ACCELEROMETER CONTROL

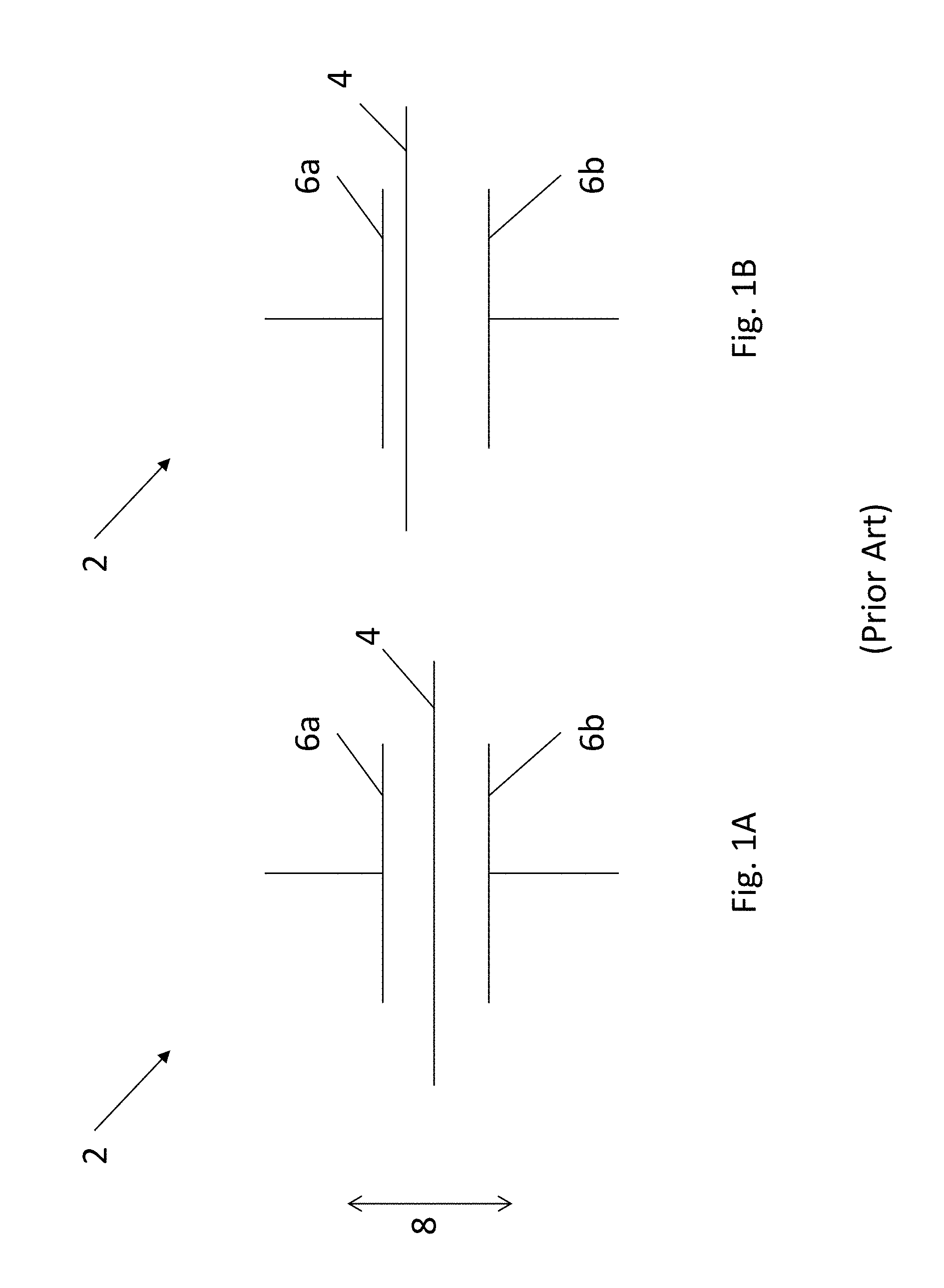

This application claims priority to Great Britain Patent Application No. 1618930.0 filed Nov. 9, 2016, the entire contents of which is incorporated herein by reference. The present disclosure relates to accelerometers, particularly capacitive accelerometers operated in closed loop. Capacitive accelerometers are typically manufactured from silicon as micro-electromechanical systems (MEMS) devices. These small devices typically comprise a proof mass moveably mounted relative to a support or “substrate” using compliant support legs and sealed so that a gaseous medium trapped inside the device provides damping for the proof mass when it moves in a sensing direction in response to an acceleration being applied. In a capacitive accelerometer, there is typically provided a set of fixed electrodes and a set of moveable electrodes attached to the proof mass, with the differential capacitance between the electrodes being measured so as to detect deflection of the proof mass. The resonant frequency of the MEMS device is defined by the mass of the proof mass and the positive spring constant of the compliant support legs. Such capacitive accelerometers can suffer from a “negative spring rate”, wherein the attractive electrostatic force between the proof mass and an electrode increases as the displacement of the proof mass increases. That is to say, the attractive electrostatic force gives rise to an effective “negative spring” that operates in the opposite direction to a conventional “positive spring” like that provided by the compliant support legs. This happens by virtue of Coulomb's law—as the proof mass is displaced from the null position, the attractive force between it and the electrode that is closer to the proof mass as a result of the displacement is increased while the attractive force between the proof mass and the other electrode decreases. Such a situation is clearly unstable, as a slight displacement of the proof mass may result in the attractive electrostatic force acting in the same direction as the force from the acceleration, rendering it more difficult to restore the proof mass to the null position under closed loop operation. U.S. Pat. No. 5,142,921 describes the use of a “constant charge forcing” regime for operating a capacitive accelerometer under closed loop. In this case the “high tension” (HT) voltage applied to each electrode—i.e. the peak amplitude of the restorative voltage applied to the electrodes—changes differentially as the proof mass moves from the null point in such a way that the attractive electrostatic force is independent of position, nullifying the negative electrostatic spring constant. U.S. Pat. No. 5,142,921 uses a time multiplexed approach, wherein a fixed current is applied for a particular time so as to provide a fixed charge to the electrodes, alternating between an electrode on one side of the proof mass and an electrode on the opposite side of the proof mass. This gives rise to a differential peak voltage which is indicative of the proof mass being offset from the null position. This differential voltage signal is then used to drive a pulse width modulation (PWM) generator with an integral loop filter to restore the proof mass to the null position, wherein an unequal mark/space ratio (i.e. not 50:50) of the PWM drive signals offsets the inertial acceleration force. However, such conventional approaches typically provide a suitable open loop gain within only a particular frequency range, outside of which the accelerometer suffers from bias shifts when under stress. It will be appreciated that the PWM drive signals are typically of a much greater frequency than the resonant frequency of the MEMS device. By way of non-limiting example only, 48 kHz PWM drive signals may be applied to a MEMS device with a resonant frequency of 3 kHz. According to a first aspect of this disclosure there is provided an accelerometer closed loop control system comprising: a capacitive accelerometer comprising a proof mass moveable relative to first and second fixed capacitor electrodes; a pulse width modulation (PWM) generator arranged to generate in-phase and anti-phase PWM drive signals with a drive frequency and an adjustable mark/space ratio, wherein said in-phase and anti-phase PWM drive signals are applied to the first and second fixed capacitor electrodes respectively such that they are charged alternately; an output signal detector arranged to detect a pick-off signal