BENDABLE SIDE LIGHT EMITTING STRUCTURE USING LED LAMP

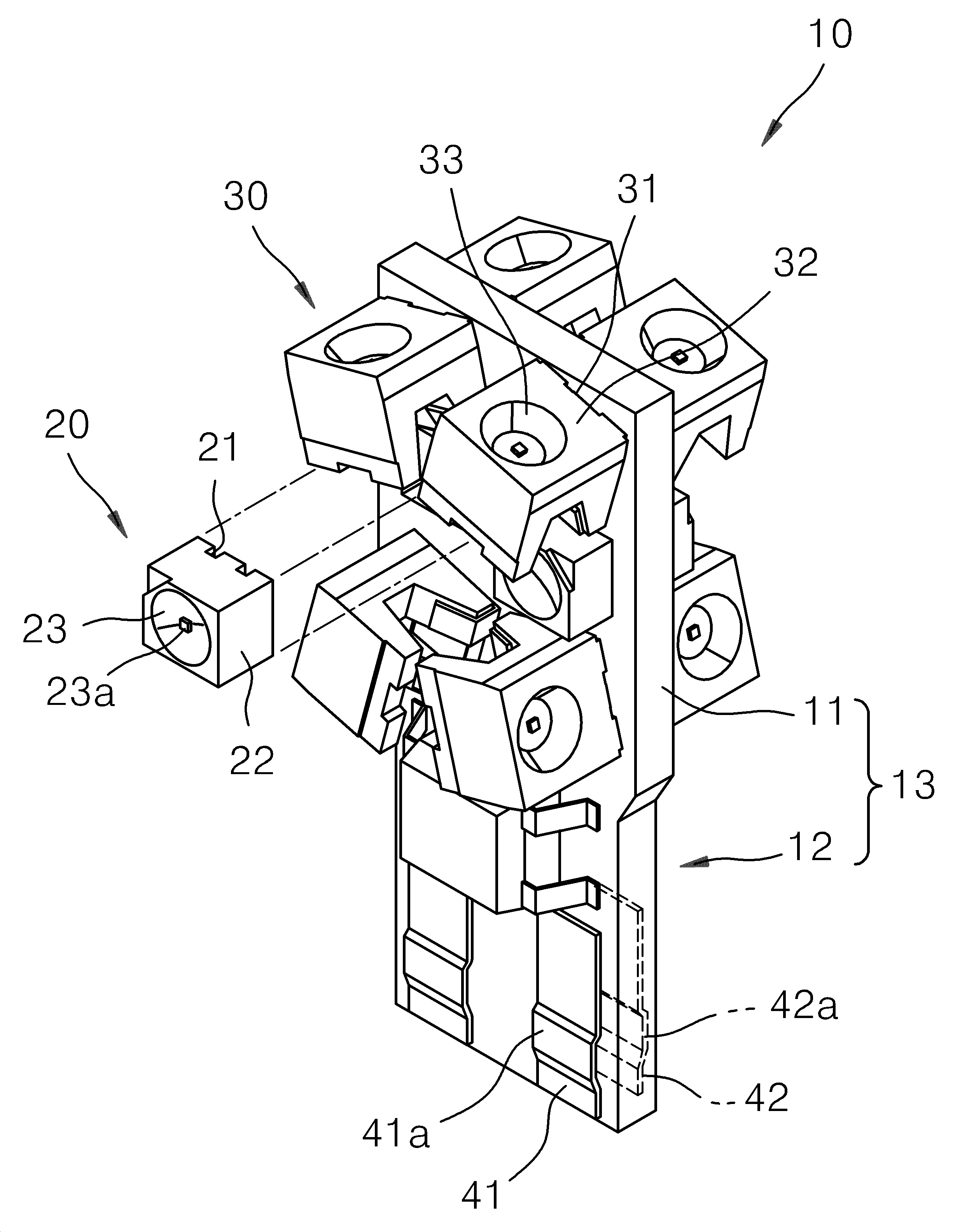

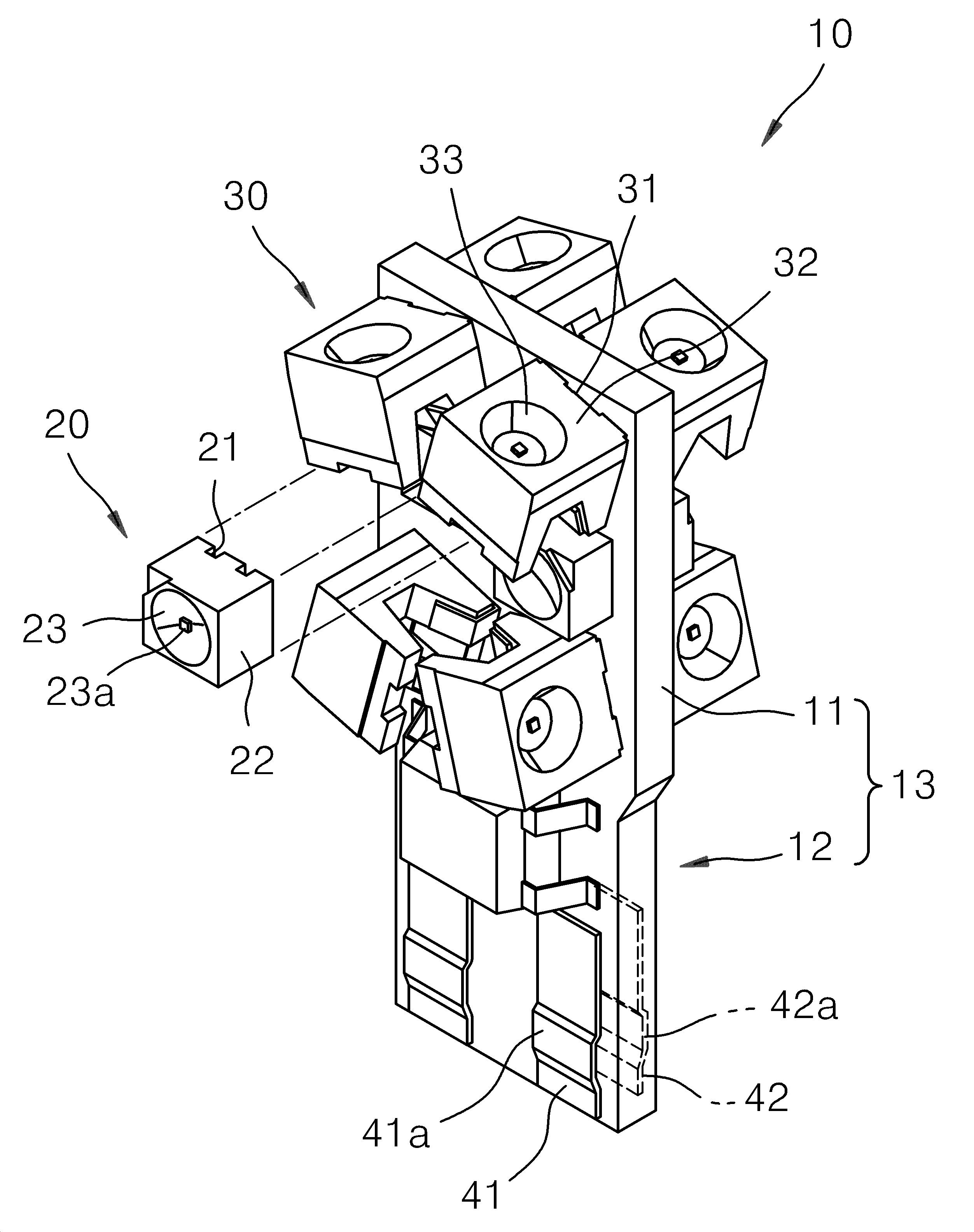

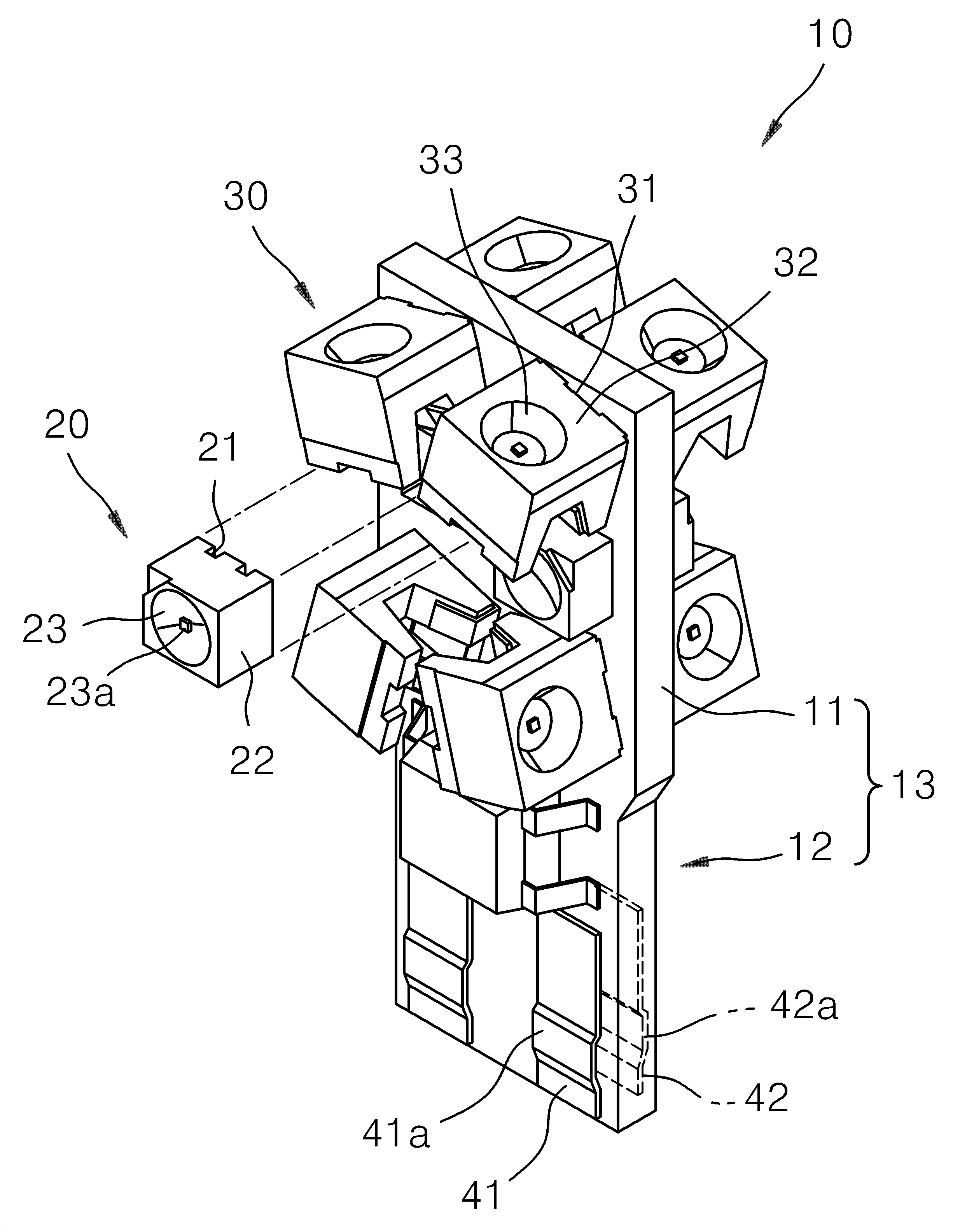

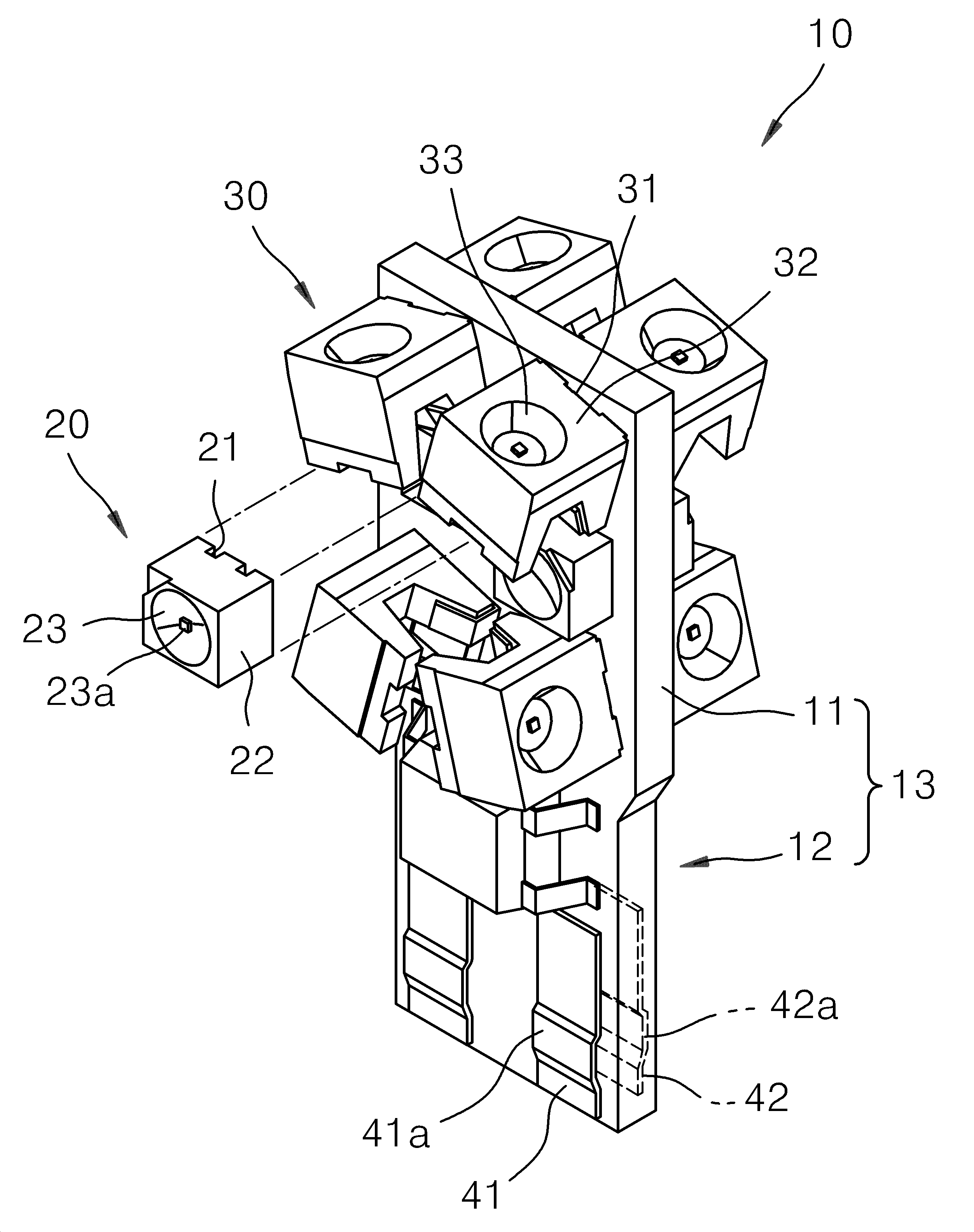

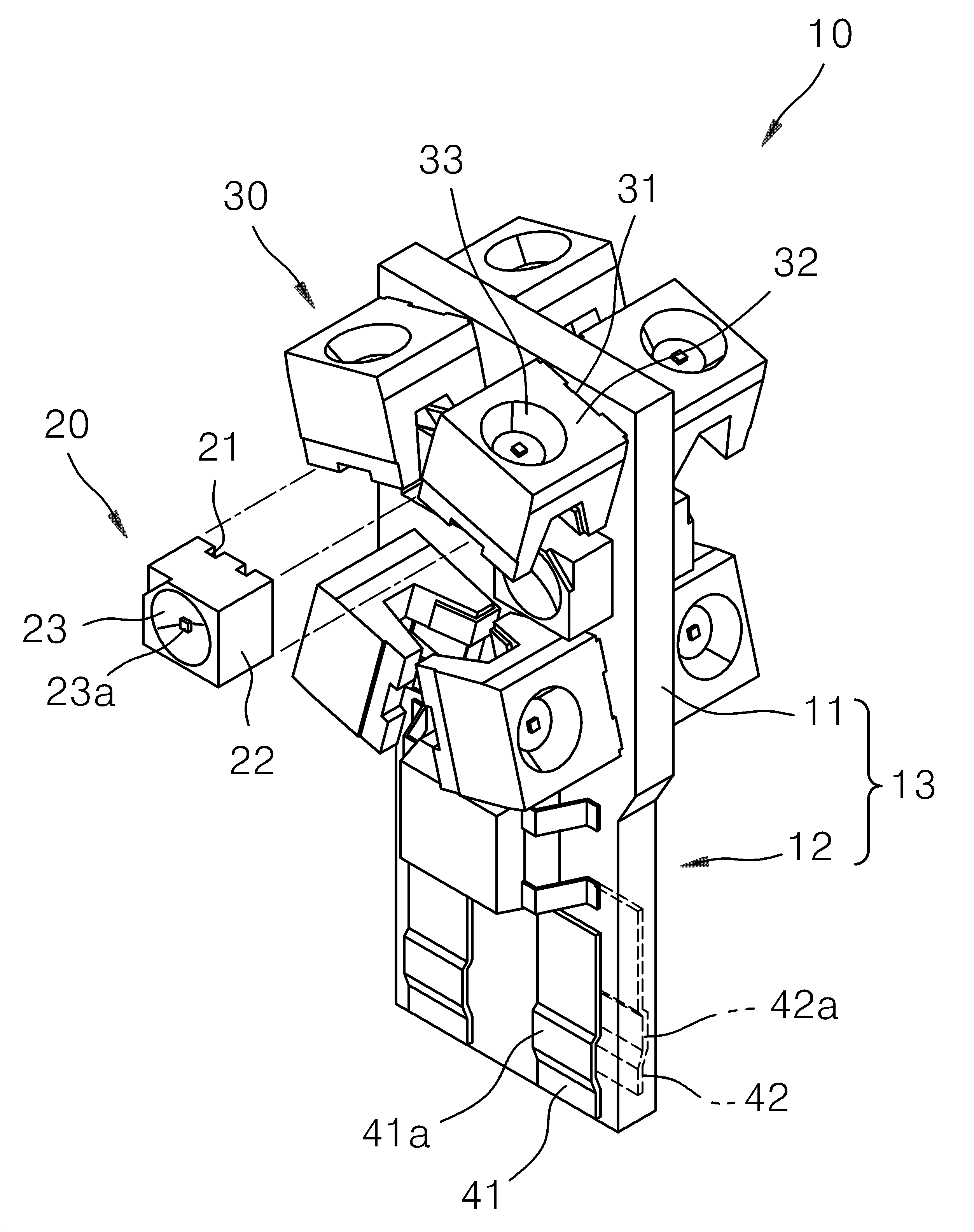

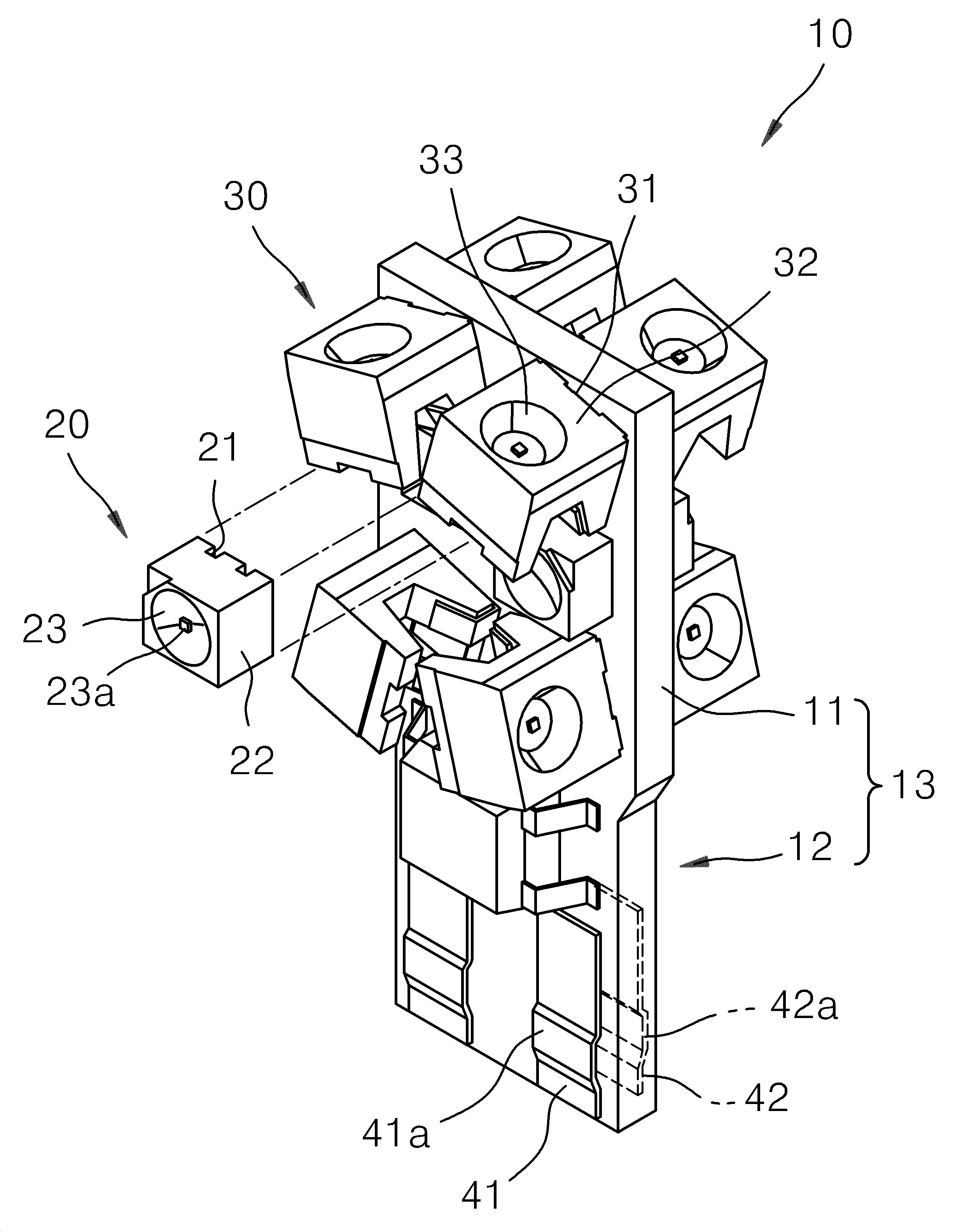

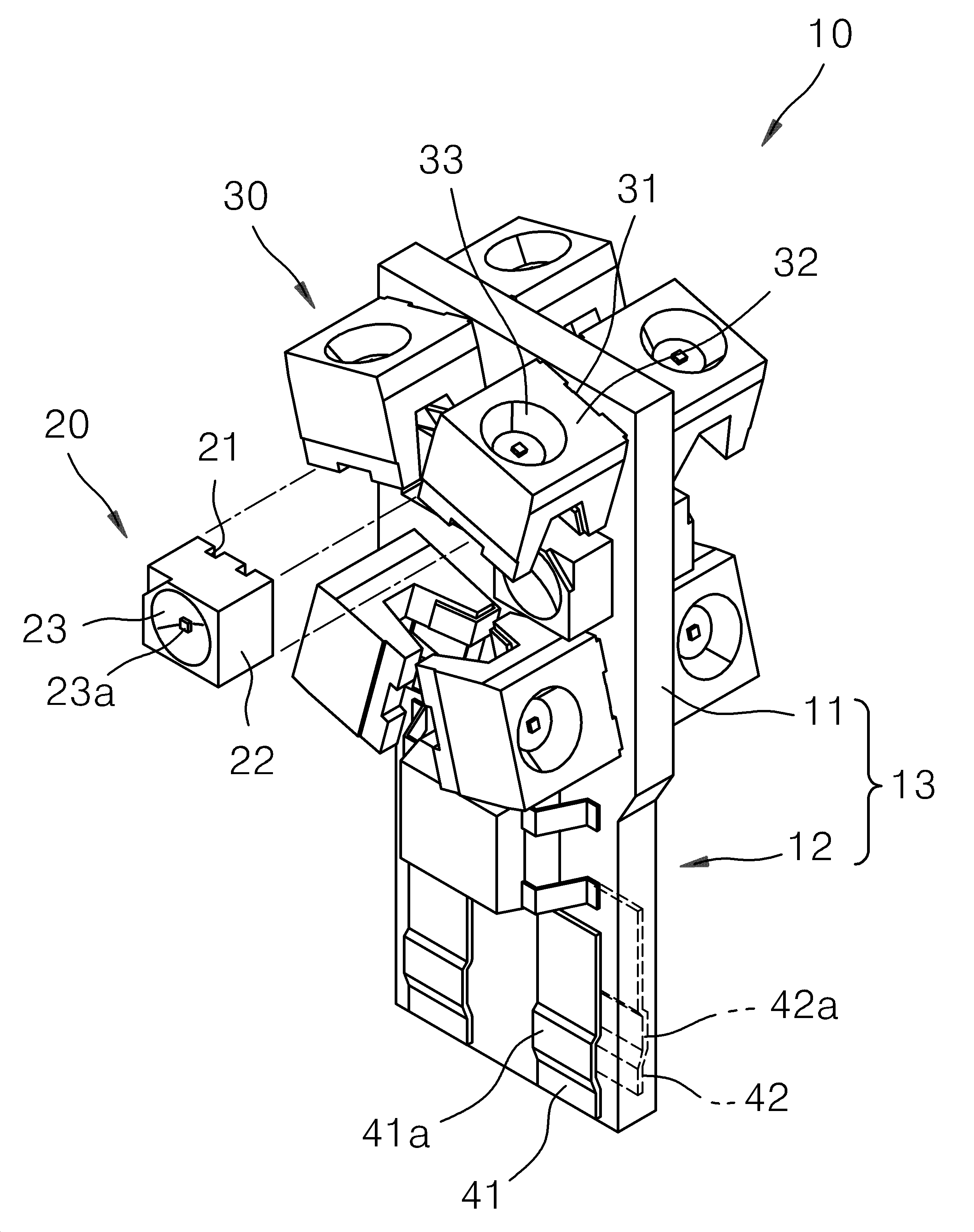

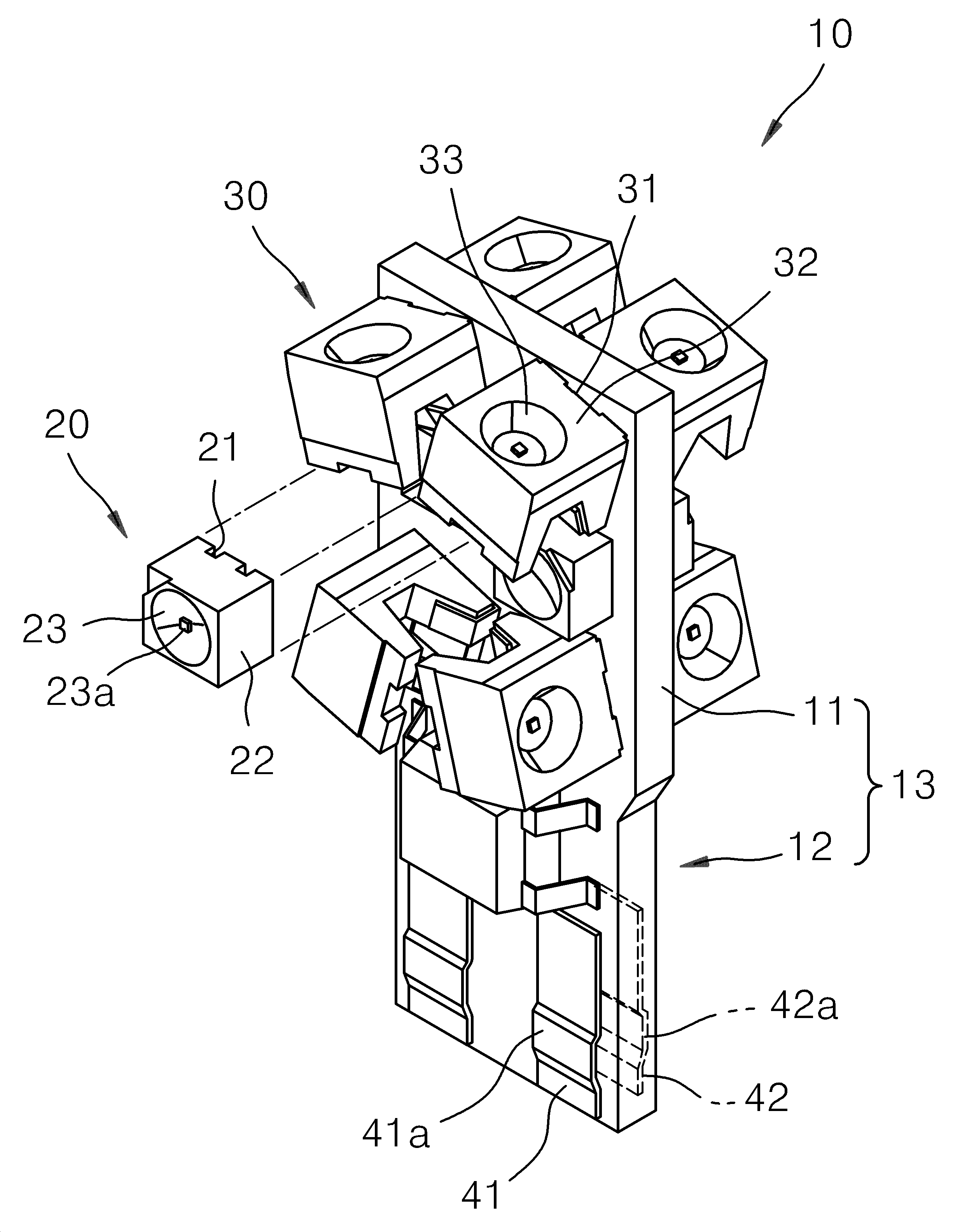

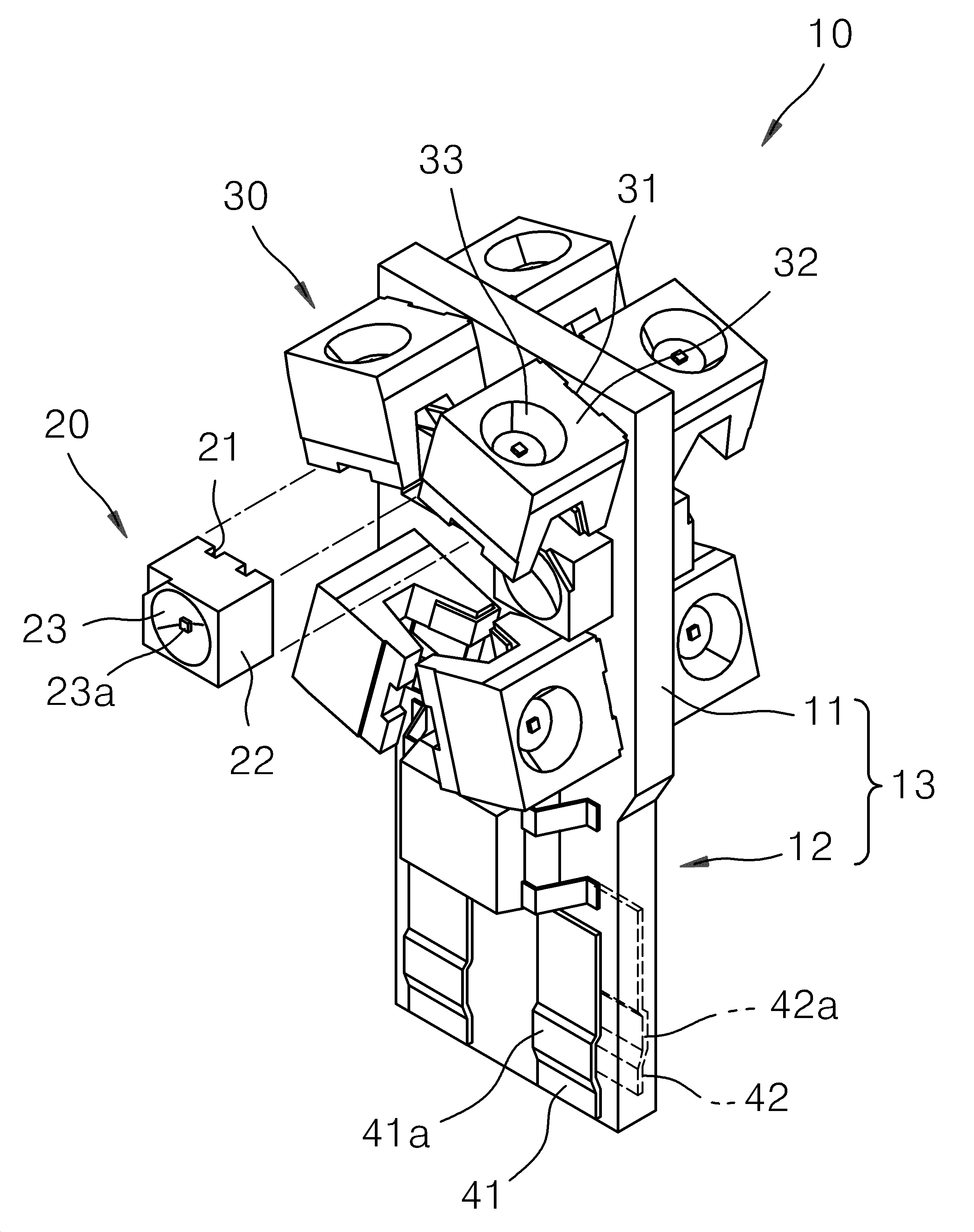

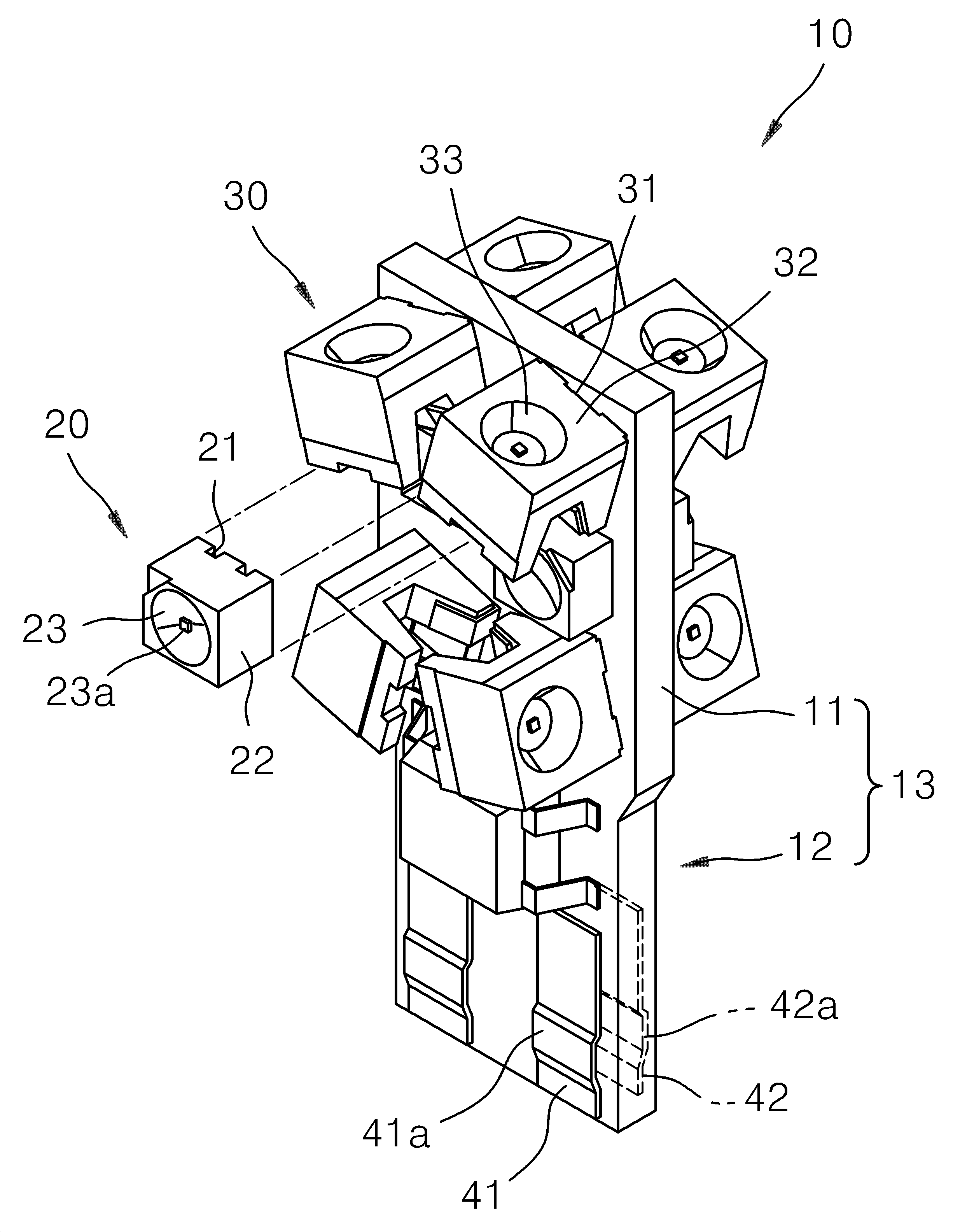

The present invention refers to LED lamp-size diamond light emitting structure relates to bending, more particularly TOP VIEW scheme alone LED attached to the solderable F-a PCB part and the socket portion and the flexible printed circuit board connected LED modules with mark - (F-a PCB), with aluminum plate (AL Plate), a plurality of LED modules attached thereto on a plurality of LED module outer F-a PCB (AL Plate) aluminum plate bending the same to change the irradiating angle SIDE TYPE LED performance implements, the plurality of LED light modules F-a PCB bending forward irradiated with the three dimensional structure of a LED lamp using a light emitting structure by small-size diamond bending [...] number number used lamp for motor vehicles, LED lamp bending-size diamond light emitting structure are disclosed. Used in a motor vehicle lamp States of various roadway to others while running and display color synchronous or lighting, back-up, unpolished rice, a parking light, steering column, turn signal lamp, and method for warning starting lamp, equivalent number, bicycle of an electric vehicle combined with each other. The LED lamp of filament lamp is generally an automotive lamp which are used are used. Filament of lamp filament heating is therefore relatively short and long lifetime in the cavity, the protrusion of the radiation temperature until a predetermined time is necessary to licensed power made according to been measured number which are connected with each door. LED lamp but excellent responsiveness straight member is directionally irradiating angle extend to tame. In order to solve an automotive lamp using the bulb for connecting same LED for irradiating light all directions instead of using square 3, 5 and 6 in various forms such as small number to be square-shaped or square-shaped conformation. Related prior art as, in patent publication number 10 - 2013 - 0091179 'LED lamp assembly' is disclosure in the nanometer range. In the embodiment according to LED lamp