BATTERY DIRECT-MOUNTED FUSIBLE LINK

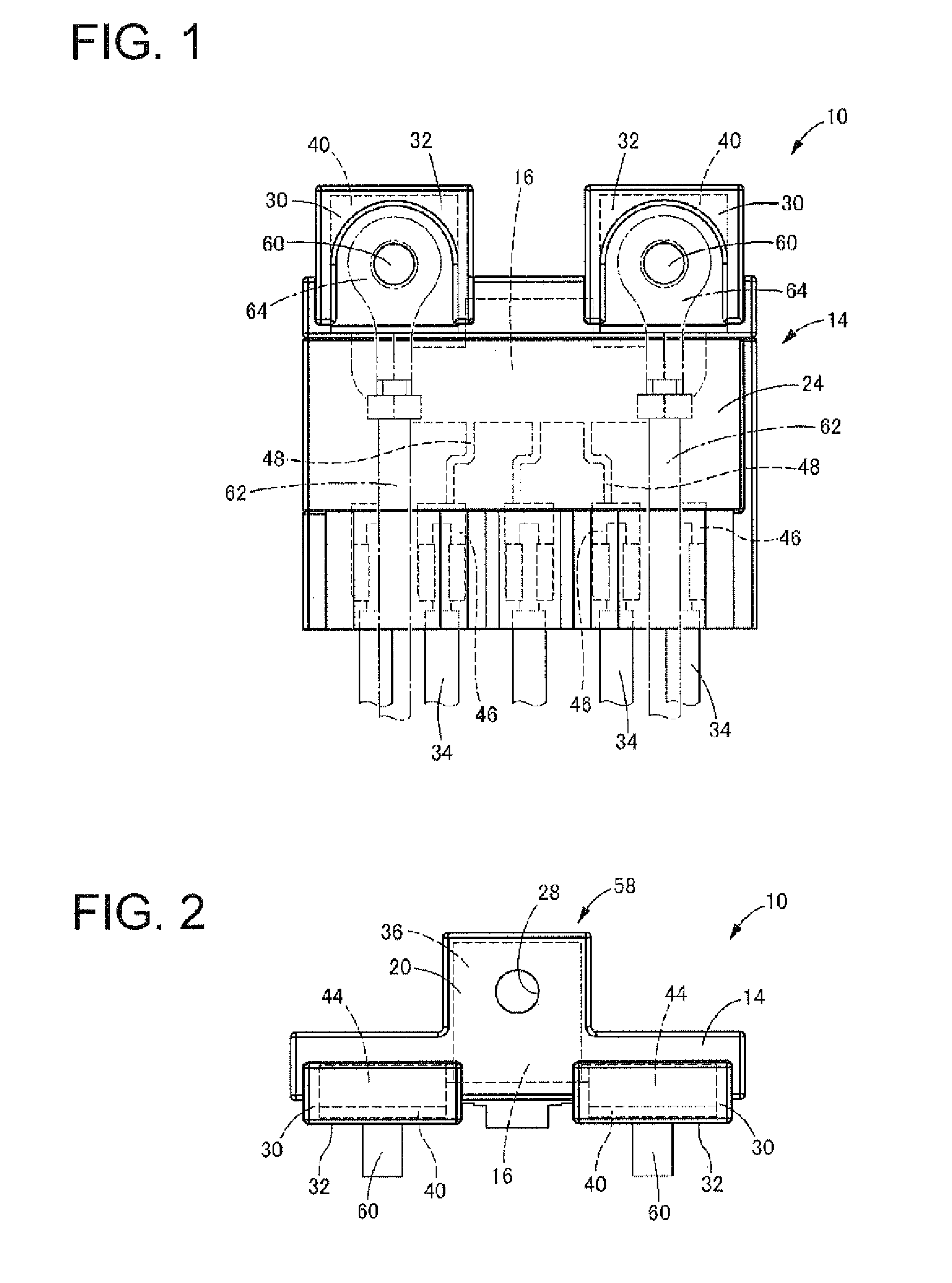

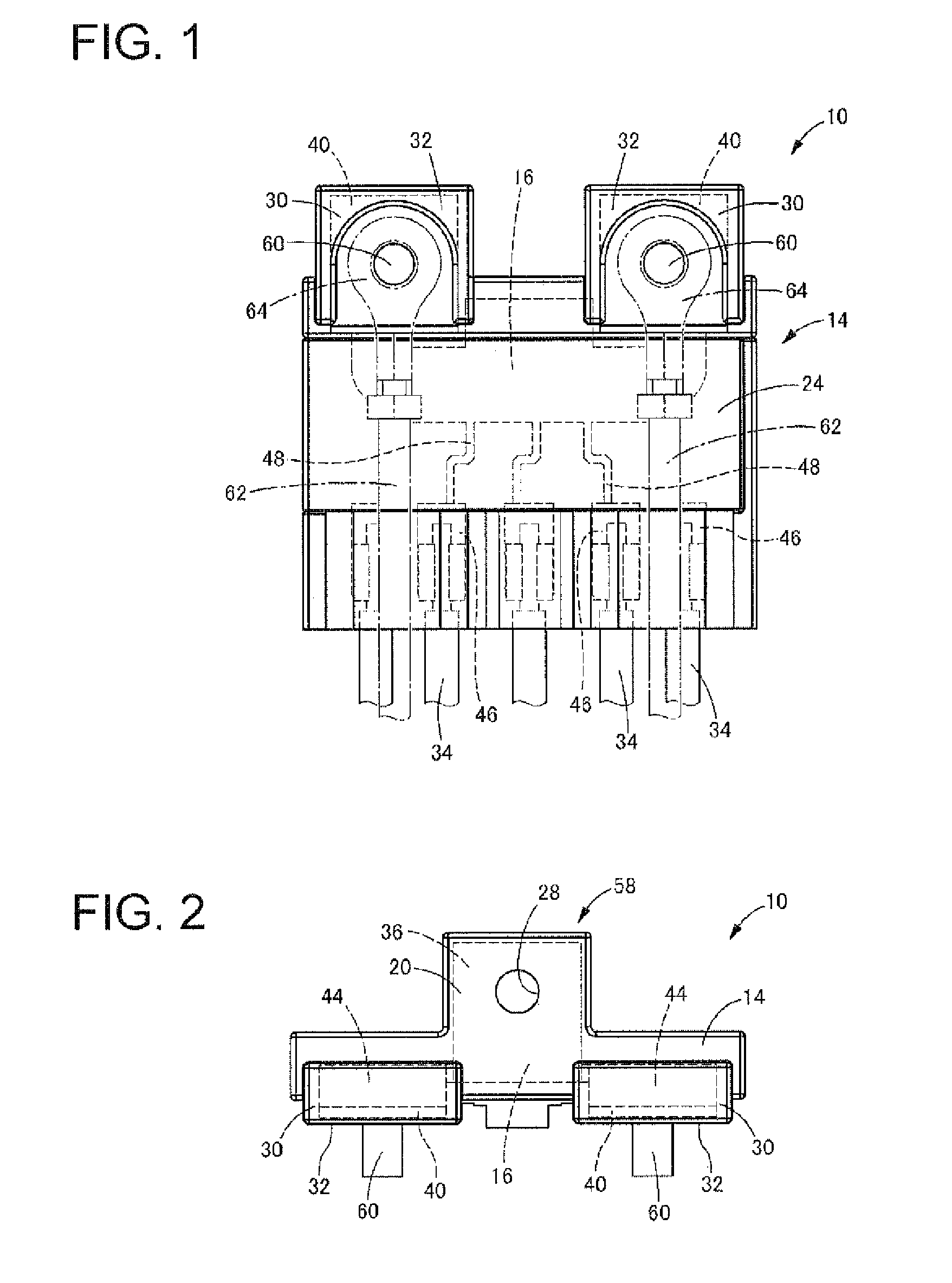

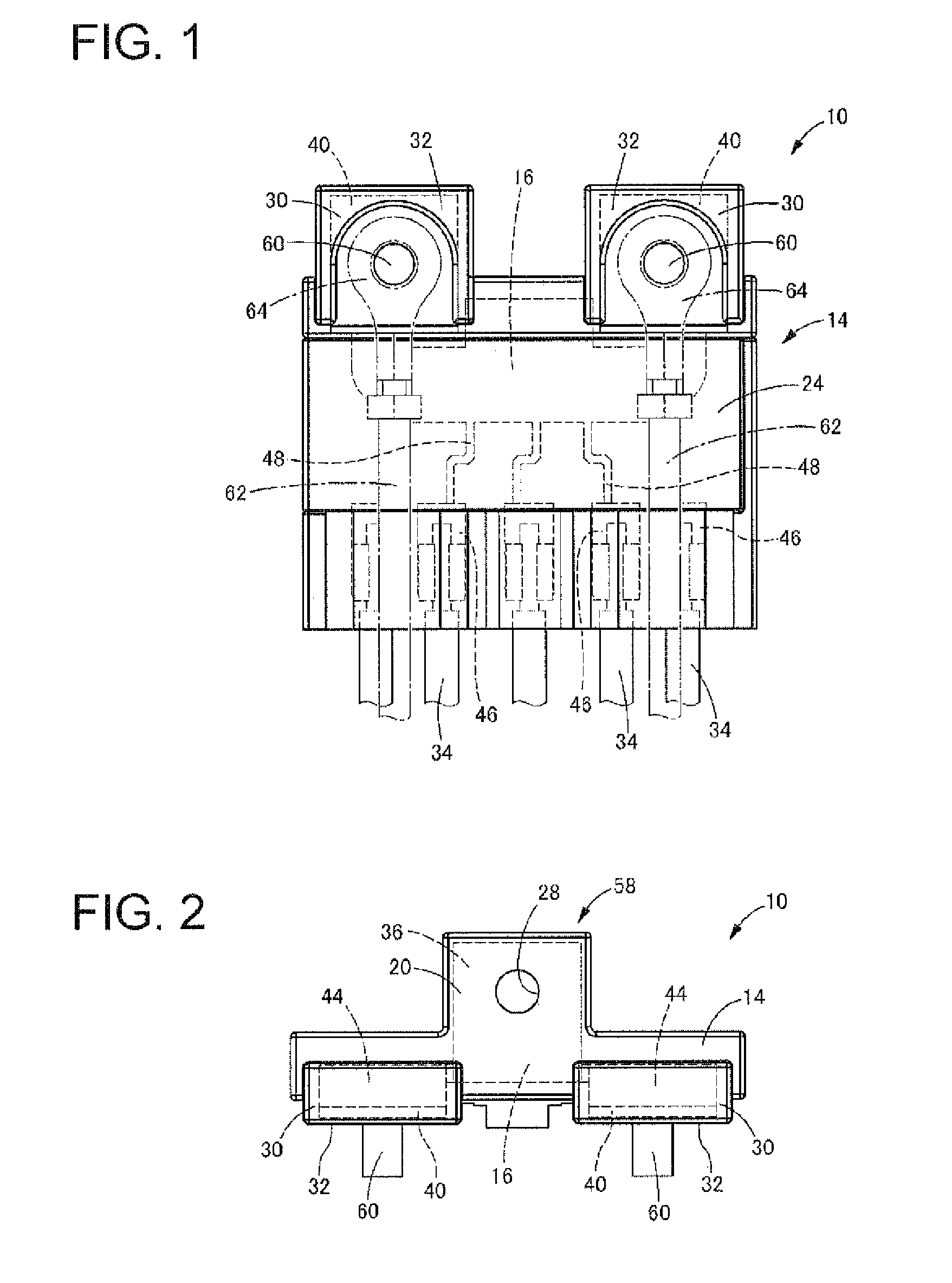

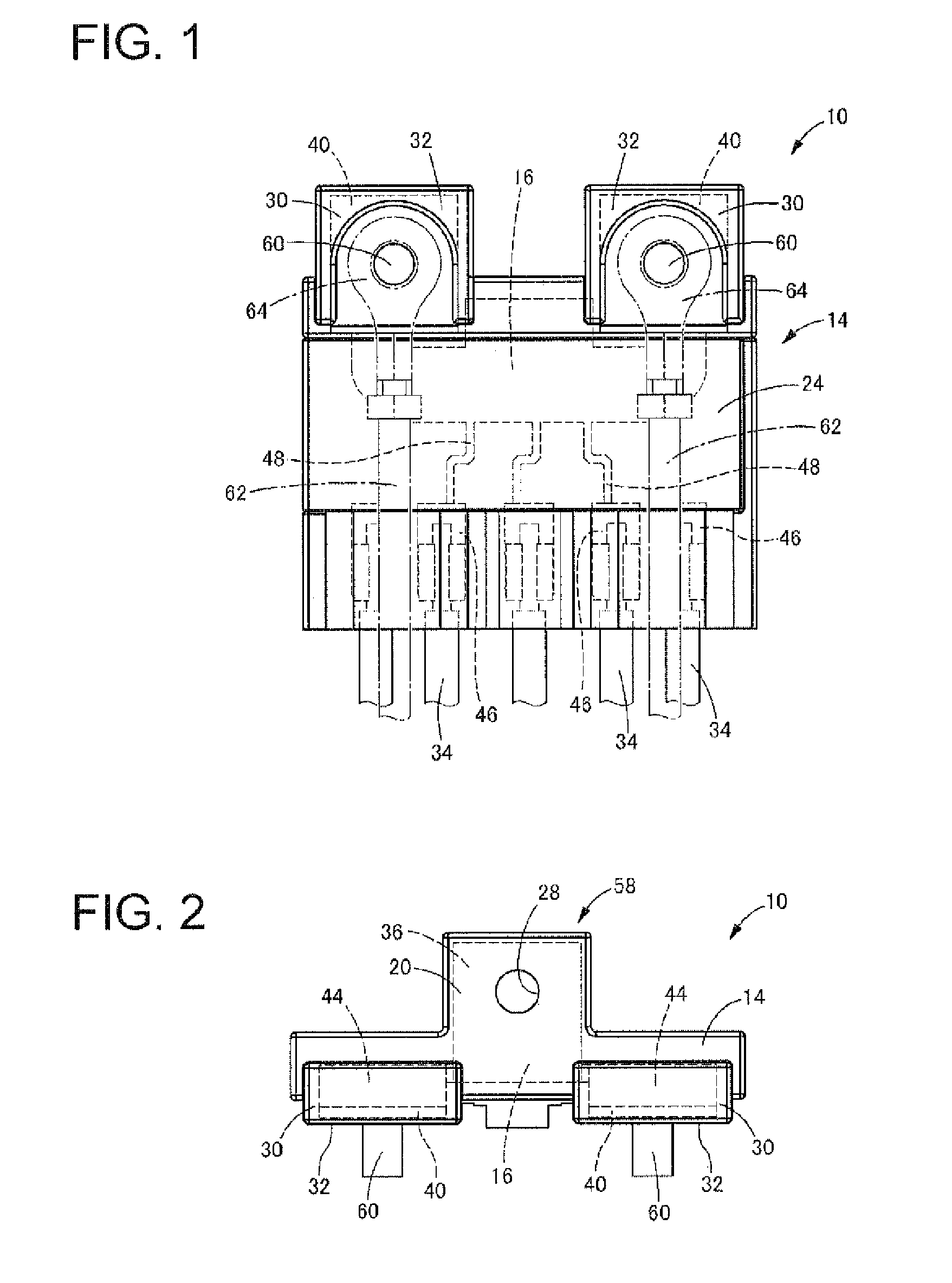

The present application relates to a battery direct-mounted fusible link to be directly mounted to a battery to connect electric wires from an alternator and various loads to the battery. Conventionally, battery direct-mounted fusible links have been used in automobiles and the like in order to allow electric wires to be connected via fusible portions to a battery without using a fuse box or the like away from the battery. The battery direct-mounted fusible link described in JP 2005-190735A (Patent Document 1), for example, has a structure including a battery connecting portion to be connected to a battery post, a stud bolt for bolt-fixing a connecting terminal provided at an end of an electric wire from an alternator or the like, and load connecting portions for connecting electric wires from various loads such as a motor, electronic components, and the like that are provided in an automobile via fusible portions to a battery. Incidentally, as also described in Patent Document 1, the battery direct-mounted fusible link is formed in an L-shape having a horizontal portion to be arranged on an upper surface of the battery and a vertical portion to be arranged on a lateral surface of the battery. The horizontal portion and the vertical portion of the battery direct-mounted fusible link are arranged over the edge portion of the upper surface of the battery, thus reducing the size of an arrangement space. However, batteries to be mounted in automobiles slightly differ in size depending on the types, makers, and the like. Therefore, battery direct-mounted fusible links can be provided with margins in the length of the horizontal portion so as to be capable of being attached to a larger number of types of batteries, and thus are configured such that, even when the battery is large, the horizontal portion goes over the edge portion of the upper surface of the battery and the vertical portion can be arranged on the lateral surface of the battery. However, there is a problem with such a structure in that the horizontal portion significantly projects from the battery to form a large gap between the vertical portion and the lateral surface of the battery if the battery is small, thus causing a decrease in efficiency of the arrangement space. Moreover, as also mentioned in Patent Document 1, in the battery direct-mounted fusible link, the battery connecting portion provided in the horizontal portion is generally fastened to the bolt-shaped battery post of the battery with