DUAL-STEP SNOW SWEEPER

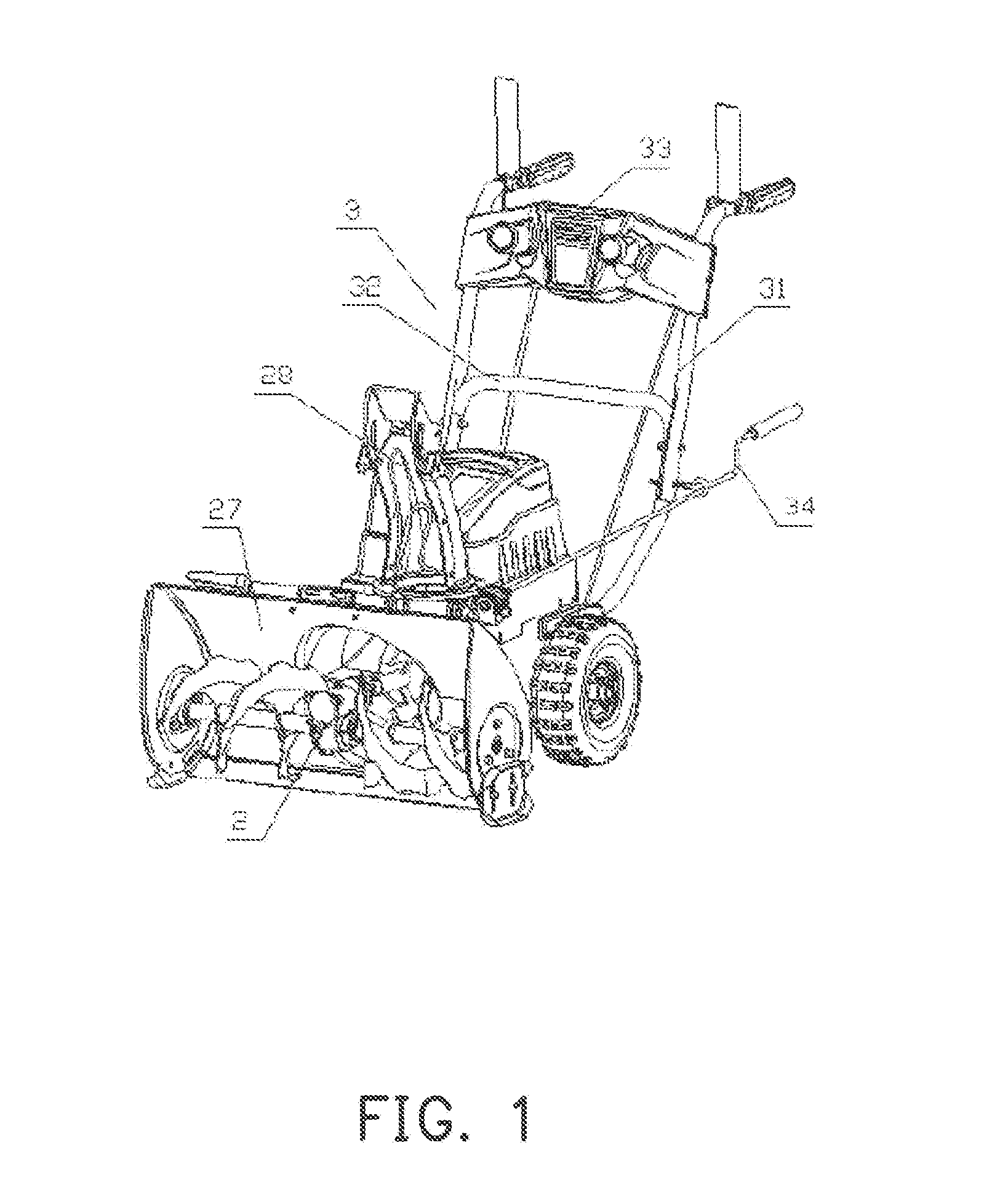

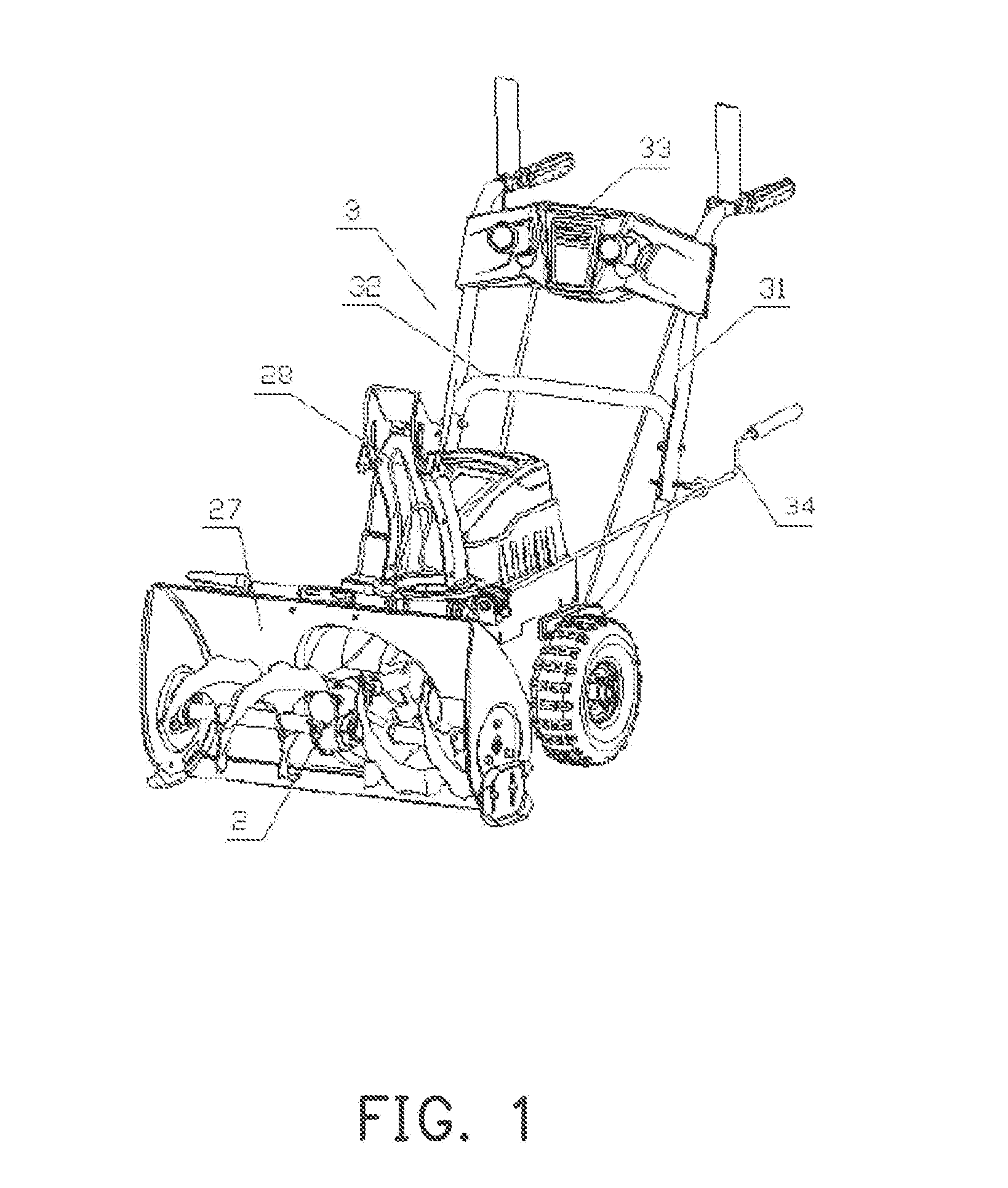

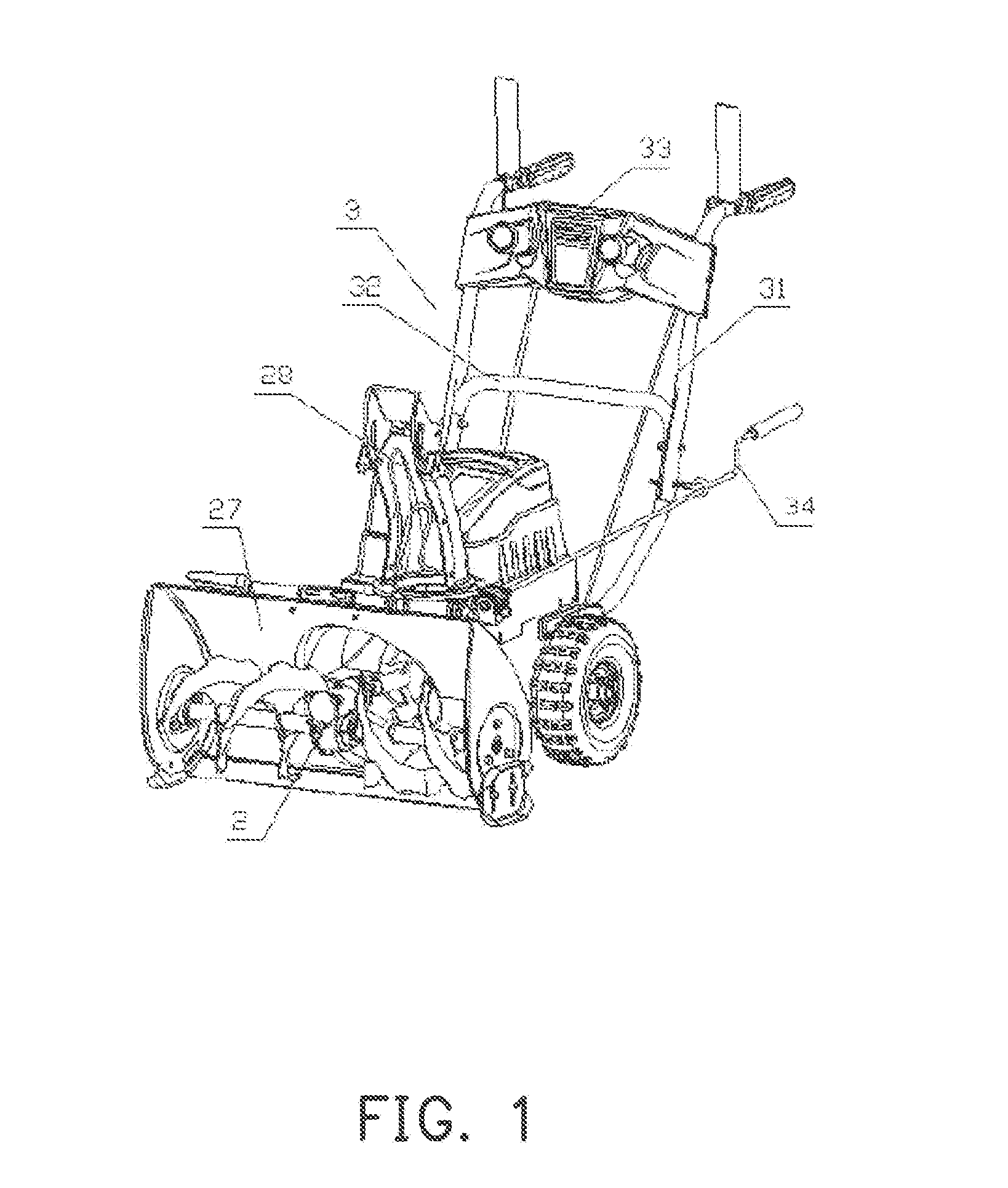

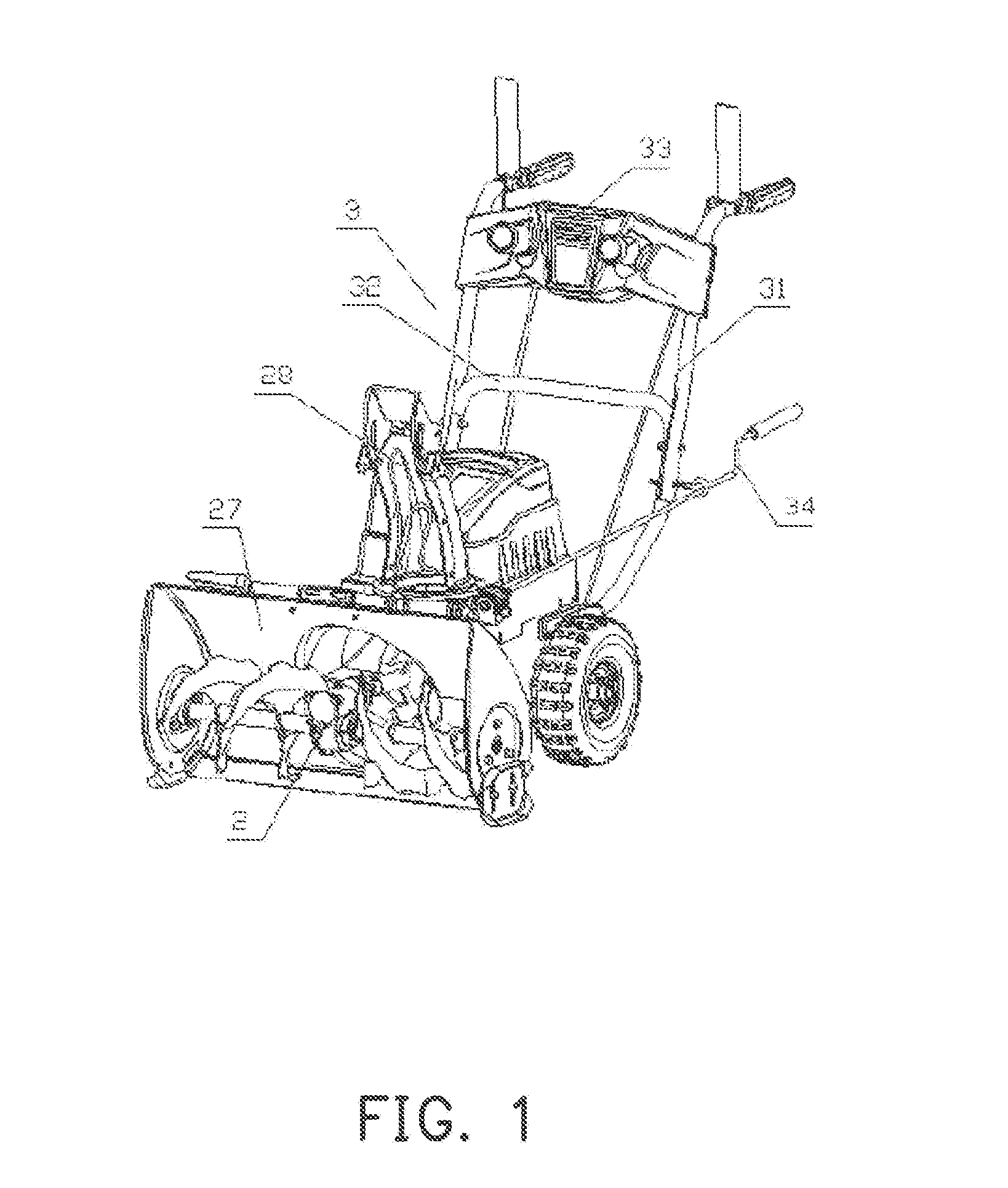

This application is a continuation of PCT application serial no. PCT/CN2015/084737, filed on Jul. 22, 2015, which claims priority to and the benefit of China Patent Application No. CN201510321309.5, filed on Jun. 11, 2015, the disclosure of which is incorporated herein by reference in its entirety. The invention relates to a dual-step snow sweeper. The dual-step snow sweeper has the following definition: the first step of snow sweeping is to operate a snow scraper, and the second step of snow sweeping is to throw out snow by an impeller through upper and lower nozzle assemblies. All the dual-step snow sweepers in the market are powered by a general engine. The engine snow sweeper is one of the most effective snow sweepers currently due to its strong power, high efficiency, and strong operability. However, the general engine snow sweeper has the following disadvantages: 1, it is complicated in structure, complicated in operation, heavy in whole machine, poor in man-machine efficiency, high in cost, and low in safety; and 2, the engine snow sweeper is large in noise, serious in environmental pollution, large in fuel consumption, and unfavourable in energy conservation and emission reduction. The technical problem to be solved by the invention is to provide a dual-step snow sweeper, which is simple in structure, stable in performance, convenient in operation, low in noise, and no in environmental pollution so as to overcome the disadvantages of the engine snow sweeper in the using process. To solve the above technical problem, the invention uses the following technical solution: a dual-step snow sweeper, comprising: a body, on which a driving device, a self-propelled device, a snow sweeping device, and a handrail control device are arranged, wherein the driving device drives the operation of the self-propelled device and the snow sweeping device, the snow sweeping device comprises a snow scraping mechanism and a snow throwing mechanism, and the driving device comprises at least one motor which is powered by a power supply device. Preferably, the