PTO DRIVEN CHIPPER SYSTEM

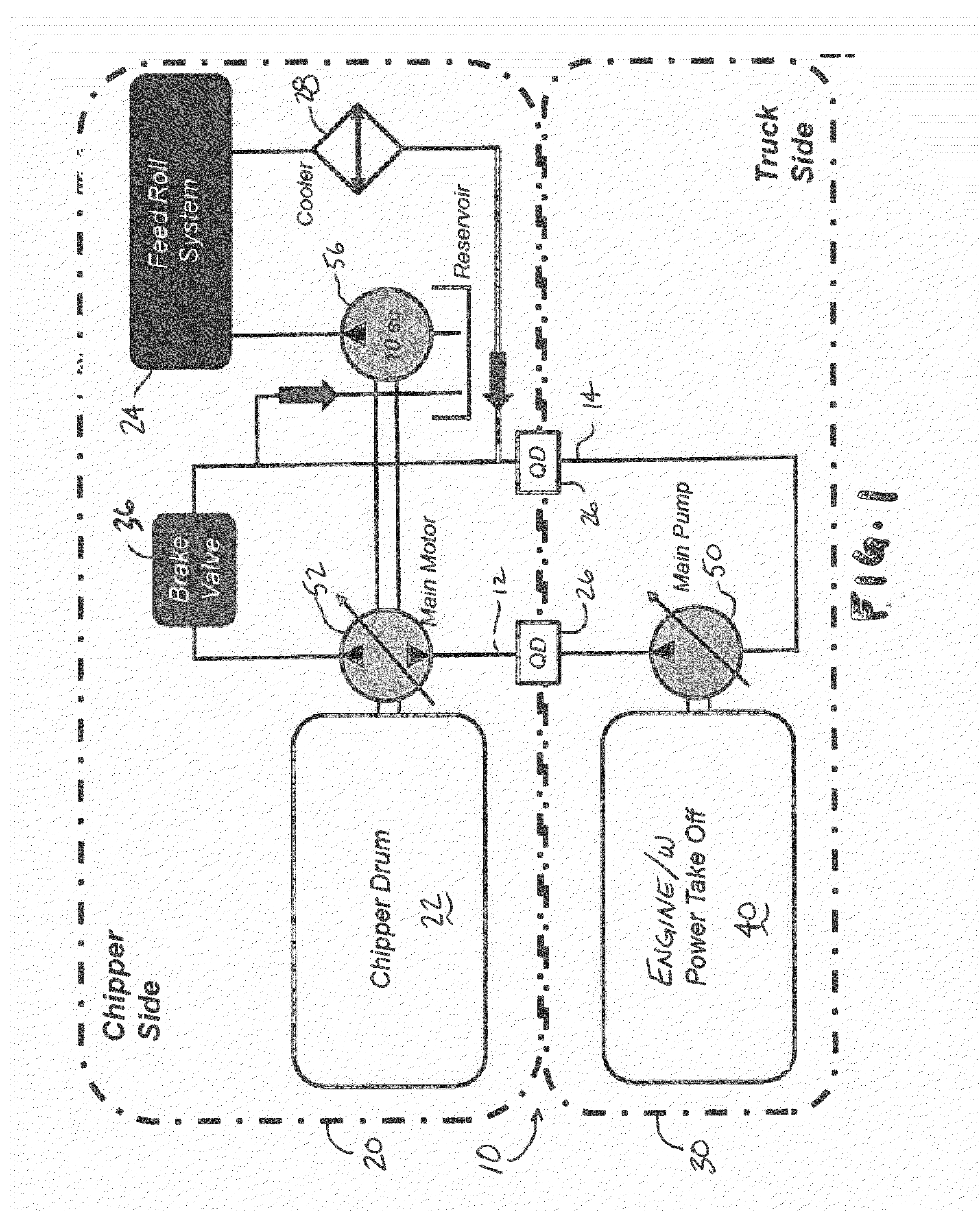

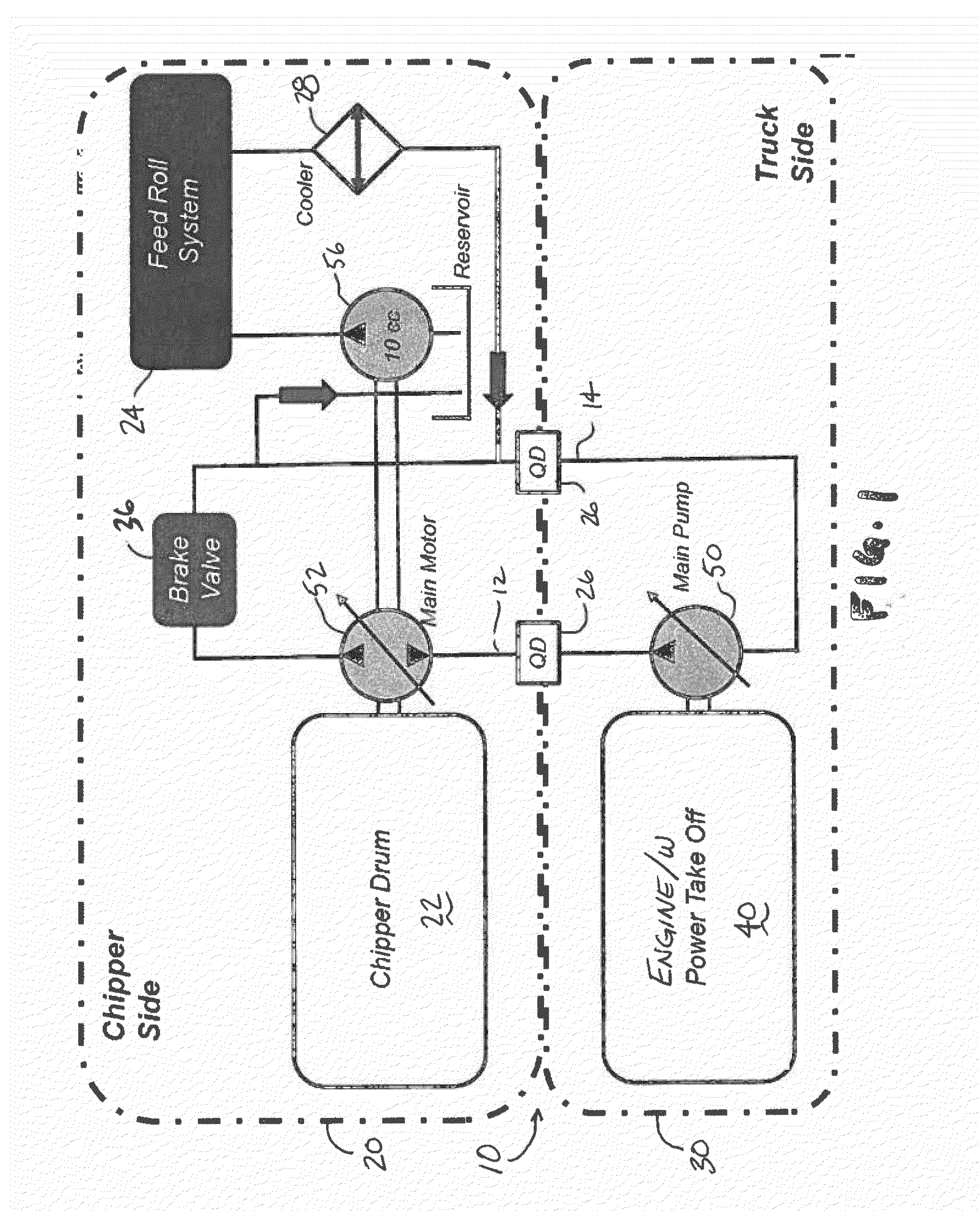

The invention relates generally to wood chippers and in particular to a wood chipper that is operated using a power take off from the engine of a vehicle that tows the chipper. Typically, wood chippers include an engine for powering a chipper and a hydraulic system for rotating a feed wheel which feeds wood material and the like into the wood chipper where the material is cut by a cutting assembly housed within the chipper. The wood chipper is typically towed by a forestry bucket truck that is used to store and haul the wood chips. The truck has an engine and a hydraulic system for the bucket lift arm. At least one embodiment of the invention provides a wood chipping system comprising: a vehicle having an engine; a power take off attached to the engine; a hydraulic pump positioned on the vehicle and driven by the power take off; a towable chipper having chipper drum driven by a hydraulic motor, the hydraulic motor driving a hydraulic pump positioned on the chipper and driving a feed roll system of the chipper; a hydraulic fluid supply line providing a supply of fluid from the vehicle to the chipper and a hydraulic fluid return line returning fluid from the chipper to the vehicle. Embodiments of this invention will now be described in further detail with reference to the accompanying drawings, in which: Referring to The chipper 20 may be in the form of a towable chipper that can be connected/disconnected from the vehicle 30. The supply line 12 and return line 24 include connectors 26 that enable the fluid lines of the vehicle and chipper to be disconnected from each other. The connectors 26 may be in the form of quick disconnect devices that are known in the art. The system includes a brake valve 36 that can be used to stop fluid flow and prevent rotation of the chipper drum 22. The stopping of the drum 22 is significantly faster than existing engine based chippers. A hydraulic schematic of the