PROCEDURE AND DEVICE FOR ROLLING UP YARN.

The invention refers to a procedure and a Vorñchtung for rolling up from yarn to one winds in accordance with the generic terms of the patent claims 1 and/or 6 in a spin machine, those provided with elner winding-on equipment, a reeling automat, a Doppeldrahtzwirnmaschine, a Falschdrahtzwirner or such ist.

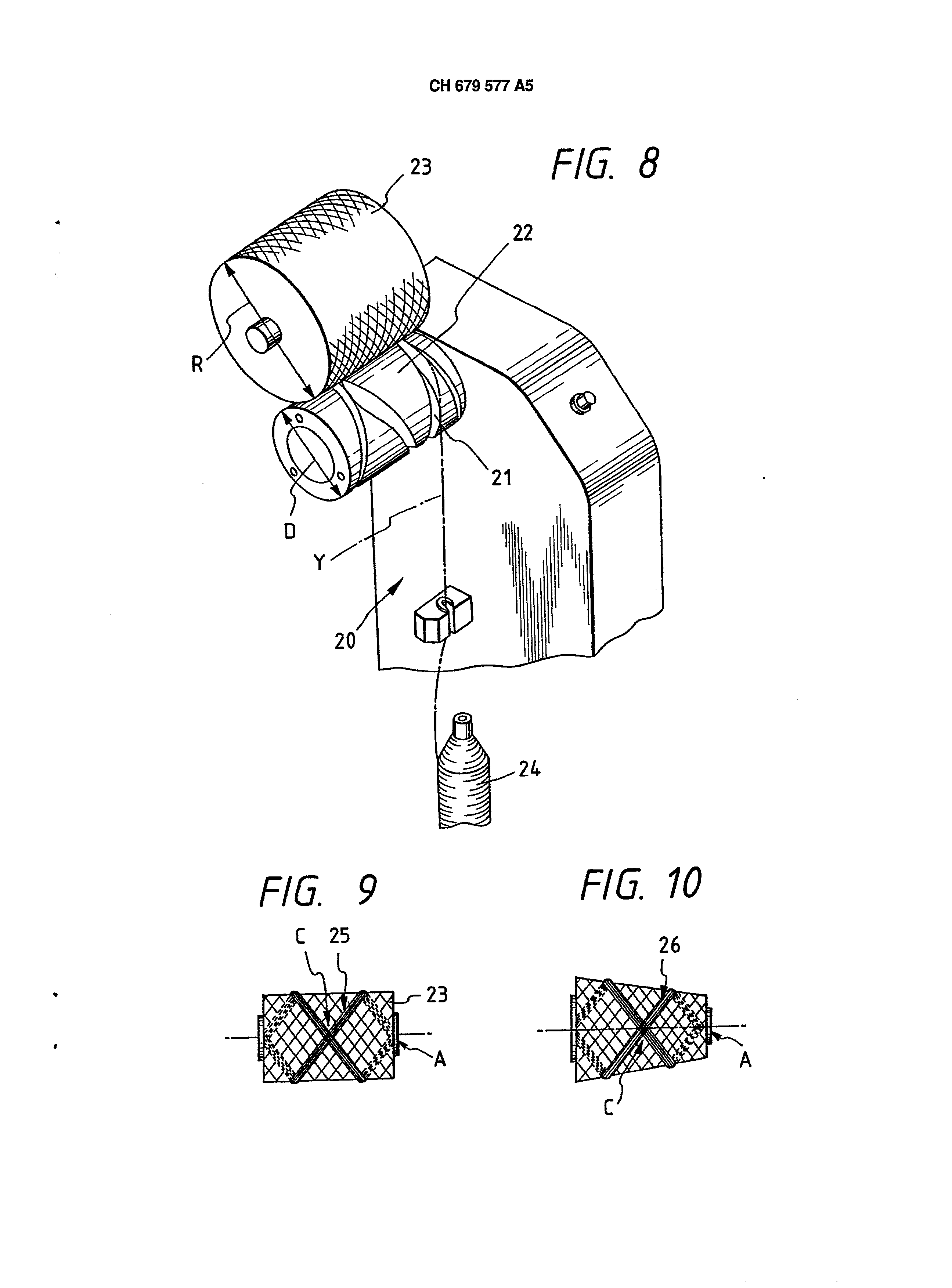

An example from the state of the art of a reeling automat is in Fig. 8 shown, on which a gesponnene spin bobbin for the education of a conical Kreuzspule or a Kreuzspule rewound wird.

With such an reeling automat 20 wind 23 from a drum 22 by Oberf] ächenkontakt propelled, whose extent surface is provided with thread guide slots 21 for the transverse leading of Gam. Such a drum is called also flaring roller. A yarn bobbin 24 during the thread leading when rewinding yarn by means of the thread guide drum 22 is unwound, if the drum diameter D and the Wickeldurchmesser R in a special relationship stands to each other, or more exactly expressed, if the Wickeldurchmesser stands in a special relationship, whereby the revolutions of the drum 22 and the Wickels 23 stand in an integral relationship, which for rewinding time with the rolling up time on wind synchronized. The yarn turns pass the same yarn way and collect lying on top of one another in the same place, in order to design as tape windings designated phenomenon. With such tape windings, if the yarn is delivered to a later Verfahrensabschnitt, a thread splitting can when reducing or requiring at a needle tongue auftreten.

The diameter R (mm) of the Wickels 23, with which one produces for tape windings, Nässt generally with the following equation to compute itself:

