DOUBLE ISOLATION FOR DOUBLE CHAMBER DIFFERENTIAL PRESSURE METER

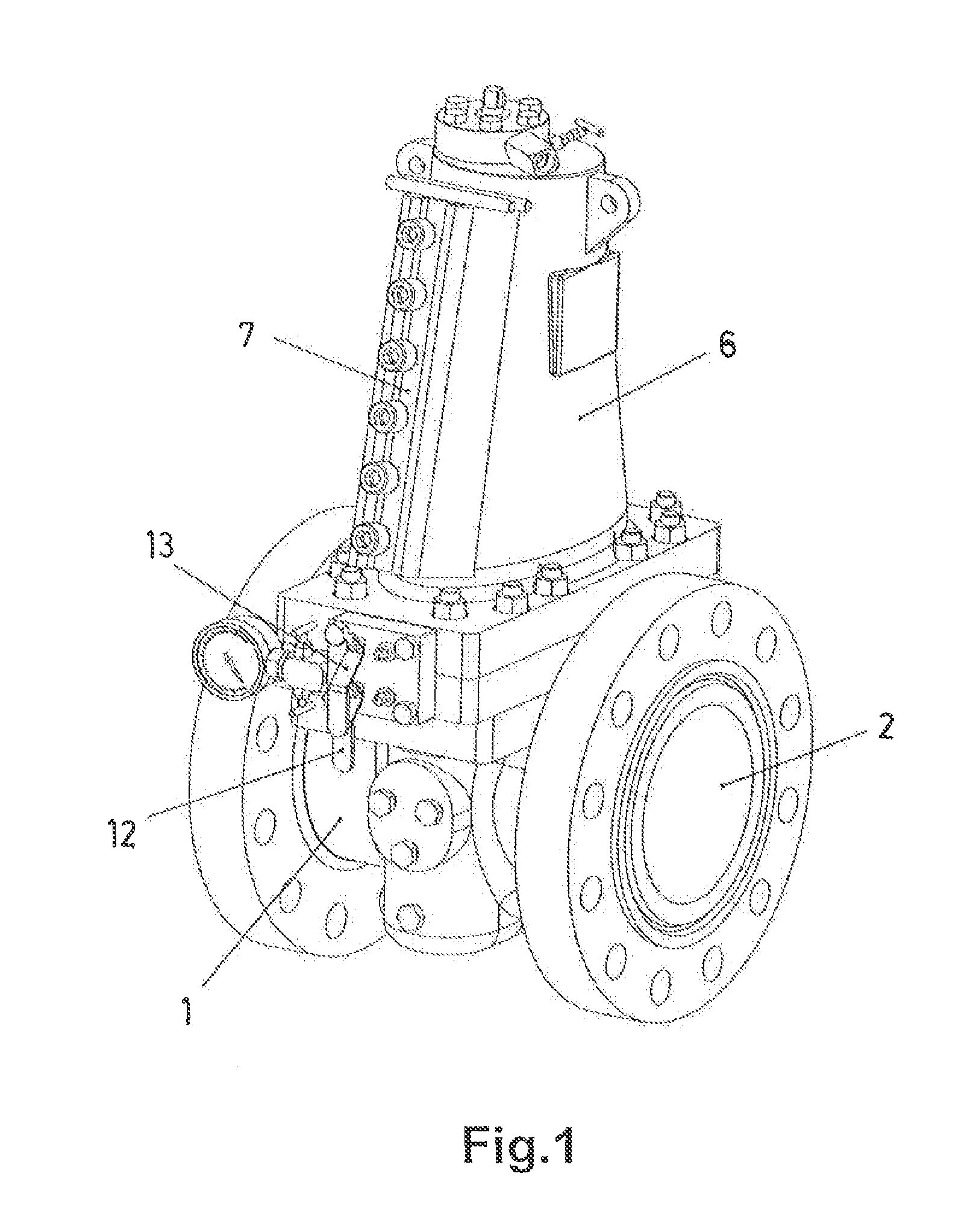

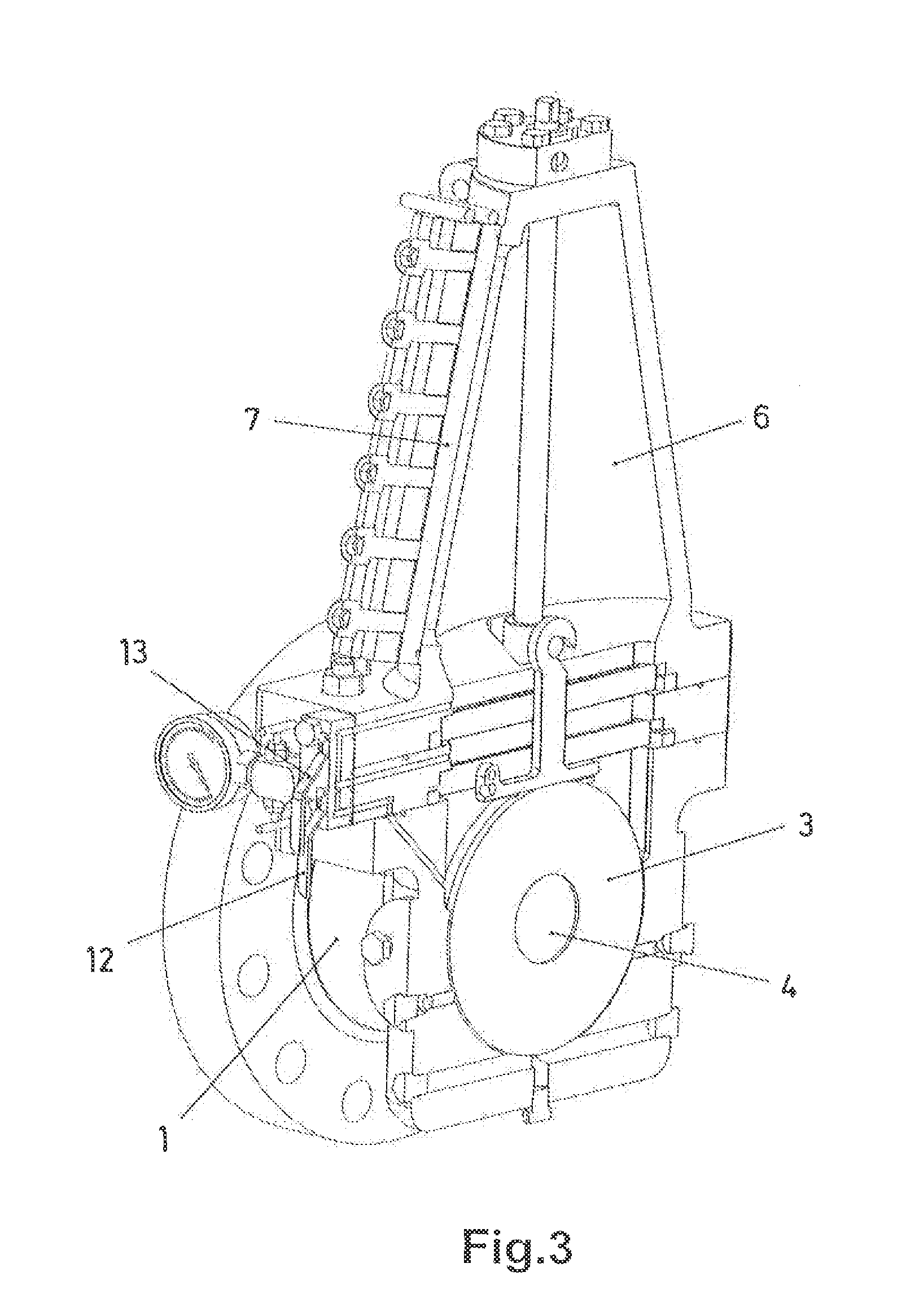

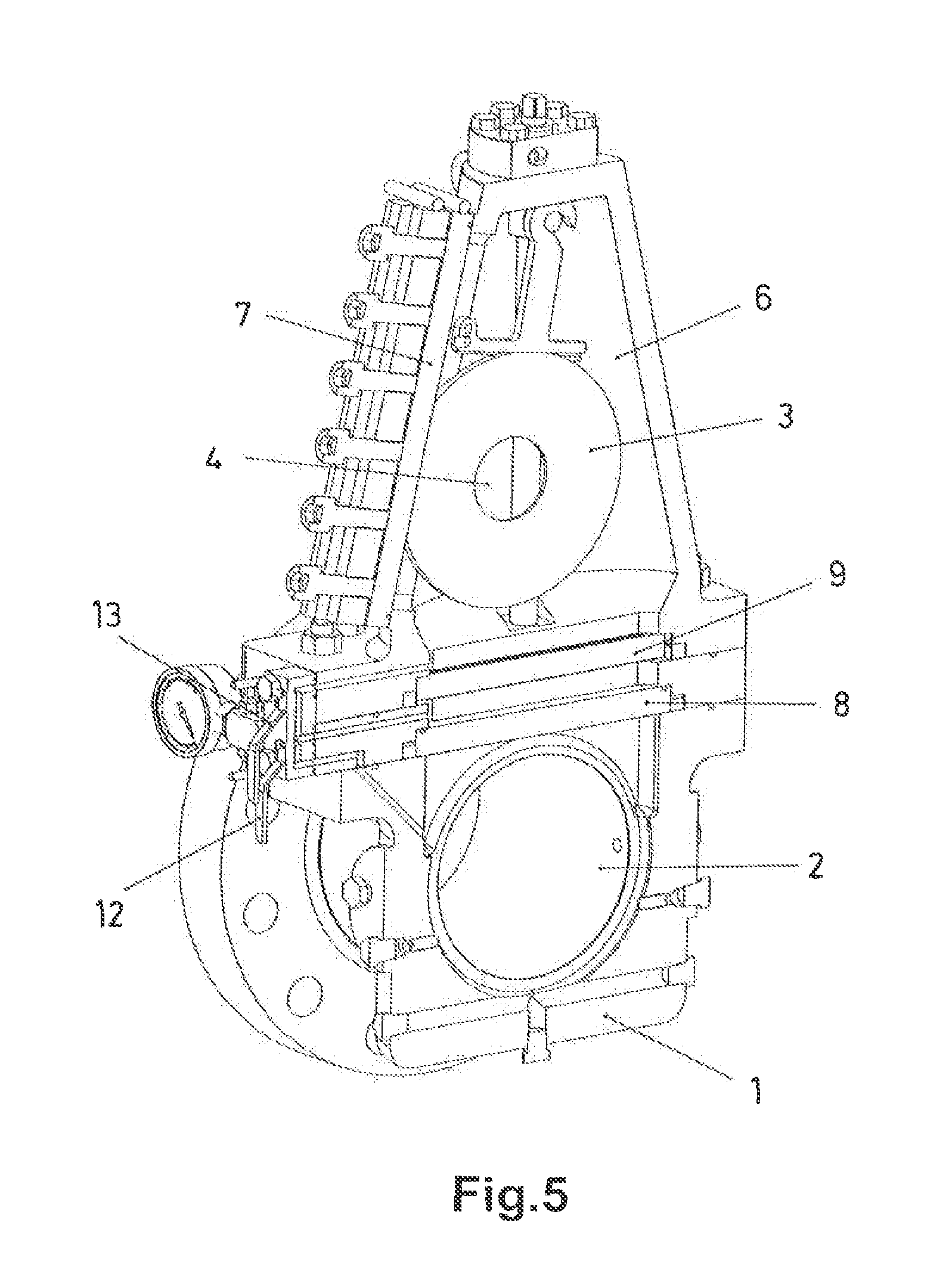

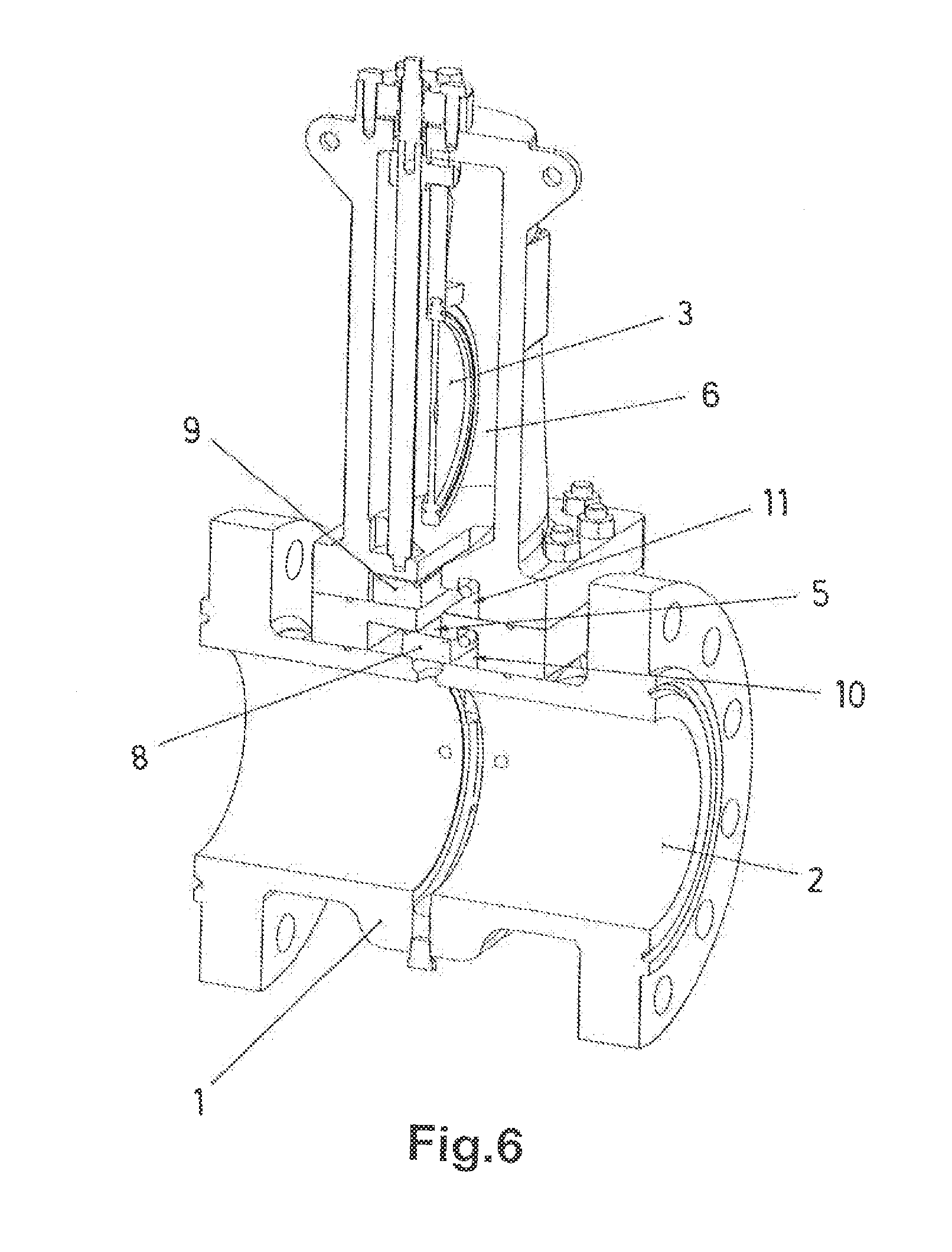

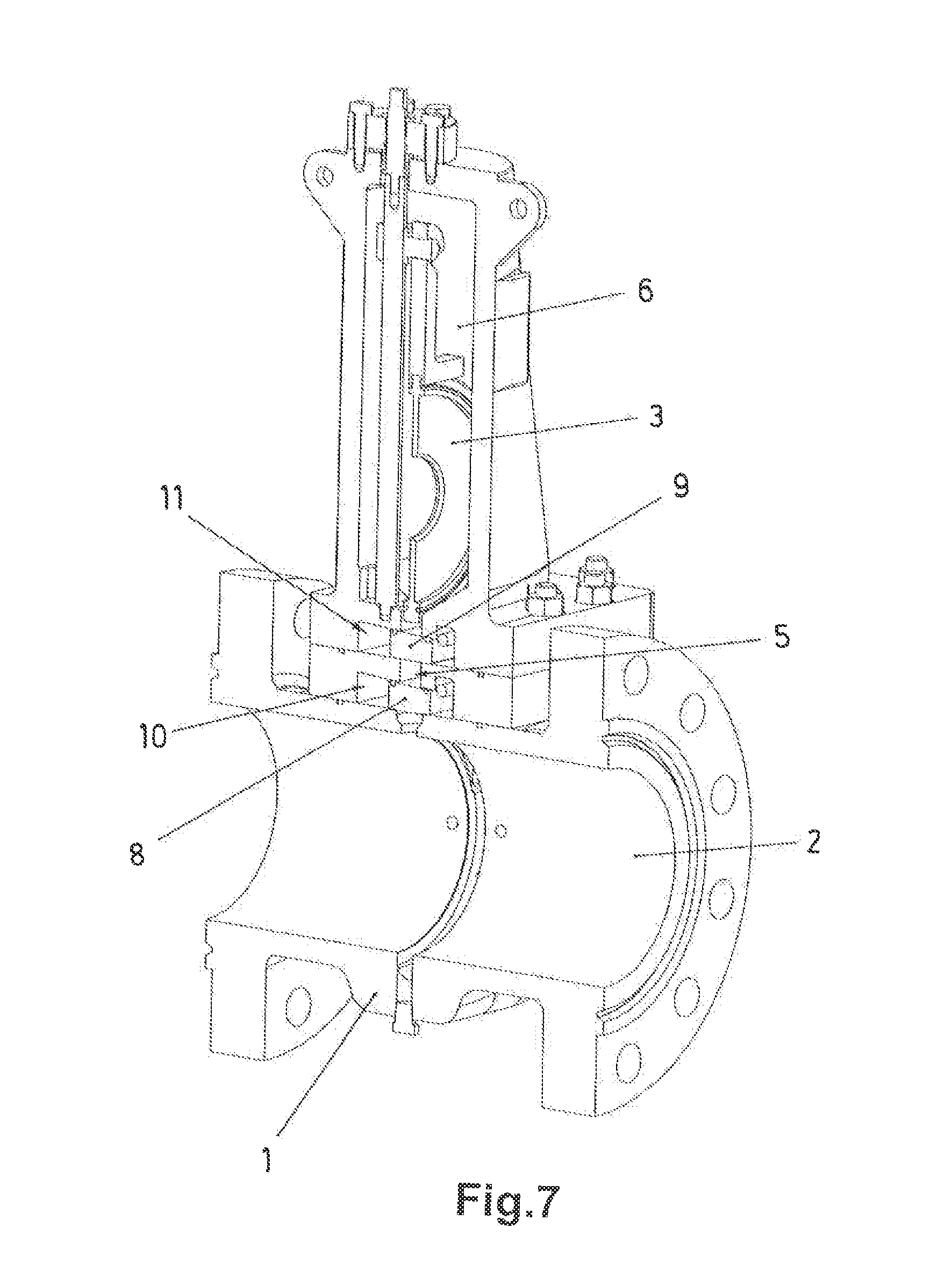

The present invention relates to measuring the flow of fluids (gas or liquid) in pipes, and particularly to flow measuring apparatus having a plate provided, with an orifice having at smaller section than the flow circulation pipe and comprising a dual chamber for removing the plate with an orifice without interrupting the flow circulation, proposing a closure system which allows establishing a completely leak-tight isolation between the two chambers of the device when the plate with an orifice is removed. To measure the flow of fluids circulating through pipes, flow meter devices which are intercalated in the pipe of application are known, there being several functional implementations of said devices. A conventional solution of the aforementioned flow meter devices includes a plate provided with an orifice having a smaller section than the fluid circulation pipe in which the flow meter device is incorporated, said orifice being concentric with the section of the pipe of application in the functional arrangement, such that the flow of the gas or fluid circulating through the pipe increases in speed as it passes through that orifice, the increase in speed creating a pressure differential that can be measured to calculate the volumetric flow of fluid according to the section of the pipe. In this functional arrangement the sharp