Apparatus And Process For Producing Pultruded FRP Rebar

The invention relates to an apparatus and process apparatus for producing bent multi-sided pultruded fibre reinforced plastic reinforcement bar for concrete (commonly known as FRP rebar). Pultruded FRP rod is produced by drawing a bundle of fibreglass or other reinforcement rovings through a resin bath to wet the roving with resin, and subsequently heating the wet roving to cure the resin and form a solid product. Reinforcing bar or rebar used as concrete reinforcing is typically formed from steel rod but may be formed from fibre reinforced bar or rod. Steel rebar may comprise straight lengths or may be bent to multi-sided shapes. Typically reinforcing in a square cross-section concrete beam for example, comprises multiple rebar lengths in the length of the beam, and three or four-sided bent steel rebar elements spaced in the length of the beam to tie the rebar lengths together. These are wire-tied to the rebar lengths to hold them in place before the beam is poured. An object of the invention is to provide an improved or at least alternative apparatus and/or process apparatus for producing bent multi-sided pultruded composite rebar. In broad terms in one aspect the invention comprises apparatus for producing bent multi-sided pultruded FRP rebar, which comprises:

In broad terms in another aspect the invention comprises a process for producing bent multi-sided pultruded FRP rebar, which comprises:

In broad terms in another aspect the invention comprises a process for producing bent multi-sided pultruded FRP rebar, which comprises:

In some embodiments the process comprises cutting the bent multi-sided pultruded FRP bar on the or each former frame into multiple individual bent multi-sided pultruded FRP rebar end products. In some embodiments the process comprises winding multiple wet rovings onto one or more rotating multi-sided former frame(s) while removing cured product(s) from one or more other former frame or frames. In broad terms in a further aspect the invention comprises apparatus for producing bent multi-sided pultruded FRP rebar, which comprises multiple resin wetting stages to simultaneously resin pressure impregnate multiple bundles of fibre rovings continuously drawn through the resin wetting stages, and multiple spiral winding stages each arranged to spiral wind a warp around a wet roving exiting one of the resin wetting stages. In this specification:

“bent” is used to describe the shape of a non-straight multi-sided pultruded FRP rebar product, having at least one bend creating at least two lengths or sides, and which may have two or three bends between three or four or more sides, and does not refer to or require that the solid rebar product have been bent after manufacture.