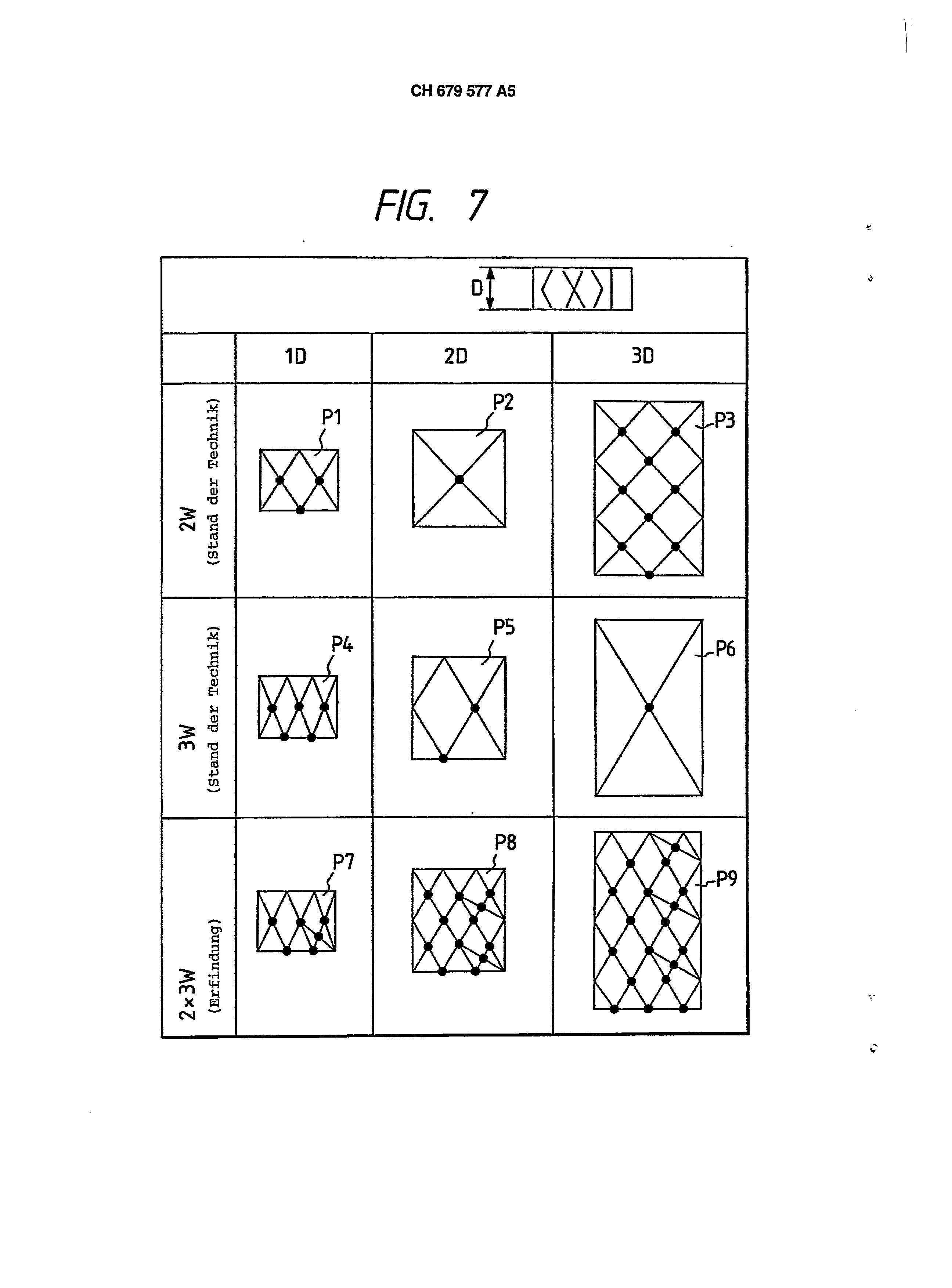

DxW R = Dx PxW D: Diameter of the drum (mm) DxW: Number of turns of the drum PxW: Number of turns of the Wickels as example: If D = 100 amounts to mm, D x W = 2 turns and P = 1 turn, the diameter g 1, with that the tape coil is produced 100 x 2/1 = 200 (mm). The tape coils 25 and 26 become, as in the Fig. g and 10 shown, produce, if the diameter of the Wickels 23 the value 200 mm einnimmt.

In such a case a crossover between yarn current to the left and current yarn exists the yarn of a crossover C during a yarn guidance passage with point A as point of origin only with C. lies exposed accordingly to the right when releasing such Wickels to the next crossover C, and from there the tendency of tearing can when reducing or at Zungennadeln zunehmen. with a high-speed releasing

Different kinds from devices to the avoidance of a volume winding or a bind-like Wickeins were suggested and are at present in the employment: For example a reeling automat possesses means, with which wind mechanically on a drum into and away from this one moves, in order to train in such a way as the surface of the Wickels a slip as the yarn distribution. Also there is types of reeling automats to produce with which a drum is periodically braked, in order a slip furthermore such, with which in direct proximity of a diameter the occurrence of bind-like winding is determined, so that the device is only operated for the prevention of such a winding in the danger zones, like this in the Japanese disclosure writing 161 681/1987 revealed ist.

The measures already obtained with the help of conventional winding-on equipments have regarding the Probiemstellung described above only one partial success furnished, in particular remain to difficulties after the high-speed release of the yarn. If for example from one wind delivered yarn of chain shears one supplies, no significant problems result in the case of a decrease speed of 300 to 600 m/min. However with for modern machines usual the high-speed releasing of 600 to 1000 m/min anticipated payment difficulties arise. Furthermore problems step up, those to significant disturbances führen. with high-speed weaving looms, e.g. with those the shot to air flow-supply are frequent, i.e. with a Freigabeoder delivery speed of 800 to 1500 m/min

A goal of the invention consists of creating a procedure and a device for rolling up from yarn to and/or the one yarn-winds produced, that is free from anticipated payment-conditioned or Zungennadein separations, if the yarn for the further processing with high speed delivered wird.

Another goal of the invention insists in the creation of a procedure and a device for winding a yarn up on one winds into producing a Garnwickels with many yarn crossovers, as the yarn is shifted in such a way that it independently of the Wickeldurchmesser determined yarn processes passiert.

The procedure after the invention for rolling a yarn up on one wind when simultaneous yarn leading covers a systematic or coincidental change of the turn number on wind, in relationship with the Garnquerführung.

After the invention a device covers for rolling up yarn on one winds a yarn transverse guidance drum with several transverse guide grooves of different turn number and a branch section of the transverse guide groove, in which a yarn is shifted to a transverse guide groove, over into another yarn running range according to the transverse guide groove transferred too werden.

Below the procedure and the device are more near described after the invention on the basis of remark examples representing designs. Show:

Fig. 1 a perspective opinion of central parts for the elucidation of an execution form of the device after the characteristics of the invention, Fig. 2 an opinion of a completion of a transverse guidance drum, those in the device after Fig. 1 is used, Fig. 3 an opinion of an execution form of a guidance means for switching the yarn to a groove on a Querfûhrungstrommel with a different turn number, Fig. 4 a front view of the guidance means in accordance with Fig. 3, Fig. 5 an opinion of the guidance means in accordance with Fig. 3 in its operating position, Fig. 6 completion to elucidation Garnlaufoereichs with according to invention procedures, with which diameters, into which small band-like windings are produced, Fig. 7 a schematic representation from completions to the elucidation of different yarn running ranges with conventionally wound up windings and with windings after the characteristics of the invention, Fig. 8 a perspective opinion of an example of a conventional winding-on equipment, Fig. 9 and 10 side views of windings in a condition, with a certain diameter b& ndchenartige turns by means of a conventional device to be produced, Fig. 11 a representation of impulse signals of a drum sensor, Fig. 12 a diagram for the illustration “l'imings for the Anund switching off according to Solenoids the impulses of the drum sensor and Fig. 13 a remark example of a switching configuration for the execution of the Anund of switching off in accordance with Fig. 12.