a bolt. Therefore, if the gap between the vertical portion and the lateral surface of the battery is large, there is a risk that the battery direct-mounted fusible link rotates about the battery post, and thus the reliability of the connection with the battery and the electric wires deteriorates. In order to address these problems, JP 2009.76409A (Patent Document 2) proposes a structure for preventing the rotation of the battery direct-mounted fusible link by interposing a block-shaped member between the vertical portion and the lateral surface of the battery. Moreover, JP 2010-61813A (Patent Document 3) proposes a structure for preventing the rotation by bringing a bent metal piece into contact with the outer surface of the battery. However, since the gap dimension between the vertical portion and the lateral surface of the battery remains the same in the structures mentioned in Patent Document 2 and Patent Document 3, the problem of the arrangement space cannot be solved, and there is a risk that the size of the arrangement space is further increased due to a newly provided special member. Patent Document 1: JP 2005-190735A Patent Document 2: JP 2009-76409A Patent Document 3: JP 2010-61813A The present application has been achieved in light of the above-described circumstances, and the problem to be solved of the present application is to provide a battery direct-mounted fusible link having a novel structure capable of achieving a more compact size while effectively reducing a risk of rotation with respect to a battery. A first aspect of the present application is a battery direct-mounted fusible link having an L-shape including a horizontal portion to be arranged on a top surface of a battery and a vertical portion to be arranged on a lateral surface of the battery, the battery direct-mounted fusible link being provided with a battery connecting portion to be connected to a battery post of the battery, at least one stud bolt to which a connecting terminal provided at an end of an electric wire is to be fastened, and at least one load connecting portion to be connected to a load, the load connecting portion being coupled via a fusible portion to the battery connecting portion, wherein only the battery connecting portion is provided in the horizontal portion, and the stud bolt and the load connecting portion are provided in the vertical portion, the stud bolt projecting from the vertical portion in a horizontal direction parallel to the horizontal portion. In the battery direct-mounted fusible link having the structure according to the present application, only the battery connecting portion to be connected to the battery post is provided in the horizontal