from the accelerometer representing a displacement of the proof mass from a null position to provide an error signal, wherein the null position is the position of the proof mass relative to the first and second fixed capacitor electrodes when no acceleration is applied; a PWM servo operating in closed loop arranged to vary the adjustable mark/space ratio of said in-phase and anti-phase PWM drive signals in response to the error signal so that mechanical inertial forces are balanced by electrostatic forces to maintain the operating point of the proof mass at the null position; and a differential voltage servo arranged to vary a difference in amplitude between the in-phase and anti-phase PWM drive signals in response to the error signal. Thus in accordance with this disclosure, a capacitive accelerometer operated in closed loop may avoid the negative spring rate issues suffered by conventional accelerometers. By varying a differential voltage applied to the two capacitor electrodes in response to the error signal, the electrostatic force can be kept substantially constant regardless of any displacement of the proof mass due to an applied acceleration. This can substantially reduce if not completely remove the effects of the negative spring rate on the accelerometer. The Applicant has appreciated that an accelerometer in accordance with this disclosure may enable the use of lower resonant frequency MEMS devices with higher open loop gain, reducing the impact of bias effects caused by mechanical stressing of the MEMS device. For example, a 3.5 kHz MEMS may undergo a displacement of 20 nm/g whereas a 1 kHz MEMS may undergo a displacement of 200 nm/g, such that a 1 nm stress error has ten times smaller an effect on bias offset for the latter device when compared to the former device, increasing the sensitivity of the device. In a conventional accelerometer, the “g range” (i.e. the acceleration range the device can measure) is directly related to the resonant frequency of the MEMS device. However, the g range of an accelerometer in accordance with this disclosure is decoupled from the resonant frequency of the MEMS, advantageously allowing the use of lower resonant frequencies while maintaining a high g range. In some preferred examples, the differential voltage servo comprises a microcontroller arranged to produce first and second digital control words, wherein: said first digital control word is input to a first digital to analogue converter arranged to receive the in-phase PWM signal at a first reference input and output a scaled in-phase PWM signal; and said second digital control word is input to a second digital to analogue converter arranged to receive the anti-phase PWM signal at a second reference input and output a scaled anti-phase PWM signal. In such examples, these digital control words are converted by the appropriate digital to analogue converters to scale the analogue output voltages that are applied to the first and second capacitor electrodes. In some examples, the output signal detector comprises a charge amplifier having an input connected to the proof mass and an output, said charge amplifier being arranged to produce at its output a voltage proportional to the capacitance between the proof mass and whichever of the first and second capacitor electrodes is charged at any given time. Such a charge amplifier acts so as to integrate the current applied at its input and produce an output voltage proportional to the integrated current (i.e. the charge accumulated over a period of time). As the charge built up will be proportional to the capacitance between the proof mass and the currently charged capacitor electrode, the voltage produced at the output of the charge amplifier is a measure of displacement of the proof mass. In a preferred set of such examples, the output signal detector further comprises a demodulator having an input connected to the output of the charge amplifier, wherein said demodulator is arranged to: sample the output of the charge amplifier while the in-phase PWM signal is high so as to produce a first sample; sample the output of the charge amplifier while the anti-phase PWM signal is high so as to produce a second sample; and calculate a difference between said first and second samples; and produce the error signal, wherein the error signal is dependent on said difference. Thus it will be appreciated that in accordance with such examples, the demodulator obtains a measure of the capacitance between the proof mass and each