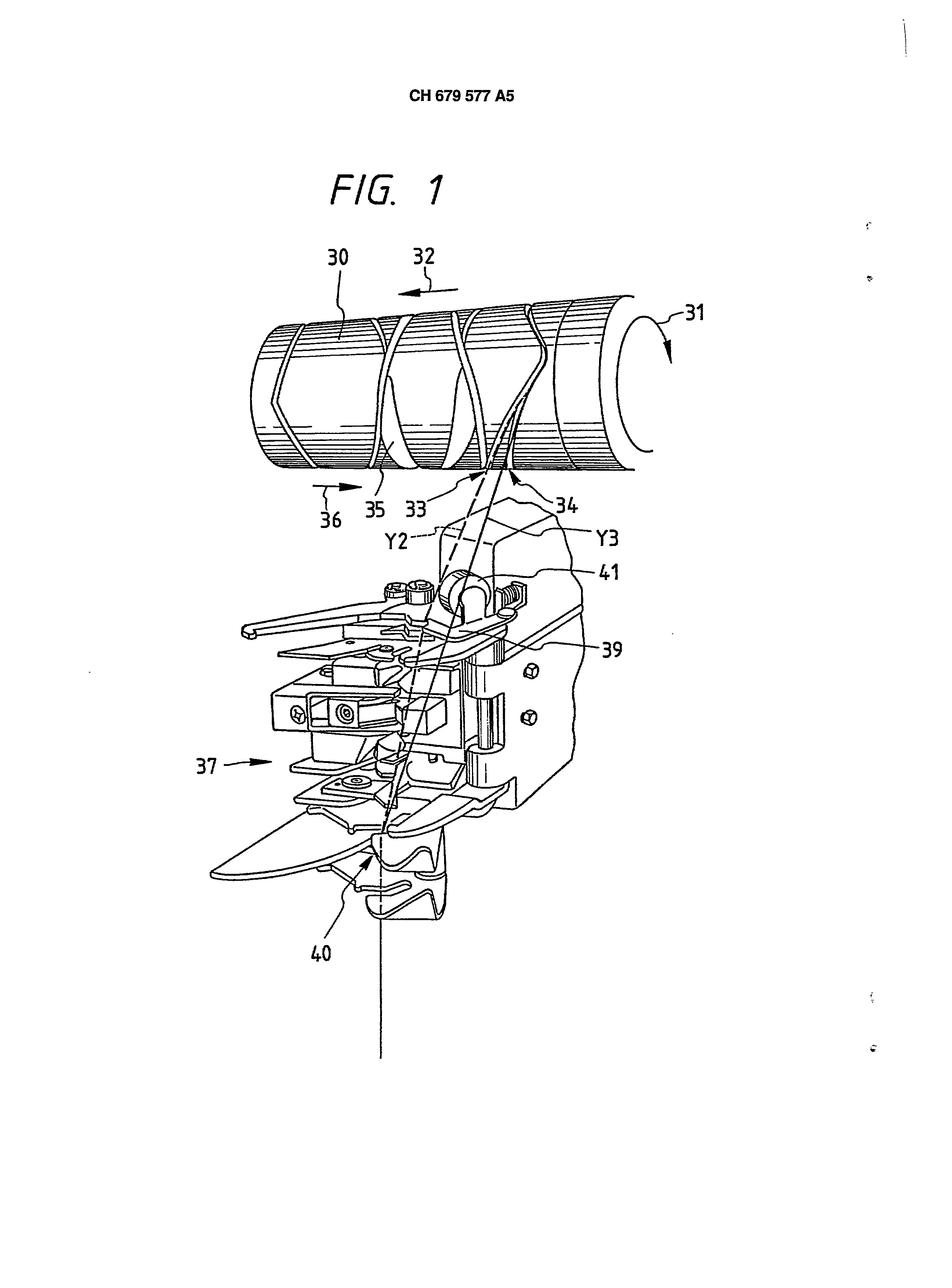

Fig. 1 points a perspective opinion of substantial parts of a winding-on equipment, and a drum 30 to the direct Garnquerführung.

In the drum 30 trained yarn guide grooves possess different Windungsnummern.

That is, that the slots 33 and 34 with different turn numbers are so formed that then, if the drum 30 is turned in a direction indicated by an arrow 31 and a yarn is transverseled from right to left toward the arrow 32 a transverse guidance takes place either via the groove 33 with 2 turns or the groove 34 with 3 turns on the drum. The transverse guidance in a direction, like it the arrow 36, thus from left to right, indicates, along the transverse guide groove with 3-Windungen is caused. On the reeling machine a yarn polarizing eating device is 37 angeordnet.

In addition, with the presented Ausfûhrungsbeispiel in the drum 30 trained transverse guide grooves are only described concerning 2eroder 3er-Windungen, naturally can find a combination of different turn numbers use. For example can be used 3Windungen and 4-Windungen as well as 1,5-Windungen and 2-Windungen and such. Although in Fig. from right to left 2und 3-Windungen they possess, could 1 represented drum the transverse guide grooves also from left to right by transverse guide grooves be caused, the different turn numbers besitzen.