edge of the orifice bore of the plate of these flow meter devices experiences wear due to the friction of the circulating gas or fluid, such that the plate with an orifice must be frequently removed for inspection, or replacement. Failure to replace or repair a plate exhibiting a worn sharp edge of the orifice manifests as increased percentage uncertainty in volumetric flow as is referenced within the standards ISO 5167-2:2003 section 5.1.7.2 and API 14-Section 3-Part 2.4.2. In some cases, however, the interruption of the fluid circulation through the pipes in which the flow is measured can be damaging, so meter devices provided with a dual chamber have been developed in which the plate provided with the orifice can be removed from the normal functional position in the device, into an accessory chamber provided with a closure which allows isolating it with respect to the main chamber in which said plate with an orifice is located in the normal functional position, the embodiments contemplated in patents U.S. Pat. No. 1,936,192, US 2005/0258389 and US 2007/0185387, for example, corresponding with this solution. The known solutions of such flow meter devices having a plate with an orifice and having a dual chamber to allow the removal of the plate with en orifice without interrupting the flow of the fluid through the pipe of application include a simple closure between the main chamber and the accessory chamber, whereby complete isolation leak-tightness between the chambers of the meter device is not assured, therefore these devices are not suitable for using in high-pressure fluid conduits, or for environments that demand a second method by which isolation can achieved, supported by visual evidence that such isolation has been both achieved and sustained. According to the invention, a closure system for establishing the isolation between the dual chamber of flow meters having a plate with an orifice susceptible to being extracted without interrupting gas or fluid circulation passing through, which allows determining a completely leak-tight isolation with a visible means of between the two chambers when the plate with an orifice is extracted, is proposed. The objective of the invention is determined with two independent closure elements which are arranged in respective superimposed positions between the two chambers of the corresponding flow meter, said closure elements having respective operating controls which allow the individual movement thereof from the outside between respective open end closed positions of each of them. The closure elements consist of angular plate valves which are arranged in a sliding assembly in corresponding housings, with the possibility of movement between a sealed position for sealing the passage between the two chambers of the flow meter and an offset position with respect to said passage. A closure system is thus obtained which, when the plate with an orifice of the flow meter is removed, from the main chamber where it is normally located in the functional position into the accessory extraction chamber, by means of moving one of the closure elements to the closed position, a seal is established in the passage between the two chambers, while the movement