SYRINGE AND PLUNGER ROD WITH STOPPER GUIDE

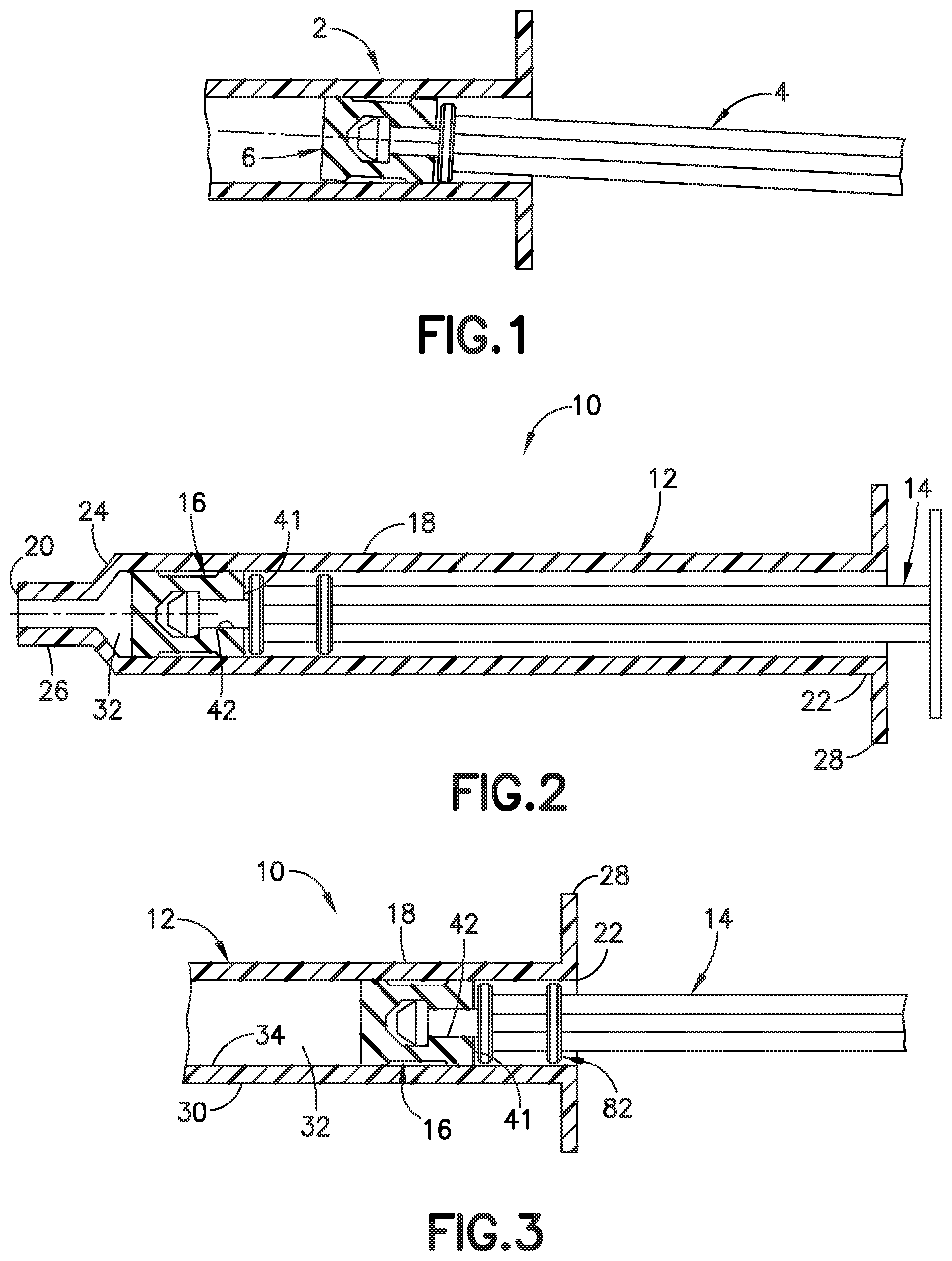

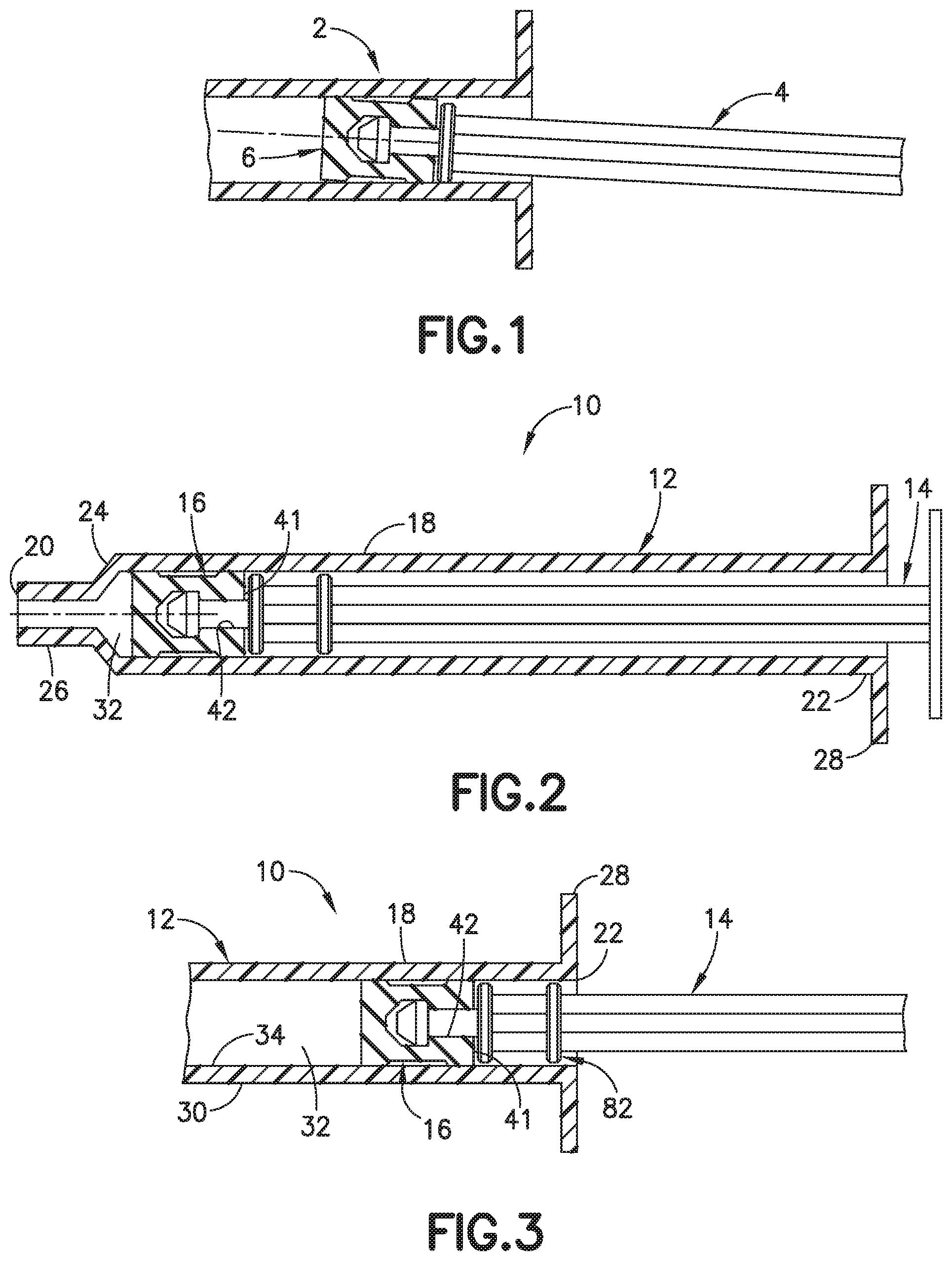

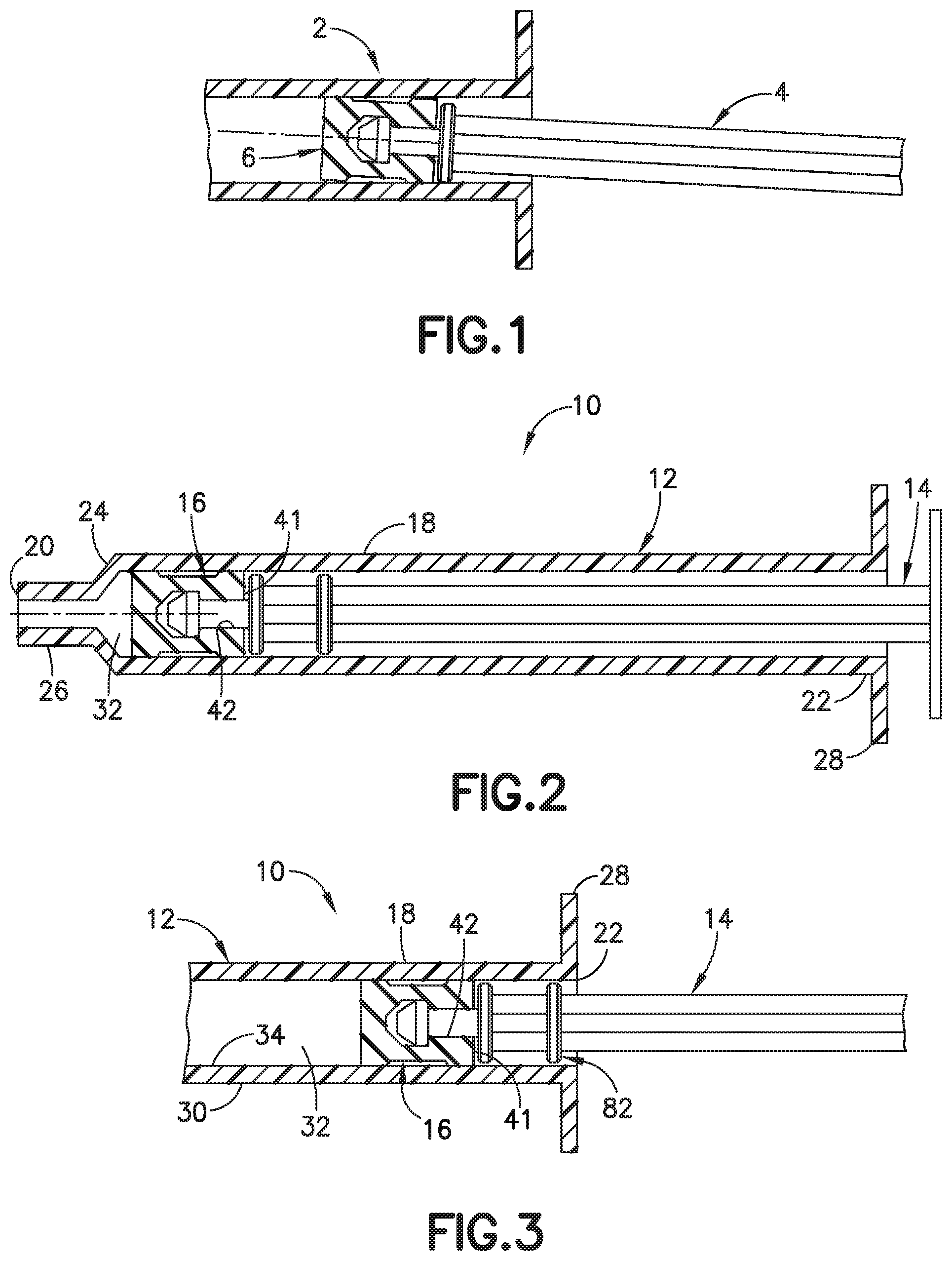

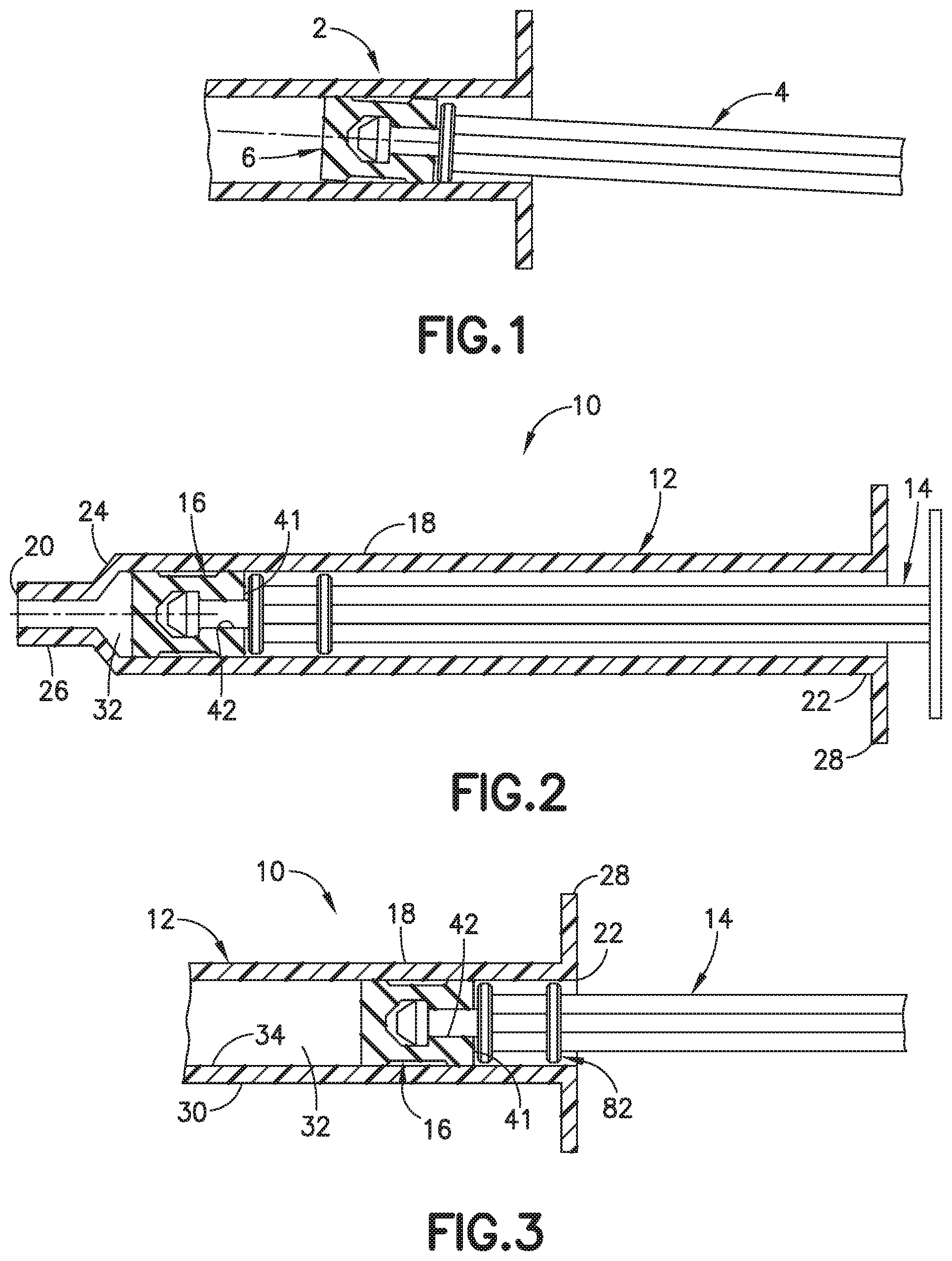

This application claims priority to U.S. Provisional Application No. 62/460,586 filed Feb. 17, 2017, which is hereby incorporated by reference in its entirety. The present invention relates generally to a syringe and a plunger rod. The invention is particularly directed to a plunger rod provided with a stopper guide for assisting in maintaining a seal and preventing leakage when the plunge rod is off axis from the syringe barrel. Syringes are used for delivering a substance and for withdrawing and collecting arterial blood samples from the body of a patient. Various types of syringes have been devised that include a plastic or glass syringe barrel, a sealing elastomeric stopper, and a plunger rod. The syringes can include a self-sealing filter that allows passage of air out of the syringe during collection of a sample, while still preventing the passage of fluid being collected. This type of syringe having a filter allows for a sample to be collected without the need to aspirate the syringe, as is required with a syringe having a plunger rod and a plunger stopper. A standard syringe having a plunger rod with the stopper attached can be subjected to side load applied to the plunger rod. A side load or force applied at an inclined angle with respect to the direction of travel of the plunder rod can result in distortion of the stopper relative the syringe barrel that may result in leakage around the stopper. Typical syringes include a two-piece plunger rod assembly comprised of an elastomeric sealing stopper attached to a plunger rod. U.S. Pat. No. 5.314.416 to Lewis et al. discloses a low friction syringe assembly having a typical two-piece plunger rod and a plunger tip assembly. The sealing stopper and plunger rod are assembled together in a separate operation prior to assembly with a syringe barrel. A silicone lubricant is usually used on the interior wall of the syringe barrel to facilitate sliding movement of the elastomeric sealing stopper against the interior wall of the syringe barrel. A needle can be connected to the syringe to dispense the contents. The needle can also access a blood vessel for collecting a blood sample where the syringe is thereafter aspirated by the holding the syringe in a fixed position and drawing the plunger rearward within the syringe barrel to draw a blood sample into the syringe barrel. After completion of the sample collection, the needle is removed and the syringe containing the collected sample is then transported to the laboratory. The plunger that