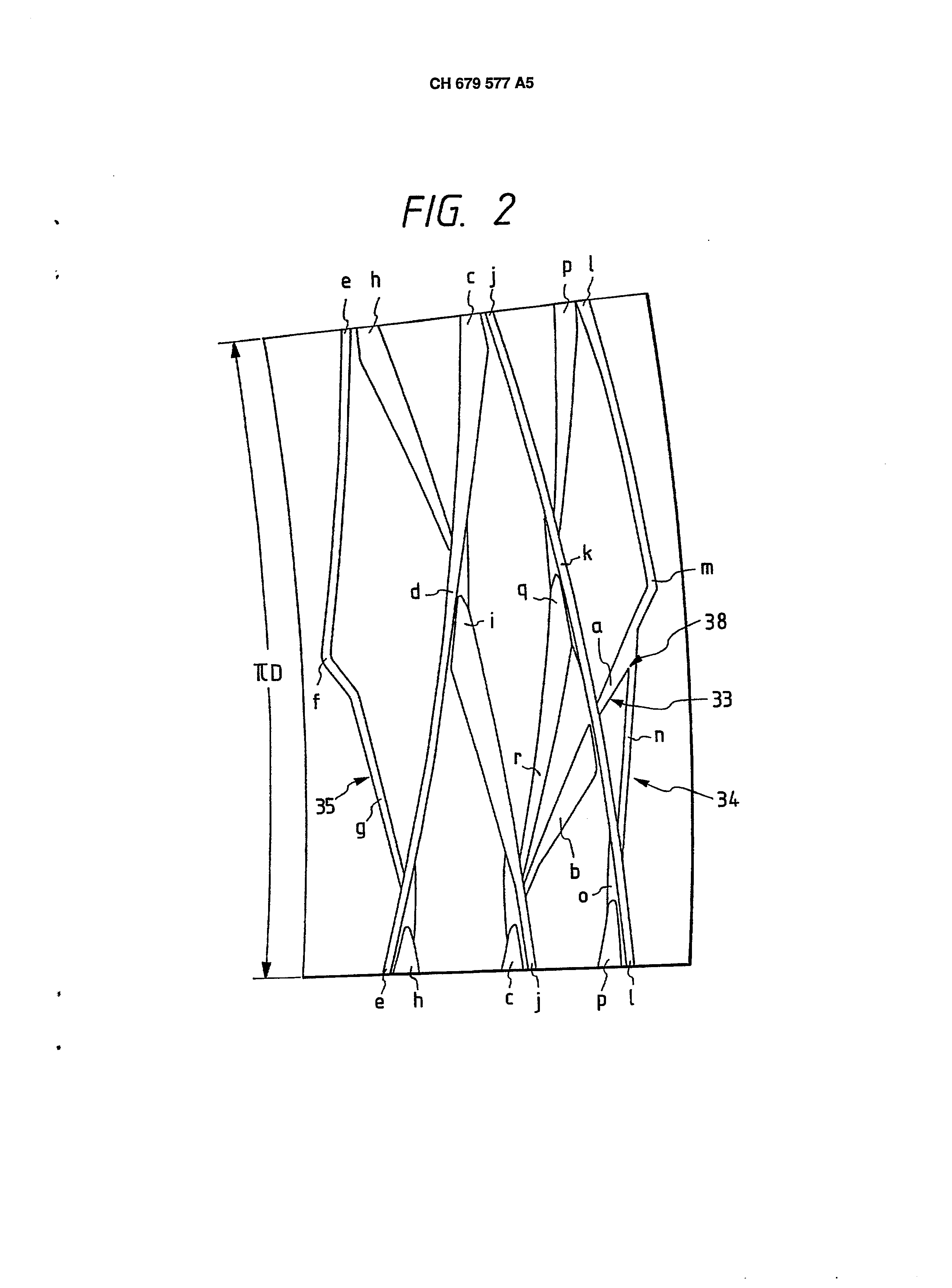

Fig. an extent completion shows 2 in Fig. 1 represented drum 30. As transverse guide grooves from right to left a groove 33 trained for 2-Windungen and a groove are 34 for 3-Windungen as well as a branch section 38 as these two kinds of slots in the proximity the reversal at the right drum end. That is, the slots 33 for 2-Windungen are by the following reference symbols ges5 mark: A, b, C, D, e and f, and the slots 34 for 3-Windungen are characterized by n, o, p, q, r, C, D, e and f, whereby a Teli is used together. The slots 35 for the transverse guidance from left to right are characterized by the following letters: g, h, i, j, k, I and m, which in this case 3Windungsnuten sind.

Accordingly 38 in the slots A and n, WindungsnumSO mem of the yarn, vary which on wind one winds up, as a function of the movement of the yarn in a branch section, which is led in the slots A or n. That is, in case of the yarn running range Y3, that in Fig. 1 with a pulled through line is represented, is the turn numbers from right to left to 3-Windungen; in the yarn running range Y2, which is represented by a broken line, the turn numbers 2Windungen.<br amount to/>

S5 the switching device for the yarn running ranges Y2 and Y3 becomes now beschrieben.

CH 67g 577 A5 as a first means can be used a passive switching device by means of a Spannungseinste] lung the yarn, is called that the Gamlaufbereich automatically by the mass inertia of the Schaiteinrichtung. is switched, whereby the switching strength comes from the transverse guidance movement of the yarn or the Anderung one of the yarn tension. For example have attempts devoted that in the case of the employment of a tightener well-known kind, with which the Gara is gotten jammed between two pressure plates for the change of a voltage level with a small voltage level the Wahrscheinlichkelt entering the 3-Windungsnut is larger than into the 2-Windungsnut, meanwhile with a high voltage level the condition turned around. Accordingly the value is stopped to a middle voltage range, whereby the yarn guidance scheinlichkelt into the slots A and n with a WahrlO from 50% erfolgt.