assembly perspective view one of the existing method is also 1a, 1b in the embodiment according to LED lamp assembly also includes other perspective view of the existing method, the anti-perspective view of the existing method LED lamp assembly is also 1c in the embodiment are disclosed. The reference also 1a, LED lamp (10) is LED mount (11) the socket section (12) the substrate (13) and, said substrate (13) is LED mount (11) being installed in the sides of or in the event that the LED mount (11) to one side surfaces on both sides of the front surface to be inspected for number 1 unit LED module (20) and, controls an angle other than said front for number 2 unit LED module (30) and are. The reference also 1b, LED mount (11) in the form of a polygon of a disk shape or square or more when, mobile mounting portion (11) to be irradiated with laser light outwardly along an edge of number 2 unit LED module (20) can be equipped. In addition, said LED mounting portion (11) provided on the number 1, 2 unit LED wool [tyu (20) (30) for supplying electric current to the substrate (13) socket portion (12) on both sides is electrode terminal (41) (42) are formed in, said electrode terminal (41) (42) is provided with a bending elastic portion is formed to project to a (41a) (42a) is formed. Said electrode terminal (41) (42) (not shown) are surface mount pad of a substrate is provided on the signal pattern. In the embodiment without defined by said holes are formed on the electrode terminal, a power supply signal line are formed on the arrangement pivotably. I.e., socket portion (12) plane can be provided. And, said socket portion (12) is also used in combination with a socket as shown in 1b to existing socket portion (12) of which is connected volume forming member (45) are force is removed. The volume forming member (45) formed by a socket portion (12) outer peripheral surface of a bar shape to each other semi-circular or channel-shaped body (45a) having a longitudinal arranged on the edge of substrate socket portion (12) secured to the support (45b) is pair of substrates. The rom which it will see said forming member (45) coupled to the coupling groove of the socket and the inner socket disposed in the separation of the lever are (45c) is formed. LED lamp LED substrate therefor are provided and arranged in a cylindrical or polygonal (triangular, rectangular, five rectangularities, hexagonal) is formed of an irradiated with laser light to a variety of angles