motor uses a single motor or double motors, wherein when a single motor is used, one motor drives the operation of the self-propelled device and the snow sweeping device simultaneously, while when double motors are used, one motor drives the operation of the self-propelled device and the other motor drives the operation of the snow sweeping device. Preferably, the snow sweeping device comprises a snow scraping mechanism and a snow throwing mechanism. The motor uses three motors, the first one of which drives the operation of the self-propelled device, the second one of which drives the operation of the snow scraping mechanism, and the third one of which drives the operation of the snow throwing mechanism Preferably, when a single motor is used, the motor is a brushless motor, a magnetic steel motor, or a series-excited motor, and when more than two motors are used, the brushless motor, the magnetic steel motor and the series-excited motor are used simultaneously or the combination of any of the above motors is used. Preferably, the power supply device is a battery pack assembly or AC power supply, in which the battery pack assembly uses a single battery pack or the combination in series or in parallel of several battery packs of the same volume, the same voltage, or different volumes, different voltages. Preferably, the power supply device uses a hybrid power system formed by AC and DC. Preferably, the DC power supply directly drives the operation of the motor when the whole machine is connected with the DC power supply; the AC power supply drives the operation of the motor when the whole machine is connected with the AC power supply in the state that the DC power supply is connected or not connected. Preferably, the handrail control device comprises a plurality of sections of handrail, and the uppermost section of handrail is connected with a control panel. Preferably, the snow sweeping device comprises a snow throwing impeller, a snow scraper, and a snow sweeping decelerating mechanism, in which the snow throwing impeller is mounted on the input end of the snow sweeping decelerating mechanism, and the snow scraper is mounted on the output end of the snow sweeping decelerating mechanism. Preferably, the self-propelled device