is protruding from the syringe barrel can make handling and transportation of the syringe difficult and special care has to be taken not to dislodge the plunger that can cause leakage. When the plunger rod is withdrawn from the syringe barrel, the plunger rod may not be stable and can deflect to a position where the axis of the plunger rod is not aligned with the axis of the syringae barrel. The stopper can be deflected at an angle that can cause leakage. While the prior devices have been generally suitable for the intended use, there is a continuing need in the industry for improved devices for collecting and delivering a substance to a patient. One embodiment of the invention is directed to a syringe and a plunger rod for dispensing and delivering a substance to a patient or for collecting a sample from patient. The invention is particularly directed to a syringe and plunger rod that reduces the incidence of leakage between the stopper and the syringe barrel. The syringe in one embodiment has a syringe barrel with an open end for receiving a plunger rod and an outlet end for dispensing or collecting a fluid. The plunger rod has a stopper coupled to one end of the plunger rod for sliding within the syringe barrel to dispense or collect the fluid. The plunger rod is configured to slide within the syringe barrel while maintaining a stable axial position within the syringe barrel. One aspect of the present invention is to provide a plunger rod having an annular plate forming a rib spaced from the distal end of the rod and spaced from the stopper that cooperates with the inner surface of the syringe barrel to stabilize and maintain the axis of the plunger rod on the axis of the syringe barrel. A further aspect of the invention is to provide a plunger rod for supporting a stopper that slides within a syringe barrel where the plunger rod has two or more axially spaced points of support that can complement or engage the inner surface of the syringe barrel. In one embodiment, two or more plates or ribs are spaced apart a distance to limit tilting of the plunger rod off axis relative to the axis of the syringe barrel thereby preventing distortion of the stopper. The two spaced apart points of support maintain the longitudinal axis of the plunger rod and the longitudinal axis of the stopper parallel to the longitudinal axis of the syringe barrel. The foregoing and/or other aspects of the present invention are achieved by providing a plunger rod for a syringe where the plunger rod has a longitudinally extending shaft with a distal first end for coupling to a stopper, and a proximal second end opposite the distal end for operating the plunger rod. An annular plate forming a rib is positioned at the first