QUIET WRENCH

The present invention relates to a hand tool, more specifically relates to a quiet wrench. In general usage of a torque wrench, hand movement in the direction of rotation is limited and can not rotate in a direction continually. In such kind of wrench, the rotation shaft of the handle and the main shaft are coaxial. When being used, the handle is first rotated in a desired direction by hand (e.g., tightening or loosening a piece), then the handle is need to be rotated in a reverse direction in order to enter the next cycle. In the above reverse rotation, generally a one-way clutch like ratchet surface mechanism is provided in the wrench, so that the main shaft can be fixed while the handle is reversed, i.e., the handle idles relative to the main shaft, to avoid the re-position of the wrench after it is disengaged from the workpiece. However, with the one-way clutch like ratchet surface mechanism, a sound will be made when the handle idles relative to the main shaft, which not only increases wearing of the wrench and has impact on the service life of wrench, but also affect the user experience of the wrench. The skilled people in the art are committed to providing a quiet wrench, which will not only be able to avoid the re-position of the wrench to the workpiece after their disengagement, but also ensure that no sound is made when the handle is idling relative to the main shaft. An object of the present invention is to provide a one-way clutch, and the one-way clutch comprises a first surface and a second surface, having a varied distance there between, and one or more wedge member(s) arranged between the first surface and the second surface. The rotation of the first surface relative to the second surface in a predetermined direction is prevented by the wedge member, i.e. the first surface drives the second surface to rotate; while in the opposite direction to the predetermined direction, the wedge member leaves the stop position, and the first surface rotate in the direction opposite the predetermined direction relative to the second surface, without driving the second surface to rotate. According to the one-way clutch provided in the present invention, when the first surface idles relative to the second surface, only the wedge member will leave the stop position and no sound will be made. Adopting such a configuration can not only reduce wearing but also extend the service life of the one-way clutch. The present invention provides a wrench, comprises a cylindrical inner surface at one end of the handle, being a first surface; the cylindrical outer surface of the torque output member, being a second surface; and one or more wedge member(s) arranged between the first surface and the second surface. A varied distance is between the first surface and the second surface, so that the wedge member can prevent the rotation of the first surface relative to the second surface in a predetermined direction, i.e. the first surface drives the second surface to rotate; while in the opposite direction to the predetermined direction, the wedge member leaves the stop position, and the first surface rotate in the direction opposite the predetermined direction relative to the second surface, without driving the second surface to rotate, i.e. the handle does not drive the torque output member to rotate, but idles relative to the torque output member. In the wrench according to the present invention, when the handle idles relative to the torque output member, only the wedge members will leave the stop position and no sound will be made. Such a wrench is a quiet wrench. Adopting such a configuration can not only reduce wearing of the wrench but also extend the service life of the wrench. And because the wrench is quiet, the user's experience will be improved. The present invention provides a one-way clutch, comprising: a first surface;

The one-way clutch provided by the present invention prevents the rotation of the first surface relative to the second surface in a predetermined direction by the wedge member, i.e. the first surface drives the second surface to rotate; while in the opposite direction to the predetermined direction, the wedge member leaves the stop position, and the first surface rotate in the direction opposite the predetermined direction relative to the second surface, without driving the second surface to rotate. According to the one-way clutch provided in the present invention, when the first surface idles relative to the second surface, only the wedge member will leave the stop position and no sound will be made. Adopting such a configuration will not only reduce wearing but also extend the service life of the one-way clutch. Further, the first surface and the second surface are arranged coaxially. Further, at least one of the first surface and the second surface has radius varying along the radial direction of the first surface. Further, the first surface is cylindrically curved surface and the second surface has radius varying along the radial direction of the second surface. Further, the cross-sectional profile of the second surface includes fold line or arc line. Further, the fold line or arc line may be one or more. Further, when there are more than one fold lines or arc lines, the lines are evenly distributed along the radial direction of the second surface. Further, the cross-sectional profile of the second surface is hexagon. Further, the second surface is cylindrically curved surface and the first surface has radius varying along the radial direction of the first surface. Further, the cross-sectional profile of the first surface includes fold line or arc line. Further, the fold line or arc line may be one or more. Further, when there are more than one fold lines or arc lines, the lines are evenly distributed along the radial direction of the first surface. Further, both the first surface and the second surface have radius varying along the radial direction of the first surface. Further, the wedge member may be cylindrical structure or spherical structure. Further, when the wedge member is cylindrical structure, the axis of the wedge member is parallel to the axis of the first surface. Further, the position where the distance between the first surface and the second surface varies clockwise from longer than the diameter of the wedge member to shorter than the diameter of the wedge member forms a first stop position; the position where the distance between the first surface and the second surface varies clockwise from shorter than the diameter of the wedge member to longer than the diameter of the wedge member forms a second stop position. Further, the wedge member is at the first stop position by a pre-tightening force applied to the second surface and the predetermined direction is clockwise direction; the wedge member is at the second stop position by a pre-tightening force and the predetermined direction is counter-clockwise direction. Further, the one-way clutch further comprises a reversing apparatus for moving the wedge member between the first stop position and the second stop position. Further, the one-way clutch further comprises a holding frame and the wedge member is mounted on the holding frame. Further, the holding frame is cage-like. Further, the reversing apparatus is a knob or toggle, the knob or toggle is fixedly connected to the holding frame. The present invention further provides a wrench, comprising: a handle for torque input, a first end of the handle having a cylindrical inner surface as a first surface;