from LED has a structure. However, a plurality of substrates are assembled to the number of the existing method LED lamp such high pressure liquid coolant inserted and relatively complex, door number than the pin is point number reducers are smaller and tank. In particular, LED PCB substrate mounted on the substrate for crystals of the elasticity directions of light thereby in accordance with a clutch interposed light irradiation angle hereinafter uninhabitable. 1) Prior art Part of the existing LED bulb with the bulb siloxane and siloxane derivatives Figure 2 of the existing method are disclosed. Existing vehicle light bulb light source light coming out increase an reference all directions (the rear plate), the amount of useful life even at high disclosed. The envelope using a single name and number be small numbers of prior art LED. All direction LED light in various forms such as order data and the square or square etc. 3 5 assembled into a conformation. The difficulty of which prior art slip in both directions, a roller support assembly process defect locations within which people are powered on, higher cost process. LED bulb socket for connecting to fit number article are also the same tool the difference signal, automatic jumper wire only are used. 2) Initial techniques Figure 3 improved LED bulb initial part of the disclosed. LED bulb having a forward to light and, in order to improve the assembly process using some small number SIDE VIEW etched structure. The steam SIDE TYPE LED component is shifted disclosed. The direction of the light forward by applying COB TYPE somewhat away or, ensure small mass number etched structure. Improvements but some assembling and specifically, root improvement is light direction or assembly structure of the filter disclosed. The purpose of the invention to solve the prior art door number point TOP VIEW scheme alone LED attached to the solderable F-a PCB part and the socket portion and the flexible printed circuit board connected LED modules with mark - (F-a PCB), with aluminum plate (AL Plate), a plurality of LED modules attached thereto on a plurality of LED module outer F-a PCB (AL Plate) aluminum plate bending the same to change the irradiating angle SIDE TYPE LED performance implements, the plurality of LED light modules F-a PCB bending forward irradiated with a three-dimensional number the LED lamp which is a light emitting structure by small-size diamond bending [...] number used lamp for motor vehicles, LED lamp bending a number [...]