of the capacitor electrodes while the capacitor formed therebetween is “active” i.e. the capacitor electrode in question is receiving a high PWM signal at the time while the other capacitor electrode is receiving a low PWM signal (typically 0 V). In some such examples, the PWM servo comprises an integral loop filter arranged to vary the adjustable mark/space ratio in response to the integral of the error signal. Thus it will be seen that in accordance with such examples, the error signal is used to drive a PWM generator with an integral loop filter in order to restore the proof mass to the null position, wherein the mark/space ratio of the PWM drive signals offsets any applied inertial acceleration force. The integral loop filter provides large DC gain and so the PWM servo responds to relatively steady accelerations. From the geometry of the device and a knowledge of the HT voltage, a linear relationship between the demodulator output signal and proof mass displacement may be obtained for any particular device. While in accordance with such examples integral control is used to set the PWM to null the inertial force, this may be extended to proportional-integral-differential (PID) control in order to optimize loop stability. In a set of potentially overlapping examples, the differential voltage servo is arranged to vary the difference in amplitude between the in-phase and anti-phase PWM drive signals in proportion to the error signal. It will be appreciated that, in accordance with such examples, a proportional servo varies the HT voltages applied to each of the first and second fixed capacitor electrodes differentially. In contrast to integral control, the proportional control provided in such examples allows the differential voltage servo to respond to short-term accelerations such as shocks and vibrations. By way of non-limiting example only, this may be achieved using a digital to analogue convertor (DAC) on the output of an accelerometer such as the “Vesta” application specific integrated circuit (ASIC) product available from Silicon Sensing Systems Ltd. controlled by the output of such a proportional servo. Thus it is an approximate constant charge forcing scheme that may be compatible with existing accelerometers. It will be appreciated that in the set of examples where the PWM servo provides integral control and the differential voltage servo provides proportional control, both will inevitably respond to accelerations that cause the proof mass to move. However under low frequency accelerations, the PWM servo dominates due to the integral term. In some such examples, the demodulator is further arranged to receive a synchronisation signal, wherein the demodulator uses said synchronisation signal to produce the error signal at a predetermined frequency. In preferred examples, the predetermined frequency is the drive frequency. In such examples, the demodulator determines the difference between the first and second samples obtained from the proof mass at least once per cycle of the drive frequency and produces the error signal in time for the next application of the PWM drive signals to the capacitor electrodes. While the error signal could be an analogue signal, in preferred examples the error signal is digital. This allows, for example, the error signal to be input directly into the digital to analogue converters so as to scale the voltages applied to the first and second capacitor electrodes. According to a second aspect of this disclosure there is provided a closed loop method of controlling a capacitive accelerometer comprising a proof mass moveable relative to first and second fixed capacitor electrodes, the method comprising: applying in-phase and anti-phase pulse width modulation (PWM) drive signals to the first and second fixed capacitor electrodes with an adjustable mark/space ratio; detecting a pick-off signal from the accelerometer representing a displacement of the proof mass from a null position to provide an error signal, wherein the null position is the position of the proof mass relative to the first and second fixed capacitor electrodes when no acceleration is applied; operating in closed loop by varying the adjustable mark/space ratio of said in-phase and anti-phase PWM drive signals in response to the error signal so that mechanical inertial forces are balanced by electrostatic forces to maintain the operating point of the proof mass at the null position; and using the error signal so as to vary a differential voltage between