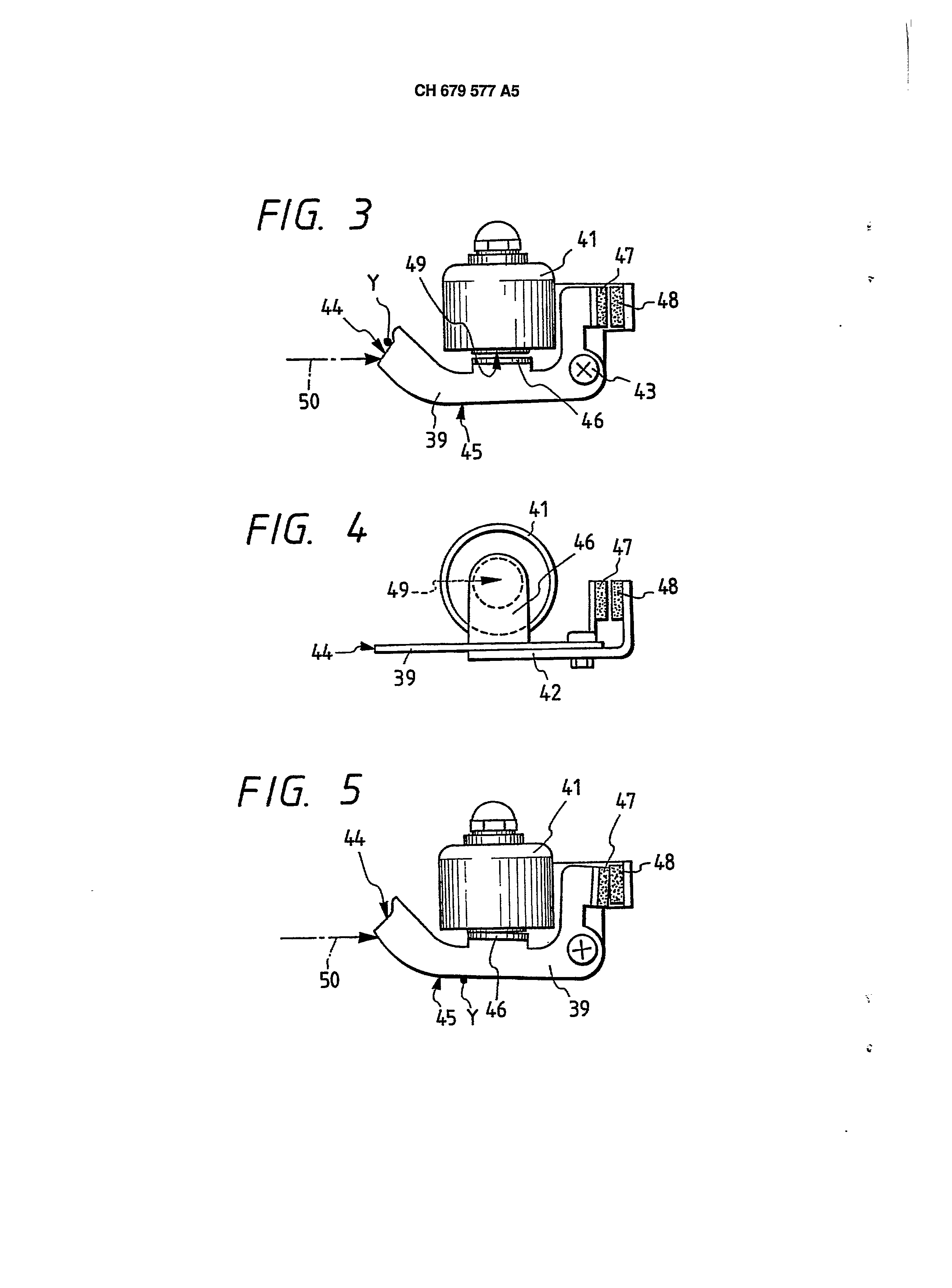

As second Schaltmittel an inevitable switching device of mechanical kind can be used, whereby a remark example in the Fig. 1 and 3 to 5 is represented. On the side of a branch section 38 for the slots A and n in the drum 30 and within the transverse guidance range of the yarn a mobile guidance 39 is intended for the delimitation of a yarn running range. The mobile guidance 3g is arranged and in two positions by means of a Elektremagnets or a Solenoids 41 is moved between the drum 30 and a guidance member 40 in the transverse command center of the yarn. Into the Fig. 3 and 4 is the mobile Fûhrung 39 on a being certain plate 42 with 43 angelenkt.

An end of the mobile guidance 39 is in such a way trained that it exhibits a first guide edge 44, in order to move yarn Y at the transverse guidance end somewhat inward concerning the normal transverse guidance end, an intermediate range is in such a way trained that it represents a second guide edge 45, in order to lead yarn too dern normal transverse guidance end, and a Kontaktglied 46, which can be tightened by the Solenoid 41, is at the intermediate sector vorgesehen.

At the other end of the Fûhrung 39 a magnet 47 is fastened, some gegenûberliegenden magnet 48, which is attached at a being certain plate 42, faces. The magnets 47 and 48 repel themselves, if they possess the same polarity (SS or N-N). If the Solenoid 41 is excited and the Kontaktglied 46 of the mobile guidance 39 to the boundary surface 49 is tightened the electromagnets, the magnets 47, are one on the other too moved 48 in order to increase so the repelling power. If however the electromagnet is switched off, the mobile guidance turns 39 immediately into its Ausgangspcsition due to the aforementioned repelling power zurück.

If the mobile Fûhrung 39 itself thus in Fig. 3 position shown finds and/or if the Solenoid 41 is switched off, the yarn Y is moved to the right toward the arrow 50 and knocks against at the first guide edge 44, whereby the yarn Y into the yarn running range Y2 in accordance with Fig. 1 is transferred. Thus the moved backward yarn moves into the groove A for 2-Windungen.

If itself on the other hand the mobile guidance 39 in the position in accordance with Fig. 5 finds, or the Solenoid 41 is turned on, the mobile guidance 39 is shifted, and the Gara Y of the transverse guidance along the arrow 50, directed to the right, is induced to the output transverse guidance end along the second guide edge 45, without it hits the first guide edge 44. Consequently the yarn extends along the yarn running range Y3, that in Fig. 1 with pulled through line is represented, and the yarn becomes, after it turned around, into the groove n for 3-Windungen hineinbewegt.

If the movement of the mobile member 39 takes place with each transverse guidance, the yarn repeats alternating with each Querfûhrung the Gamlauf in the 2-Windungsnuten and the 3-Windungsnuten.

Timing for Einund switching the electromagnets can be switched in the suitable way and stop themselves the repetition frequency for the introduction of the 2-Windungsverlaufs and the 3-Windungsverlaufs the Nässt off in an appropriate way. In addition the 2-Windungsverlauf and the 3Windungsverlauf can be changed periodically or after the Zufallspdnzip, it however are preferably in such a way adjusted that altogether the relationship between 2-Windungswickeln and 3-Windungswickeln one in each case 50%-igen portion besitzen.

An example of a mechanism to the alternative 2-Windungswickeln and 3-Windungswickeln with each transverse guidance becomes now erläutert.