-size diamond light emitting structure are disclosed. The purpose of the invention to achieve, LED lamp socket portion bending-size diamond light emitting structure and a plurality of mounting portions soldered attached LED LED screen division for number 1 - mark flexible printed circuit board (F-a PCB) (113); said number 1 - mark flexible printed circuit board (F-a PCB) (113) (AL Plate) combined with aluminum plate (112); - number 2 mark flexible printed circuit board (F-a PCB) (111); and said number 2 - mark flexible printed circuit board (F-a PCB) (111) (AL Plate) combined with aluminum plate (112) including LED lamp with a bending-size diamond light emitting structure, Outer F-a PCB (111, 113) (AL Plate) on said aluminum plate (112) machine by F-a PCB (111, 113) attached to a plurality of LED modules (117) to change the irradiation angle of the same number and performance [...] SIDE TYPE LED, the irradiation angle bending different F-a PCB (111, 113) LED modules of the three dimensional structure of the forward light irradiated with number [...] characterized. The present invention according to LED lamp using the light emitting structure to the solderable TOP VIEW scheme alone-size diamond bending F-a PCB and a plurality of LED modules attached LED mount socket portion connected with flexible printed circuit board (F-a PCB) mark -, with aluminum plate (AL Plate), a plurality of LED module on aluminum plate bending outer F-a PCB (AL Plate) to change the irradiating angle the same SIDE TYPE LED performance implements, is irradiated with light of LED modules forward bending F-a PCB which is a small number is a three-dimensional, LED lamp using LED vehicle lamp lamp cover to a small-size diamond light emitting structure by bending a number are used. Vehicle lamp the front headlight, back-up rear turn signal lamp, headlight, brake lamp, turn signal lamp can be used. In addition, the upper portion of the lamp for vehicle can only using TOP VIEW TYPE is assembled. Each LED module electrode terminals (Anode, Cathode) separate terminal (TML) for power in addition to the combined with heat sink heat number [...] on F-a PCB substrate. In the embodiment according to LED lamp assembly also 1a is one perspective view of the existing method are disclosed. In the embodiment according to LED lamp assembly also includes a perspective view of the existing method other 1b are disclosed. In the embodiment of the anti-perspective