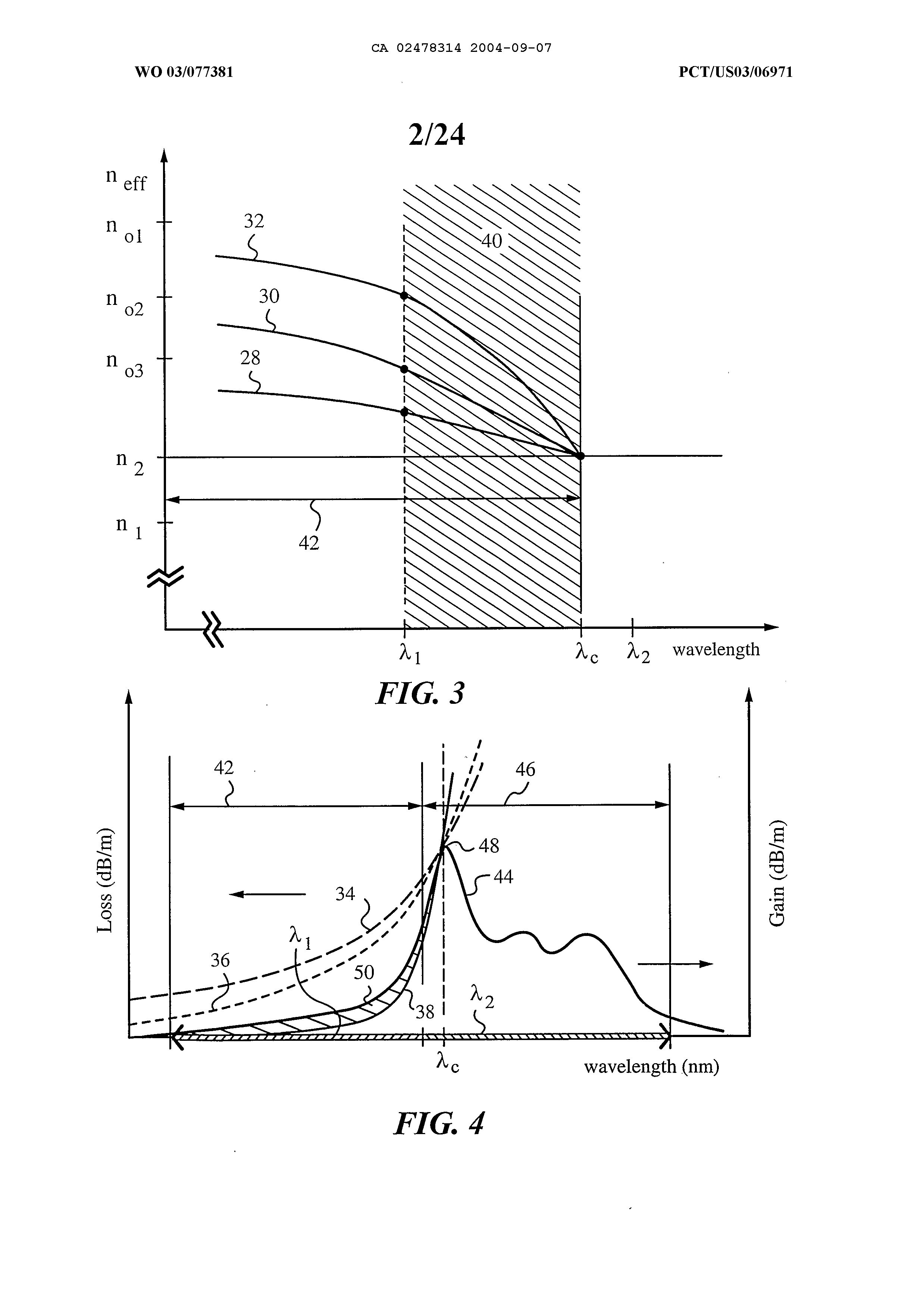

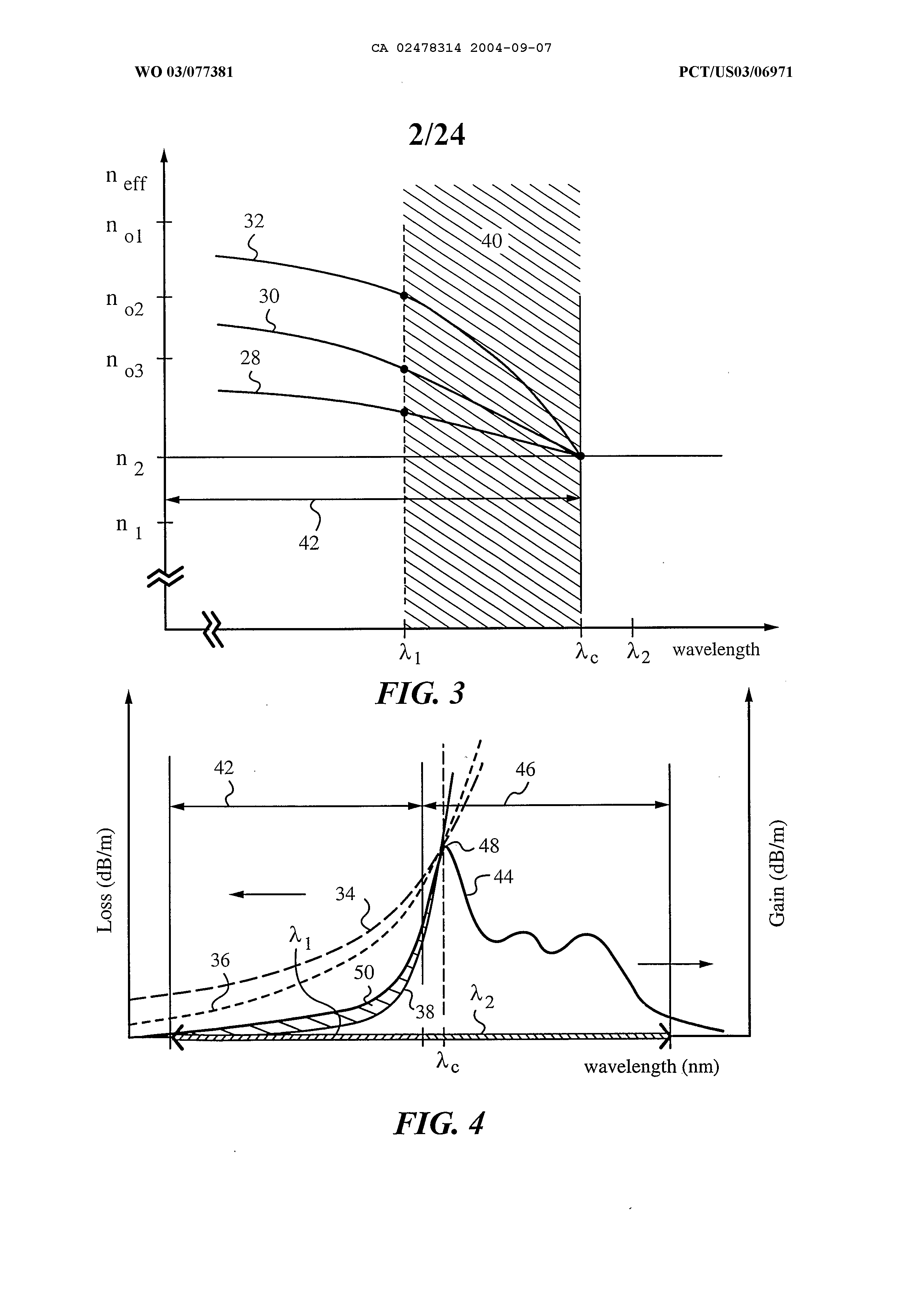

