FROM OUTSIDE BREITHALTER HELD FOR SCHLAUCHWARE.

The invention concerns a Breithalter for Schlauchware, held from the outside, after the generic term of the patent claim 1.

Breithalter are well-known in different execution forms. One of their substantial characteristics consists of the fact that they contain in transport of goods direction extending guiing devices, which are outward spreadable and against the hose width puts on itself from the inside and thus spreads and stretches these. Gegenrollen put from the outside ago in recesses of the Breithalters, whereby the Breithalter floating held wird.

Generally the Breithalter are built flat and consist of two apart spreadable parallel skids, over which the Schlauchware is pulled. In addition, there is Breithalter well-known, which do not only stretch and flathold in one level, but spatial aufweiten.

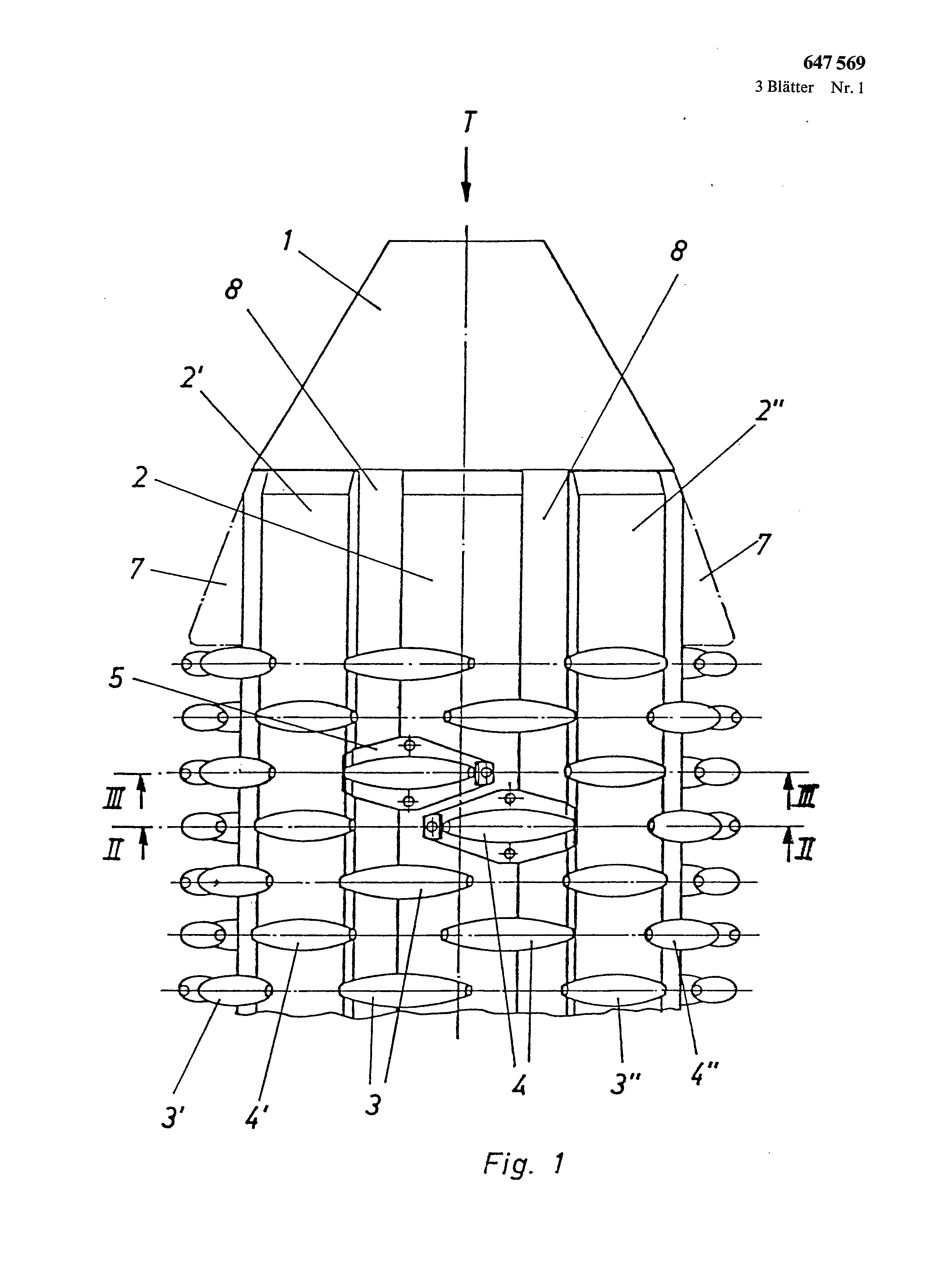

A cylindrical Breithalter for Schlauchware, held from the outside, was already suggested, with at a central carrier radially adjustable spreadable supports intended is and by the supports segment-like guiing devices for the treatment of the Schlauchware, in particular with liquid Behandlungsmit2 Fig. I a side view of the upper part of a cylindrical Breithalters, Fig. 2 and 2b a cross section by Fig. 1 in accordance with the line II-II and Fig. 3a and 3b a cross section by Fig. 1 in accordance with the line II1-III.