comprises a self-propelled decelerating mechanism which is provided with a clutch mechanism, the handrail control device is provided with a stay wire which is connected with the clutch mechanism, and the clutch mechanism is controlled by the stay wire. The self-propelled device and the dual-step snow sweeper in the invention are driven by the motor. In addition, the power supply device used in the invention can use battery supply separately, and can supply power by being connected with alternating current through an AC-DC power supply system as well, or operate in such a way that the AC directly drives an AC motor. Therefore, the invention is simple in structure, stable in performance, convenient in assembly, humanized in operating mode, clean in energy, reducing in environmental pollution, and low in noise so as to achieve the purpose of environmental protection. The invention will be further described in combination with the accompanying drawings and specific embodiments: As shown in The snow sweeping device comprises a snow throwing impeller, a snow scraper, and a snow sweeping decelerating mechanism, in which the snow throwing impeller is mounted on the input end of the snow sweeping decelerating mechanism, and the snow scraper is mounted on the output end of the snow sweeping decelerating mechanism. The self-propelled device comprises a self-propelled decelerating mechanism which is provided with a clutch mechanism. The handrail control device comprises an upper handrail 31 and a lower handrail 32. The handrail control device is provided with a stay wire which is connected with the clutch mechanism, and the clutch mechanism is controlled by the stay wire. The upper handrail 31 is connected with a control panel 33. The control panel is provided with a gear selecting module and a power supply control module so that the user achieves the control selection of the forward and backward functions of the whole machine. The control panel is provided with a self-propelled motor control module for controlling the multistage speed rotation and direction change of the self-propelled motor as well. The motor uses a single motor or double motors. When a single motor is used, one motor drives the operation of the self-propelled device and