ADJUSTABLE OVERHEAD DOOR HINGE

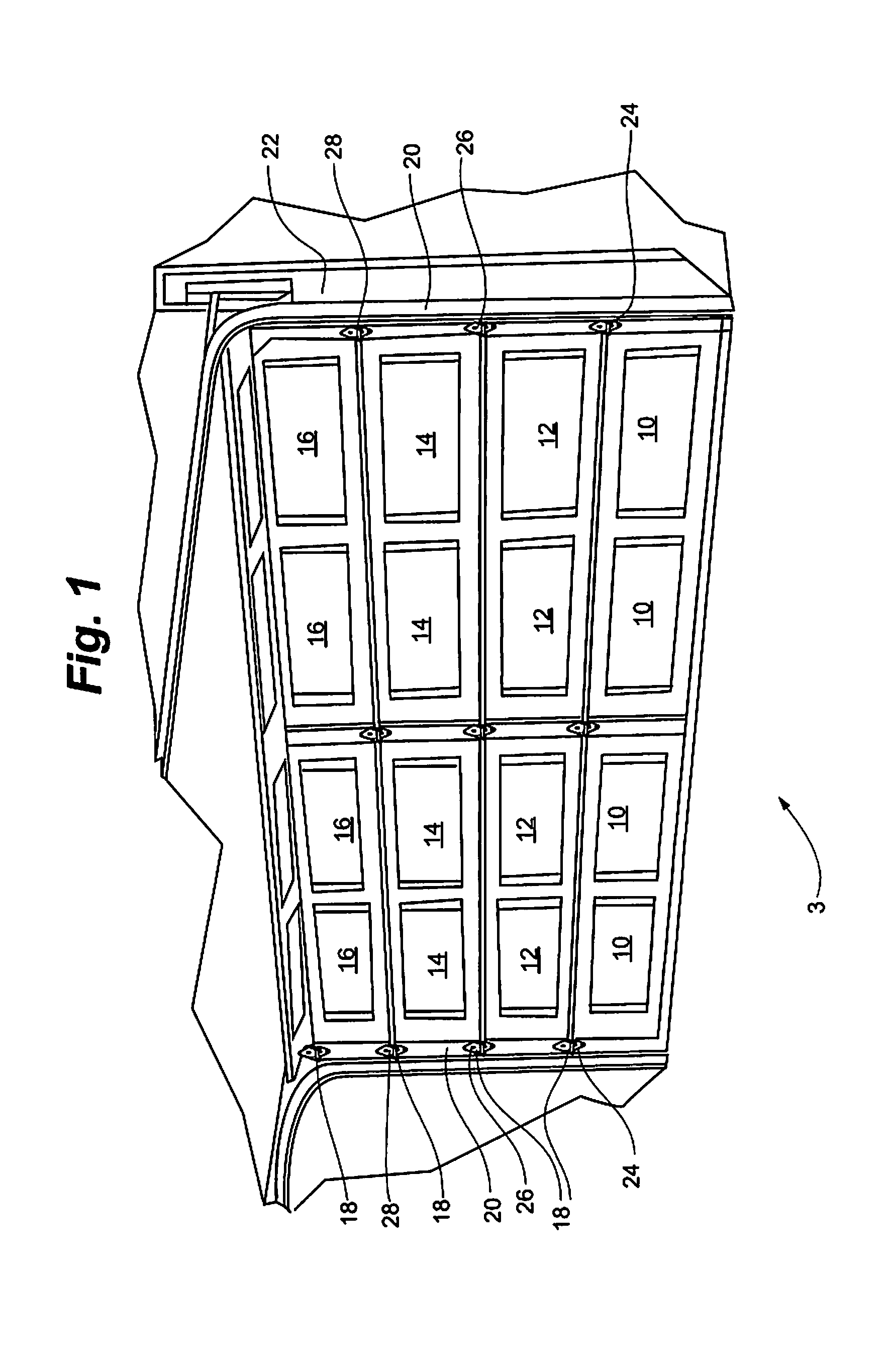

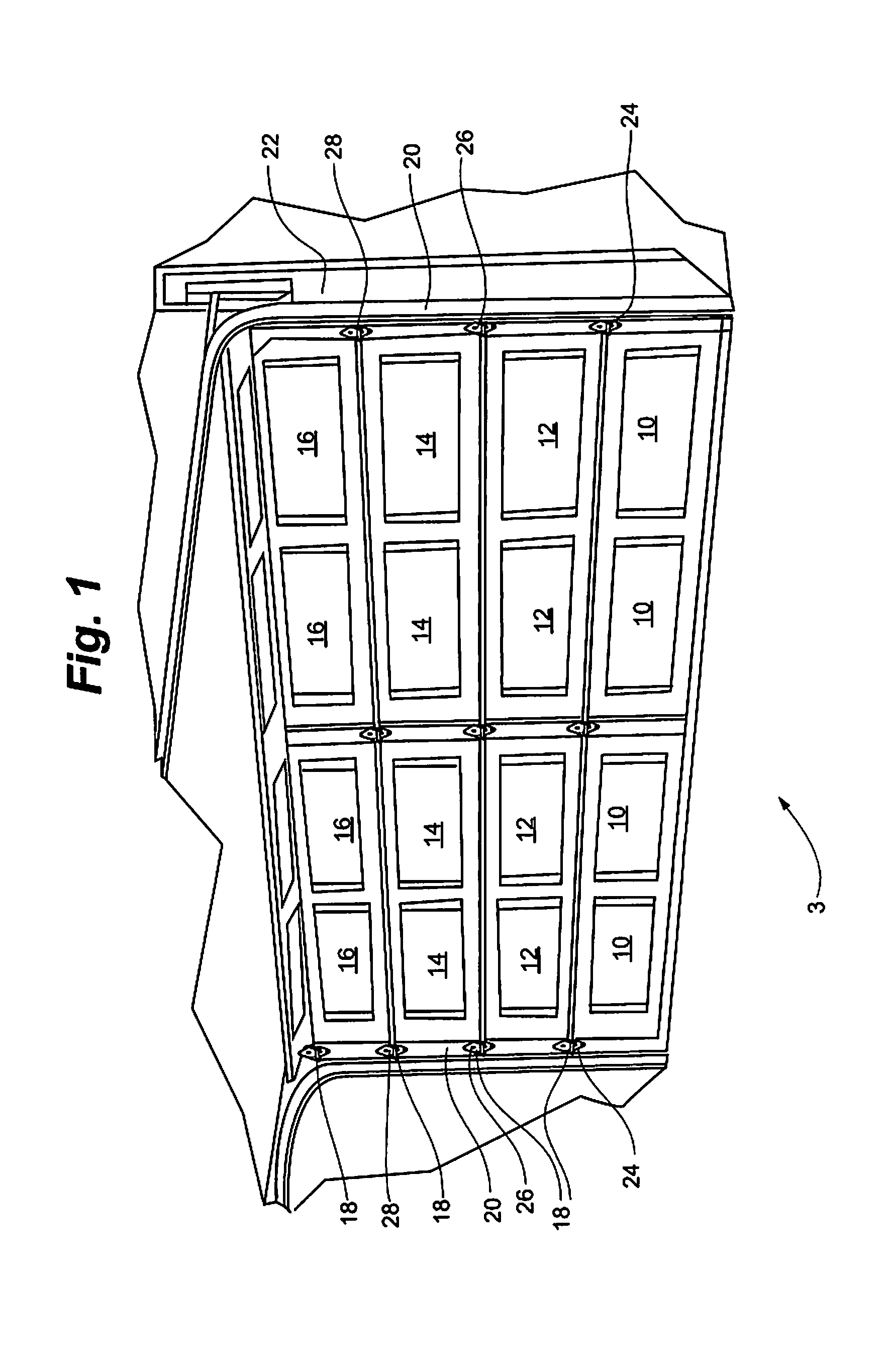

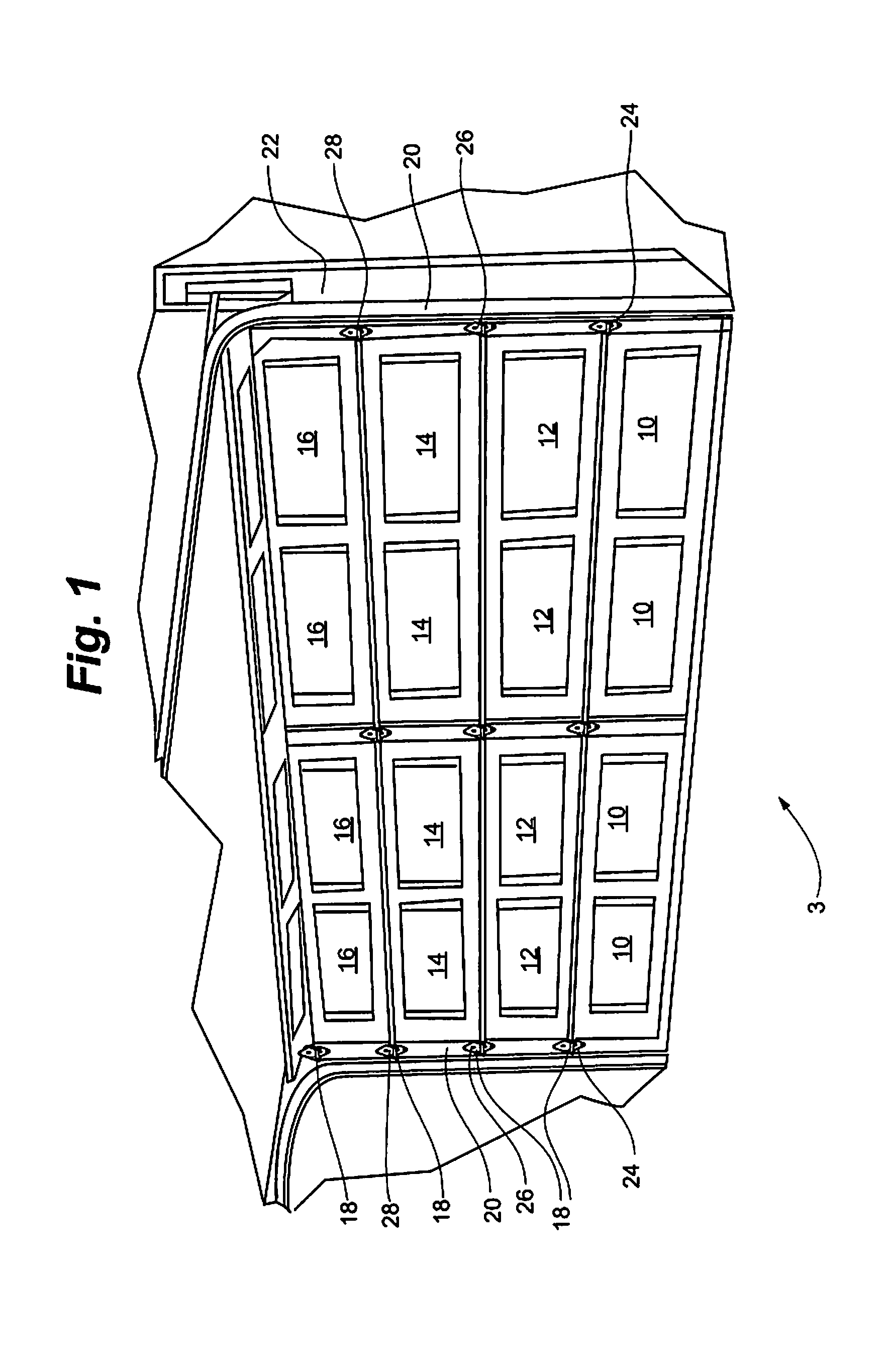

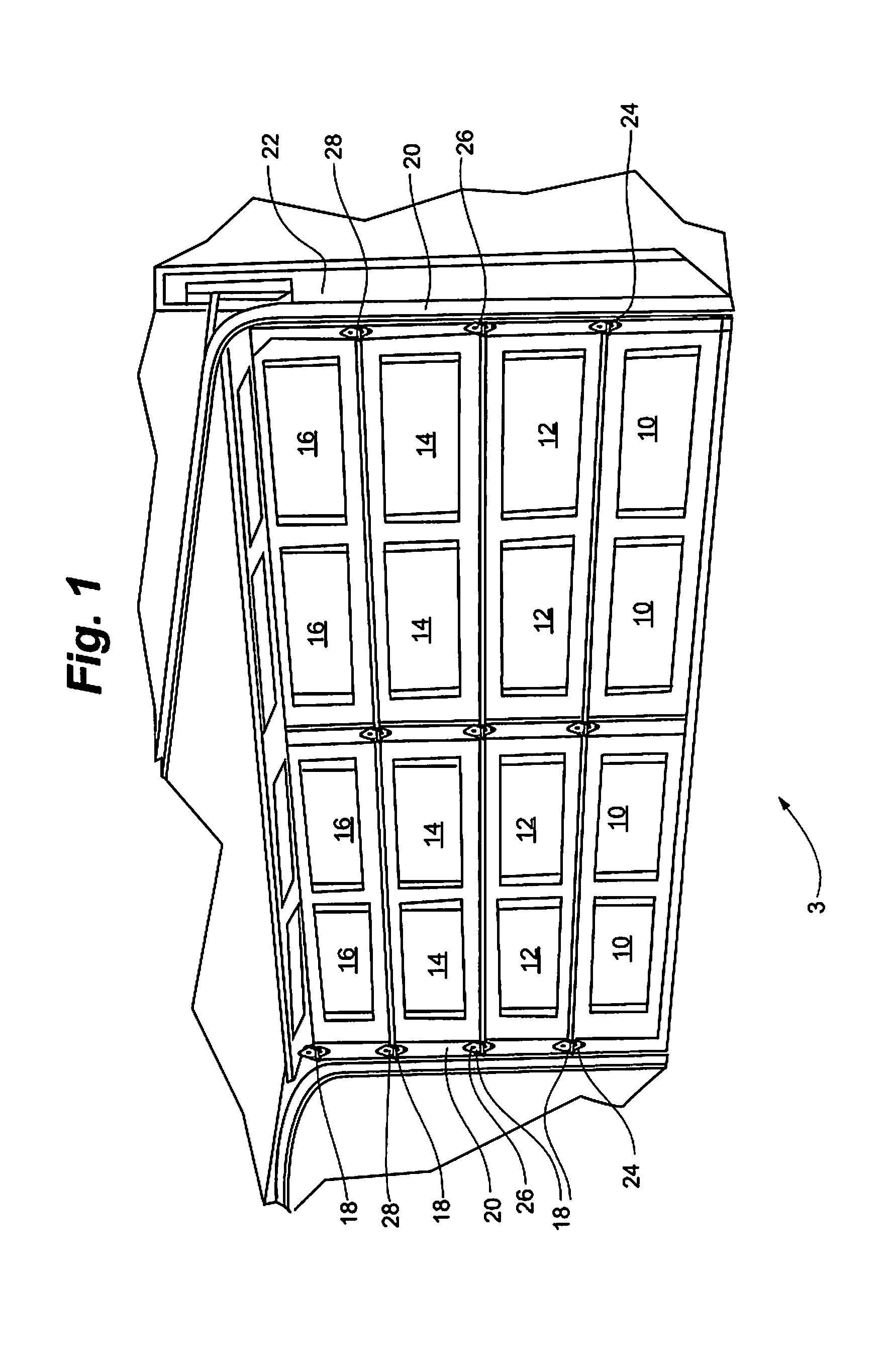

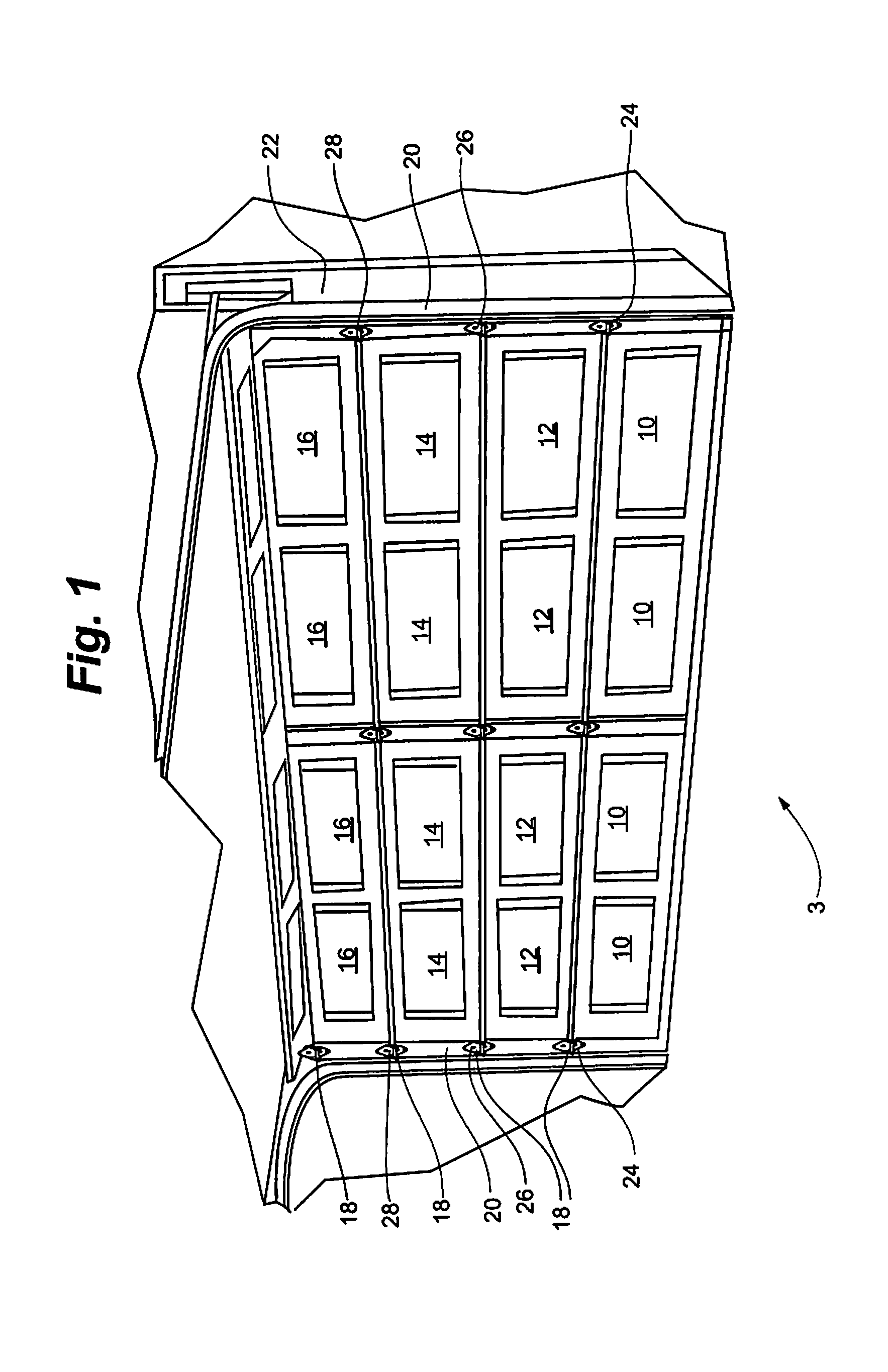

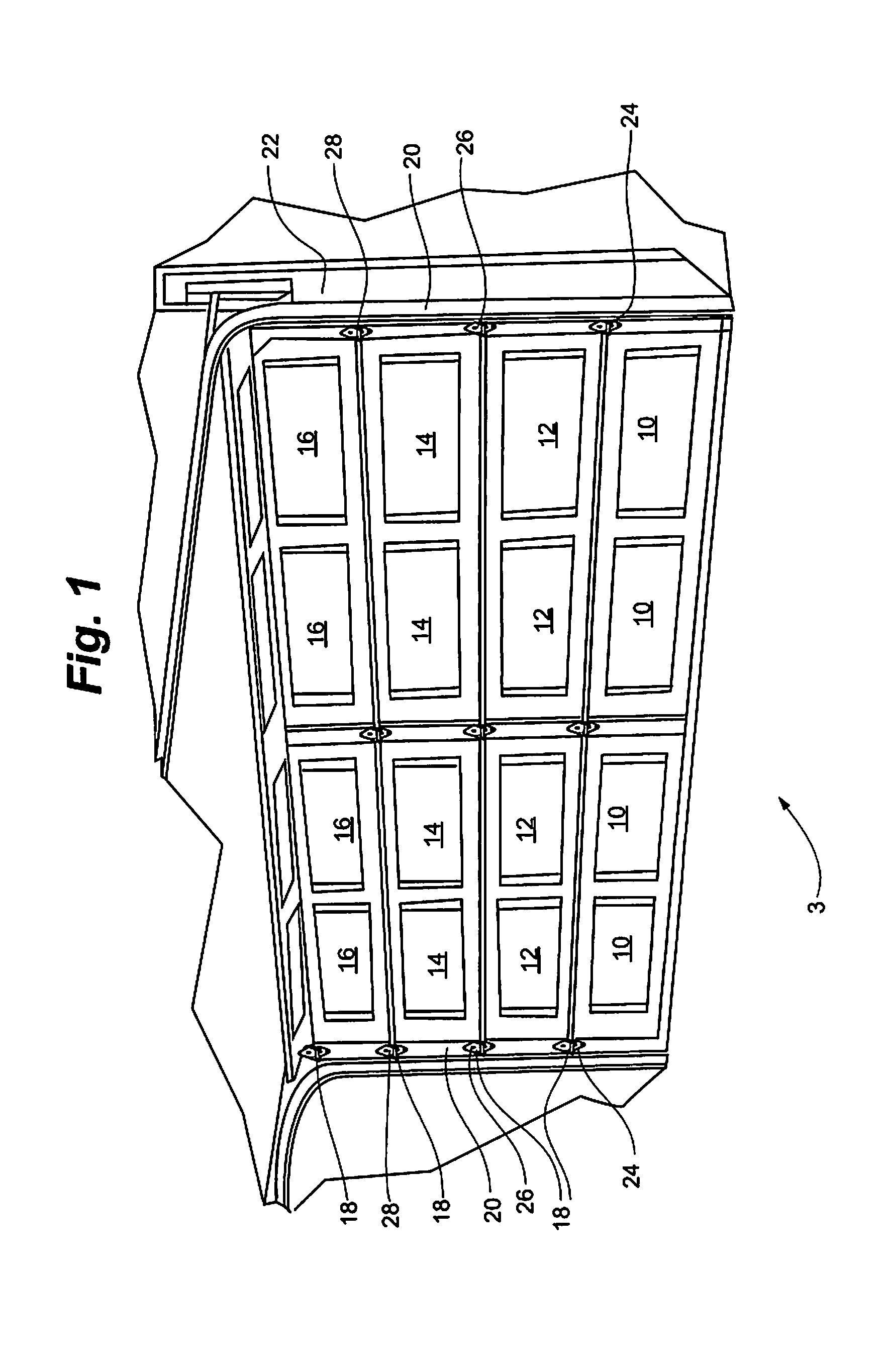

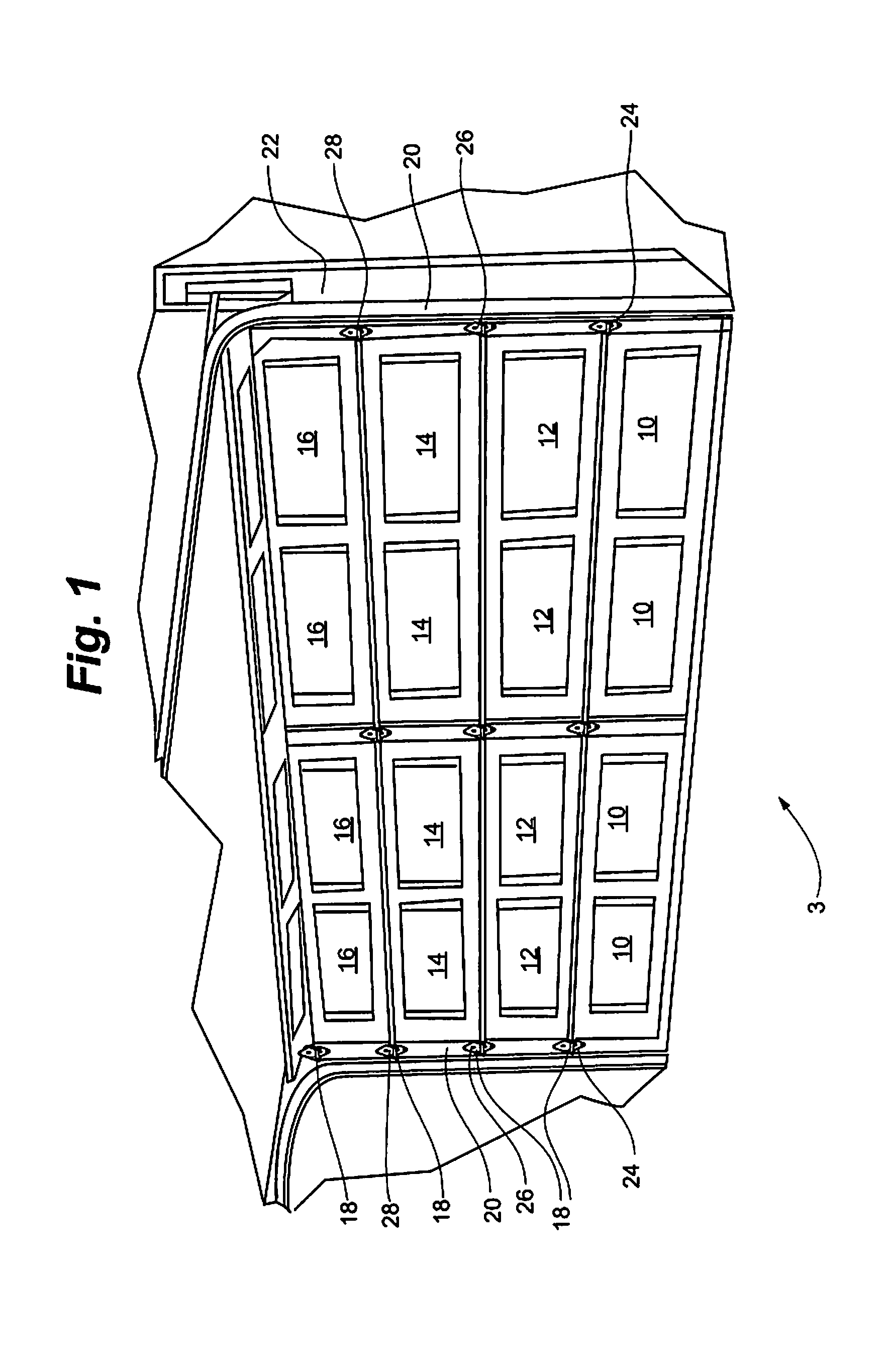

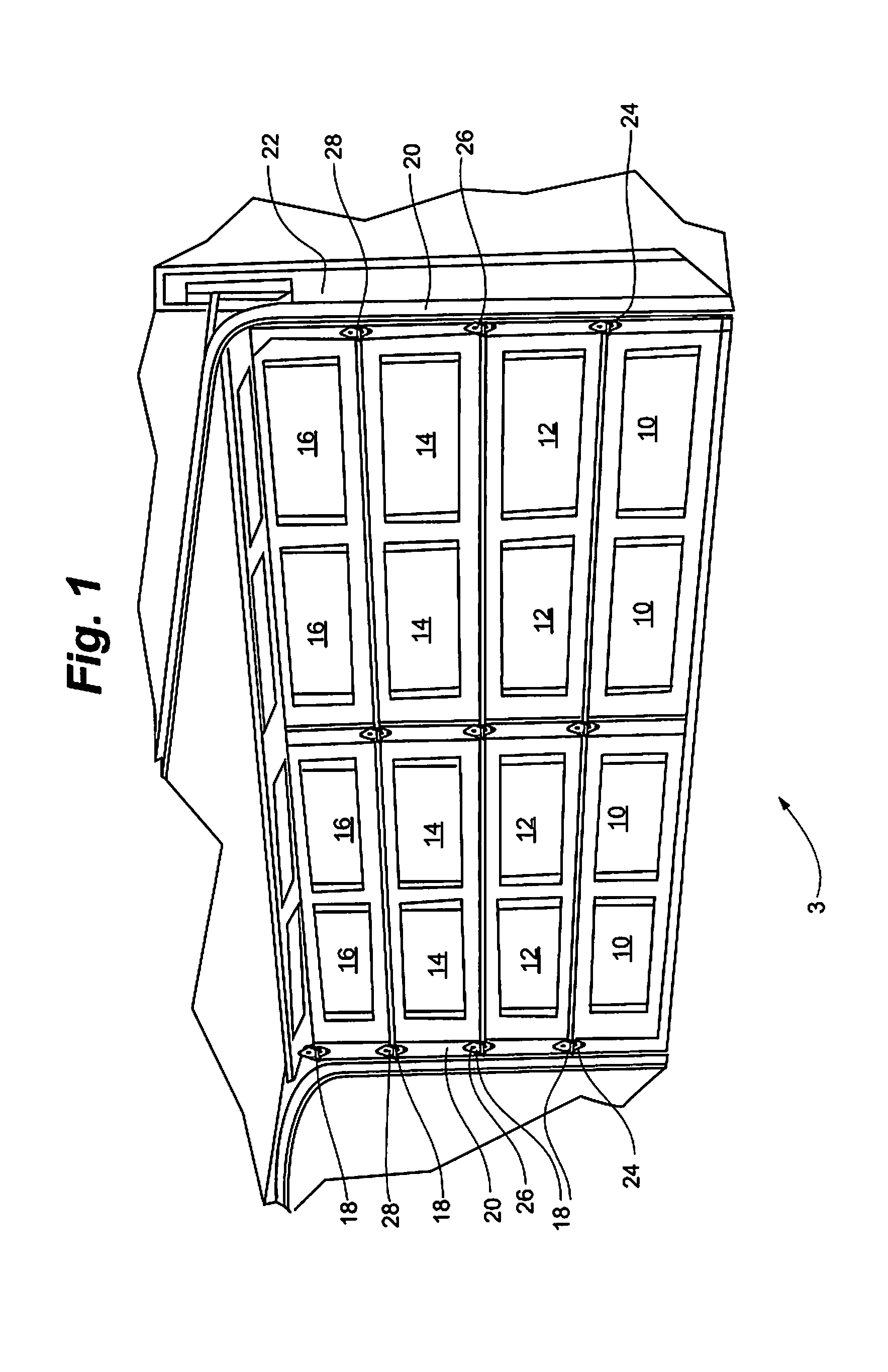

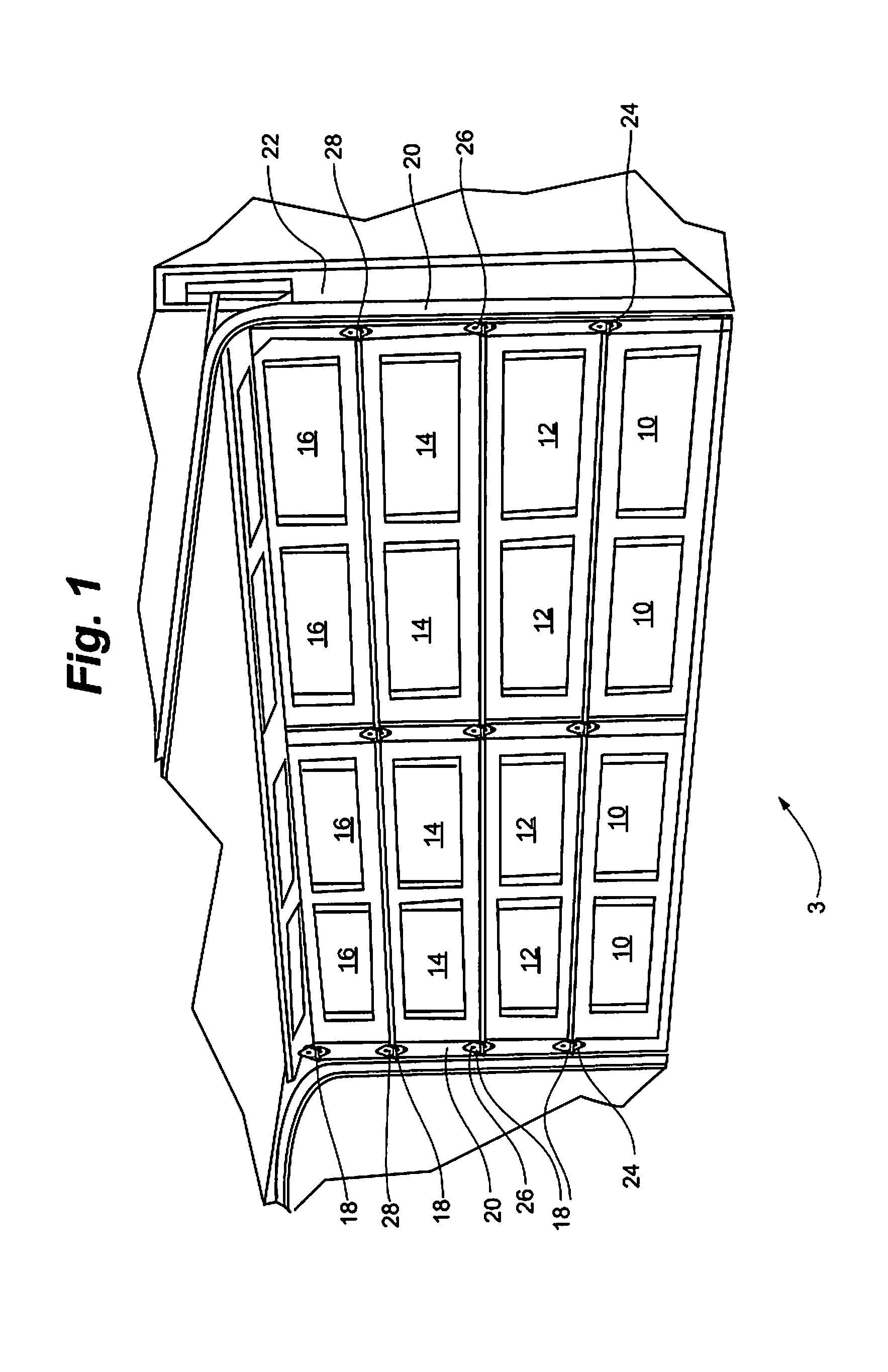

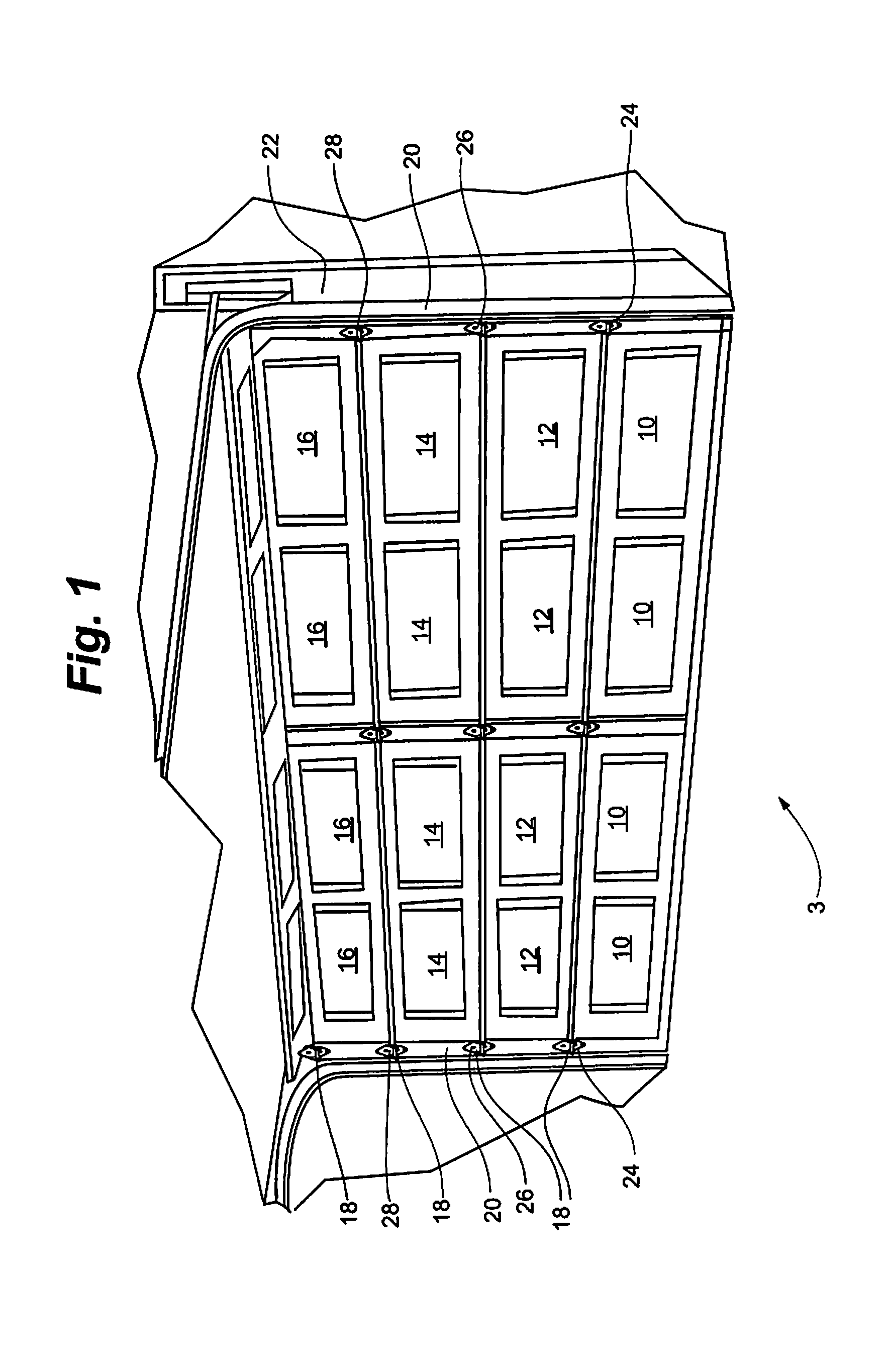

This application claims the benefit of U.S. Provisional Application No. 61/880,879, entitled ADJUSTABLE OVERHEAD DOOR HINGE, filed Sep. 21, 2013, said application hereby fully incorporated herein by reference. The invention relates generally to hinges for overhead doors, and more specifically to an adjustable hinge for an overhead garage door. An overhead garage door 8 as depicted in It is desirable that all the door sections 10, 12, 14, 16 are as close as possible to door frame 22 when door 8 is in the closed position in order to facilitate sealing of the opening defined by frame 22 against weather and against the passage of unwanted insects and pest animals. As a result, the hinges between the successive vertical door sections 10, 12, 14, 16 have slightly different geometry, and are actually numbered for uniformity in the industry as depicted in Referring now to prior art This leads to inefficiency in manufacturing in having to supply the different hinges, and to extra cost and delay when an installer or repair technician must ensure that a correctly numbered hinge is available and installed at each vertical door panel hinge point. What is needed in the