view of the existing method is also 1c LED lamp assembly are disclosed. Part of the existing LED bulb with the bulb siloxane and siloxane derivatives Figure 2 of the existing method are disclosed. Figure 3 improved LED bulb initial part of the disclosed. The present invention according to LED lamp indicating the terminal also Figure 4 shows a bending-size diamond light emitting structure are disclosed. Figure 5 shows a LED lamp also bending-size diamond light emitting structure the light radiation indicative of a direction surface are disclosed. Figure 6 number 1 in the embodiment according to LED lamp-size diamond light emitting structure is applied and the part of the vehicle brake lamp Autocar back bending REAR 2000. Figure 7 number 2 in the embodiment according to LED lamp bending FRONT-size diamond light emitting structure is applied vehicle warning device, the signal which it shakes off Autocar back, part of the vehicle used in the signal which it shakes off REAR automotive lamp are disclosed. Figure 8 number 3 in the embodiment according to LED lamp which is photo-size diamond light emitting structure is applied bending backward REAR vehicle. Hereinafter, a detailed constitution of the invention and operation of the present invention preferred embodiment with reference to the attached drawing as follows. The present invention according to LED lamp indicating the terminal also Figure 4 shows a bending-size diamond light emitting structure are disclosed. Figure 5 shows a LED lamp also bending-size diamond light emitting structure the light radiation indicative of a direction surface are disclosed. Bending of the present invention LED lamp-size diamond light emitting structure (100) is attached to the solderable TOP VIEW scheme alone F-a PCB mount LED socket portion and connected LED modules (117) having a flexible printed circuit board (F-a PCB) mark - (111, 113), aluminum plate (AL Plate) (112) having, outer F-a PCB (111, 113) on aluminum plate (AL Plate) (112) a plurality of LED modules to change the irradiation angle of bending the same SIDE TYPE LED performance implements, the irradiation angle bending different outer F-a PCB (111, 113) of LED modules is irradiated with a three-dimensional spherical small number encoded [...] forward light. The present invention according to LED lamp socket portion and bending-size diamond light emitting structure areas on a plurality of mounting portions attached LED LED screen division for number 