the snow sweeping device simultaneously, while when double motors are used, one motor drives the operation of the self-propelled device and the other motor drives the operation of the snow sweeping device. In addition, the motor is not limited to the use of one or two motors described above. The motor can use a plurality of motors as well. For example, since the snow sweeping device comprises a snow scraping mechanism and a snow throwing mechanism, the motor can use three motors, the first one of which drives the operation of the self-propelled device, the second one of which drives the operation of the snow scraping mechanism, and the third one of which drives the operation of the snow throwing mechanism. The use of a single motor for driving has the following advantages: it can save motor cost, but will also make the structure of the drive system complicated, while the use of double motors or a plurality of motors has the following advantages: each system can be controlled separately so as to simply the structure of the drive system. When a single motor is used, the motor is a brushless motor, a magnetic steel motor, or a series-excited motor, and when more than two motors are used, the brushless motor, the magnetic steel motor and the series-excited motor are used simultaneously or the combination of any of the above motors is used. As shown in As shown in As shown in After being output by the motor, it is output by the planetary gearbox after deceleration. The rotating speed slows down and the self-propelled torque increases. It is connected to the self-propelled worm and gear mechanism by the self-propelled belt mechanism in a decelerating way. The self-propelled worm drives the self-propelled worm gear to achieve deceleration and increase the torque, and drives the drive shaft and the wheels to achieve self-propel. Since the self-propelled worm and gear mechanism does not have the self-locking function of the worm and gear, the mechanism can control the self-propelled tensioning pulley to tension the self-propelled belt through the self-propelled tensioning control handle connected to the self-propelled tensioning stay wire on the handrail so that the self-propelled worm gear drives the drive shaft and the wheels to rotate. As