the in-phase and anti-phase PWM drive signals. The preferred and optional features described hereinabove in relation to the first aspect apply equally to the second aspect. Certain examples of the disclosure will now be described, by way of example only, with reference to the accompanying drawings in which: In such a conventional accelerometer 2, these PWM drive signals represent voltages that are driven to the fixed capacitor electrodes 6 The mark space ratio servo 16 comprises a PWM loop filter 22 and a PWM generator 24. The high tension servo 18 comprises a high tension loop filter 26 and an inverter 28. The operation of these two servos 16, 18 will be described in further detail below. The charge amplifier 12 is arranged such that its input is connected to the proof mass 4 while its output is connected to the input of the demodulator 14. As will be appreciated by those skilled in the art, a charge amplifier produces at its output a voltage that is proportional to the integral of a current at its input, i.e. the voltage 42 at the output is proportional to the charge at the input. Under acceleration, the voltage 42 produced at the output of the charge amplifier 12 will take two different values in each period of the fixed-height PWM drive signals 30 The demodulator 14 is arranged to sample the output voltage 42 of the charge amplifier 12 twice per period of the PWM drive signals, once when the in-phase, fixed height PWM signal 30 The mark space ratio servo 16 is arranged to use integral control in order to vary the mark space ratio of the fixed height PWM drive signals 30 By way of contrast, the high tension servo 18 is arranged to vary the amplitude of the PWM drive signals 40 The two DACs 20 While the mark space ratio servo 16 acts to vary the mark space ratio of the drive signals 40 Thus the system of the present disclosure uses a constant voltage regime and not a constant charge regime. However, whereas previous constant voltage systems applied the same voltage to each of the capacitor electrodes in their respective half-cycles, and applied the same voltage constantly from one cycle to the next, the control system 10 of the present disclosure varies a differential voltage applied to the capacitor electrodes in their respective half-cycles (i.e. they do not necessarily receive the same voltage) and varies this differential voltage from one PWM cycle to the next. This differential voltage is varied in accordance with displacement of the proof mass 4 such that the electrostatic force between the proof mass 4 and each of the capacitor electrodes 6 However, at time tnull, the proof mass 4 is restored to the null position even though it is still undergoing acceleration. As such, the output signal 42 of the charge amplifier 12 becomes constant and equal to the reference voltage Vref described previously and the error signal 44 produced by the demodulator 44 drops to 0 V. In turn, the control words 34 Thus it will be seen that the present disclosure provides an improved method for control of a closed loop capacitive accelerometer that does not suffer from a negative spring rate. By removing the effect of the negative spring rate, MEMS-based capacitive accelerometers may be implemented with lower resonant frequencies and higher open loop scale factors. This can help to alleviate the bias effects due to mechanical stressing of the MEMS. It will be appreciated by those skilled in the art that the examples described above are merely exemplary and are not limiting on the scope of the invention. An accelerometer closed loop control system comprising: a capacitive accelerometer comprising a proof mass moveable relative to first and second fixed capacitor electrodes; a PWM generator to generate in-phase and anti-phase PWM drive signals with an adjustable mark/space ratio, wherein said drive signals are applied to the first and second electrodes such that they are charged alternately; an output signal detector to detect a pick-off signal from the accelerometer representing a displacement of the proof mass from a null position to provide an error signal, wherein the null position is the position of the proof mass relative to the fixed electrodes when no acceleration is applied; a PWM servo operating in closed loop to vary the mark/space ratio of said PWM drive signals in response to the error signal so that mechanical inertial forces are balanced by electrostatic forces. 1. An accelerometer closed loop control system comprising:

a capacitive accelerometer comprising a proof mass moveable relative to first and second fixed capacitor electrodes; a pulse width modulation (PWM) generator arranged to generate in-phase and anti-phase PWM drive signals with a drive frequency and an adjustable mark/space ratio, wherein said in-phase and anti-phase PWM drive signals are applied to the first and second fixed capacitor electrodes respectively such that they are charged alternately; an output signal detector arranged to detect a pick-off signal from the accelerometer representing a displacement of the proof mass from a null position to provide an error signal, wherein the null position is the position of the proof mass relative to the first and second fixed capacitor electrodes when no acceleration is applied; a PWM servo operating in closed loop arranged to vary the adjustable mark/space ratio of said in-phase and anti-phase PWM drive signals in response to the error signal so that mechanical inertial forces are balanced by electrostatic forces to maintain the operating point of the proof mass at a null position; and a differential voltage servo arranged to vary a difference in amplitude between the in-phase and anti-phase PWM drive signals in response to the error signal. 2. The accelerometer closed loop control system as claimed in said first digital control word is input to a first digital to analogue converter arranged to receive the in-phase PWM drive signal at a first reference input and output a scaled in-phase PWM drive signal; and said second digital control word is input to a second digital to analogue converter arranged to receive the anti-phase PWM drive signal at a second reference input and output a scaled anti-phase PWM drive signal. 3. The accelerometer closed loop control system as claimed in 4. The accelerometer closed loop control system as claimed in sample the output of the charge amplifier while the in-phase PWM drive signal is high so as to produce a first sample; sample the output of the charge amplifier while the anti-phase PWM drive signal is high so as to produce a second sample; and calculate a difference between said first and second samples; and produce the error signal, wherein the error signal is dependent on said difference. 5. The accelerometer closed loop control system as claimed in 6. The accelerometer closed loop control system as claimed in 7. The accelerometer closed loop control system as claimed in 8. The accelerometer closed loop control system as claimed in 9. The accelerometer closed loop control system of 10. A closed loop method of controlling a capacitive accelerometer comprising a proof mass moveable relative to first and second fixed capacitor electrodes, the method comprising:

applying in-phase and anti-phase pulse width modulation (PWM) drive signals to the first and second fixed capacitor electrodes with an adjustable mark/space ratio; detecting a pick-off signal from the accelerometer representing a displacement of the proof mass from a null position to provide an error signal, wherein the null position is the position of the proof mass relative to the first and second fixed capacitor electrodes when no acceleration is applied; operating in closed loop by varying the adjustable mark/space ratio of said in-phase and anti-phase PWM drive signals in response to the error signal so that mechanical inertial forces are balanced by electrostatic forces to maintain the operating point of the proof mass at the null position; and using the error signal so as to vary a differential voltage between the in-phase and anti-phase PWM drive signals. 11. The closed loop method as claimed in produce first and second digital control words; using said first digital control word and the in-phase PWM drive signal to produce a scaled in-phase PWM drive signal; and using said second digital control word and the anti-phase PWM drive signal to produce a scaled anti-phase PWM drive signal. 12. The closed loop method as claimed in 13. The closed loop method as claimed in sampling the voltage proportional to the capacitance while the in-phase PWM drive signal is high so as to produce a first sample; sampling voltage proportional to the capacitance while the anti-phase PWM drive signal is high so as to produce a second sample; and calculating a difference between said first and second samples; and producing the error signal, wherein the error signal is dependent on said difference. 14. The closed loop method as claimed in 15. The closed loop method as claimed in TECHNICAL FIELD

BACKGROUND

SUMMARY