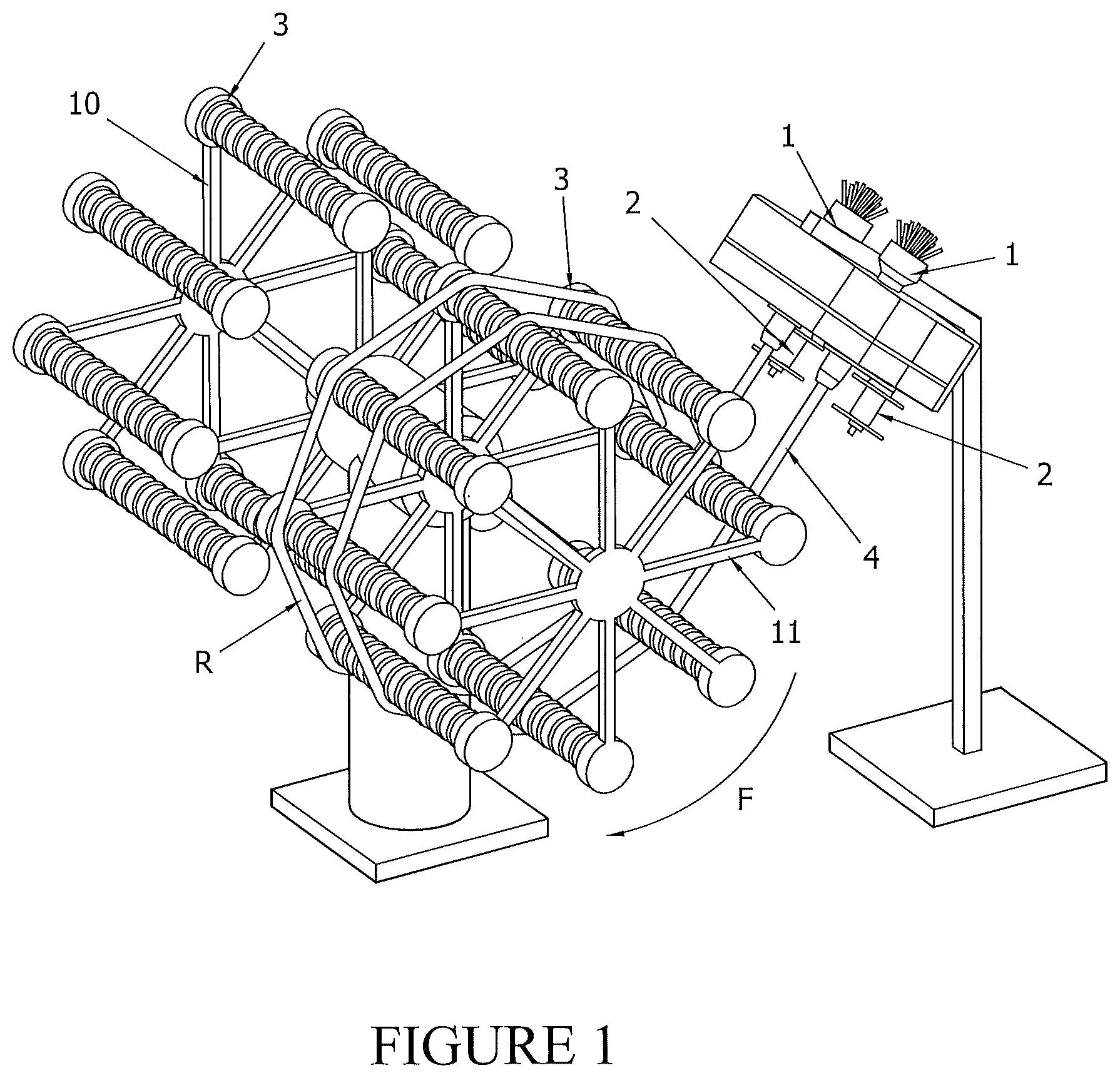

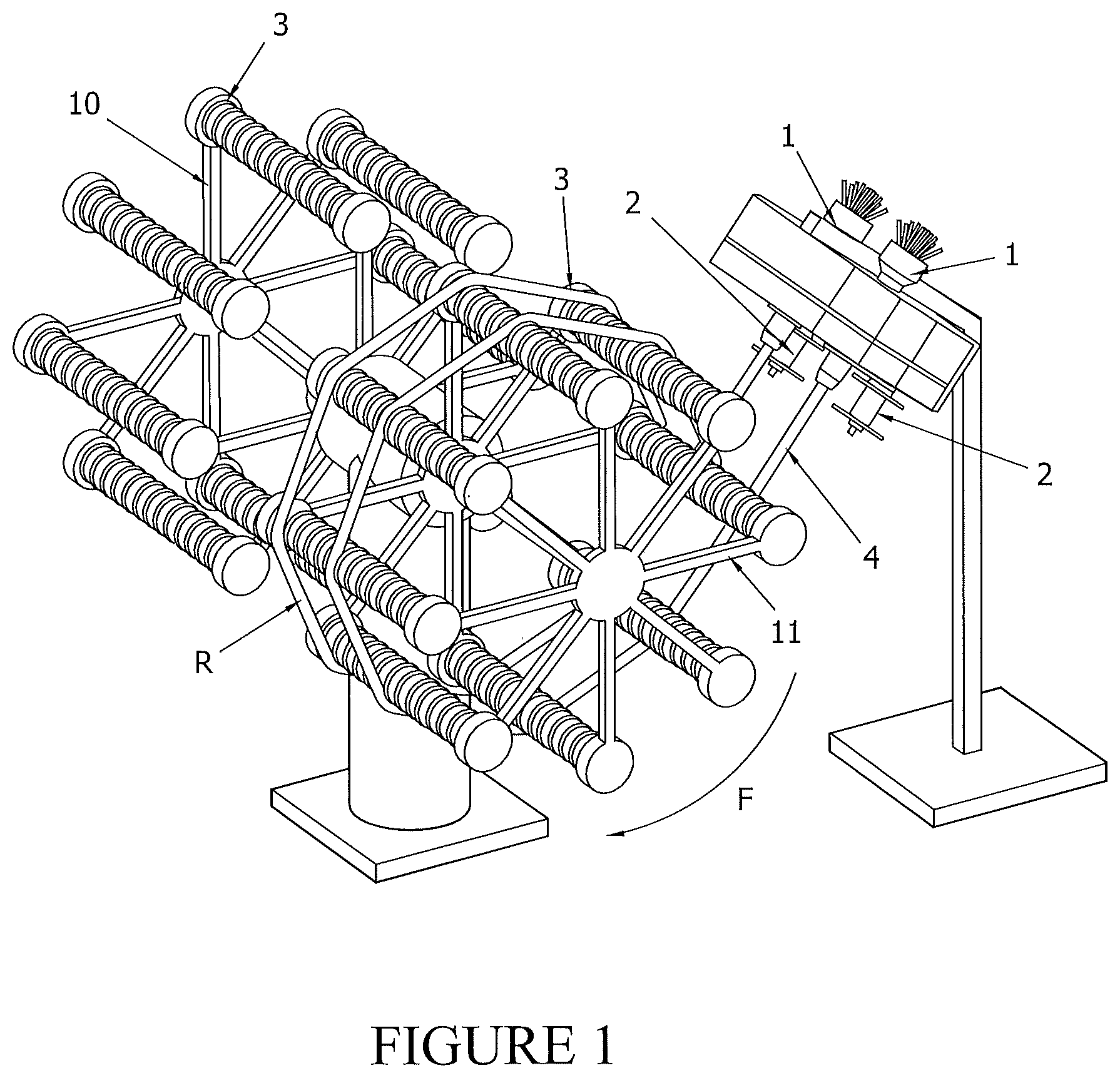

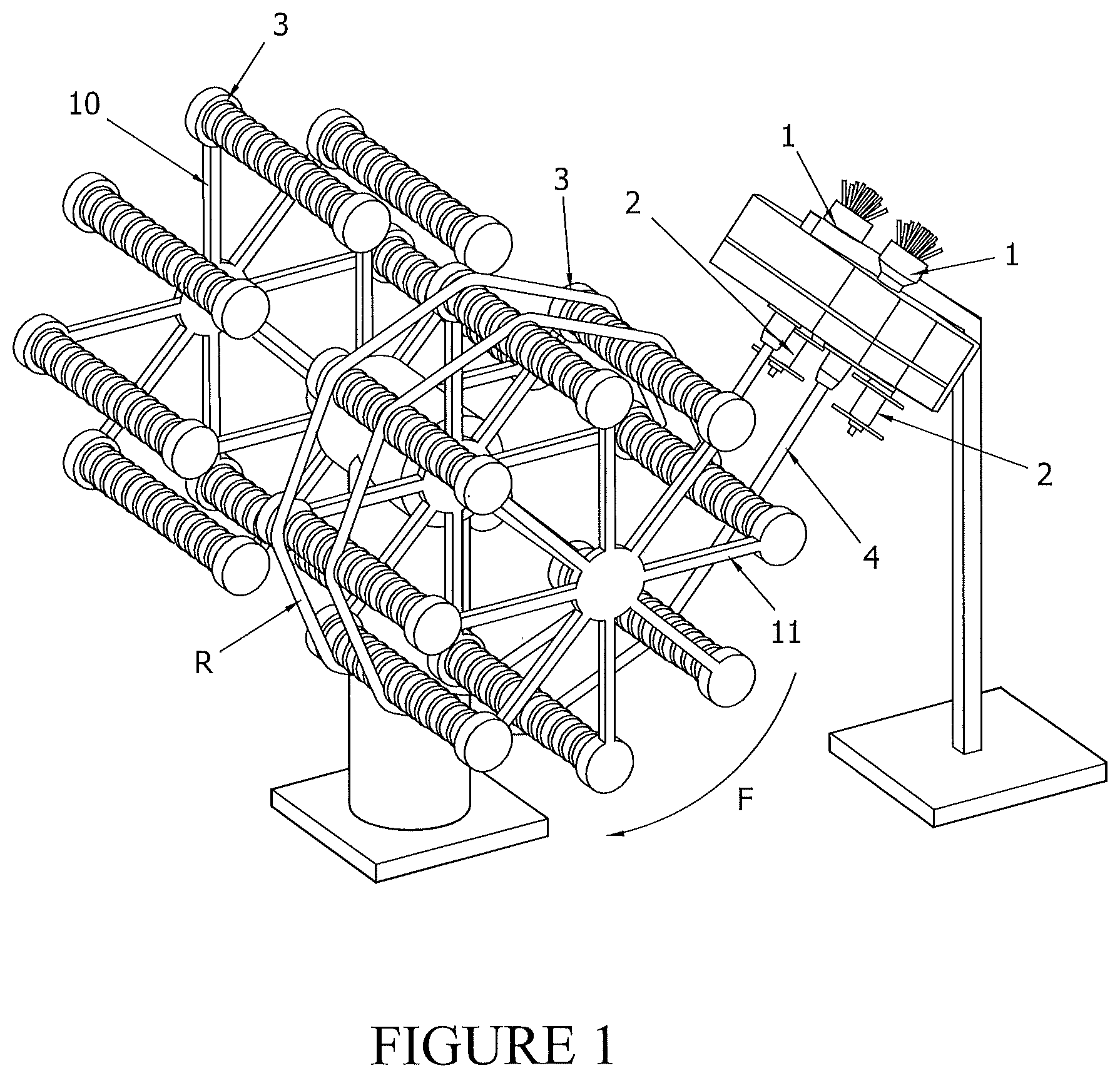

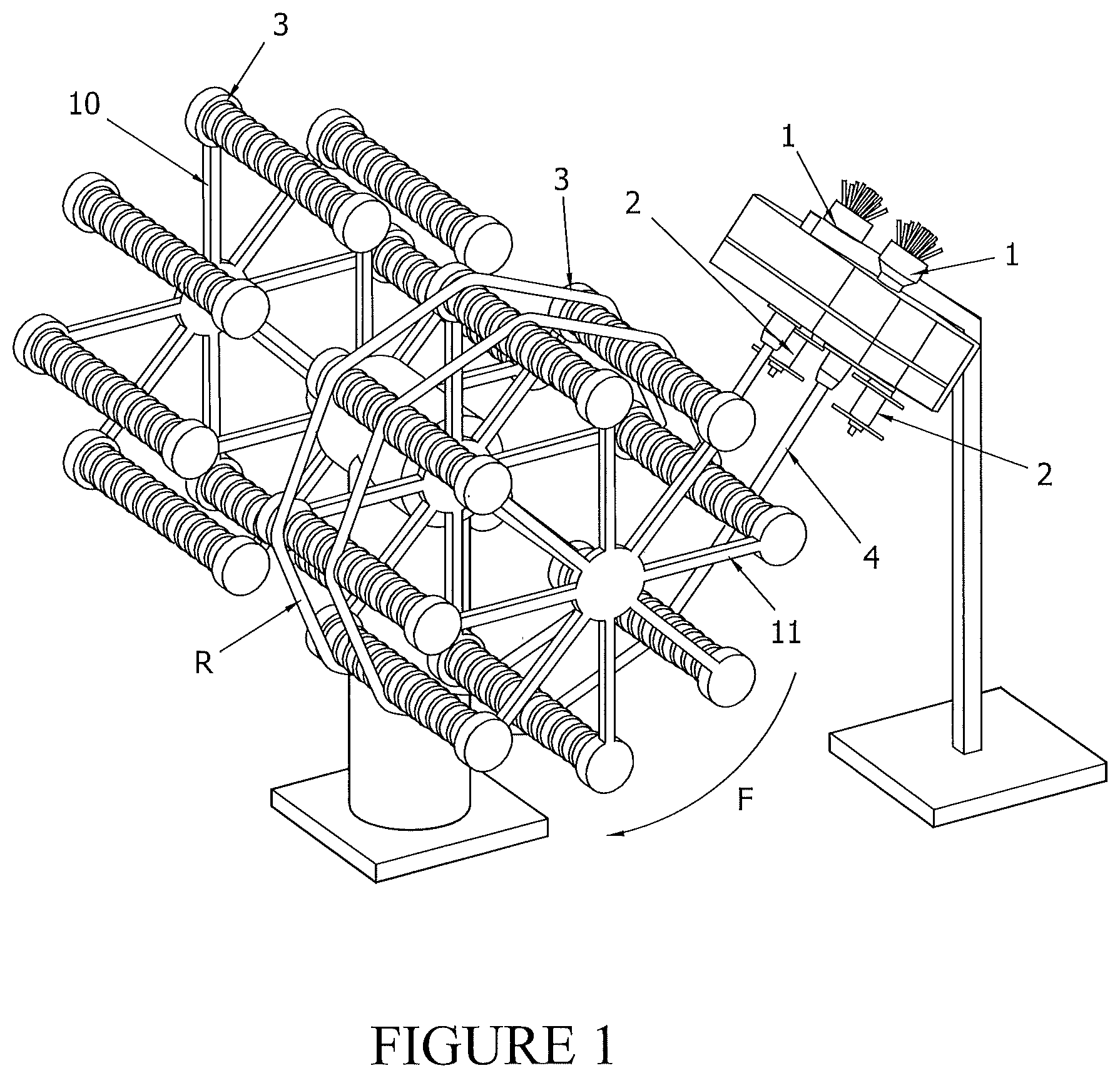

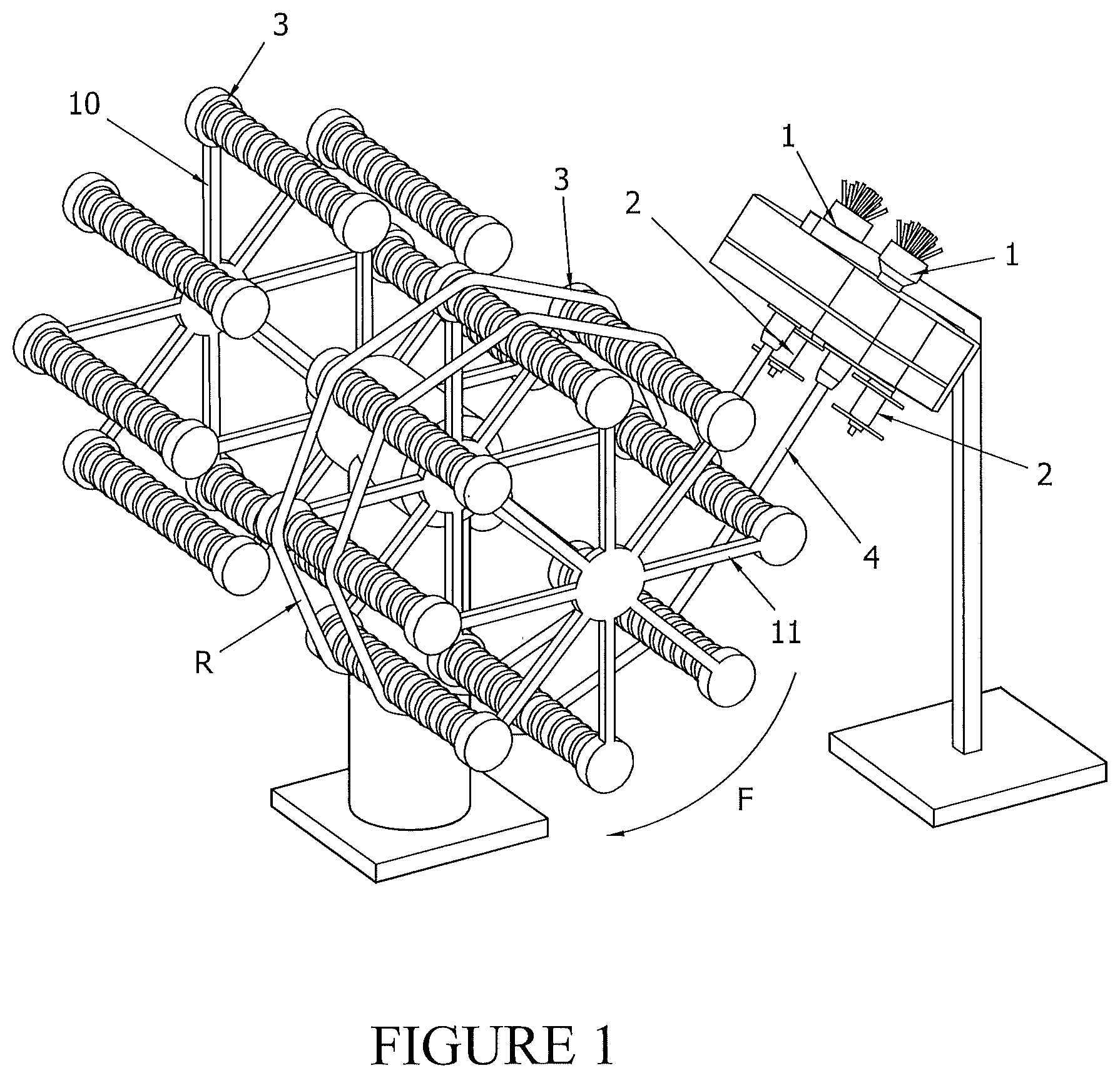

The invention is further described with reference to the accompanying figures, by way of example and without intending to be limiting. In the figures: Referring first to As the wet rovings R exit the impregnation stage a warp is spiral wound around each wet rovings bundle. Each warp may comprise a single strand or a small bundle of multiple strands, of the same material as the fibre rovings, or other suitable material such as Nylon or other synthetic material or cotton or other organic material for example. The spiral warp is wound at a spaced pitch, such that for example if the impregnated rovings bundle has a cross-section dimension in the range 1-3 cm for example, then the warp pitch may also be in the range 1-3 cm. The spiral warp is preferably wound at a tension to slightly compress the rovings bundles beneath the warp along the length of the warp where it contacts the rovings, relative to the rovings segments between warp