shown in The motor drives the worm to rotate through the snow sweeping belt mechanism, and then the worm drives the snow sweeping worm gear to operate. The snow sweeping worm gear drives the snow scraper to start operation through the snow scraping support shaft. The first step is to sweep snow as the operation of the snow scraper, and the second step is to throw out snow, that is to say, the impeller starts to throw out snow through the snow outlet after snow enters the snow scraping cover, so as to achieve the purpose of dual-step snow sweeping. The above self-propelled device and the dual-step snow sweeping device are driven by the same motor. The single motor drives the operation of the dual-step snow sweeping device and the self-propelled device simultaneously through double pulleys and double belts after passing through the planetary gearbox. As shown in As shown in In addition, as another structure of the self-propelled device, a planetary gear assembly can be mounted inside the wheels. The wheels are driven to rotate by the planetary gear assembly. The self-propelled motor is a double-output shaft motor. The planetary gear assembly comprises a gear ring and a planetary gear engaged on the internal circumference side of the gear ring. After being output by the self-propelled motor, the output rotating speed after the deceleration by the planetary gear assembly slows down and the self-propelled torque increases. The motor output shaft on both sides of the self-propelled motor drives the planetary gear to rotate as a sun gear. The planetary gear rotates within the gear ring. The wheels are driven to rotate by the output shaft of the planetary gear so as to be self-propelled. As shown in In addition, the bottom of the snow outlet 28 is fixed on the rotating gear ring which is engaged with the control gear. The driving handle 34 mounted on the handrail controls the control gear to rotate. The direction of the snow sweeping outlet can be controlled conveniently so as to control the direction of snow throwing. The snow sweeping motor and the self-propelled motor described above are powered by power supply. The self-propelled motor and the snow sweeping motor share the same power supply. Each of the self-propelled motor and