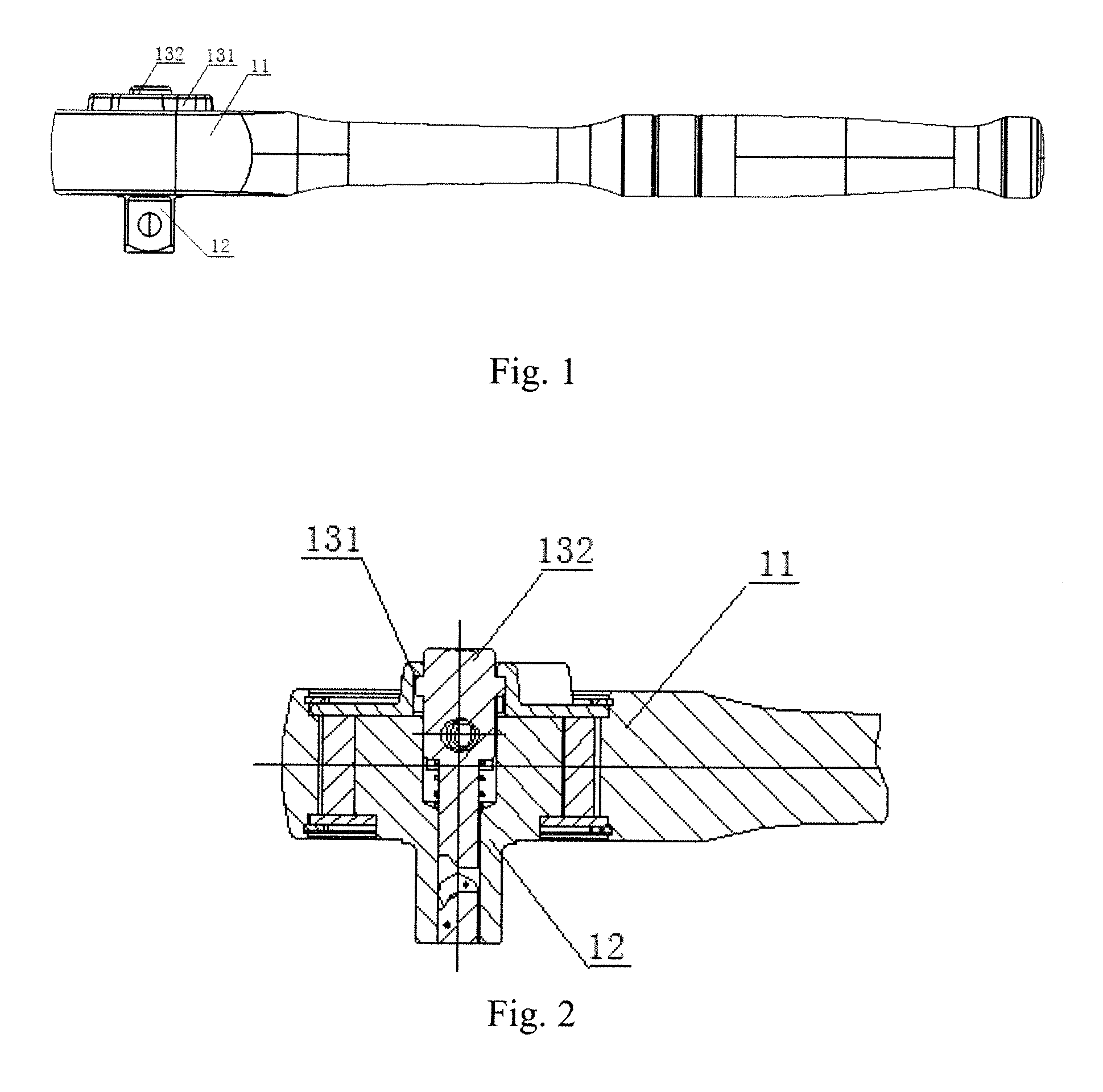

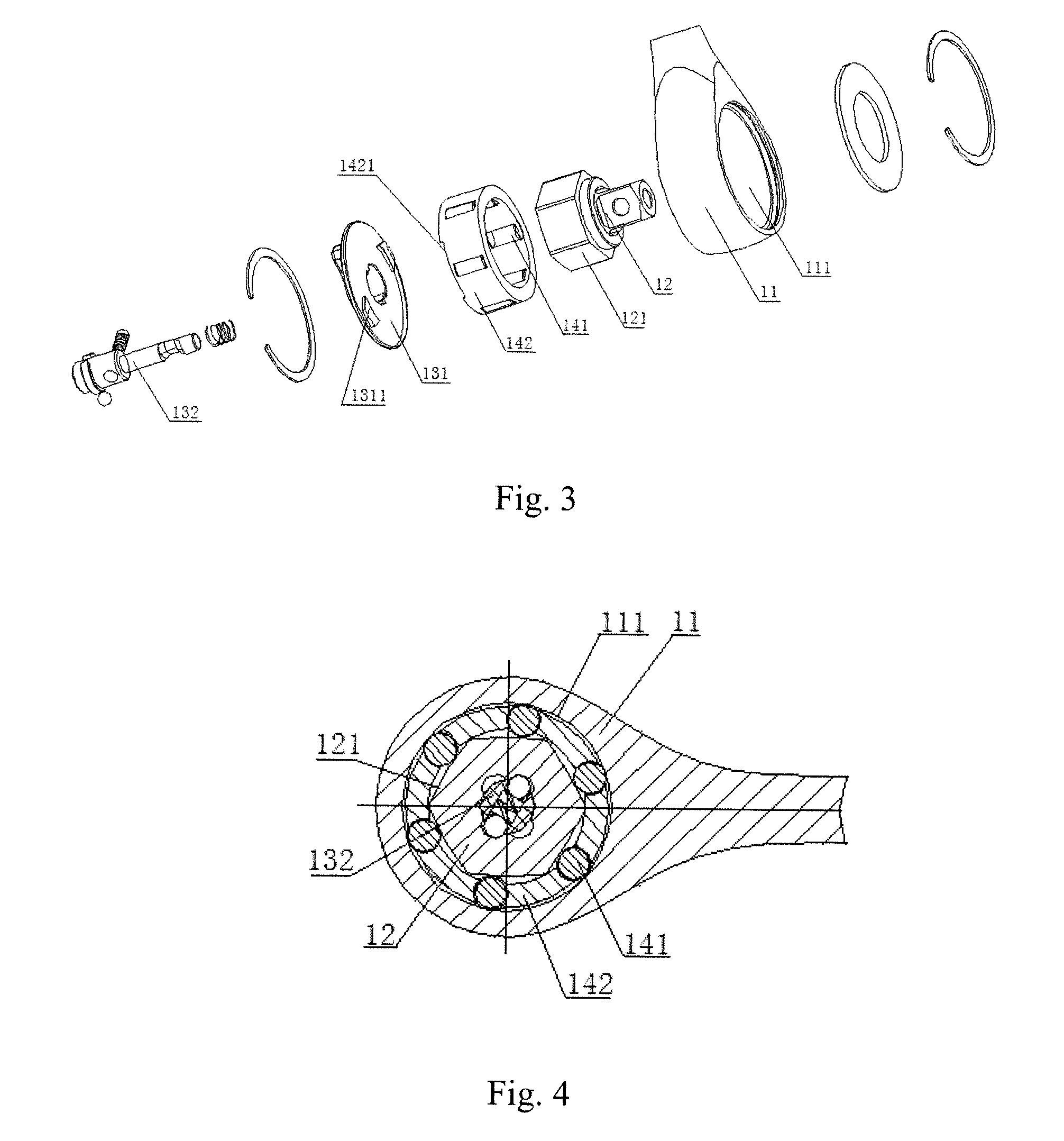

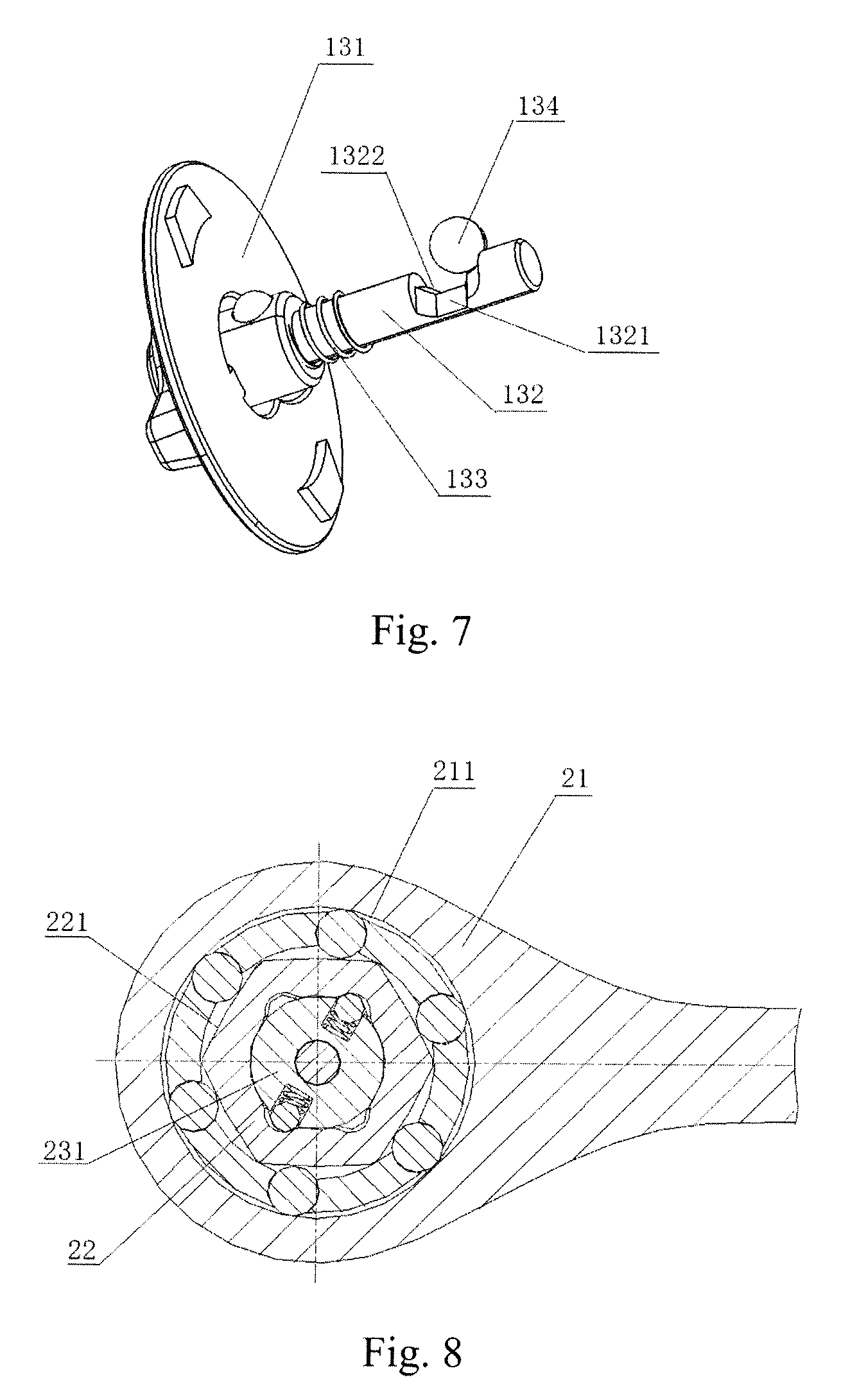

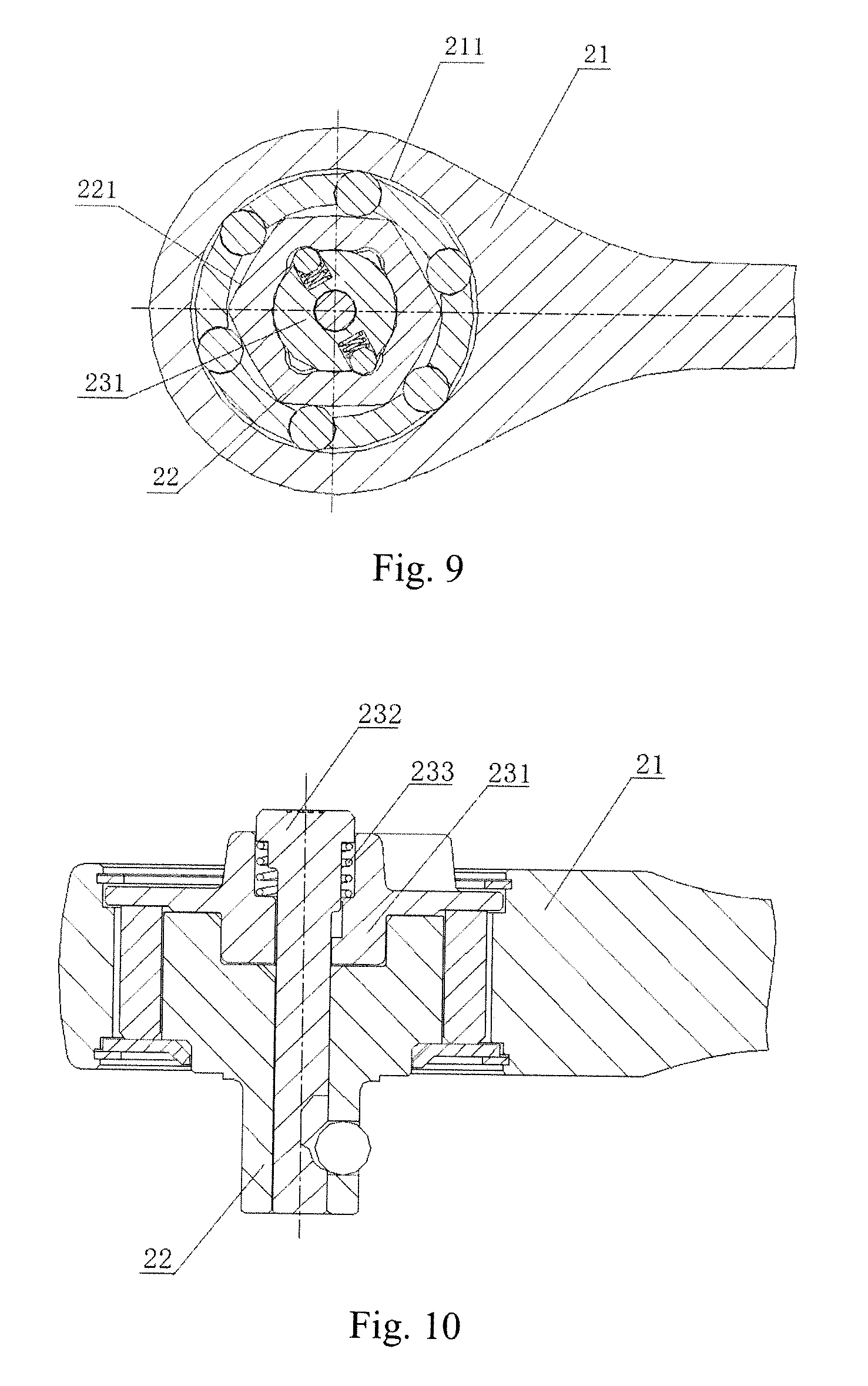

The wrench according to the present embodiment adopts the wedge members to prevent the rotation of the first surface relative to the second surface in a predetermined direction, that means the handle drives the torque output member to rotate; while in the opposite direction to the predetermined direction, the wedge members leave the stop position, and the first surface rotates in the direction opposite the predetermined direction without driving the second surface to rotate, that means the handle does not drive the torque output member to rotate and the handle idles relative to the torque output member. In the wrench according to the present invention, when the handle idles relative to the torque output member, only the wedge members will leave the stop position and no sound will be made. Such a wrench is a quiet wrench. Adopting such a configuration can not only reduce wearing of the wrench but also extend the service life of the wrench. And because the wrench is quiet, the user's experience will be improved. Further, the first surface and the second surface are arranged coaxially. Further, at least one of the first surface and the second surface has radius varying along the radial direction of the first surface. Further, the first surface is cylindrically curved surface and the second surface has radius varying along the radial direction of the second surface. Further, the cross-sectional profile of the second surface includes fold line or arc line. Further, the fold line or arc line may be one or more. Further, when there are more than one fold lines or arc lines, the profile of the lines are evenly distributed along the radial direction of the second surface. Further, the cross-sectional profile of the second surface is hexagon. Further, the second surface is cylindrically curved surface and the first surface has radius varying along the radial direction of the first surface. Further, the cross-sectional profile of the first surface includes fold line or arc line. Further, the fold line