spirals, which help create a non-smooth exterior surface on the finished solid rebar product and may give it a slightly varying diameter. Referring to The frames 10/11 at each of eight corners comprise a slotted former 14 (all marked in The two cured roving turns on that frame 10 (multiple turns for example 6 turns) may be cut into individual (for example 10) multisided products which are then individually removed from the frame 10, or in an alternative embodiment the whole frame may be removed and replaced with another empty frame, and the roving turns cut from that frame while off the machine, into individual products. While one of the frames on one side of the machine is driven to rotate, and take up wet roving the cured roving on the other side of the machine is being removed. The speed of rotation of the moving frame is co-ordinated with the speed of movement of the roving bundles through the machine. In the embodiment described above the two resin wetting stages and spiral warp winding stages feed one of the two former frames while the other former frame is stationary during curing and removal but in a higher volume production embodiment three or four or more resin wetting and spiral warp winding stages may feed three or four or more former frames. The foregoing description of the invention includes preferred forms thereof. Modifications may be made thereto without departing from the scope of the invention as defined in the accompanying claims. Apparatus for producing bent multi-sided pultruded fibre reinforced plastic reinforcement bar for concrete (commonly known as FRP rebar) comprises multiple resin wetting stages to simultaneously resin impregnate multiple bundles of fibreglass rovings continuously drawn through the resin wetting stages, multiple spiral winding stages arranged to spiral wind warps around the multiple wet rovings, and multiple rotating multi-sided former frames for continuously winding thereon the multiple wet rovings and holding the multiple rovings while curing. A related method is also claimed. 1. A process for producing bent multi-sided pultruded FRP rebar, which comprises:

continuously drawing multiple bundles of fibre rovings through at least one resin wetting stage to resin impregnate the rovings, spiral winding warps around the multiple wet