the snow sweeping motor separately drives the self-propelled device and the dual-step snow sweeping device to operate. No matter it is driven by a motor or double motors or a plurality of motors, the same power supply device is used. The power supply device is a battery pack assembly or AC power supply. The AC power supply converts AC into DC which is the same as the voltage of the battery pack via a rectifier or a transformer. Of course, the power supply device can use a hybrid power system formed by AC and DC as well. As shown in As shown in A dual-step snow sweeper includes a body, on which a driving device, a self-propelled device, a snow sweeping device, and a handrail control device are arranged. The driving device drives the operation of the self-propelled device and the snow sweeping device, the snow sweeping device includes a snow scraping mechanism and a snow throwing mechanism, and the driving device includes at least one motor which is powered by a power supply device. The power supply device can use battery supply separately, and can supply power by being connected with alternating current through an AC-DC power supply system as well, or operate in such a way that the AC directly drives an AC motor. 1. A dual-step snow sweeper, comprising: a body, on which a driving device, a self-propelled device, a snow sweeping device, and a handrail control device are arranged, wherein the driving device drives the operation of the self-propelled device and the snow sweeping device, and the snow sweeping device comprises a snow scraping mechanism and a snow throwing mechanism, wherein the driving device comprises at least one motor which is powered by a power supply device. 2. The dual-step snow sweeper according to 3. The dual-step snow sweeper according to 4. The dual-step snow sweeper according to 5. The dual-step snow sweeper according to 6. The dual-step snow sweeper according to 7. The dual-step snow sweeper according to 8. The dual-step snow sweeper according to 9. The dual-step snow sweeper according to 10. The dual-step snow sweeper according to 11. The dual-step snow sweeper according to CROSS-REFERENCE TO RELATED APPLICATION

TECHNICAL FIELD

BACKGROUND

SUMMARY

BRIEF DESCRIPTION OF THE DRAWINGS

DETAILED DESCRIPTION