industry is a universal overhead door hinge that can be easily adjusted to accommodate installation at any of the vertical locations on the door. Embodiments of the invention meet the need in the industry for a universal overhead door hinge that can be easily adjusted to accommodate installation at any of the vertical locations on the door. In an embodiment, a hinge for a multi-panel door includes a first bracket, a second bracket pivotally coupled to the first bracket, and a carrier link carrying a roller adapted to engage in a door track. The first bracket is adapted to be operably attached to a first panel of the multi-panel door, the second bracket is adapted to be operably attached to second panel of the multi-panel door, and the carrier link is pivotally attached to one of the first bracket or the second bracket. The carrier link is selectively positionable in a plurality of pre-defined positions, such that at each of the pre-defined positions, the roller is disposed at a different position relative to the first bracket and the second bracket. The carrier link can include a bushing, wherein the bushing receives an axle with the roller coupled to the axle. The first bracket may have a planar central portion with a pair of upstanding spaced-apart flanges, the second bracket may have a planar central portion with a pair of upstanding spaced-apart flanges, and the first bracket may be pivotally coupled to the second bracket with a hinge pin extending through each of the upstanding flanges. The hinge may include a spring operably coupled to the carrier link and arranged to bias the carrier link relative to the first bracket or the second bracket. The upstanding flanges of the first bracket or the second bracket can define a plurality of notch pairs, each notch pair corresponding to a separate one of the pre-defined positions of the carrier link, wherein ends of the spring are receivable in each of said notch pairs to position the carrier link. In a further embodiment, the carrier link may be coupled to the first bracket or the second bracket with a selectively removable pin. In a further embodiment, a door has a plurality of separate panels and a track, wherein each of the panels is pivotally coupled to at least one vertically adjacent panel with a separate hinge, and each hinge includes a first bracket, a second bracket pivotally coupled to the first bracket, and a carrier link carrying a roller engaged in the track. The first bracket is attached to a first one of the panels, the second bracket is attached to second one of the panels, and the carrier link is pivotally attached to one of the first bracket or the second bracket. The carrier link is selectively positionable in a plurality of pre-defined positions, such that at each of the pre-defined positions, the roller is spaced outwardly at a different distance relative to the door. In an embodiment, each hinge may include a bushing, wherein the bushing receives an axle, and wherein the roller is coupled to the axle. The first bracket of each hinge may have a planar central portion with a pair of upstanding spaced-apart flanges, the second bracket of each hinge may have a planar central portion with a pair of upstanding spaced-apart flanges, with the