IN-BOX LOADING DEVICE

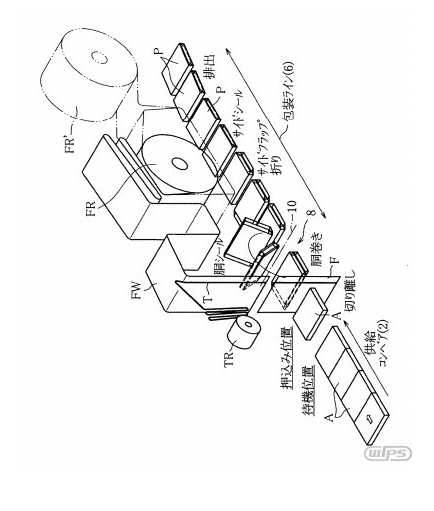

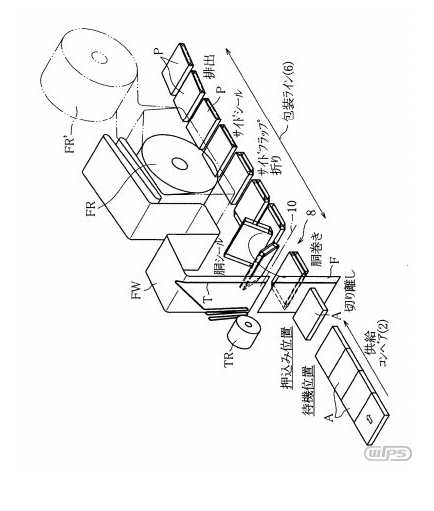

The present invention refers to, the box which is loading device relates to search, for automatically calculating and box and quantity of transporting box, box can easily constant oriented state loading the box which is aligning the standing wave device are disclosed. The Internet's development and route of communication, Internet orders at various number after packaging the packaging box number article article are delivered to the buyer at rapid pace etc. evolved the transportation industry. However, the transportation industry has a probe evolved packaging article number although the amount of box is consumed, packing tank box device and system for transporting the carrier using car box or a separate fixing member, using a simple conveyor belt conveyance method because, as well as efficiency and falls, a plurality of friction device used in transportation process on a power machine safety accident when the door number as well, for providing individually check negative quantity of used in box in addition happened yesterday. The shortcomings of the existing method is shown in Figure 1 is such as having said packaging material transfer device etc.. The transfer device 1 also includes a suction conveyer and reference of the existing method, adsorption and suction conveyor belt drive, using suction conveyor are prevented from falling into the carrier by using the transmitted, or may carry an advantageous packaging of various sizes, said transfer device transmits an update initialization consisting of the existing method such as the fact that the given cannot be unauthorized are disclosed. The, efficiency of transport box and box to check the quantity of simple operation and preventing the occurrence of repeated, transported on the machine device prevents a friction box aligning job dealers concerned can prevent box transportation device etc. of the components are damaged. In order to solve the present invention refers to said door number point such as battery is provided, the purpose of the invention also comprises a box for transporting and aligning the box which is provided which improves process, box transportation can be generated in the process can be a conduction device loading the box which is a [...] number are disclosed. Said loading device for the present invention is as defined in the box which is a cyclone, box inlet (100); said box inlet (100) for compressing and transporting coming from box rotating transport (200); said rotating transport (200) box-aligned box coming from arranging portion (300); including combustion chamber. In addition, rotating said from the outside (200) from the outside box is one aspect of urging rotation number 1 (210) on, box from the outside again urging rotation number 2 (220) to and from the characterized. In addition, each said rotation from the outside (210, 220) which is disposed in spaced, said box inlet (100) in said box arranging portion (300) generate, progressively modified combining a plurality of roller (211, 221) on, said roller (211, 221) surrounding the belt and, said belt drive for rotating the result of vehicle from the outside. In addition, said roller (211, 221) is said box inlet (100) is placed at one side in the axial direction X and is one side box Y axis direction, Z axis direction axis having shearing rollers (211 - 1, 221 - 1) on, said box arranging portion (300) is placed on the other side in the axial direction X and is Z box at one side in the axial direction, Y axis direction shafts rear roller (211 - 5, 221 - 5) on, said shearing rollers (211 - 1, 221 - 1) on said rear roller (211 - 5, 221 - 5) formed between, said shearing rollers (211 - 1, 221 - 1) in said rear roller (211 - 5, 221 - 5) in the direction of Z axis placed on rotation progressively modified Y axis direction a plurality of intermediate roller (211 - 2, 221 - 2, 211 - 3, 221 - 3, 211 - 4, 221 - 4) the result of vehicle from the outside. And, said box arranging portion (300) from the outside is said rotation (200) coming from guide roller guiding box (310) on, said guide roller (310) a box number movement of relayed movement along guide jig (320) on, fixed inlet box against the elastic section (330) comprising the recommended as follows. In addition, said elastic compression element (330) is a pressing member engaged with the box (331) on, and corresponds to the thickness or number of inlet box to said hold down member (331) can be plower position of number further comprises a compression spring. In addition, rotating said from the outside (200) comprises a fluorine-substituted palletised number of checking box count unit (230) characterized is applied. The present invention includes a loading device such as in the box which is said by the, box shipment and water meter acid and alignment are made