of the other closure element to the closed position assures complete leak-tightness of the seal, completely preventing the possibility of leaks between the two chambers, such that the flow meter is applicable for high-pressure fluid conduits, with the possibility of extracting and incorporating the plate with an orifice in a completely secure manner without having to interrupt the flow of the fluid since the dual closure system completely prevents leaks. This solution also satisfies the requirement of providing double isolation for health and safety purposes. The closure system of the invention therefore has very advantageous features for the functional capacity of the flow meters for which it is intended, its application in said flow meters acquiring its own identity and preferred character. The object oil the invention relates to a closure system for flow meters comprising a body (1) longitudinally provided with an axial conduit (2) corresponding in diameter with a fluid (gas or liquid) circulation pipe the flow of which is to be measured, a plate (3) provided with an orifice (4) having a smaller section than the axial conduit (2) being transversely incorporated in the axial conduit (2). These flow meters are intercalated in the fluid circulation pipe the flow of which is to be measured, such that when the fluid passes through the orifice (4) of the plate (3) the flow increases in speed, giving rise to a pressure differential the measurement of which allows determining the volumetric flow of the fluid. The axial conduit (2) determines a main chamber in the flow meter in which the plate (3) provided with the orifice (4) is arranged in the normal functional position, as can be seen in With respect to the passage (5) communicating the main chamber defined by the axial conduit (2) with the accessory chamber (65, a practicable sealing closure is arranged between an open position and a closed position, such that when it is necessary to extract the plate (3) in order to inspect or replace it due to the wear of the orifice (4) by friction of the fluid passing there through in the flow meter application function, said plate (3) can be extracted from the main chamber defined by the axial conduit (2) to the accessory chamber (6), as shown in Once this is done, the circulated fluid is prevented from passing to said accessory chamber (6) by closing the communication passage (5) between the axial conduit (2) and the accessory chamber (6), being able to remove the cover (7) to extract the plate (3), as depicted in According to the invention, there is arranged between the main chamber defined by the axial conduit (2) and the accessory chamber (6) a closure formed by two independent angular plate valves (8 and 9) which are included in respective housings (10 and 11) intersecting the communication passage (5) between the axial conduit (2) and the accessory chamber (6) with the possibility of movement of each of said angular plate valves (8 and 9) in their respective housings (10 and 11) between a position in which they do not interfere with the aforementioned passage (5) between the axial conduit (2) and the accessory chamber (6) and a position in which they interrupt said passage (5). Therefore, when