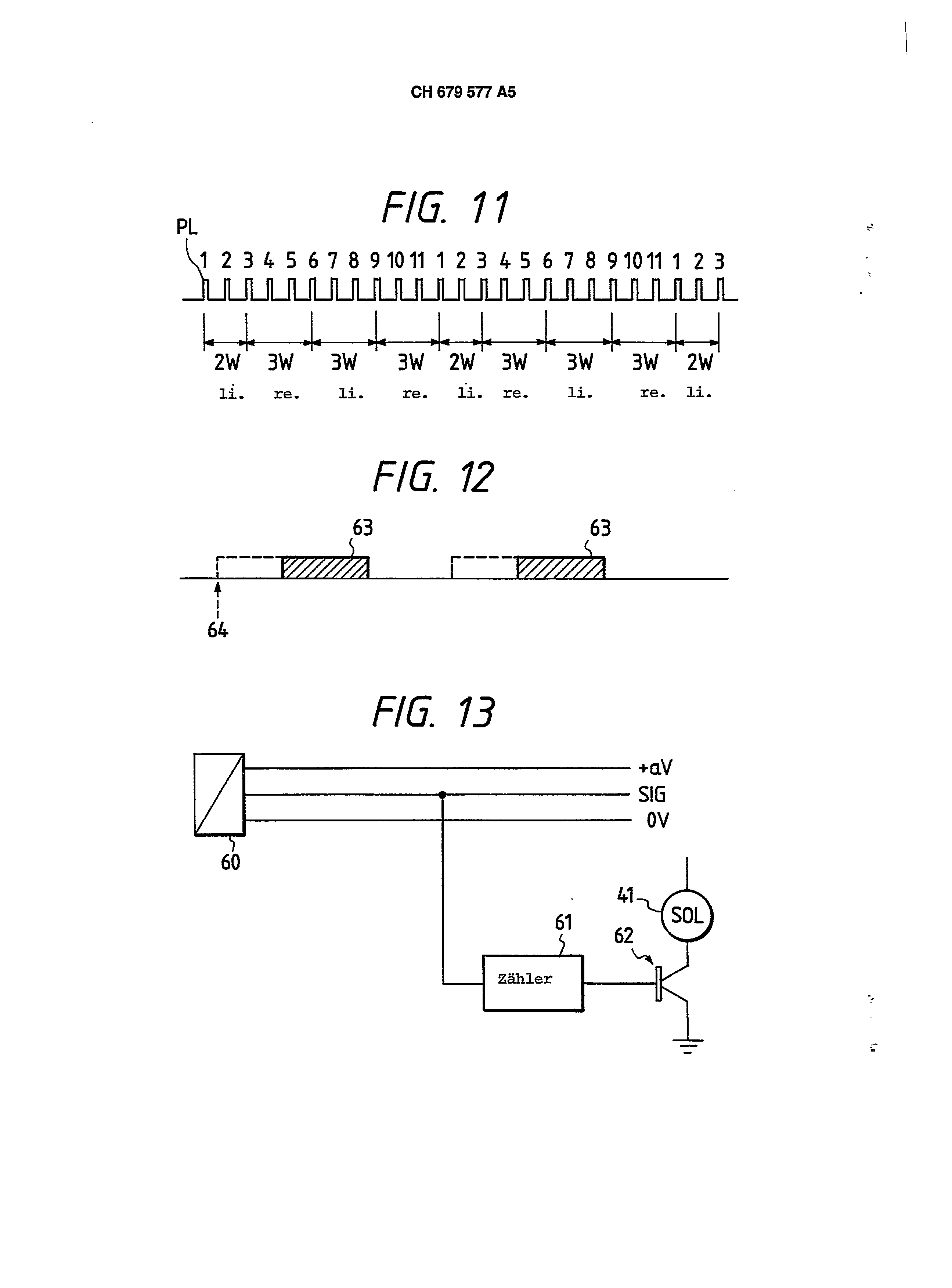

As into the Fig. 11 to 13 represented, a drum sensor is intended, which an impulse PL with each turn of a Querführungst] 'ommel produces, whereby the turn of the drum is coupled with in elimination of a Solenoids 41 of the mobile guidance 39. 11 impulses of the drum impulse signal constitutes a cycle. A counter 61 and a contact 62 are intended in a Solenoidschaltkreis, so that the Solenoid 41 is only turned on during 5. to 9th impulses, which the drum sensor 60 produces, as in Fig. 12 shown. With the above-described remark example this means that the groove for 2 turns and the groove for 3 turns, which are trained on the drum are headed for thus that with the 2-Windungsnut the drum is twice turned and the yarn transverse guidance takes place from right to left; with the 3-Windungsnut running to the right the drum is three times turned, and the yarn transverse guidance takes place from left to right. If the Solenoid 63 in the center of the movement or tax type running to the right is thus turned on, tightening the mobile guidance takes place, and the yarn moves on the course Y gernäss Fig. 5, and if it is turned around, the yarn becomes into the groove 34 for the 3 turns going to the right hineinbewegt.

Consequently takes place a repetition of cycle of the turn numbers for winds with winding way taking place in a direction as follows: 2-Windungen, 2-Windungen, 3-Windungen and 3-Windungen.

If the yarn of a in this way wound up wind one releases, this takes place, as the turn numbers run off as follows from left to right over alternating the 2-Windungen and 3-Windungen: 2, 3, 2, 3, 2, 3-Windungen. The Solenoid can at the time 64 in accordance with Fig. 12 with the impulse PL2 to be switched on, if the yarn is moved along the 2-Windungsnut. Point of switch-on time is in Fig. 11 broken dargestellt.

Also different than the switching device described above, which works with electromagnets, can be used for the change of the turn number. For example the mobile guidance can be moved by a rotation cam or an air jet nozzle, whereby this can be arranged in a place of the mobile guidance 39, it permitted to blow an intermittent air jet against the yarn, which accumulates at the transverse guidance end, around as the Gamführungsbereiche Y2 and Y3, as in Fig. 1 shown, abzugrenzen.