rovings, continuously winding the multiple wet rovings simultaneously onto a rotating multi-sided former frame, and curing the resin in the multiple rovings while on the former frame(s) to form bent multi-sided pultruded FRP product. 2. A process according to 3. A process according to 4. A process according to 5. A process according to 6. A process according to 7. Apparatus for producing bent multi-sided pultruded FRP rebar, which comprises:

multiple resin wetting stages to simultaneously resin impregnate multiple bundles of fibreglass rovings continuously drawn through the resin wetting stages, multiple spiral winding stages each arranged to spiral wind warps around the multiple wet rovings, and a rotating multi-sided former frame or frames for continuously winding thereon the multiple wet rovings and holding the multiple rovings while curing. 8. Apparatus according to 9. Apparatus according to 10. Apparatus according to 11. Apparatus according to 12. Apparatus according to 13. Apparatus for producing bent multi-sided pultruded FRP rebar product, which comprises multiple resin wetting stages to simultaneously resin pressure impregnate multiple bundles of fibreglass rovings continuously drawn through the resin wetting stages, and multiple spiral winding stages each arranged to spiral wind a warp around a wet roving exiting one of the resin wetting stages. 14. Apparatus for producing bent multi-sided pultruded FRP rebar, which comprises:

multiple resin wetting stages to simultaneously resin impregnate multiple bundles of fibreglass rovings continuously drawn through the resin wetting stages, multiple spiral winding stages each arranged to spiral wind warps around the multiple wet rovings, and multiple rotating multi-sided former frames for continuously winding thereon the multiple wet rovings and holding the multiple rovings while curing, enabling one or more former frames to rotate to wind on multiple wet rovings while removing cured product(s) from one or more other former frames, and then said one or more former frames to rotate to wind on multiple wet rovings while removing cured product(s) from said one or more other former frames.FIELD OF INVENTION

BACKGROUND

SUMMARY OF INVENTION

Definitions

BRIEF DESCRIPTION OF THE FIGURES

DETAILED DESCRIPTION OF EMBODIMENT(S)