or arc line may be one or more. Further, when there are more than one fold lines or arc lines, the lines are evenly distributed along the radial direction of the first surface. Further, both the first surface and the second surface have radii varying along the radial direction of the first surface. Further, the wedge member may be cylindrical structure or spherical structure. Further, when the wedge member is cylindrical structure, the axis of the wedge member is parallel to the axis of the first surface. Further, the position where the distance between the first surface and the second surface varies clockwise from longer than the diameter of the wedge member to shorter than the diameter of the wedge member forms a first stop position; the position where the distance between the first surface and the second surface varies clockwise from shorter than the diameter of the wedge member to longer than the diameter of the wedge member forms a second stop position. Further, the wedge member is at the first stop position by a pre-tightening force applied to the second surface and the predetermined direction is clockwise direction; the wedge member is at the second stop position by a pre-tightening force and the predetermined direction is counter-clockwise direction. Further, the wrench further comprises a reversing apparatus for moving the wedge member between the first stop position and the second stop position. Further, the wrench further comprises a holding frame and the wedge member is mounted on the holding frame. Further, the holding frame is cage-like. Further, the reversing apparatus comprises a knob and a reversing shaft, and the knob is mounted on one end of the reversing shaft. The knob is fixedly connected to the holding frame and the reversing shaft and the torque output member are coaxial. Further, the reversing apparatus also comprises two beads in the opposite recesses on the side facing the torque output member of the knob. By adopting such a configuration, the force applied on the beads has a larger moment, thus a greater pre-tightening force can be provided, which can effectively reduce the interval, making the operation smoother. Further, the