end and oriented to engage the inner surface of a syringe barrel during sliding of the plunger rod within the syringe barrel to maintain the axis of the plunger rod parallel to the longitudinal axis of the syringe barrel. By maintaining the plunger rod on the axis of the syringe barrel, the plunger remains on the axis of the syringe barrel to reduce the occurrence of leakage. The features of the present invention are achieved by providing a syringe assembly having a syringe barrel, a plunger rod and a stopper coupled to the distal end of the plunger rod. The plunger rod has a shaft with a distal end and a proximal end. A coupling member extends from the distal end for supporting the stopper. At least one support is positioned at: the distal end for cooperating with the syringe barrel to limit tilting of the plunger rod relative to the syringe barrel. The various features of the present invention are also achieved by providing a plunger rod with at least two spaced apart supports providing at least two supporting points for the plunger rod and supporting the position of the plunger rod within the syringe barrel during use. The shaft includes a base plate at the distal end forming a first support point and for mating with and supporting the stopper. The second support point is provided by a support spaced axially from the based plate a distance to limit tilting of the plunger rod within the syringe barrel. In one embodiment, the support is a support plate or an outwardly extending projection. The features of the invention are further attained by providing a syringe assembly including a syringe barrel and a plunger rod. The syringe barrel has an axial dimension with an axial passage with an open end. The plunger rod has a shaft with a first end with a stopper coupled to the first end for sliding in the syringe barrel. The shaft of the plunger rod has a second end for actuating the plunger rod by the user. At least one rib extends outward from the shaft to engage the inner surface of the syringe barrel when the plunger rod is tilted relative to the axis of the syringe barrel. The features of the invention provide at least one support, such as a support plate, extending outward from the plunger shaft where the support plate is spaced from the first end a distance to stabilize and resist tilting of the plunger rod when the plunger rod is withdrawn toward the open end of the syringe barrel. A syringe assembly in one embodiment includes a syringe barrel having an open end and an axial passage and a plunger rod. The plunger rod includes a shaft having a longitudinal axis with a first end and a second end opposite said first end. A stopper support is provided at the first end forming a first contact point