first bracket pivotally coupled to the second bracket with a hinge pin extending through each of the upstanding flanges. Each hinge further may include a spring operably coupled to the carrier link and arranged to bias the carrier link relative to the first bracket or the second bracket. The upstanding flanges of the first bracket or the second bracket may define a plurality of notch pairs, each notch pair corresponding to a separate one of the pre-defined positions of the carrier link, and wherein ends of the spring are receivable in each of said notch pairs to position the carrier link. The carrier link may be coupled to the first bracket or the second bracket with a selectively removable pin. The embodiments of the present invention may be more completely understood in consideration of the following detailed description of various embodiments in connection with the accompanying drawings, in which: While the present invention is amenable to various modifications and alternative forms, specifics thereof have been shown by way of example in the drawings and will be described in detail. It should be understood, however, that the intention is not to limit the present invention to the particular embodiments described. On the contrary, the intention is to cover all modifications, equivalents, and alternatives falling within the spirit and scope of the present invention. An adjustable hinge 110 according to an embodiment of the invention is depicted in Second bracket 116 generally includes plate 126 and parallel flanges 128. Plate 126 defines elongate aperture 130, and aperture 132. Each flange 128 defines a pin-receiving aperture 134, notches 136 Carrier link 114 generally includes center portion 140 and spaced-apart flanges 142. Center portion 140 has spring-receiving plate 144 oriented perpendicularly thereto. Each of flanges 142 defines a first aperture 146 and a second aperture 148. First bracket 112 is pivotally coupled to carrier link 114 and second bracket 116 with hinge pin 150 extending through apertures 124, 134, and 146. Bushing 152 is carried in apertures 148 of carrier link 114. Bushing 152 rotatably receives an axle 153 with a roller 155 that engages and rolls in track 120. As depicted in It will be appreciated that ends 156 of spring 154 can be shifted to any pair of notches 136 As those of skill in the art will appreciate, hinge 110 can thus be used in any of the locations #1, #2, #3, and so on, assuming there are appropriately located notches 136 Those of skill in the art will also appreciate that spring 154 applies a bias to carrier link 114, such that, when closed, door 8 can be lightly spring loaded against the seal around frame 22, so as to better seal against weather and the entry of insects and other unwanted pests. The spring suspension provided by spring 154 can also make up for thermal expansion and contraction, and shift as necessary to account of settling of the garage and wear of the various components (door, frame, door trim, track, etc). Moreover, in that the hinge can flex to a changing environment through the action of spring 154, the need for service calls can be reduced relative to prior art doors and installation methods. In an embodiment of the invention, there may be