portion to be arranged on the upper surface of the battery. This makes it possible to reduce the length dimension of the horizontal portion compared with cases where a stud bolt and the like are also provided in the horizontal portion. As a result, the vertical portion can be arranged nearer to the lateral surface of the battery, thus making it possible to make the arrangement space for the battery direct-mounted fusible link more compact. Since the gap between the vertical portion and the lateral surface of the battery is made small, when the battery direct-mounted fusible link is to rotate about the battery post, the rotation of the battery direct-mounted fusible link can be prevented by the vertical portion coming into contact with the lateral surface of the battery, thus making it possible to improve the reliability of the connection with the battery and the electric wires. Moreover, since the stud bolt is provided in the vertical portion and projects from the vertical portion in a horizontal direction parallel to the horizontal portion, it becomes unnecessary to form a connecting terminal of the electric wire on a side to be connected to the stud bolt into an L-shape in order to extend the electric wire downward, thus making it possible to simplify the shape of the connecting terminal and to reduce cost. A second aspect of the present application is the battery direct-mounted fusible link according to the first aspect, wherein an end of an electric wire to be connected to the load is directly secured to the load connecting portion. In this aspect, the end of the electric wire is directly secured to the load connecting portion without using a connector or the like. Accordingly, it becomes unnecessary to form a space or the like for accommodating the connector in the battery direct-mounted fusible link, thus reducing the size. It should be noted that in an embodiment wherein the end of the electric wire is directly secured to the load connecting portion, soldering, welding, or the like may be performed, or a crimping piece may be provided in the load connecting portion and the end of the electric wire may be crimped, for example. A third aspect of the present application is the battery direct-mounted fusible link according to the second aspect, wherein the load connecting portion is provided with a crimping piece for crimping the end of the electric wire to be connected to the load. With this aspect, the end of the electric wire can be firmly fixed with a simple operation by being crimped. A fourth aspect of the present application is the battery direct-mounted fusible link according to any one of the first to third aspects, wherein the stud bolt and the load