with an inner surface of said syringe barrel. A coupling member is provided on the stopper support at the first end and a stopper is coupled to the coupling member. The stopper has an outer dimension for sliding in the axial passage of said syringe. The shaft has at least one plunger rod support extending radially outward from the shaft and spaced from the first end forming at least one second contact point with the inner surface of the syringe barrel. The at least one plunger rod support has an outer dimension for engaging the inner surface of the syringe barrel to resist lateral movement and tilting of the plunger rod relative to the syringe barrel. The plunger rod support is spaced from the stopper support a distance of about 1 to 1.5 times an inner diameter of the syringe barrel. Additional and/or other aspects and advantages of the present invention will be set forth in part in the description that follows and, in part, will be apparent from the description, or by practicing of the invention. The above and/or other aspects and advantages of embodiments of the invention will be more readily appreciated from the following detailed description, taken in conjunction with the accompanying drawings, in which: Reference is made in detail to embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to the like elements throughout. The descriptions of these embodiments exemplify the present invention by referring to the drawings. For purposes of the description hereinafter, the terms “upper”, “lower”, “right”, “left”, “vertical”, “horizontal”, “top”, “bottom”, “lateral”, “longitudinal”, and derivatives thereof shall relate to the invention as it is oriented in the drawing figures. However, it is to be understood that the invention may assume various alternative variations, except where expressly specified to the contrary. It is also to be understood that the specific devices illustrated in the attached drawings, and described in the following specification, are exemplary embodiments of the invention. Specific dimensions and other physical characteristics related to the embodiments disclosed herein arc not to be considered as limiting. The embodiments are not intended to be mutually exclusive so that the features of one embodiment can be combined with other embodiments. As used herein, the term “proximal” refers to a location assembly according to the embodiments of this invention that, during normal use, is closest to the clinician using the device and farthest from the patient in connection with whom the device is used. Conversely, the term “distal” refers to a location on the assembly of this invention that, during normal use, is farthest from the clinician using the device and closest to the patient