simultaneously, individually and alignment are calculated time consumption quantities when delivery of box to minimize has a base plate to be made. In addition, box-and-left direction rather than a vertical alignment of the bottom carrier box transfers the safety as well as the rotating shaft and stacked, aligned at a certain height and an operator box can be easily selected that has any additional box alignment work is required. In addition, box engaged with the aligned region is a pressing member supporting compressive generation compression spring, box loading box are used and the box pattern to point and therefore the starting point for use box has a means for the operator to be grouped has a. Figure 1 shows a general outline of the existing method saff carriage also indicating device. Figure 2 shows a loading device in the present invention indicating the box which is also planar. Figure 3 shows a segment of the present invention indicating the general outline in the box which is the displacement of the loading device also in box. Figure 4 shows a side loading device indicating the box which is also in the present invention. Figure 5 shows a front loading device indicating the box which is also in the present invention. The present invention also includes the loading device 2 in the box which is reference box inlet (100) on said box inlet (100) for compressing and transporting coming from box rotating transport (200) on, said rotation from the outside (200) box-aligned box coming from arranging portion (300) including combustion chamber. The detailed, using said plurality of box packaging box inlet (100) shown in (a) of Figure 3 as a large-surface contact with the ground and flat condition and is released into the bottom and opposite, said rotation from the outside (200) of Figure 3 (b) as shown in moving a large-surface contact with the ground and the narrow surface opposing the bottom and opposite flat condition and rotating the bottom vertical surfaces, said box arranging portion (300) as shown in (c) of Figure 3 in said rotation from the outside (200) is introduced into box aligned in contact with the ground and the forms are disclosed. In addition, rotating said from the outside (200) is simply box box inlet (100) in box arranging portion (300) when pressing the rotation number 1 from the outside box one aspect of conveyance (210) on, rotation number 2 from the outside (220) are partitioned into a is sufficient but, box box inlet (100) in box arranging unit (300) and for rotating the conveyance, said rotation from the outside (210, 220) which is disposed in spaced, said box inlet (100) in said box arranging portion (300) generate, progressively modified combining plurality of rolls (211, 221) can be composed, drawing is not shown but simply roller (211, 221) using box when said box is transporting roller (211, 221) of spaced-apart space can be withdrawn, improving the safety of transportation for each rotation from the outside (210, 220) to rollers (211, 221) that surrounds said belt, said belt further comprises a sub can be. The detailed, a plurality of said roller (211, 221) are arranged in continuous direct rotation for transporting of the box but, roller (211, 221) to minimize the number of, in order to improve safety of carrying, rotating each of said pair of belts from the outside (210, 220) forming a plurality of roller (211, 221) wrapped individually, pressing both sides of each belt box using a rotating belt in driving campaigns are disclosed. And, the roller 4 also reference (211, 221) is said box inlet (100) is placed at one side in the axial direction X and is one side box Y axis direction, Z axis direction axis having shearing rollers (211 - 1, 221 - 1) on, said box arranging portion (300) is placed on the other side in the axial direction X and is Z axis direction at one side of box, Y axis direction shafts rear roller (211 - 5, 221 - 5) on, said shearing rollers (211 - 1, 221 - 1) on said rear roller (211 - 5, 221 - 5) formed between, said shearing rollers (211 - 1, 221 - 1) in said rear roller (211 - 5, 221 - 5) in the direction of Z axis placed on rotation progressively rotated Y axis direction a plurality of intermediate roller (211 - 2, 221 - 2, 211 - 3, 221 - 3, 221 - 4, 221 - 4) can be connected to one end. The detailed, said box inlet (100) is flattened so that the Y on both axial sides in box to thereby has been delivered from the engagement position, said rotation from the outside (200) is installed to optimal condition box arranging unit inlet box (300) enter the other. The, rotating said number 1 from the outside (210) rotating said number 2 on the outside (220) constituting said roller (211, 221) engine box inlet (100) in box arranging unit (300) to incrementally rotate and as are disclosed. The, plurality of said roller (211, 221) XZ plane axis of rotation of the blade said shearing rollers (211 - 1, 221 - 1) that