Vorrichtung zur herstellung hygienisch einwandfreier getränke

The invention concerns a device for the production of hygenically perfect beverages.

For the production of beverages of all kinds, like lemonades, isotonische beverages, mineral water, oral Rehydratationslösungen, prepared fresh milk from Mil¢hpulver, Instantgetränke and pure drinking water as output product water is e.g. used, which does not correspond always to the hygenic requirements to the condition of the water for use as drinking water after the drinking water regulation “rvo and the regulations of the World Health Organization WHO. Thus pathogene microorganisms - bacteria and viruses - can arrive in from to such water of manufactured beverages and by the benefit and of a hygenically not perfect beverage in such a way germinated serious illnesses Magen-und of intestine tract cause.

The risk of infection through in the beverages existing pathogene microorganisms is in particular in Entwicklungsländem extraordinarily high. According to the estimations get sick to the World Health Organization in the developing countries more than 500 million humans annually by the benefit of a hygenically not perfect water, and more than 5 million babies and children die at choleraähnlichen illnesses, acute Gastroenterithis and other Magenund intestine diseases, primarily by failure and vomiting, a condition, which is intensified by anyway in most cases the bad nourishing condition of the children.

The World Health Organization WHO recommends the use of oral Rehydrationssalzen, which in a litre drinking water are to be given dissolved to the child gotten sick during a daily for the fight of the Dehydration caused by choleraähnliche illnesses. This oral Rehydrationssalze with hygenically not perfect and verkeimtem water is in most cases prepared, so that a successful Rehydration is not possible.

Also the preparation of lemonades and other not-alcoholic soaking as well as the preparation of fresh milk from milk powder in most developing countries take place with hygenically not perfect verkeimtem water, whereby likewise choleraähnliche illnesses Magenund of intestine tract 2s can be caused.

However the danger that hygenically perfect verkeimtes water does not come from the water pipeline, exists in particular during the decentralized potable water supply of house wells or sources, in addition, with damage to the drinking water pipelines or long service lives in the drinking water pipelines of the public water supply nets also in the industrialized countries.

Also beverages, which are made of such drinking water, which is burdening by pathogene microorganisms, can cause serious illnesses Magenund of intestine tract, as is to be taken out of the not at all so rare press reports.

The available invention aims off to create a device it made possible in such a way to regenerate hygenically not perfect Rohwasser before its use as drinking water or for further processing to alcohol-free beverages of all kinds that it is freely from mechanical impurities, freely from chemical pollutants and free from pathogenen microorganisms - bacteria and viruses -.

The device according to invention is characterised by it, da8 in only one housing, framework rack od.dgl, a drinking water processing combination building group consisting of a filter mechanism, an activated charcoal filter and a UV-C sterilization mechanism arranged is, which feed a receiver for the admission of the hygenically perfect drinking water, from which the drinking water over a cooling equipment and preferably dosing equipment for additives in firm or liquid form to a withdrawal mechanism flows.

With this device it is reached that the filtration, activated charcoal treatment and chemistry-free disinfection by irradiation with ultraviolet jets, the wavelength 253.7 Nm, in a only one =s combination of units and be arranged in such a way with the beverage manufacture device (Mischund filling up device) and/or the beverage donor automat in form of a compact unit can be e.g. summarized that the device is operational as pre-mounted and prefabricated unit everywhere set up and immediately. The device can be coupled favourably also with Kühlund warming device, whereby the addition of the additives for beverage production, for example fruit saft concentrates, flavour materials, vitamins, mineral materials, trace elements are actually added to etc. either liquid over suitable, well-known Dosiervordchtungen, or in Pulveroder tablet form, also as shower tablets, directly before the filling up procedure with filling up devices for example in bottles, or with beverage PEND automats before the Portionierung into glasses, cup or the like, whereby in latter case the beverage PEND automats can deliver or warm beverages also cooled over suitable devices.

ss by an interpretation of the invention-towards-eaten device for an enterprise within the low-voltage range of 12 V or 24V direct current the individual combinations of units can be operated line current-independently with solar electricity over photovoltaische solar modules with load automatic controller and solar batteries, so that a pollution free power supply system is available, without the well-known disadvantages of RK 404,539 B Benzinoder Diesel current generators with their Geruchsund noise generation and logistics problems with the fuel necessary for the enterprise. Thus the device according to invention is suitable particularly well for the application in lines of development, where long lasting current disturbances at the agenda are and where no hygenically perfect drinking water is in most cases available.