in connection with whom the device is used. Furthermore, the term “proximal direction” indicates a direction of movement away from the patient and toward the user of the blood collection assembly, whereas the term “distal direction” indicates a direction of movement away from the user of the assembly and toward the patient. Referring to The open end 22 includes a flange 28 for manipulating syringe barrel 12 in a standard manner. The syringe barrel 12 is formed with a side wall 30 having an axial passage 32 defining an inner chamber for containing the substance to be delivered by sliding plunger rod 14 and stopper 16 toward first open end 20. The axial passage 24 is formed with a smooth inner surface 34. In the embodiment shown, barrel 12 has a substantially cylindrical shaped side wall 30. A suitable lubricant, such as a silicone lubricant, can be applied to the inner surface to assist in the sliding of the stopper within the syringe barrel. The syringe barrel can be made of glass or a suitable rigid clear plastic material. The plunger rod can also be made of a rigid plastic material. The syringe assembly 10 of the invention is constructed to reduce the incidence of leakage between stopper 16 and the inner surface of the syringe barrel during use. The plunger rod 16 is configured to maintain the plunger rod on the intended axis and in line with the axis of the syringe barrel. The plunger rod 16 includes at least one and typically two points of support with respect to the syringe barrel to limit the tilting of the plunger rod with respect to the syringe barrel and limit distortion of the stopper. As shown in In the embodiment show, stopper 16 has a substantially cylindrical shape with an outer annular surface 36, an outer end 38, and a recess 40 at an inner end 41 opposite the outer end 38. The outer end 38 provides an end surface for contacting the contents of the syringe and dispensing the contents from the syringe barrel. Recess 40 is formed with an annular lip 42 that extends radially inward for coupling to plunger rod 14. Outer surface 36 of stopper 16 in the embodiment shown in Referring to Distal end 56 of shaft 52 includes a coupling member 62 for receiving and supporting stopper 16. The coupling member 62 includes a post 64 and an enlarged head 66 for mating with stopper 16. As shown in The head 66 has an outer annular face 68 and a bottom face 70 extending radially outward from post 64 to form a ledge 72 with outer annular face 68 for coupling with the stopper 16. The axial end of the head 66 has a conical shaped portion 74 converging to a substantially flat axial face 76 as shown in the end view of The shaft 52 includes a base plate 78 forming a push plate at distal end 56 at the