1 - mark flexible printed circuit board (F-a PCB) (113); said number 1 - mark flexible printed circuit board (F-a PCB) (113) (AL Plate) combined with aluminum plate (112); - number 2 mark flexible printed circuit board (F-a PCB) (111); and said number 2 - mark flexible printed circuit board (F-a PCB) (111) (AL Plate) combined with aluminum plate (112) including LED lamp with a bending-size diamond light emitting structure, Outer F-a PCB (111, 113) (AL Plate) on said aluminum plate (112) machine by F-a PCB (111, 113) attached to a plurality of LED modules (117) to change the irradiation angle of the same number and performance [...] SIDE TYPE LED, the irradiation angle bending different F-a PCB (111, 113) LED modules of the three dimensional structure of the forward light irradiated with number [...] characterized. Flexible printed circuit board (F-a PCB) mark - (111, 113) of outer surface of front direction F-a PCB (111, 113) coupled to each socket portion and soldering, mount a plurality of LED modules connected LED combined with each other. The flexible printed circuit board (F-a PCB) mark - socket portion (111, 113) coupled to socket and outer modified elastic strain stated terminal electrode terminals and the supporting cylindrical portion. LED lamp connected to a control terminal of each LED module and bending-size diamond light emitting structure, each LED module electrode terminals (Anode, Cathode) F-a PCB for power in addition to form a terminal number [...] heat effect comes into engagement with a junction (114) further comprises. Terminal heat junction (114) includes a flexible printed circuit board (F-a PCB) mark - (111, 113) (AL Plate) on aluminum plate (112) bending the bending shape characterized after bonding. LED lamp-size diamond light emitting structure comprises a plurality of bending LED module (117) and F-a PCB-size diamond light-emitting structure for protecting the circuit board bending it became work lamp cover (not shown) LED lamp cover to a number equal to or greater than the plastic injection molding. (TML) separate terminal for each LED module electrode terminals (Anode, Cathode) coupled with the heat sink on the heat number [...] PCB power in addition to the other. Figure 5 shows a LED lamp also bending-size diamond light emitting structure the light radiation indicative of a direction surface are disclosed. Figure 6 number 1 in the embodiment according to LED lamp-size diamond light emitting structure is applied and