about ⅜ inch of spring loaded travel when the hinge is installed in each of positions #1, #2, #3 or #4. An adjustable hinge 210 according to an alternative embodiment of the invention is depicted in Second bracket 216 generally includes plate 226 and parallel flanges 228. Plate 226 defines elongate aperture 230, and aperture 232. Each flange 228 defines pin-receiving apertures 234, 235, and notches 236 Carrier link 214 generally includes center portion 240 and spaced-apart flanges 242. Center portion 240 has spring-receiving plate 244 oriented perpendicularly thereto. Each of flanges 242 defines a first aperture 246 and a second aperture 248. First bracket 212 is pivotally coupled to second bracket 216 with hinge pin 250 extending through apertures 224, 234. Carrier link 214 is pivotally coupled to second bracket 216 with pin 270 extending through apertures 235, 246. Bushing 252 is carried in apertures 248 of carrier link 214. Again, bushing 252 rotatably receives an axle 253 with a roller 255 that engages and rolls in track 120. Just as for the first embodiment described above, it will be appreciated that ends 256 of spring 254 can be shifted to any pair of notches 236 References to relative terms such as upper and lower, front and back, left and right, or the like, are intended for convenience of description and are not contemplated to limit the invention, or its components, to any specific orientation. All dimensions depicted in the figures may vary with a potential design and the intended use of a specific embodiment of this invention without departing from the scope thereof. Each of the additional