connecting portion are lined up in a direction in which the vertical portion extends from the horizontal portion. With this aspect, the stud bolt and the load connecting portion are lined up in the direction in which the vertical portion extends, thus making it possible to stack and compactly dispose the electric wire extending from the stud bolt and the electric wire extending from the load connecting portion. A fifth aspect of the present application is the battery direct-mounted fusible link according to any one of the first to third aspects, wherein the stud bolt and the load connecting portion are lined up in a direction orthogonal to a direction in which the vertical portion extends from the horizontal portion. With this aspect, the electric wire extending from the stud bolt and the electric wire extending from the load connecting portion are disposed in parallel in the horizontal direction, thus making it possible to reduce the risk that the electric wires become tangled with one another. In the battery direct-mounted fusible link according to the present application, only the battery connecting portion to be connected to the battery post is provided in the horizontal portion to be arranged on the upper surface of the battery, and the stud bolt and the load connecting portion are provided in the vertical portion to be arranged on the lateral surface of the battery. This makes it possible to reduce the length dimension of the horizontal portion and the gap dimension between the vertical portion and the lateral surface of the battery. As a result, a more compact size can be achieved, and when the rotation about the battery post is to occur, the rotation can be prevented by the vertical portion coming into contact with the lateral surface of the battery, thus making it possible to improve the reliability of the connection with the battery and the electric wires. Hereinafter, embodiments according to the present application will be described with reference to the drawings. First, a battery direct-mounted fusible link 10 according to a first embodiment of the present application is shown in The housing 14 is made of a non-conductive member such as a synthetic resin. The housing 14 is formed in an L-shape including a horizontal portion 20 that is to be arranged along a top surface 18 of the battery 12 and extends in a horizontal direction (left-right direction in As is clear from On the other hand, the vertical portion 24 has a hollow box shape that is open downward (downward in The bus bar 16 is accommodated in this housing 14. The bus bar 16 is provided with a battery connecting terminal 36. As also shown in Furthermore, two terminal plate portions 40 are