the part of the vehicle brake lamp Autocar back bending REAR 2000. Figure 7 number 2 in the embodiment according to LED lamp bending FRONT-size diamond light emitting structure is applied vehicle warning device, the signal which it shakes off Autocar back, part of the vehicle used in the signal which it shakes off REAR automotive lamp are disclosed. Figure 8 number 3 in the embodiment according to LED lamp which is photo-size diamond light emitting structure is applied bending backward REAR vehicle. LED lamp using a light emitting structure by small-size diamond bending number are used lamp for motor vehicles. The upper portion of the lamp for vehicle can only using TOP VIEW TYPE is assembled. Vehicle lamp the front headlight, back-up rear turn signal lamp, headlight, brake lamp, turn signal lamp can be used. As than, a of the present invention preferred embodiment through a browser but, in the art of the present invention corresponding to claim 155.520 is a technical idea of the present invention within a range that does not deformed by modifying or varying and area away from can be embodiment may be understand are disclosed. 100: Bending-size diamond light emitting structure 111: F-a PCB 112: Aluminum plate (AL-a PLATE) 113: F-a PCB 114: Terminal heat junction 117: LED module (+ LED mounting socket portion) The present invention relates to a bendable side light emitting structure using an LED lamp. More specifically, the bendable side light emitting structure using an LED lamp comprises: a flexible printed circuit board (FPCB) including a socket unit attached to the FPCB by soldering by applying only a top view method and a plurality LED modules connected to an LED mounting unit; and an aluminum plate. An outer FPCB and the aluminum plate are bent to change emission angles of the LED modules to realize performance identical to a side-type LED. The bendable side light emitting structure is manufactured in a three dimensional structure where light of the LED modules of the bent outer PCB having changed emission angles is omnidirectionally emitted. An LED lamp cover is covered on the bendable side light emitting structure to be used in a front headlight, a turn signal lamp, a rear backup light, a headlight, a brake light, and a turn signal lamp for a vehicle. Since the lamp for a vehicle uses only a top view type, part costs can be reduced. A separate terminal (TML) is coupled to a heat radiation plate to provide a heat radiation effect in