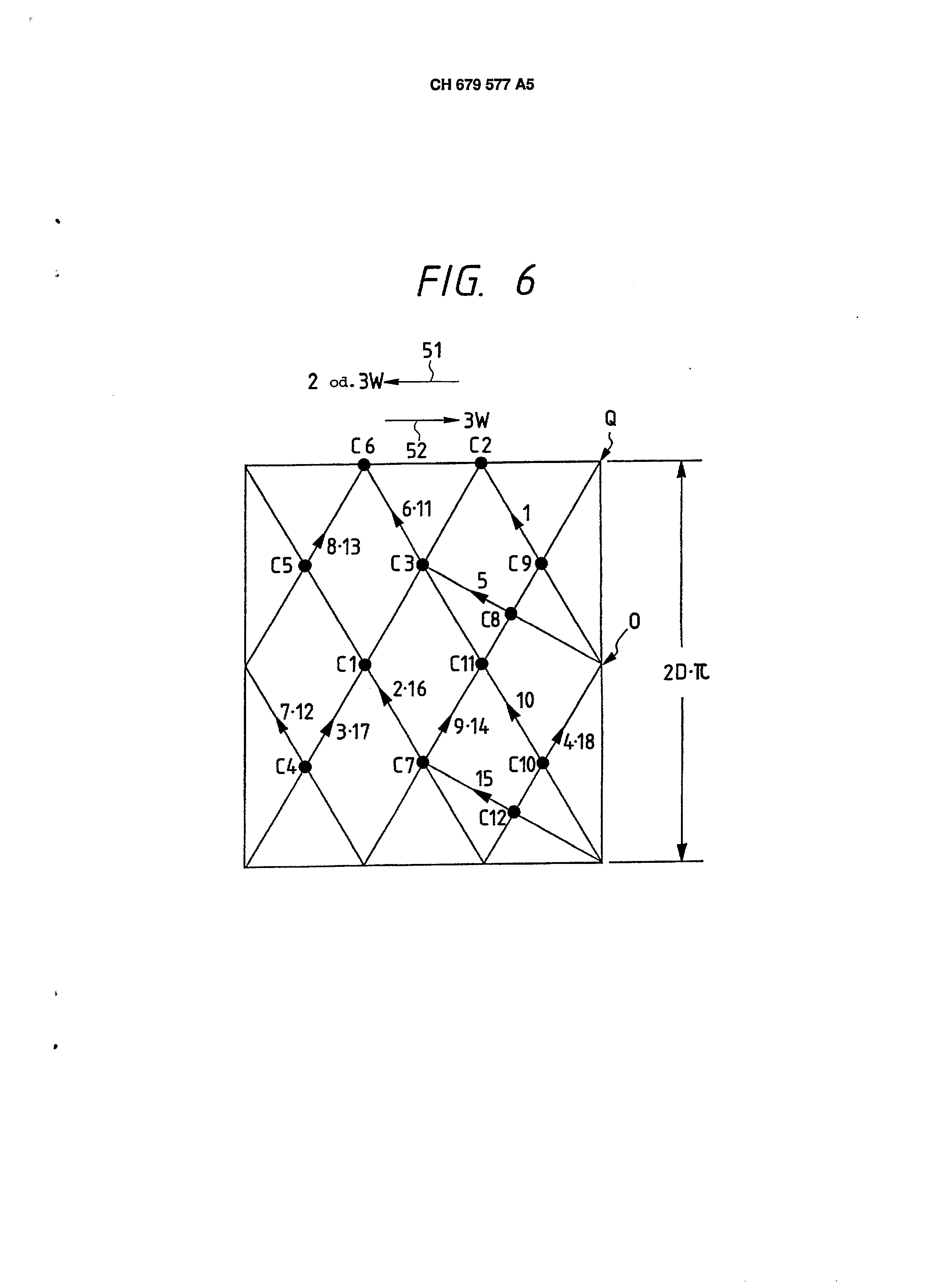

The procedure for the yarn rolling up by means of in Fig. 1 device shown becomes now with reference to Fig. 6 described. Fig. 6 an extent completion of a Wickels and the turn condition of the Wickels with the diameter 2D, is produced by the employment of a Guerführungstrommel of the diameter D, that shows the slots in accordance with Fig. and a mobile guidance 39 possesses 2 as switching device. In case of the movement 51 going to the left switching to the groove for 2-Windungen and the groove for 3-Windungen takes place, meanwhile with the transaction type 52 only the 3-Windungen going to the right is switched on. On the assumption that the point 0 at the right end represents a starting point of the Guerf0hrung, it runs the yarn of the yarn running range 1 for 3-Windungen and turns around in the place O, over 2 - 3 - 4, in the indicated order. If the mobile guidance 39 into the position in accordance with Fig. 3, the Gara is adjusted with the following post+left-moved into the groove A for 2-Windungen, as described above, is moved, runs by the yarn running range 5 and returns to the point Q at the right end of the Wickels over the following stations: 6 7 8 9. at this time, if the movable member 39 again into the position in accordance with Fig. 5, runs the yarn is shifted by the yarn run guidance for 3-Windungen: 10 11 12 13 14.

Furthermore the yarn runs with the employment of the mobile guidance in accordance with Fig. 3 by the yarn running range for 2-Windungen over 15 16 17 18 and returns to the starting point 0. That is, that concerning the starting position 0 the yarn after four Guerführungen zurückkehrt.

Between the four Querfûhrungen twelve Kreuzungsstellen for the yarn in the order become (; 1 (; 2 03… (; 12 trained. At the Kreuzungsstelle (; the yarns, which are marked with 2 and 3, are appropriate for 1, whereby both yarns are so crossed that the yarn 3 with the larger number on the yarn 2 with the smaller number is positioned. The same meets fûr the other crossovers ZU.

Fig. 7 shows the condition of crossovers, with a coil diameter, with which bind-like rolling up by means of a conventional winding-on equipment wûrde take place, and in the measures after the invention. In Fig. a case is shown 7 after the state of the art, with which the diameter of the transverse guidance drum amounts to D and which amount to turn numbers of the drums 2-Windungen and 3-Windungen both backwards and vorwãrts; furthermore the case is with the drum in accordance with Fig. 2 after the invention shown. With the conventional 2-Windungstrommel possesses wind P2 a Kreuzungsstelle at a position, where the coil diameter amounts to 2D. With the invention however winds P8 possesses 12 Kreuzungsstellen at a position, where the diameter of the Wickels amounts to 2D. With the conventional 3-Windungstrommel possesses wind P6 a Kreuzungsstelle at a position, with which the diameter of the Wickels amounts to 3D, meanwhile with the invention wind for P9 18 Kreuzungsstellen at a position possesses, with which the diameter of the Wickels amounts to 3D. That is, the smaller the number of Kreuzungsstellen is, lies the yarn running range with the diameter, with which a small band-like winding arises, always in the same circulation, why the density of the small band-like turns is large and much yarn passes the same run, in order to collect in a condition, in which the yarn running range substantially is away and a voltage fluctuation with the yarn delivery becomes particularly noticeable. On the other hand are then, if many Kreuzungsstellen are produced with the diameter, with which normally small band-like turns arise, as small with the windings P8 and P9, the yarn runs by only one yarn running range sind.

Accordingly small band-like rolling up is distributed, and such a dispersion reduces also a yarn voltage fluctuation when the yarn removing or yarn taking off, whereby reducing and involvement of the yarn arise only heavily kann.

The distribution value of the turn number of the Garnwickels, how it is produced with the winding-on equipment after the invention, is indicated in table 1. Attempts were accomplished, in order to determine the behavior of cotton yarn with Ne40, at a yarn speed of 1000 m/min. As switching device fûr 2-Windungsnuten and 3-Windungsnuten of the used Quertel become, like the change-over over the mobile guidance 39 in accordance with Fig. 1. in the table 1 for passive elements of the Garnspu] ungswert to 15 g it was adjusted and the yarn released by the wound up wind slowly, in order to examine whether it concerns a 2-Windung or a 3-Windung. If the rolled up Gara on in Fig. 7 shown wind for P8 from left to right abge6S nommen, it showed oneself that the yarn numbers are with 2-Windungen three and with 3-Windungen seven, in the order: 3, 2, 3 3…. 3, 3, as in the highest column in table 1 dargestellt.

For the case of the attitude of the voltage level on 15 g it was shown that the yarn numbers amounted to with 2-Windungen 19 and with 3-Windungen 31, and the relationship from 2-Windungen to 3-Windungen amounted to 38% and 62%. Furthermore it was shown that the relationship from 2-Windungen to 3Windungen amounted to 52% and 48%, if the voltage level on 23 g were employed and conditions from 2-Windungen were to 3-Windungen about 72% and 28%, if the voltage level 30 g betrug.