formed in the bus bar 16. The terminal plate portions 40 each have a rectangular plate shape that extends perpendicularly. The terminal plate portions 40 are formed by bending upward the front end-side edge portions of base end portions 44 that are respectively coupled to the front ends of coupling portions 42 extending from the main portion 38 of the bus bar 16 and that extend perpendicularly with respect to the main portion 38. It should be noted that the terminal plate portions 40 are to be connected to an alternator and a starter (not shown), respectively. Furthermore, the bus bar 16 is provided with a plurality of (five in this embodiment) load connecting portions 46. The load connecting portions 46 each have a shape in which a tab-shaped plate is provided with a pair of crimping pieces 50, and are coupled to the main portion 38 via a fusible portion 48 that fuses when an overcurrent flows. These (five in this embodiment) load connecting portions 46 are formed in parallel with appropriate spacings between them on a lower side (lower side in The load electric wires 34 to be connected to loads provided in a vehicle body, such as a motor and other electric components, are connected to the load connecting portions 46, respectively. The load electric wires 34 are directly secured to the load connecting portions 46 without using a connector, a connecting terminal, or the like by crimping a core wire 54 exposed from the end of the load electric wire 34 to the load connecting portion 46 with the crimping pieces 50. The battery direct-mounted fusible link 10 is configured by accommodating this bus bar 16 in the housing 14. The battery connecting terminal 36 of the bus bar 16 is arranged in the horizontal portion 20 of the housing 14 in a state in which the bus bar 16 is accommodated in the housing 14. Accordingly, the battery connecting portion 58 is formed in the horizontal portion 20 of the housing 14. The load connecting portions 46 are coupled via the fusible portions 48 to the battery connecting terminal 36 included in the battery connecting portion 58, and thus are coupled via the fusible portions 48 to the battery connecting portion 58. The terminal plate portions 40 of the bus bar 16 are arranged in the bolt arranging portions 30 of the housing 14, respectively. Stud bolts 60 are inserted into the bolt arranging portions 30 and overlap the terminal plate portions 40. Accordingly, the stud bolts 60 are arranged in the vertical portion 24 and project in the horizontal direction (left-right direction in As shown in With the battery direct-mounted fusible link 10 of this embodiment, only the battery connecting portion 58 is provided in the horizontal portion 