the plate (3) is in the accessory chamber (6), the seal of said passage (5) is established by means of the movement of the first angular plate valve (8) in its housing (10) to the position in which it interrupts the passage (5) between the axial conduit (2) and the accessory chamber (6), as depicted in That leak-tightness provided by the dual closure or this system of the invention between the axial conduit (2) and the accessory chamber (6) allows securely extracting and incorporating the plate (3) of the flow meter without interrupting the fluid circulation, even in applications for high-pressure fluid conduits, or in environments where double isolation is a requirement on Health, and Safety grounds. The angular plate valves (8 and 9) of the closure system of the passage (5) communicated with the main chamber defined by the axial conduit (2) and the accessory chamber (6) nave respective controls (12 and 13) located on the outside of the flow meter, such that by actuating said controls (12 and 13) the aforementioned angular plate valves (8 and 9) of the closure system can move between their respective sealed and open positions for sealing and opening the passage (5) when necessary. Double isolation for double chamber differential pressure meter, where the differential pressure meter comprising an axial conduit in which there is arranged a plate provided with an orifice which can be extracted into an accessory chamber which communicates with the axial conduit through a passage there being arranged in relation to said passage a closure formed by two angular plate valves which can move independently between a position in which they do not interfere with the aforementioned passage and a position in which they interrupt it such that said angular plate valves allow establishing a leak-tight closure between the axial conduit and the accessory chamber to extract the plate without interrupting the flow of gas or fluid through the axial conduit. 1. Double isolation for double chamber differential pressure meter for sealing a communication passage between an axial fluid circulation conduit which fluid is to be measured and an accessory chamber, there being arranged in the axial conduit a plate provided with an orifice having a smaller section than said axial conduit which can be extracted into the accessory chamber to be removed without interrupting the flow of the fluid through the axial conduit, characterised in that in relation to the communication passage there is arranged between the axial conduit and the accessory chamber a closure formed by two independent angular plate valves which are included in respective housings intersecting the passage with the possibility of movement of each of said angular plate valves in their respective housings between a position in which they do not interfere with the aforementioned passage and a position in which they interrupt said passage establishing a dual closure between both angular plate valves which determines a leak-tight seal for that passage. 2. Double isolation for double chamber differential pressure meter according to FIELD OF THE ART

STATE OF THE ART

OBJECT OF THE INVENTION

DESCRIPTION OR THE DRAWINGS

DETAILED DESCRIPTION OF THE INVENTION