The Fig. I shows cylindrical broad owner with a truncated cone-like intake body 1. the transport of goods direction in simplified representation is suggested by the arrow T. Of course the structure of the Breithalters is not bound to a certain transportation direction, on the contrary the commodity can be pulled also in opposite direction over lo the Breithalter. Subsequently, to the intake body I several are parallel and in transport of goods direction running longitudinal elements 2.2 ' and/or 2 " drawn in. The longitudinal elements extending between Einund to discontinued item correspond themselves in the Beschreiis bungseinleitung guiing devices mentioned, exercise however no direct guide function more. Between these longitudinal elements Zwisehenräume 8. the supports of the longitudinal elements and their adjuster do not lie are shown for the sake of simplicity. The individual longitudinal elements 2.2 ' and/or 2 " show all the same structure, so that the description of the structure and the impact can be limited to individual longitudinal element 2. Each longitudinal element 2 contains two series of roles, whereby each role row is arranged in longitudinal direction of the longitudinal elements. The 2s axes of rotation of the roles is broken drawn in and run transverse to the transportation direction T. the one row contains the roles of 3 and the other row contains the roles of 4.

The two role rows are thus laterally against each other transferred and in addition in longitudinal direction against each other aa transferred. Thereby the roles of 4 stand for favourable way a row on gap between roles a 3 the other Reihe.

In each case for one of the roles of these two rows is in the Fig. 1 a mounting plate 5 suggested. With the remaining roles these mounting plates are for the sake of simplicity omitted, as as from the Fig. 2 and 3 to see is, can it thereby simple screw onable mounting plates 5 concern. The surface of the longitudinal element 2 needs to be no more curved and a part of a hydraulic cylinder barrel, but can be evenly trained. Preferably all roles are trained same and exhibit a curved profile. With the profile one deals further down still more in greater detail. The arrangement of the roles on the individual longitudinal elements is so met that the roles of 3.3 ', 3 " and/or 4.4 ' appropriate in their altitude are appropriate, 4 " on the particulars it for longitudinal elements 2.2 each other in each case ', 2 " in a common lateral plane of the Breithalters. As example is in Fig. 2 a lateral plane for the roles of 4 with II and a lateral plane for the roles of 3 with Ili designates. The roles of 3 and/or 4 lying in two neighbouring lateral planes are now transferred on their zugeordso neten longitudinal element 2 laterally so far against each other that they overlap themselves in the center of the longitudinal element 2 with its ends still another piece. The other ends of the roles of 3 and/or 4 get over 8 to the neighbouring longitudinal element 2 ' and/or 2 " over the Seitenkanten of the longitudinal element 2 and rise up into the gap. Also these role ends project so far that also with a greatest possible Aufweitnng of the Breithalters in the enterprise still another overlap between a role of 3 and a role of 4 ' to neighbouring lateral planes and longitudinal elements next to one another stattfindet.

The guidance of the Schlauchware is thus shifted from the surface of the guiing devices specified above away on the role roles of the longitudinal elements. At the beginning and end of each longitudinal element 2 still ramps 7 can be planned, around the transition of the Einlaufoder discharge body I to the role rows favorably auszubilden.

The roles from two neighbouring levels overlap themselves 647,569 in their whole so far that them the entire extent of the Schlauchware which can be treated überdecken.

A further important characteristic of the invention is on the basis the Fig. 2 and 3 describes. These figures show cross sections of the Breithalters in accordance with after Fig.1 in Fig. 1 drawn in lateral planes IL and/or III. thereby shows the Fig. 2a and 3a in each case the cross section with smallest broad owner extent and the Fig. 2b and 3b the cross section during largest expansion of the Breitha [ters. Into the Fig. 2a to 3b are in each case ' drawn in longitudinal elements 2 and 2. They are here represented as even plates. The supports of the longitudinal elements 2 and/or the adjustment arms for the expand are with 6 angedeutet.

Into the Fig. 2a and 2b are thus ', which lie in a common lateral plane II, with taken off lines and drawn in the roles of 4 and 4 on their mounting plates 5. The roles of 3 and 3 belonging to the neighbouring lateral plane 111 ' are dash-dotted registered. The axes of rotation of all roles lie transverse to the transportation direction T. from the design are clearly the curvature of the roles recognizable in such a manner that one role role from neighbouring lateral planes, e.g. the roles of 3 and 4 of the guiing device 2 complement each other in such a way that the curvature continues a role in the curvature of the other role. The outer delimitation of the two curvatures lies in the cross section on a concentric circle around the Breithalter. Kreismittelpunkt is in the Fig. 2a in the axle of the Breithalters. The curvature fulfills besides still the condition that the circle mentioned finds its continuation in the pair of roles 3 ', 4 ' of the neighbouring longitudinal element 2 '. This circle from the curvatures of the roles of 4.3.4 ' and 3 ', regarded in the projection, corresponds to the smallest extent of the Breithalters.<br adjustable in the enterprise/>

The longitudinal elements 2 and 2 ' of the Breithalters are thereby cheek by jowl and the gap between them are on a narrow gap geschrumpft.