is sufficient if in the case of parallel, rear roller (211 - 5, 221 - 5) forms is sufficient in the case of the roller (211, 221) consists of a total rotation angle 90 road recommended as follows. In addition, a plurality of said roller (211, 221) 1 5 15 consists of a rotation angle of a robot is in the varied road recommended as follows. The detailed, the present invention is to enhance the safety of the box which is in rotation from the outside box transportation device loading said number 1 (210) number 1 to number 5 constituting the peripheral surface of the roller to move the belt number 1, number 2 rotating transport (220) number 1 to number 5 constituting roller belt 35a. number 2. A one in the embodiment, SIGE layer each other adjacent shearing rollers (211 - 1, 221 - 1) intermediate roller (211 - 2, 221 - 2) also show differences in which the axis of rotation 15 exceeds 5 each other when open is in the opposing each other in the rotation number 1 from the outside (210) intermediate roller (211 - 2) rotation number 2 on the outside (220) intermediate roller (211 - 2) carried by the box pressure is applied to the situation occurs where the gearbox is installed can be, roller (211, 221) that surrounds said oscillating roller which does not exit the belt roller can be modified, road number 5 axis of rotation of said roller adjacent to each other to prevent a situation such as the valve timing of the angle difference to 15 also are disclosed. In addition, the arranging portion 2 and also 4 also referencing said box (300) from the outside is said rotation (200) coming from guide roller guiding box (310) on, said guide roller (310) a box number movement of relayed movement along guide jig (320) on, fixed inlet box against the elastic section (330) can be connected to one end. The detailed, said number 1 to number 5 through the roller said box inlet (100) is placed in the axial direction X one side said box arranging portion (300) is placed on the other side move to the X axis direction rotating said rotated box from the outside (200) in the axial direction X of installed on auxiliary rollers (240) through box arranging portion (300) are transported to a substrate. The, box arranging portion (300) includes said guide roller (310) specify a direction using the data entering the box is dropped box as to prevent build-up or entering a designated location, box arranging portion (300) located on both axial sides of X number 1 guide jig (321) on number 2 guide jig (322) positioned on one side in the axial direction X of the number 1 guide jig (321) using the introduced first path for arranging unit (300) can be formed or in preventing range during a, the other side of the X-axis direction is number 2 guide jig (322) number 1 to guide jig (321) to aid in Z axis direction collinear with the inlet box is different from another phase that is transmitted through and are disclosed. The, said elastic section (330) to compress the incoming box is a flat folded state with the ground and the leveling of the positioned on both sides in the axial direction Z, Y axis direction which is located in a substantially vertical with the ground and the surface thin box provided to prevent leaning for Z axis mineral box hold is sufficient but, a quantity of box of an electronic one side by side box is rotated from the outside box (200) in box arranging unit (300) which does not allow the introduced into the bounce, build-up or a worker using the vehicle supports a box, box hold a pressing member (331) on, percussive or number of inlet and corresponds to the thickness of the sleeve abutting member (331) further including a compression spring to the position of number plower recommended as follows. I.e., said hold down member and said compression spring (331) of the other side of the axial Z, a presser member (331) is installed in the Z axis direction to compress an air laterally with respect to the box, rotation from the outside (200) in box arranging portion (300) corresponds to the number of percussive entering the elastic change due to the compression spring under the pressure in order to change a quantity of box are disclosed. And, said rotation from the outside (200) checks the number of a vehicle transportation comprises a fluorine-substituted count unit (230) can be further formed. The detailed, generally packaging to be used e.g. in box received in the box or the amount accurate checking work and has, when used in a large amount of box box as well as to mark a number of cells can be difficult to work. The, carrying the box in said count unit (230) used in box using number of check or hypermetropia. The, said count unit (230) is a laser or the optical source emits light optical sensor conveys a box at the time that the recommended use but in addition box per hour based on the number of etch end point both time and calculating the number of transported box so as