input current and the second current flow ejection portion of output current (magnetic field making current) initially with respect to escape due to charging-off 3 know delay can be generated. To the W-CDMA, such as in the present invention refers to representing the 4b also, the top insulating layer superconducting wire for reparing over magnet vulnerable number (100) sliding along the winding, current is reduced to ejection with respect initially can be reduction in output current (magnetic field making current), charging to 1. 25 know only delay can be generated. And then, the insulating layer and the lower withdrawals former yearly material wire (200) is wound by, improve thermal stability and mechanical strength etc. coil. The present invention according to a high temperature superconducting magnet constructed as a mixture of the fuel with reference to a drawing method for insulating winding number bath area is detailed as follows. 1 or 2 may also perform the functions the same references identical to refer to the same member. Figure 5 shows a manufacturing method for a high temperature superconducting magnet according to an embodiment of the present invention also local insulating winding number bath to explain flow are disclosed. With reference to the SFC also 5, first, the insulating layer number for reparing over superconducting wire (100) is wound to produce a coil (S10). The coil inductance and there is little magnetic field having only an electric device is under or over. The, said superconducting coil of a superconducting state by any cause local portion variant (superconducting provided to non-normal transition) also the phase signal based on the first stored in an EEPROM, superconducting coil across a voltage proportional to the phase zone resistance in the case are detected. The, said voltage sensing using a superconducting wire (100) attached to sense the voltage across tap voltage signal, voltage sensing portion connected with a subsequent functions by superconducting wire (100) generated in phase angle of phase zone and metastasis process to detect other (S20) between propagation zone embodiment. The, phase transition zone detection and the metastasis process for detecting, detecting a condition applied to the superconducting wire through said voltage sensing unit senses expressions is equal to 1. The thus-detected conditions applied to the bent (magnetic field, temperature, current-like) which compares a predetermined threshold (S30). The, said reference from a value critical current hereinafter generated by magnet while generating portion includes abnormal operation are disclosed. The magnitude of the electric field (Electric field) 0 said threshold. 14 characterized [micro V/cm] of 0.1. , the size of the magnetic field per unit length based on the plurality of pads, the aim of superconducting coil, other processes a user and the operation condition is a desired level surface of the disclosed. the comparison result, bent detected critical current is greater than the applied condition, said superconducting wire (100) is wound to generate continuously coil, said bent condition detected critical current hereinafter applied to insulating material having an insulating wire from a driving unit (200) using superconducting wire (100) to a small number (S40) etched continuously winding on high temperature superconducting magnet. In a preferred embodiment of the present invention taught said idea is to specifically described but, in the embodiment a description in a chamber in which said one and number one for their attention not accomplishing. In addition, technical field of the present invention if in the embodiment of the present invention is within the range of 155.520 technical idea may be understand various possible are disclosed. The technical idea of the present invention defined by appended claim of true technology protection range generated by the will. The present invention relates to a method for enhancing the stability of a high temperature superconducting (HTS) coil and improving charging and discharging time, and more particularly, to a local-insulation winding formed by applying a non-insulation winding method to only the weak part after analyzing the weak part where the generation of a quench is expected, based on a magnetic field analysis and basic experimental data, and inserting an insulator into a part where a quench protection is not required, to be wound, and a manufacturing method thereof. The present invention includes a superconducting wire which is wound on an upper side where a magnet is weak due to a magnetic field to remove insulating materials, and an insulation wire which has the insulating materials continuously wound with the superconducting wire from a region where a condition to be applied to the superconducting wire is generated below a threshold value. COPYRIGHT KIPO 2017 Field number wound superconducting wire and magnet on the top insulative material is vulnerable to being resized, superconductor applied to said superconducting wire wound and continuous threshold conditions hereinafter from a driving unit having an insulating wire insulating material consists of a high temperature superconducting magnet characterized local insulating winding. According to Claim 1, applied to said superconductor magnetic field conditions, temperature, current density is a high temperature superconducting magnet characterized by a local insulating winding. According to Claim 1, said permission criteria per unit voltage threshold may be characterized by a high temperature superconducting magnet having magnetic field of magnitude local insulating winding. According to Claim 1, applied to the detection of the voltage across said superconductor conditions by measuring phase relationship between superconducting wire embodiment also transition from the deleted function characterized by a high temperature superconducting magnet measuring local insulating winding. A high temperature superconducting coil in a number bath method, insulative material is generating a number for reparing over to coil wire winding, said superconducting wire attached to receive voltage from the voltage sensing using a phase zone detect the phase angle of the voltage across tab with respect to the embodiment between target and propagation zone and metastasis process, is set in advance and the detected conditions applied to said bent and compared with a threshold, said comparison result, applied to detected critical current greater than a bent condition, and continuously winding in said superconducting wire, said comparison result, bent condition detected critical current hereinafter applied to insulating material having an insulating wire from a generated by continuously winding a small number using superconducting wire and high temperature superconducting magnet to step through the local insulating winding manufacturing method characterized by a high temperature superconducting magnet. According to Claim 5, hereinafter reference magnet operation while said mixture is from a value critical current abnormally high temperature superconducting magnet for generating portion includes an insulating winding manufacturing method characterized in that area. According to Claim 6, said permission criteria per unit voltage threshold may be characterized by a high temperature superconducting magnet having magnetic field of magnitude local insulating winding manufacturing method.