wrench also comprises a sheath-off apparatus. Further, the sheath-off apparatus comprises the reversing shaft and a spring, the spring being arranged between the reversing shaft and the knob. With this structure, when the reversing shaft moves away from the torque output member, due to the elastic force toward the torque output member, the knob will not move away from the torque output member, thus the beads arranged at the recesses of the knob will not move away from the torque output member, and thus the beads will not come off from the recesses, resulting in unexpected reversion. Therefore the wrench according to the present embodiment can reliably guarantee a predetermined direction in use. Further, the reversing apparatus comprises a toggle, and knob is fixedly connected to the holding frame. The wrench according to the present embodiment has the following beneficial effects: when the handle idles relative to the torque output member, only the wedge members will leave the stop position and no sound will be made. Such a wrench is a quiet wrench. Adopting such a configuration not only can reduce wearing of the wrench and extend the service life of the wrench. And at the meantime, because the wrench is quiet, the user's experience will be improved. Providing pre-tightening force can effectively reduce the interval and make the operation smoother. A further description will be made as to the conception, detailed structure, and expected technical effects of the present invention with reference to the accompanying drawings to make the objects, features, and advantages of the present invention fully understood. As shown in In the present embodiment, six wedge members 141 are arranged between the first surface 111 and the second surface 121. As shown in The holding frame 142 is closed. In the manufacturing process of the wrench, the wedge members 141 are wedged into the holding frame 142 first, and then the formed holding frame 142 with wedge members 141 is integrally assembled; thus the assembly of the wrench can be simplified. The wedge member 141 may also be spherical structure. The one-way clutch of the present embodiment comprises a first surface 111;