20 to be arranged along the top surface 18 of the battery 12. This makes it possible to reduce the length dimension L of the horizontal portion 20 compared with a case where the stud bolts 60 are also provided in the horizontal portion 20. As a result, the size of the battery direct-mounted fusible link 10 can be reduced, and the efficiency of the arrangement space can be improved. Furthermore, the gap dimension G between the vertical portion 24 and the lateral surface 22 of the battery 12 can be reduced, and when the battery direct-mounted fusible link is to rotate about the battery post 26, the rotation can be prevented by the vertical portion 24 coming into contact with the lateral surface 22 of the battery 12. As a result, it is possible to improve the reliability of the connection between the battery direct-mounted fusible link 10 and the load electric wires 34 and electric wires 62. Since the stud bolts 60 are arranged in the vertical portion 24 and project in the horizontal direction, it becomes unnecessary to bend the connecting terminals 64 into an L-shape in order to extend the electric wires 62 connected to the stud bolts 60 downward (toward the lower side in Furthermore, in this embodiment, the stud bolts 60 and the load connecting portions 46 are lined up in the direction in which the vertical portion 24 extends from the horizontal portion 20, that is, in the up-down direction. This makes it possible to stack and compactly dispose the electric wires 62 connected to the stud bolts 60 and the load electric wires 34 connected to the load connecting portions 46. Moreover, the load electric wires 34 to be connected to the load connecting portions 46 are directly secured to the load connecting portions 46 with the crimping pieces 50. Accordingly, connectors, connecting terminals, and the like can be made unnecessary, and the manufacturing cost can be reduced. Furthermore, it is unnecessary to form connector accommodating portions and the like in the housing 14, thus making it possible to reduce the size of the battery direct-mounted fusible link 10. Next, a battery direct-mounted fusible link 70 according to a second embodiment according to the present application is shown in The vertical portion 24 of the housing 14 of this embodiment is formed into a laterally elongated shape as a whole in which the length in the horizontal direction (left-right direction in Moreover, the two bolt arranging portions 30 are formed in parallel at the lower end portion of the housing 14 on one side (right side in As shown in In the battery direct-mounted fusible link 70 of this embodiment, the stud bolts 60 and the load connecting portions 46 are lined up in the horizontal