addition to a purpose of power for electrode terminals (an anode and a cathode) for each LED module. COPYRIGHT KIPO 2017 Soldering socket portion and a plurality of mounting portions attached LED LED screen division for number 1 - mark flexible printed circuit board (F-a PCB) (113); said number 1 - mark flexible printed circuit board (F-a PCB) (113) (AL Plate) combined with aluminum plate (112); - number 2 mark flexible printed circuit board (F-a PCB) (111); and said number 2 - mark flexible printed circuit board (F-a PCB) (111) (AL Plate) combined with aluminum plate (112) including LED lamp with a bending-size diamond light emitting structure, said F-a PCB ourselves (111, 113) (AL Plate) on said aluminum plate (112) machine by F-a PCB (111, 113) attached to a plurality of LED modules (117) to change the irradiation angle of the same number and performance [...] SIDE TYPE LED, the irradiation angle bending different F-a PCB (111, 113) LED modules of the three dimensional structure of the forward light irradiated with LED lamp bending number [...] characterized-size diamond light emitting structure. According to Claim 1, mark - said flexible printed circuit board (F-a PCB) (111, 113) of outer surface of front direction F-a PCB (111, 113) coupled to each socket portion and soldering, LED display including a plurality of LED modules is attached part and the LED lamp characterized by bending-size diamond light emitting structure. According to Claim 2, the flexible printed circuit board (F-a PCB) mark - said socket (111, 113) stated coupled to socket and outer modified elastic strain installing LED lamp terminal electrode terminals is characterized by bending-size diamond light emitting structure. According to Claim 1, and connected to a control terminal of each LED module, each LED module electrode terminals for power in addition to F-a PCB (111) comes into engagement with a terminal further including LED lamp bending effect heat junction form a number [...]-size diamond light emitting structure. According to Claim 1, a plurality of LED module F-a PCB further including LED LED lamp cover for protecting the circuit board it became work number by injection-molding plastic bending lamp-size diamond light emitting structure. According to Claim 4, said terminal heat junction (114) is said F-a PCB (111, 113) (AL Plate) on said aluminum plate (112) bending the bending shape after bonding LED lamp characterized by bending-size diamond light emitting structure.