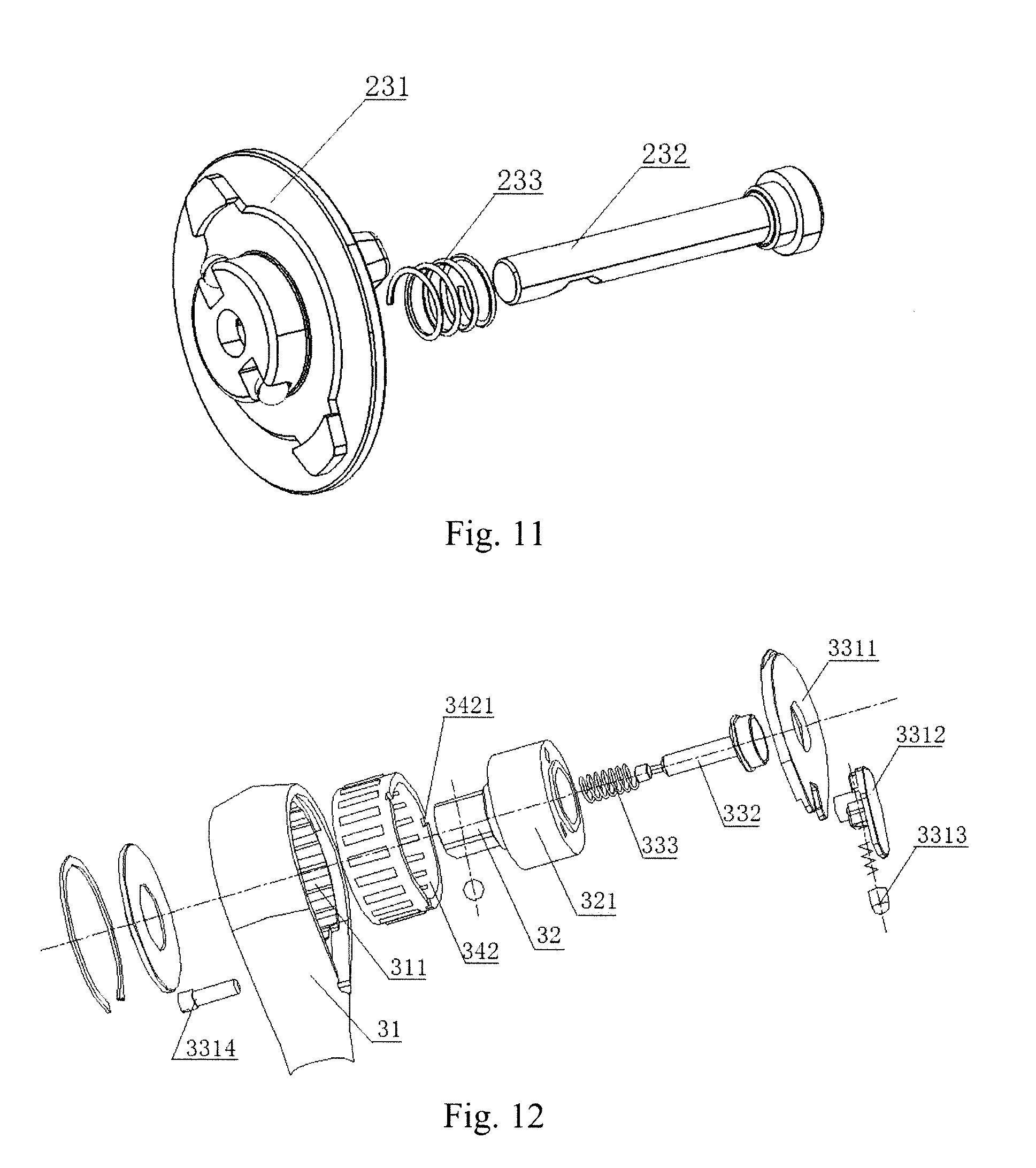

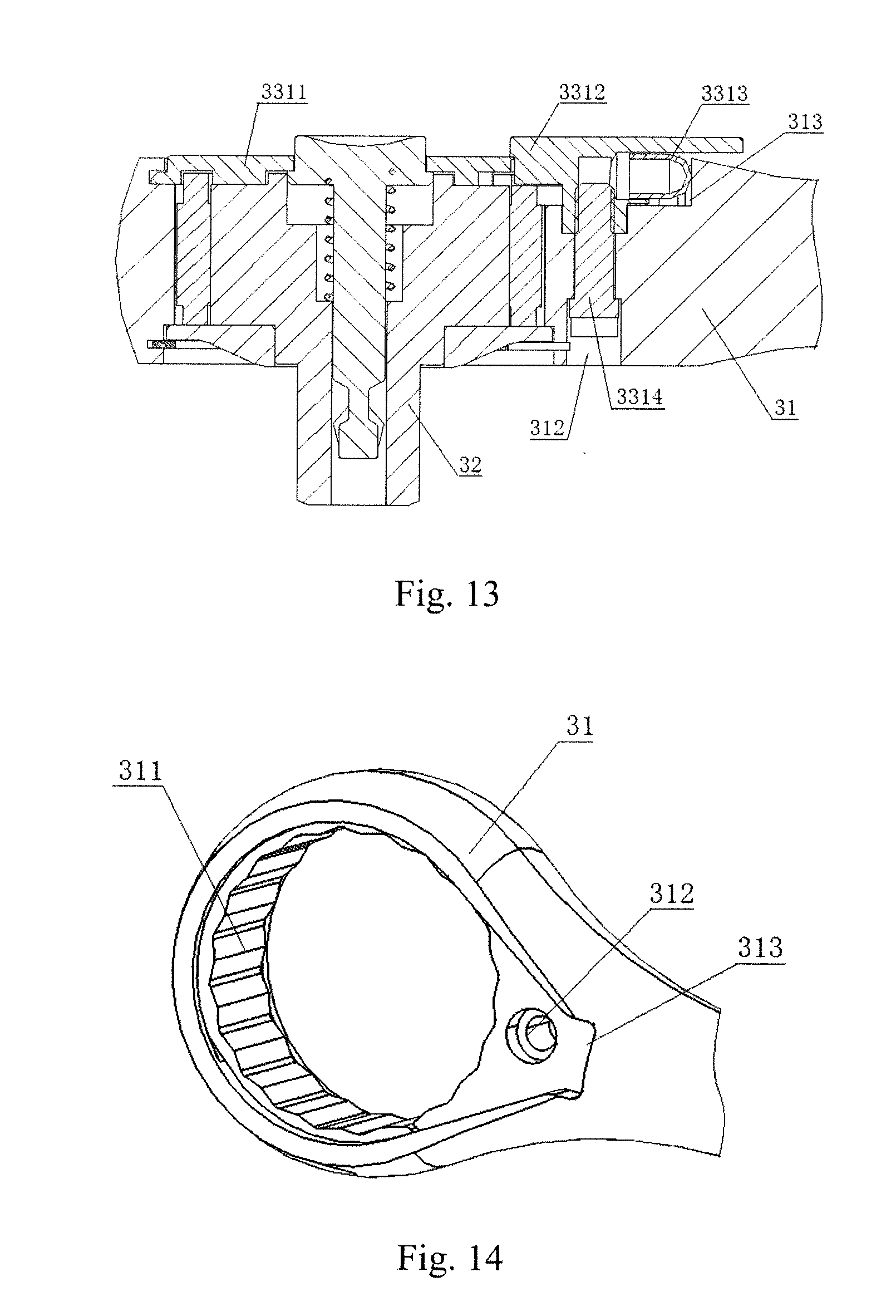

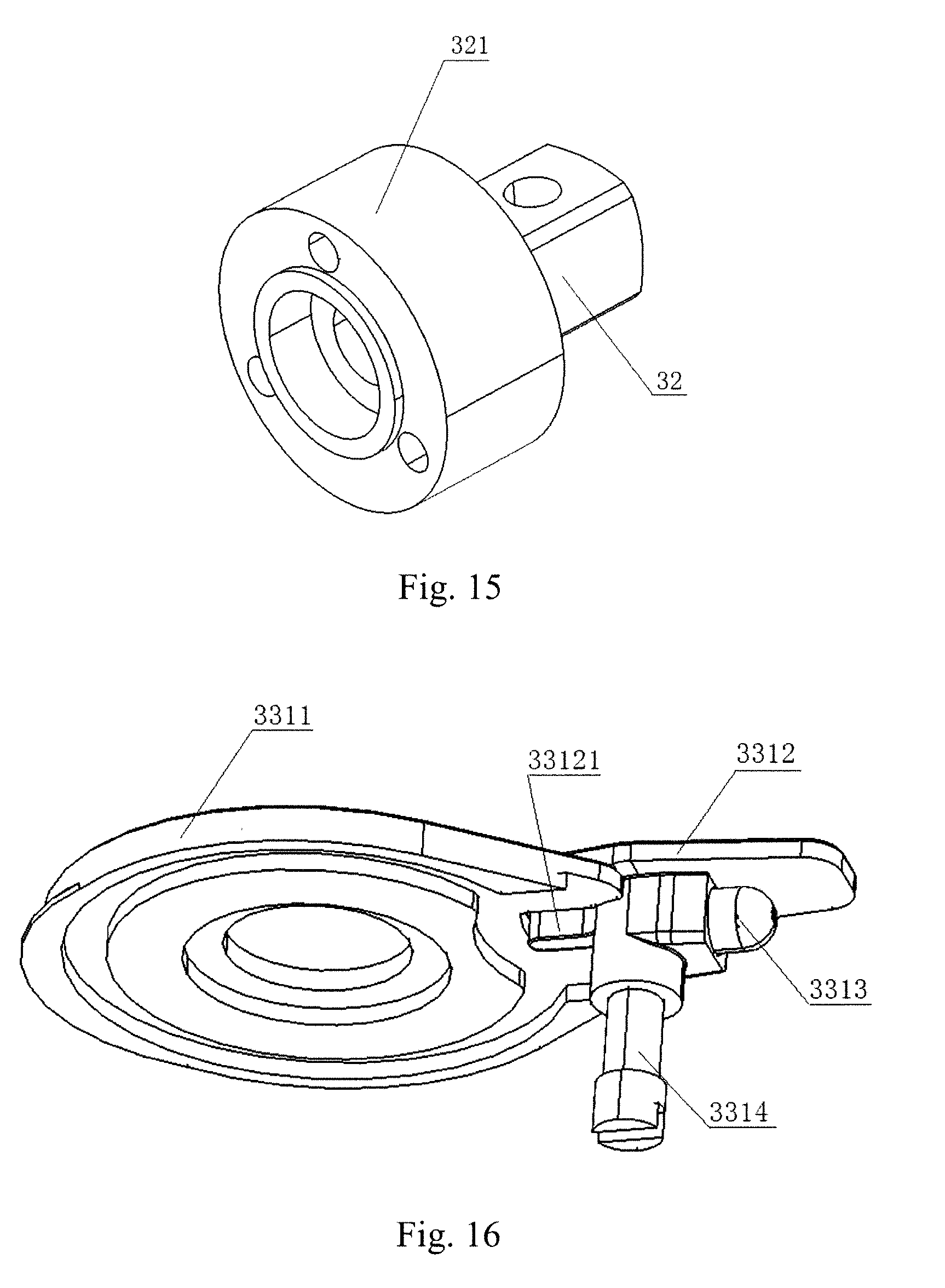

The number of wedge member 141 may also be one. In the present embodiment, the first surface 111 is a cylindrically curved surface, and the cross-sectional profile of the second surface 121 is hexagon. The cross-sectional profile of the second surface 121 includes fold lines, and the fold lines are evenly distributed along the radial direction of the second surface 121. The first surface 111 and the second surface 121 of the present invention are not limited to the above-described curved surfaces, as long as there is a varied distance between the first surface and the second surface, so that the wedge member can prevent the rotation of the first surface relative to the second surface in a predetermined direction. There may be the following situations: (1) the first surface is cylindrically curved surface, i.e., not having radius varying along the radial direction of the first surface; and the second surface has radius varying along the radial direction of the first surface, e.g., the cross-sectional profile of the second surface comprising fold line(s) or arc line(s); (2) the first surface has radius varying along the radial direction of the first surface, e.g., the cross-sectional profile of the second surface comprising fold line(s) or arc line(s); and the second surface is cylindrically curved surface, i.e., not having radius varying along the radial direction of the second surface; (3) the first surface has radius varying along the radial direction of the first surface, and the second surface has radius varying along the radial direction of the first surface. All of the above situations can make a varied distance between the first surface and the second surface, so that the wedge member 141 can prevent the rotation of the first surface 111 relative to the second surface 121 in a predetermined direction. When there are more than one fold lines or arc lines, the lines may be evenly or unevenly distributed along the radial direction. The position where the distance between the first surface 111 and the second surface 121 varies clockwise from longer than the diameter of the wedge member 141 to shorter than the diameter of the wedge member 141 forms a first stop position. The wedge members 141 are at the first stop position by a pre-tightening force applied to the second surface 121, as shown in When the first surface 111 is rotated clockwise relative to the second surface 121, the first surface 111 contacting with the wedge members 141 will drive the wedge members 141 to rotate clockwise. Because the wedge members 141 are in the wedge-shaped position formed by the first surface 111 and the second surface 121, i.e., the first stop position, the wedge members 141 can not be rotated clockwise, which enables the wedge members 141 to prevent the clockwise rotation of the first surface 111 relative to the second surface 121, in other words, the first surface 111 drives the second surface 121 to rotate clockwise. When the first surface 111 is rotated counter-clockwise relative to the second surface 121, the first surface 111 contacting with the wedge members 141 will drive the wedge members 141 to rotate counter-clockwise, which makes the wedge members 141 leave the wedge-shaped position formed by the first surface 111 and the second surface 121, i.e., the first stop position, and thus the wedge members 141 can not prevent the counter-clockwise rotation of the first surface 111 relative to the second surface 121, in other words, the first surface 111 does not drive the second surface 121 to rotate counter-clockwise. The predetermined direction is clockwise direction. The position where the distance between the first surface 111 and the second surface 121 varies clockwise from shorter than the