base of post 64 so that post 64 extends axially from plate 78. Base plate 78 has a substantially circular shape with an outer annular edge 80 and an axial thickness to provide sufficient support for stopper 16 during the forward movement of plunger rod 14 in use. The outer annular edge 80 provides a first support point for plunger rod 14 and stopper 16 relative to syringe barrel 12. As shown in A support 82 is formed on shaft 52 and spaced axially from base plate 78 a distance to stabilize the plunger rod when received in syringe barrel 12 and limit tilting of the shaft off axis from the axis of the syringe barrel when a side load is applied. In the embodiment shown, the support member 82 has a circular shape corresponding to the inner shape and dimension of the inner surface of the syringe barrel. The support can have other shapes that are able to contact the inner surface of the syringe barrel and support the plunger rod. In an alternative embodiment, the support can be a plurality of prongs or ribs spaced apart a distance to support the plunger rod. The support is spaced from the base plate a distance equal to or greater than the inner diameter of the syringe barrel. In the embodiment shown, the support is a support plate 82 extending radially outward from the shaft 52 and has an outer radial outer dimension substantially the same as base plate 78. The outer annular edge 84 of support plate 82 is substantially coaxially aligned with the outer annular edge of base plate 78. Support plate 82 has an outer diameter slightly less than the inner diameter of syringe barrel 12 to allow sliding movement and maintain support of plunger rod 14 within the syringe barrel. The outer diameter of the base plate and support plate has a nominal diameter less than the inner diameter of the syringe barrel for sliding and supporting the plunger rod on the axis of the syringe barrel when a side load is applied to the plunger rod. The axial spacing between the base plate and support plate is sufficient to contact the inner surface of the syringe barrel during normal use of the syringe. The spacing is selected so that the support plate is retained within the syringe barrel when the syringe is filed with contents prior to dispensing the contents to stabilize the plunger rod within the syringe barrel. The support plate is oriented relative to the base plate so that support plate is positioned within the syringe barrel throughout the normal operating position of the plunger rod with respect to the syringe barrel. The spacing between the base plate and support plate can vary depending on the inner diameter of the syringe barrel and the axial length of the plunger rod and the axial length of the stopper. The spacing between