As sample applications would be to be among other things emphasized: oral Rehydrationslösungen, isotonische beverages, from milk drying powder manufactured fresh milk, from drying concentrates manufactured lemonades, Fruchtund of vegetable juices, vitaminiserte and mineralized beverages etc.

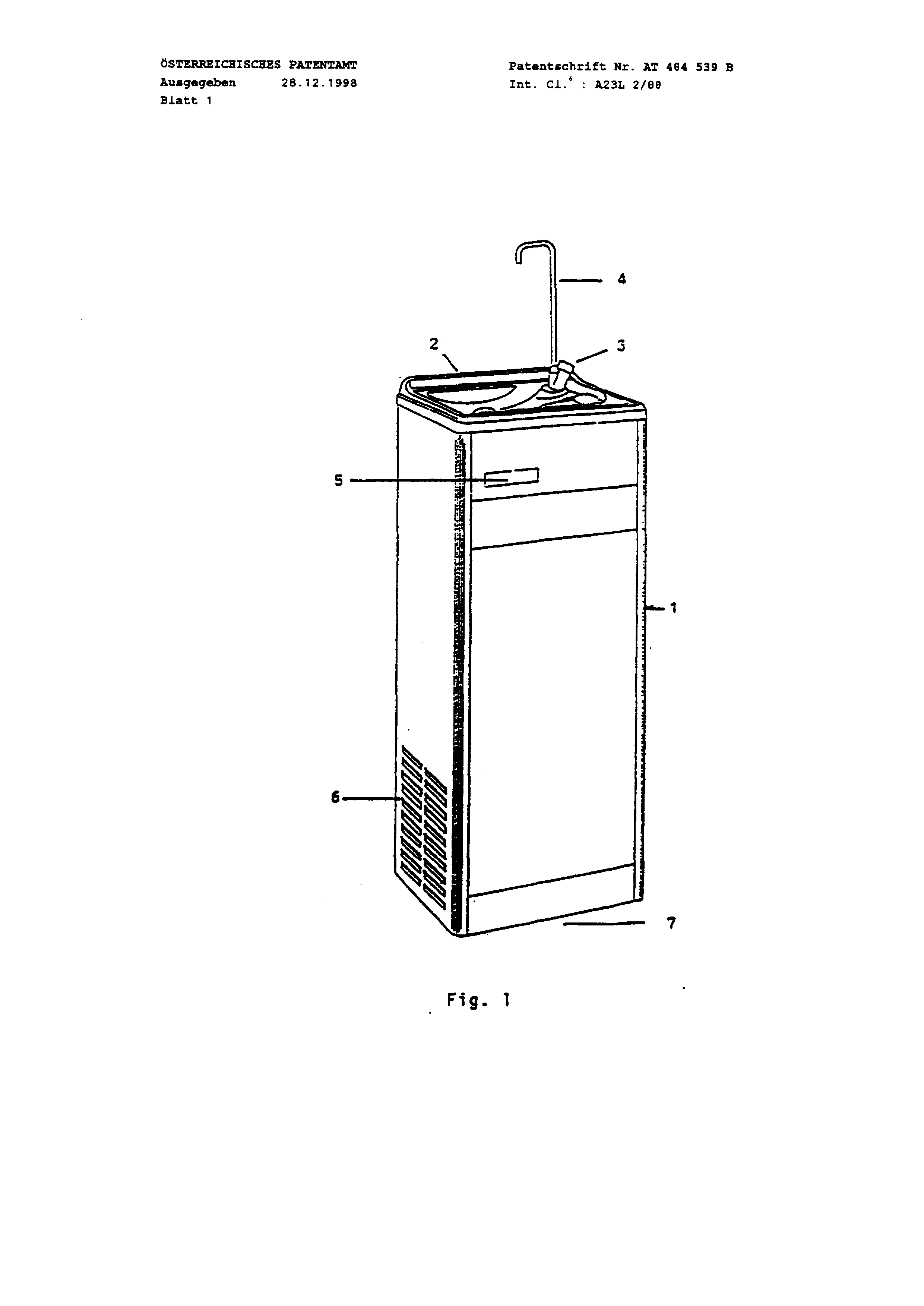

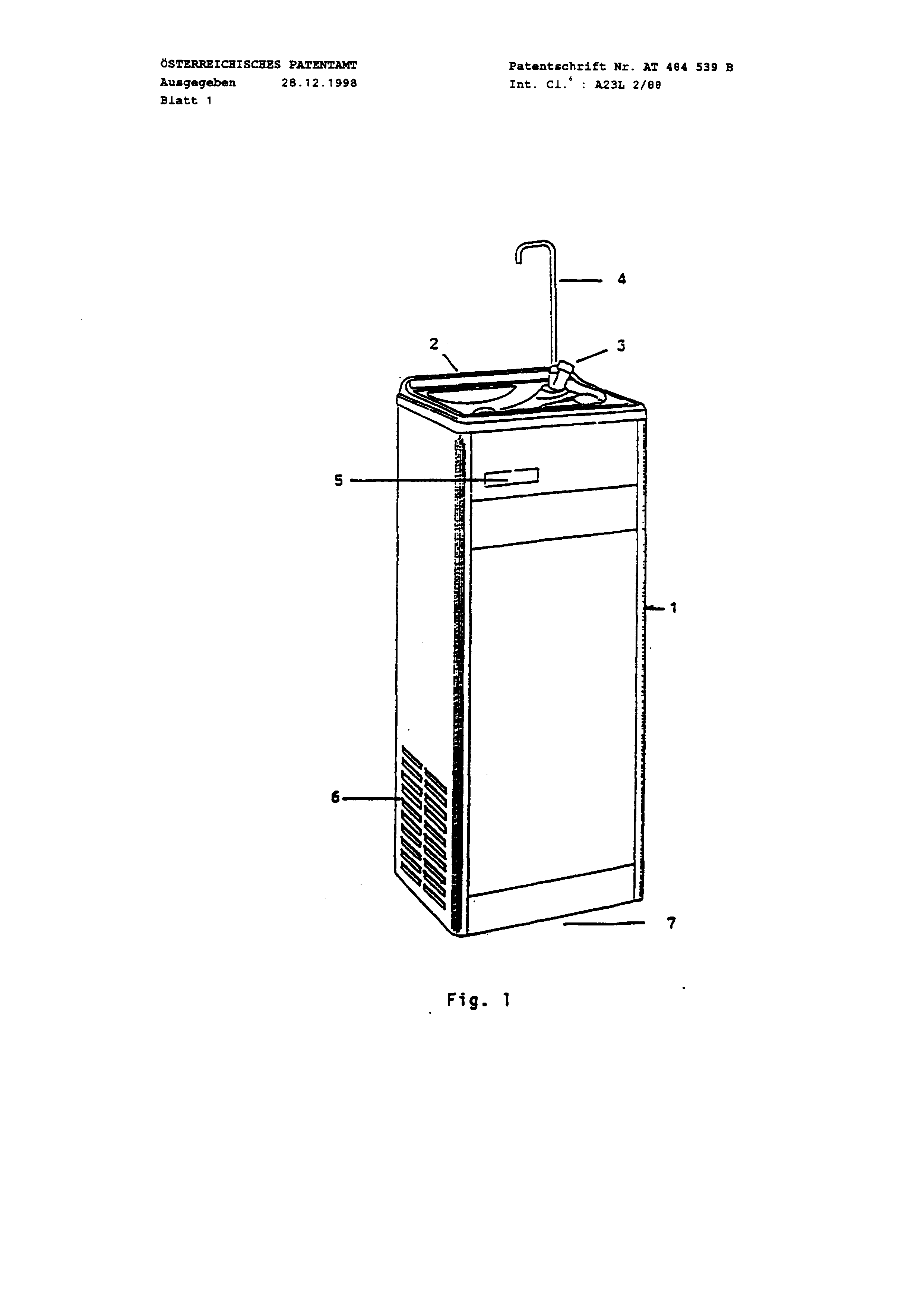

Further characteristics of the invention are more near described in the following with a remark example with reference to the design, those in Fig. 1 a device in accordance with the invention and in Fig. 2 a schematic sketch of the device shows.

In Fig. 1 is shown a drinking water donor with a housing 1. The hygenically perfect drinking water is caught in a basin 2. By one operatinglift) 3 flows the drinking water after manipulation of the lever or a pushbutton over a discharge device 4 into the basin 2. the discharge of the drinking water can also over a pedal (suggested in the design by the reference symbol 7) be caused. At the front of the housing 1 the controls, like Einund circuit breaker, are indicator light, hour meter among other things in a putting in device 5 arranged, at the side of the housing 1 are louvers 6 for the derivative of the compressor warmth and cooling intended.