diameter of the wedge member 141 to longer than the diameter of the wedge member 141 forms a second stop position. The wedge members 141 are at the second stop position by a pre-tightening force applied to the second surface 121, as shown in When the first surface 111 is rotated clockwise relative to the second surface 121, the first surface 111 contacting with the wedge members 141 will drive the wedge members 141 to rotate clockwise, which makes the wedge members 141 leave the wedge-shaped position formed by the first surface 111 and the second surface 121, i.e., the second stop position, and thus the wedge members 141 can not prevent the clockwise rotation of the first surface 111 relative to the second surface 121, in other words, the first surface 111 does not drive the second surface 121 to rotate clockwise. When the first surface 111 is rotated counter-clockwise relative to the second surface 121, the first surface 111 contacting with the wedge members 141 will drive the wedge members 141 to rotate counter-clockwise. Because the wedge members 141 are in the wedge-shaped position formed by the first surface 111 and the second surface 121, i.e., the second stop position, the wedge members 141 can not be rotated counter-clockwise, which enables the wedge members 141 to prevent the counter-clockwise rotation of the first surface 111 relative to the second surface 121, in other words, the first surface 111 drives the second surface 121 to rotate clockwise. The predetermined direction is counter-clockwise direction. The one-way clutch according to the present embodiment adopts the wedge members 141 to prevent the rotation of the first surface 111 relative to the second surface 121 in a predetermined direction. When the first surface 111 idles relative to the second surface 121, only the wedge members 141 will leave the stop position and no sound will be made. Adopting such a configuration can not only reduce wearing but also extend the service life of the one-way clutch. The wrench according to the present embodiment adopts the wedge members 141 to prevent the rotation of the first surface 111 relative to the second surface 121 in a predetermined direction, that means the handle 11 drives the torque output member 12 to rotate; while in the opposite direction to the predetermined direction, the wedge members 141 leave the stop position, and the first surface 111 rotates in the direction opposite the predetermined direction without driving the second surface 121 to rotate, that means the handle 11 does not drive the torque output member 12 to rotate and the handle 11 idles relative to the torque output member 12. In the wrench according to the present embodiment, when the handle 11 idles relative to the torque output member 12, only the wedge members 141 will leave the stop position and no sound will be made. Such a wrench is a quiet wrench. Adopting such a configuration can not only reduce wearing of the wrench but also extend the service life of the wrench. And because the wrench is quiet, the user's experience will be improved. The wrench according to the present embodiment further comprises a reversing apparatus for moving the wedge members 141 between the first stop position and the second stop position. The reversing apparatus comprises a knob 131 and a reversing shaft 132, and the knob 131 is mounted on one end of the reversing shaft 132. As shown in The torque output member 12 is arranged sheathing the reversing shaft 132. One end of the reversing shaft 132 is arranged with a through-hole, and a spring is arranged in the through-hole, and each opening of the through-hole are arranged with a bead. The inner side of the torque output member 12 is arranged with two sets of opposite dents. Turn the knob 131, so that the beads arranged at the openings of the through-hole are in the set of opposite dents shown in