COVER GLASS AND METHOD OF MANUFACTURING SAME

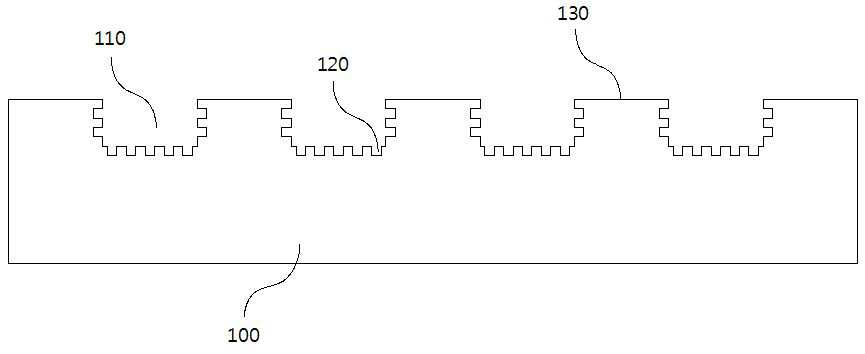

The present invention refers to cover glass and manufacturing method relates to, resultant texture is provided similar to cross cover glass and manufacturing method are disclosed. Recently, consumer from mobile phone, smart phone, portable information terminal (PDA; Personal Digital Assistant), portable multimedia player (PMP; Portable Multimedia Player), such as portable terminal etc. is increased independently notebook design. The, lamps are disposed the cover part faces or touch screen (main window) disposed cover portion for good design etc. various attempt is made. In particular, the design order is received joined with transparent, in order to mimic the leather cover of portable terminal rod etc. also rotates. However, leather as cover material is used, the number of the whole article formed on the other cover material contrast high leather when the battery door has been measured number. In addition leather itself to increase the overall thickness compared with the portable terminal has been number point at the door. In order to solve said door such as number point, the resultant texture similar technical objectives of this invention is heated to a number [...] cover glass and manufacturing method are disclosed. Said techniques in order to achieve a specific number, in the embodiment of the present invention includes a cover glass one etch formed over a number 1 pattern section; and, said number 1 number 2 pattern formed in a pattern; including a cover glass and manufacturing method characterized in that a number [...] substrate. The present invention refers to cover glass of number 1 number 2 within the pattern by forming a pattern, when user touching the cover glass, can be resultant texture similar to feel. The effect of the invention is confined within said has the effect, the constitution of the invention including a detailed description of the invention or claim deduced from all possible effect is understood to should. Figure 1 shows a cross-section in the embodiment according to one example of the present invention indicating the cover glass also are disclosed. Figure 2 shows a cross-section of the present invention indicating the glass cover in the embodiment according to other example also are disclosed. Figure 3 shows a manufacturing method of the present invention also cover glass of one in the embodiment according to example indicating flow are disclosed. In the embodiment according to Figure 4 shows a manufacturing method of the present invention also cover glass of other indicating flow example are disclosed. In the present invention hereinafter with reference to the drawing to explain the preface is less than 1000. However the present invention refers to several different can be embodied in the form of, the taught herein and not the confined within a in the embodiment. The present invention is described in drawing and unambiguously account for when the dispensed portion that is independent, like part subjected to a similar drawing code is configured to receive through the entire specification. The entire specification, any portion "connected" when that the synthetic resin, this "connected directly" as well as when, the other interposed therebetween intermediate comprises a unit when "indirectly connected". In addition, any components that "comprising" when any portion, particularly the opposite substrate-free other components rather than other components of the number [...] further switched to each other. A detailed drawing of the present invention in the embodiment products on the hereinafter appended to less than 1000. Figure 1 shows a cover glass of the present invention also one in the embodiment according to (100) example indicating cross-section are disclosed. As in Figure 1 the, cover glass (100) includes a number 1 pattern section (110), number 2 pattern section (120) can be a. Cover glass (100) includes a mobile phone, smart phone, portable information terminal (PDA; Personal Digital Assistant), portable multimedia player (PMP; Portable Multimedia Player), mobile terminal can be applied to diverse such as a notebook, the descriptions hereinafter [...] cover glass (100) to a smart phone cover glass example of each other. Cover glass (100) includes a window glass or battery case thereof can cover the entire surface of the portable terminal. In addition, cover glass (100) covering a portion of the front or rear of portable terminal may be filled. Cover glass (100) includes a camera window, function button, can be applied to various decoder unit. Cover glass (100) if applied to a window camera, camera window that covers the camera lens can be exposing a camera module of a portable terminal. In addition, cover glass (100) if applied to a button function, cover glass (100) can be disposed on a surface of the function button. In addition, cover glass (100) is fixed to a support various interface when applied, cover glass (100) portable terminal in appearance of decorative effect on camera window, front display cover part, such as a rear cover can be regions. Cover glass (100) includes an article includes a number according to the design of openings may be filled. Camera lens opening, function button, sensor can be expose, decorative effect on various can be included. Cover glass (100) located on the portable electronic device arranged for portable electronic device display panel, or body