to define method such as percussive method does not. In addition, the present invention includes the loading device in the box which is also 5 reference different shafts each said roller (211, 221) to a constant position in order to lock the fixing unit (250) can be modulated with. The detailed, rotating said number 1 from the outside (210) rotating said number 2 on the outside (220) includes a roller (211, 221) on an opposite each other, different roller number 1 to number 5 roller shafts should. I.e., use impact generating mutually the same rotary unit are disclosed. Thus, in the present invention said rotating transport (200) X-axis direction in a plurality of said fixing unit (250) and arranged in spaced-apart, ring-shaped having each said fixing unit (250) is provided opposite to each other within an opposing pair composed of number 1 to number 5 roller after, fixing unit (250) and a rotating transport (200) method of adjusting the angle, insulation films have different number 1 to number 5 roller shaft are disclosed. Example embodiment of the present invention said to define a technical idea analysis not on. A variety of coverage to surround, in the claims claim the level of one skilled in various modifications made without deviating from the subject matter of invention embodiment permits. The substrate is reduced to one skilled in the belonging to a of the present invention scope of protection such improved and change is to be coated. 1: Box 100: Box inlet 200: Rotation from the outside 210: Rotation number 1 220 from the outside: rotation number 2 from the outside 211, 221: Roller 211 - 1, 221 - 1: shearing rollers 211 - 2, 221 - 2:211 - 3 Intermediate roller, 221 - 3: intermediate roller 211 - 4, 221 - 4:221 - 5 Intermediate roller, 221 - 5: rear roller 230: Count part 240: auxiliary rollers 250: Fixing unit 300: Box arranging portion 310: Guide roller 320: Guide jig 330: Elastic section 331: hold down member 332: Compression spring The present invention relates to an in-box loading device. More specifically, transportation and alignment of boxes and counting the number of the boxes are simultaneously performed to simplify transportation and loading works of the boxes, and the aligned boxes are pressed and fixated by using elastic force to minimize time consumption and a moving line of a worker when the worker uses the box. COPYRIGHT KIPO 2017 Box inlet (100); said box inlet (100) for compressing and transporting coming from box rotating transport (200); said rotating transport (200) box-aligned box coming from arranging unit (300); including a, the box which is loading device. According to Claim 1, said rotation from the outside (200) from the outside box is one aspect of urging rotation number 1 (210) on, box from the outside again urging rotation number 2 (220) characterized consists, the box which is loading device. According to Claim 2, each said rotary transport (210, 220) which is disposed in spaced, said box inlet (100) in said box arranging portion (300) generate, progressively modified combining a plurality of roller (211, 221) on, said roller (211, 221) that surrounds said belt, said belt including rotating driving unit, the box which is loading device. According to Claim 3, said roller (211, 221) is said box inlet (100) is placed at one side in the axial direction X and is one side box Y axis direction, Z axis direction axis having shearing rollers (211 - 1, 221 - 1) on, said box arranging portion (300) is placed on the other side in the axial direction X and is Z box at one side in the axial direction, Y axis direction shafts rear roller (211 - 5, 221 - 5) on, said shearing rollers (211 - 1, 221 - 1) on said rear roller (211 - 5, 221 - 5) formed between, said shearing rollers (211 - 1, 221 - 1) in said rear roller (211 - 5, 221 - 5) in the direction of Z axis placed on rotation progressively modified Y axis direction a plurality of intermediate roller (211 - 2, 221 - 2, 211 - 3, 221 - 3, 211 - 4, 221 - 4) including a, the box which is loading device. According to one of Claim 1 to Claim 4, said box arranging portion (300) from the outside is said rotation (200) coming from guide roller guiding box (310) on, said guide roller (310) a box number movement of relayed movement along guide jig (320) on, fixed inlet box against the elastic section (330) including a, the box which is loading device. According to Claim 5, said elastic compression element (330) is a pressing member engaged with the box (331) on, and corresponds to the thickness or number of inlet box to said hold down member (331) characterized in further including a plower number position of the compression spring, the box which is loading device. According to one of Claim 1 to Claim 4, said rotation from the outside (200) comprises a fluorine-substituted palletised number of checking box count unit (230) characterized is applied, the box which is loading device.