the base plate and the support plate is a distance that prevents distortion of the stopper that can otherwise cause leakage. In one embodiment, the spacing between the base plate and the support plate can be equal to or greater than an inner diameter of the syringe barrel. Typically, the axial spacing between the base plate and the support plate is not less than an inner diameter of the syringe barrel. The spacing between the base plate and the support plate relative to the inner diameter of the syringe barrel in one embodiment can be about 1:1 to 2:1. In one embodiment, the ratio of the axial spacing between the base plate and support plate relative to the inner diameter of the syringe barrel is about 1:1 to about 1.5:1. In another embodiment, the axial spacing between the base plate and the support plate is about 1:1 with respect to the inner diameter of the syringe barrel so that the axial spacing is about equal to the inner diameter of the syringe barrel. In a further embodiment, the spacing between the base plate and the support plate is about 1 to 1.5 times the inner diameter of the syringe barrel. As shown in Although only a few exemplary embodiments of the present invention have been described in detail above, those skilled in the art will readily appreciate that many modifications are possible in the exemplary embodiments without materially departing from the novel teachings and advantages of this invention. Accordingly, all such modifications are intended to be included within the scope of the appended claims and equivalents thereof. A syringe assembly (10) has a syringe barrel (12), a plunger rod (14) and stopper (16) where the syringe barrel has an open end receiving the plunger rod and stopper in a sliding direction. The plunger rod includes a shaft (52) having a longitudinal axis with a first end having a coupling member (62) for coupling with the stopper. The shaft has a least one plunger rod support (82) extending radially outer from the shaft and spaced from the first end for cooperating with an inner surface of the syringe barrel (12) to resist lateral movement and tilting of the plunger rod relative to the longitudinal axis of the axial passage of the syringe barrel. The shaft in one embodiment has at least two spaced apart points of support (41) and (82) for maintaining the axis of the plunger rod on axis with the syringe barrel to limit twisting and tilting of the stopper thereby resisting distortion of the stopper that can cause leakage. 1. A plunger rod configured for use with a syringe barrel, said plunger rod comprising:

a shaft having a longitudinal axis with a first end and a second end opposite said first end; a coupling member at said first end configured for coupling to a stopper; said shaft having at least one support extending radially outward from said shaft and having a dimension for engaging an inner surface of the syringe barrel to resist lateral movement of said plunger rod relative to the syringe barrel. 2. The plunger rod according to 3. The plunger rod according to 4. The plunger rod according to 5. The plunger rod according to 6. The plunger rod according to 7. The plunger rod according to 8. A syringe assembly comprising:

a syringe barrel having an open end and an axial passage; a plunger rod including a shaft having a longitudinal axis with a first end and a second end opposite said first end; a coupling member at said first end and a stopper coupled to said coupling member, said stopper having an outer dimension for sliding in said axial passage of said syringe; said shaft having at least one support extending radially outward from said shaft and spaced from said first end, said at least one support having an outer dimension for engaging an inner surface of the syringe barrel to resist lateral movement and tilting of said plunger rod relative to the syringe barrel. 9. The syringe assembly according to 10. The syringe assembly according to 11. The syringe assembly according to 12. The syringe assembly according to 13. The syringe assembly according to 14. The syringe assembly according to 15. The syringe assembly according to 16. A syringe assembly comprising:

a syringe barrel having an open end and an axial passage; a plunger rod including a shaft having a longitudinal axis with a first end and a second end opposite said first end, and a stopper support at said first end forming a first contact point with an inner surface of said syringe barrel; a coupling member on said stopper support at said first end and a stopper coupled to said coupling member, said stopper having an outer dimension for sliding in said axial passage of said syringe; said shaft having at least one plunger rod support extending radially outward from said shaft and spaced from said first end forming at least one second contact point with the inner surface of the syringe barrel, said at least one plunger rod support having an outer dimension for engaging the inner surface of the syringe barrel to resist lateral movement and tilting of said plunger rod relative to the syringe barrel, and where said plunger rod support is spaced from said stopper support a distance of about 1 to 1.5 times an inner diameter of said syringe barrel. 17. The syringe assembly of 18. The syringe assembly of 19. The syringe assembly of FIELD OF THE INVENTION

BACKGROUND OF THE INVENTION

SUMMARY OF THE INVENTION

BRIEF DESCRIPTION OF THE DRAWINGS

DETAILED DESCRIPTION OF EXEMPLARY EMBODIMENTS