figures and methods disclosed herein may be used separately, or in conjunction with other features and methods, to provide improved devices, systems and methods for making and using the same. Therefore, combinations of features and methods disclosed herein may not be necessary to practice the invention in its broadest sense and are instead disclosed merely to particularly describe representative embodiments of the invention. For purposes of interpreting the claims for the present invention, it is expressly intended that the provisions of 35 U.S.C. §112(f) are not to be invoked unless the specific terms “means for” or “step for” are recited in the subject claim. A hinge for a multi-panel door includes a first bracket, a second bracket pivotally coupled to the first bracket, and a carrier link carrying a roller adapted to engage in a door track. The first bracket is adapted to be operably attached to a first panel of the multi-panel door, the second bracket is adapted to be operably attached to second panel of the multi-panel door, and the carrier link is pivotally attached to one of the first bracket or the second bracket. The carrier link is selectively positionable in a plurality of pre-defined positions, such that at each of the pre-defined positions, the roller is disposed at a different position relative to the first bracket and the second bracket so that the roller can be spaced apart a variety of different distances from the door. 1. A hinge for a multi-panel door, the hinge comprising:

a first bracket; a second bracket pivotally coupled to the first bracket; and a carrier link carrying a roller adapted to engage in a door track, wherein the first bracket is adapted to be operably attached to a first panel of the multi-panel door, the second bracket is adapted to be operably attached to second panel of the multi-panel door, and the carrier link is pivotally attached to one of the first bracket or the second bracket, the carrier link selectively positionable in a plurality of pre-defined positions, such that at each of the pre-defined positions, the roller is disposed at a different position relative to the first bracket and the second bracket. 2. The hinge of 3. The hinge of 4. The hinge of 5. The hinge of 6. The hinge of 7. A door having a plurality of separate panels and a track, wherein each of the panels is pivotally coupled to at least one vertically adjacent panel with a separate hinge, each hinge comprising:

a first bracket; a second bracket pivotally coupled to the first bracket; and a carrier link carrying a roller engaged in the track, wherein the first bracket is attached to a first one of the panels, the second bracket is attached to second one of the panels, and the carrier link is pivotally attached to one of the first bracket or the second bracket, the carrier link selectively positionable in a plurality of pre-defined positions, such that at each of the pre-defined positions, the roller is spaced outwardly at a different distance relative to the door. 8. The door of 9. The door of 10. The door of 11. The door of 12. The door of RELATED APPLICATIONS

FIELD OF THE INVENTION

BACKGROUND OF THE INVENTION

SUMMARY OF THE INVENTION

BRIEF DESCRIPTION OF THE DRAWINGS

DETAILED DESCRIPTION