Turn the knob 131, so that the beads arranged at the openings of the through-hole are in the set of opposite dents shown in The wrench according to the present embodiment further comprises a sheath-off apparatus. As shown in When the reversing shaft 132 is pressed, the bead can enter the first groove 1321 or the second groove 1322 to complete the sheath-off; when the reversing shaft 132 is released, the elastic force arranged by the spring 133 return the reversing shaft 132 to its original position, making the bead pop out again. As shown in The difference between the present embodiment and the embodiment shown in As to the wrench according to the embodiment shown in As to the wrench according to the embodiment shown in As shown in As shown in The profile of the cross section of the first surface 311 may also include a plurality of arc lines. As shown in A varied distance is formed between the first surface 311 and the second surface 321, so that the wedge members 141 between the first surface 311 and the second surface 321 can prevent the rotation of the first surface 311 relative to the second surface 321 in a predetermined direction. It may also be adopted that the first surface 311 is a cylindrically curved surface, and the cross-sectional profile of the second surface 321 includes a plurality of fold lines. As shown in The toggle 3312 is coaxially connected with the screw 3314. When the toggle 3312 is turned, the toggle 3312 will rotate around the screw 3314. The toggle 3312 and the screw 3314 are mounted in the through-hole 312 of the handle 31, as shown in As shown in The wrench according to the present embodiment has the following beneficial effects: when the handle idles relative to the torque output member, only the wedge members 141 will leave the stop position and no sound will be made. Such a wrench is a quiet wrench. Adopting such a configuration not only can reduce wearing of the wrench and extend the service life of the wrench. And at the meantime, because the wrench is quiet, the user's experience will be improved. Providing pre-tightening force can effectively reduce the interval and make the operation smoother. The invention has been exemplified above with reference to specific embodiments. However, it should be understood that a multitude of modifications and varieties can be made by a common person skilled in the art based on the conception of the present invention. Therefore, any technical schemes, acquired by the person skilled in the art based on the conception of the present invention through logical analyses, deductions or limited experiments, fall within the scope of the invention as specified in the claims. The present invention provides a wrench comprising a handle, having a cylindrical inner surface as a first surface; a torque output member, arranged within the first surface of the handle, the torque output member having a cylindrical outer surface as a second surface; one or more wedging member(s), arranged between the first surface and the second surface; varied distance being between the first surface and the second surface, so that the wedge members can prevent the rotation of the first surface relative to the second surface in a predetermined direction. The wrench according to the present invention adopts wedge member to prevent the rotation of the handle relative to the torque output member. When the handle idles relative to the torque output member, only the wedge member will leave the stop position and no sound will be made. Such a wrench is a quiet wrench. Adopting such a configuration not only can reduce wearing of the wrench, extend the service life of the wrench, and improve the user's experience. Providing pre-tightening force can effectively reduce the interval and make the operation smoother. 1. A one-way clutch, characterized in that said one-way clutch comprises:

a first surface; a second surface; said first surface and said second surface being cylindrically curved surfaces, said second surface being located inside said first surface; one or more wedge member(s), arranged between said first surface and said second surface; and a distance between said first surface and said second surface varying along the radial direction of the first surface, so that said wedge member(s) can prevent the rotation of said first surface relative to said second surface in a predetermined direction. 2. A one-way clutch according to 3. A one-way clutch according to 4. A one-way clutch according to 5. A one-way clutch according to 6. A one-way clutch according to 7. A one-way clutch according to 8. A one-way clutch according to 9. A one-way clutch according to 10. A one-way clutch according to 11. A one-way clutch according to 12. A one-way clutch according to 13. A one-way clutch according to 14. A one-way clutch according to 15. A one-way clutch according to 16. A one-way clutch according to 17. A one-way clutch according to 18. A one-way clutch according to 19. A one-way clutch according to 20. A one-way clutch according to 21. A one-way clutch according to 22. A wrench, comprising:

a handle for torque input, a first end of said handle having a cylindrical inner surface as a first surface; a torque output member, arranged in said first surface of said handle, said torque output member having a cylindrical outer surface as a second surface; one or more wedge member(s), arranged between said first surface and said second surface; and a distance between said first surface and said second surface varying along the radial direction of the first surface, so that said wedge member(s) can prevent the rotation of said first surface relative to said second surface in a predetermined direction. 23. A wrench according to 24. A wrench according to 25. A wrench according to 26. A wrench according to 27. A wrench according to 28. A wrench according to 29. A wrench according to 30. A wrench according to 31. A wrench according to 32. A wrench according to 33. A wrench according to 34. A wrench according to 35. A wrench according to 36. A wrench according to 37. A wrench according to 38. A wrench according to 39. A wrench according to 40. A wrench according to 41. A wrench according to 42. A wrench according to 43. A wrench according to 44. A wrench according to 45. A wrench according to 46. A wrench according to FIELD OF THE INVENTION

DESCRIPTION OF THE PRIOR ART

SUMMARY OF THE INVENTION

a second surface;

the first surface and the second surface being cylindrically curved surfaces, the second surface being located inside the first surface;

one or more wedge member(s), arranged between the first surface and the second surface; and

a distance, which varies along the radial direction of the first surface, is between the first surface and the second surface, so that the wedge member(s) can prevent the rotation of the first surface relative to the second surface in a predetermined direction.

a torque output member, arranged in the first surface of the handle, the torque output member having a cylindrical outer surface as a second surface;

one or more wedge member(s), arranged between the first surface and the second surface; and

a distance, which varies along the radial direction of the first surface, is between the first surface and the second surface, so that the wedge member(s) can prevent the rotation of the first surface relative to the second surface in a predetermined direction.

BRIEF DESCRIPTION OF THE DRAWINGS

DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

a second surface 121;

the first surface 111 and the second surface 121 being cylindrically curved surfaces, and the second surface 121 being located inside the first surface 111;

a plurality of wedge members 141, arranged between the first surface 111 and the second surface 121; and

a distance between the first surface 111 and the second surface 121, which varies along the radial direction of the first surface 111, so that the wedge members 141 can prevent the rotation of the first surface 111 relative to the second surface 121 in a predetermined direction.