The Fig. 2b shows the Breithalter in expand Stellung.

The adjustment arms 6 are represented from there longer. Ansserdem is between the longitudinal elements next to one another 2und 2 ' a larger gap 8. the relative situation of the roles of 3 and 4 located on a longitudinal element remains unchanged now. Clearly recognizably it is anch here that the curvature of the two roles of 3 and 4 itself in addition to a circular arc. The ends of the two roles overlap themselves 3 and 4. the same are valid also for the pair of roles 3 ', 4 ' on the longitudinal element 2 ' in the center of the longitudinal element 2. By spreading and/or expand of the Breithalters, i.e. by developing the intermediate area 8, changes however opposite Fig. 2 the mutual distance between role of 3 of the longitudinal element 2 and role of 4 ' of the longitudinal element 2 '. It is clearly recognizable also here that the ends of the roles 3 and/or 4 project ' over the Seitenkanten of the longitudinal elements 2 and/or 2 ' so far that it itself in the center of the intermediate area 8 still überlappen.

The structure of the roles for the Quers5 even 3 is completely accordingly in the Fig. 3a and 3b dargestellt.

From the Fig. it shows itself 2 and 3 that anywhere more does not affect a part of the longitudinal elements the Schlauchware and that by the alternating arrangement of the roles in the lateral planes in a level the existing gaps between the individual Ro [len to be covered by the roles of the neighbouring level of the respective working position of the Breithalters is called independent with each adjustable degree of expansion of the Breithalters, because the ends of the roles get over in such a way it the far over Seitenkanten of the longitudinal elements that they tower above the center • of the intermediate area 8 between neighbouring longitudinal elements 2 und2' also with spread position of the Breithalters. The entire extent of the 647,569 Schlauchware is thus led and loaded thus evenly. Thus no more longitudinal strips can do entstehen.

In addition the Breithalter offers the advantages of the initially mentioned wavy formations or corrugation in the surface of the guiing devices. It is here possible anch, as already suggested arranging circularly in order the Breithalter around nozzles for spraying out a treatment medium. The treatment medium can come instead of in the wave valleys of a corrugation here between the roles optimally to the effect. Supplementing it is still mentioned that for instance the lateral planes do not have to be from each other arranged all in the same distance, but that the lateral planes in pairs in each case zusammenges seizes become can. Also it is not necessary to plan the role arrangement over the whole longitudinal extending of a Breithalters on the contrary it can be sufficient in some cases anch, if only one part of the Breithalters equips with the loose roles ist.

B 3 sheet designs i of 647,569 3 pages No. 1 1 8 2!! \, \,/! 7 i - ““Al 3” 4 ' 3 Fig. 1 This invention relates to an improvement in an externally held cylindrical expander for tubular ware with a central support for radially adjustable, spreading rest means and sector-shaped longitudinal elements borne by said rest means, in particular for the treatment of the tubular ware with liquid treatment means, the longitudinal elements extending between bodies tapering in the longitudinal direction, mounted between the ends of the support, and acting as entry and exit means, the improvement comprising: (a) rollers with axes of rotation transverse to the ware transport direction T mounted on the outsides of the individual longitudinal elements in transverse planes of the expander, (b) the rollers located in a common transverse plane covering the gaps between rollers located in an adjoining transverse plane, (c) the rollers from adjoining transverse planes mounted on one longitudinal element overlap by their ends at the center of the longitudinal element, (d) the other ends of the rollers project beyond the side edges of the longitudinal element and overlap with the rollers of the adjoining longitudinal element, and (e) the rollers evince a convex profile of such kind that the convex curvature of all rollers located in a common transverse plane on the expander periphery coincides with the smallest settable circumference of the expander in its unspread position. 1. In an externally held cylindrical expander for tubular ware with a central support for radially adjustable, spreading rest means and sector-shaped longitudinal elements borne by said rest means, in particular for the treatment of the tubular ware with liquid treatment means, the longitudinal elements extending between bodies tapering in the longitudinal direction, mounted between the ends of the support, and acting as entry and exit means, the improvement comprising: (a) rollers with axes of rotation transverse to the ware transport direction T mounted on the outsides of the individual longitudinal elements in transverse planes of the expander, (b) the rollers located in a common transverse plane covering the gaps between rollers located in an adjoining transverse plane, (c) the rollers from adjoining transverse planes mounted on one longitudinal element overlap by their ends at the center of said longitudinal element, (d) the other ends of the rollers project beyond the side edges of said longitudinal element and overlap with the rollers of the adjoining longitudinal element, and (e) the rollers evince a convex profile of such kind that the convex curvature of all rollers located in a common transverse plane on the expander periphery coincides with the smallest settable circumference of the expander in its unspread position. 2. An expander according to claim 1 in which the roller ends projecting beyond the side edges of the longitudinal elements cover the center of the maximum gap between two adjoining longitudinal elements when the expander is in the spread-out position. 3. An expander according to claim 1 or claim 2 in which the transverse planes are paired. 4. An expander according to claim 1 in which the longitudinal elements include feed incline means for the tubular ware at the beginning and end of the roller arrangement.