In Fig. the structure of the device is schematically represented 2. The Rohwasser is introduced over the inlet 10 and the housing 1 and flows over Grobund fine filter 20 and an activated charcoal filter 30, whereby the promotion of the water river is caused by a pump 50. After flowing through a UVC sterilization mechanism 40 flow the filtered, activated charcoal-treated and UV-C entkeimte and now hygenically perfect drinking water into a receiver 60, from which it arrives over a cooling equipment at the delivery over the lever 3 and the discharge 4. The cooling is made by a compressor 80 and a Kühlleitung - a cooling circuit 90. The warmth produced by the compressor 80 is dissipated over the radiator 26 with a fan 25. The pressure control is made by a pressure control valve 18. Furthermore the device is equipped with single solenoid valves 19 and 27, check valves 21 and 23, a regulating valve 22 and a thermostat 24. The emptying of the device is made by a discharge 13. The device can be cleaned by a flushing over an inlet 16 and an expiration 15. Between the receiver 60 and the cooling device 70 a metering of firm or liquid concentrates can be made for enrichment with mineral materials, trace elements and other vital materials, a direct feed of these concentrates is also by a metering unit (here not represented and an inlet 14. possible.

3.5 example 1 into a storage vessel, which serves as collecting main for a FlaschenabfUIIvorrichtung, is entered the additives needed for the production of the finished beverage, concentrates, flavours etc. in the quantities co-ordinated for the collecting main container either liquid or in Pulveroder tablet form and the collecting main containers then filled up with hygenically perfect drinking water, which in a combined filter activated charcoal UV sterilization plant was prepared before. The enterprise of the drinking water processing plant and the filling up device can take place continuously or intermittent, händisch, half or fully automatic. The entire plant is pre-mounted in a framework rack as compact unit with simplified Anund inlets for the individual components, so that their assembly and 4.5 list can be everywhere accomplished very simply and at short notice. The filling can take place in bottles or bottles hnliche bundles, Tetrapack's or plastic bags or similar containers, which are afterwards locked, labeled and packed for the further transport.

Example 2 in a beverage donor automat is arranged a Trinkwasseraufbereitungsvordchtung consisting of a filter stage, a activated charcoal treatment stage and a sterilization stage for disinfection by UV-C jets for killing all pathogenen microorganisms - bacteria and viruses - in such a way that the Rohwasser needed for the beverage dispenser is regenerated hygenically perfectly, before it is delivered by the beverage dispenser. In such a way prepared hygenically perfect drinking water can be filled up as such, if necessary also cooled by portion or continuously over manipulation one foot or hand lever in a glass or an other arbitrary container. Alternatively also all other beverages, as for example oral Rehydratations solutions, know from TrockenAT 404,539 B milk powder manufactured fresh milk, lemonades, Obstund of fruit saft beverages, isotonische beverages and vitaminisierte and mineralized beverages thereby to be manufactured, da8 either in the Vorlagebehäiter of the beverage donor the necessary additives in liquid or firm form as tablets, powder or the like in this device.

, or however directly into the beverage dispenser the container placed held or forwards, s are metered at the same time or after the drinking water filling in the quantity co-ordinated with the water content to be metered. The delivery of the desired and programmable quantity of water and/or beverage quantity is made automatically by means of a photoelectric cell control or by a Handoder FuBhebelbetätigung. The total device is accommodated as a compact unit in only one housing and can be operated also netzstrornunabhängig over photovoltaische solar modules, so that it is applicable everywhere o and not to existing electricity mains be attached must, whereby it is particularly suitable for the employment in developing countries. 7,5 1.

Device for the production of hygenically perfect beverages, by the fact characterized that in a only one housing (1), framework rack od.dgl, a drinking water processing combination building group consisting of a filter mechanism (20), an activated charcoal filter (30) and a UV-C sterilization mechanism (40) arranged is, which for the admission of the hygenically perfect drinking water feeds a receiver (60), from soft the drinking water over a cooling equipment (70) and preferably dosing equipment for additives in firm or liquid form to a withdrawal mechanism (3, 4) flows.