system 10 shows additional detail of the brake valve 36 in The chipper drum brake is engaged using a “panic” bar. Panic bars are used in chipper systems to stop the feed rollers. In the present invention, when the operator pushes the panic bar not only will the feed roller system stop, but the chipper drum 22 will also stop. The panic bar includes an input device, either a contact switch, a proximity switch, or some type of sensor or input that will provide a signal to the software once the operator pushes the panic bar. The input device provides a signal that the bar has been pushed, the software then commands to de-energize the solenoid valve 38 which closes the brake valve 36. The back pressure on the motor 52 causes the chipper drum 22 to stop in a matter of two to four seconds. It is also contemplated that a manual valve could be used in place of the solenoid valve 38 to engage the chipper drum brake. Although the principles, embodiments and operation of the present invention have been described in detail herein, this is not to be construed as being limited to the particular illustrative forms disclosed. They will thus become apparent to those skilled in the art that various modifications of the embodiments herein can be made without departing from the spirit or scope of the invention. A wood chipping system including a vehicle having an engine and a power take off attached to and selectively powered by the engine. A hydraulic pump is positioned on the vehicle and is driven by the power take off. The system can include a towable support having a chipper mounted thereon, the chipper having a chipper drum driven by a hydraulic motor, the hydraulic motor driving a hydraulic pump that drives a feed roll system of the chipper. The system can include a brake valve associated with the main motor to stop rotation of the chipper drum. 1. A wood chipping system comprising:

a vehicle having an engine; a power take off attached to and selectively powered by the engine; a hydraulic pump positioned on the vehicle and driven by the power take off; a towable support having a chipper mounted thereon, the chipper having a chipper drum driven by a hydraulic motor, the hydraulic motor driving a hydraulic pump positioned on the towable support, the hydraulic pump on the towable support driving a feed roll system of the chipper; a hydraulic fluid supply line providing a supply of fluid from the vehicle to the hydraulic motor on the towable support and a hydraulic fluid return line returning fluid from the towable support to the vehicle; and a brake valve associated with the main motor to stop rotation of the chipper drum. 3. The wood chipping system of 4. (canceled) 5. A system comprising a power take off for driving a first hydraulic pump to supply hydraulic fluid to a hydraulic motor via a hydraulic fluid supply line, the hydraulic motor driving a chipper drum and a second hydraulic pump that drives a feed roll system of a chipper, the hydraulic fluid returning to the first hydraulic pump via a hydraulic fluid return line; and a brake valve associated with the hydraulic motor for stopping rotation of the chipper drum. 6. (canceled) 7. The system of 8. The system of 9. The system of 10. The system of 11. A chipper system comprising:

a hydraulic motor; a chipper drum driven by the hydraulic motor; a hydraulic pump driven by the hydraulic motor, the hydraulic pump providing hydraulic power to a feed roll system; and a hydraulic circuit fluidly connecting the hydraulic motor to a source of hydraulic fluid power, the hydraulic circuit including a brake valve, the brake valve having a first and second position, the first brake valve position allowing fluid flow to the hydraulic motor, the second brake valve position stopping fluid flow to the hydraulic motor. 12. The system of 13. The system of 14. The system of 15. The system of 16. The system of 17. The system of 18. The system of 19. The system of 20. The system of TECHNICAL FIELD

BACKGROUND

SUMMARY

BRIEF DESCRIPTION OF THE DRAWINGS

DETAILED DESCRIPTION OF THE DRAWING