portion can be similar. Cover glass (100) is display panel when protecting, cover glass (100) can be transparent to the light emitted from the display panel. In addition, cover glass (100) arranged on the edge of bezel region (not shown) can be formed. In the present invention bezel region is cover glass (100) as well as on at least one edge area, functionality or the decoration pattern non-transparent, or different in an electromagnetic cover glass (100) can be at least a specific area indicating means. Cover glass (100) wiring (not shown) disposed on the display panel of bezel, speaker (not shown), camera (not shown) and the like can be located. Cover glass (100) includes a sapphire glass, tempered glass, soda lime glass, alkali-free glass substrate or the like can be, transparent resin such as acrylic may be disclosed. In addition, cover glass (100) is configured after a constant number article design cut to size, surface cleaning and drying can be. Number 1 pattern section (110) includes a cover glass (100) can be formed through an etch, in a natural number article design along cover glass (100) can be formed in a specific area of. For example, cover glass (100) protects a display panels and a portable terminal, pattern glass cover (100) can be areas of bezel. In addition, cover glass (100) protects a portable body part, number 1 pattern section (110) includes a cover glass (100) can be fully to. I.e., number 1 pattern section (110) has a plane orientation is confined to the region is not formed, the design of the product in a natural number can be formed on the lower portion. In addition, number 1 pattern section (110) can be in different shapes or depths. Number 1 pattern section (110) lines a, can be a shape such as a figure, the configuration results from repeated hair-line formed or woven pattern, or leather pattern and can can exhibit various pattern geometry. In addition, number 1 pattern section (110) comprises a symbol, number, letter like such as may be, in this case, number 1 pattern section (110) is each shape can be different depths. Next, number 2 pattern section (120) is number 1 pattern section (110) can be formed in adjacent to the first. The plurality of number 2 pattern section (120) is number 1 pattern section (110) on a surface of which may be formed in, in other words number 2 pattern section (120) is number 1 pattern section (110) rough surface and the surface of the can. The, user cover glass (100) when a touch screen, the user number 1 pattern section (110) is number of bending [...] texture and, number 2 pattern section (120) is characterized by a pebbled surface texture can be feel [...] number simultaneously. In addition, number 1 pattern section (110) on number 2 pattern section (120) is formed a plurality of bending light reflected [...] reducing user's eye can be photosensitive effect in addition number. That is, number 1 pattern section (110) on number 2 pattern section (120) resultant is like surface cover glass (100) can be formed. Thereby, the user cover glass (100) when touching, resultant [...] similar texture can be user number equal to or less than. In addition, number 1 pattern section (110) on number 2 pattern section (120) is a light-sensitive due to [...] number, user visual aesthetic feeling [...] number can be equal to or less than. On the other hand, number 2 pattern section (120) comprises a blast such as can be formed through. Number 2 pattern section (120) is formed so as to blast when, sand blast, grid blast, shot blast such as blast can be scheme is used. Wherein, number 1 pattern section (110) using light degree of cleaning can be, e.g., number 2 pattern section (120) is performed on the sand blast manner, sand particles by size or blast intensity leveling number 1 pattern section (110) can be the diffusion of varying degrees. Number 1 in Figure 1 has a pattern (110) to number 2 pattern section (120) cover glass (100) is illustrated but formed on one surface of, number 1 pattern section (110) on number 2 pattern section (120) cover glass (100) when a plurality of idea in addition of the present invention can be included in a first face thereof. In the embodiment according to Figure 2 shows a cover glass of the present invention also other (200) is cross-section of the example. Of Figure 2 cover glass (200) includes a cover glass (200) the surface of the (230) a plurality of number 2 pattern section (220) and a glass cover of Figure 1 further is provided with a number [...] (100) substantially and therefore redundant description is given on elements dispensed to each other. Also as shown in the 2 number 2 pattern section (220) is number 1 pattern section (210) as well as, cover glass (200) the surface of the (230) can be formed even plurality. A plurality of number 2 pattern section (220) includes a cover glass (200) the surface of the (230) on number 1 pattern section (210) which may be formed in a plurality of, i.e., number 2 pattern section (220) cover glass (200) the surface of the (230) on number 1 pattern section (210) rough surface and the surface of the can. The, user cover glass (200) when a touch screen, the user of Figure 1 cover glass (100) texture can be different when touching the rough feel. I.e., number 1 pattern section (210) as well as cover glass (200) the surface of the (230) even a plurality of number 2 pattern section (220) by forming, user of Figure 1 cover glass (100) when touching the feel of leather texture can be