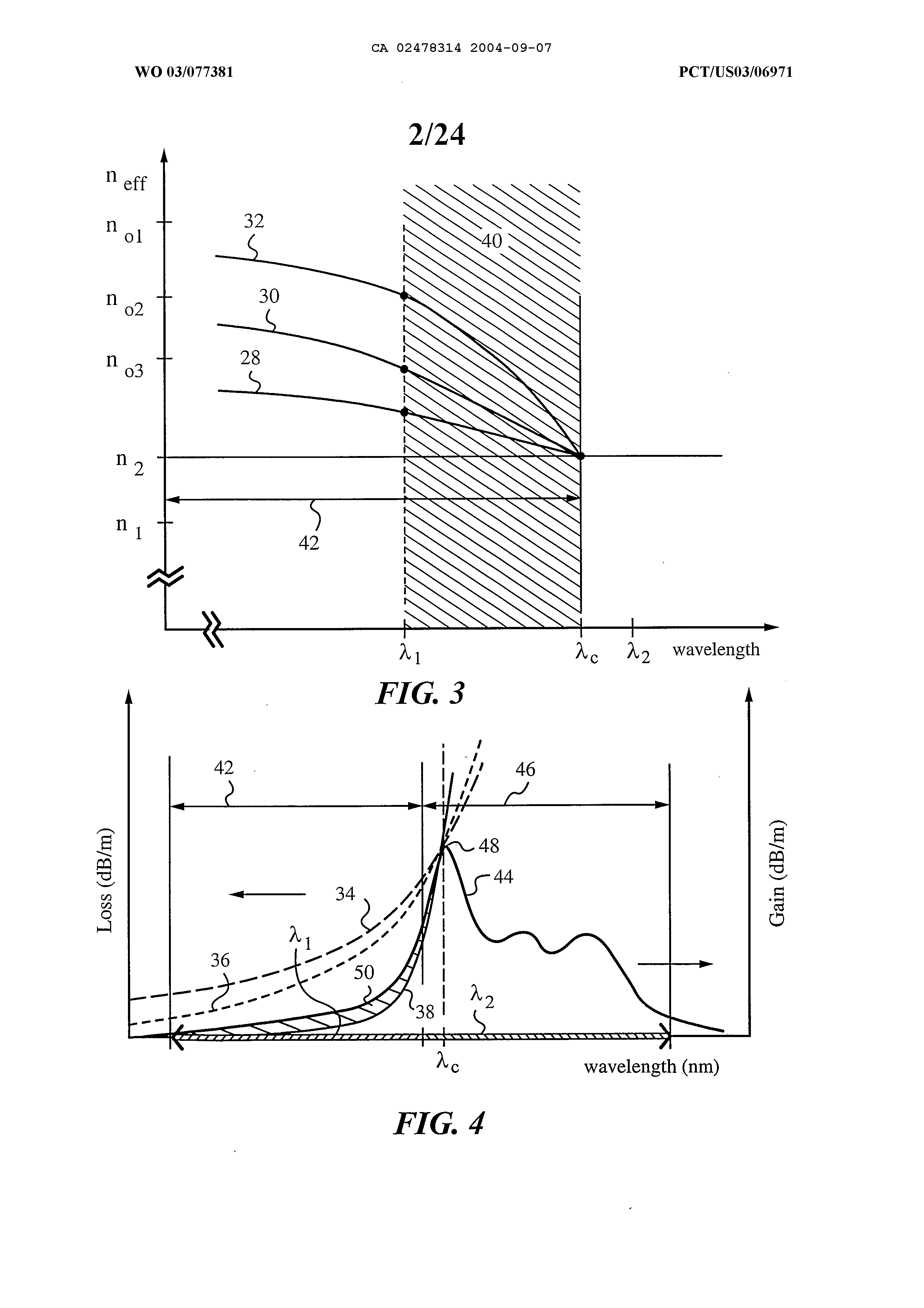

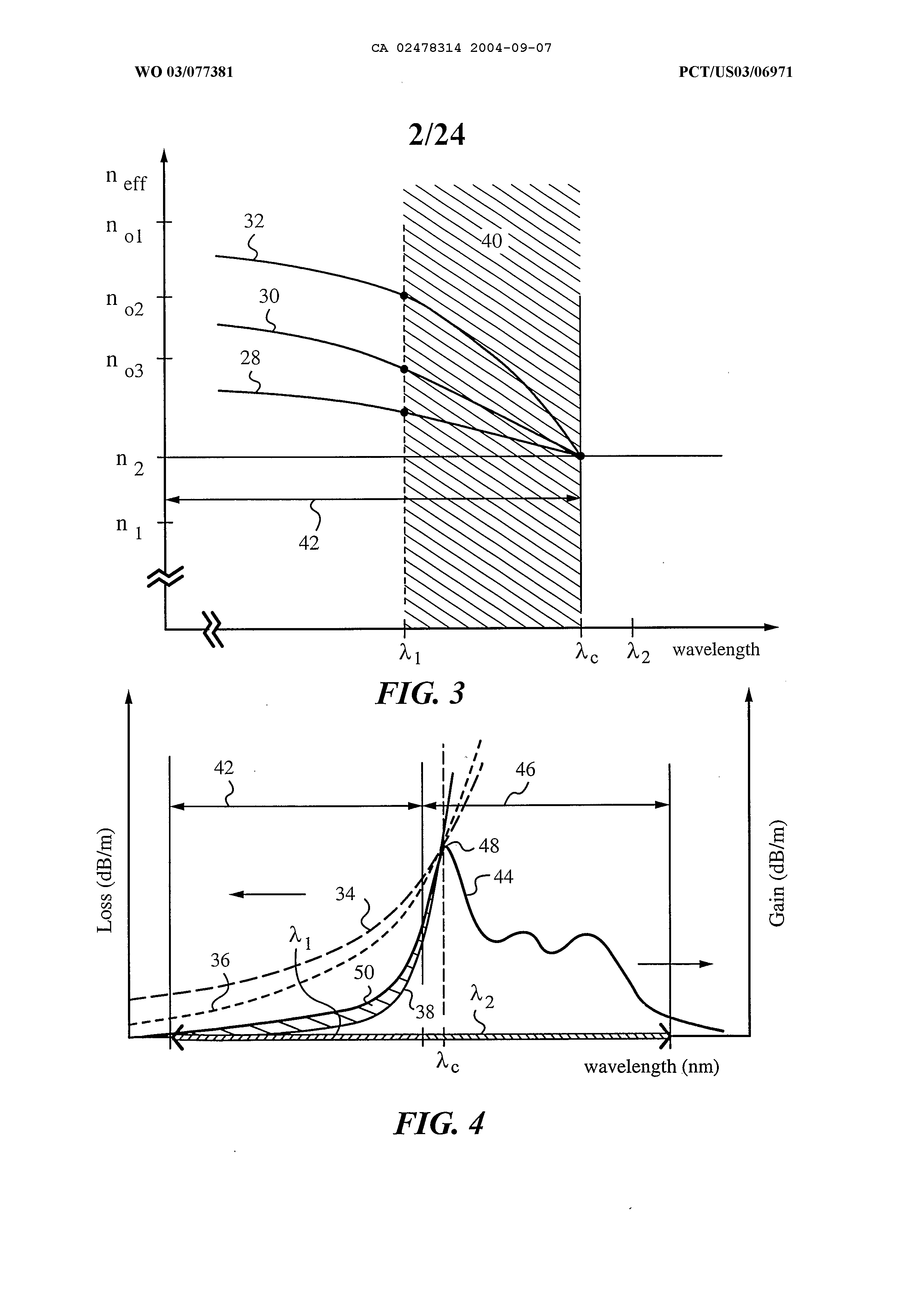

AMPLIFIERS AND LIGHT SOURCES EMPLOYING S-BAND ERBIUM-DOPED FIBER AND L-BAND THULIUM-DOPED FIBER WITH DISTRIBUTED SUPPRESSION OF AMPLIFIED SPONTANEOUS EMISSION (ASE)