direction. This makes it possible to dispose the electric wires 62 connected to the stud bolts 60 and the load electric wires 34 connected to the load connecting portions 46 in parallel such that they do not overlap one another, and to reduce a risk that the electric wires 62 and load electric wires 34 are tangled with one another. Although the embodiments according to the present application have been described in detail, the present application is not limited to the specific description. For example, the numbers of the stud bolts and the load connecting portions can be set as desired. Moreover, as an embodiment of the direct securing of the electric wires to the load connecting portions, the ends of the electric wires may be secured by crimping as described in the above embodiment as well as by soldering or welding, or may be secured using a glue, for example. A battery direct-mounted fusible link that is to be directly connected to a battery post and has an L-shape extending over a top surface and a lateral surface of a battery, the battery direct-mounted fusible link having a novel structure which may be capable of achieving a more compact size while effectively reducing a risk of rotation with respect to the battery Only a battery connecting portion to be connected to a battery post is provided in a horizontal portion to be arranged on a top surface of the battery, whereas a stud bolt and a load connecting portion to be connected to a load are provided in a vertical portion to be arranged on a lateral surface of the battery. 1. A battery direct-mounted fusible link having an L-shape comprising:

a horizontal portion configured to be arranged on a top surface of a battery, the horizontal portion including a battery connecting portion configured to be connected to a battery post of the battery; and a vertical portion configured to be arranged on a lateral surface of the battery, the vertical portion including (i) at least one stud bolt configured to be connected to a connecting terminal provided at an end of an electric wire, the stud bolt projecting from the vertical portion in a direction opposite to a direction in which the horizontal portion extends from the vertical portion, and (ii) at least one load connecting portion configured to be connected to a load, the load connecting portion being coupled to the battery connecting portion via a fusible portion. 2. The battery direct-mounted fusible link according to 3. The battery direct-mounted fusible link according to 4. The battery direct-mounted fusible link according to 5. The battery direct-mounted fusible link according to BACKGROUND

SUMMARY

BRIEF DESCRIPTION OF THE DRAWINGS

DETAILED DESCRIPTION