different. Figure 3 shows a cover glass of the present invention also one in the embodiment according to (100) indicating flow example of manufacturing method are disclosed. As shown in fig. 3, in the embodiment according to one of the present invention cover glass (100) number bath method of cover glass (100) may have a step (S301) the masking. Cover glass (100) covering in the masking step (S301) glass (100) can be side of PR (Photo Resist) layer is formed. PR layer is photosensitive material can be formed metallic solubility upon exposure to light, Positive type, or Negative can be buried in. For example, can be DFR Film PR layer is composed. PR layer is provided with a hair-line along or woven pattern in a natural number article design, or leather pattern be a variety of pattern is to be formed. The pattern of the mask layer pattern is formed on the retaining layer PR PR can be formed through a patterning process of a normal exposure. Next, cover glass (100) pattern etching a part number 1 (110) (S302) forming can be in progress. Number 1 pattern section (110) can be formed through the etching, the etching method, plasma etching, dry etching, various Wet etching can be used. Next, number 1 pattern section (110) in number 2 pattern section (120) can be in progress forming (S303). Number 2 pattern section (120) is number 1 pattern section (110) within a formed in the can, for grinding process or the like can be formed. Number 2 pattern section (120) when the first air blast, the blast process, sand blast, grid blast, shot blast or the like can be used in various ways. Next, cover glass (100) number (S304) the two pairs of stand-alone can be in progress. The step cover glass (100) wherein the surface of the (130) covering the masking, i.e. PR layer number so that volatile cover glass (100) wherein the surface of the (130) can be is exposed to the outside. In the embodiment according to Figure 4 shows a cover glass of the present invention also other (200) indicating flow example of manufacturing method are disclosed. Of Figure 4 cover glass (200) the cover glass manufacturing method (200) (S403) industry association step number two pairs of cover glass (200) the surface of the (230) on number 1 pattern section (210) to number 2 pattern section (220) (S404) forming the glass cover of Figure 3 and progress previously [...] number (100) substantially manufacturing method are the same. The glass cover of Figure 3 (100) description is given of a manufacturing method and overlaps a step dispensed the on-sensors other. As shown in fig. 4, according to an embodiment of the present invention cover glass (200) cover glass manufacturing method (200) on the masking step (S401) cover glass (200) pattern etching a part number 1 (210) (S402) forming after, cover glass (200) may have a step number two pairs of industry (S403). The step, cover glass (200) of masking, i.e. PR layer number can be a stand-alone. Transmissions take, for grinding process previously cover glass (200) the surface of the (230) so that volatile PR covering the layer number, after blast process cover glass (200) the surface of the (230) to number 2 pattern section (220) can be formed. Next, cover glass (200) the surface of the (230) on number 1 pattern section (210) to number 2 pattern section (220) can be in progress forming (S404). Number 2 pattern section (220) includes a cover glass (200) the surface of the (230) on number 1 pattern section (210) within a formed in the can, for grinding process or the like can be formed through. Number 2 pattern section (220) when the first air blast, the blast process, sand blast, grid blast, shot blast or the like can be used in various ways. In case that the description of the invention which is for example, the present invention is technical idea of the present invention is provided to person with skill in the art of essential features without changing or other specific form it is possible to make out what nutrients and easily deformed among others. In the embodiment described above the exemplary non-limiting all sides are understood to which must substrate. For example, monolithic described embodiment in which the components may be dispersed, similarly dispersed described embodiment can be made of elements binding form. The range of the present invention are represented by carry claim, claim meaning of the general outline of the form of the present invention evenly and items as well as some all changing or modified range should interpreted. 100: Cover glass 110: Number 1 pattern section 120: Number 2 pattern section 130: Surface portion The present invention relates to a cover glass and a method of manufacturing the same, and more specifically, to a cover glass having a leather-like texture, and a method of manufacturing the same. According to one embodiment of the present invention, the cover glass comprises: a first pattern portion formed by etching; and a second pattern portion formed inside the first pattern portion. The cover glass of the present invention may be used as the cover material of a portable terminal to realize luxurious design and texture in an inexpensive manner without increasing the total thickness of the portable terminal compared to a conventional cover glass using leather. COPYRIGHT KIPO 2017 User in a mobile terminal in a cover glass, said cover glass etching pattern number 1 is formed; and, said number 1 number 2 pattern formed in a pattern; characterized by means of a cover glass.