That is, that the probability, with which the 2-Windungsnut and the 3-Windungsnut were switched automatically with a voltage level of approximately 23 g 1/2 betrug.

On the other hand transverse guidance the 2Windungen and the 3-Windungen, as in table 1 shown, arise in alternating in case of the use of inevitable switching means, i.e. with the manipulation of the mobile guidance with each. The turn numbers are evenly distributed. That is, that the yarn transverse guidance surely into the slots, independently of the yarn tension inserted wurde.

6 table I data of the VerhMitnisses from 2 W to 3W 2 W3 W u% “Q4 O 3 2 3 3 2 3 2 3 3 3 3 3 3 2 2 2 2 2 3 3 3 3 3 3 3 3 3 3 3 3 2 3 3 3 2 2 2 2 2 3 2 2 2 2 2 3 3 3 3 3 2 2 3 2 2 3 3 3 3 2 2 3 3 2 2 3 3 2 2 S 3 3 2 3 2 2 2 2 3 3 2 2 3 2 2 2 2 2 2 2 3 3 3 3 3 3 2 3 2 3 2 2 3 2 2 2 2 2 2 2 3 3 3 3 2 2 2 2 3 2 2 2 2 2 2 3 2 3 2 2 3 2 3 2 2 2 2 3 2 3 2 2 2 2 2 2 2 3 3 2 3 2 3 2 3 2 3 2 3 2 3 2 3 2 3 2 3 2 3 2 3 2 2 3 2 3 2 3 2 3 3 2 3 2 3 2 3 3 2 3 3 2 3 2 3 2 3 2 3 2 3 0 6 l subject 9 2 7 4 31-facl 1 8 26fach 24 fac] 9 8 6 8 36-faci 1 2 4 2 14-lac 6 26 oh 4 24-fac to the managing explanation is to be still noticed that then, if the yarn is gefûhrt directly by the transverse guidance drum the invention for a reeling machine be used it can, with which a transverse guidance to a wave is fastened, itself between the Spuleinheiten extended, and with which a cam shoe is put on on a drum with a cam groove, which different turn numbers, similarly a groove, which is trained in the drum at the end of the wave, exhibits, in order several yarns in the rewinding range to lead at the same time. FOr this case of application are necessary inevitable distribution switchboards, around the cam shoe into the cam groove with different turn numbers umzuschaltan. The mobile guidance in accordance with Fig. 1 is needed in a place, where the guidance in contact with the cam thrust steht.

With the available invention with each diameter, with which a bind-like winding would develop, the yarn guide way is distributed, whereby wind with many Kreuzungsstellen of the yarn be produced can. Thus for Nässt with the help of the invention wind up yarn-wind yourself provide, the one even yarn delivery, particularly with high-speed decreases permitted. A method and an apparatus for winding a yarn on a package in which the wind number of the package is changed regularly or rapidly at random in relation to the traverse of the yarn. A traverse drum having a plurality of grooves of different wind number and a branch portion of the traverse grooves is used to wind the yarn. 1. Procedures for winding up yarn on one wind during the transverse leading of the yarn, by the fact characterized that the turn number of the Wickels is changed regularly or according to the random principle in relation for the transverse guidance of the yarn. 2. Procedures for winding up yarn on one wind during the transverse leading of the yarn, according to requirement 1, thereby marked that the yarn on wind using a transverse guidance drum (30) one winds up, with the transverse guide grooves (33, 34, 35) as well as different turn numbers possess a bypass section (38) into the distribution of a yarn on yarn running ranges (Y2, Y3) according to the trained transverse guide grooves. 3. Procedures for winding up Gara on one wind during the transverse leading of the yarn according to requirement 2, by it characterized that a yarn running range, which is limited by a transverse guide groove possesses a different turn number than the aforementioned yarn running range to another Garnlaufbereioh, which is limited by another transverse guide groove however, at which branch point, which connects the transverse guide grooves, by change of the tension of the current yarn one changes. 4. Procedures for winding up Gam on one wind during the transverse leading of the yarn transferred after requirement 2, by it characterized that a yarn running range, which is limited by a transverse guide groove possesses a different turn number than the aforementioned yarn running range to another yarn running range, which is limited by another transverse guide groove however, at the branch point, which connects the transverse guide grooves, by a mechanical Umschalteinfichtung wird.

Procedures for winding up yarn on one wind during the transverse leading of the yarn according to requirement 4, by the fact characterized that the mentioned mechanical distribution switchboard is coupled with the turn of the transverse guidance drum (30), in order to change the turn number in such a way that it is changed periodically up to a pre-determined number in relation for the rotation of the transverse guidance drum. 6. Device for the execution of the procedure according to requirement 1 marked by a transverse guidance drum, which possesses transverse guide grooves for direct or indirect yarn leading, by the fact that the transverse guidance drum (30) possesses several transverse guide grooves (33, 34, 35) as well as with different turn numbers a branch section (38) of the transverse guide grooves, where a yarn is distributed to another yarn running range according to the transverse guide groove with different turn number. 7. Device according to requirement 6, by it characterized that a distribution switchboard is intended, in order a yarn, which arrives at the branch section (38) of the transverse guide groove to lead up to other transverse guide grooves with different turn number. 8. Device according to requirement 7, by the fact characterized that the switching device a mobile guidance (39) for the inevitable distribution of a yarn at the branch section (38) and that this mobile guidance possesses is operationally with the rotation of the transverse guidance drum (30) coupled. 9. Device according to requirement 8, by the fact characterized that the mobile guidance (39) is arranged within the Quefführungsbereiches of the Gams and on the side of the branch section (38) for the transverse guide groove and that the mobile Fûhrung by means of a Solenoids (41) in two positions shiftable ist.

Device according to requirement 7, by the fact characterized that the distribution switchboard possesses one beso wegliche guidance (39), which on a tap of of a being certain plate (42) is tiltable stored that the mobile guidance exhibits a first guide edge (44), in order the yarn (Y) at the end of the transverse guidance somewhat inward concerning the normal transverse guidance end to lead as well as a second guide edge (45) to leading the yarn to a normal transverse guidance end that furthermore at the mobile guidance an attraction member (46) is intended and faces a Solenoid (41), which this, in order it to actually pull, if the Solenoid is switched on and that furthermore a mechanism (47, 48) is intended, in order to before-load the mobile guidance (39) against the suit effect of the Solenoids. 11. Device according to requirement 10 to determine by it characterized that a drum sensor (60) is intended, over the revolutions of the drum and that the distribution switchboard is headed for over a signal by a circuit, which the Solenoid (41) of the distribution switchboard, which is coupled with the rotation of the transverse guidance drum (30), betätigt.

RST